Positioning fixture for drum-like part turning

A technology for positioning tooling and parts, applied in the field of mechanical processing tooling, can solve problems affecting the strength of support rods, etc., and achieve the effects of improving production efficiency, convenient use, and quick and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

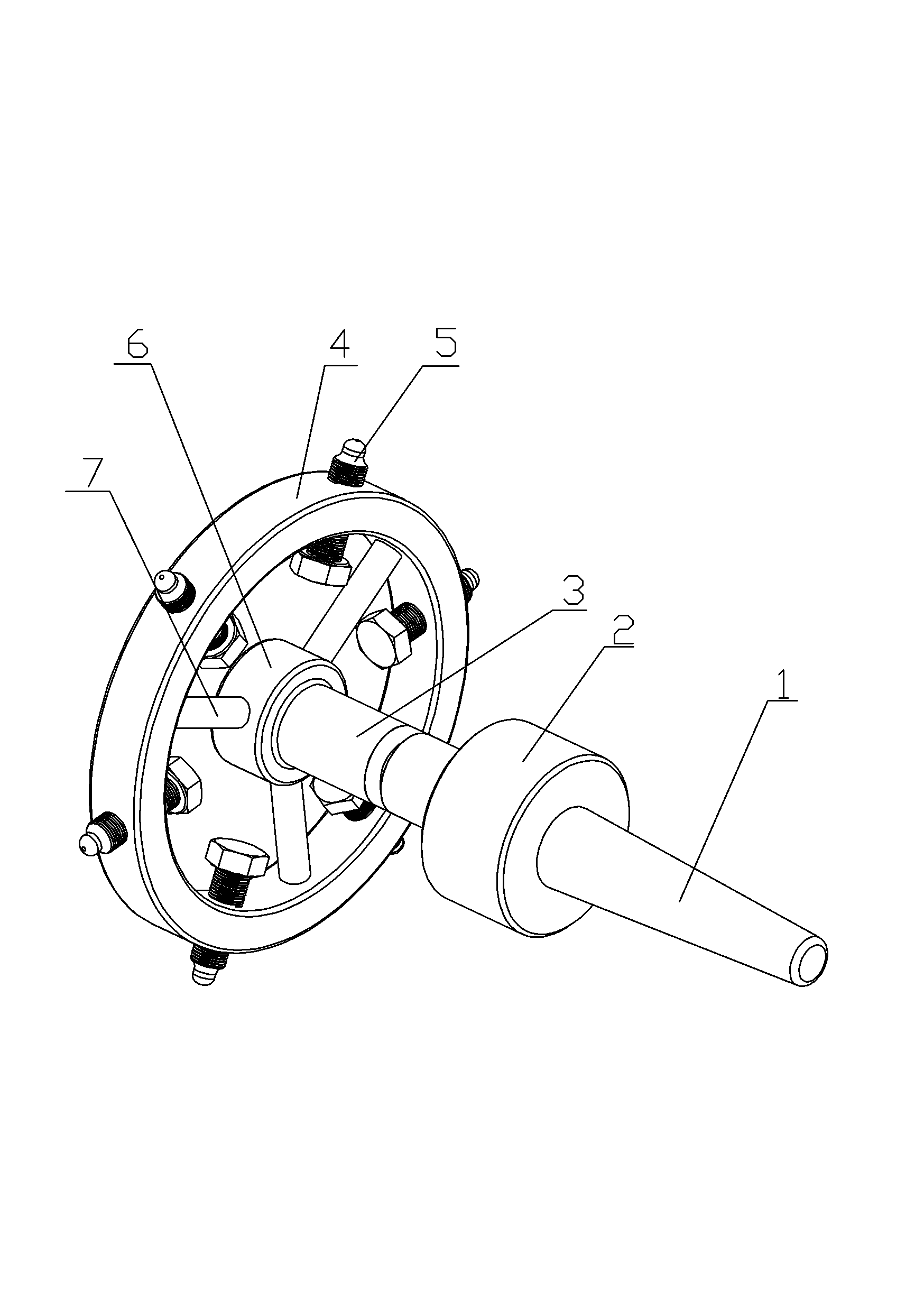

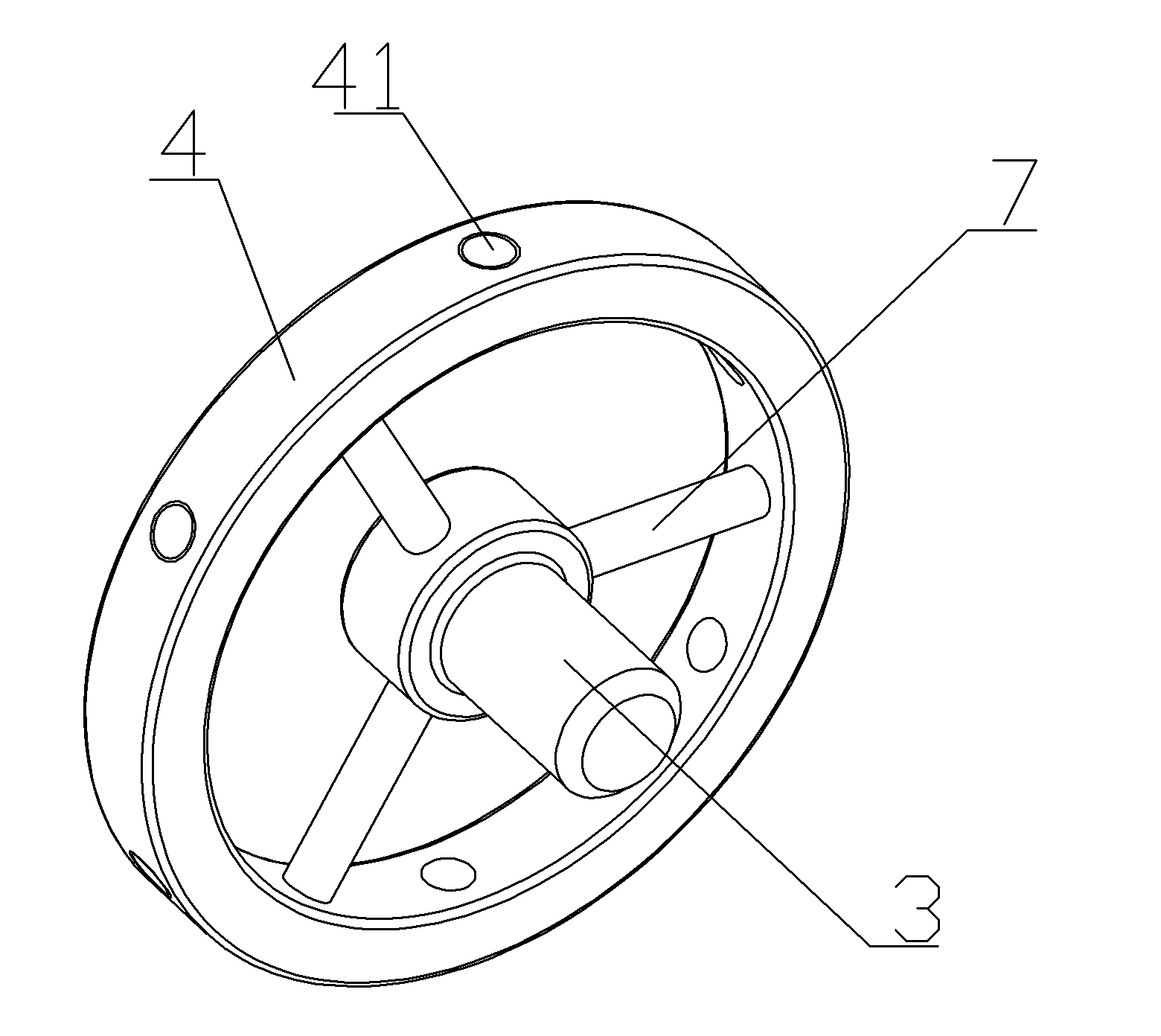

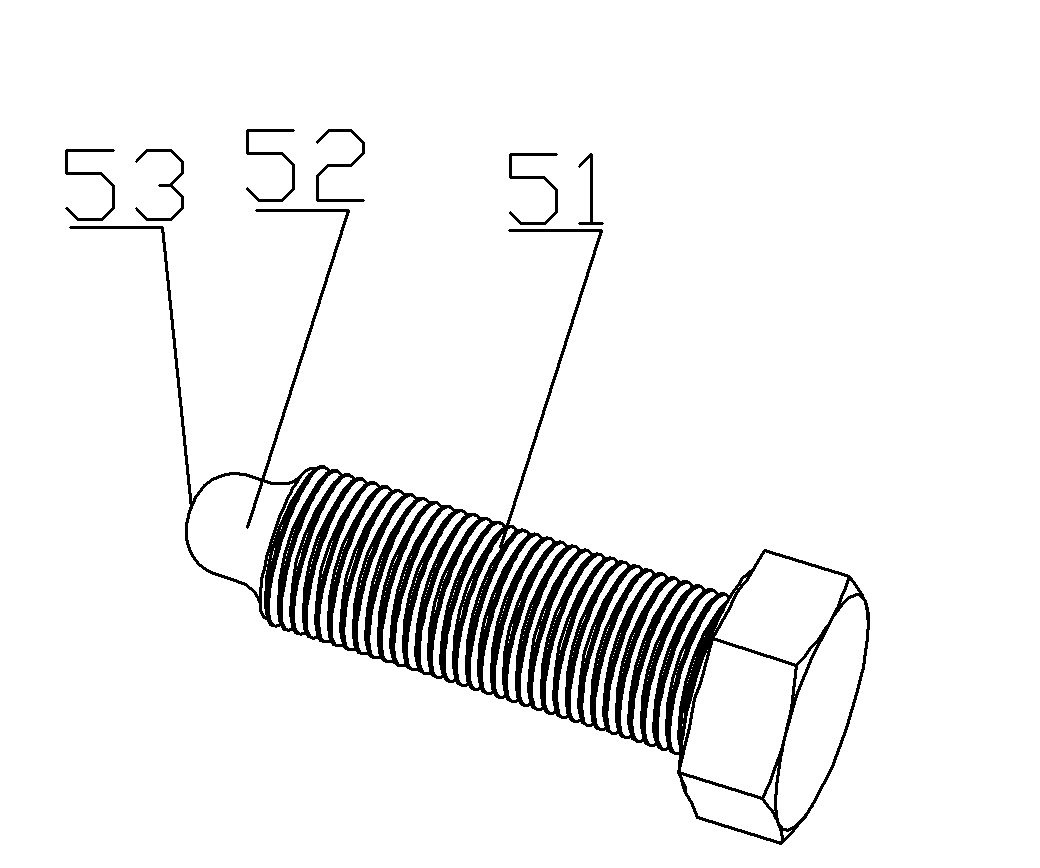

[0014] Such as figure 1 , figure 2 , image 3 As shown, an embodiment of a positioning tool for turning processing of cylindrical parts, the positioning tool in this embodiment includes a rotating support seat 2 as a rotating pair assembled on the tailstock of a lathe during use, and the rear of the rotating support seat 2 The end is provided with a Morse taper handle 1 that is assembled on the tailstock of the lathe and extends backward along the rotation center axis of the rotating support 2 as a rotating pair when used. The front end of the rotating support 2 is coaxially fixed with a rotating support seat. The support rod 3 extending forward from the central axis of rotation of the support rod 3 is provided with a support device inserted into the inner hole of the cylindrical part during use at the front end of the support rod 3, and the support device includes a coaxially wound around the support rod 3 outside The support wheel 4, the support wheel 4 and the support rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com