Installation process of upper module on offshore oil platform

A technology of offshore oil and installation technology, which is applied in the field of offshore oil engineering, can solve problems such as occupying a large space, greatly affecting safety, and shortage of floating crane resources, and achieves the effect of strong automation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

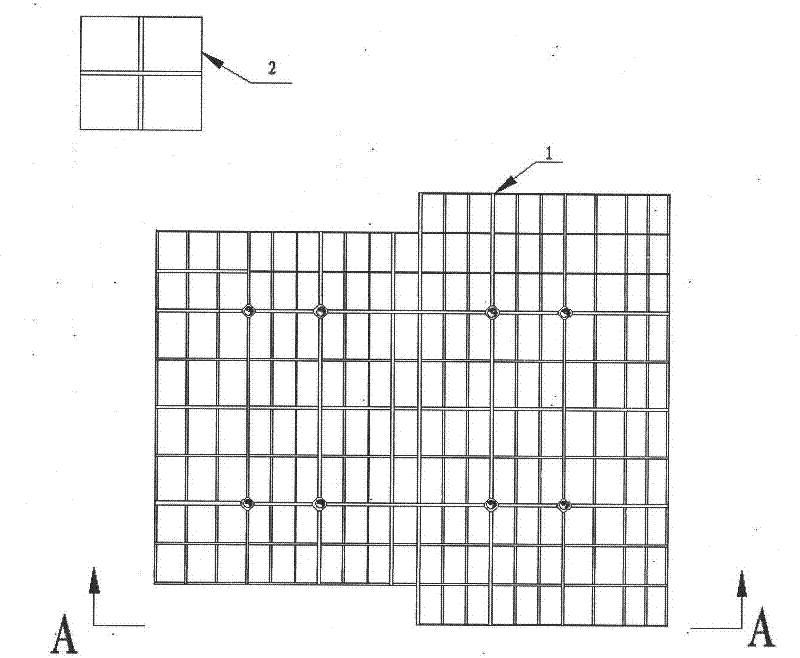

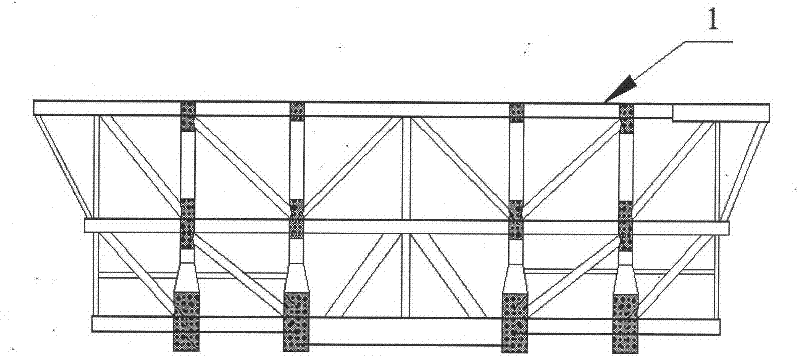

[0053] Such as figure 1 , figure 2 As shown, after the topside module 2 of the offshore oil platform is constructed in a different place, it will be transported to the construction site of the offshore oil platform 1 . Can adopt self-propelled hydraulic module car 12 to finish its loading and unloading operation as required.

[0054] The present invention is realized through the following steps:

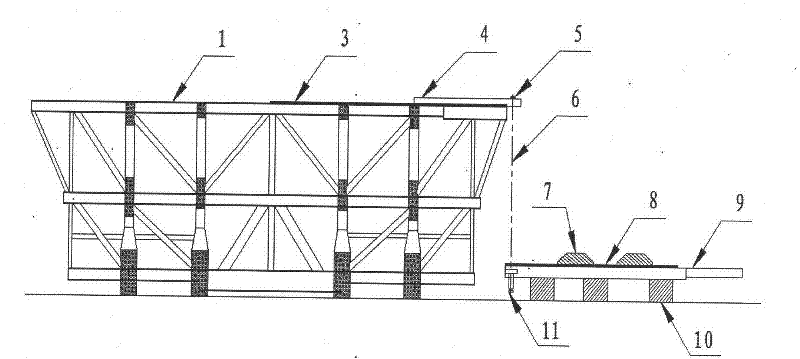

[0055] The first step: the layout of the sliding track device

[0056] Such as figure 1 , figure 2 , image 3 , Figure 9 , Figure 10 , Figure 11As shown, when the upper module 2 needs to be installed during the construction process of the offshore oil platform 1, a sliding track device is arranged in the lifting operation area of the offshore oil platform 1. The sliding track device includes: several sliding rails fixed on the offshore oil platform 1 Moving track 3, several upper support cantilever beams 4 connected with the main body of offshore oil platform 1, sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com