Evaporative cooling system of hybrid motor stator

A motor stator, evaporative cooling technology, applied in the magnetic circuit shape/style/structure, magnetic circuit static parts, winding conductor shape/style/structure, etc., can solve the waste of evaporative cooling medium, increase the motor air gap, Cost control and other issues, to achieve the effect of reducing sealing performance and process difficulty requirements, reducing rigidity requirements, and reducing radial thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

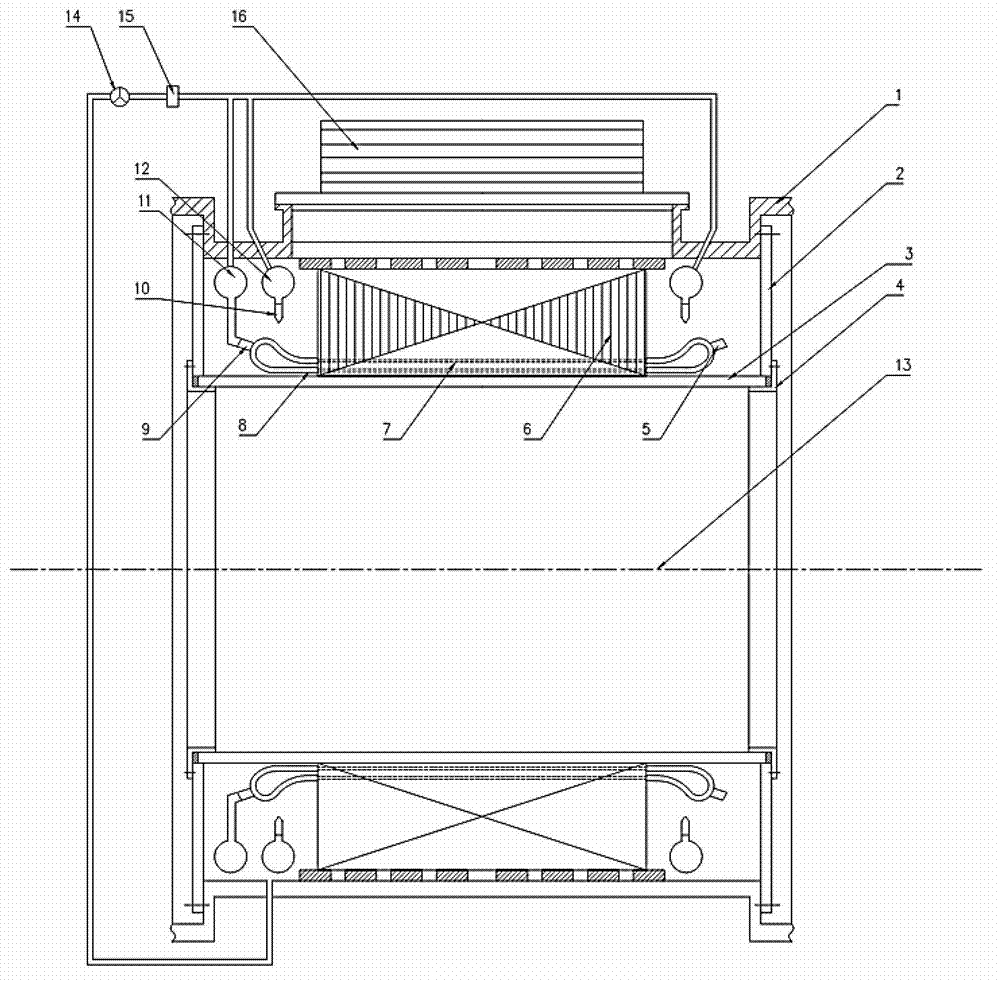

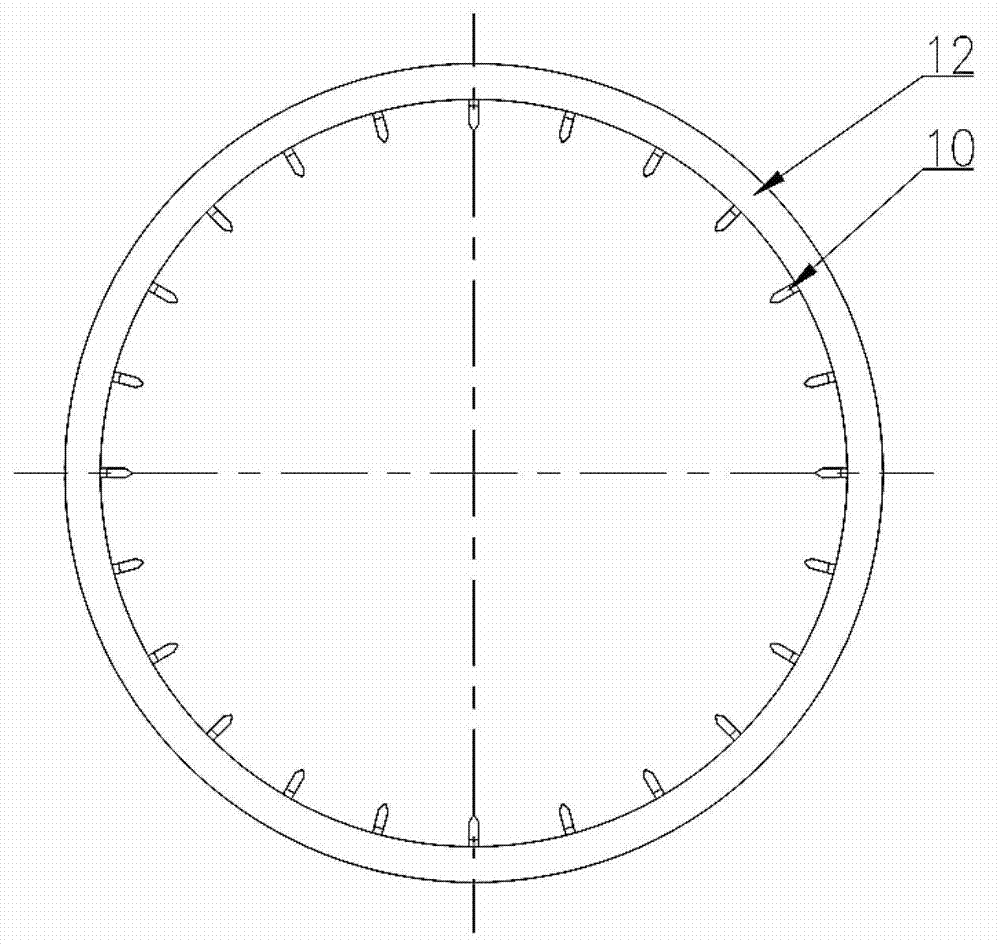

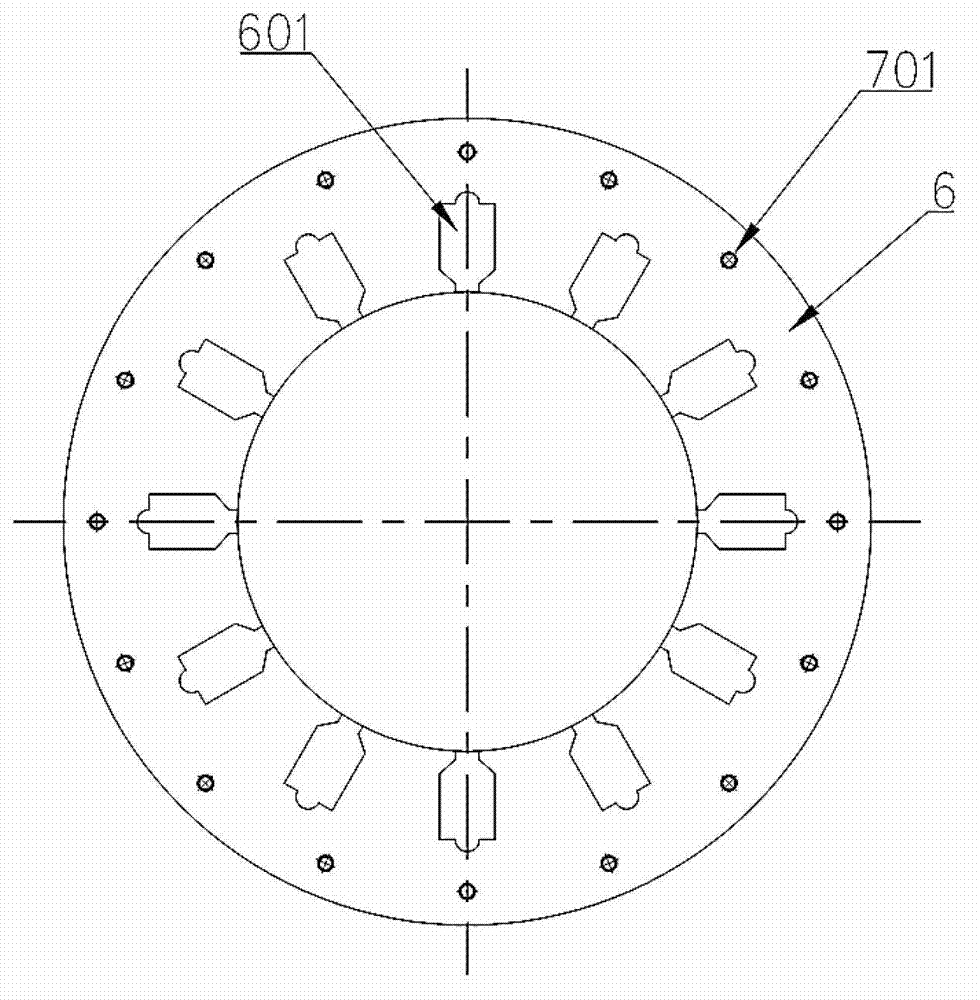

[0024] The structure composition of the hybrid motor stator evaporative cooling system of the present invention is as follows: figure 1shown. Install the non-magnetic isolation sleeve 3 at the inner circle of the stator core 6 of the motor, the end sealing end cover 2 is installed at both ends of the stator casing 1 and the non-magnetic isolation sleeve 3, and the pressure stop ring 4 is installed with the end sealing end cover 2 Outside. A condenser 16 is installed on the top of the stator casing. The forced circulation system of the evaporative cooling system is set outside the stator casing, including circulation pump 14 and filter 15 and other components. The road is connected to the filter 15, and the rear end of the filter 15 is connected to the liquid distributors 11 and 12 through the pipeline. The circulation pump 14 draws the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com