High-intensity aluminum alloy thick-plate low-heat input stirring friction welding method

A friction stir welding, aluminum alloy technology, applied in welding equipment, metal processing, welding equipment, etc., can solve the problems of softening zone and welding structure deformation, insignificant cooling effect, grain growth in weld zone, etc., to achieve welding Small residual stress and deformation, reducing welding residual stress and deformation, and reducing the total heat input of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

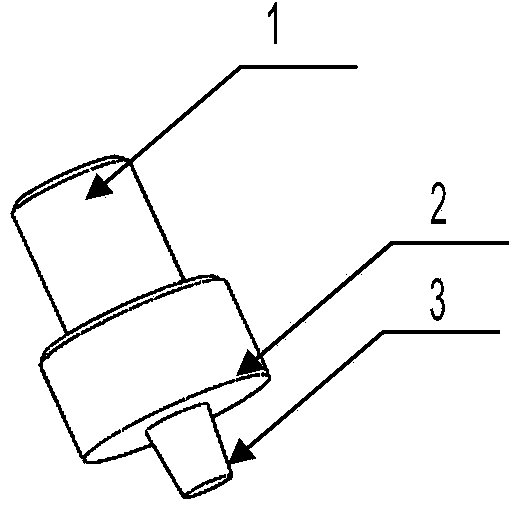

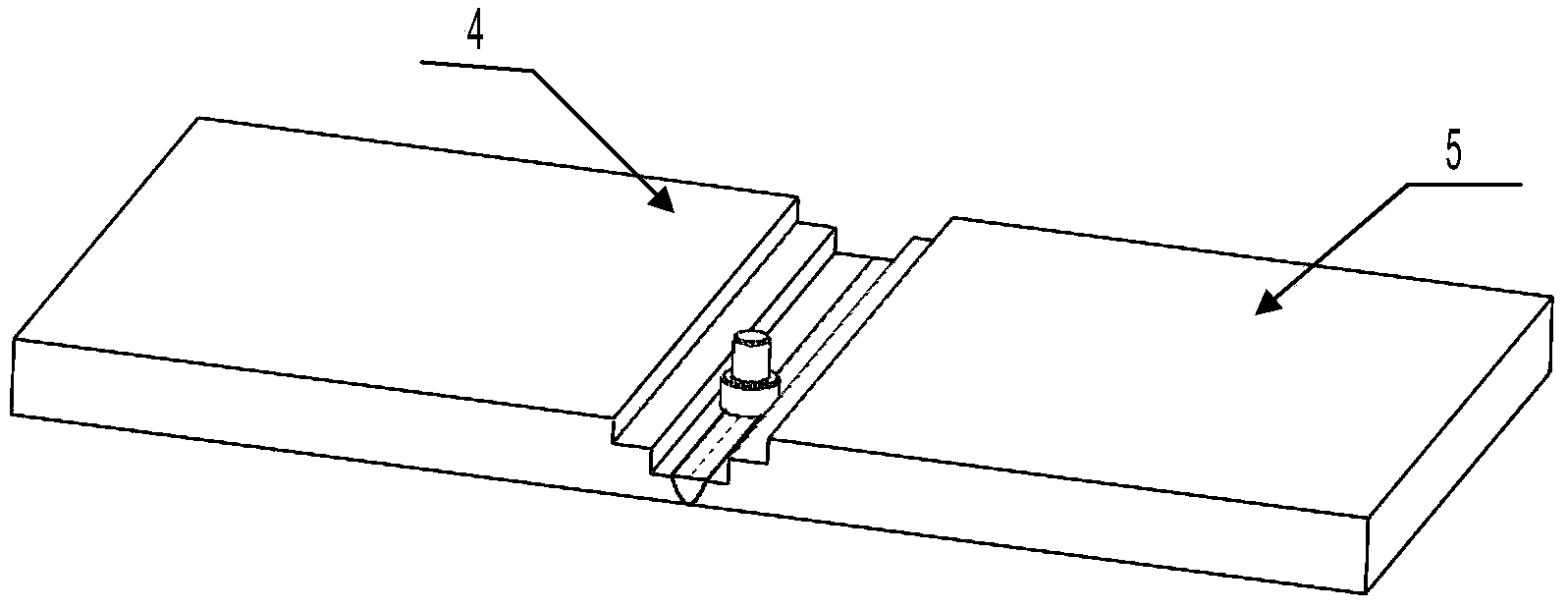

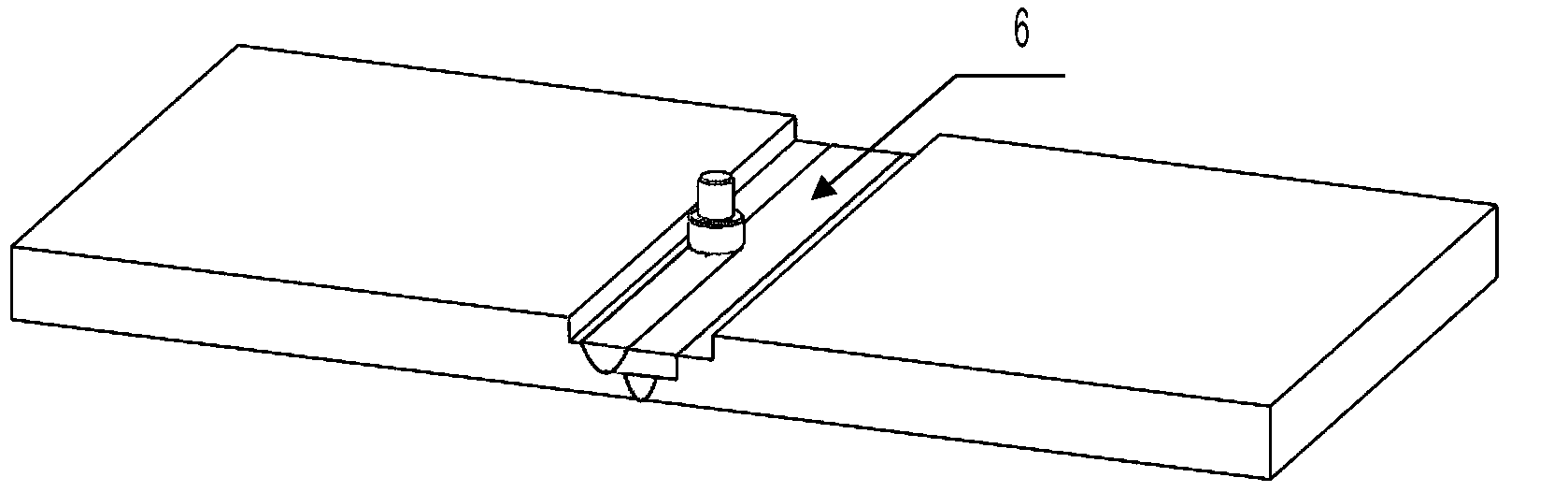

[0024] The stirring head 1 that the inventive method adopts, as figure 1 As shown, there is a shaft shoulder 2 and a stirring needle 3 on it. Machining the edge side of the thick plate to be welded to form a two-stage step shape with a specified size, the height of each step is 2mm, and the width is equal to the radius of the shoulder of the stirring head; the processed sides of the two plates to be welded are horizontally oppositely assembled And fixed on the working platform of the welding equipment, the trapezoidal edge at the bottom of the plate is close to form an upward "V"-shaped notch shape, such as figure 2 shown. Slowly insert a stirring needle with a rotating speed of 1500 rpm into the butt joint of workpieces 4 and 5. At this time, the length of the stirring needle is less than 0.1mm of the thickness of the bottom plate. After the shoulder and the surface of the workpiece are in contact and stay for 5 seconds, stir The head or workpiece moves along the welding d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com