Transparent adhesive sheet for flat panel display, and flat panel display

A flat panel display, adhesive sheet technology, applied in the direction of film/sheet adhesive, adhesive type, polyether adhesive, etc., can solve the problems of high price, difficult separation of display panels, etc. The effect of sticky state, excellent visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] The composition (manufactured by Kaneka Corporation) was cast in a stirrer (Mini Dappo, manufactured by Seatec Corporation) equipped with a vacuum device, and sterilized by stirring in a vacuum (100 Pa) for 1 hour. foam, the composition comprising a polyoxyalkylene polymer (component A) (number average molecular weight: about 20000), a hydrosilyl compound (component B) and a hydrosilylation catalyst (component C), wherein the composition The excess of hydrosilyl groups in part B (the total moles of hydrosilyl groups in component B - the total moles of alkenyl groups in component A) is the amount ratio of 50% of the total moles of alkenyl groups in component A Divide A and component B, and every 1 mol of alkenyl in component A is 2×10 -4 mol amount is mixed into component C. Then, the vacuum defoaming composition was coated (cast) on a base release layer (support) made of a release-treated polyester film (thickness: 100 μm) using a roll coater at room temperature so tha...

Embodiment 2

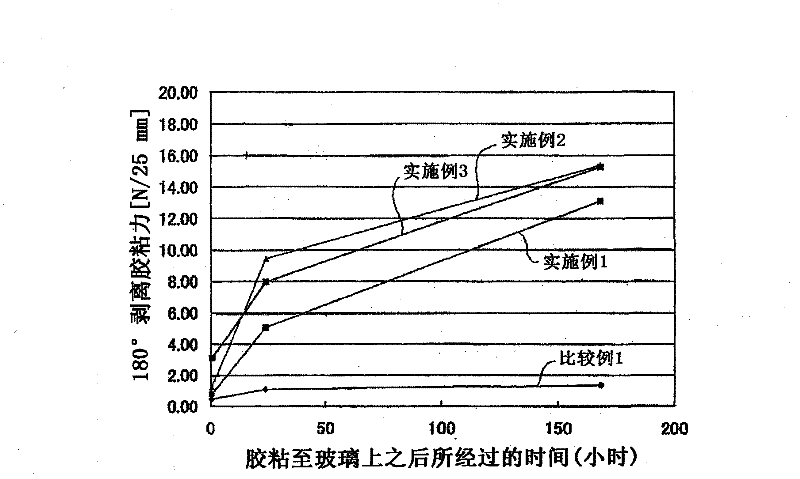

[0131] Except that the moles of excess hydrosilyl groups in component B (total moles of hydrosilyl groups in component B - total moles of alkenyl groups in component A) are relative to the total moles of alkenyl groups in component A A transparent adhesive sheet was prepared in the same manner as in Example 1 except that the amount of the hydrosilyl compound (component B) in the composition comprising components A to C was changed so as to be 100%.

[0132] The haze value of the obtained transparent adhesive sheet was 0.3%. The 180° peel adhesive force (peel force to glass) of the transparent adhesive sheet was evaluated.

Embodiment 3

[0134] Except that the moles of excess hydrosilyl groups in component B (total moles of hydrosilyl groups in component B - total moles of alkenyl groups in component A) are relative to the total moles of alkenyl groups in component A A transparent adhesive sheet was prepared in the same manner as in Example 1 except that the amount of the hydrosilyl compound (component B) in the composition comprising components A to C was changed in such a manner as to be 150%.

[0135] The haze value of the obtained transparent adhesive sheet was 0.3%. The 180° peel adhesive force (peel force to glass) of the transparent adhesive sheet was evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com