Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

250results about How to "Reduced stiffness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atmospheric plasma chemical processing method of WC and SiC optical molding molds

ActiveCN101659568AIncreased durabilityEfficient removalGlass pressing apparatusPlasma jetChemical reaction

The invention relates to an atmospheric plasma chemical processing method of WC and SiC optical molding molds, which belongs to the atmospheric plasma chemical processing methods of the optical molding molds. The atmospheric plasma chemical processing method can solve the problems that the grinding and polishing technology which is used for processing after processing and forming of the optical molding molds made of SiC and WC materials has the disadvantages of low processing efficiency, poor surface quality, damage of a sub-surface layer and short service life of the molds. The method comprises the steps of: introducing a mixture of plasma gas, reaction gas and oxygen into space between a cathode and an anode of a plasma generator, imposing radio frequency power signals on the cathode andthe anode, producing the plasma discharge between the two electrodes, then placing the surface to be processed of the WC or SiC optical molding mold in a plasma jet region for carrying out chemical reaction and realizing the optical surface processing of the optical molding molds made of the SiC and WC materials. The method is used for carrying out the optical processing on the surfaces of the WCand SiC optical molding molds.

Owner:HARBIN INST OF TECH

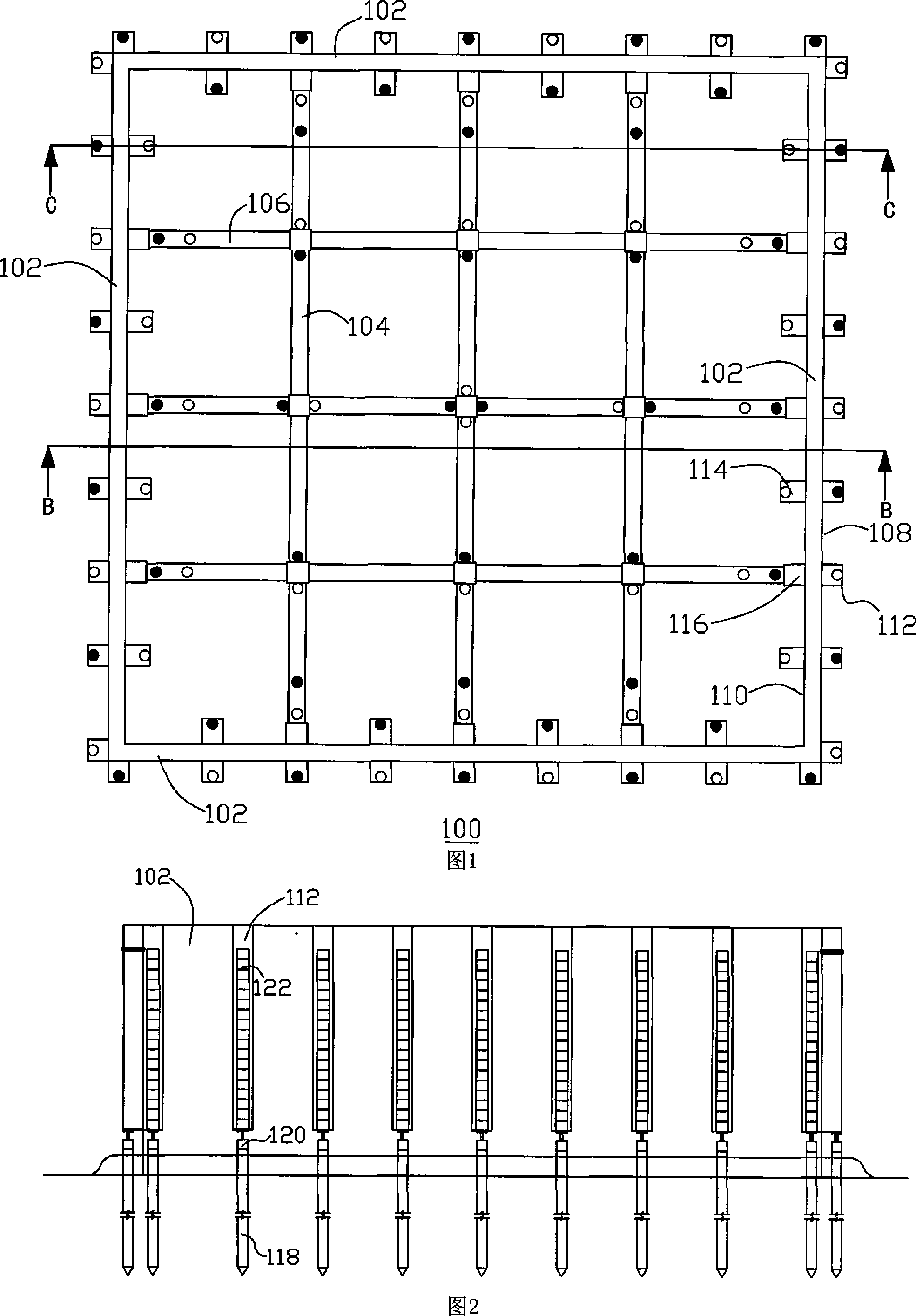

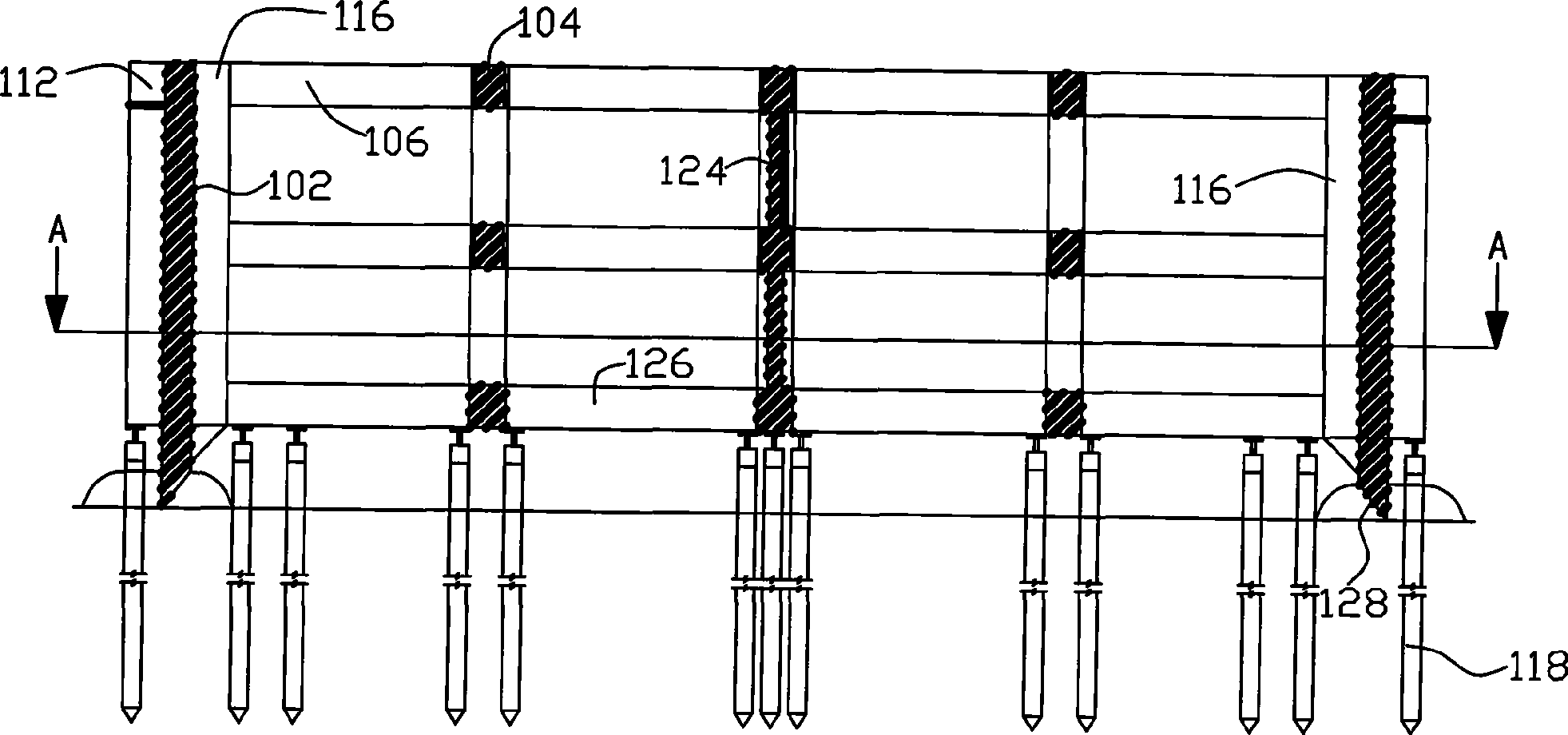

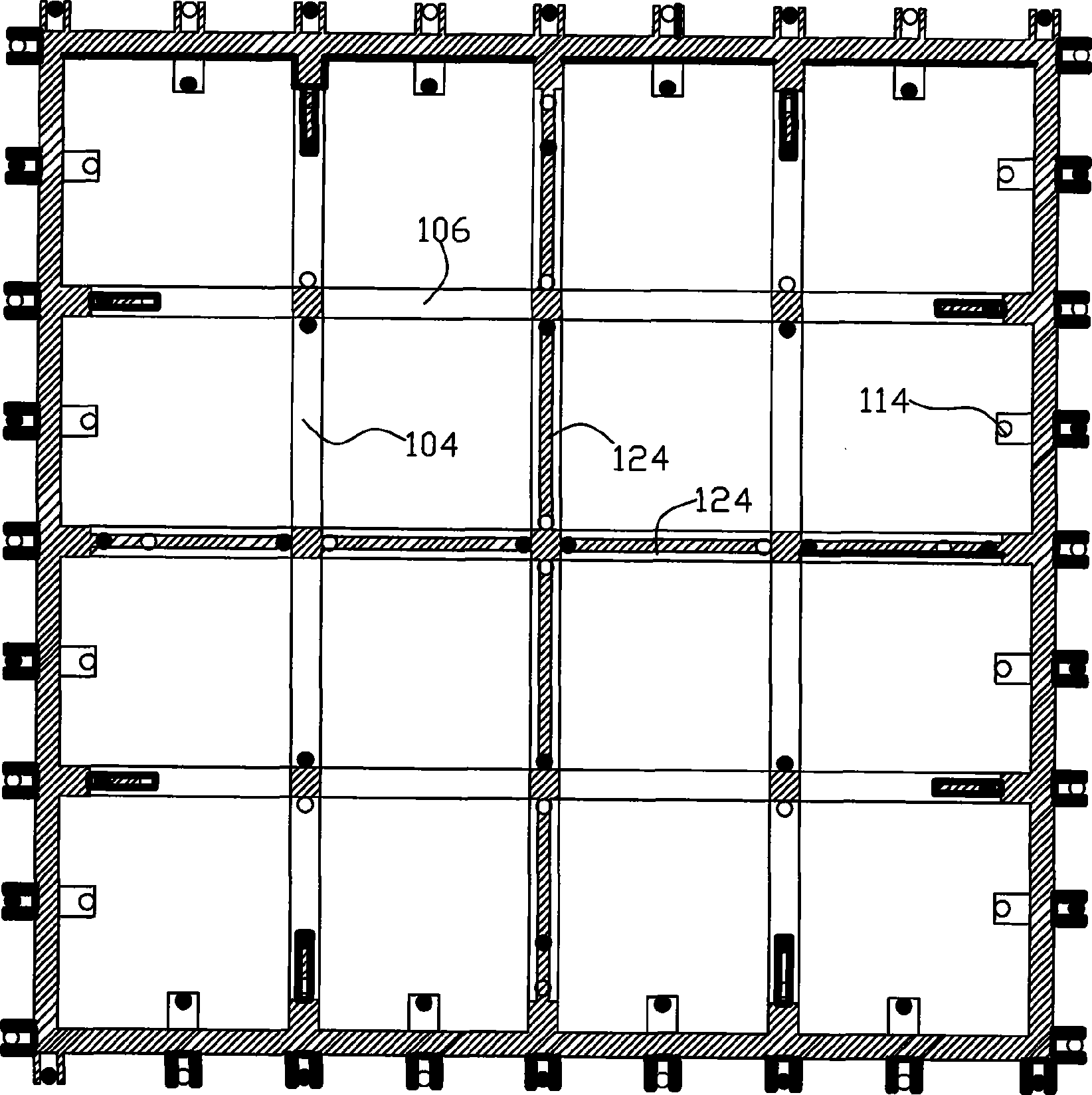

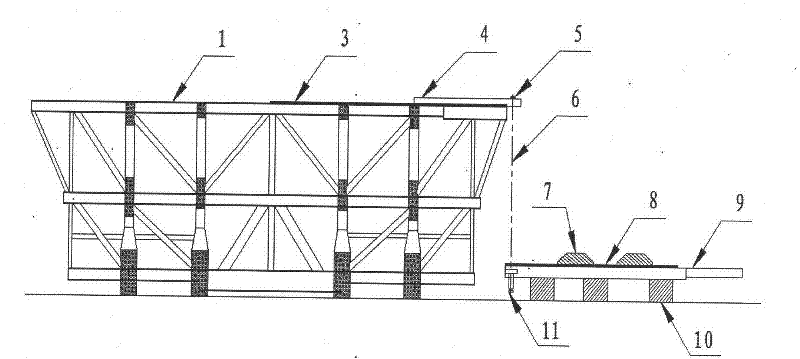

Caisson structure and method for smoothly and accurately sinking caisson structure into earth surface

InactiveCN101418573AAccurate final sinkReduced stiffness requirementsCaissonsEngineeringEarth surface

The invention provides a well sinking structure, which comprises a closed shaft wall, wherein the shaft wall is provided with inner wall surfaces and outer wall surfaces which are opposite to the inner wall surfaces; a plurality of frame beams which are mutually staggered inside the horizontal surface and the vertical surface and underframe beams which are close to the lowest end of the shaft wall are arranged between the inner wall surfaces; a plurality of constant-height inner supporting blocks are formed on the inner wall surfaces; a plurality of constant-height outer supporting blocks are arranged on the outer wall surfaces; the outer supporting blocks are higher than the inner supporting blocks; bottom surfaces of the underframe beams are planes which are provided with no shoe; and a shoe provided with a bevel is formed on the lowest end of the shaft wall. The invention simultaneously provides a method for accurately settling down the well sinking structure into the ground. The method can accurately guarantee gradual settlement of a sinking well by the controllable method, and is accurate in final settlement, so as to avoid significant safety and quality accidents such as sudden settlement, super-settlement, off-centering, plane revolution, vertical inclined settlement, deformation and fracture, water inflow inside a well and sinking outside the well in the prior construction method.

Owner:丁慈鑫 +1

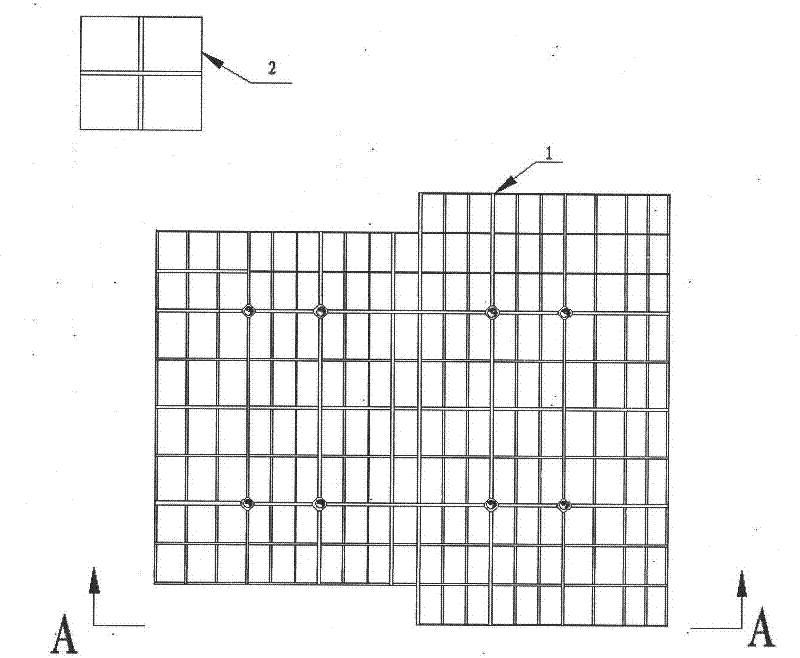

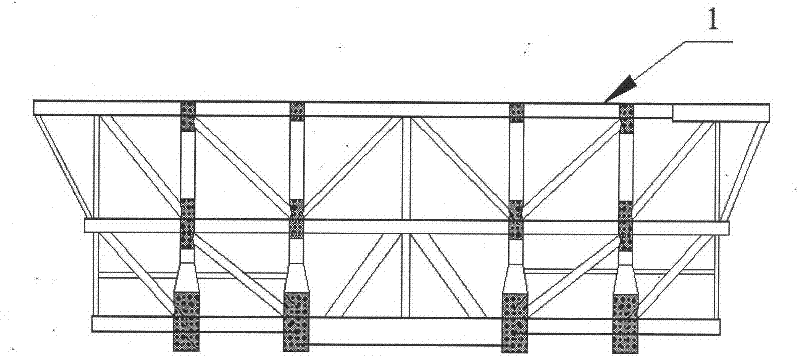

Installation process of upper module on offshore oil platform

ActiveCN102337736AEasy to installStrong automation propertiesArtificial islandsUnderwater structuresOperation safetyBuilding construction

The invention provides an installation process of an upper module on an offshore oil platform. The installation process comprises the following steps: (1) arranging a slipping track device in a platform lifting operation area; (2) transporting the upper module to a platform construction area and putting the upper module on the slipping track device; (3) arranging a hydraulic lifting and slipping device at one side of the slipping track device; (4) starting lifting operation; (5) after a slipping track to be lifted is parallel and level with a slipping track on the platform, stopping the lifting operation and connecting the two slipping tracks into a whole; (6) slipping the upper module to a set position; and (7) stopping slipping and putting the upper module on lower support structures tocomplete connection between the upper module and the lower support structures. The installation process has the following beneficial effects: accurate positioning of the upper module and installationoperation of the upper module in any position on the offshore oil platform can be achieved; at the same time, the installation process has no special requirements for the arrangement position of the site for offshore oil platform construction and is slightly affected by external factors; and the installation process is convenient for site operation and has the effects of lowering the operation cost and improving the operation safety.

Owner:CHINA NAT OFFSHORE OIL CORP +2

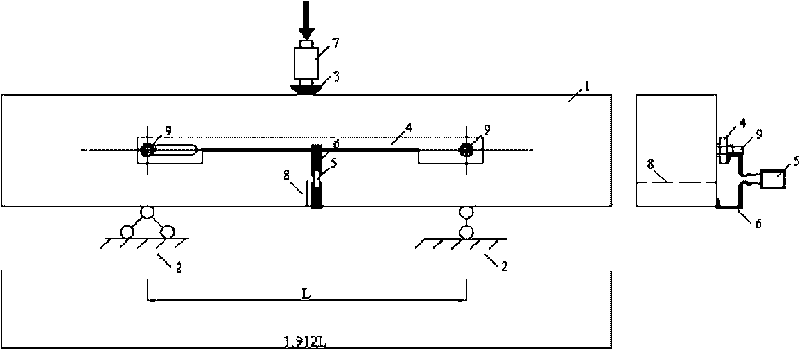

Device for testing fracture energy of concrete by three-point bending beam without self-gravity doing work

ActiveCN101706389AReduced Stiffness RequirementsSimplify calculation stepsMaterial strength using tensile/compressive forcesSelf weightCurve fitting

The invention discloses a method for testing the fracture energy of concrete by a three-point bending beam without self-gravity doing work, and belongs to the technical field of civil engineering. The method is characterized by manufacturing a concrete beam of which the total length is 1.912 times of clear span. A test device comprises a sensor, an angle steel connecting rod, a clip-on extensometer, a sheet bar and the like. Through a tested load-deflection curve, the fracture energy of the concrete is calculated directly without fitting a curve. The fracture energy of the concrete is the ratio of an area enclosed by the load-deflection (the work done by a load) to the area of a beam ligament. The device for testing the fracture energy of the concrete by the three-point bending beam without self-gravity doing work has the advantages that: the self-gravity of a concrete test piece is counteracted without adding any connecting rod or weight to counteract the work done by the self-gravity; requirements on the rigidity of a test machine are low; the fracture energy is calculated without fitting the curve or calculating the work done by the gravity; calculation processes are simplified; and a test device is simple and easy to operate, so the device is suitable for small and medium laboratories with small test machine rigidity.

Owner:FANGYUAN CONSTR GRP REAL ESTATE DEVT CO LTD +2

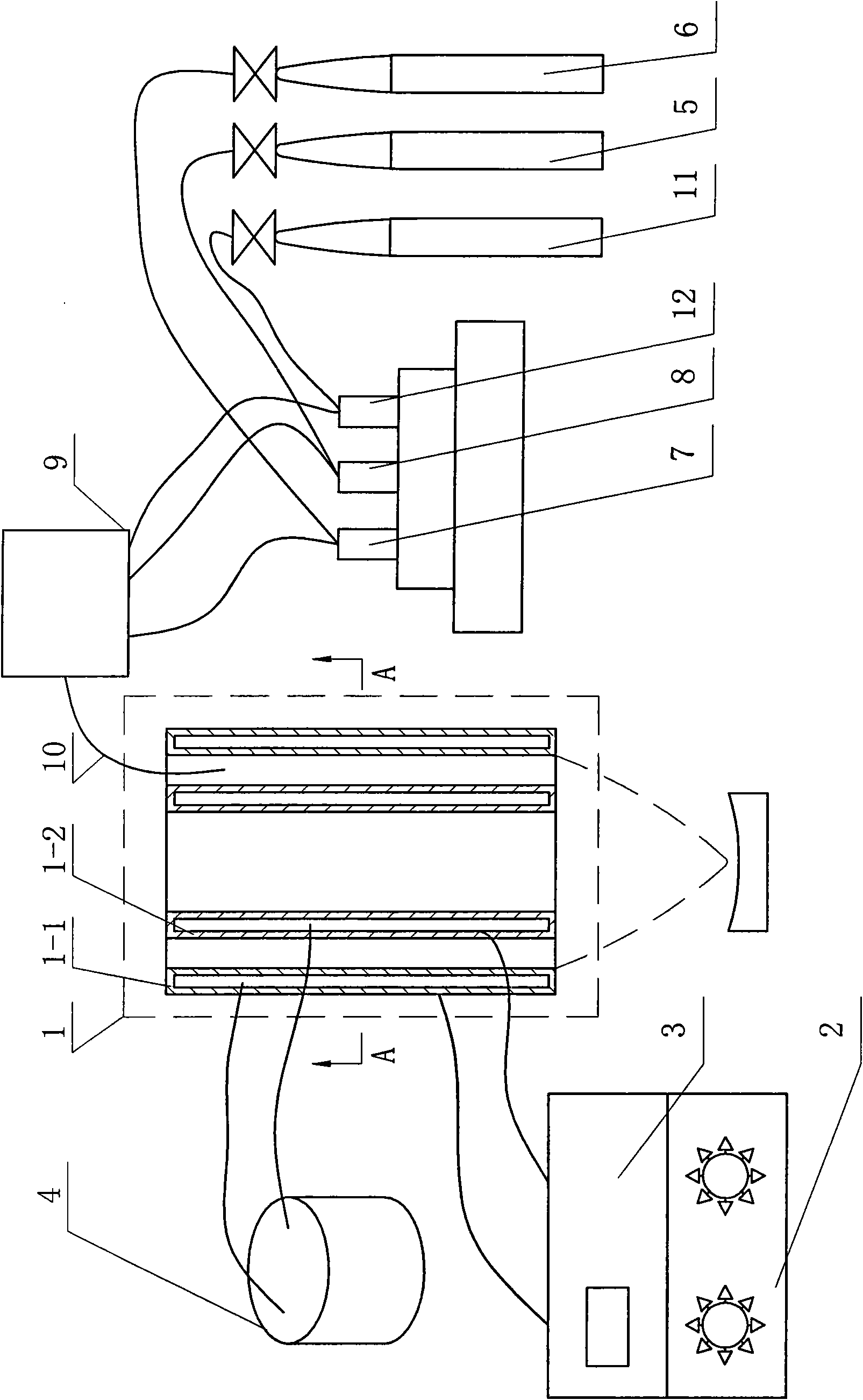

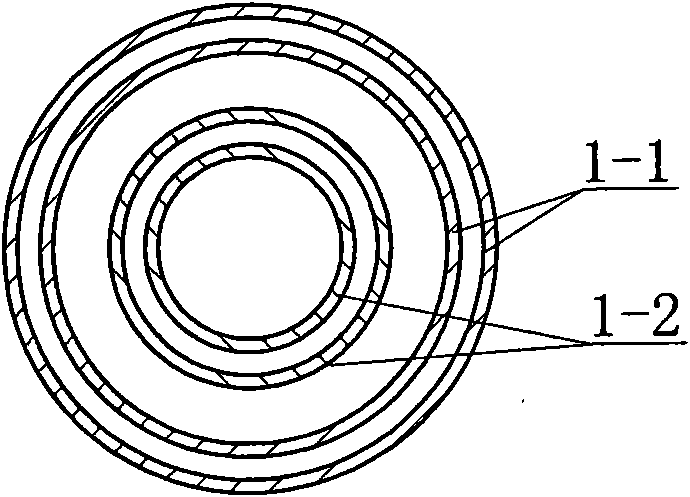

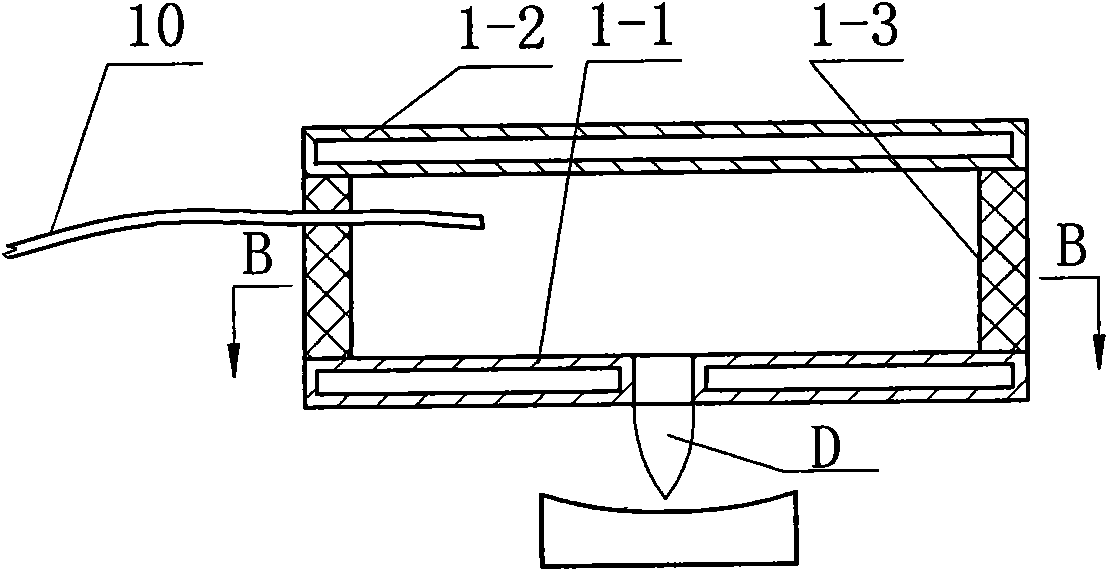

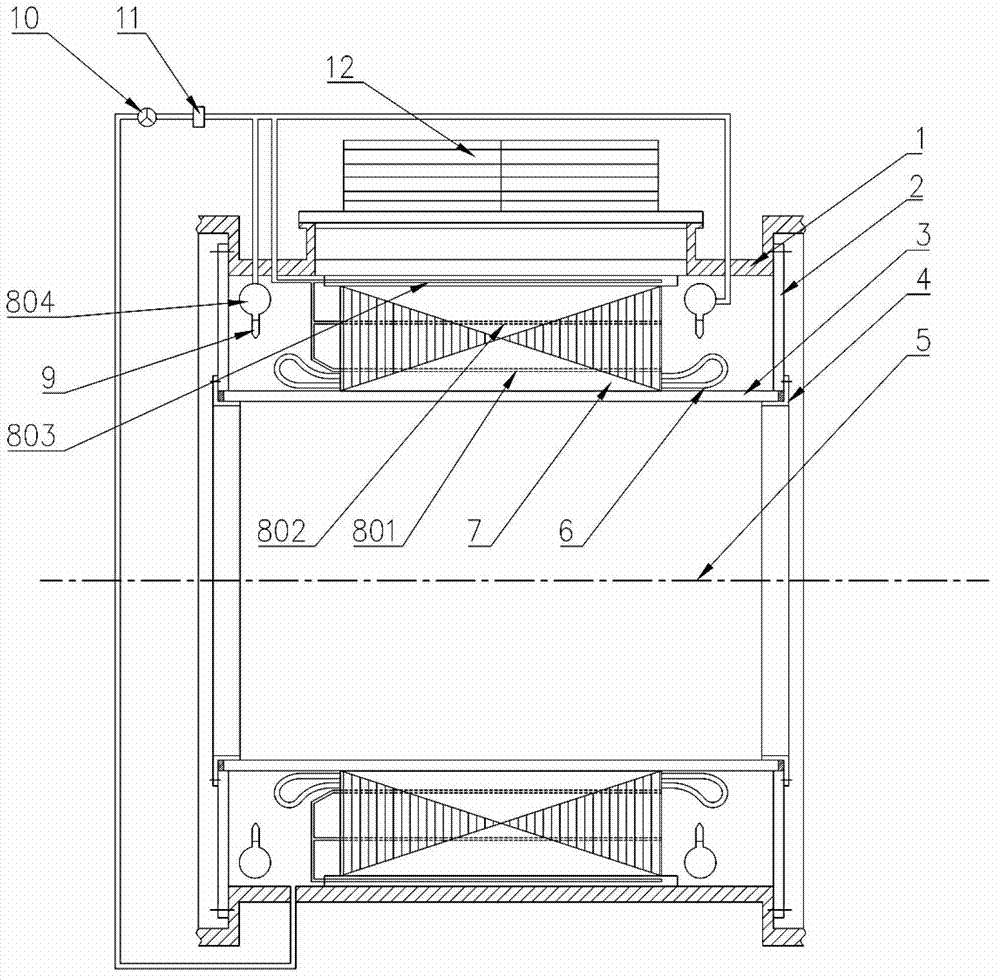

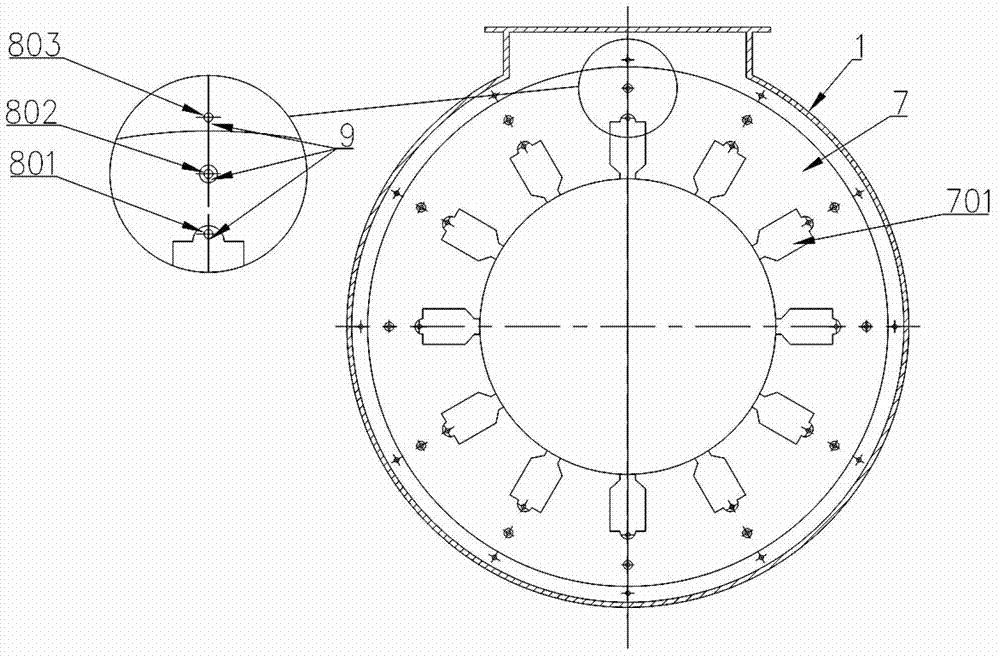

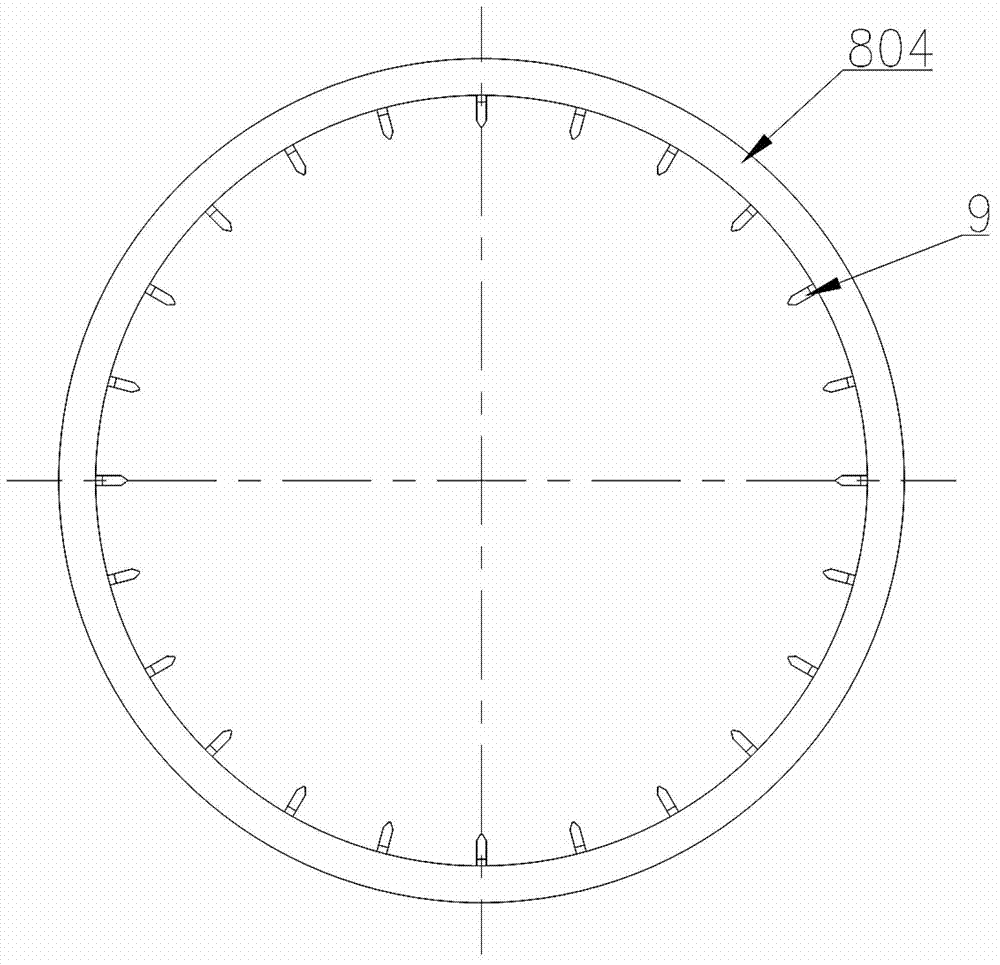

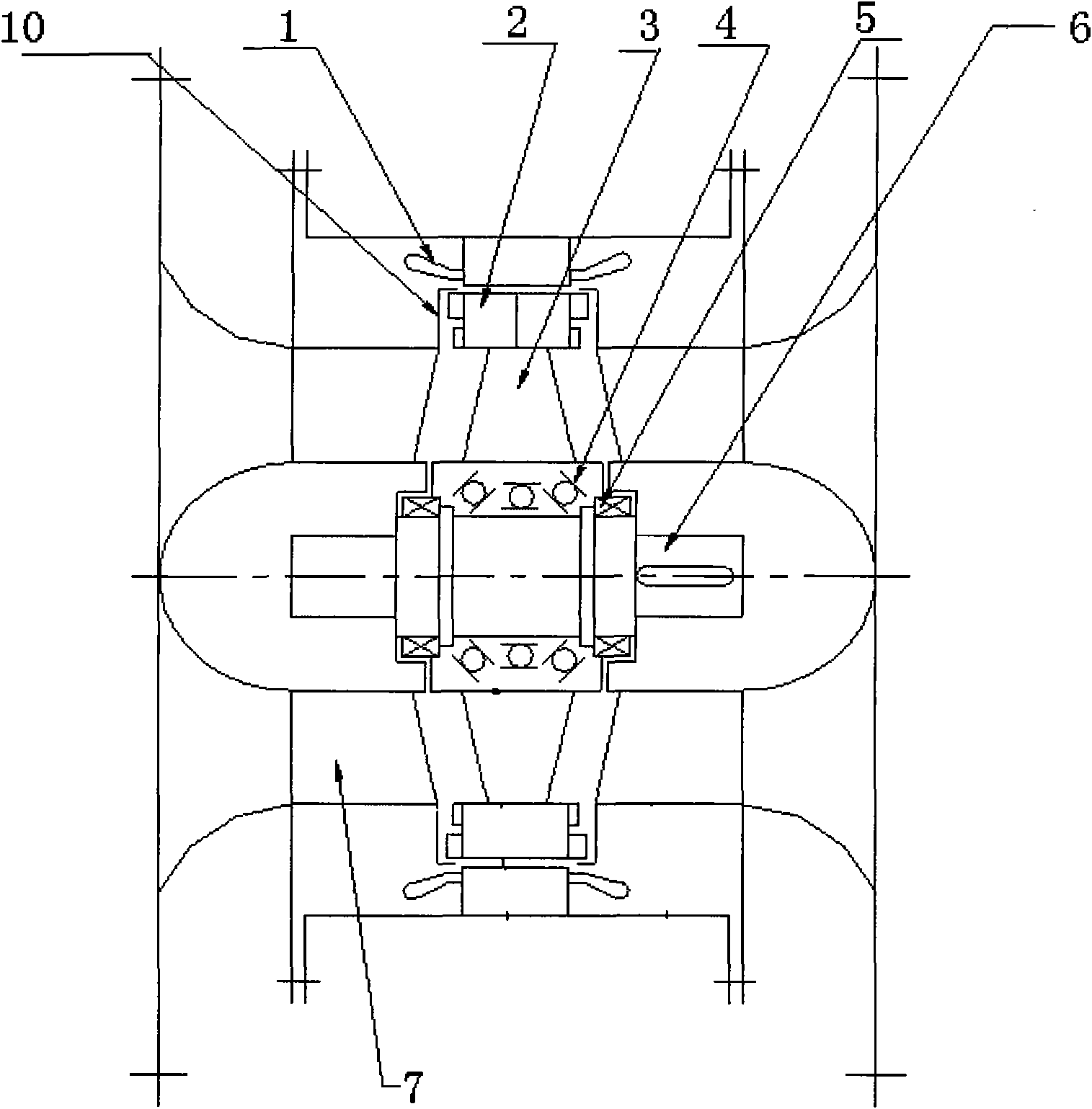

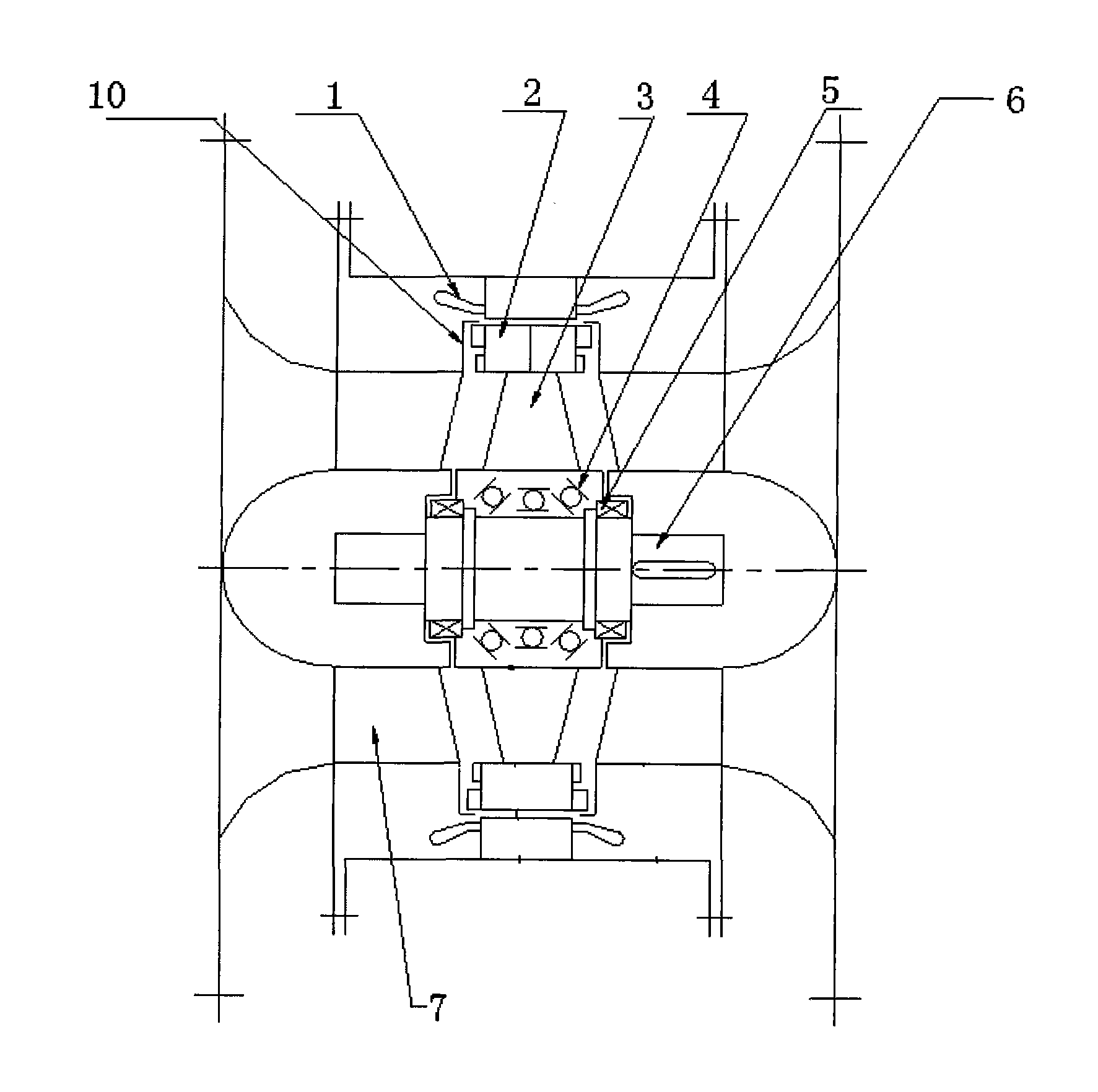

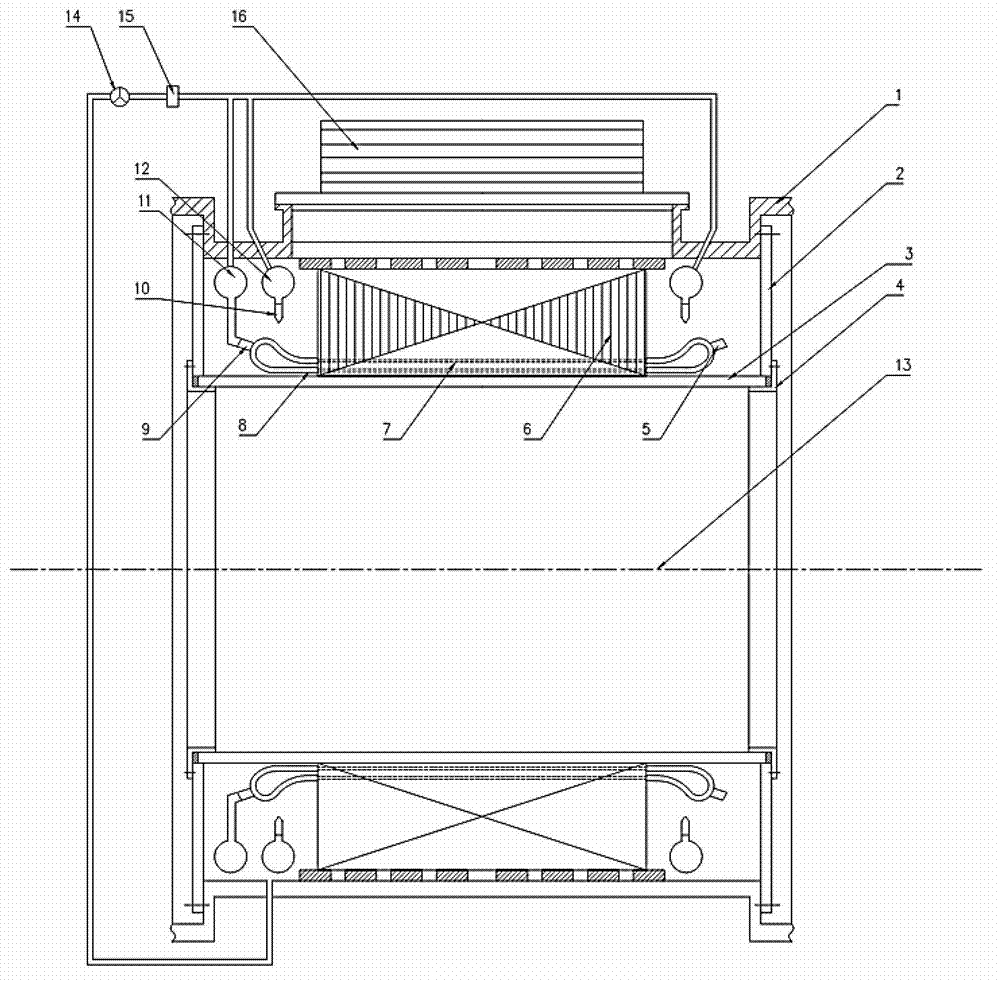

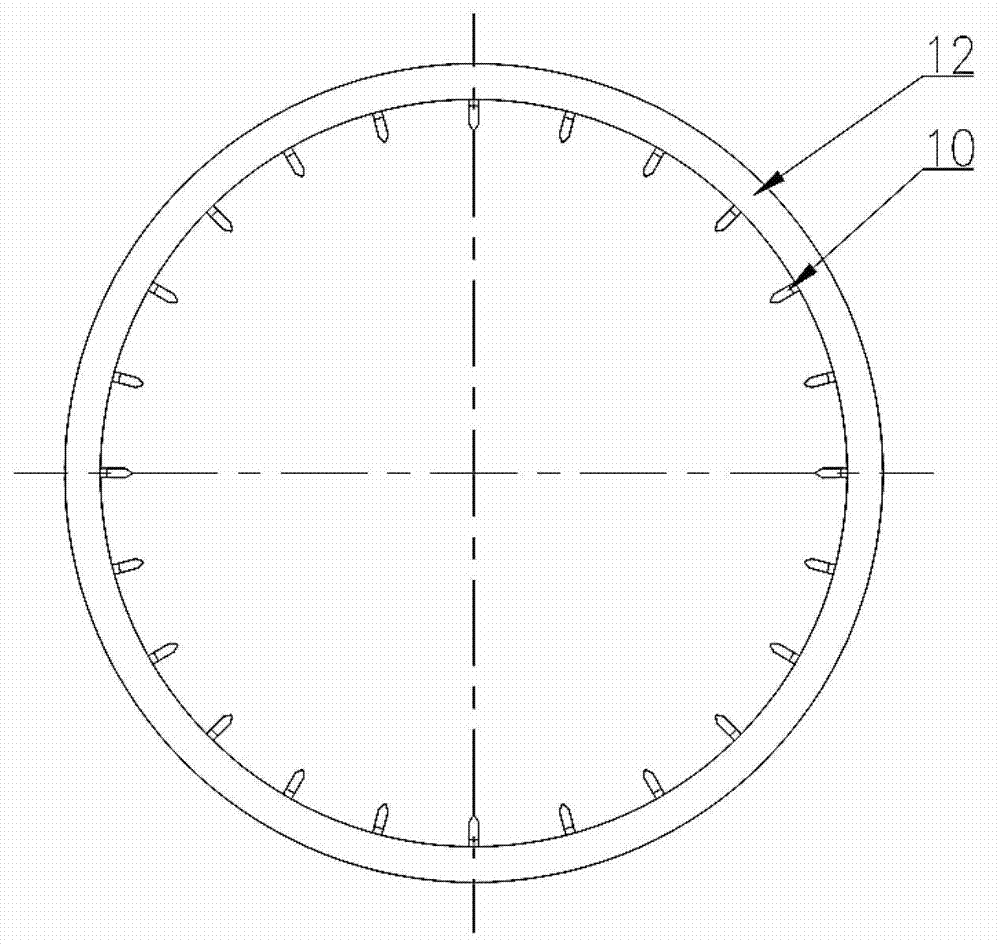

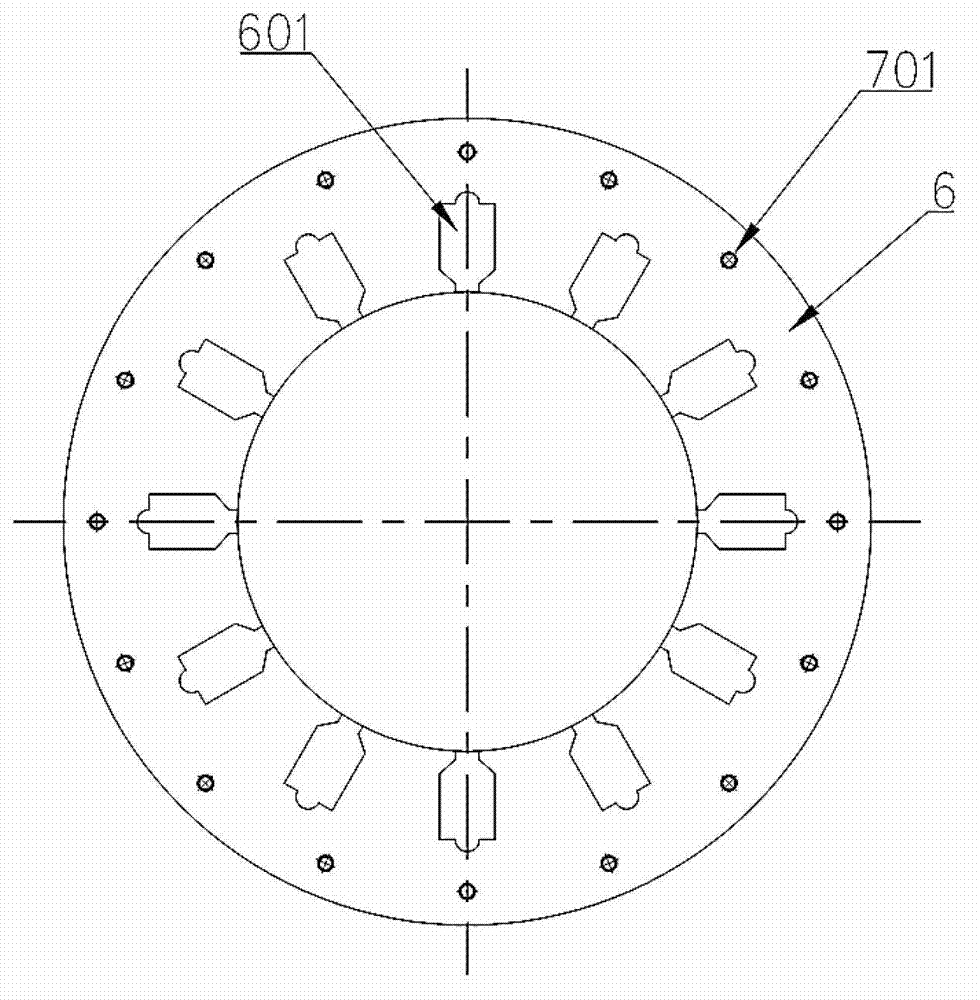

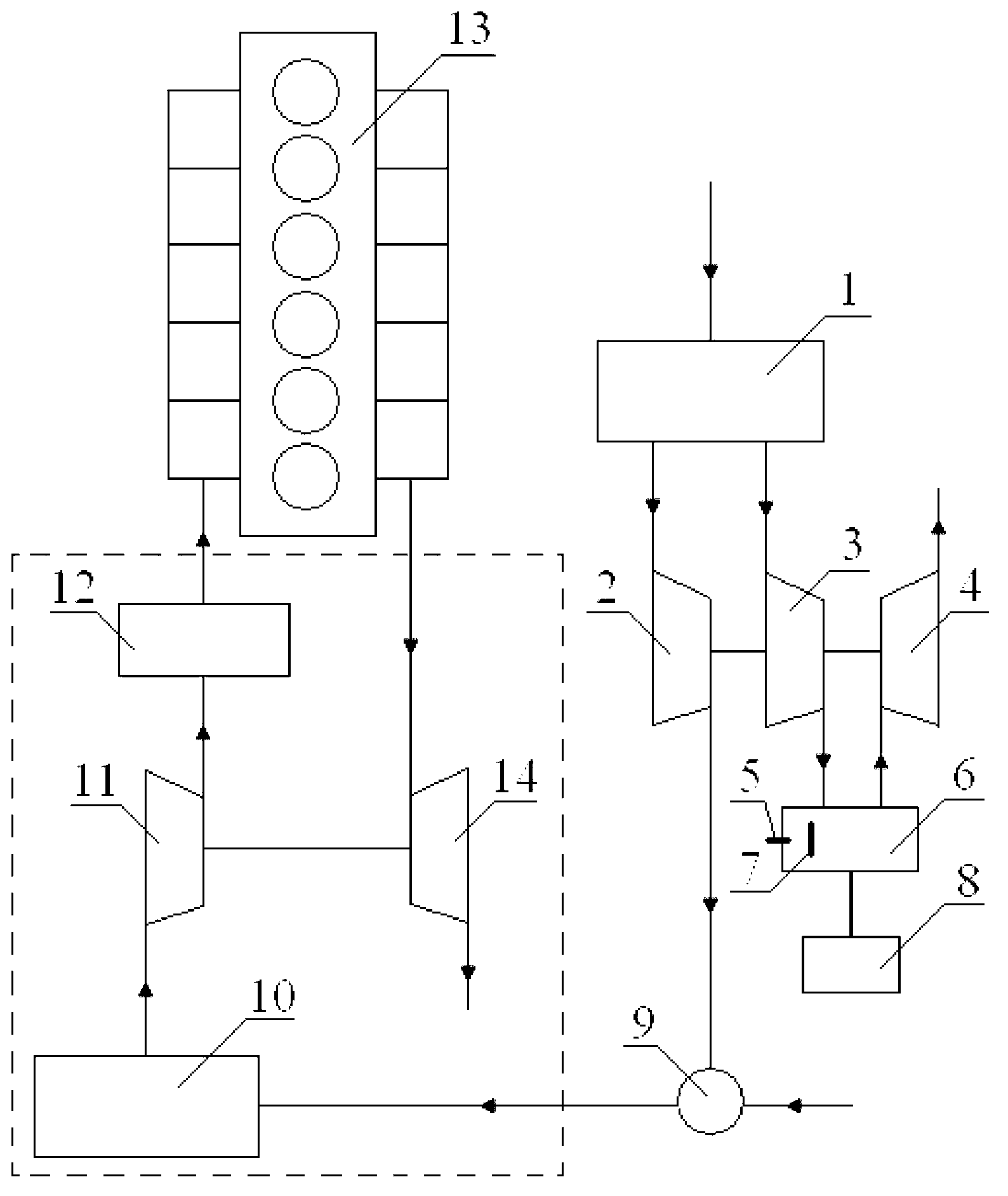

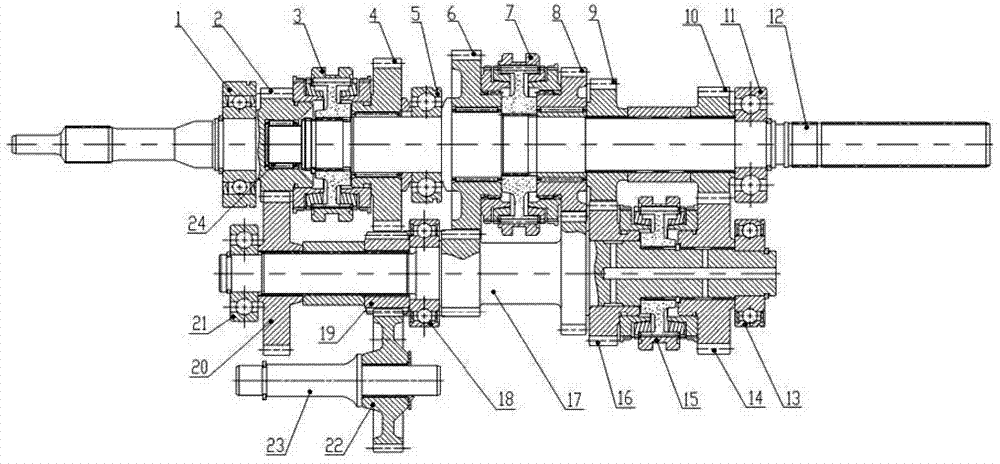

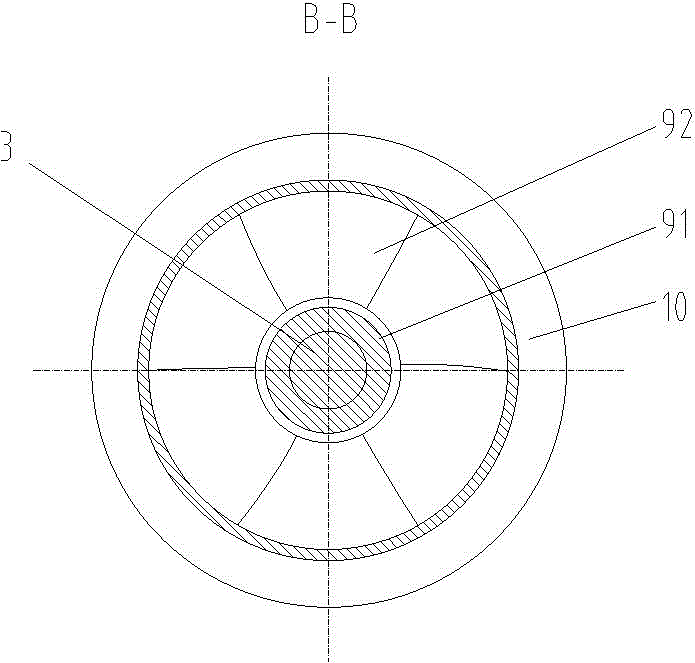

Spray type motor stator evaporative cooling system

ActiveCN102820738AReduce in quantityReduced tightnessMagnetic circuit stationary partsCooling/ventillation arrangementSpray nozzleConductor Coil

The invention discloses a spray type motor stator evaporative cooling system, wherein a stator enclosed space consists of a stator enclosure (1), a spacing sleeve (3) and an end cover (2). A spraying system comprises liquid dispensers (801, 802, 803 and 804) which are distributed at the back part of a stator core (7), in the stator core (7), in a stator slot bottom subslot and the periphery of the end part of a stator winding (6) and nozzles (9) which are arranged on the liquid dispensers (801, 802, 803 and 804). A circulating pump (10) in an outer forced circulation system pumps an evaporative cooling medium from the bottom of the stator enclosed space, and the evaporative cooling medium is filtered by a filter (11), and is delivered to the nozzles (9) through the liquid dispensers (801, 802, 803 and 804). The atomized evaporative cooling medium is directly sprayed to all the heating elements of the stator. The evaporative cooling medium which is subjected to heat exchange flows into the stator enclosed space, the vaporized evaporative cooling medium flows into a condenser (12) at the top of the stator enclosure (1), and is changed into the liquid after being condensed by the condenser (12), and the liquid flows back into the stator enclosed space.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Novel fully-tubular electric submerged pump with shaft incapable of transferring torque

InactiveCN101787978AImprove electrical insulation strengthImprove reliabilityPump componentsPump installationsImpellerThrust bearing

The invention relates to a novel fully-tubular electric submerged pump with a shaft incapable of transferring torque; a submerged motor adopts wet stator winding structure, the impeller of a water pump is arranged in the inner cavity of a motor rotor, the vanes of the impeller are integrally welded with the inner circle of the motor rotor assembly by silicon steel plates through stacking, a radial bearing and a bidirectional thrust bearing are arranged in the inner seal bearing cavity of the motor rotor with the impeller, the motor rotor with the impeller is rotational and the shaft cannot rotate, and the inner rotational bearing cavity adopts dynamic seal structure. The invention has the beneficial effects that: the winding wire improve the electric insulation intensity of the electric submerged motor, so the reliability of the whole pump is improved, the vanes of the impeller are integrally welded with the inner circle of the motor rotor assembled by silicon steel plates through stacking to reduce the outer diameter of the motor rotor and improve the motor efficiency, the strength and rigidity requirements for the shaft are greatly reduced, the reliability is improved, the dynamic seal structure is compact and the seal effect is good, the axial length also can be reduced to realize compact structure, and the material consumption is also reduced.

Owner:TIANJIN GANQUAN GROUP

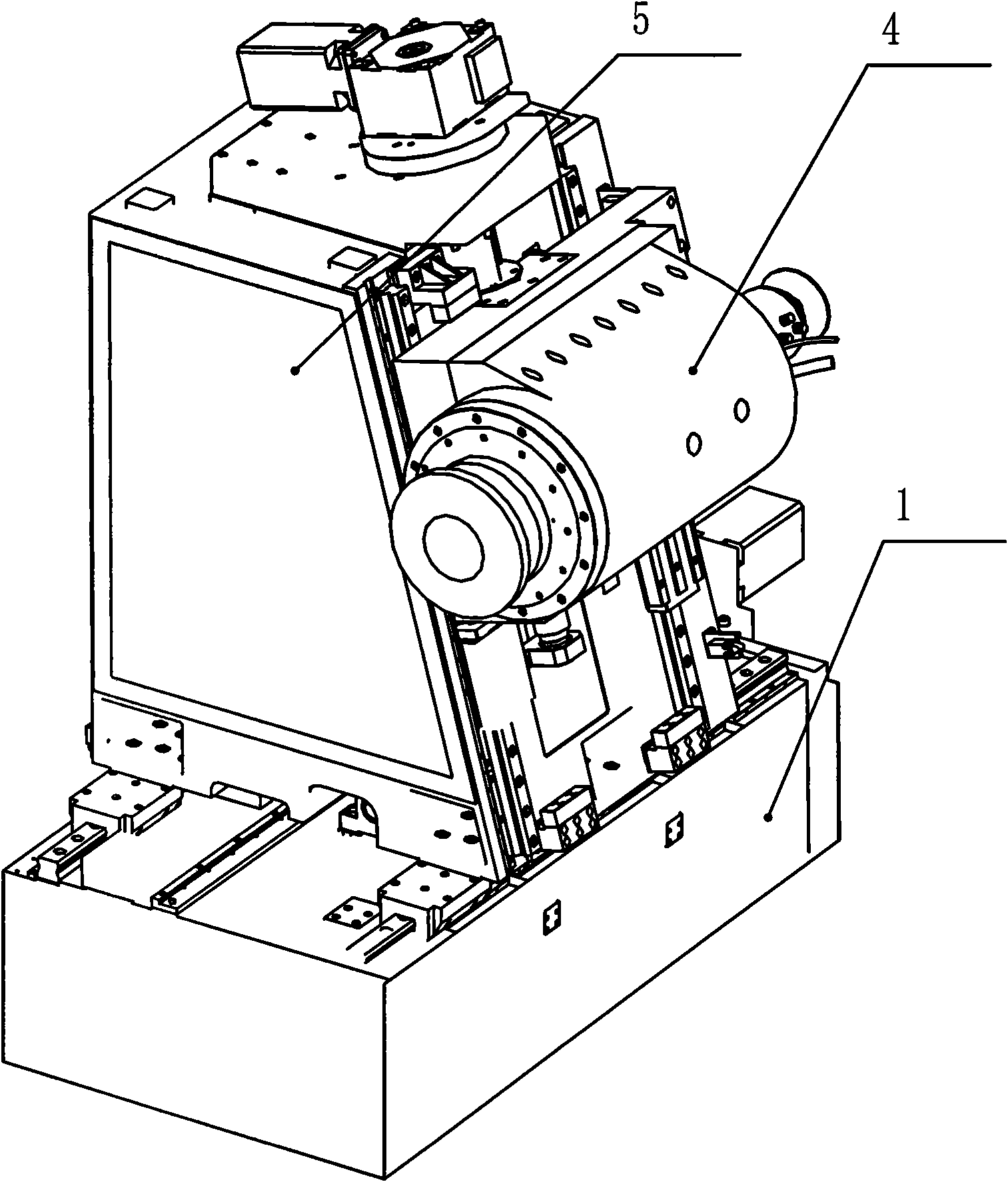

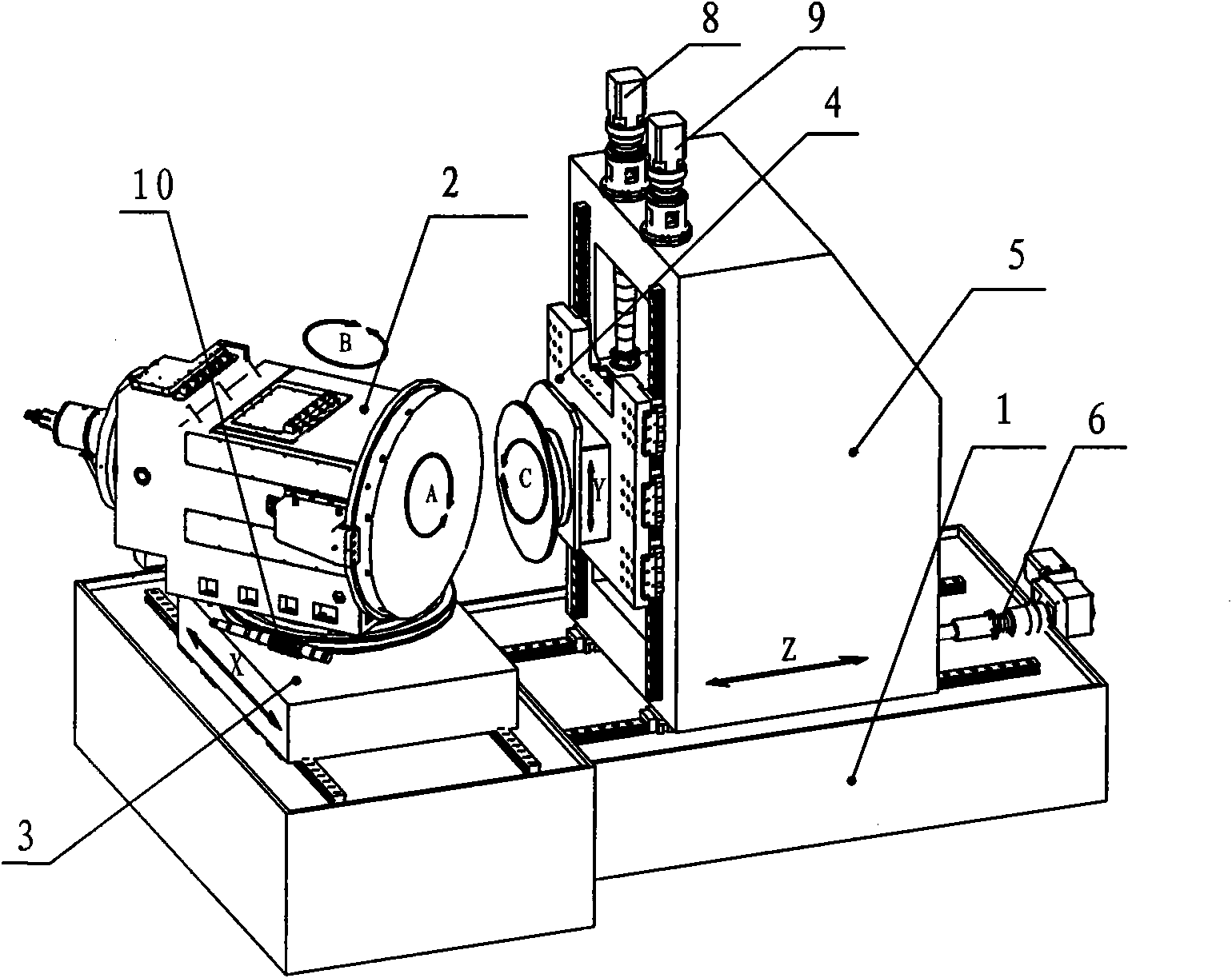

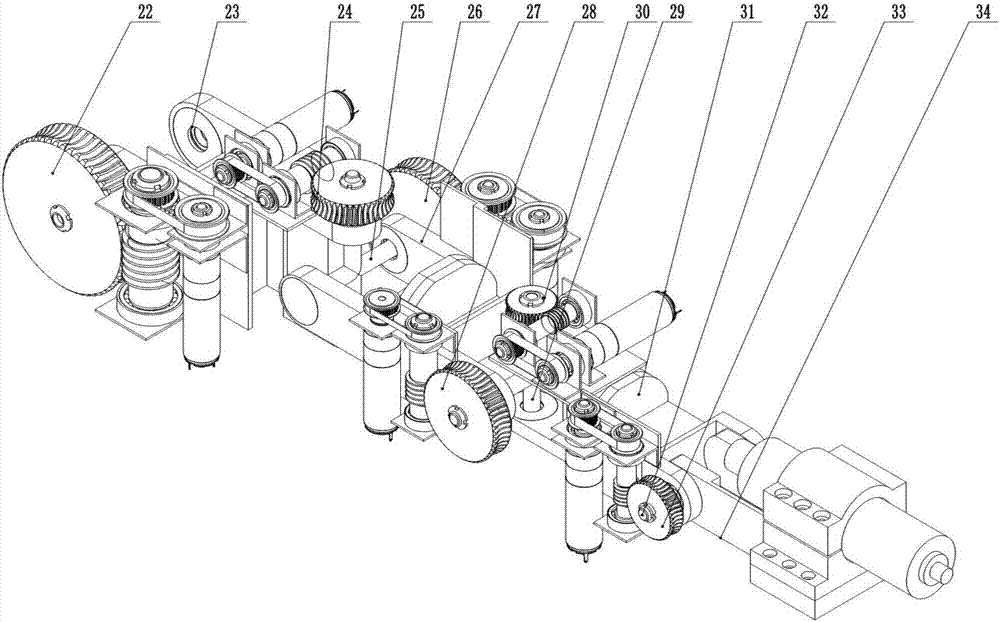

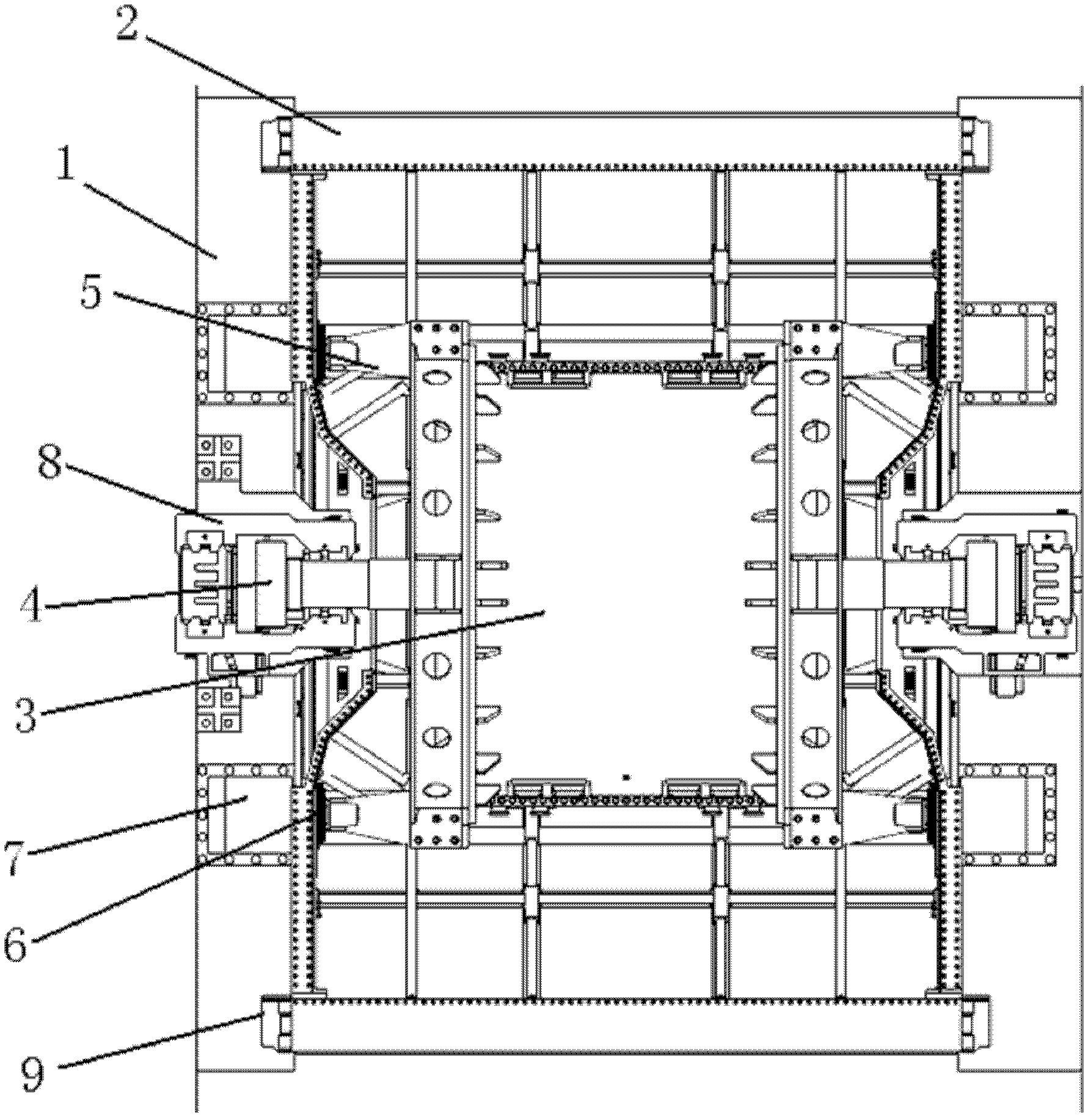

Numerical-control machine tool for processing spiral bevel gear

InactiveCN101537517ACompact structureSmall turning radiusGear-cutting machinesGear teethEngineeringMachine tool

The invention provides a numerical-control machine tool for processing spiral bevel gear, which comprises a machine tool body, a workpiece box, a turn table of the workpiece box, a tool box and the supporting post of the tool box, wherein, the machine tool body is T-shaped, and two groups of rails X and Z which are perpendicular to each other are formed on the machine tool body; the turn table of the workpiece box is mounted on the rail X; the supporting post of the tool box is mounted on the rail Z; the workpiece box is mounted on the turn table thereof via turntable bearings; the supporting post of the tool box has a gantry structure, the sliding rail Y of the tool box is formed on one side of the gantry, and two traction screw rods are arranged in the gantry; and screw holes are formed on the tool box, the tool box is rotationally mounted on the traction screw rods via the screw holes, and one end of the tool box is stuck to the rail Y via slideway. The invention has the following advantages: the structure is reasonable, the operation and the application are convenient, the workpiece box has a small turning radius and large turning angle, the machine tool has small volume and stable operation, and the tool has high positioning accuracy, so that the invention is applicable to industrialized production, in particular to the numerical-control processing of large-size spiral bevel gear.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

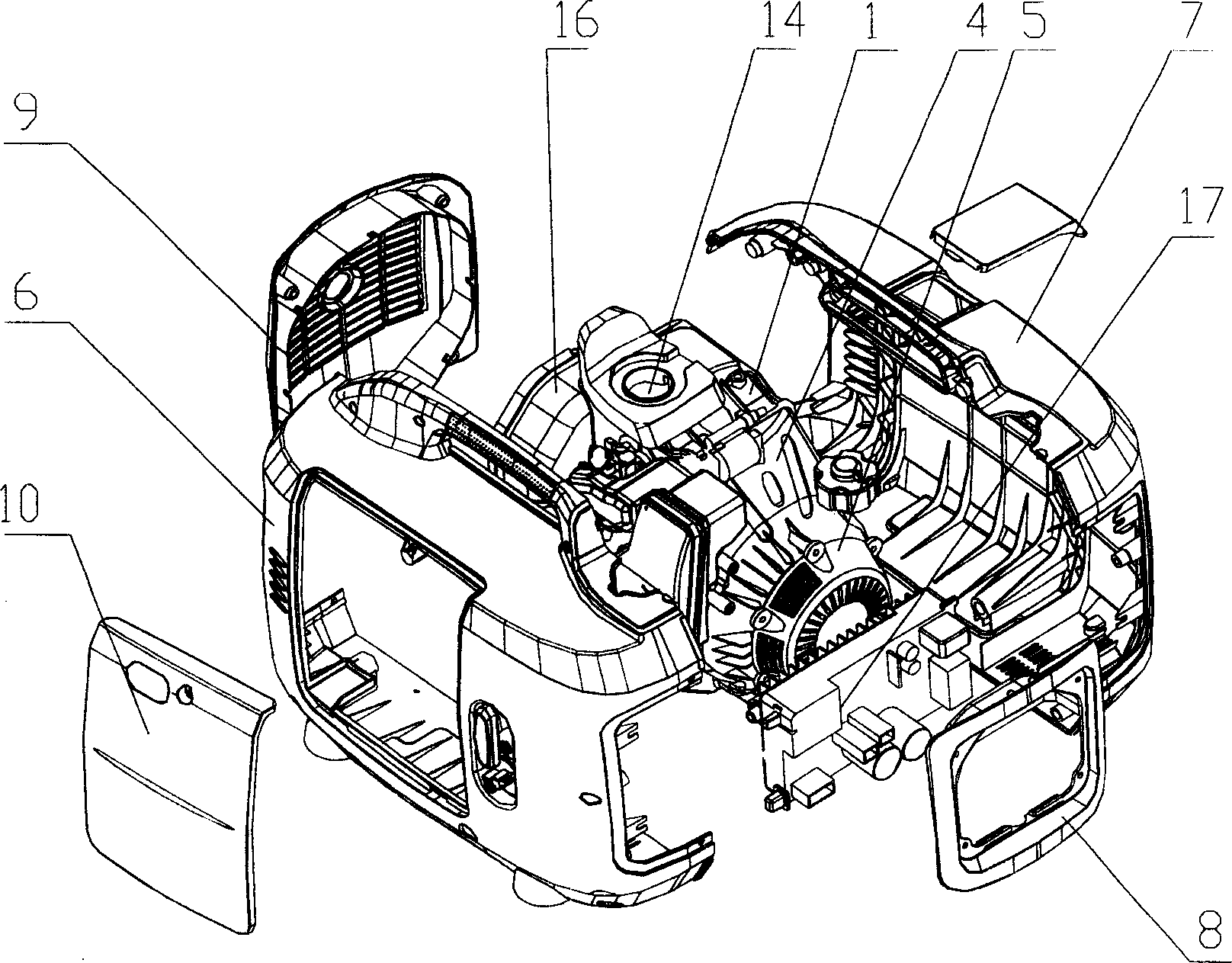

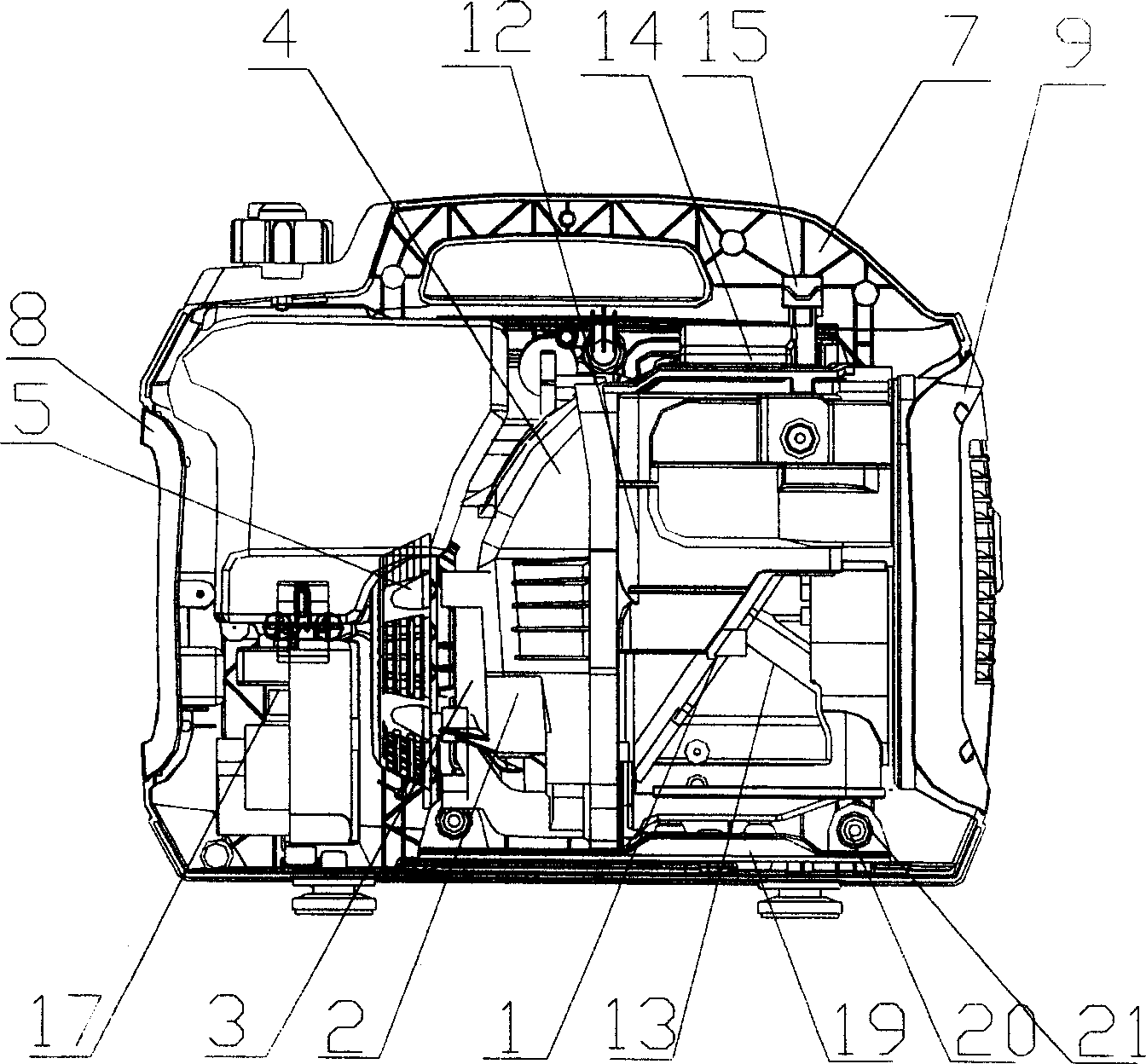

Portable generator

Present invention discloses a portable generator. It includes shell, engine, motor and electric control system, two penetrate holes in engine bottom, penetrate pivot in penetrate core hole, penetrate two ends connected with shell, pressed block between shell and engine for compressing engine. Pressed block and two penetrate pivots form a steady triangle, engine is held in shell. Whole generator weight is shared by two penetrate pivots to reduce engine rigidity, which makes engine more light and convenient carrying.

Owner:WUXI KIPOR POWER CO LTD

Evaporative cooling system of hybrid motor stator

ActiveCN102832726AReduce in quantityReduced tightnessMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineEvaporation

The invention discloses an evaporative cooling system of a hybrid motor stator. A stator sealing space comprises a stator housing (1), an insulated sleeve (3) and an end cover (2), wherein a hollow pipeline (7), an end part spraying system, a stator evaporation space and a condenser (16) which are arranged in a stator core (6) or the straight line section of a stator winding (8), and an external forced circulation system form an evaporative cooling loop. Heat produced by the straight line section of the stator winding (8) is transferred to an evaporative cooling medium inside the hollow pipeline (7). A plurality of nozzles (10) are arranged around the end part of the stator winding (8), and the evaporative cooling medium is directly sprayed on the end part of the stator winding (8) after atomized by the nozzles (10) for absorbing the heat produced on the end part. A liquid part subjected to heat exchange in the evaporative cooling medium on two parts flows into the stator sealing space, the vaporized evaporative cooling medium raises to enter the condenser (16), and is condensed by the condenser (16) to become liquid, and the liquid flows back to the stator sealing space.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

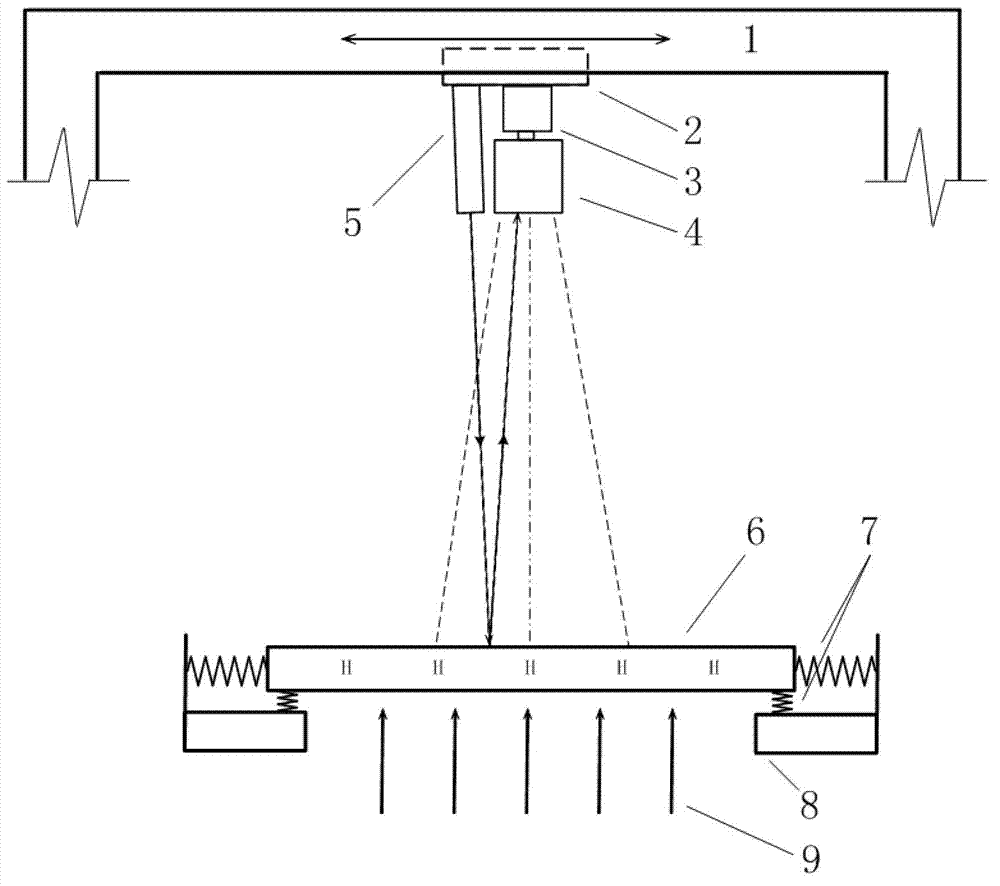

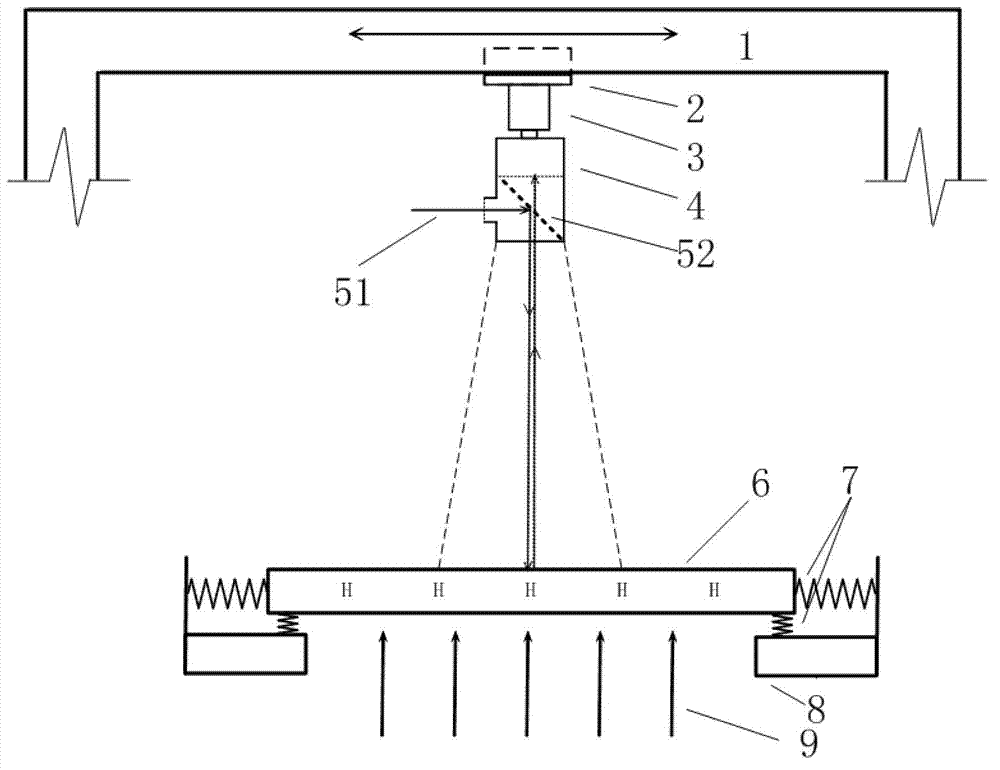

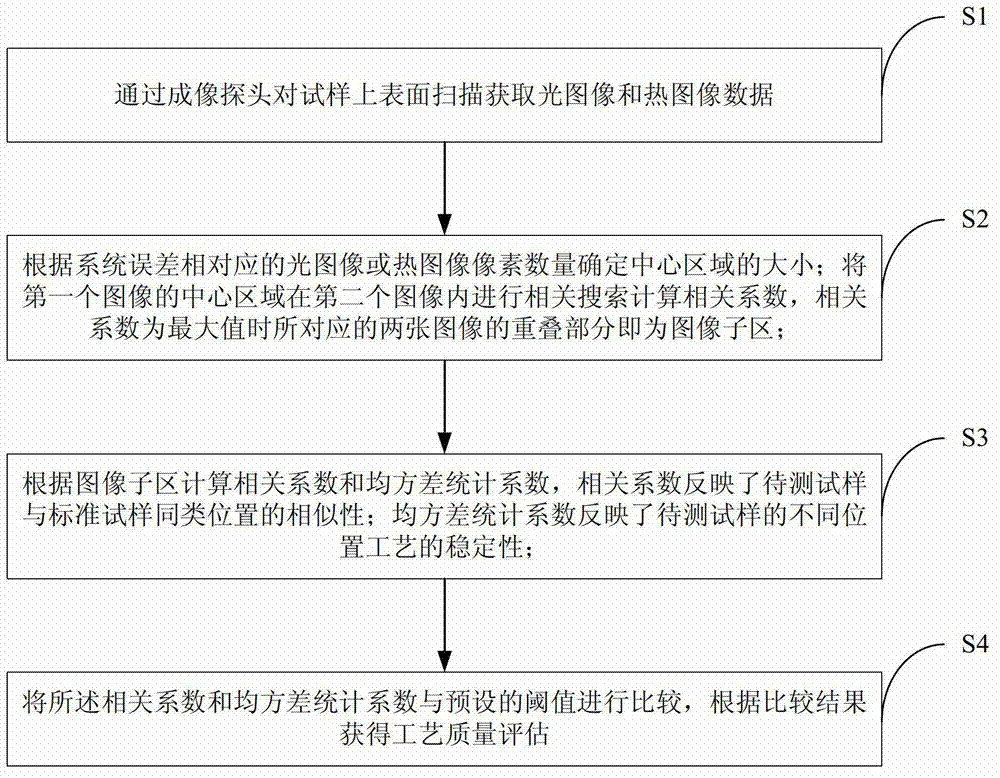

Device and method for detecting micro-electronic packaging process quality based on photo-thermal imaging

ActiveCN102901445AReliable detection and evaluationPrecise Positioning AnalysisScattering properties measurementsOptically investigating flaws/contaminationCorrelation coefficientMean square

The invention discloses a device for detecting micro-electronic packaging process quality based on photo-thermal imaging. The device for detecting the micro-electronic packaging process quality based on the photo-thermal imaging comprises an image acquiring device, a working bench, a control device and a data processing device, wherein the image acquiring device comprises a support cross beam, a translational motion motor, an imaging probe and a light transmitter. The translational motion motor is fixed on the lower lateral face of the cross beam, and the imaging probe is perpendicular to a moving block fixed in the translational motion motor. The light transmitter is connected to the moving block through an adjustable connecting piece, and emitted light is reflected by a sample and then enters the imaging probe by adjusting the adjustable connecting piece. The data processing device is used for processing light images and heat image data acquired by the image acquiring device to obtain correlation coefficient and mean square error statistic coefficient, comparing the correlation coefficient and the mean square error statistic coefficient and a preset threshold value and obtaining process quality evaluation according to a compared result. The device for detecting the micro-electronic packaging process quality based on the photo-thermal imaging can achieve recognition of residual particles, voids and material quality and measurement of microvoid depth and is reliable in detection and evaluation.

Owner:HUAZHONG UNIV OF SCI & TECH +1

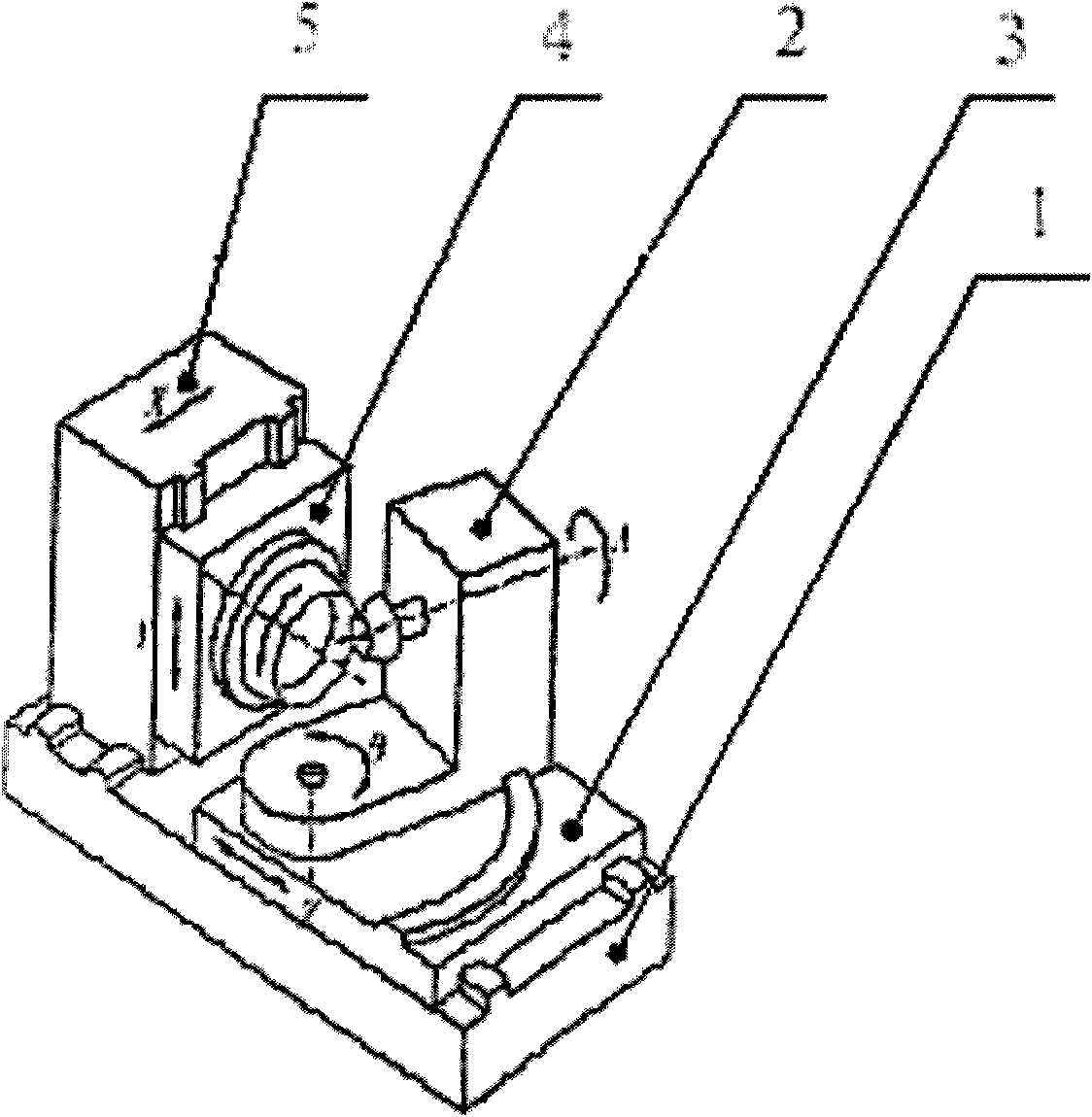

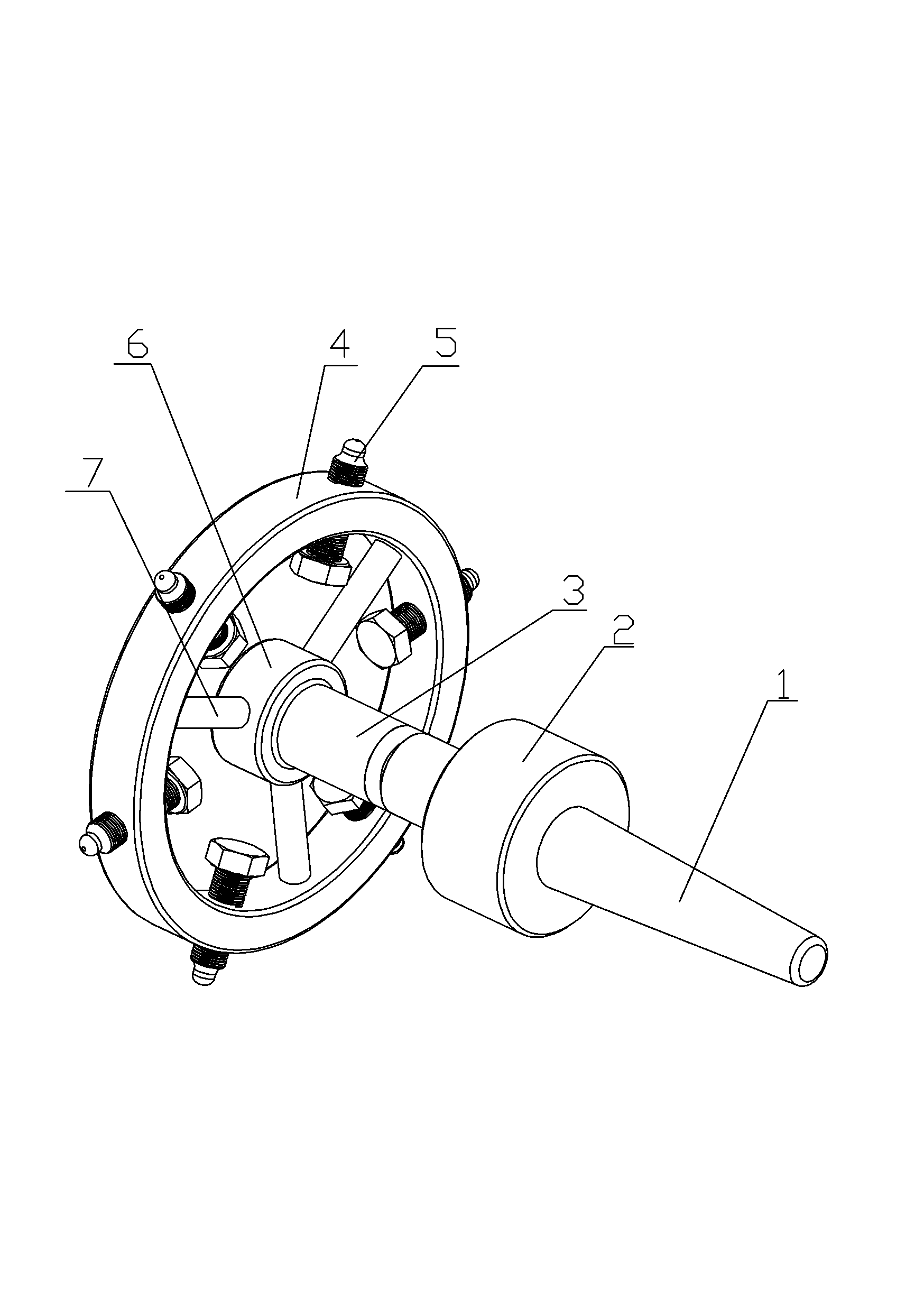

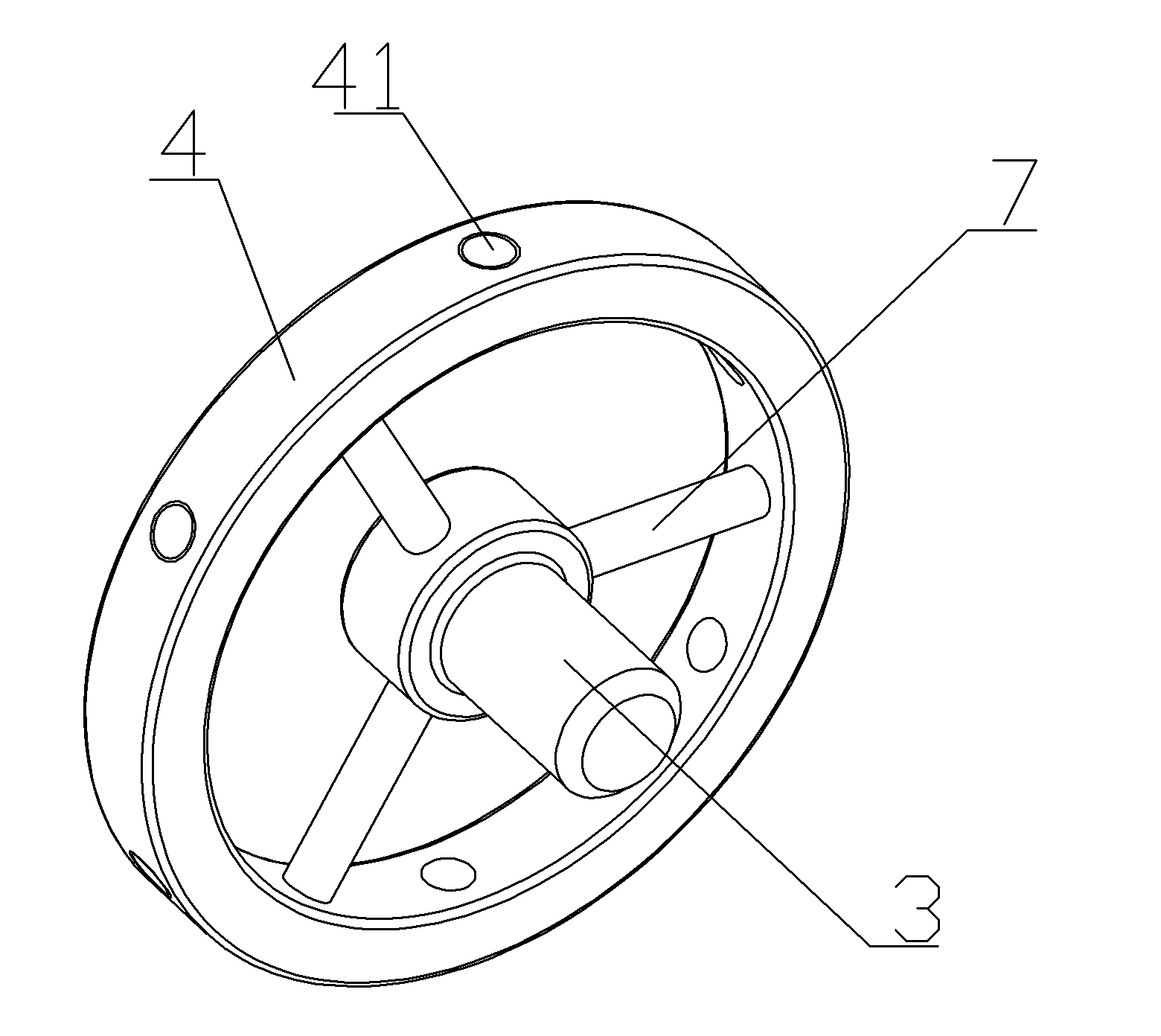

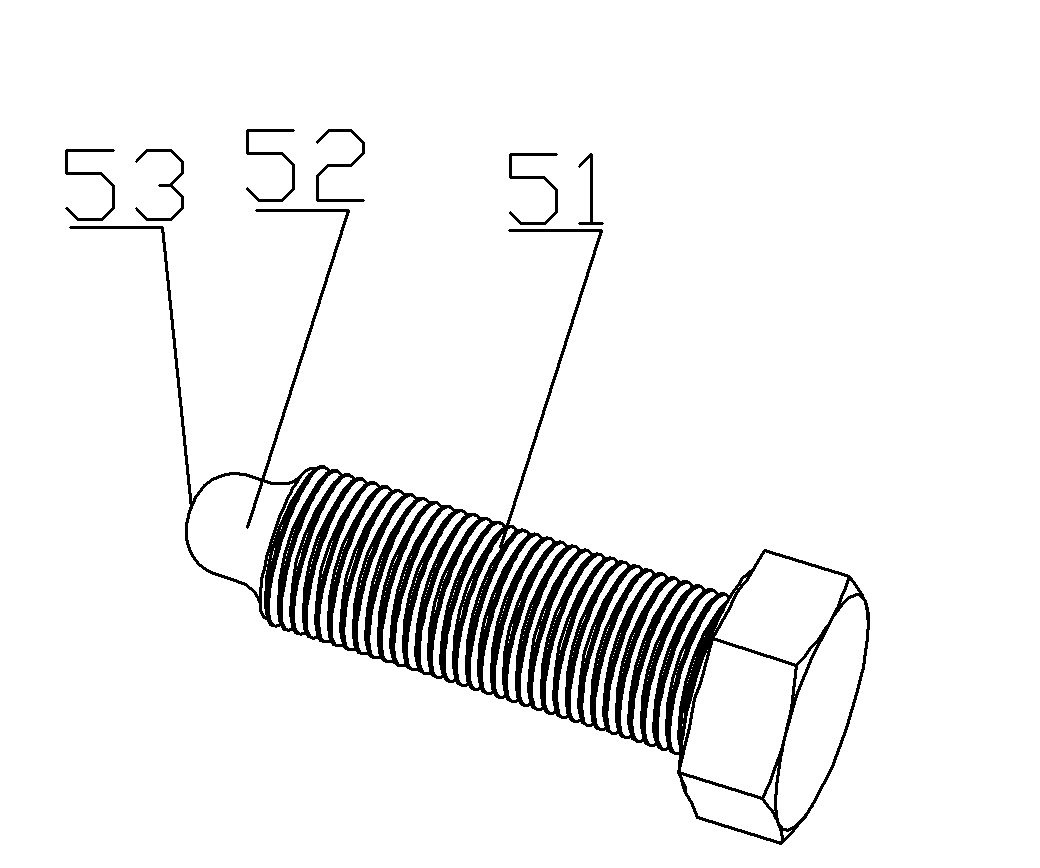

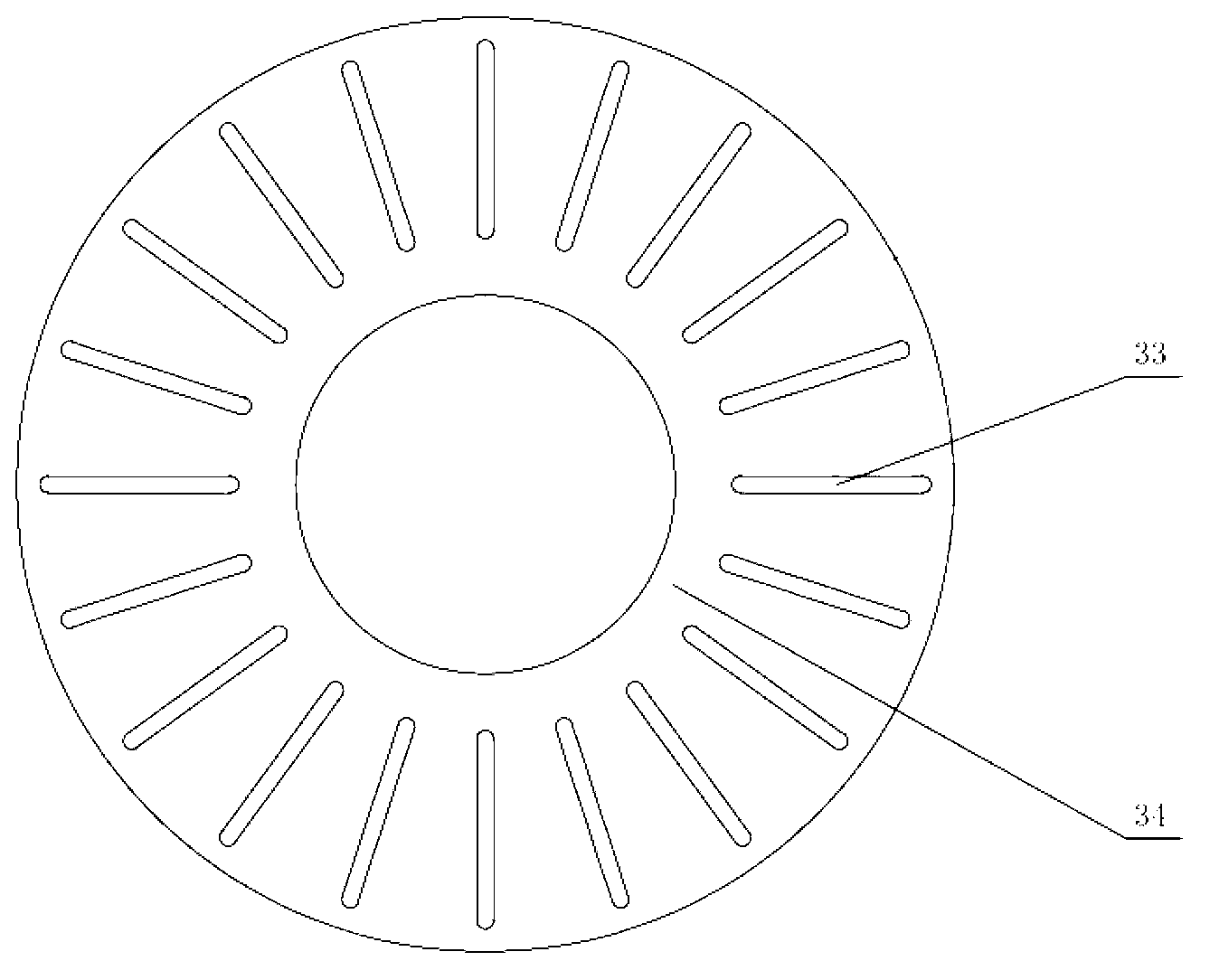

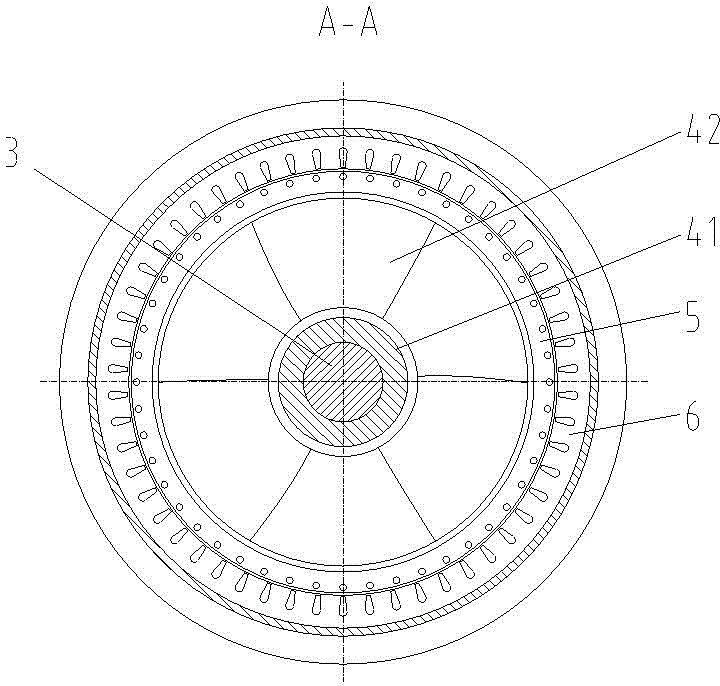

Positioning fixture for drum-like part turning

ActiveCN102699718ASimple structureEasy to usePositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention discloses a positioning fixture for drum-like part turning. The positioning fixture comprises a support bar, wherein the front end of the support bar is coaxially provided with a support device which is inserted in the inner hole of a drum-like part when in use; the supporting device comprises a support wheel coaxially wound at the outer side of the support bar; a spoke structure used for supporting and fixing the support wheel is fixedly arranged between the support wheel and the support bar; spiral mounting holes, which extend along the radial direction of the support wheel, are uniformly and circumferentially distributed in the external ring surface of the support wheel; support studs are spirally assembled in the spiral mounting holes; and one end, away from the support bar, of each support stud is provided with a propping end which is used for propping against the inner hole wall of the drum-like part when in use. Holes are not required to be formed in the support bar, so that the strength of the support bar is not influenced, multiple spiral mounting holes can be formed in the support wheel, so that more support stud can be inserted so as to improve the supporting effect of the support device.

Owner:HENAN PINGGAO ELECTRIC +1

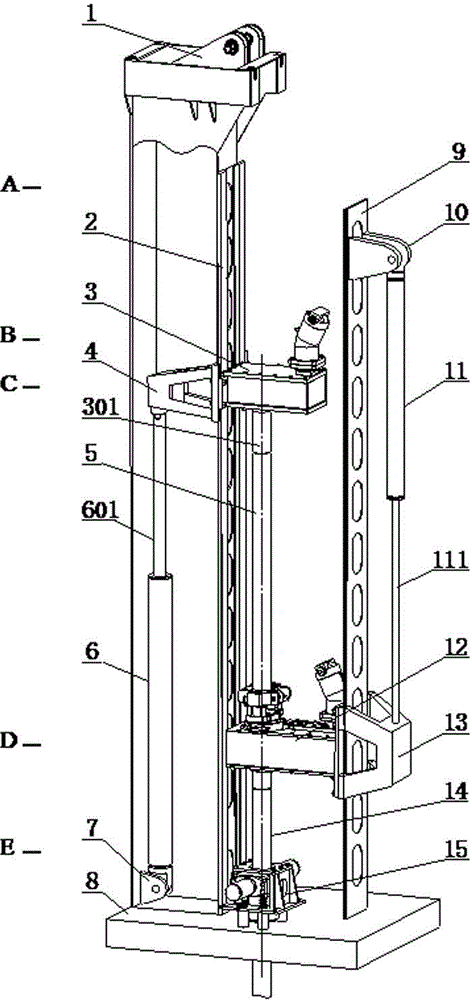

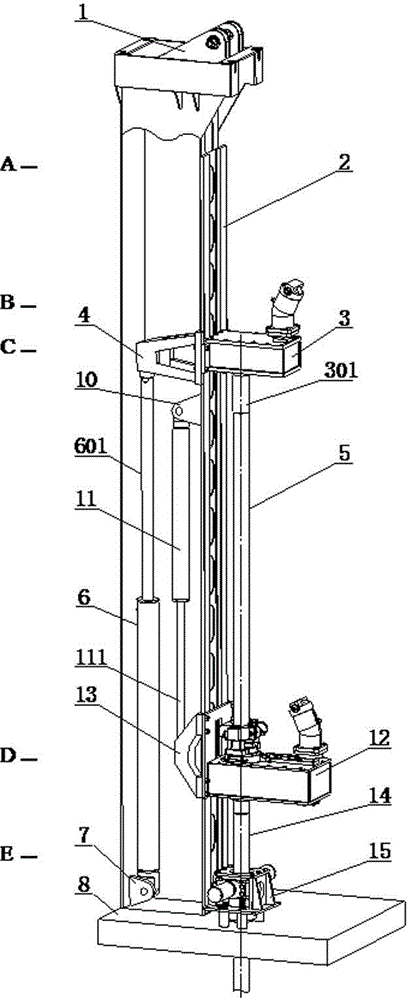

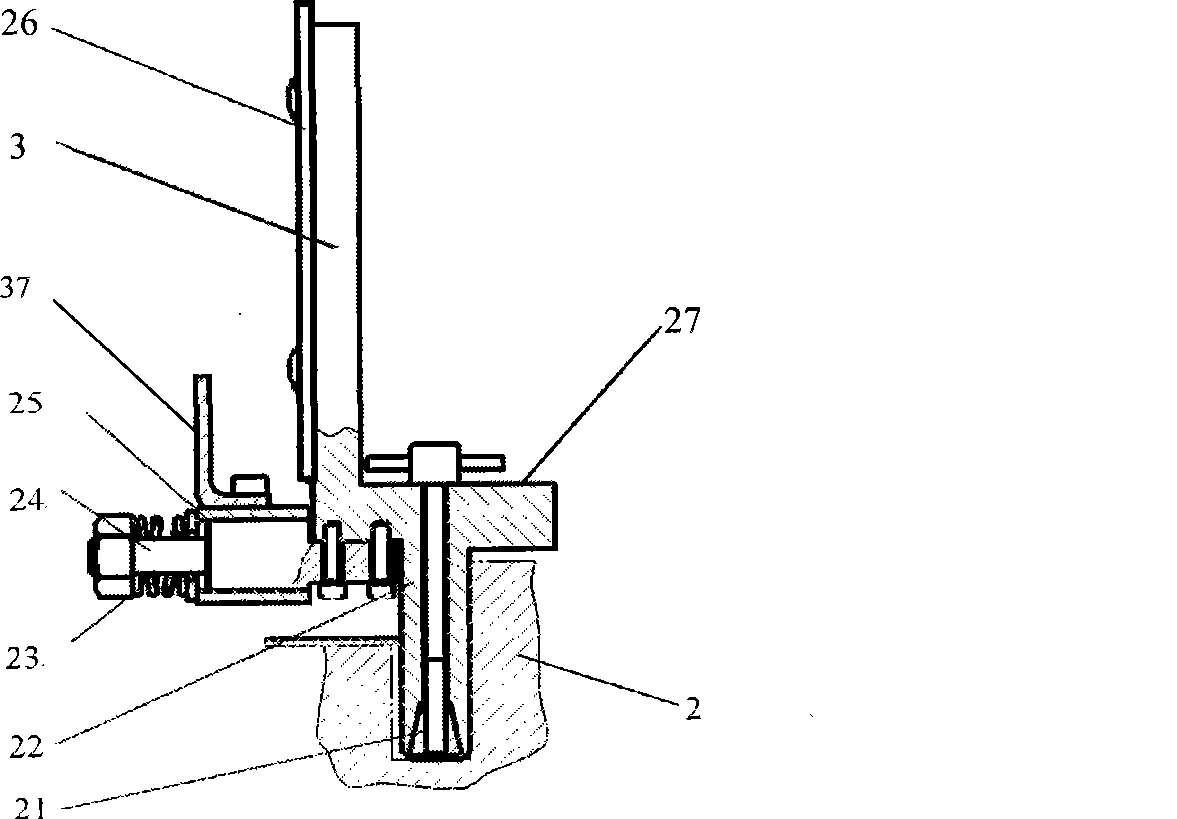

Drill rod unloading device suitable for submarine drilling rig

InactiveCN105239940AReduced clamping effectReduced stiffness requirementsDrilling rodsDrilling casingsScrew threadSubmarine

The invention discloses a drill rod unloading device suitable for a submarine drilling rig; a power chuck for drill rod clamping and screw thread unloading on a traditional submarine drilling rig is formed to a whole component having a slide support piece; an installation mode thereof on the submarine drilling rig guarantees the axis of a center through hole thereof to be always coaxial with the axis of a driving drill rod on a drilling power head of the submarine drilling rig; meanwhile, the submarine drilling rig is additionally provided with a lifting hydraulic oil cylinder and a slide rail frame having an installation direction parallel to a slide way of the drilling power head of the submarine drilling rig; and the whole component of the power chuck can be driven by the lifting hydraulic oil cylinder to vertically move along the slide rail frame. The drill rod unloading device uses the advantage of capability of shifting the position of the power chuck, so that the power chuck can be used for unscrewing upper and lower screw threads of a drill rod, and when the upper and lower screw threads of the drill rod are not totally unscrewed, the drill rod is always kept in a center hole of the power chuck and prevented from tilting; and meanwhile, when the upper and lower screw threads of the drill rod are both unscrewed, and the drill rod needs to displace in parallel, the drill rod can be disconnected for providing a space.

Owner:HUNAN UNIV OF SCI & TECH

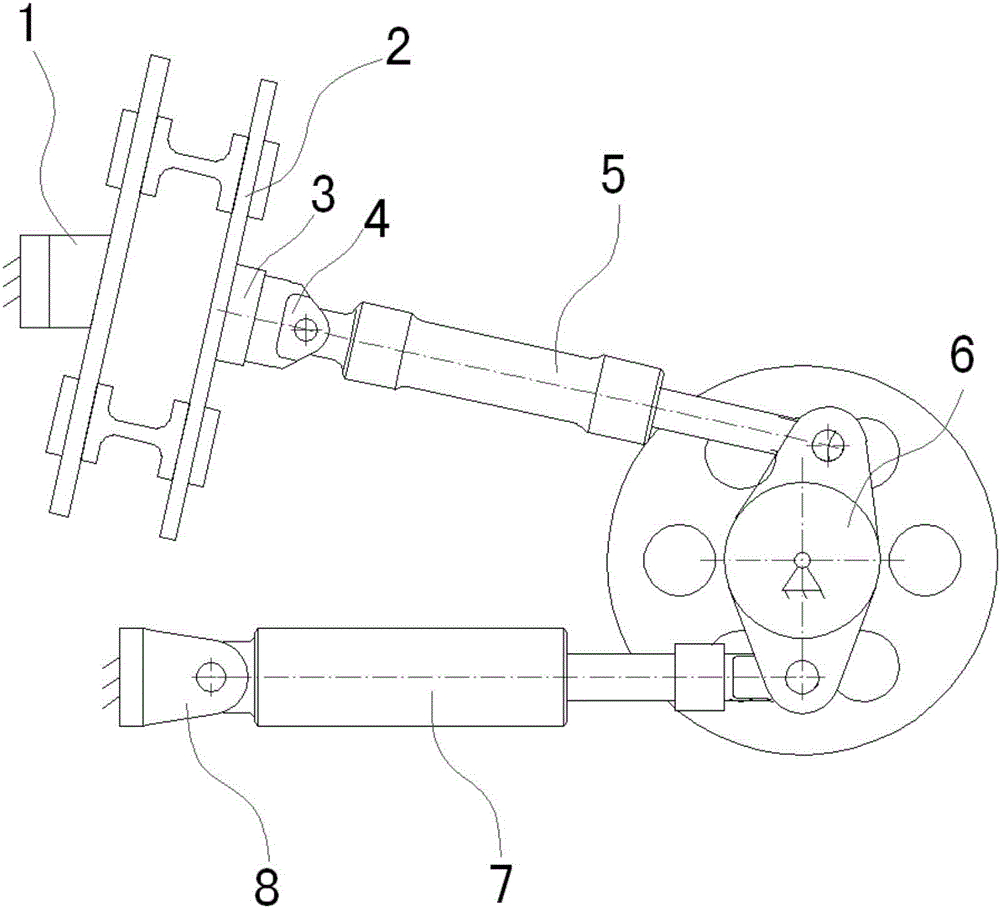

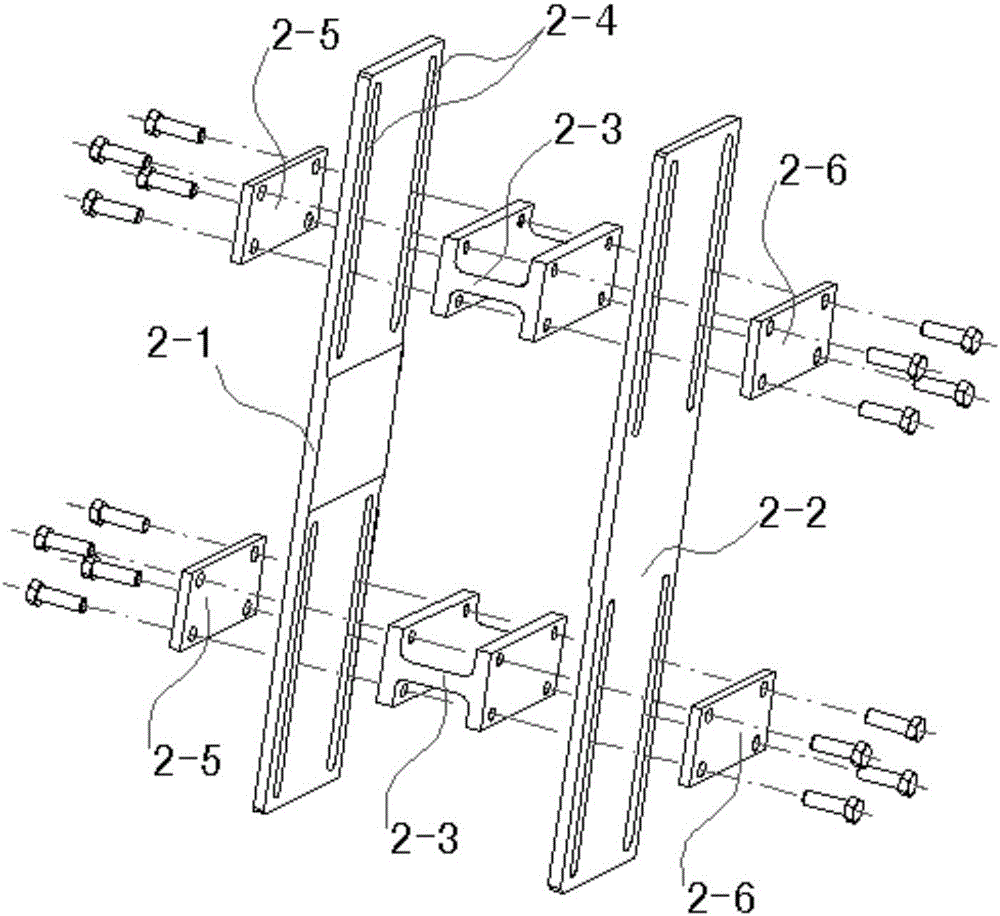

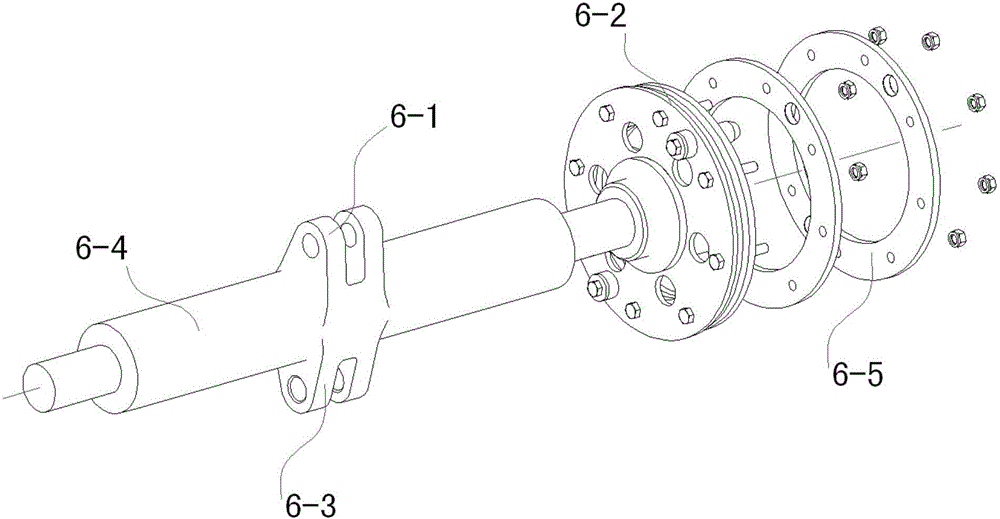

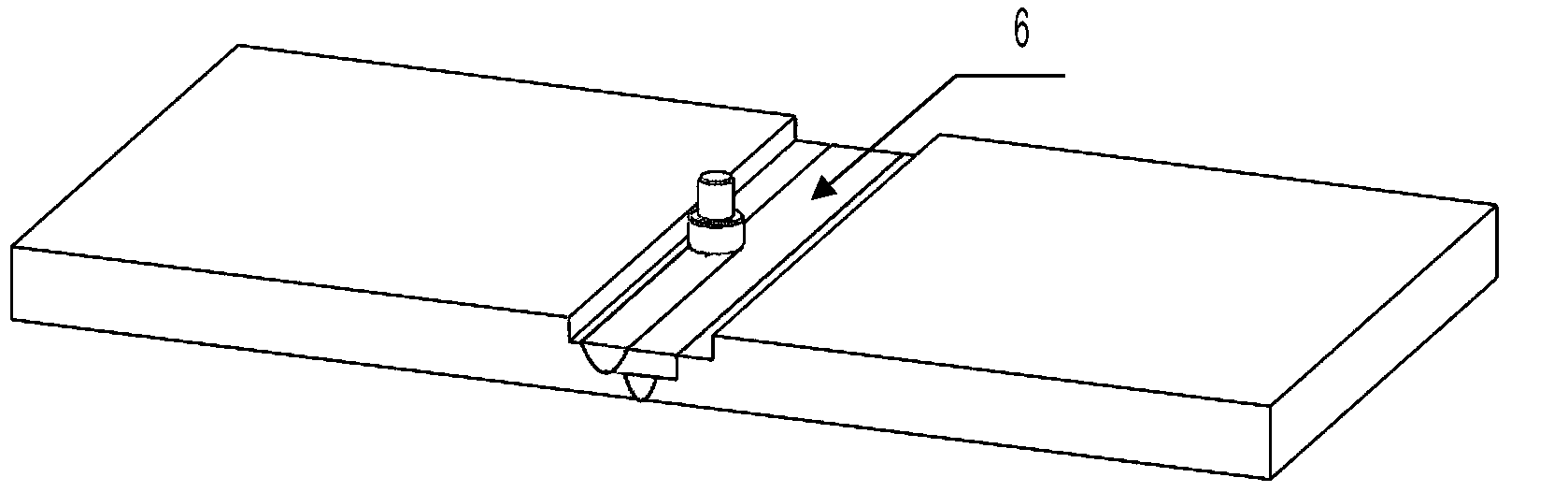

Performance testing device of airplane steering surface drive actuator

ActiveCN106828972ASolve the problem of difficult output force measurementReduced stiffness requirementsAircraft components testingBench testActuator

The invention relates to an iron bird bench test system, in particular to a performance testing device of an airplane steering surface drive actuator. The device comprises a bracket, the steering surface drive actuator (5), a steering surface imitation part (6) and a loading actuator (7); the steering surface imitation part (6) comprises rocker arms (6-1 and 6-3), mass plates (6-2) and a rotary shaft (6-4); the rocker arms (6-1 and 6-3) are fixedly connected with the rotary shaft (6-4); the mass plates (6-2) are symmetrically fixed to the two ends of the rotary shaft (6-4); one end of the steering surface drive actuator (5) is fixed through the bracket; the other end of the steering surface drive actuator (5) is connected with the steering surface imitation part (6) through the rocker arm (6-1); one end of the loading actuator (7) is fixed through the bracket; and the other end of the loading actuator (7) is connected with the steering surface imitation part (6) through the rocker arm (6-3). By means of the performance testing device of the airplane steering surface drive actuator, the problems that in traditional design, a loading system is not convenient to install, output force of an airborne actuator is difficult to measure, the stiffness analog is dispersed and accuracy is low are solved, and optimal design of the iron bird bench actuator and a back end system is achieved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

High-intensity aluminum alloy thick-plate low-heat input stirring friction welding method

InactiveCN103624398AThe total heat input of welding is smallSmall overall deformationWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingThick plate

The invention provides a high-intensity aluminum alloy thick-plate low-heat input stirring friction welding method, which is mainly characterized in that multiple stages of step shapes are processed at the edge side of a welded thick plate, the low-heat input specification of a high-rotating-speed stirring head and a high-advancing-speed combination is adopted for welding, and the thick plate is cooled to the room temperature after the welding completion; then, a filling plate corresponding to the first stage of step is mounted, in addition, the identical welding parameters are adopted for multi-time parallel overlapping welding in the layer range, and the overlapping width of the adjacent welding seams is not smaller than the radius of a shaft shoulder of the stirring head. The same welding process as that of the first layer filling plate welding is respectively adopted for the welding of each other layer. The method provided by the invention has the advantages that small-size stirring friction welding equipment can be used for realizing multi-time multilayer low-heat input stirring friction welding on medium and thick plate workpieces; the technical problems that the large-thickness plate material stirring friction welding has special requirements on the material performance of the stirring head materials, the fracture easily occurs in the welding, and the like are avoided; meanwhile, the joint region softening problem easily occurring in the high-intensity aluminum alloy thick plate stirring friction welding is also avoided.

Owner:YANSHAN UNIV

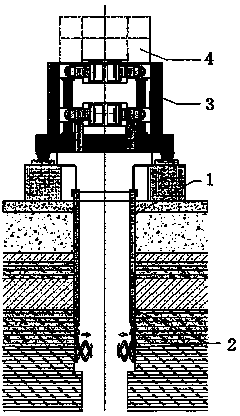

Method for in-hole guiding deviation rectification and steel pipe column straightening based on one-column-one-pile back insertion method

The invention relates to a method for in-hole guiding deviation rectification and steel pipe column straightening based on a one-column-one-pile back insertion method. The method comprises the steps that (1) a drilling machine is removed, and a hole opening is cleaned; (2) a 5-meter-long guiding deviation rectification device is placed in a long pile casing; (3) hydraulic oil pipe lines are connected; (4) a back insertion straightening device is placed, centered and leveled; (5) a hydraulic oil pipe of the in-hole guiding deviation rectification device is connected with a control console of the back insertion straightening device; (6) a steel pipe column is inserted into a hole to the position 50 cm higher than a concrete surface in the hole through the back insertion straightening device; (7) a support of the guiding deviation rectification device is unfolded and abuts against the outer wall of the steel pipe column; (8) the perpendicularity of the steel pipe column is adjusted; (9) the guiding deviation rectification device is locked; (10) the steel pipe column is inserted by a designed depth; (11) the perpendicularity of the steel pipe column is checked; (12) the guiding deviation rectification device is removed and hoisted away. According to the method for in-hole guiding deviation rectification and steel pipe column straightening based on the one-column-one-pile back insertion method, the difficulty in perpendicularity adjustment in the one-column-one-pile back insertion construction process is effectively reduced, and work efficiency and precision of steel pipe column straightening are improved.

Owner:SHANGHAI FOUND ENG GRP

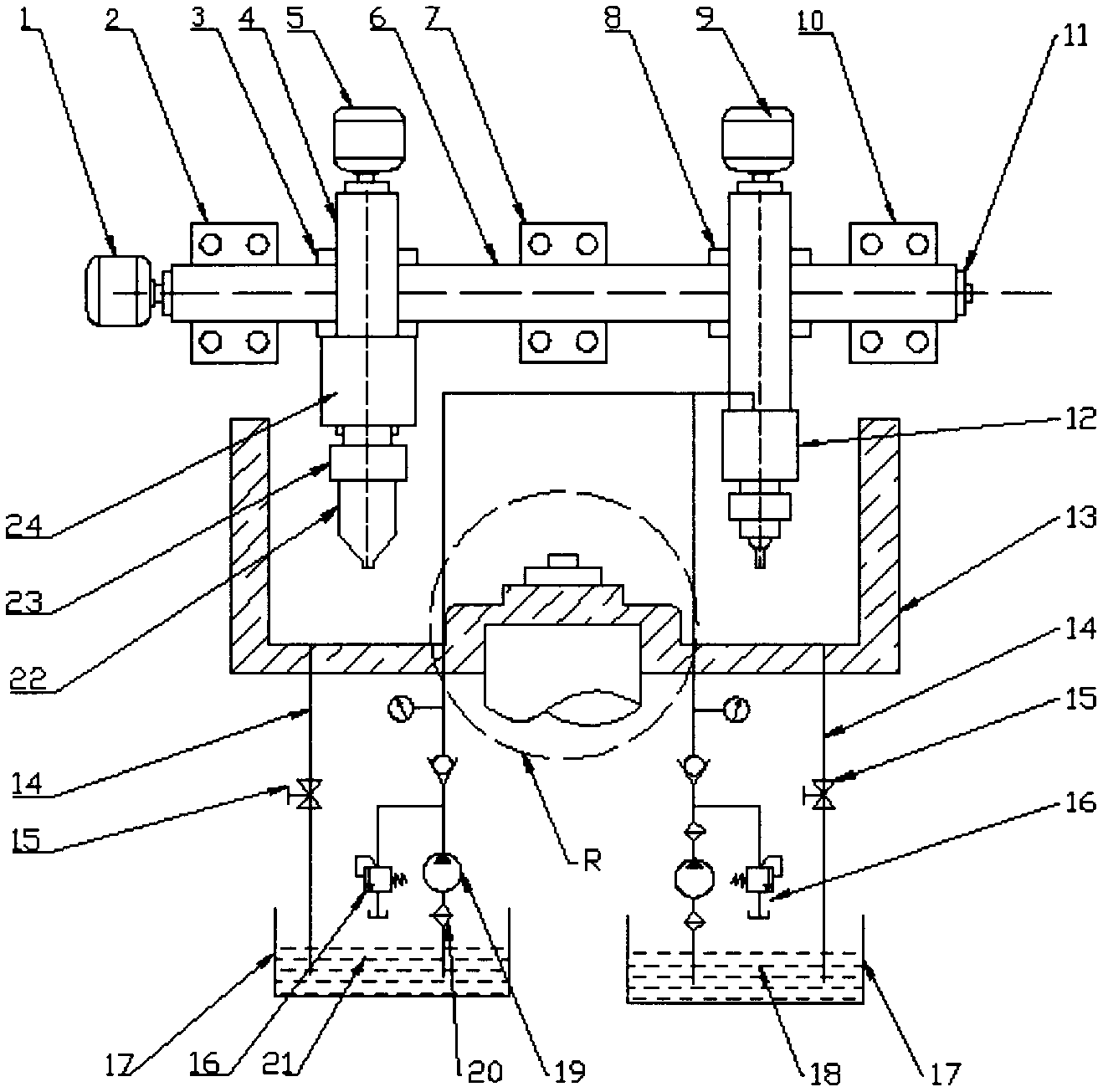

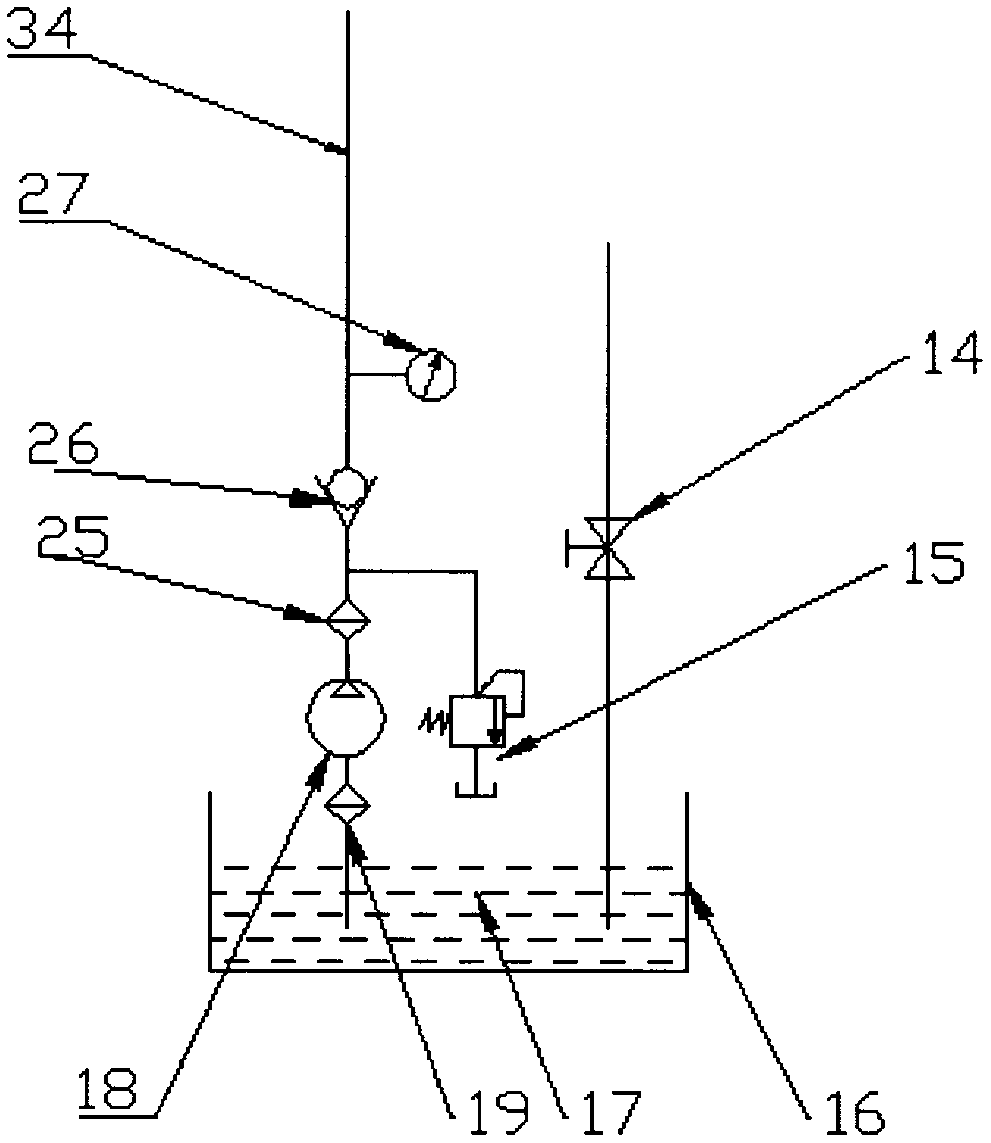

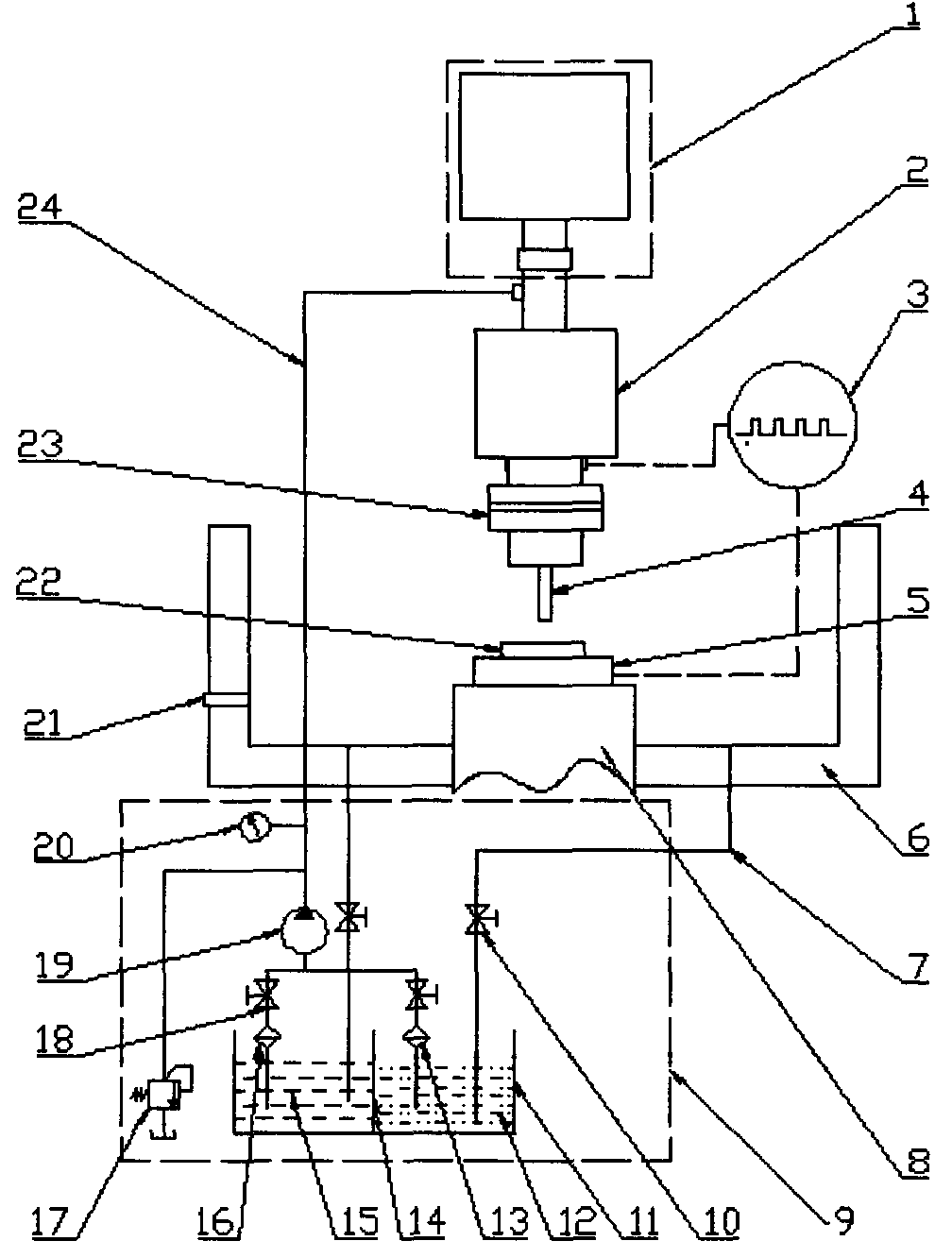

Combined laser-electric spark-electrolysis machining method and device for micro holes with countersunk heads

The invention relates to a combined laser-electric spark-electrolysis machining method and device for micro holes with countersunk heads. The method comprises the steps: carrying out through hole pre-machining on the micro holes with the countersunk heads on a workpiece through a laser beam, carrying out electric spark machining on the countersunk heads of the micro holes through a tubular copper electrode to achieve needed precision of the shape of the countersunk heads basically, and carrying out electrolytic machining electrolysis machining on the whole micro holes with the countersunk heads through a high-speed jet electrolyte beam coaxial with the electric spark machining electrode to remove recast layers remaining after the former two machining steps. The device comprises a laser generation device, a combined electric spark machining and electrolysis machining device, a machining mode conversion device, a working solution circulation system, a power supply and a control system. According to the method, laser machining and electric spark machining are the main machining modes and supplemented by electrolysis machining, and the high speed, high precision and high quality can be achieved at the same time. By means of the method and device, rapid machining of the micro holes with the various special-shaped countersunk heads can be achieved, and various shortcomings caused by the adoption of a single specific machining mode in the prior art can be overcome.

Owner:JIANGNAN UNIV

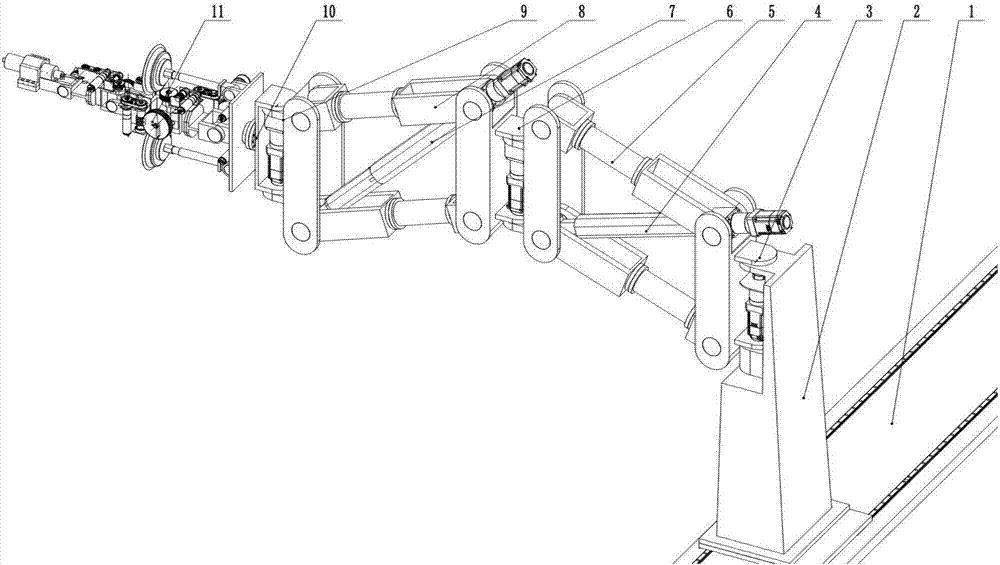

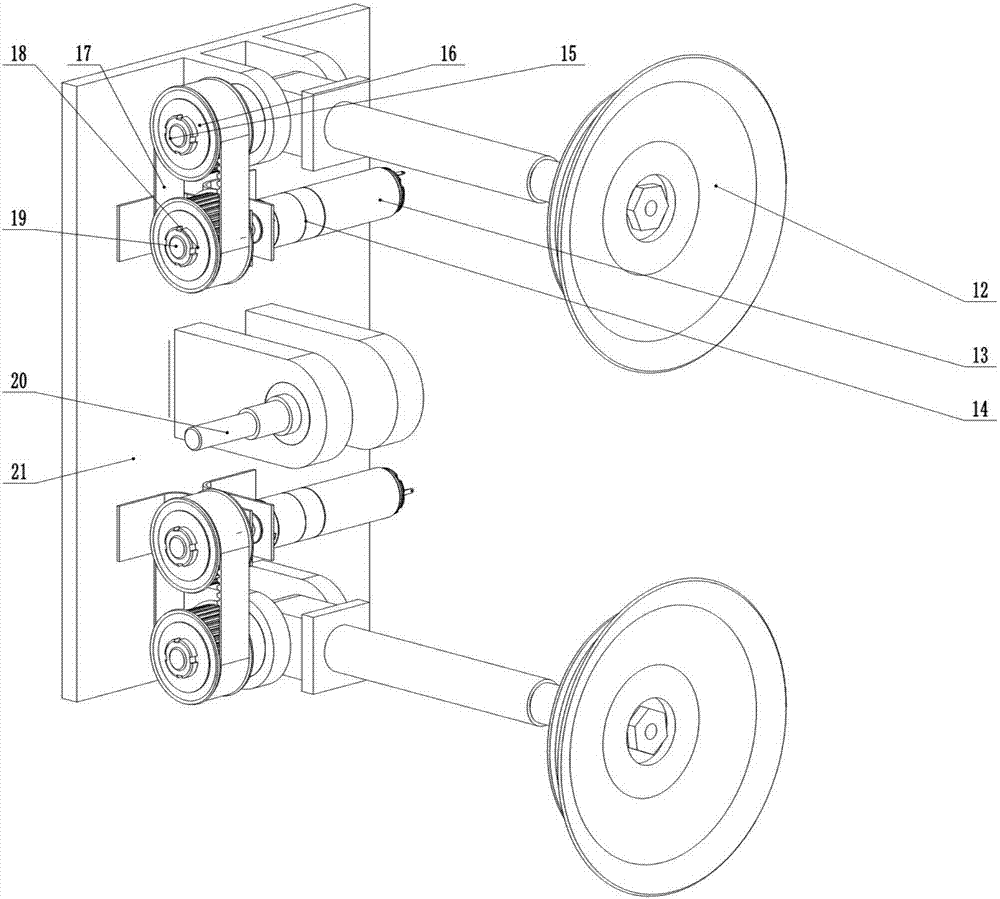

Device used for aircraft skin drilling

ActiveCN107159936ALarge drilling spaceIncrease flexibilityWork benchesManipulatorMechanical engineeringAirplane

The invention provides a device used for aircraft skin drilling. The device comprises a large arm part with multiple degrees of freedom, a supporting connecting base, a small arm part with multiple degrees of freedom and a sucking disc part, wherein the large arm part can slide along a guide rail; the tail end of the large arm part is fixedly arranged on the first side surface of the supporting connecting base; the small arm part and the sucking disc part are independently mounted on the second side surface of the supporting connecting base; the large arm part can drive the supporting connecting base to move to a working region of aircraft skin; the supporting connecting base is fixed relative to the skin by virtue of a sucking disc of the sucking disc part; and the small arm part drills on a plurality of positions of the working region. Compared with existing skin drilling equipment, the device provided by the invention is more suitable for a complex surface of aircraft skin, has greater drilling space and greater flexibility.

Owner:NORTHEASTERN UNIV

Jet-flow-guided laser-spark-electrolysis combined machining device

The invention relates to a jet-flow-guided laser-spark-electrolysis combined machining device, and belongs to the field of non-traditional machining. The jet-flow-guided laser-spark-electrolysis combined machining device adopts the structure integrating three non-traditional machining methods, and is composed of a laser generator, a machining module, a working solution circulation system and a power supply module, wherein the laser generator is placed above the machining module, and laser beam machining and spark machining are ensured to be coaxial; an electrode in the machining module for sparking machining can be stationary or rotary; the working solutions for jet-flow-guided laser machining and spark machining employ deionized water, and form a set of working solution circulation system with the working solution for electrolytic machining. When the device is used for machining, the jet-flow-guided laser machining and spark machining are employed as the main means for removing material, being accompanied by electrolytic machining; speed, accuracy and surface quality of part manufacturing are all taken into consideration; thereby, rapid machining of various micro holes with abnormal countersunk heads, and various defects caused by using single non-traditional machining method are overcome.

Owner:JIANGNAN UNIV

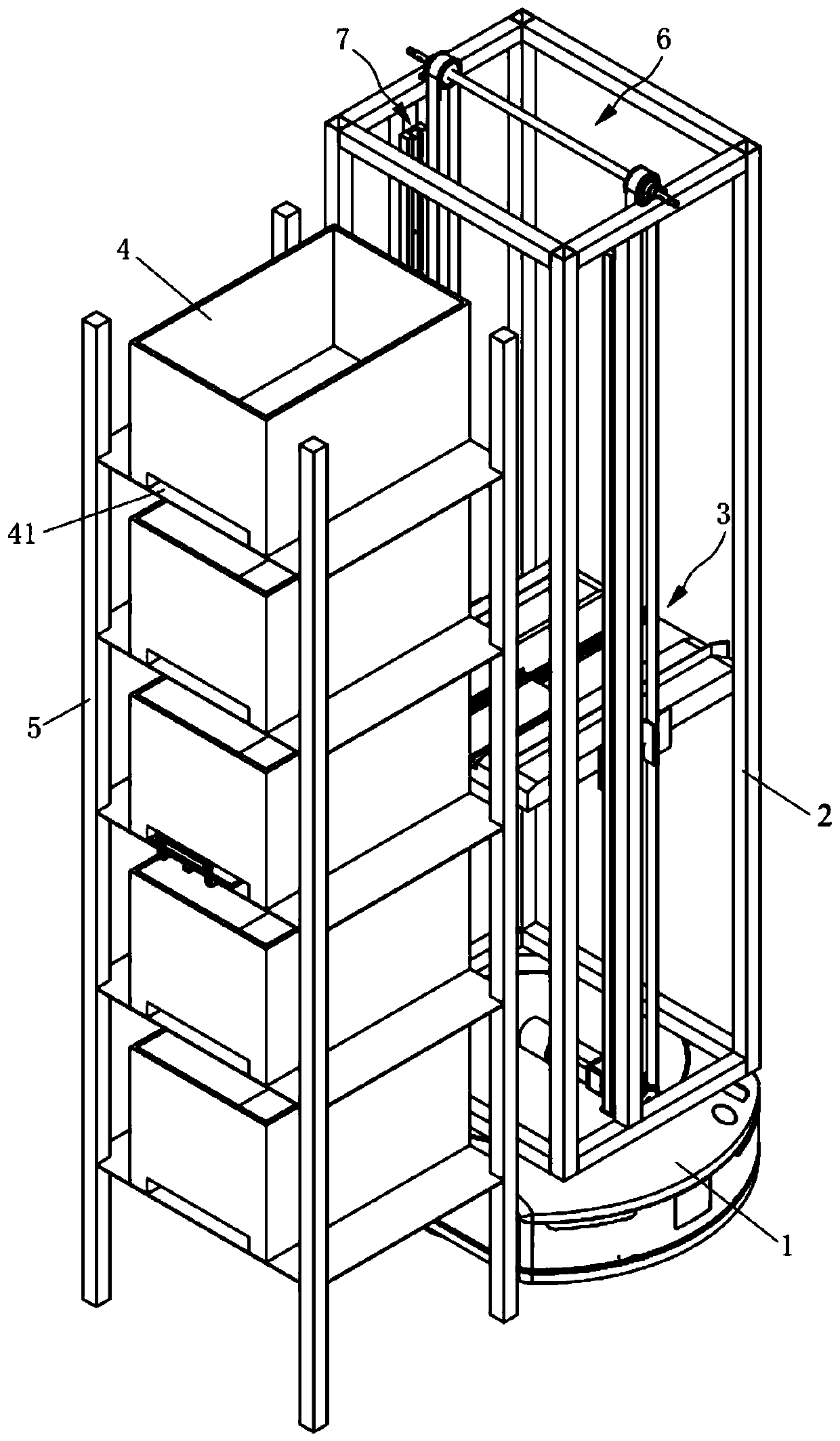

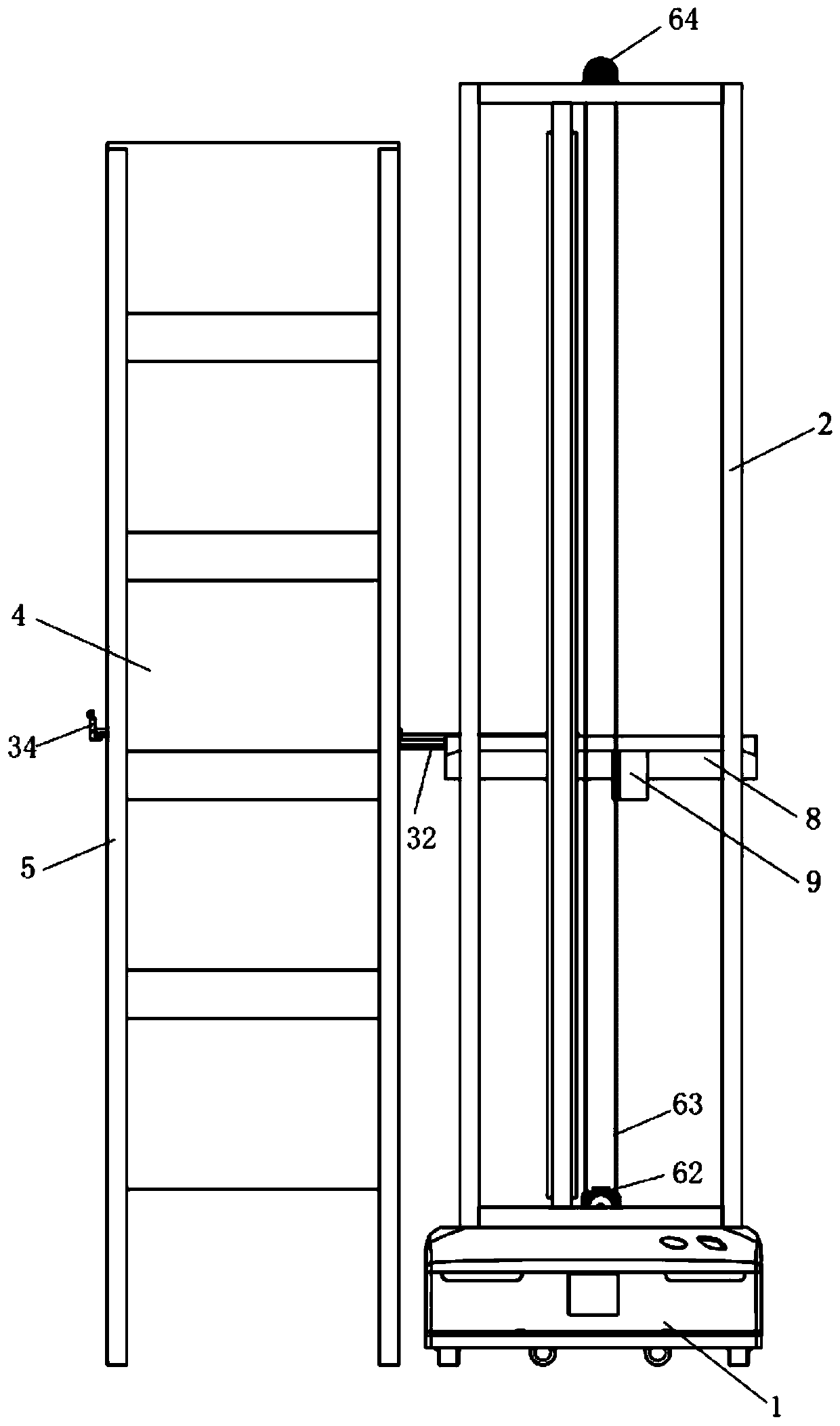

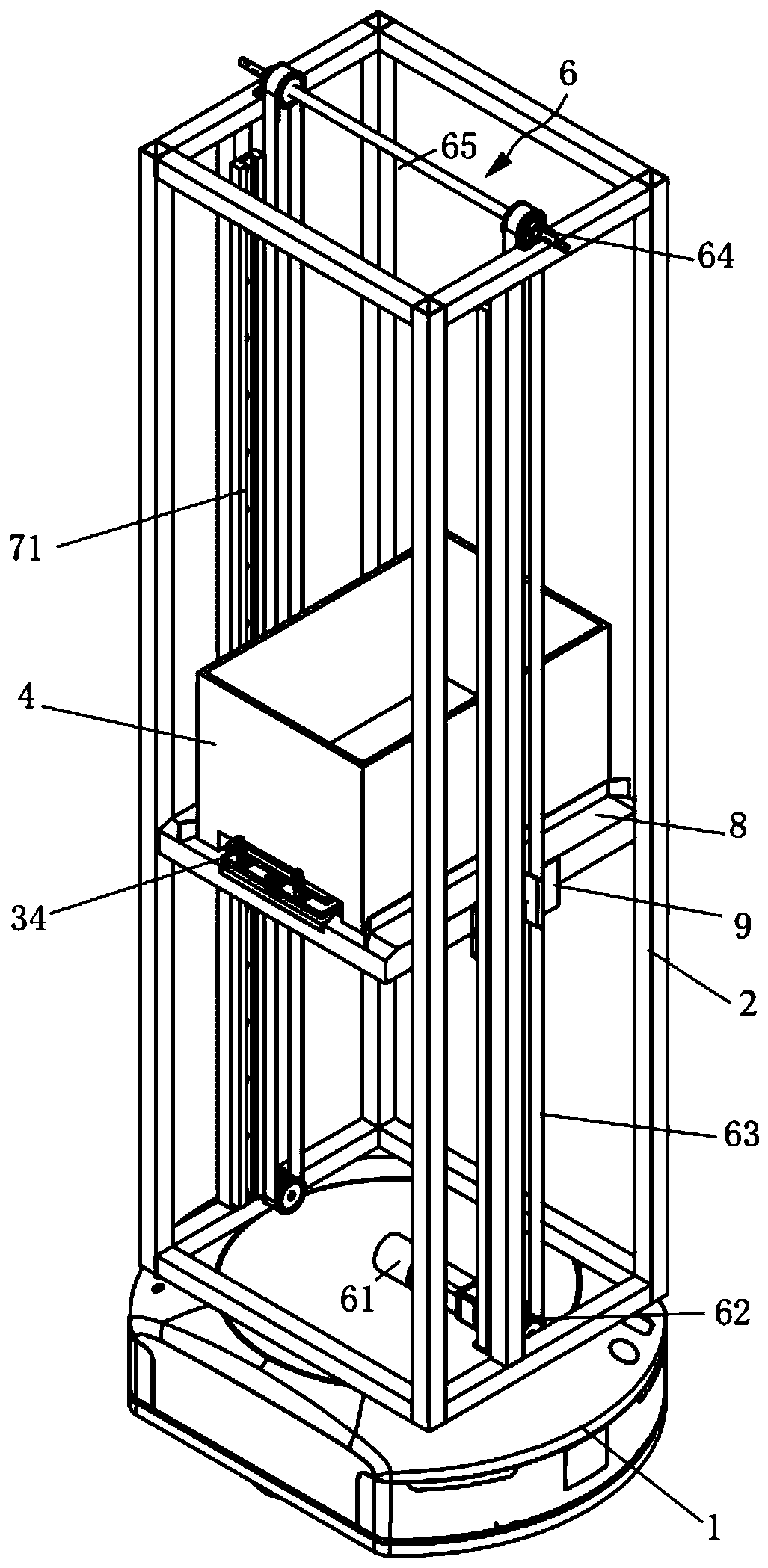

Carrying robot

PendingCN109941652AReduced stiffness requirementsImprove stabilityStorage devicesEngineeringFriction force

The invention discloses a carrying robot and belongs to the technical field of warehousing robots. The carrying robot comprises a movable base, an object carrier, a telescopic assembly and a shiftingfinger, wherein one end of the telescopic assembly is connected with the object carrier, and the other end of the telescopic assembly is connected with the shifting finger; the shifting finger is configured to have a first position which is no higher than the upper surface of an upper fork and a second position which is higher than the upper surface of the upper fork; and under the action of the telescopic assembly, the shifting finger can penetrate through the lower part of a to-be-transferred object to abut against the back surface of the to-be-transferred object, and drag the to-be-transferred object into and out of the object carrier. The carrying robot only needs to overcome the friction force acting on the to-be-transferred object in the dragging process when the to-be-transferred object is transferred, the rigidity requirement for the telescopic assembly is reduced, and the design difficulty and the manufacturing cost are favorably reduced; and the shifting finger penetrates through the lower part of the to-be-transferred object and then abuts against the back surface of the to-be-transferred object, so that the stability when the to-be-transferred object is dragged is improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

Bamboo-shaped buckling-restrained brace

ActiveCN105714952AShorten the lengthDestabilization will not happenShock proofingBuckling-restrained braceCoaxial line

The invention discloses a bamboo-shaped buckling-restrained brace, comprising a core component, an external restrained component and reinforced connecting components, wherein the core component is formed by alternately arranging a plurality of circular energy dissipation sections and a plurality of circular elastic sections along a longitudinal coaxial line; each circular elastic section comprises a plurality of middle elastic sections and two end elastic sections; the cross sectional area of each circular energy dissipation section is smaller than that of the corresponding circular elastic section; the core component is positioned in the external restrained component; each reinforced connecting component is composed of a node section, a connecting section and a reinforcing barrel. The bamboo-shaped buckling-restrained brace disclosed by the invention has the advantages that all the circular energy dissipation sections are shorter, and only yield without buckling under the action of an axial force, so that mortar is unnecessarily added or additional parts are unnecessarily arranged for restraining the circular energy dissipation sections, the cross sectional area of each circular energy dissipation section is smaller than that of each circular elastic section, the yielding force is less, and the rigidity requirement on the external restrained component is lower, therefore the external restrained component can be a simple circular casing, and the effects of simple structure, convenience in processing and lighter dead-weight are achieved.

Owner:SOUTHEAST UNIV

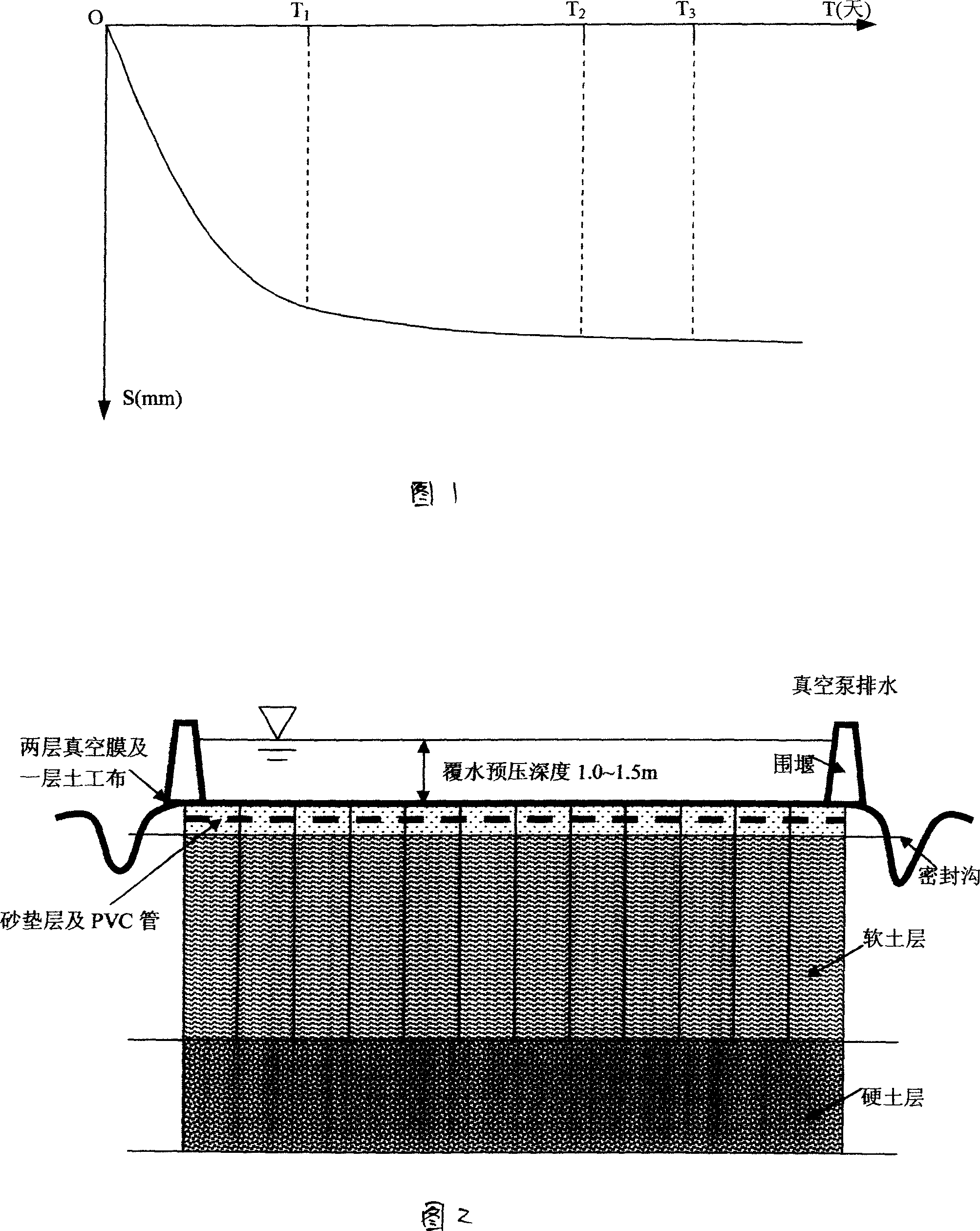

'Short-distance overload vacuum precompression and dynamic water-drainage consolidation united method' soft foundation processing method

ActiveCN1963038AReduce moisture contentImprove soil consolidationIn situ soil foundationSoil preservationCushionEngineering

A ''short-range overloading vacuum prepressing---dynamic discharging consolidation combination method'' to dealing with the soft soil ground foundation, its features are : overloading prepressing the vacuum membranes of conventional vacuum prepressing method with covering water; proceeding the settlement observation to each settlement observation points according the vacuum prepressing operating rules, continuing prepressing 5~10 days after the prepressing settlement above 80% of calculate settlement, then stopping the water overloading vacuum prepressing after ensuring stable completely; removing the vacuum membrane and sun-curing 1~2 days, then proceeding the dynamic dewatering consolidation to eliminating the stored water in sand cushions which is leaved when overloading vacuum prepressing rapidly, then dynamic consolidation or roller compaction after the water level below 1.5m. Its beneficial effects are: it can eliminate the water in muck soil during a short time and enhance the consolidation degree; it makes the skin soil layer get the greatest density, meets the requirements of load bearing capacity and rigidity rapidly and prevents rebound phenomenon; it shortens the construction period and lowers the costs and applies to large area project filling soil recently which has large thickness saturated soft soil particularly.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

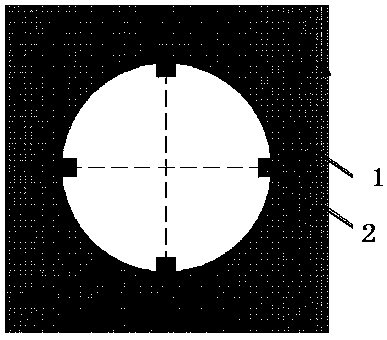

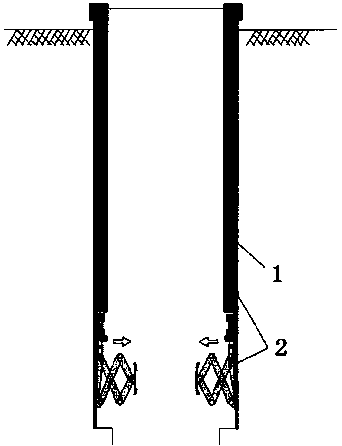

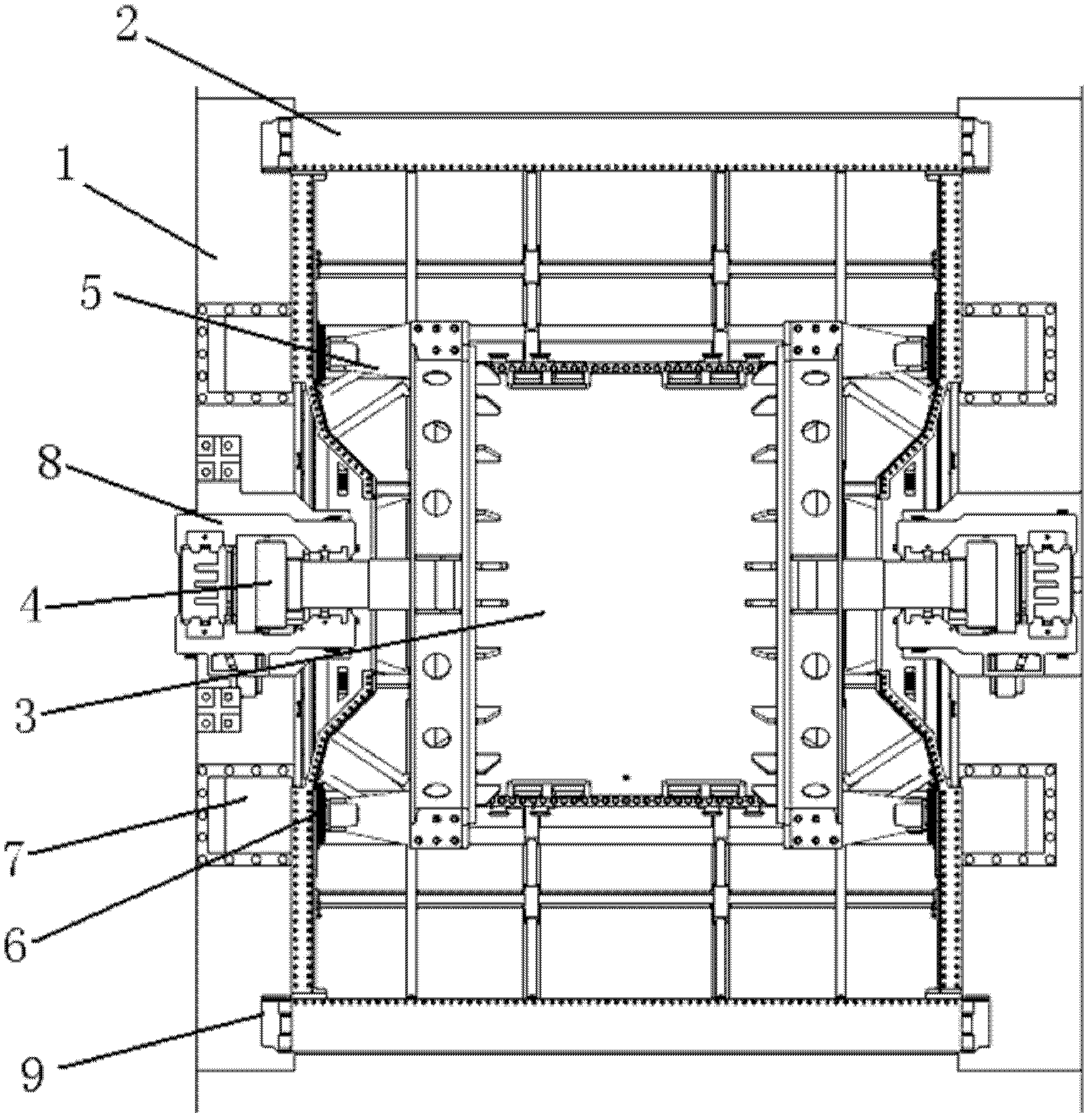

Supporting structure of low-pressure cylinder module of high-power nuclear steam turbine

ActiveCN102322306AReduced Stiffness RequirementsReduce design difficultyMachines/enginesEngine componentsFoot supportsEngineering

The invention discloses a supporting structure of a low-pressure cylinder module of a high-power nuclear steam turbine. The low-pressure cylinder module is positioned on a base platform and comprises an outer cylinder, an inner cylinder and a rotor, wherein the inner cylinder is positioned in the outer cylinder; a low-pressure end part steam seal is arranged on the end part of the rotor; the outer cylinder is supported on the base platform; a plurality of inner cylinder cat foot supports are arranged on the inner cylinder, are extended out of the outer cylinder and are supported on a supporting component of the base platform; and the rotor is supported on the base platform through a rotor bearing support base. Due to the adoption of the supporting structure, the design difficulty of the outer cylinder and the base platform can be reduced, the production cost can be reduced, and the economy and the safety of the turbine are effectively improved.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

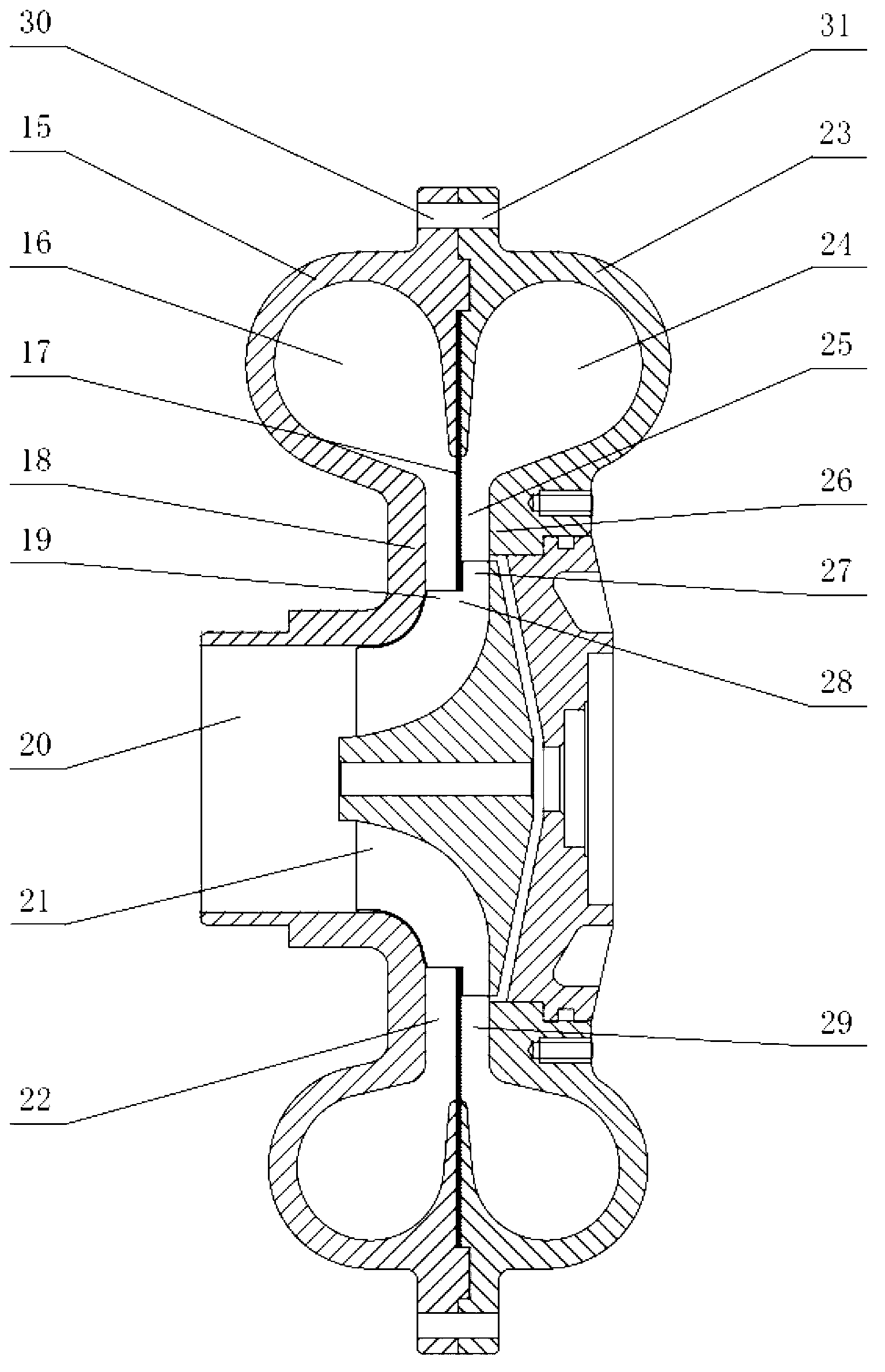

Centrifugal compressor used for generating two different pressure ratios

InactiveCN102840169AImprove balanceReduced bending resistancePump componentsPumpsEngineeringInternal combustion engine

The invention relates to a centrifugal compressor used for generating two different pressure ratios. The centrifugal compressor belongs to the technical field of a supercharging of an internal combustion engine and comprises a front shell of a compressor, a rear shell of the compressor, an annular splitter plate and step-shaped centrifugal compressor impellers. A compressor air inlet and a compressor front air collecting runner volute are arranged on the front shell of the compressor, a compressor back air collecting runner volute is arranged on the rear shell of the compressor; the compressor front air collecting runner volute is connected with the compressor back air collecting runner volute by adopting a bolt, and the annular splitter plate is arranged between the compressor front air collecting runner volute and the compressor back air collecting runner volute; a pressure enlarging passage consisting of the compressor front air collecting runner volute and the compressor back air collecting runner volute is divided into two parts by the annular splitter plate, thereby forming a dual-runner vaneless diffuser; step shaped centrifugal compressor impellers are arranged at the inner parts of the front shell of the compressor and the rear shell of the compressor; the outlets of the impellers are provided with big and small diameters, so that the outlets of the impeller are formed to be in a ladder shape. By using one compressor, two compressed airs with different pressure ratios is generated; the centrifugal compressor is applicable to the condition required to generate the compressed air with two pressure ratios simultaneously.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

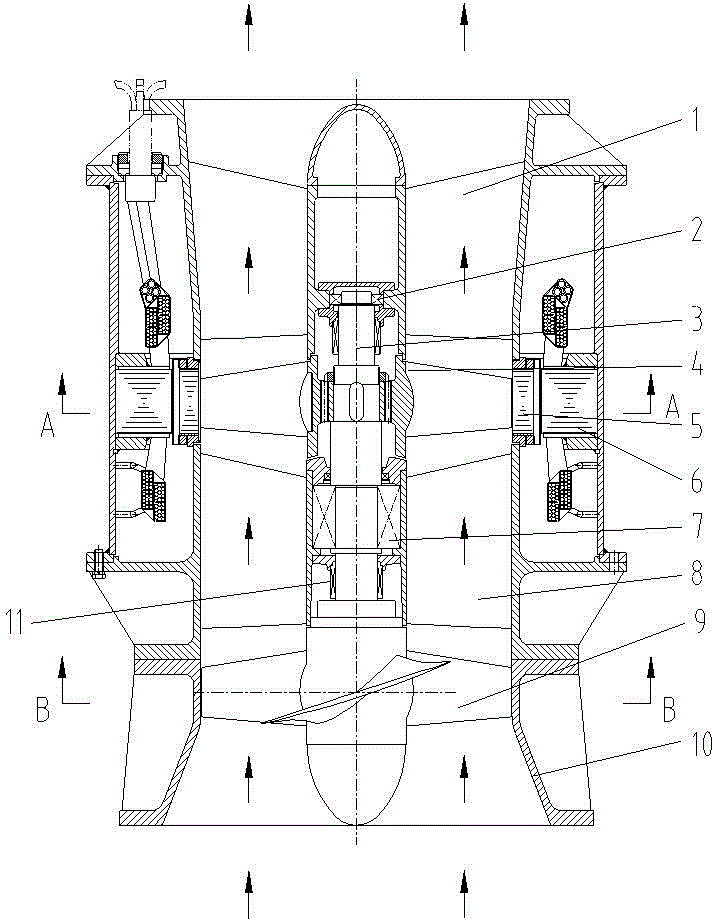

Vane wheel built-in submersible electric pump with stator coil protection sleeve

ActiveCN106351852AShorten the axial lengthCompact structureMagnetic circuit stationary partsMechanical energy handlingImpellerAdverse effect

The invention discloses a vane wheel built-in submersible electric pump with a stator coil protection sleeve. The vane wheel built-in submersible electric pump comprises a vane guide body, an integrated rotor, a protection sleeve positioning seat, a motor stator and a ring-shaped stator shell, wherein two axial ends of the stator shell are correspondingly connected with the periphery of the protection sleeve positioning seat and the periphery of a guide shell; a protection sleeve is mounted on the vane guide body via the protection sleeve positioning seat; the guide shell is mounted on the protection sleeve via a sealing ring; the vane guide body, the guide shell, the sealing ring, the protection sleeve, the stator shell and the protection sleeve positioning seat form a sealed space; the space is filled with clean soft water; a winding coil of the motor stator is a water-resistant winding coil. According to the vane wheel built-in submersible electric pump, a winding is placed in the sealed space filled with the clean soft water; cooling of a stator winding during normal operation of a water filling type submersible motor is facilitated; meanwhile, adverse effects caused by contact between the stator winding of the ordinary vane wheel built-in submersible electric pump and environment water can be avoided; the safe reliability of the winding and even the whole unit is improved.

Owner:HEFEI HENGDAJIANGHAI PUMP IND CO LTD

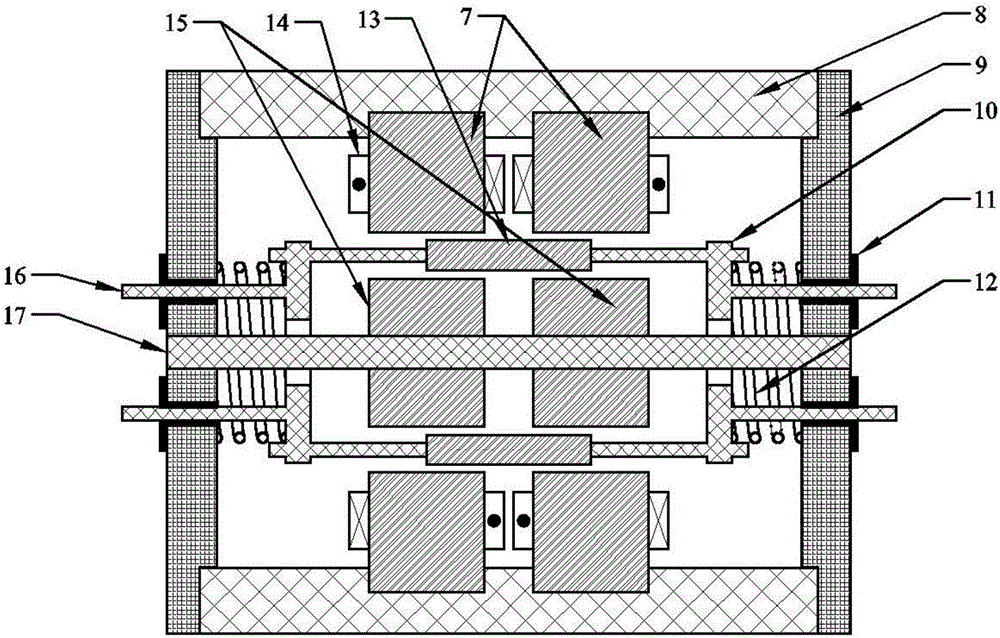

Inner stator permanent-magnet moving iron core-type linear oscillation motor

ActiveCN106849592AImprove reliabilityImprove overload capacityDynamo-electric machinesConductor CoilMagnet

The invention discloses an inner stator permanent-magnet moving iron core-type linear oscillation motor which comprises an inner stator iron core, an outer stator iron core, a rotor iron core, a cage-type rotor iron core bracket, permanent magnets, an armature winding and a resonant spring, wherein multiple permanent magnets are uniformly embedded into a yoke of each annular stator iron core of the inner stator iron core along the peripheral direction; multiple coils for forming the armature winding are wound on outer stator iron core teeth; the rotor iron core comprises multiple segments of arc-shaped iron cores; various segments of arc-shaped iron cores are fixedly connected into a whole by using the cage-type rotor iron core bracket; the whole is arranged in an air gap between the inner stator iron core and the outer stator iron core; and the resonant spring sleeves the part between the cage-type rotor iron core bracket and an end cover. The permanent magnets do not participate in reciprocating vibration, so that the security, the reliability and the robustness of the motor can be greatly improved; the permanent magnets and the armature winding are put on different stators, so that high-temperature magnetic losses of the permanent magnets can be avoided; the mass of a rotor is reduced; the requirements of a system on the rigidity of the resonant spring can be reduced; and improvement of the resonant frequency is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

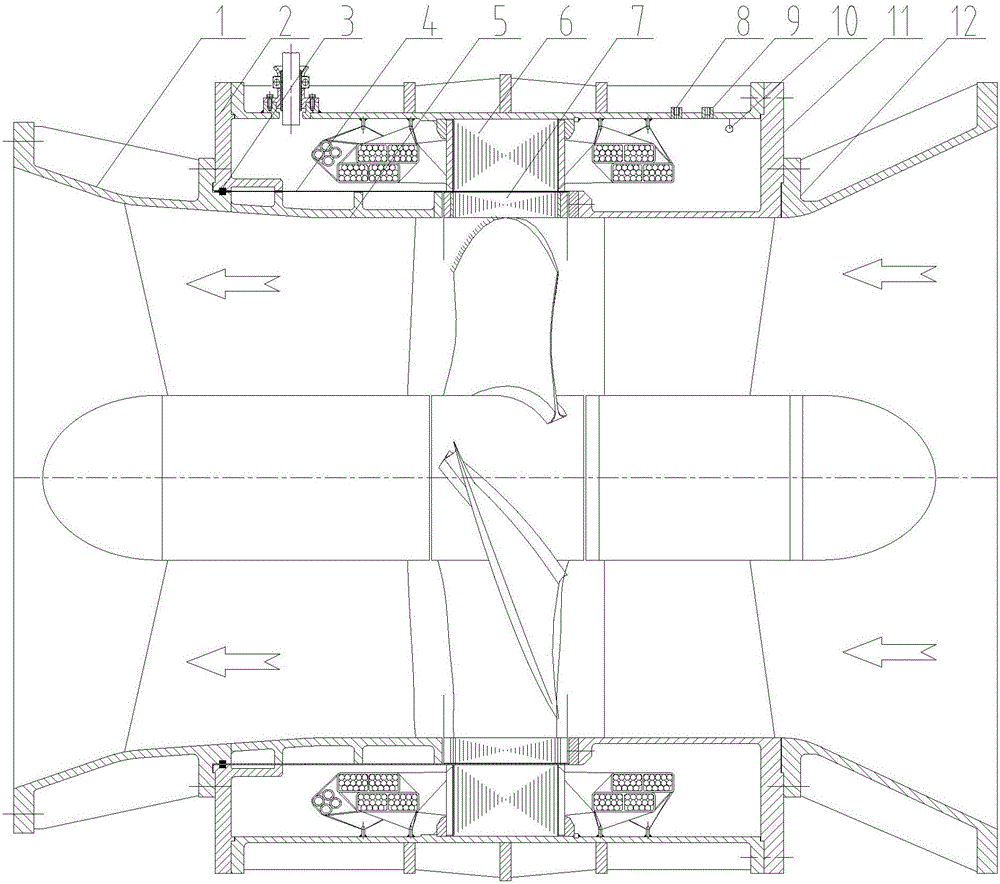

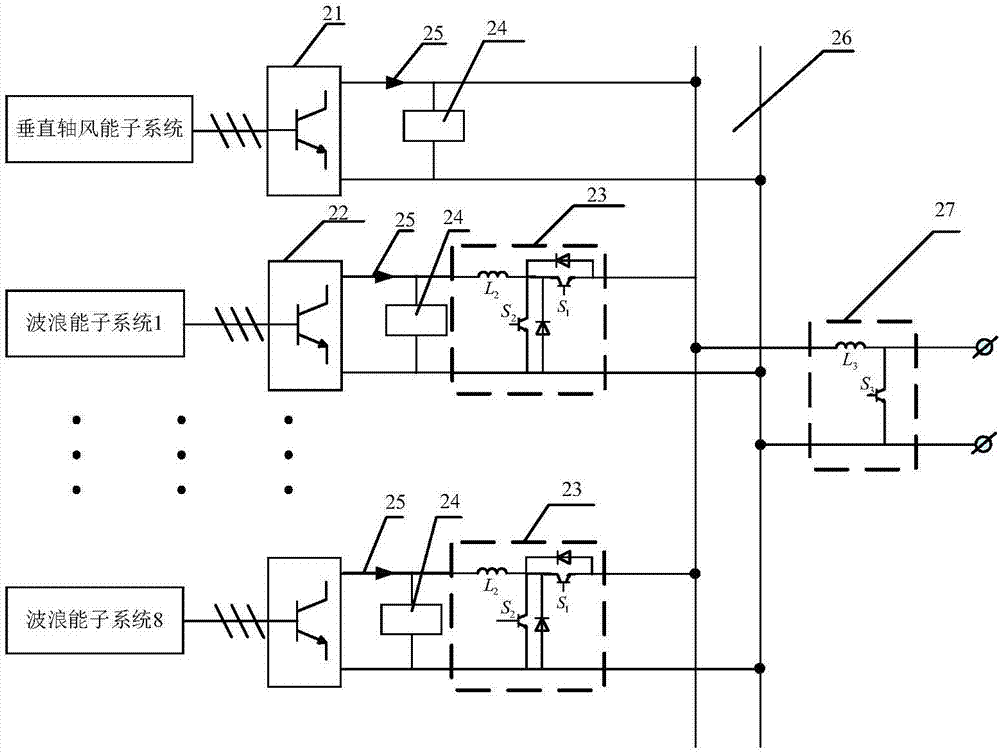

Flexible direct-current transmission wind and wave hybrid power generation system

PendingCN107882686ASmoothing volatilityCalming Intermittent ProblemsWind motor controlWind energy with water energyEngineeringWind power generation

The invention discloses a flexible direct-current transmission wind and wave hybrid power generation system. The flexible direct-current transmission wind and wave hybrid power generation system comprises a mouse cage type tower frame platform, a wind energy subsystem, a wave energy subsystem, a power regulation unit and a flexible direct-current power transmission station; wind power generation and wave energy power generation are combined, the characteristic that dynamic response of the wave energy subsystem is rapid is fully exerted, wind power generation fluctuation power restraining and tower frame platform inclination active regulation can be achieved, the mouse cage type tower frame platform supports the wind and wave hybrid power generation system, a rigid oval floating body passively regulates the inclination angle of a tower frame, the wave energy subsystem is inversely hung on a round platform, power generation and electric modes can be rapidly switched according to the station, and power grid scheduling power and tower frame inclination angle stability can be ensured; the power regulation unit achieves wind and wave maximum power capturing and power dual-way flowing; the flexible direct-current power transmission station finishes converging and feed of wind wave capturing power. Wind and power output power and tower frame inclination angle stability can be improved,the mounting and maintaining cost can be greatly reduced, and development of the wind and wave hybrid power generation system can be promoted.

Owner:QUFU NORMAL UNIV

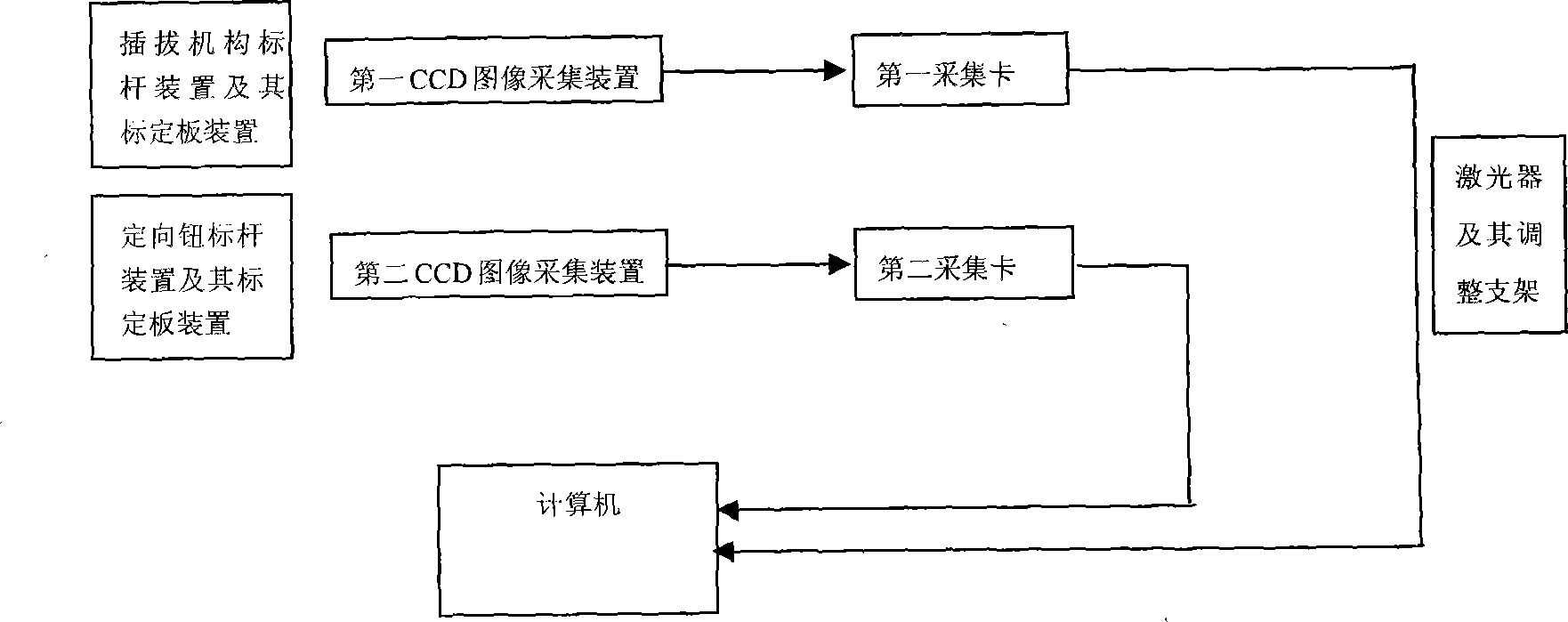

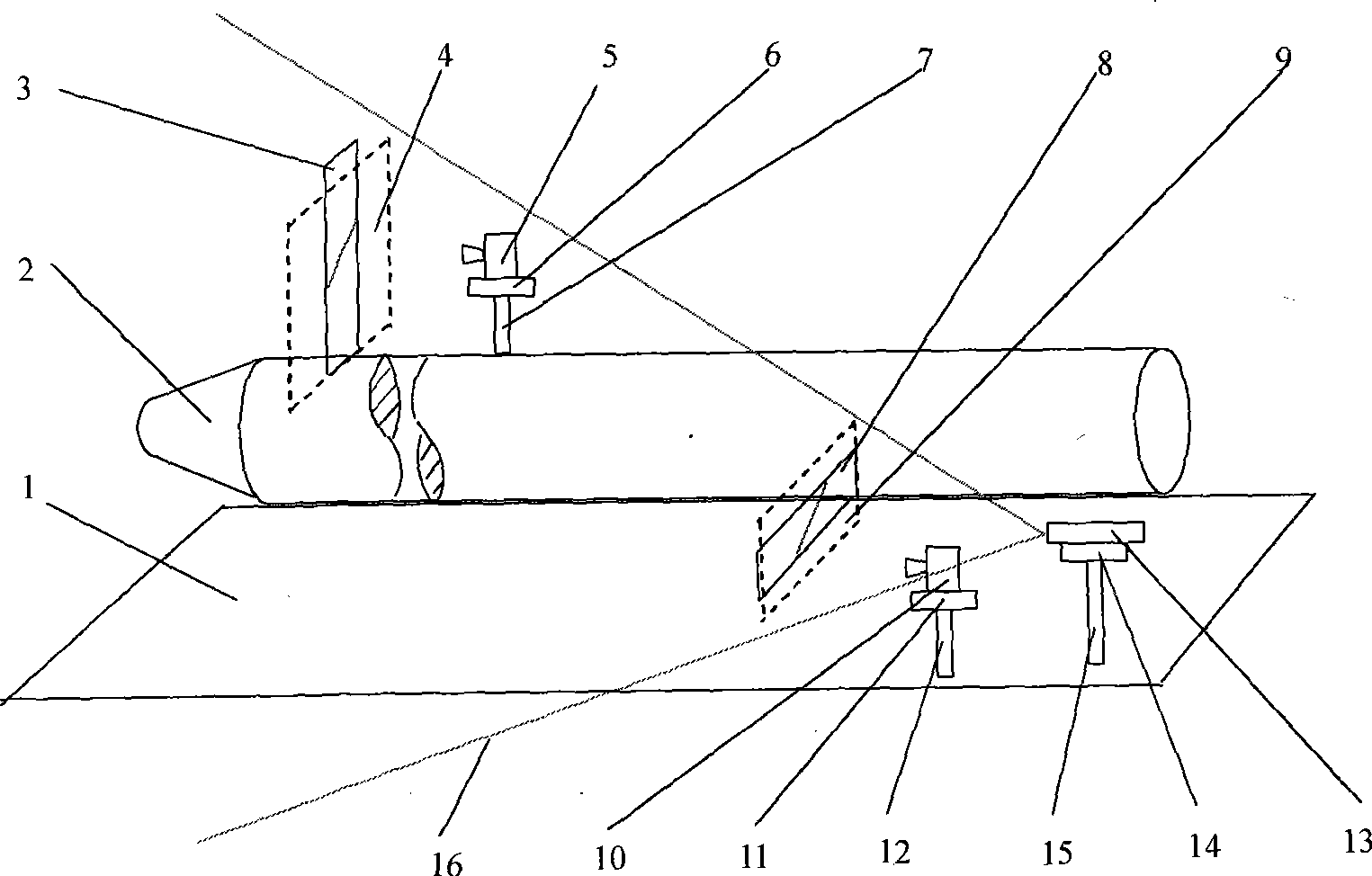

Space bifacial phase angle laser detecting system

InactiveCN101545763AReduced stiffness requirementsGuaranteed lightweightUsing optical meansPush pullRocket

The invention relates to a space bifacial phase angle laser detecting system, which comprises a detection assembly platform, a push-pull mechanism marker post device, an orienting button marker post device, a push-pull mechanism demarcating plate device, an orienting button demarcating plate device, a first CCD image acquisition device, a second CCD image acquisition device, a first acquisition card, a second acquisition card, a laser and an adjusting bracket thereof, and a computer provided with measurement software. The system has the advantages that: (1) the system can quickly and accurately finish the measurement of a 85-degree space bifacial phase angle of a rocket shell; and (2) the measurement result is nearly not influenced by the rigidity of the detection assembly platform of the rocket shell and other factors, the requirement for the integral rigidity of the detection assembly platform can be greatly reduced, and the light weight of the detection assembly platform is ensured.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA +1

Shaft system structure of five-gear rear drive transmission

ActiveCN104214282AIncrease spacingShorten the lengthToothed gearingsGearing controlLow speedEngineering

The invention discloses a shaft system structure of a five-gear rear drive transmission with small gear-shifting synchronous inertia. A spindle reverse gear assembly (4) is mounted on the left side of a spindle front bearing (5), a spindle first-gear gear assembly (6), a low-speed synchronizer component (7), a spindle second-gear gear assembly (8), a spindle third-gear gear (9) and a spindle fourth-gear gear (10) are sequentially mounted on a spindle (12) from left to right and positioned between the spindle front bearing and a spindle rear bearing (11), the low-speed synchronizer component, the spindle third-gear gear and the spindle fourth-gear gear are fixedly connected with the spindle, the spindle first-gear gear assembly and the spindle second-gear gear assembly rotatably sleeves the spindle, and a middle shaft fourth-gear gear assembly (14), a third-gear and fourth-gear synchronizer component (15) and a third-gear gear assembly (16) are sequentially mounted on a middle shaft (17) from right to left and positioned on the left side of a middle shaft rear bearing (13).

Owner:CHONGQING TSINGSHAN IND

Two-stage impeller embedded submersible axial-flow pump

ActiveCN104389796AShorten the axial lengthImprove efficiencyPump componentsPump installationsAxial-flow pumpImpeller

The invention relates to a two-stage impeller embedded submersible axial-flow pump. A water absorption chamber, an impeller mechanism and a water outlet chamber which are coaxially communicated in sequence are formed in a shell of the pump; the impeller mechanism is fixed on a revolving shaft; a stator of a motor is arranged on the inner wall of the shell; a rotor is fixed on the outer circumference of an impeller shell; the impeller mechanism is a two-stage impeller; a first-stage impeller is fixed on the revolving shaft corresponding to the water absorption chamber; the first-stage impeller, the rotor and the two-stage impeller form an integral rotating body. The axial length of the submersible axial-flow pump is shortened greatly, and the structure is compact; on the other hand, the distance between two supporting points of the revolving shaft is short, so that the requirements on the intensity and rigidity of the revolving shaft are lowered; under the coaction of the first-stage impeller and the second-stage impeller, the lift of the submersible axial-flow pump can be over 20 meters, so that the application range of the submersible axial-flow pump is expanded greatly; the motor is placed outside a runner, so that the pumping water current of a submersible electric pump is not influenced, and the efficiency of the submersible electric pump is increased.

Owner:HEFEI HENGDAJIANGHAI PUMP IND CO LTD

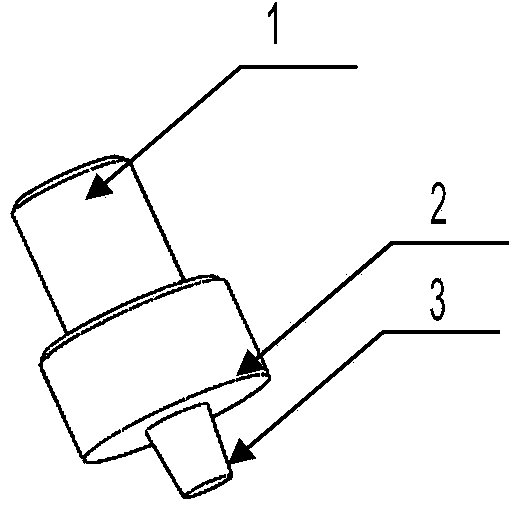

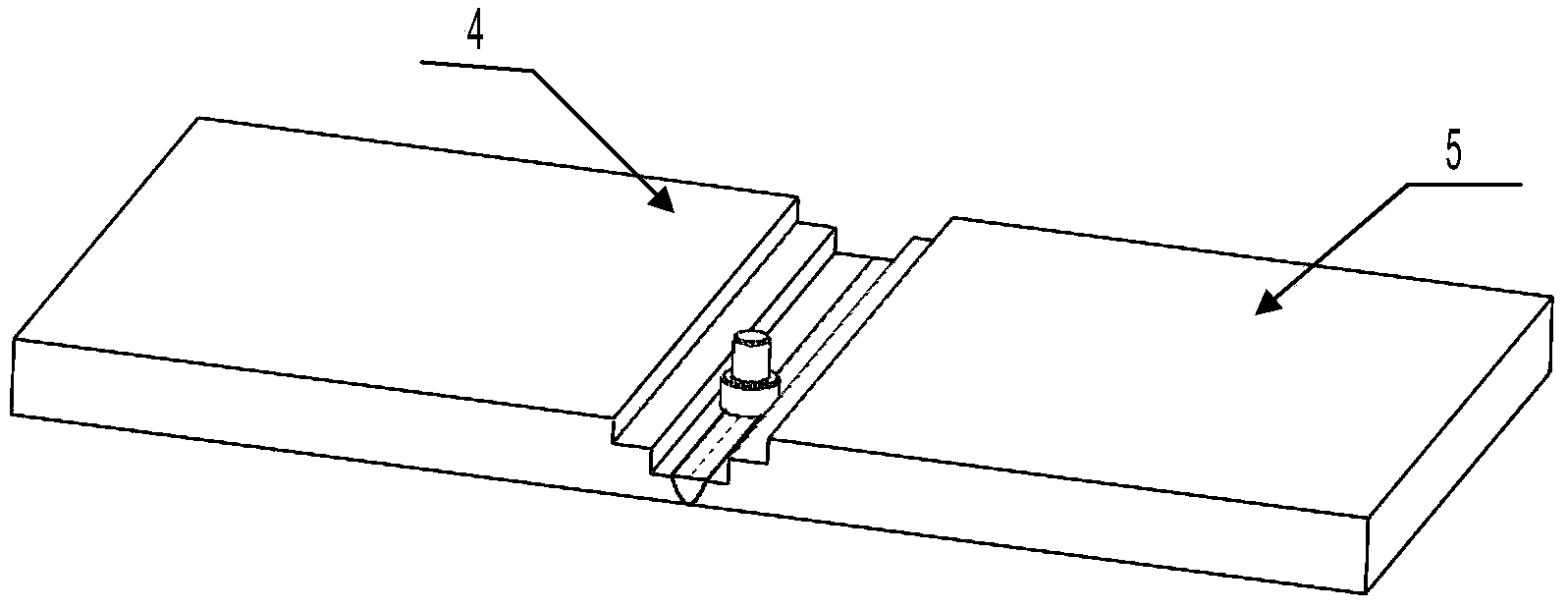

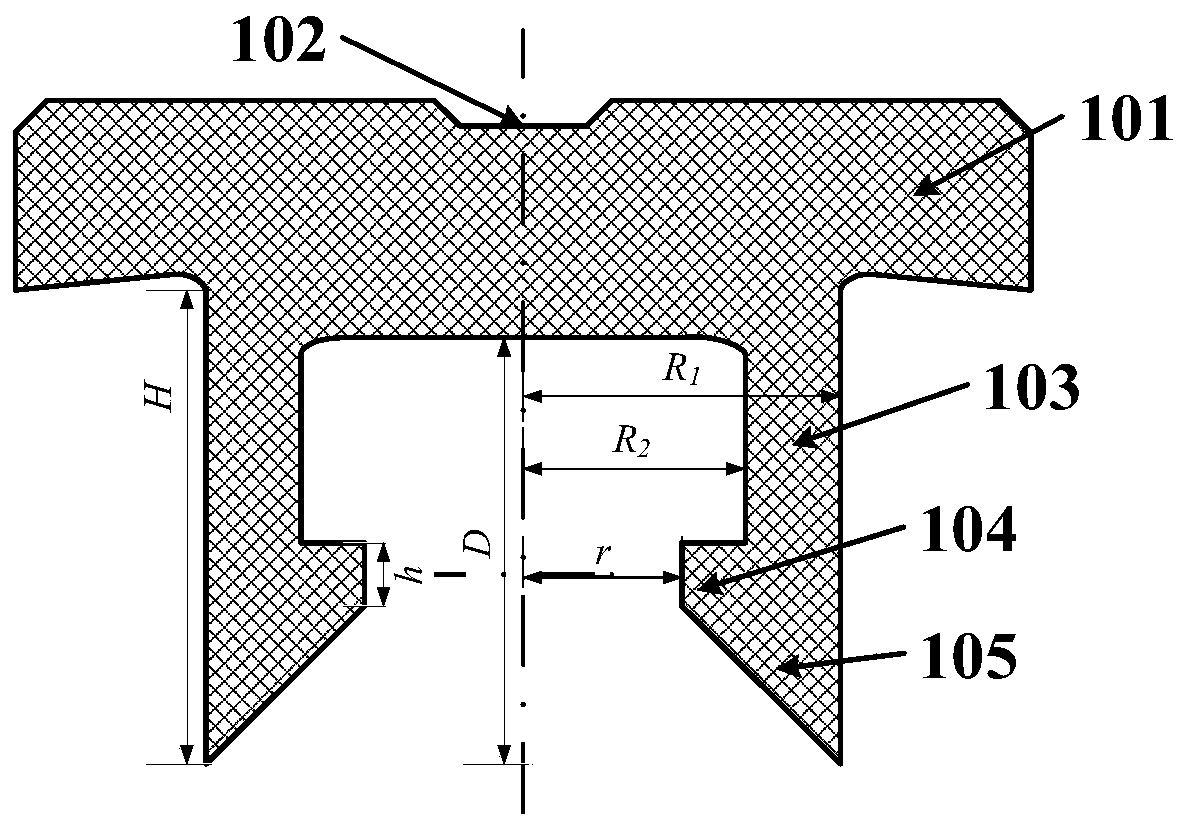

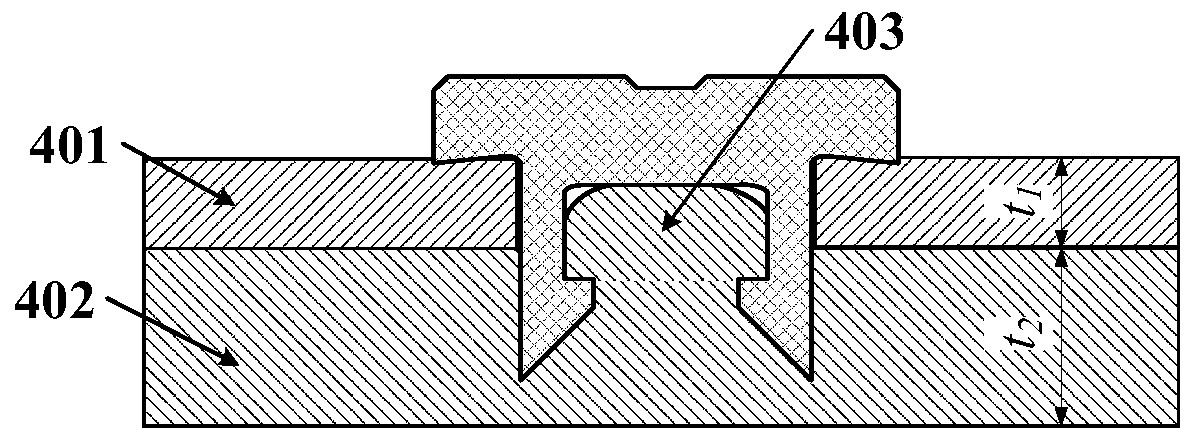

Inner self-locking rivet, and rivet composite connection device and connection method

The invention provides an inner self-locking rivet, a rivet composite connection device and a rivet composite connection method. The inner self-locking rivet comprises a rivet body (103), an inner self-locking boss (104), a rivet body end portion (105) and a rivet body head assembly, wherein a rivet cavity is formed in the rivet body (103), one end of the rivet cavity is connected with the rivet body head assembly, the other end of the rivet cavity is connected with the rivet body end portion (105), the inner self-locking boss (104) is arranged on one side, close to the rivet body end portion(105), of the rivet cavity, the rivet body end portion (105) comprises a wedge-shaped structure matched with the inner self-locking boss (104), and surface structures are arranged on the inner wall and / or the outer wall of the rivet body (103), and each surface structure comprises an arbitrary type or a combination of multiple arbitrary types of a smooth structure, a threaded structure and a grooved structure.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com