Supporting structure of low-pressure cylinder module of high-power nuclear steam turbine

A support structure and low-pressure cylinder technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems affecting the dynamic and static clearance between the inner cylinder and rotor, the difficulty of outer cylinder strength design, and the difficulty of low-pressure outer cylinder strength design. Achieve the effect of reducing design difficulty, reducing material volume and weight, and reducing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

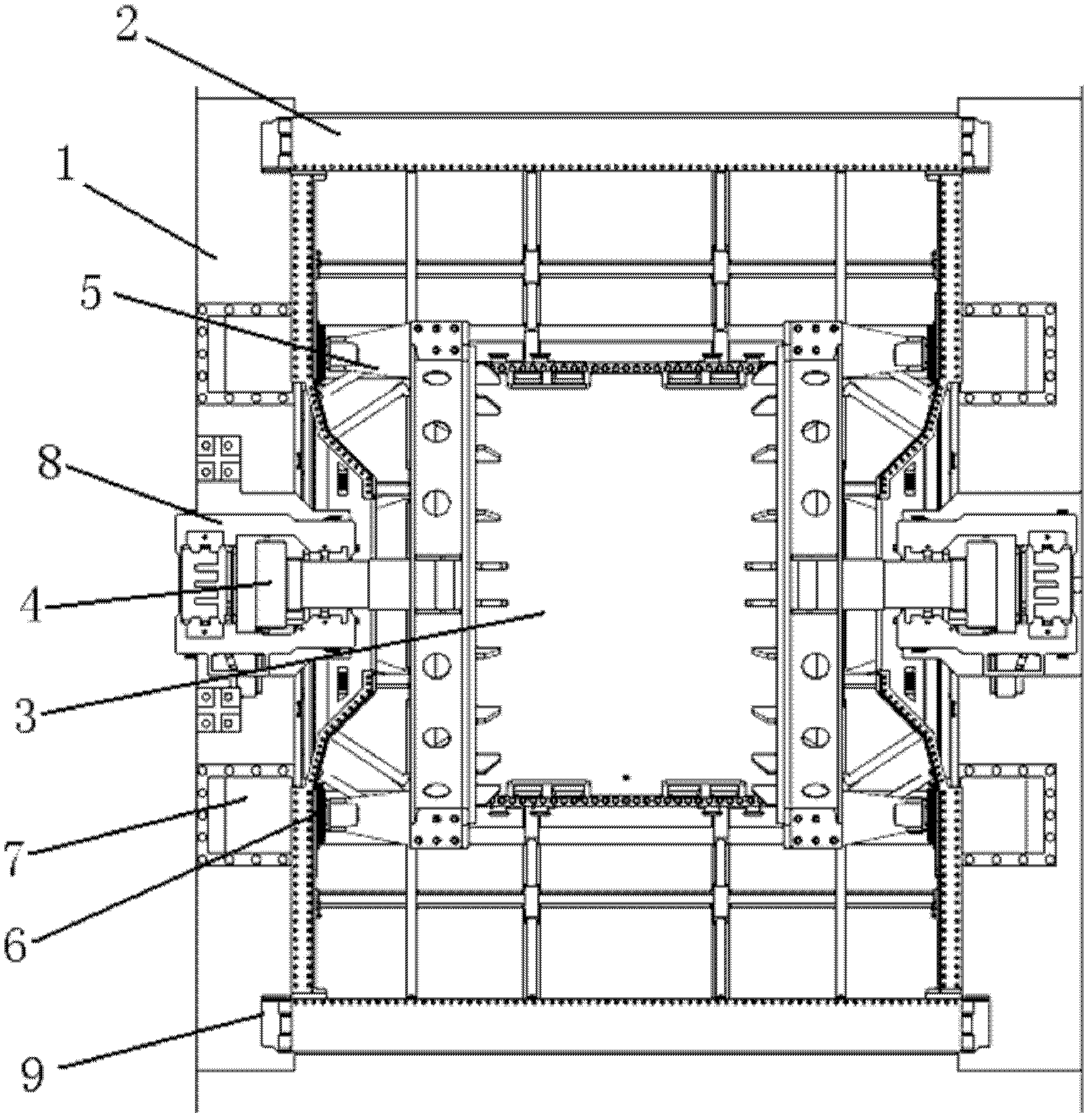

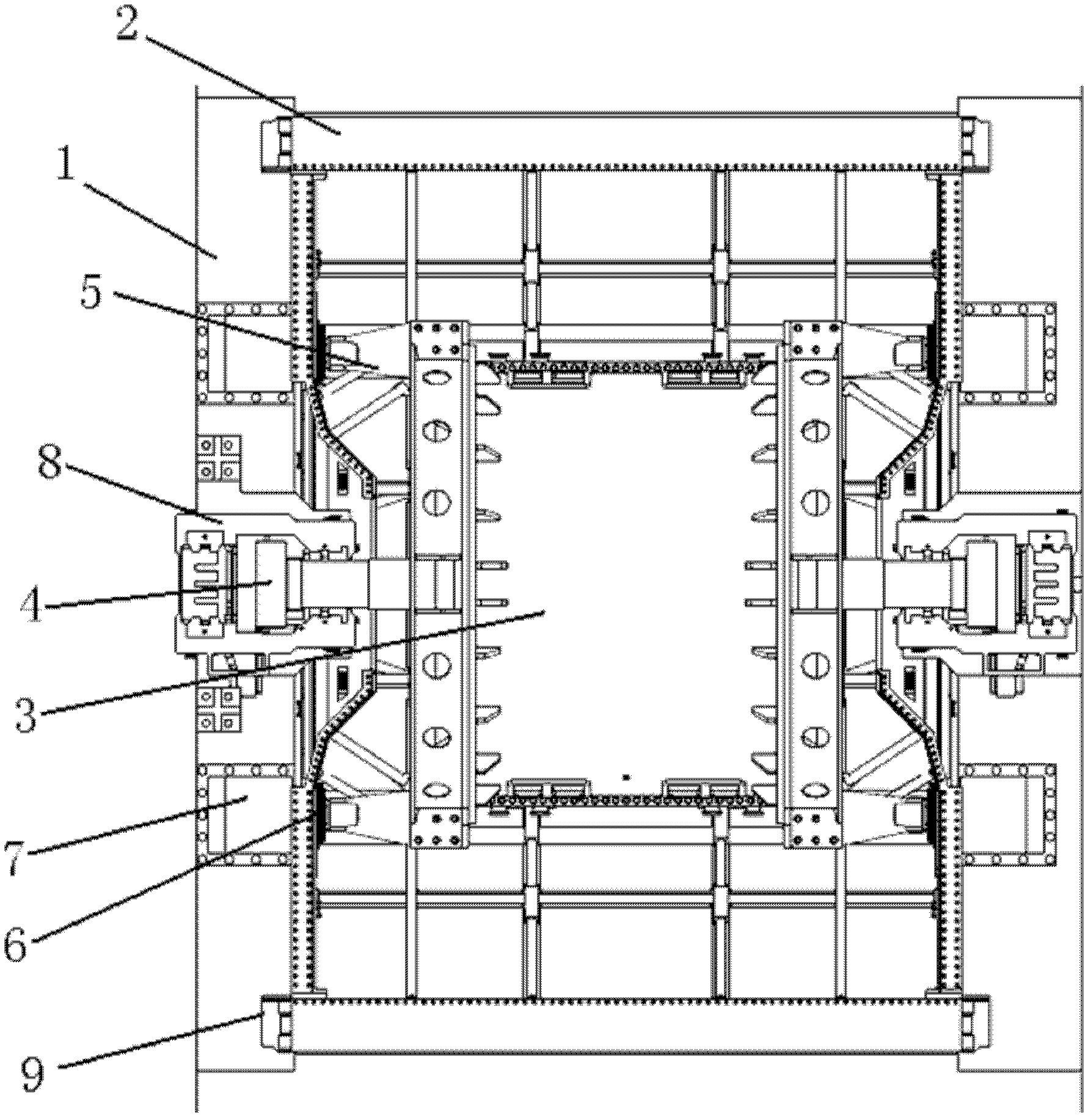

[0016] Such as figure 1 As shown, the low-pressure cylinder module of the supporting structure of the high-power nuclear power steam turbine low-pressure cylinder module is located on the base platform 1, and the low-pressure cylinder module includes an outer cylinder 2, an inner cylinder 3 and a rotor 4. The four corners of the outer cylinder 2 are respectively provided with an outer cylinder cat foot support 9, and the outer cylinder 2 is supported on the foundation platform 1 through the outer cylinder cat foot support 9. The four outer cylinder cat foot supports 9 are supported on the embedded parts fixed together with the foundation platform 1, the embedded parts are fixed on the foundation platform 1, and the adjusting gaskets are set between the embedded parts and the outer cylinder cat foot supports 9 To adjust the elevation and leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com