Sheet separation apparatus and separation method, and sheet attaching apparatus and attaching method

A technology of peeling device and peeling sheet, which is applied in the fields of sheet peeling device and peeling and sheet sticking device and sticking, can solve the problems of complicated device structure, large-scale overall device, etc., achieve simple structure, improve bending rigidity, restrain The effect of constructing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

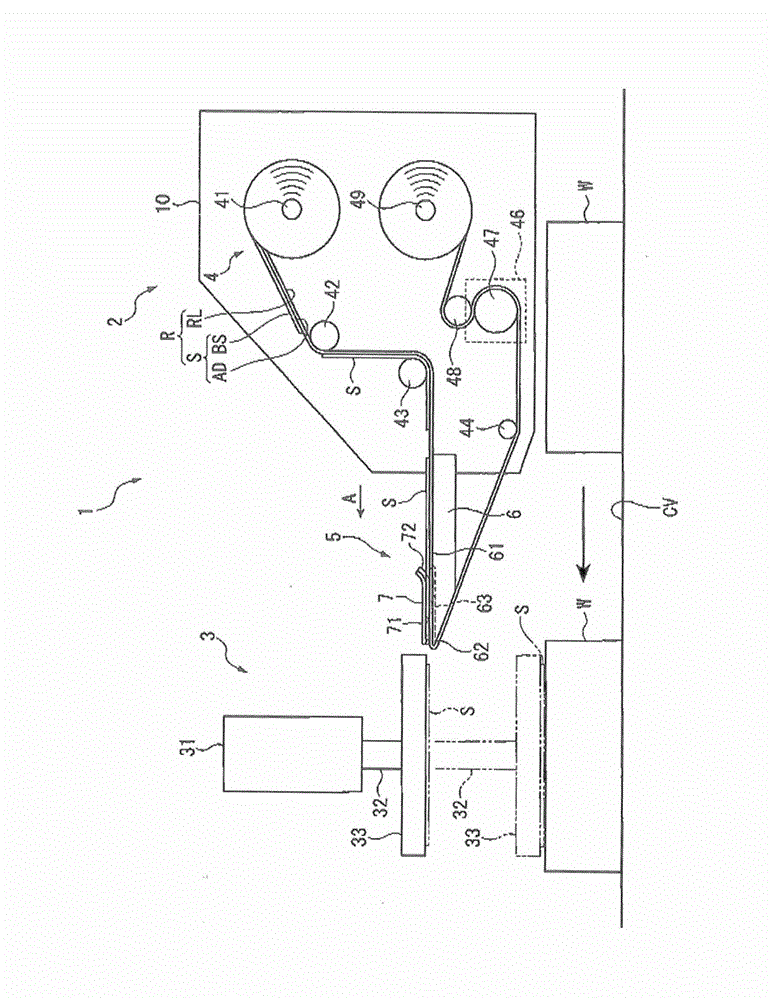

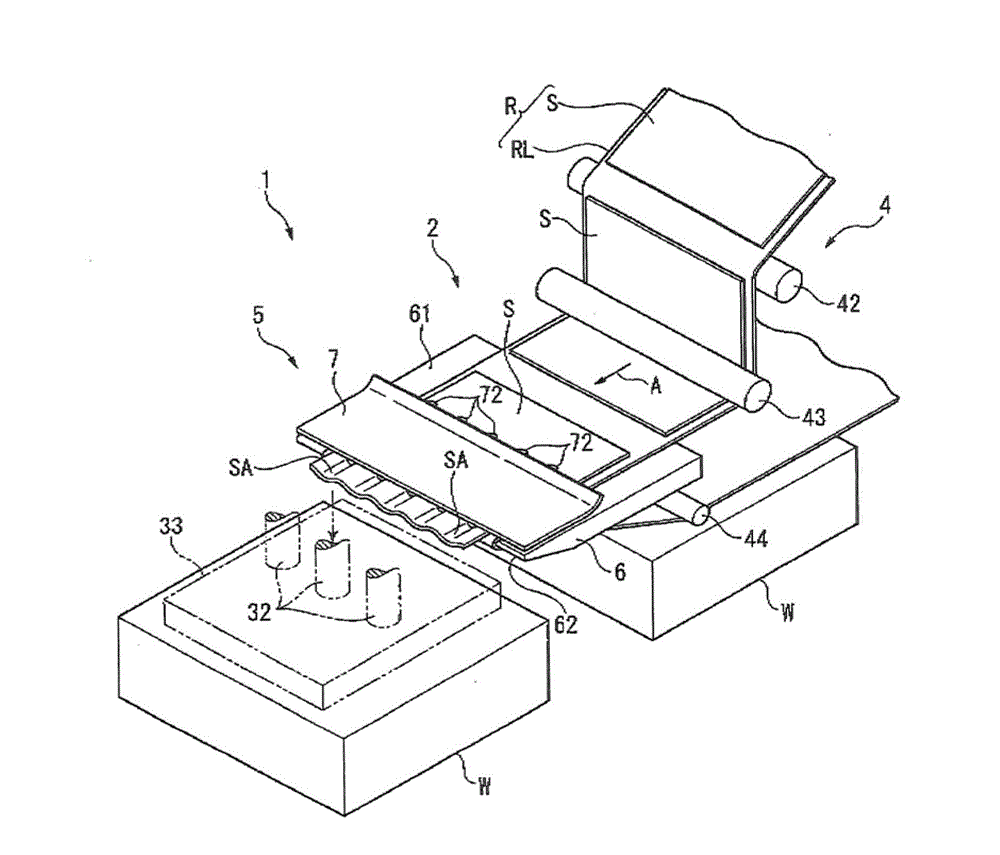

[0051] Such as figure 1 and figure 2 As shown, the sheet sticking device 1 of this embodiment peels the adhesive sheet S temporarily attached to one side of the strip-shaped release sheet RL from the release sheet RL, and sticks the peeled adhesive sheet S on the surface to be bonded. The device on the body W. Here, the adhesive sheet S is formed by laminating an adhesive layer AD on one side of the base sheet BS, and is prepared in advance as a raw material R temporarily bonded to one side of the release sheet RL with the adhesive layer AD interposed therebetween. prepare.

[0052] The sheet sticking device 1 includes a sheet peeling device 2 for peeling an adhesive sheet S from a release sheet RL of a raw material R, and a pressing unit 3 for pressing the peeled adhesive sheet S to an adherend W and sticking it thereto. The sheet peeling device 2 is provided with the take-out part 4 which takes out the raw material R, and the peeling part 5 which bends the peeling sheet ...

no. 2 approach 〕

[0067] Next, based on Figure 4 A second embodiment of the present invention will be described.

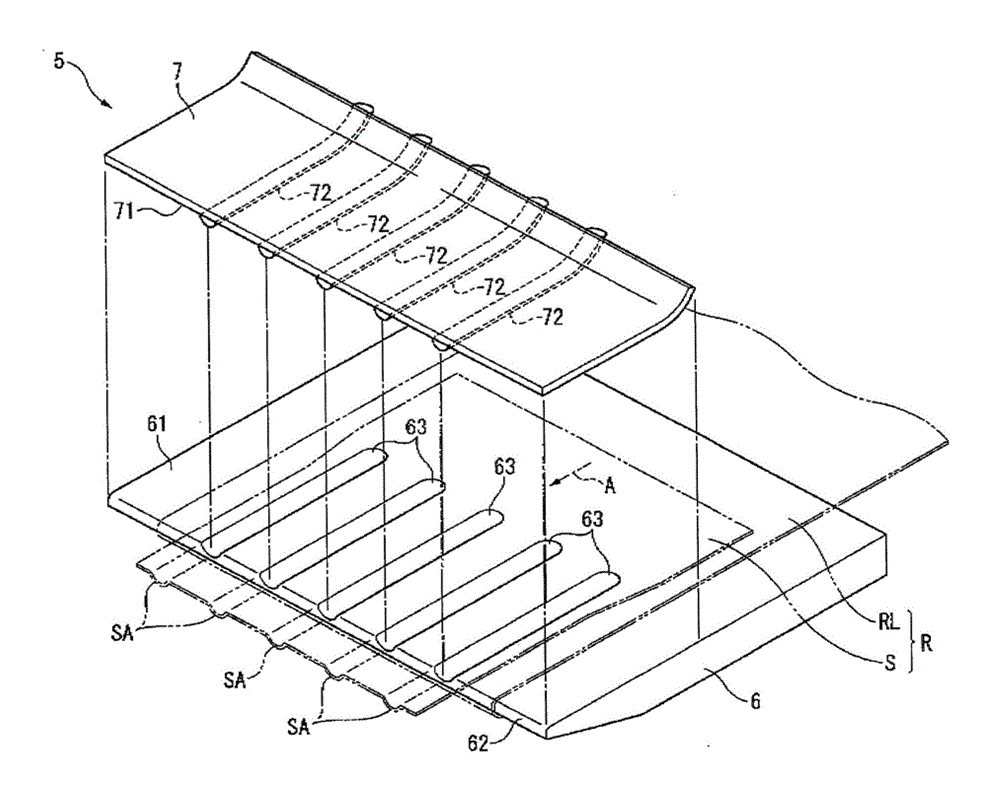

[0068] The peeling unit 5 in the sheet sticking apparatus 1A of this embodiment differs from the above-mentioned first embodiment only in that it includes a suction port 64 as a suction unit as a following unit in addition to the guide member 7 , and thus an overall view is omitted. In this sheet sticking apparatus 1A, by sucking the raw material R toward the peeling plate 6 side, a plurality of anti-bending regions SA in a concave-convex shape along the take-out direction A are formed on the adhesive sheet S.

[0069] Specifically, a plurality of suction ports 64 are provided in the groove portion 63 of the peeling plate 6 , and these suction ports 64 are connected to a suction device such as a decompression pump (not shown). In the sheet sticking device 1A provided with the peeling unit 5, the anti-folding area SA is also formed on the adhesive sheet S. Therefore, the bending r...

no. 3 approach 〕

[0071] Next, based on Figure 5 A third embodiment of the present invention will be described.

[0072] The peeling part 5 in the sheet|seat sticking apparatus 1B of this embodiment differs from the said 1st Embodiment in the point which provided the gas ejection part 8 other than the guide member 7 as a following part.

[0073] That is, the peeling unit 5 includes a peeling plate 6 and a gas ejection portion 8 facing the peeling plate 6 with the raw material R interposed therebetween. The gas ejection unit 8 includes a plurality of ejection ports (not shown) opened on the side of the adhesive sheet S, and ejects gas toward the raw material R. As shown in FIG.

[0074] In the above sheet sticking device 1B, the anti-folding area SA is formed on the adhesive sheet S by the gas ejection from the gas ejection unit 8, so that the adhesive sheet S can be reliably peeled off from the release sheet RL. . In this case, the adhesive sheet S is not in direct contact with the adhesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com