Novel fully-tubular electric submerged pump with shaft incapable of transferring torque

A technology for torque transmission and submersible electric pumps, which is applied to components, pumps, pump devices, etc. of elastic fluid pumping devices, and can solve problems such as the difficulty of installing gate pumps, affecting the efficiency of water pumps, and easy water ingress in motor chambers. , to achieve the effect of compact structure, good sealing effect, reduced strength and rigidity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

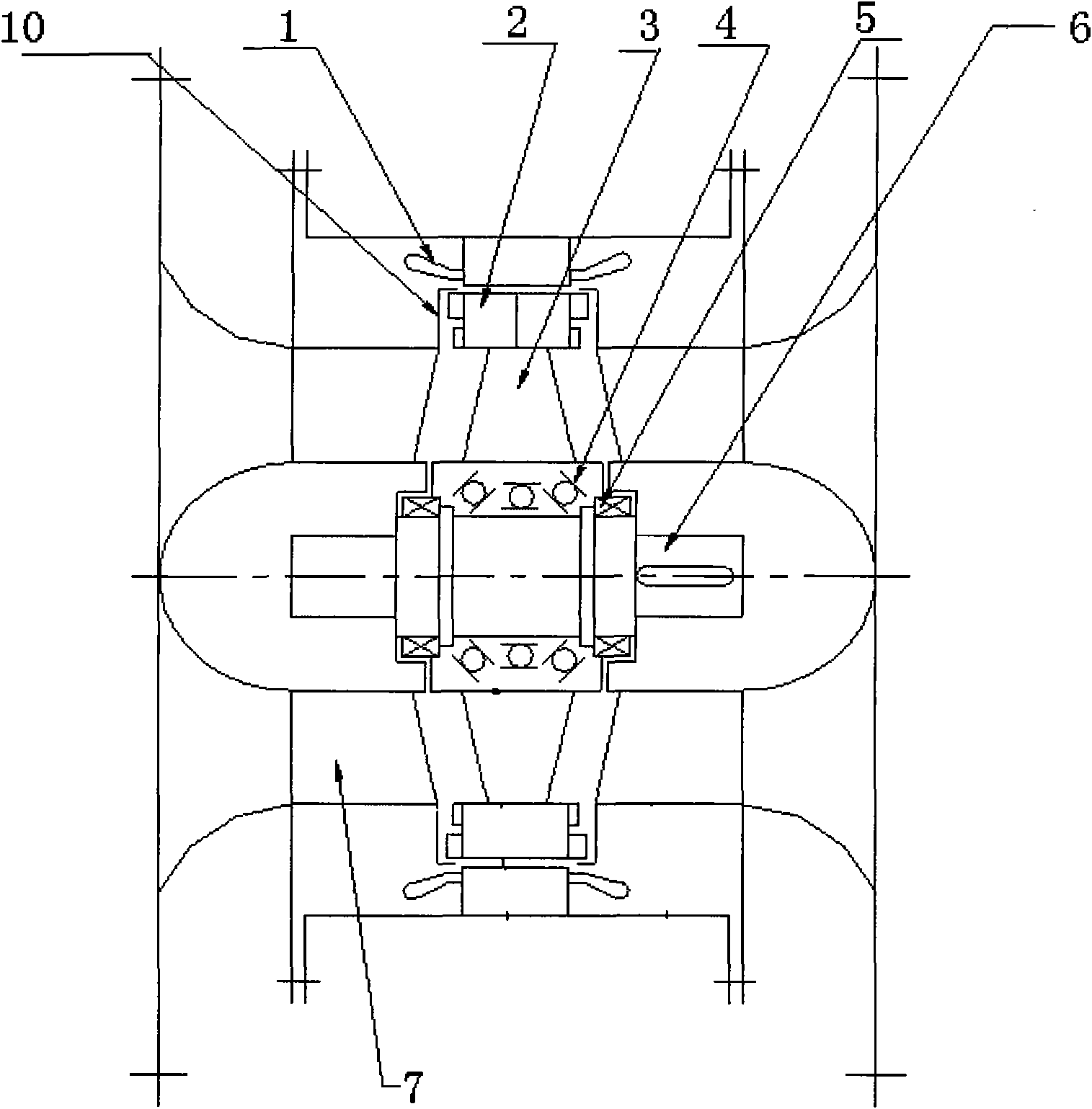

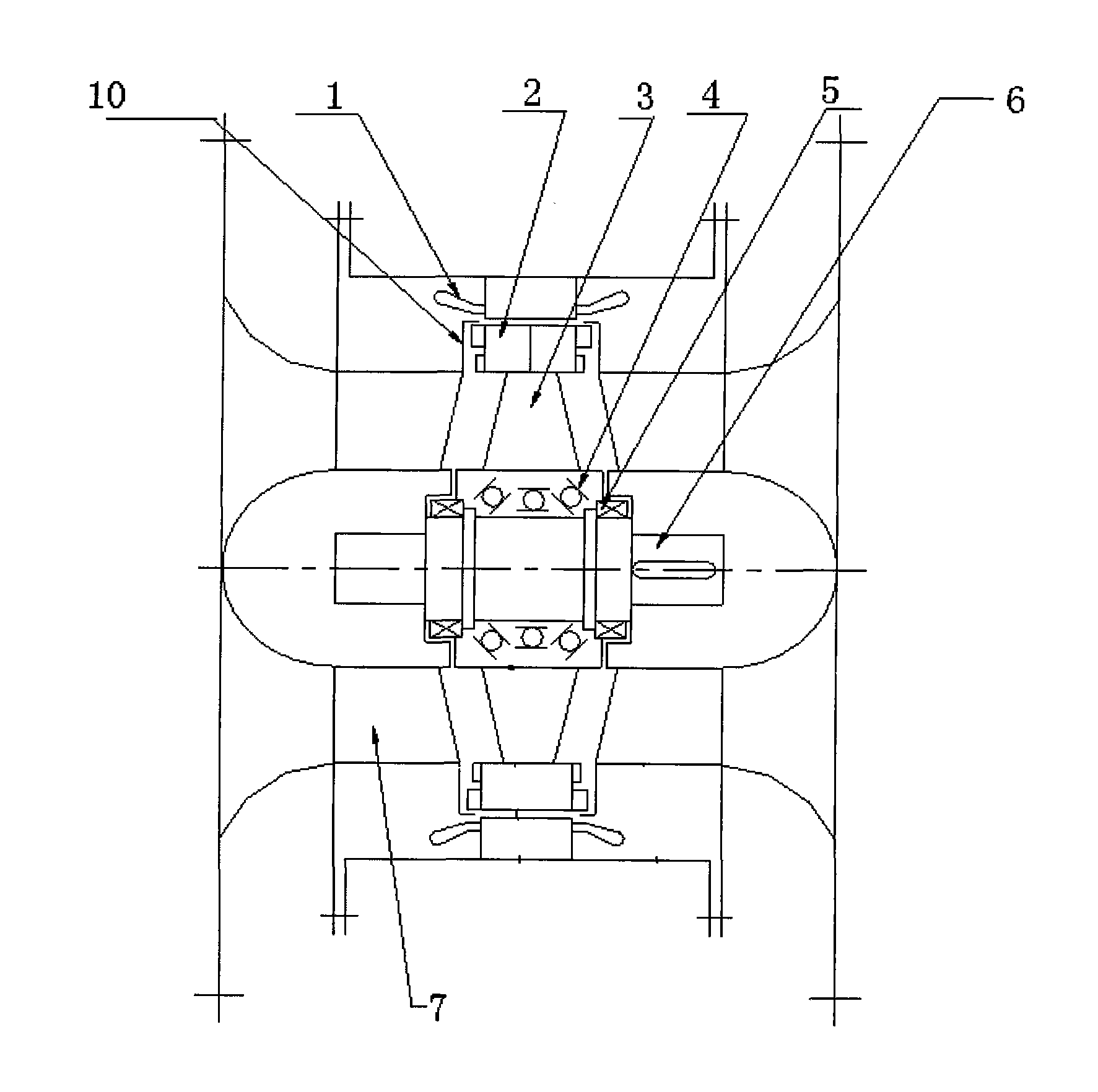

[0010] The structure of the present invention is as figure 1 Shown: a new type of full-through submersible electric pump with no torque transmitted by the shaft, its main components are: the submersible motor adopts a wet stator winding (1) structure, and the impeller (3) of the water pump is placed in the inner cavity of the motor rotor (2) , the blades of the impeller (3) are welded together with the inner circle of the motor rotor (2) formed by stacking silicon steel plates, and the power of the impeller (3) to pump liquid is the rotating magnetic field of the submersible motor to drive the impeller (3) through electromagnetic induction Generated by rotation, the shaft (6) does not transmit torque, and the internal sealed bearing cavity of the motor rotor (2) with the impeller (3) is provided with radial bearings and two-way thrust bearings, and the rotor with the impeller (3) is rotating , the shaft does not rotate, and a dynamic seal structure (5) is used in the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com