Device for testing fracture energy of concrete by three-point bending beam without self-gravity doing work

A technology of three-point bending beams and concrete beams, applied in measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve the problems of large number of specimens, waste of materials and labor, and cumbersome data processing, etc. Achieve the effect of reducing stiffness, simple calculation steps and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

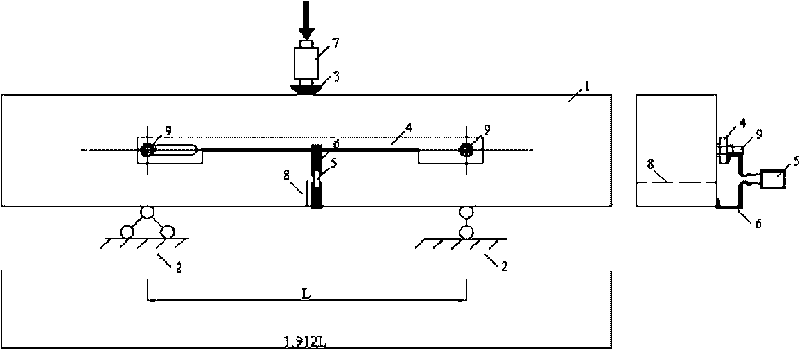

[0011] Concrete beam 1 with a total length of 1.912 times the clear span is poured at one time. The height, width, span, and prefabricated joint length of the beam are determined according to the test method for testing the fracture energy of concrete for three-point bending beams recommended by RILEM. The support 2 is a hinge The support, the force sensor 7 and the force transmission backing plate 3 are placed in the middle of the top span of the concrete beam, and the angle steel connecting rod 4 is fixed at the middle point of the beam above the specimen support with screws 9, between the midpoint of the angle steel connecting rod and the bottom of the beam. A thin steel sheet 6 is pasted at the middle of the span, and the clip-type extensometer 5 is fixed between the two thin steel sheets. Both the sensor 7 and the clip-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com