rotary valve

A rotary valve and rotor technology, applied in the field of rotary valves, can solve the problems of serious accumulation and achieve the effect of preventing adhesion and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

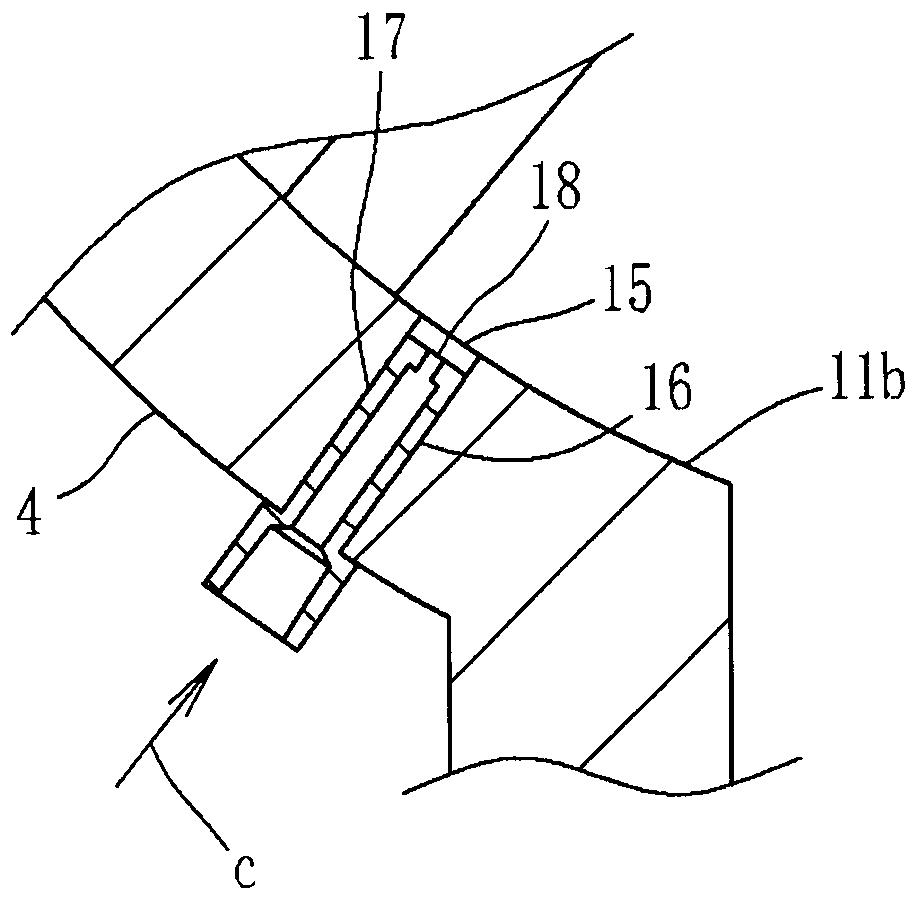

[0048] An embodiment of the present invention will be described below with reference to the drawings. figure 1 It is a block diagram of the pressure cooking apparatus 40 provided with the rotary valve 1 which concerns on one Example of this invention. The pressure cooking device 40 is used to cook the raw material 50 in steam. The raw material 50 is, for example, grain raw materials such as round soybeans, crushed soybeans, defatted soybeans, flat soybeans, bran, rice, and wheat. Among them, round soybeans, crushed soybeans, defatted soybeans, and flat soybeans are mainly used for brewing soy sauce.

[0049] The pressure cooking device 40 is provided with an input port 41 and a discharge port 42 for the raw material 50 . The rotary valve 1 is installed in the input port 41 , and the rotary valve 2 is installed in the discharge port 42 . A mesh conveyor belt 43 for transporting raw materials 50 is arranged in the pressure cooking device 40 . The mesh conveyor 43 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com