Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Reduce uneven thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

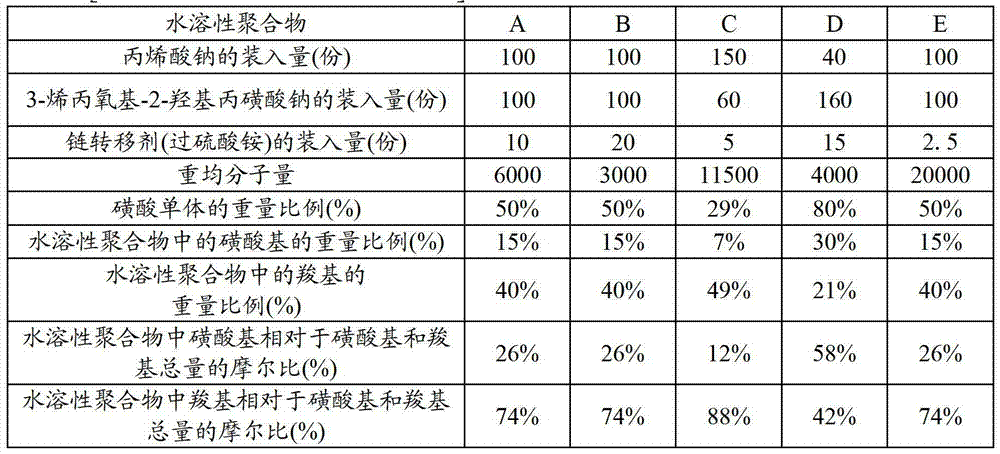

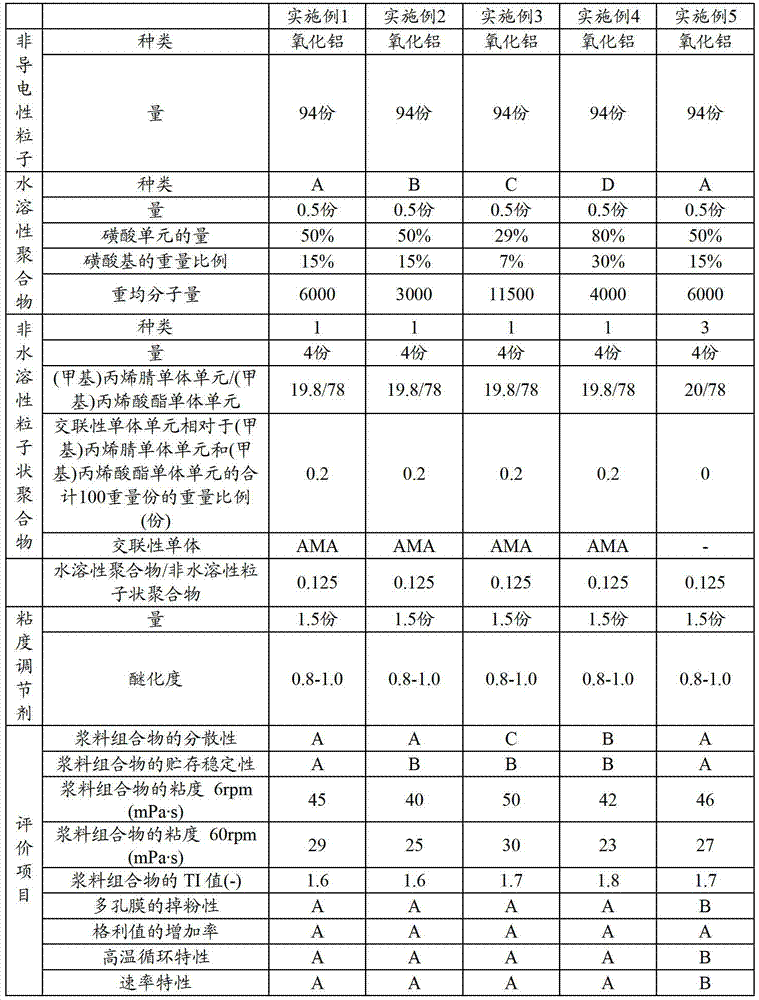

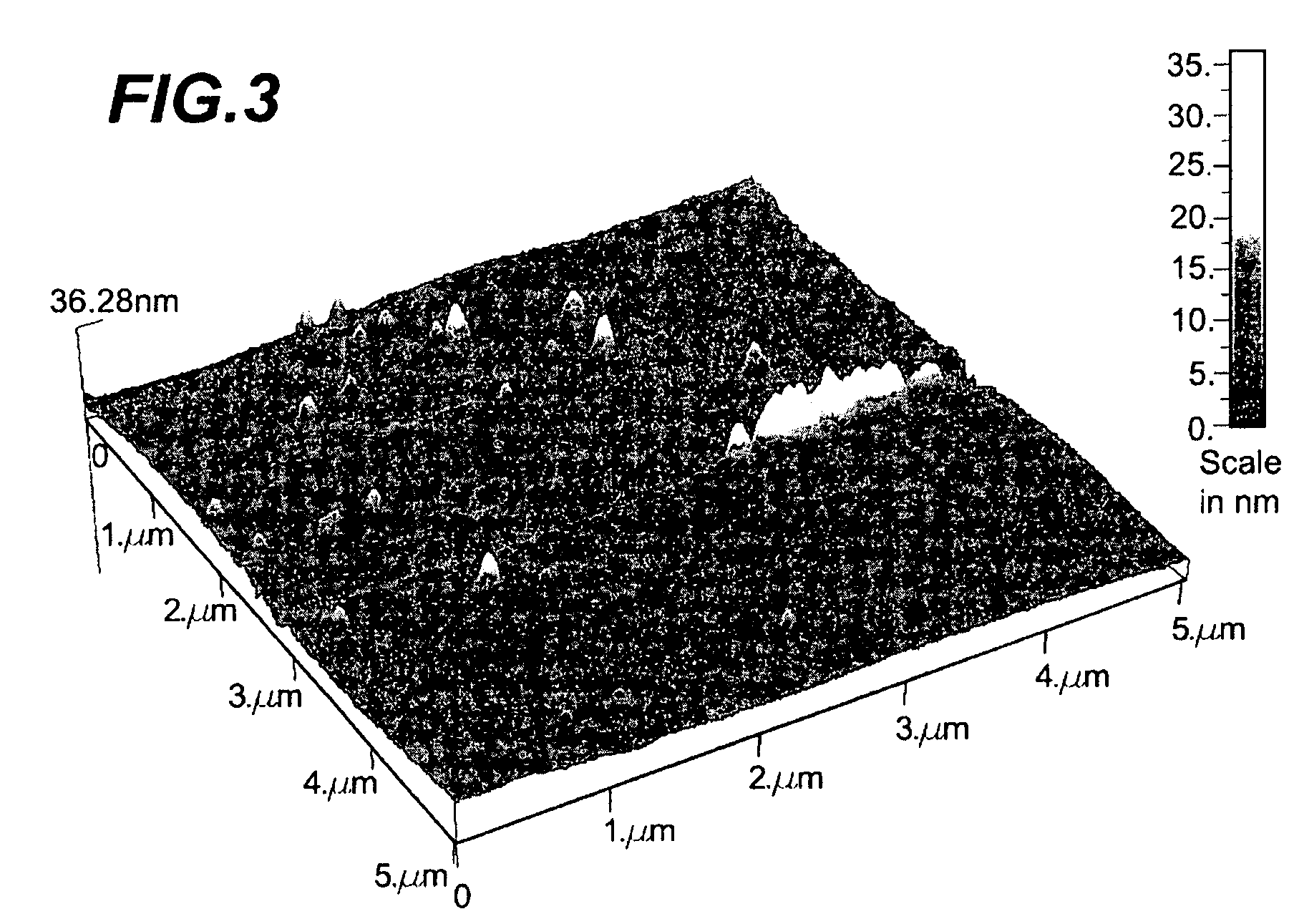

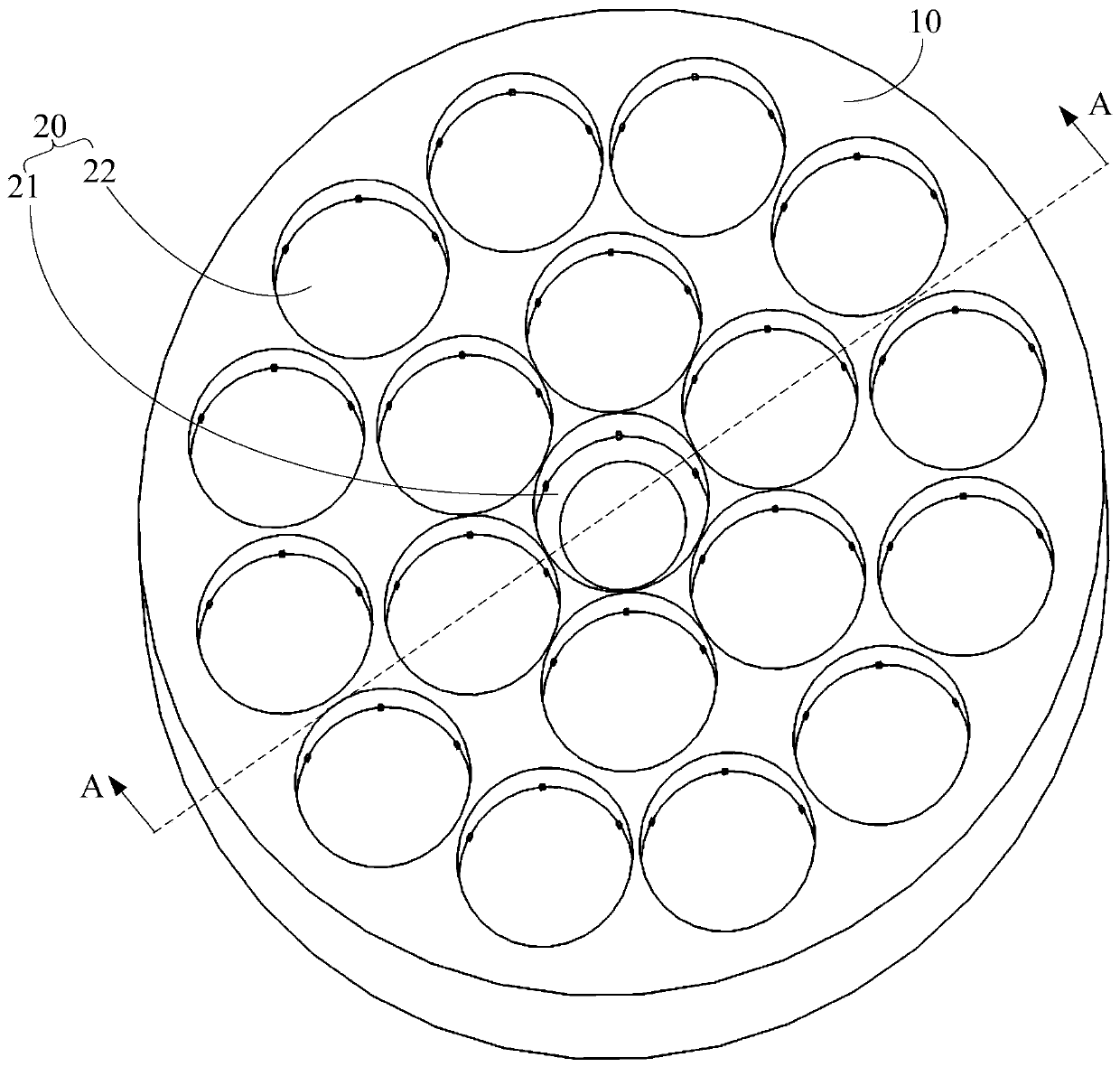

Slurry composition for porous film in battery, method for manufacturing porous film for secondary battery, porous film for secondary battery, electrode for secondary battery, separator for secondary battery, and secondary battery

ActiveCN103081181AGood dispersionEfficient preparationElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesParticulatesWater insoluble

Provided is a slurry composition for a porous film in a battery, the composition containing: 70-99 parts by weight of non-electroconductive particles, 0.1-4 parts by weight of a water-soluble polymer having a sulfonic acid group and a weight-average molecular weight of 1000-15000, 0.1-10 parts by weight of a water-insoluble particulate polymer, and water. Also provided are a method for manufacturing a porous film for a secondary battery, a porous film for a secondary battery, an electrode for a secondary battery, a separator for a secondary battery, and a secondary battery in which the slurry composition is used.

Owner:ZEON CORP

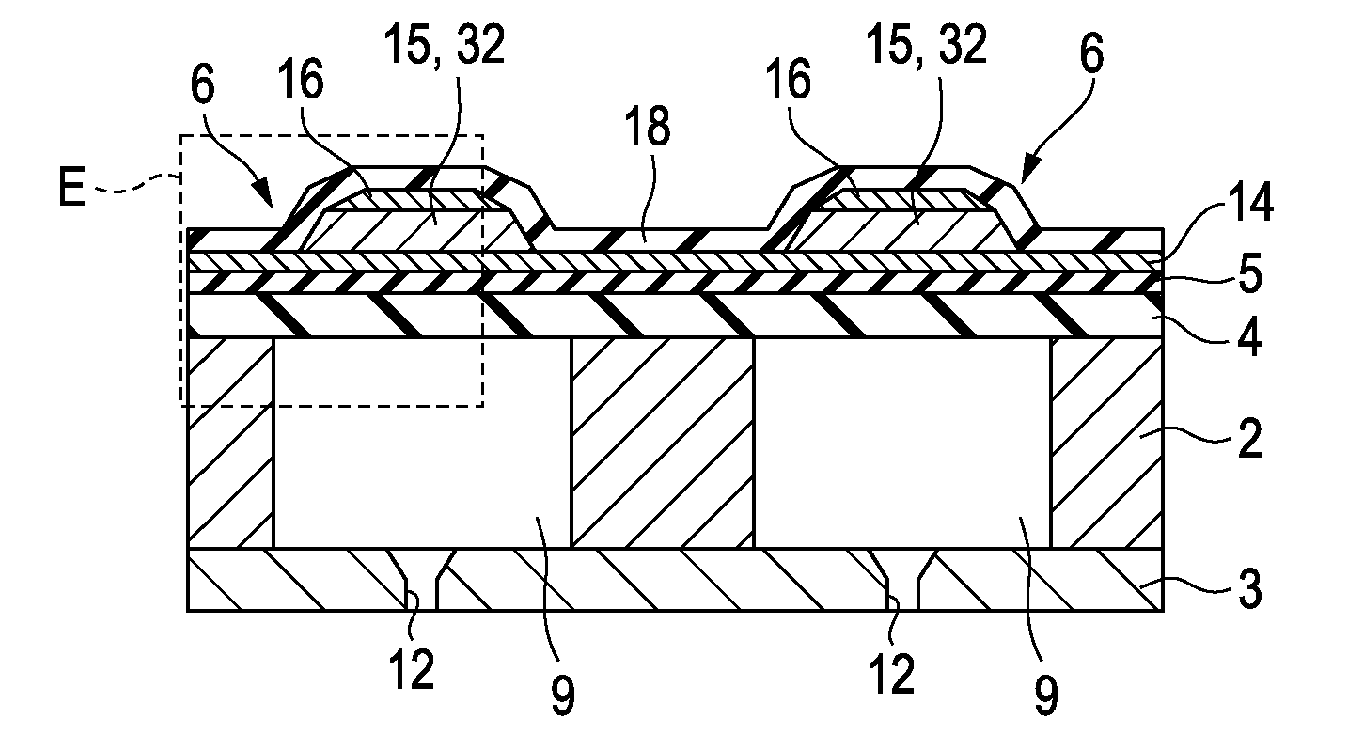

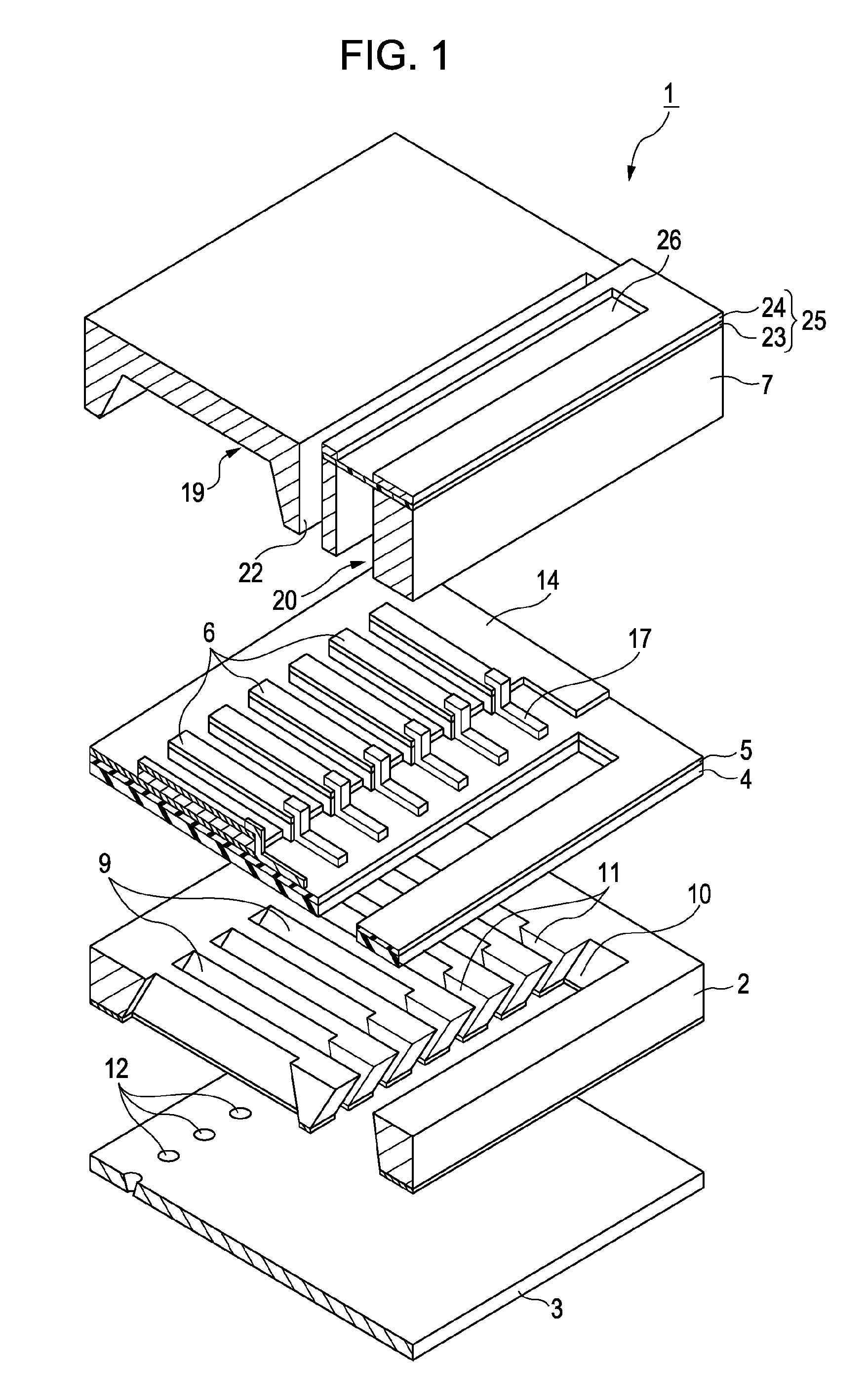

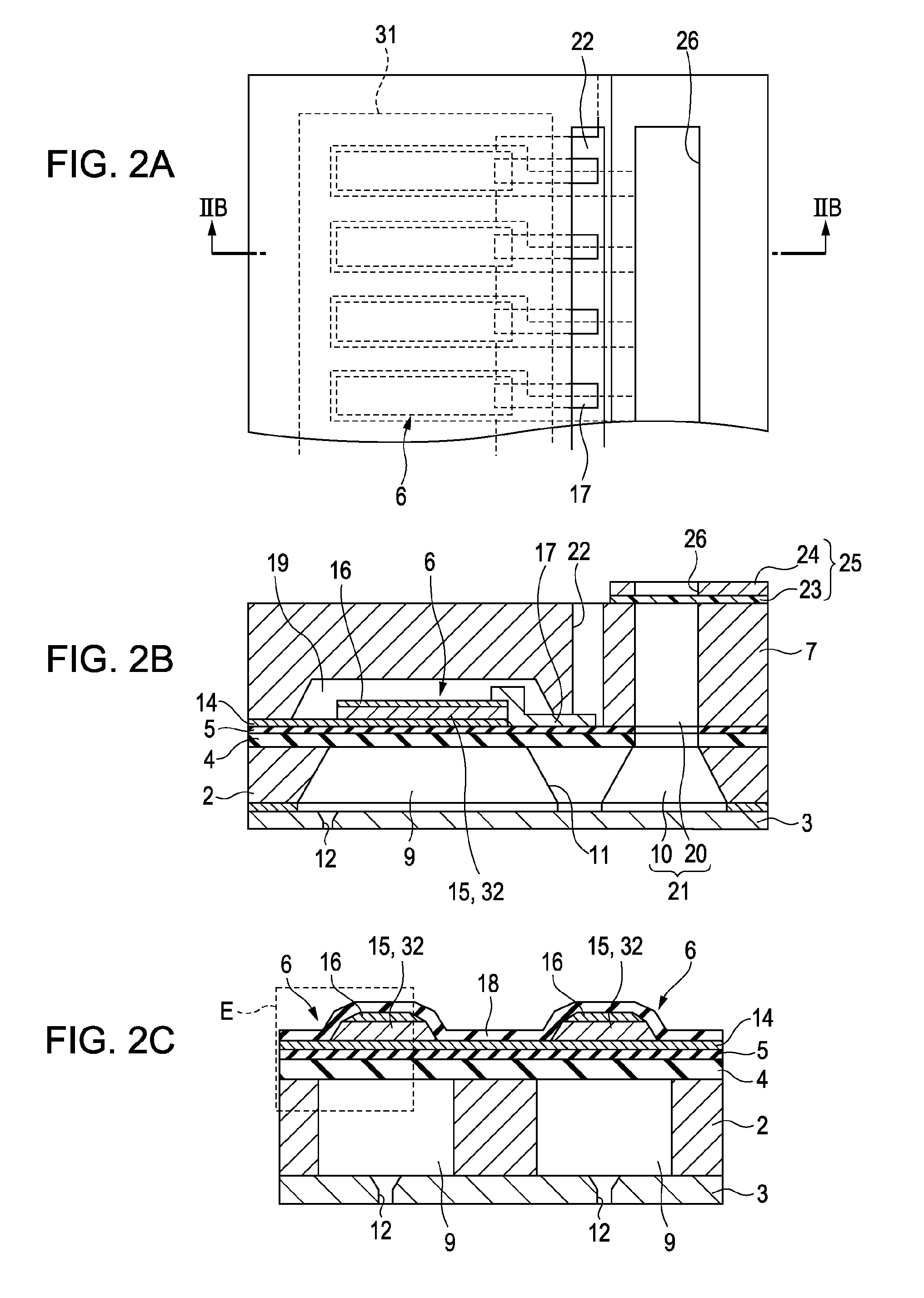

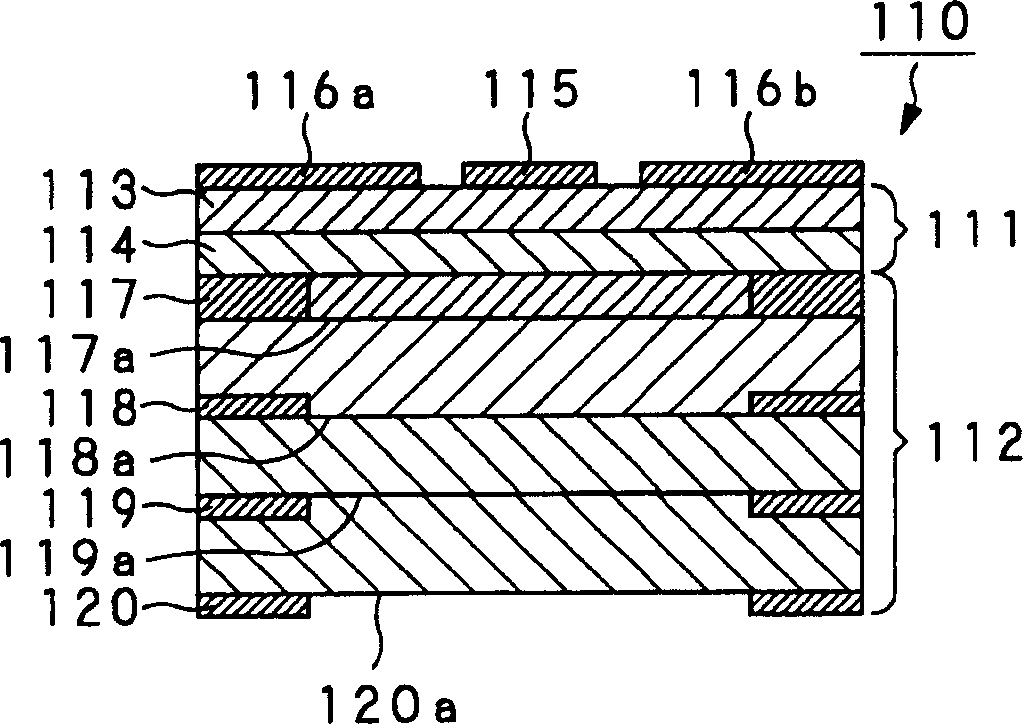

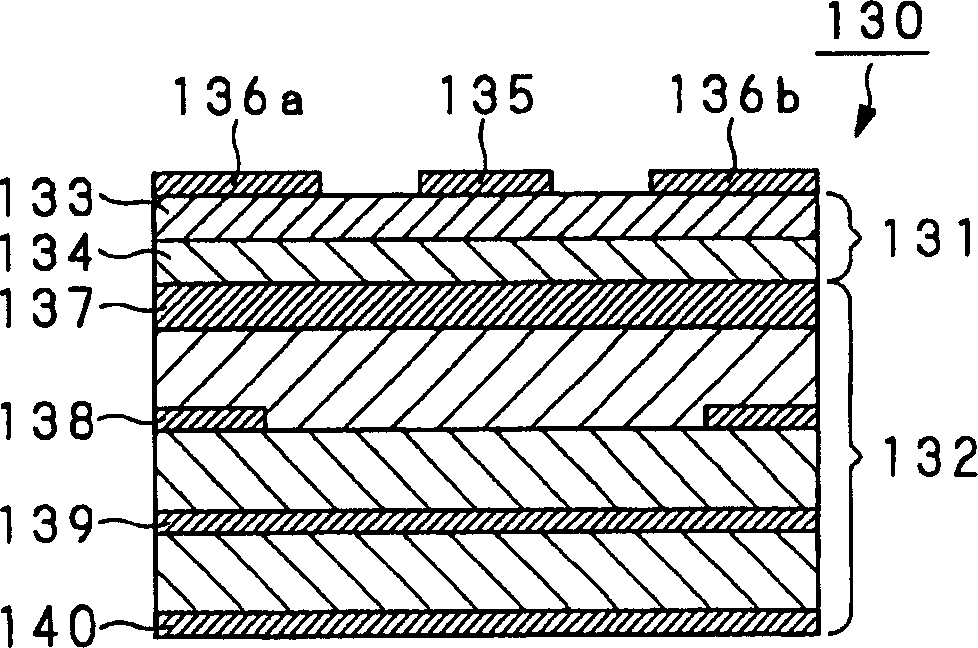

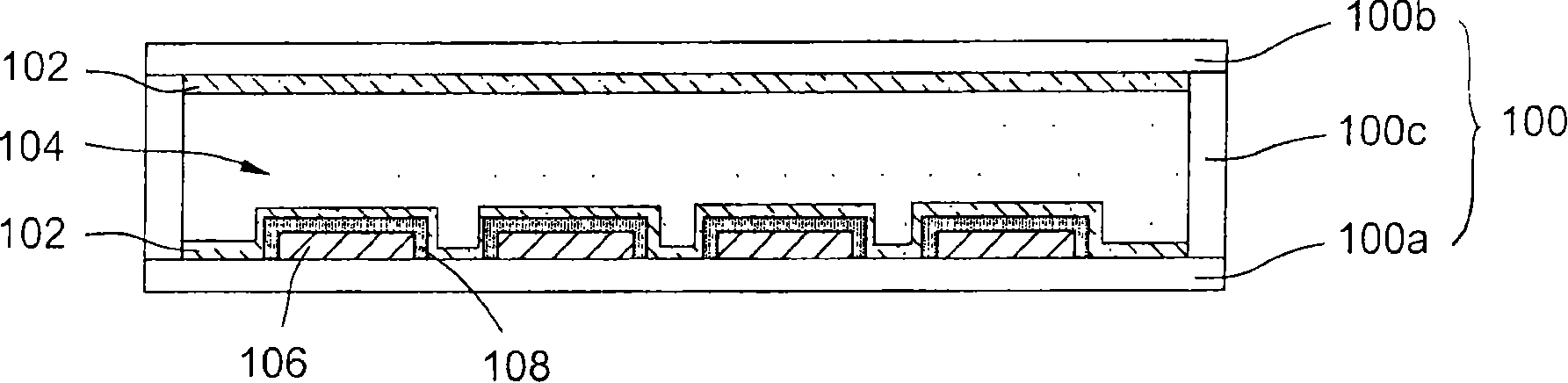

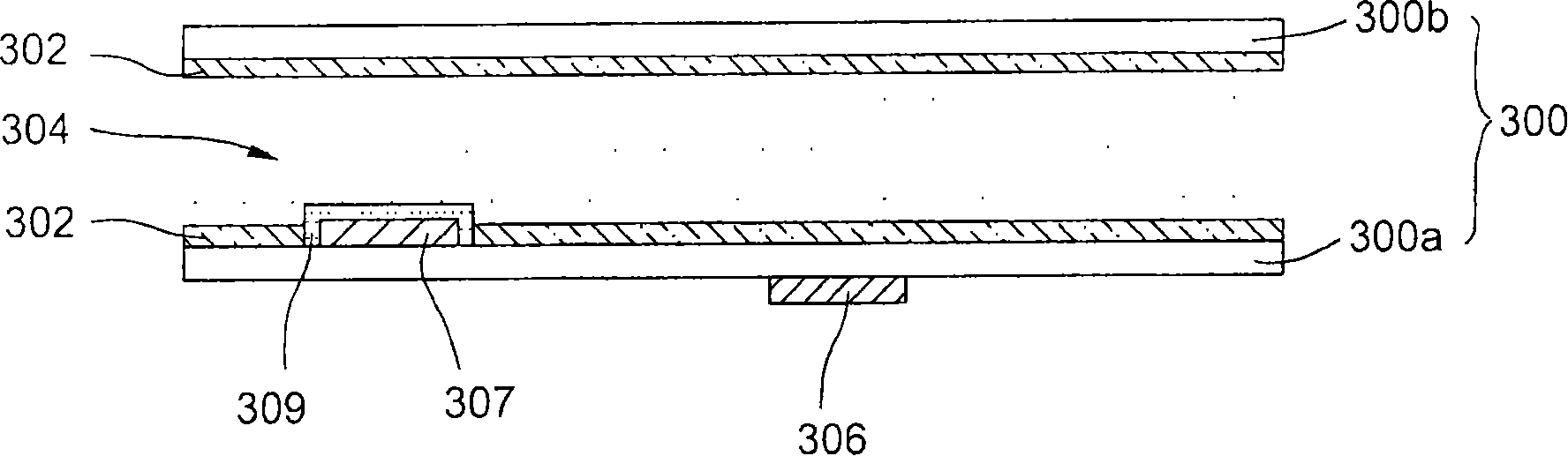

Piezoelectric element, liquid ejecting head, and liquid ejecting apparatus

InactiveUS20100079558A1Increased durabilityReduce stress concentrationPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusEngineeringElectrode

A piezoelectric element includes in a laminated state a piezoelectric layer, a first electrode formed on a first surface of the piezoelectric layer, and a second electrode formed on a second surface of the piezoelectric layer which is opposite to the first surface. The piezoelectric layer has a film thickness of 5 μm or less, and has a flat portion formed as a second surface in parallel with the first surface, and a lateral portion inclined downwardly from the flat portion towards the first surface. The second electrode has a central portion formed in parallel with the flat portion, and a slope portion inclined downwardly from the central portion towards the flat portion. The inclination angle of the slope portion to the flat portion is gentle as compared with the inclination angle of the lateral portion to the first surface.

Owner:SEIKO EPSON CORP

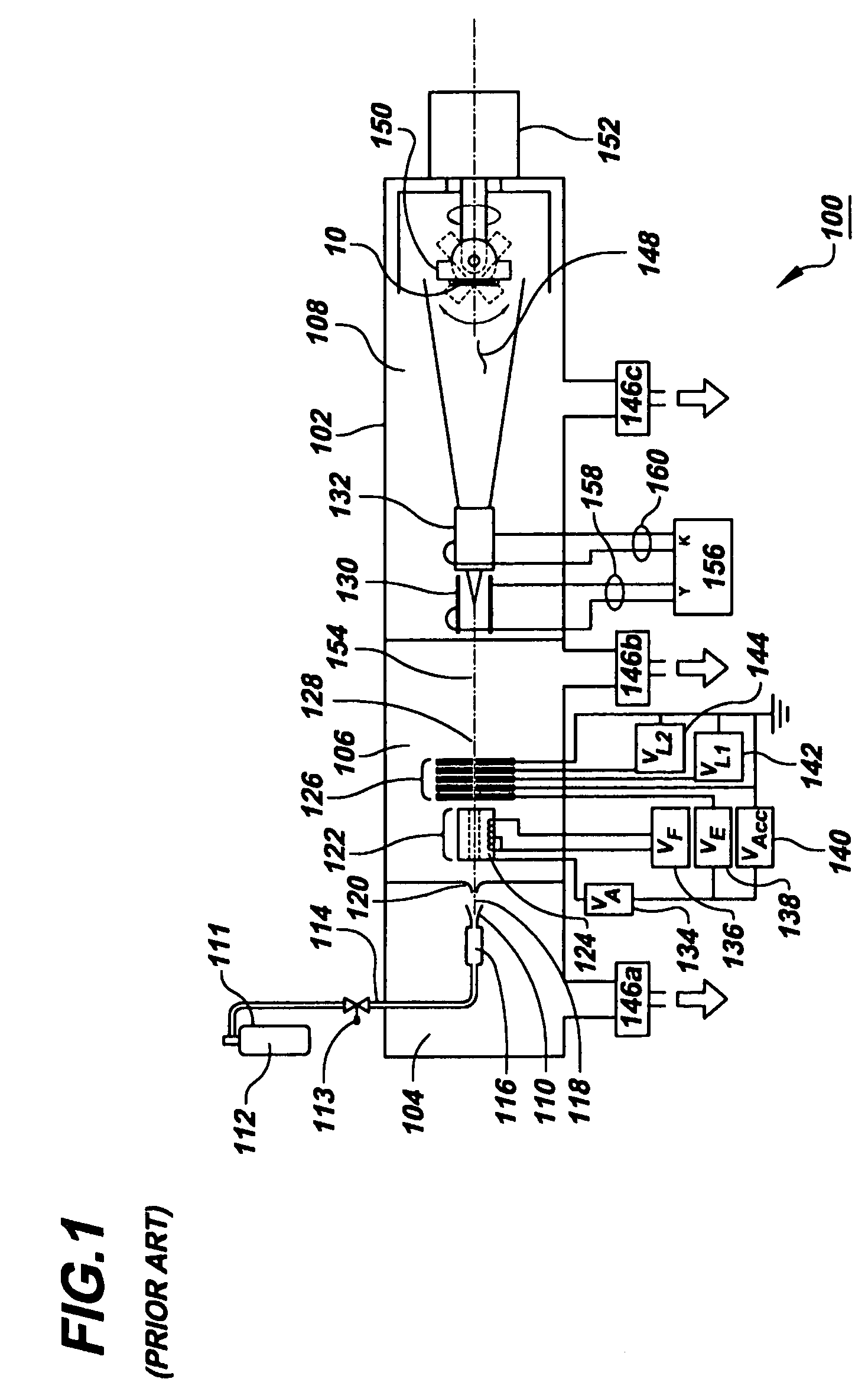

Method of controlling a drug release rate

InactiveUS7666462B2Eliminate needEasy doseSurgeryVacuum evaporation coatingDrug release rateMedicine

A method of controlling the drug release rate of a drug coated endovascular stent by depositing a drug material layer on the stent and then modifying the drug material using gas cluster ion beam irradiation to create a carbon matrix with interstices containing the original drug. The rate at which the drug elutes through the interstices can be controlled by processing parameters. Multiple layers may be employed to create time varying release rates.

Owner:EXOGENESIS CORP

plaster plate

InactiveCN102259082AGuaranteed thicknessGuaranteed parallelismLiquid surface applicatorsLead-acid accumulator electrodesEngineeringMechanical engineering

Owner:JIANGSU LEOCH BATTERY

Film forming apparatus

InactiveUS20070012249A1Uniform thicknessUniform qualityChemical vapor deposition coatingChemical speciesPolymer chemistry

A film forming apparatus includes a material reservoir that retains a material, at least one nozzle that discharges the material or a chemical species generated from the material as a precursor, and a chemical species generation section that generates the chemical species.

Owner:SEIKO EPSON CORP

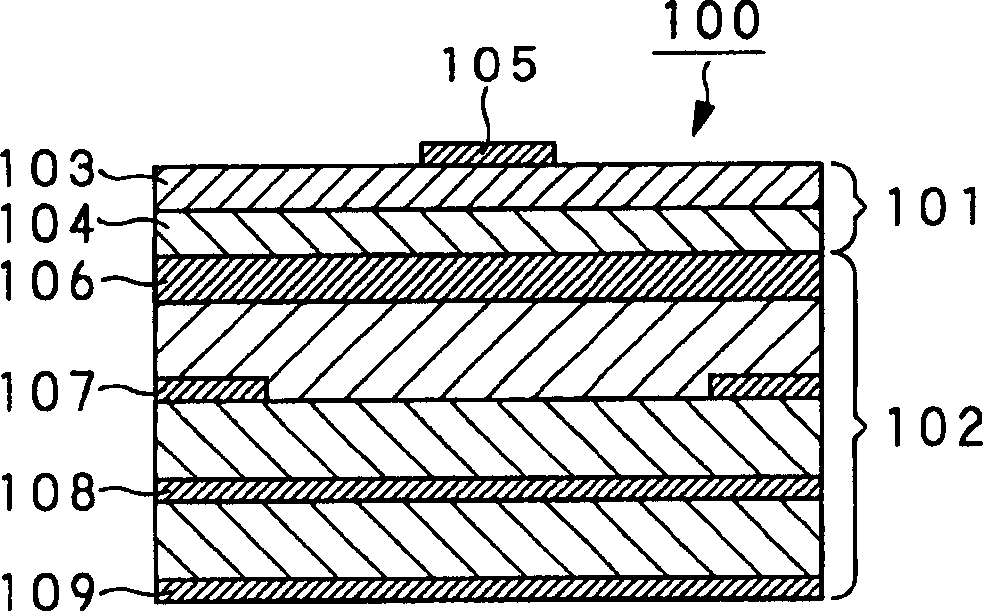

High frequency module

InactiveCN1507671ALow costReduce uneven thicknessCross-talk/noise/interference reductionSemiconductor/solid-state device detailsSemiconductor chipEngineering

The present invention provides a high frequency module having a base substrate unit ( 2 ) which has its uppermost layer planarized to form a buildup-forming surface ( 16 ), a high frequency circuit unit ( 3 ) having multiple wiring layers which are formed on the base substrate unit ( 2 ), each of which layers has a wiring pattern and film elements formed on a dielectric insulating layer thereof, whose uppermost wiring layer ( 17 ) has plural lands ( 22 ) and ground patterns ( 20 ) formed thereon together with the wiring pattern and inductor elements ( 19 ), and a semiconductor chip ( 4 ) mounted on the wiring layer ( 17 ) of the high frequency circuit unit ( 3 ). Transmission lines ( 24 ) to connect the inductor elements ( 19 ) and lands ( 22 ) which are formed on the wiring layer ( 17 ) are directed within hollowed pattern regions ( 20 c) formed at the ground pattern ( 20 ) to constitute coplanar type transmission lines.

Owner:SONY CORP

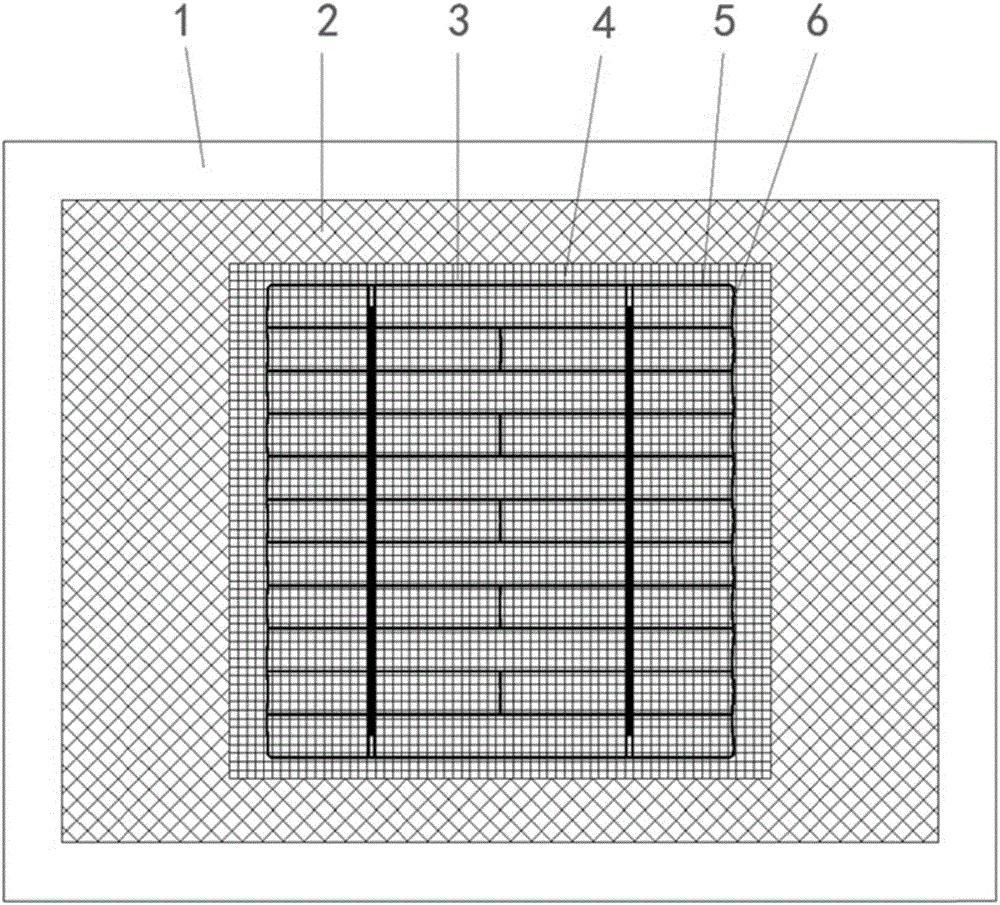

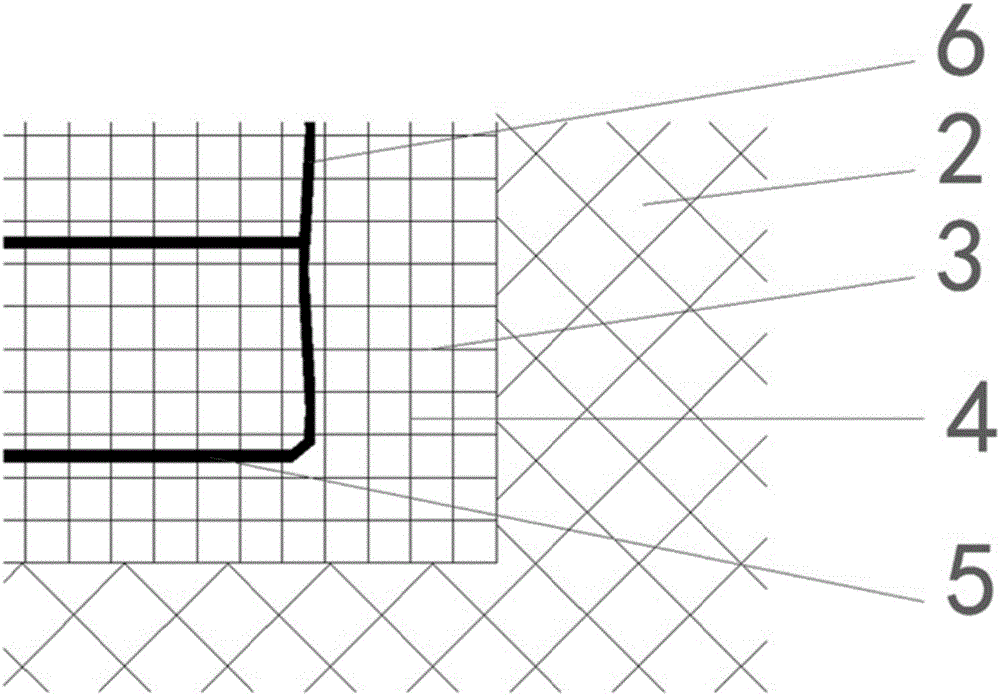

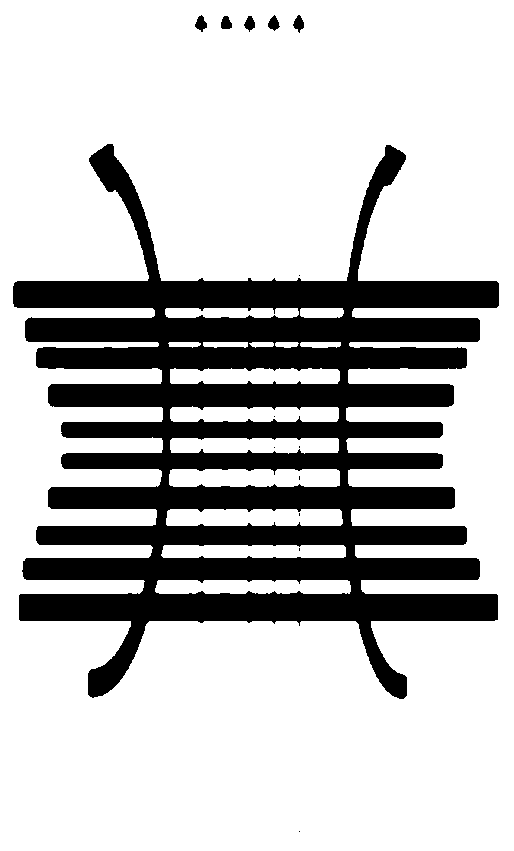

Net-knot-free screen printing plate

InactiveCN106739448AAvoid distractionsAvoid low ink permeabilityScreen printersScreen printingEngineering

The invention discloses a net-knot-free screen printing plate. The net-knot-free screen printing plate comprises a net frame; a plurality of warps and a plurality of wefts are installed in the net frame, wherein the warps and the wefts are formed by stretching a wire mesh, the warps are arranged in parallel, and the wefts are also arranged in parallel; the warps and the wefts are perpendicularly arranged, contacting positions between the warps and the net frame and between the wefts and the net frame are fixed through sticking, a printing figure is installed in the middle of the net frame, and transverse printing lines in the printing figure are located in the middle of a grid parallel to the direction of the warps; and a longitudinal figure frame, a longitudinal grate-breaking prevention vertical line and the longitudinal main grate edge of the printing figure are all of a waved structure. According to the net-knot-free screen printing plate, interference of net knots is avoided, so that a printed line is thinner and higher, and product photovoltaic conversion efficiency is promoted.

Owner:赫日光电(苏州)有限公司

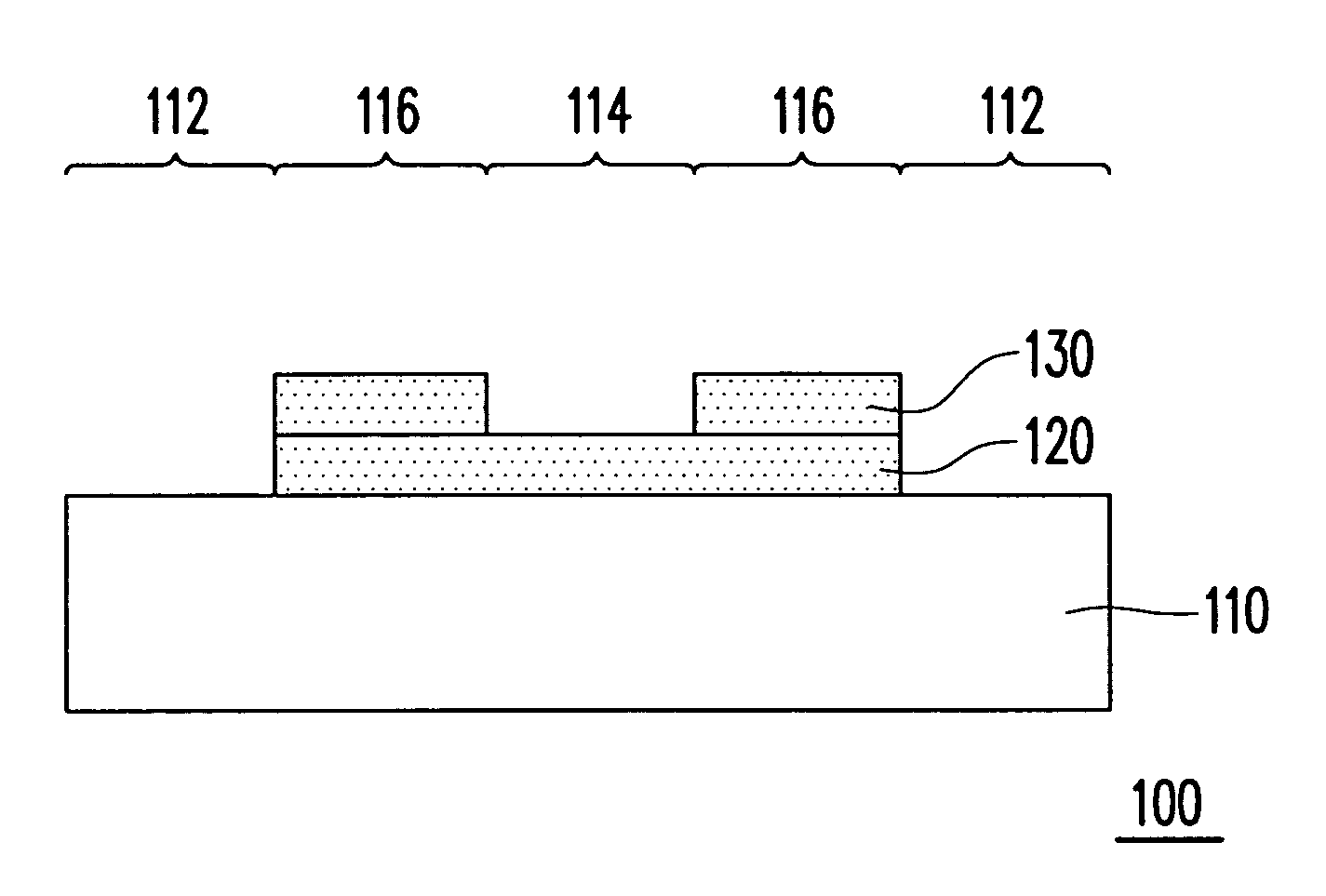

Novel button anti-reflection film structure

InactiveCN1385884AImprove flatnessReduce uneven thicknessPhotomechanical apparatusSemiconductor/solid-state device manufacturingPhotolithographyFilm structure

This invention applies a technique of a base anti-reflection film (BARC) composed of organic BARC and inorganic BARC. This invention puts forward a complex anti-reflection structure combined organic and inorganic BARC with the inorganic BARC under the organic BARC which utilizes either the advantage of organic BARC flat or reduces wide line loss in the traditional organic BARC etching since inorganic BARC etching since inorganic BARC of good selection is used.

Owner:SHANGHAI HUA HONG GROUP

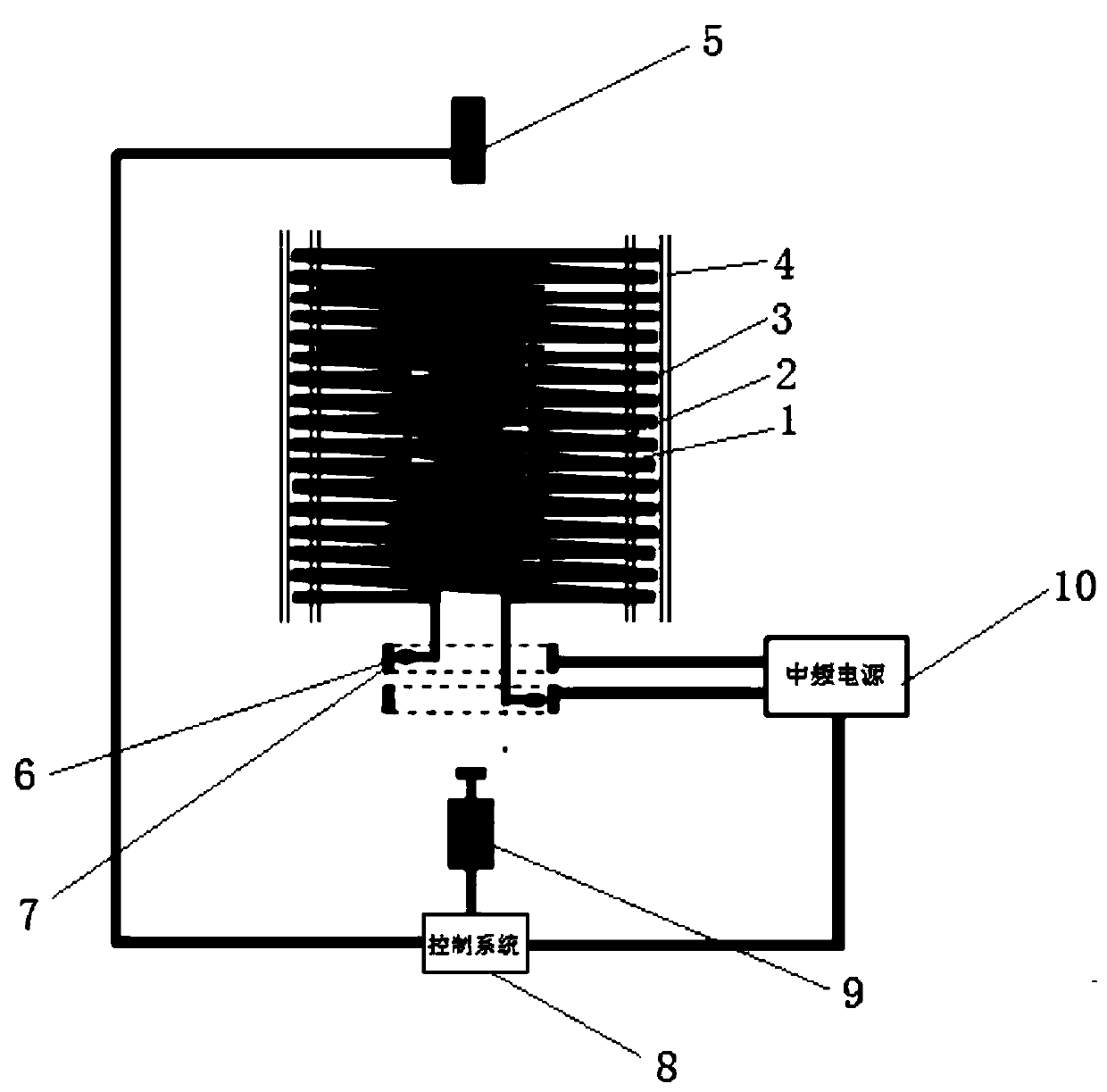

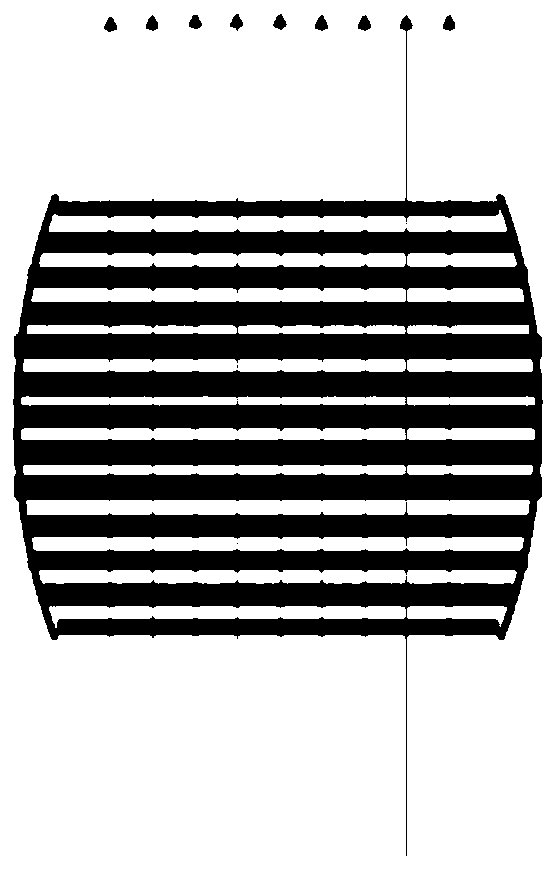

Method for growing large-size silicon carbide single crystal

InactiveCN110777430AReduce turn spacingRaise the ratioPolycrystalline material growthFrom condensed vaporsCarbide siliconSingle crystal

The invention provides a method for growing a large-size silicon carbide single crystal. The method includes the step of heating a crystal growth chamber by using an induction coil. In the single crystal growth process, the rotation of the induction coil is controlled by a rotation mechanism, and the spacing of turns of the induction coil is reduced and the ratio of the height of the coil to the diameter of the coil is increased to control the uniformity of a temperature field in the crystal growth chamber. Through optimization of the setting of the induction coil, the uniformity of a magneticfield generated by the induction coil is improved, temperatures around the crystal growth chamber are as uniform as possible, the phenomenon of uneven thickness around the crystal is effectively reduced, the collapse, happening on a material surface, in one direction is effectively reduced, the erosion rates of the crystal growth chamber in all directions are the same, the number of use times ofconsumables is increased, the stability of crystal growth is improved, uneven heat generation of a crucible is reduced, and the uniformity of crystal growth is improved.

Owner:济宁天岳新材料科技有限公司

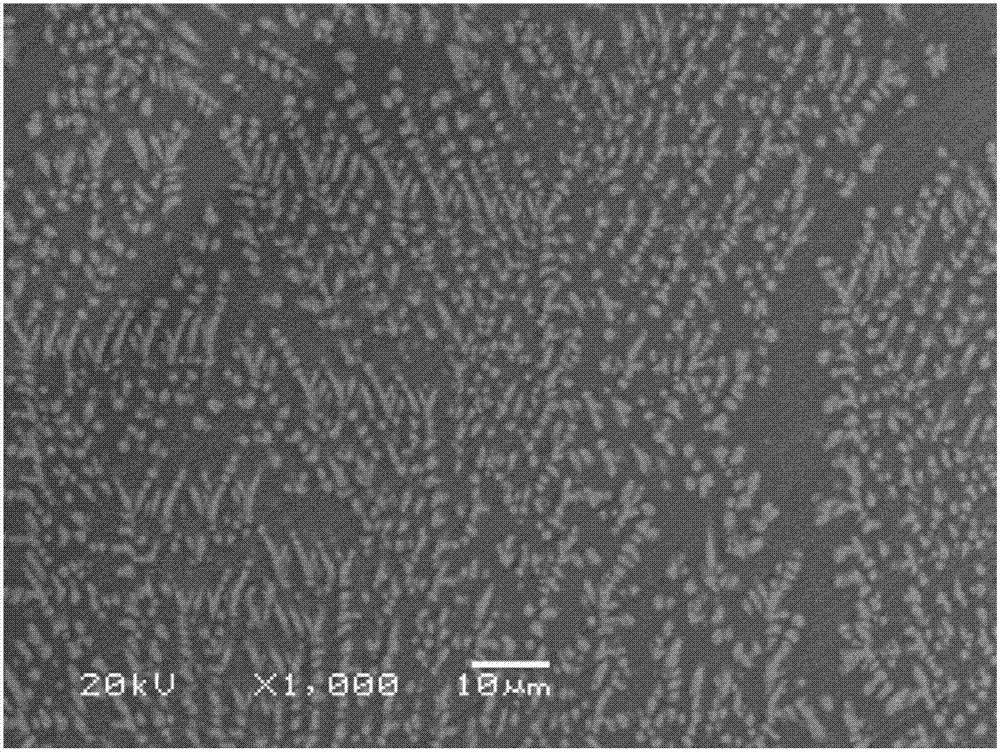

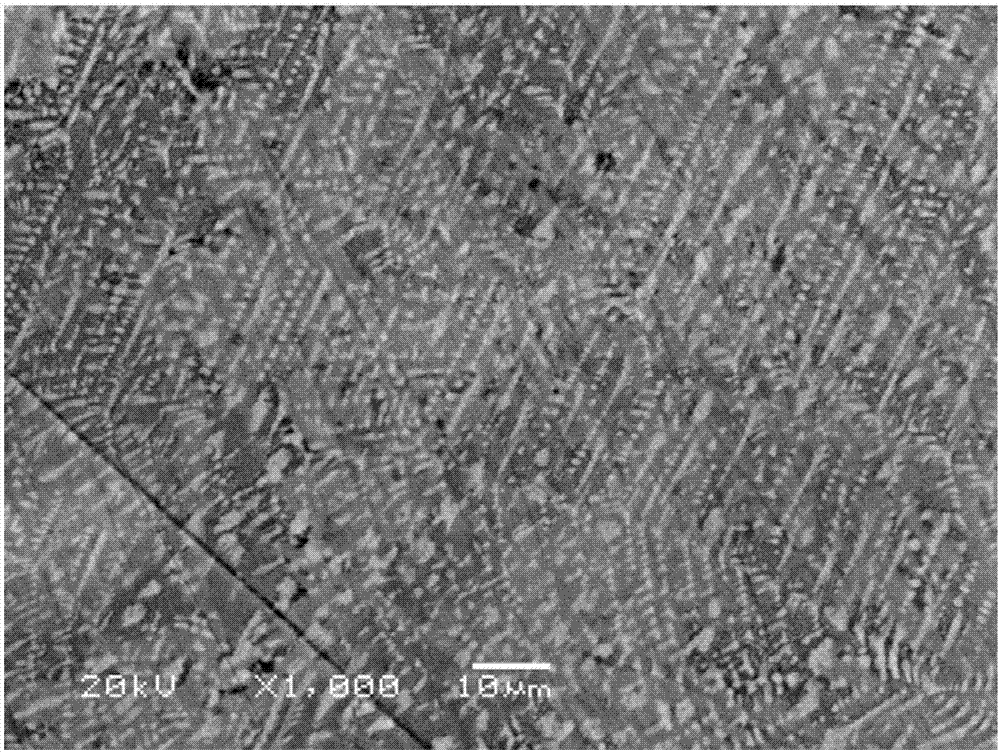

ZrO2-contained vehicle TWIP steel protection slag and application thereof

The invention discloses ZrO2-contained vehicle TWIP steel continuous casting crystallizer protection slag and application thereof. The protection slag consists of the following oxide components in percentage by mass: 20-40% of CaO, 8-20% of SiO, 13-30% of Al2O3, 5-12% of Na2O, 1-6% of Li2O, 3-16% of BaO, 2-8% of MnO2, 4-13% of F-, 1.5-3.5% of ZrO2, 1.3-2.4 of (CaO+BaO) / Al2O3, 1.9-2.5 of CaO / SiO2, and 1.6-2.2 of Al2O3 / SiO2. The protection slag can be preferably applied to the continuous casting process of TWIP steel with 15-25 mass% of Mn and 2-4 mass% of Al.

Owner:CENT SOUTH UNIV

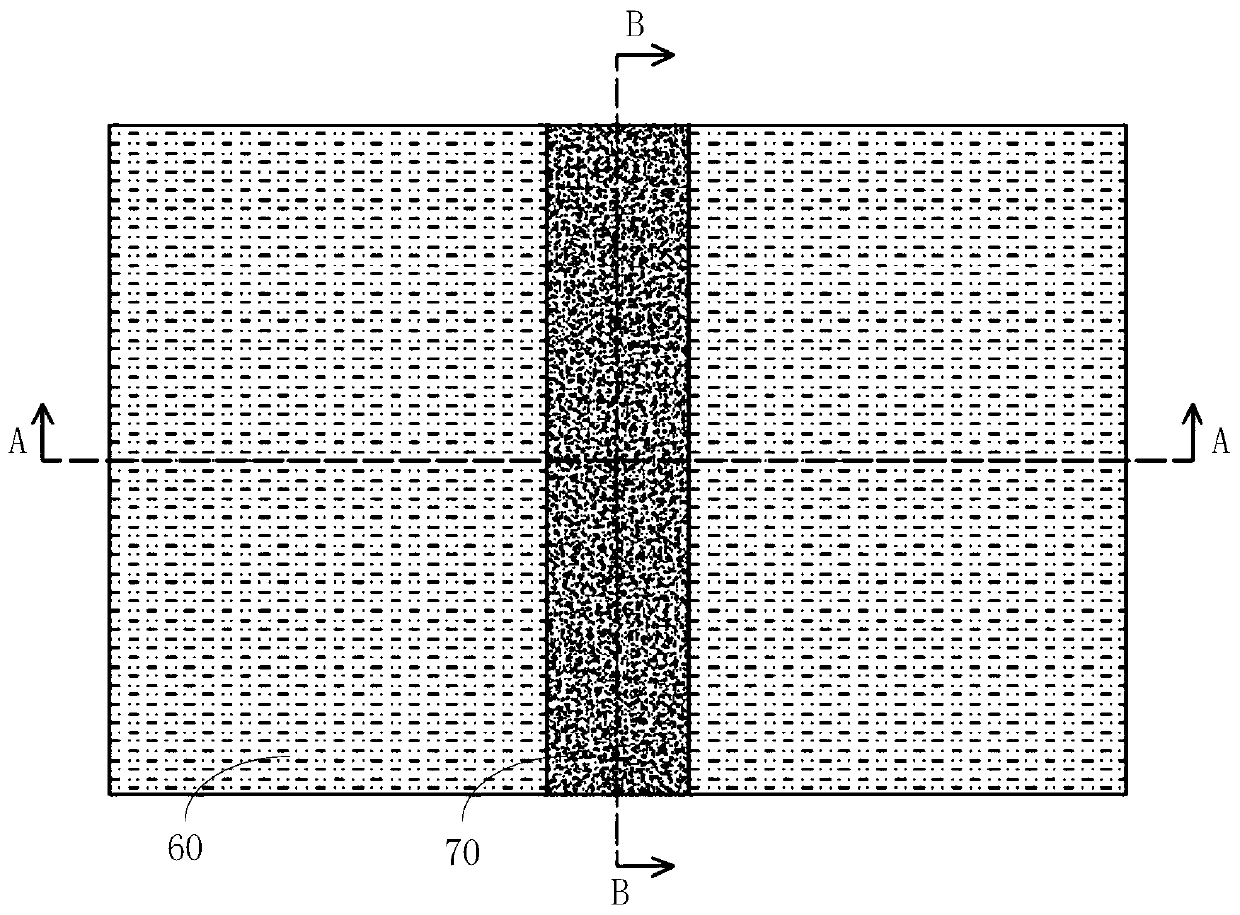

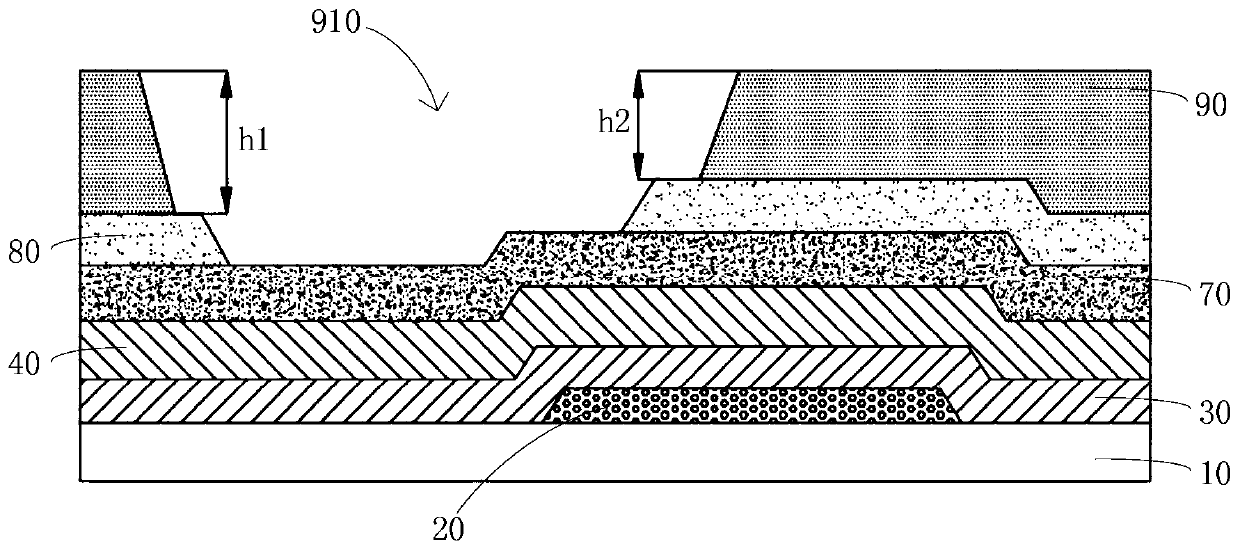

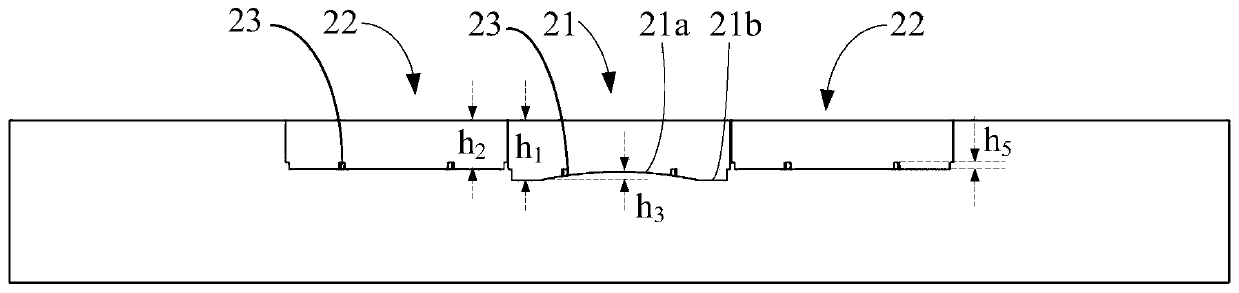

Display device, display panel and manufacturing method thereof

ActiveCN110767738AReduce height differenceReduce uneven thicknessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to a display device, a display panel and a manufacturing method thereof. The display panel comprises a substrate, a conducting layer, a grid insulating layer, a grid layer, an interlayer dielectric layer and a wiring layer. The conducting layer is arranged on one side of the substrate; the grid insulating layer is arranged on one side, away from the substrate, of the conducting layer; the grid layer is arranged on one side, away from the substrate, of the grid insulating layer; and the thickness of the grid layer is greater than that of the conducting layer. The grid layer comprises a plurality of gate lines. The gate lines form grooves which extend towards the substrate and cut off the gate lines; the grooves are opposite to the conducting layer; and the broken gatelines at the two sides of the grooves penetrate through the grid insulating layer and are connected with the conducting layer. The interlayer dielectric layer is arranged on one side, away from the substrate, of the grid layer, and covers the conducting layer and fills the grooves; the wiring layer is arranged on the side, away from the substrate, of the interlayer dielectric layer; the wiring layer comprises a plurality of auxiliary electrode wires; and the orthographic projections of the auxiliary electrode wires on the grid layer intersect with the gate wires in the grooves, and the orthographic projections of the intersection parts on the grid layer are completely located in the grooves.

Owner:BOE TECH GRP CO LTD +1

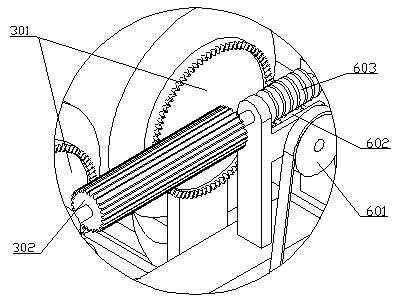

Fret bar for ingot slicing, ingot to which fret bar is stuck, and ingot cutting method using fret bar

InactiveCN102083598ALess lateral shakeAvoid lateral shakingMetal sawing devicesSemiconductor/solid-state device manufacturingWaferingIngot

The present invention provides a fret bar for ingot slicing, an ingot to which the fret bar is stuck, and an ingot cutting method using the fret bar. The object of the invention is to, in cutting an ingot by using a multi-wire saw, to improve material use efficiency by reducing variations in thickness among wafers to be obtained to thereby reduce material loss in cutting and improve working efficiency by shortening the time required for slicing. Means for solving problems is that in cutting an ingot by a multi-wire saw, a fret bar for ingot slicing is used in order to form notches at the start of the cutting. The fret bar for ingot slicing is characterized by being a columnar body stuck along the length direction of the ingot to a portion of the surface of the ingot.

Owner:SHINANO ELECTRIC REFINING

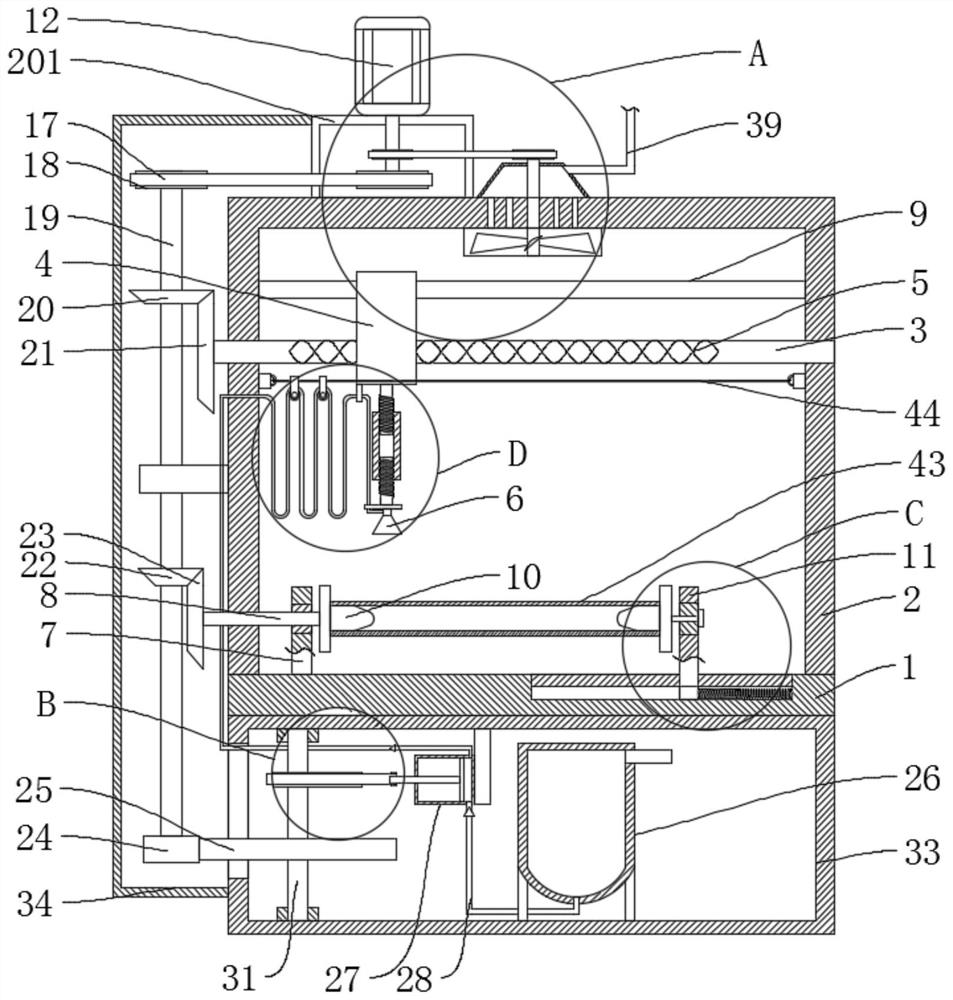

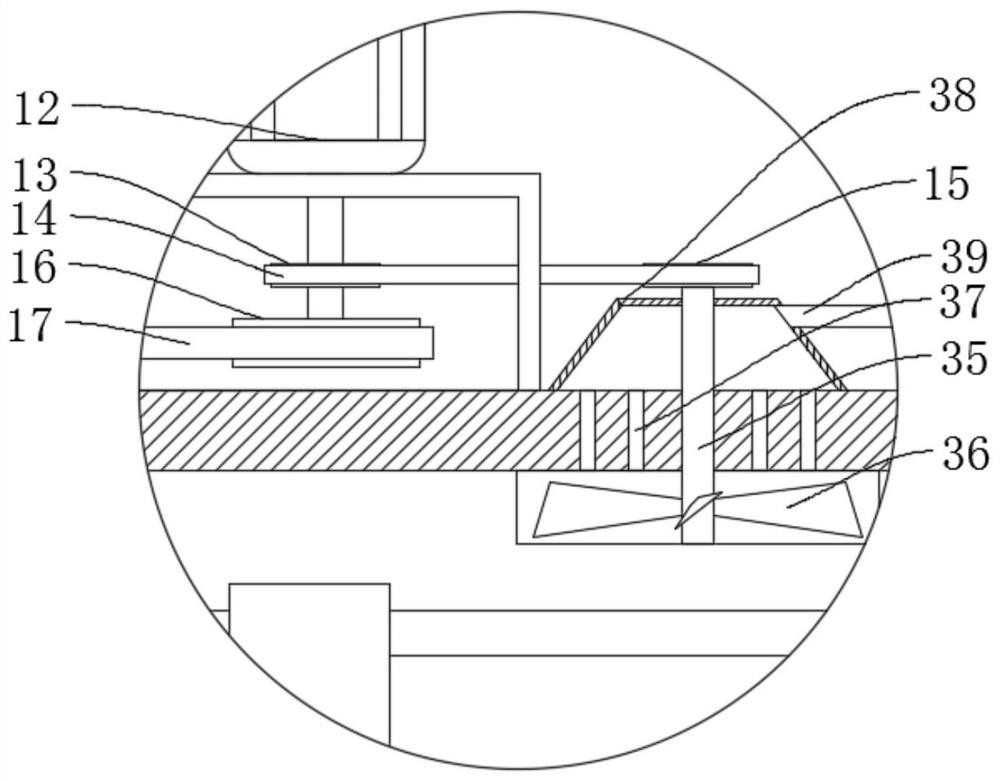

Industrial spraying robot

InactiveCN112892918AReduce uneven thicknessImprove uniformitySpraying apparatusManipulatorWorkbenchSupport plane

The invention discloses an industrial spraying robot, and belongs to the field of industrial spraying. The industrial spraying robot comprises a workbench and a part to be sprayed, wherein a supporting frame is fixedly connected onto the workbench; a driving mechanism is fixedly connected onto the supporting frame; a lead screw is rotatably connected onto the supporting frame and is provided with a reciprocating sliding groove; a sliding block is slidably connected onto the reciprocating sliding groove; a spraying head is fixedly connected onto the sliding block; a first fixing seat is fixedly connected onto the workbench; a second fixing seat is fixedly connected onto the workbench; fixing blocks are rotatably connected onto the first fixing seat and the second fixing seat; the to-be-sprayed part is connected onto the fixing blocks in a sleeving mode; and the driving mechanism is rotatably connected with the lead screw and the fixing blocks. The industrial spraying robot provided by the invention is easy to use and convenient to operate, the labor intensity of manual spraying is reduced by driving the spraying head and the part to be sprayed to rotate, the spraying efficiency is improved, and meanwhile, the uniformity of the spraying thickness is improved.

Owner:付雪君

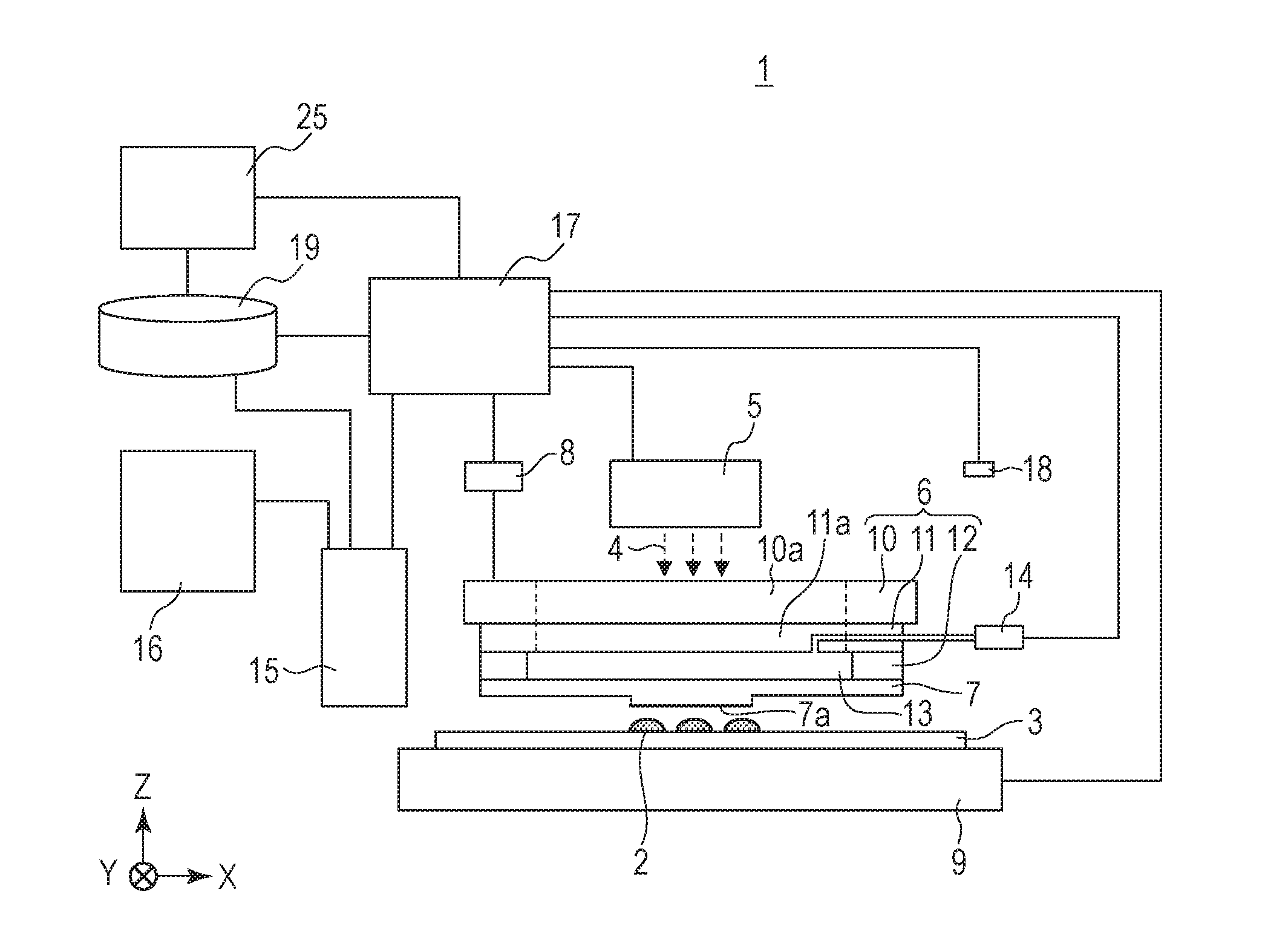

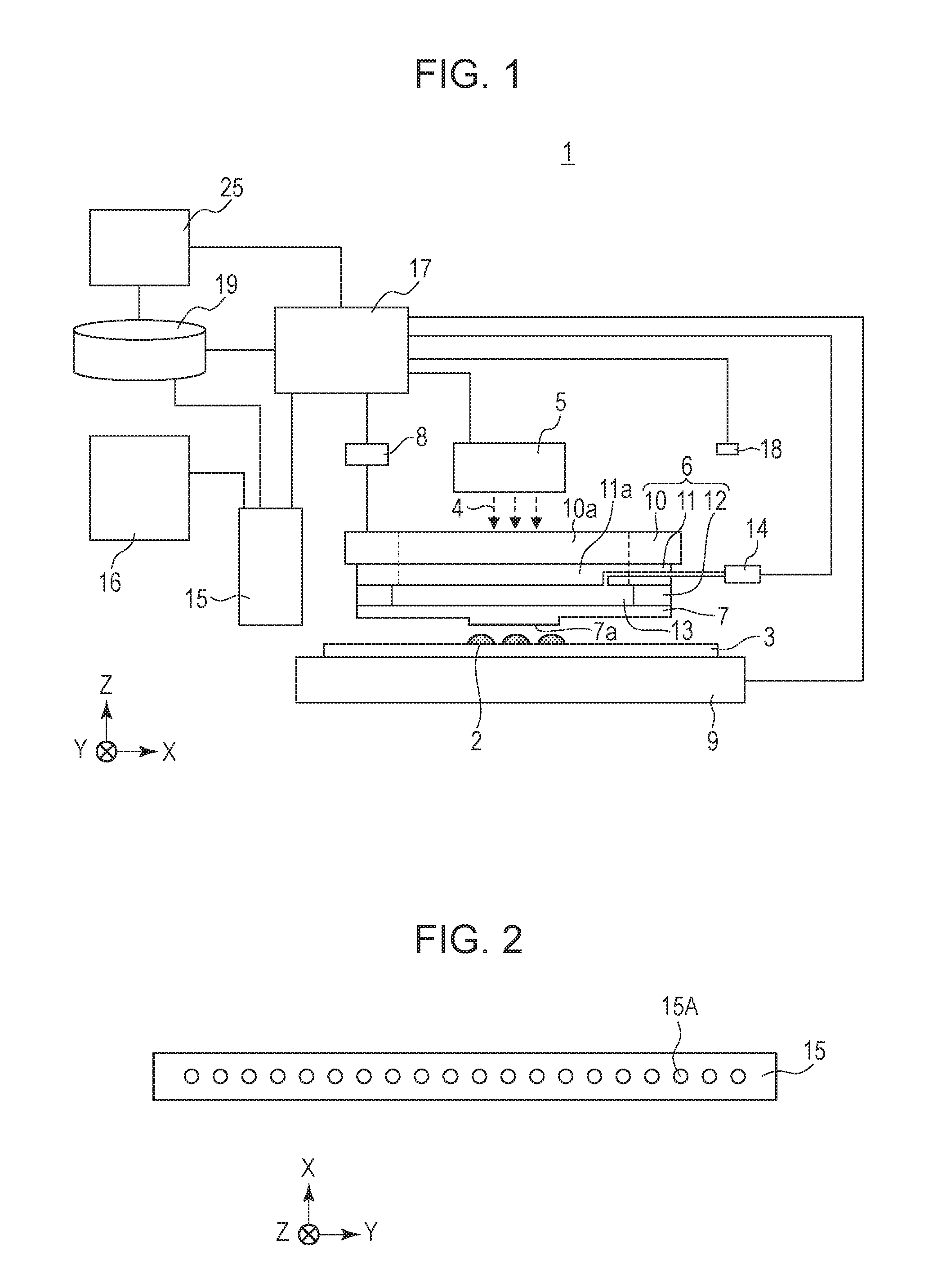

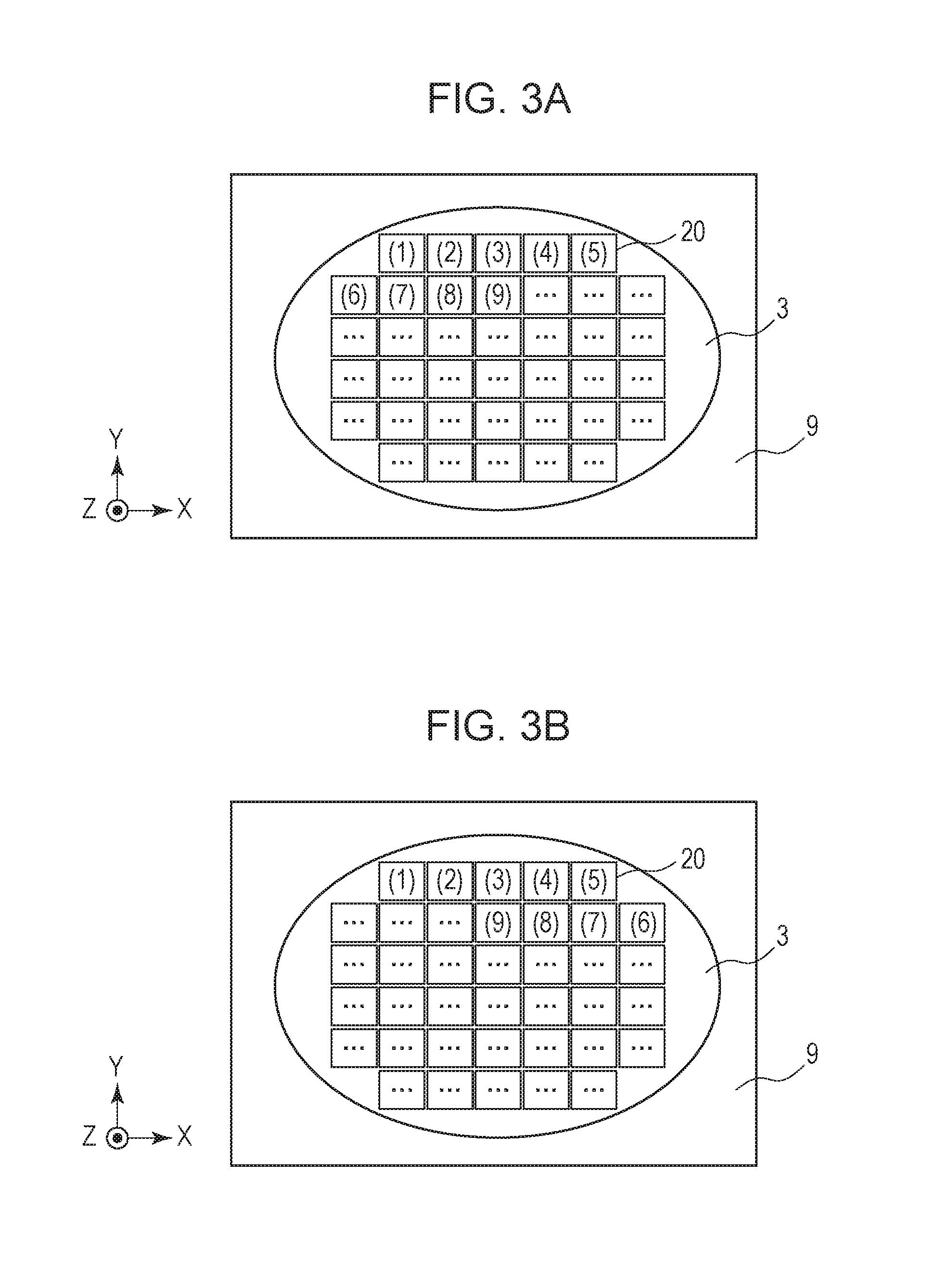

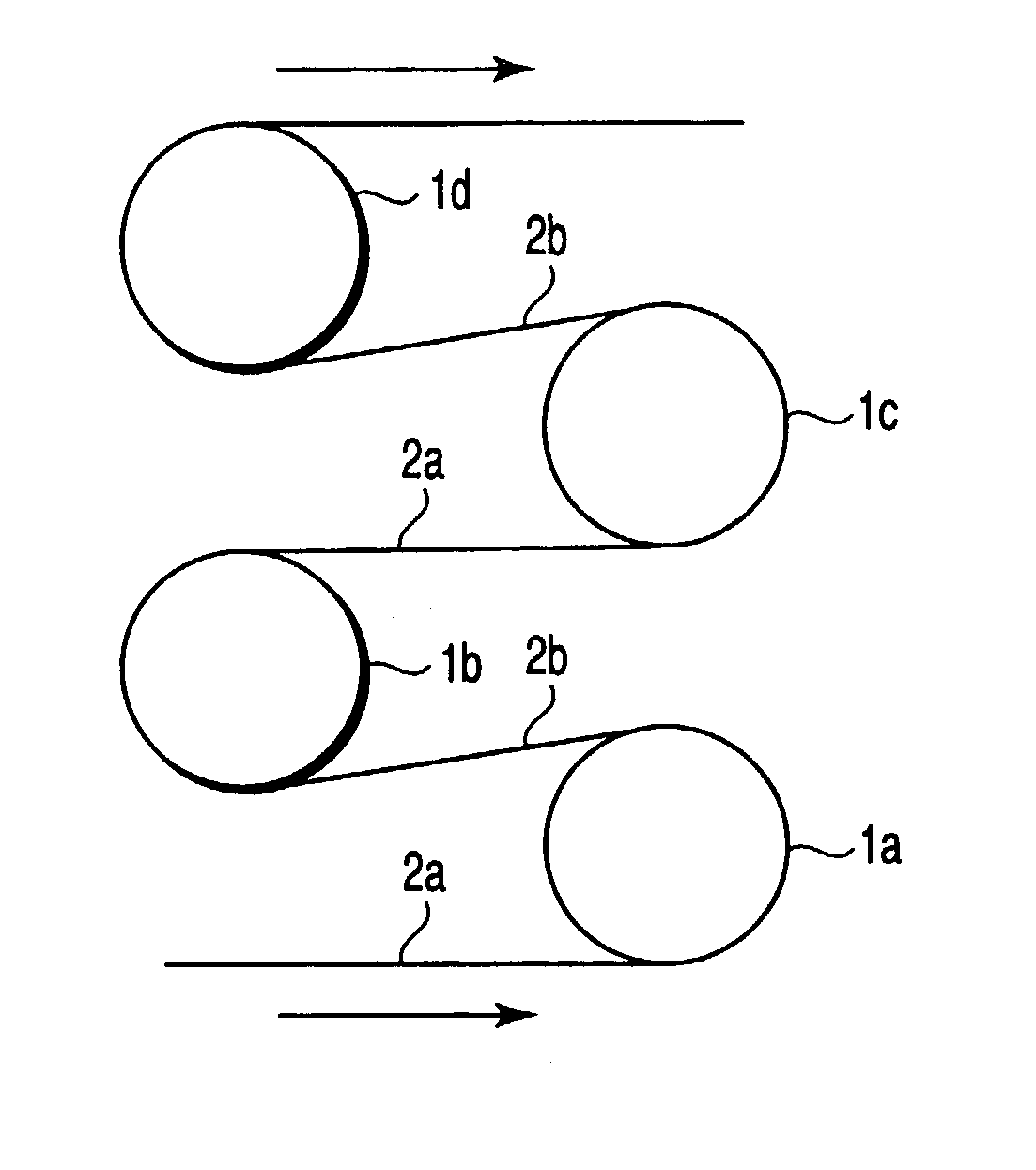

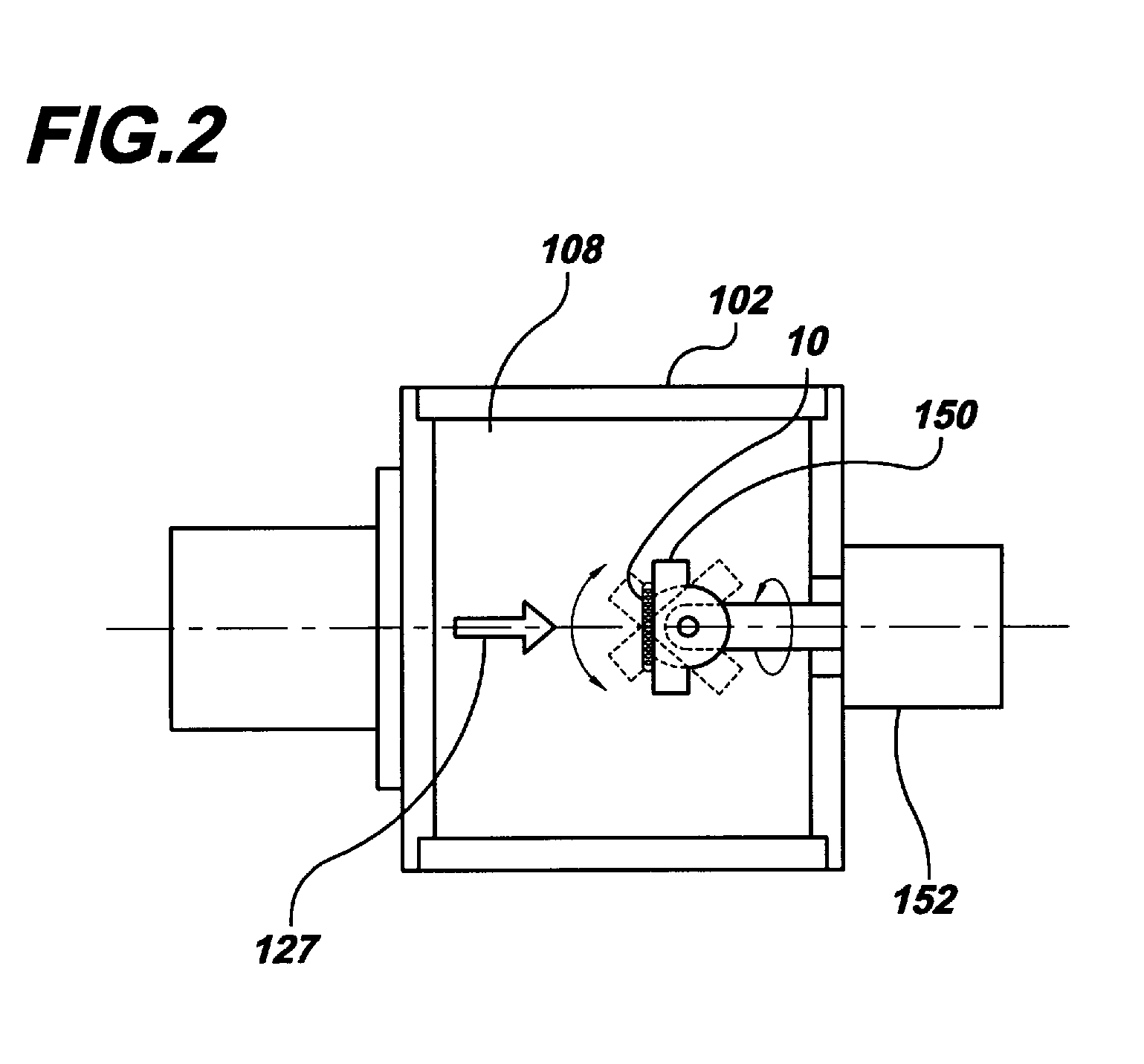

Imprinting apparatus, imprinting method, and article manufacturing method

ActiveUS20160291485A1Reduce uneven thicknessReduce unevennessPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineering

Provided is an imprinting apparatus that forms patterns sequentially on a plurality of areas of a substrate by using a mold and imprint material. The apparatus includes a moving unit configured to move along a horizontal plane while carrying the substrate, and an adjusting unit configured to adjust an inclination of the mold with respect to the substrate. The adjusting unit adjusts the inclination of the mold with respect to the substrate based on information related to a state of the imprint material provided on the substrate and information related to an order of pattern formation. The information related to the state of the imprint material on the substrate is variable with the movement of the moving unit.

Owner:CANON KK

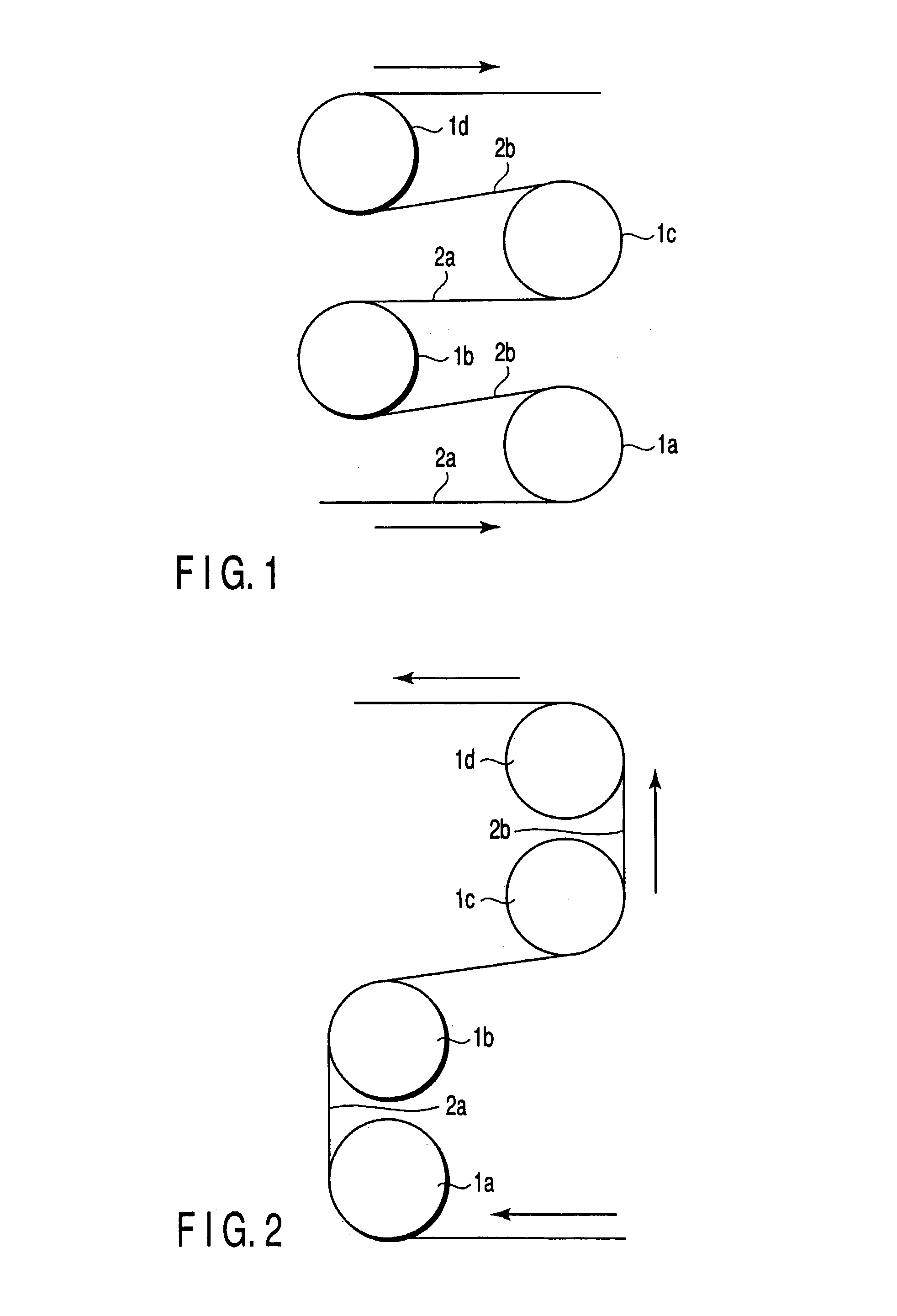

Manufacturing method of compressible printing layer and manufacturing method of blanket for printing

InactiveUS7128802B2Reduce uneven thicknessSmall in nonuniformity of thicknessConfectioneryPress rollersEngineeringElectrical and Electronics engineering

The present invention provides a manufacturing method of a compressible printing layer, comprising a vulcanizing step comprising a first heating process in which one surface of a compressible printing layer including an unvulcanized compressible layer containing microcapsules is heated by bringing the one surface of the compressible printing layer into contact with the surface of at least one heated metal roll while applying tension to the compressible printing layer, and a second heating process in which the other surface of the compressible printing layer is heated by bringing the other surface of the compressible printing layer into contact with the surface of at least one heated metal roll while applying tension to the compressible printing layer.

Owner:KINOYOSHA CO LTD

Manufacturing process of crystal diode

ActiveCN105097504AAvoid damageReduce uneven thicknessSemiconductor/solid-state device manufacturingPlastic packagingWafer dicing

The invention relates to a manufacturing process of a crystal diode. The manufacturing process comprises the following steps: (S1) wafer cutting; (S2) wafer assembly, namely putting a wafer lead on a lead track, sequentially grabbing each wafer to put into the wafer lead, and cutting the wafer lead into wafer lead segments of 216-360 products through a segmentation machine, and sequentially putting the wafer lead segments into the lead box; (S3) wire soldering, namely transferring the lead box with the wafer lead segments into a work bench of a wire soldering machine, adjusting the power of the wire soldering machine to be 30-50mW, the pressure to be 250-350mN and the temperature to be 240-320 DEG C, putting each wafer lead segment in the lead box on the wire soldering machine for wire soldering, so as to obtain the wafers with pins; (S4) injection molding; (S5) electroplating; (S6) separating; (S7) testing; and (S8) band loading, namely loading the tested and qualified crystal diodes to a stripped carrier band with a band loading mechanism, and carrying out plastic packaging to obtain the product. The manufacturing process has the advantages that transportation is facilitated in the manufacturing process; the product quality is improved; and classified transportation or storage is facilitated.

Owner:SICHUAN BLUE COLOR ELECTRONICS TECH

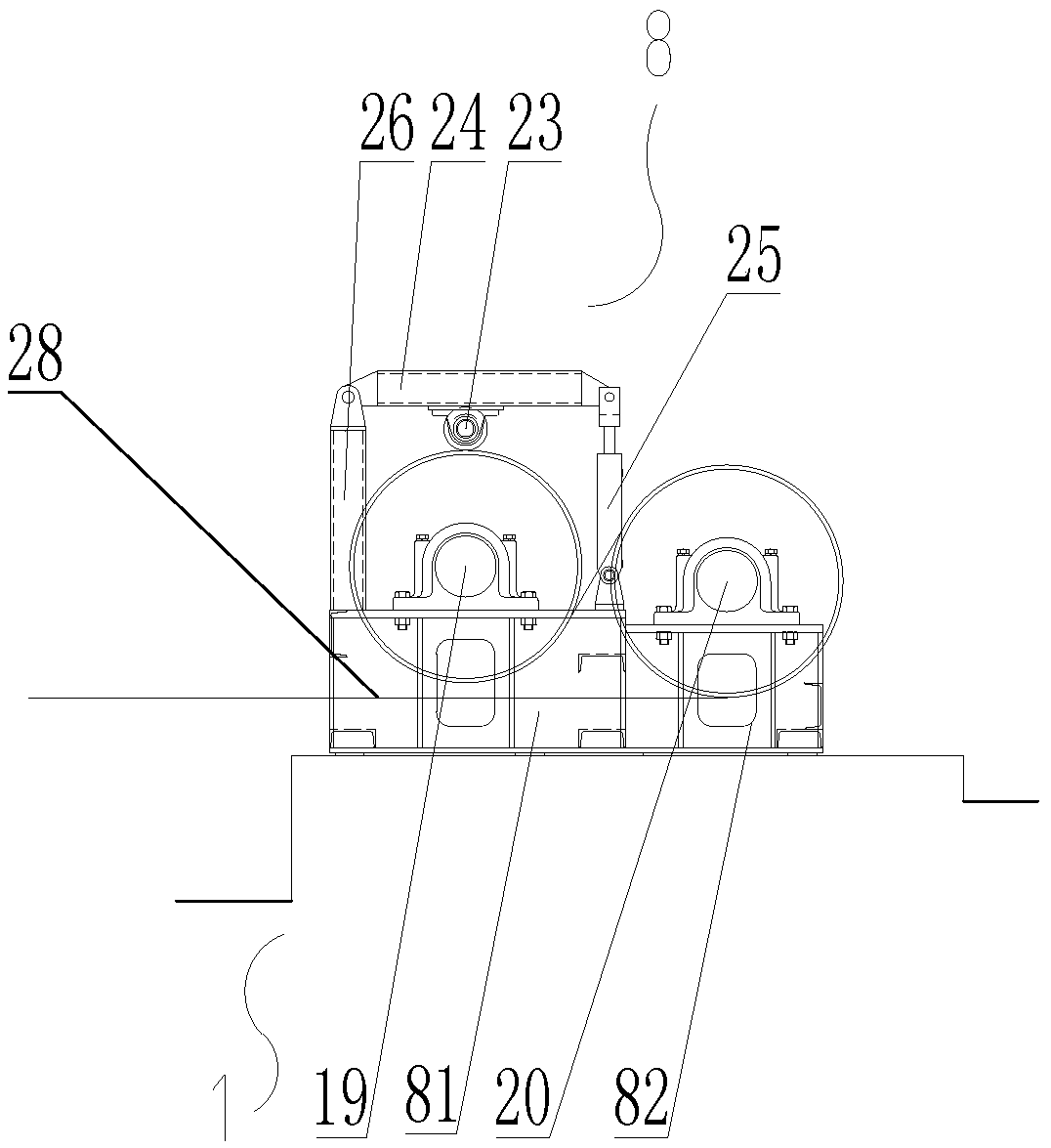

Strip steel flattening machine

InactiveCN108273870ASmooth throughSolve uneven thicknessMetal-working feeding devicesPositioning devicesEngineeringStrip steel

The invention provides a strip steel flattening machine. The strip steel flattening machine comprises a base. A roller is arranged on the base through a roller support and comprises a two-roller flattening machine. One side of the two-roller flattening machine is sequentially provided with a first tension S roller, a welding machine reserved gap, a first steering carrier roller, a first hydraulicshear, a first clamping conveying roller and an uncoiling machine, and the other side of the two-roller flattening machine is sequentially provided with an upper roller and a lower roller which are arranged on an upper base and a lower base in an up-down symmetry manner correspondingly. A first drive device is arranged at the upper end of the upper roller. Each of the first tension S roller and the second tension S roller comprises a first tension roller and a second tension roller which are arranged on a left support and a right support in a left-right symmetry manner, wherein a first pressing roller is arranged above the first tension roller and is hinged and installed to the left support through a swing arm, and a second drive device is arranged on the swing arm.

Owner:WUXI CITY XIDONG RUBBER & PLASTICS MACHINERY

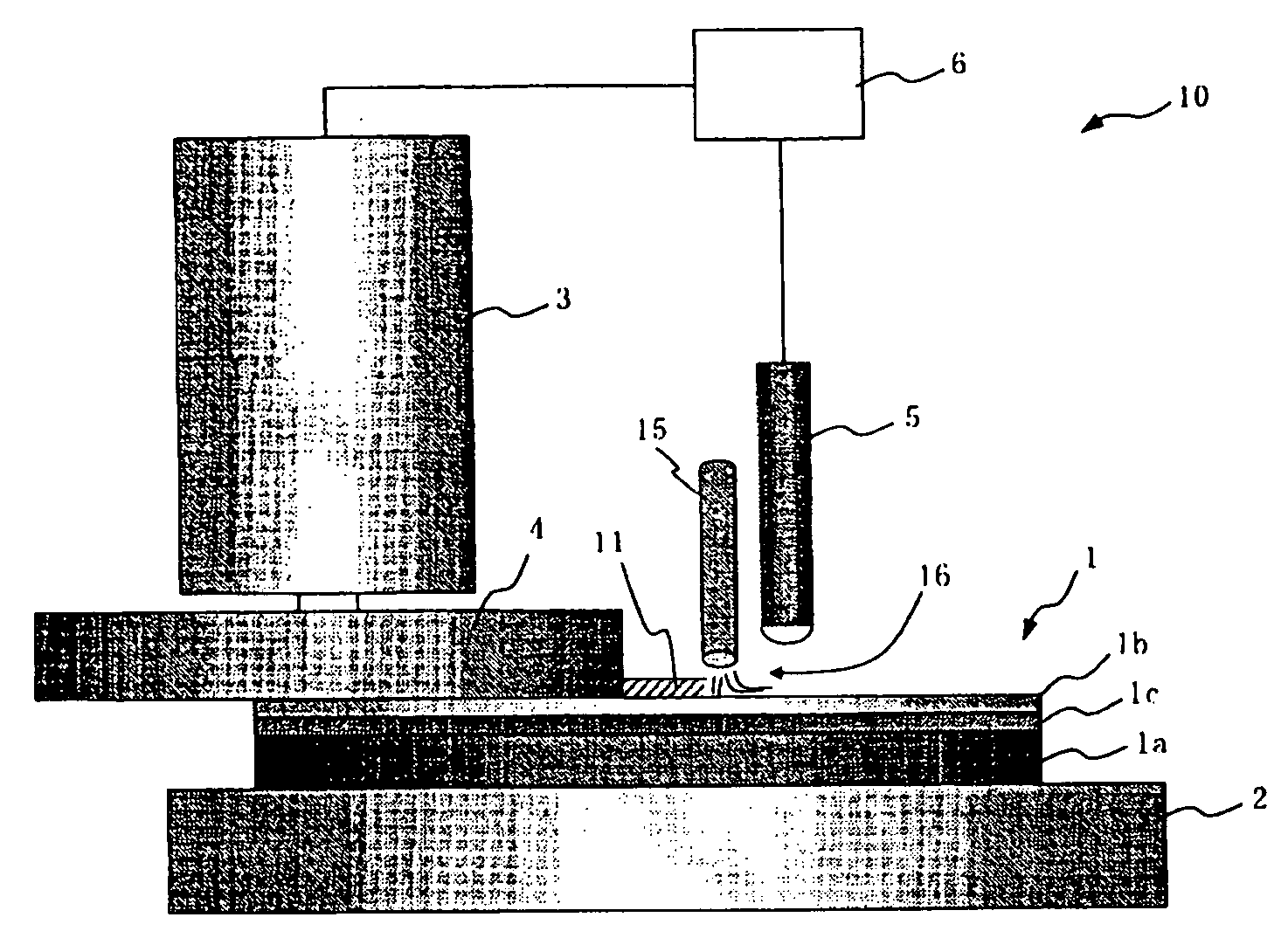

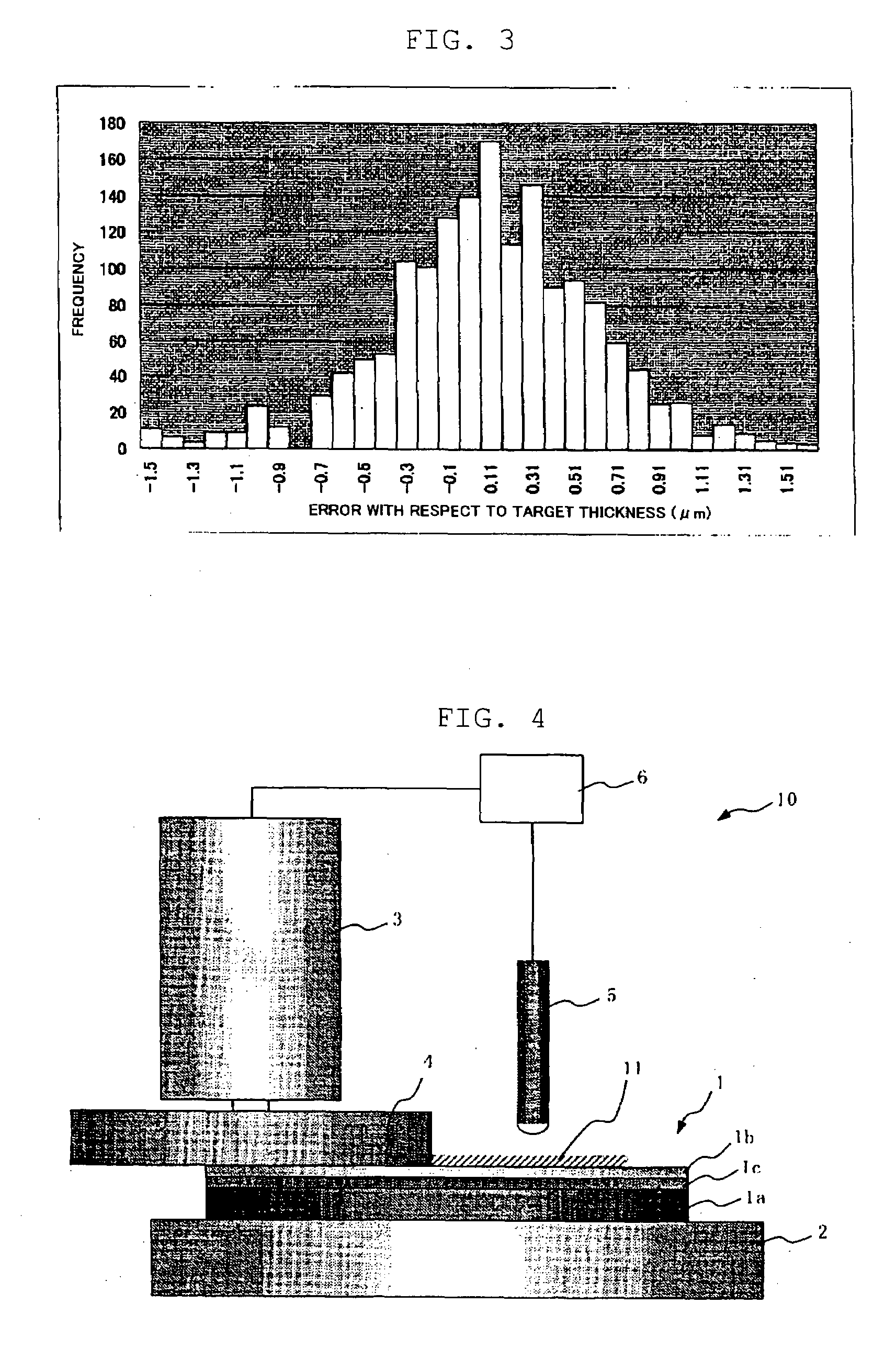

Method for Producing Bonded Wafer, Bonded Wafer, and Surface Grinding Machine

InactiveUS20090233109A1Reduce uneven thicknessAccurate acquisitionSemiconductor/solid-state device testing/measurementLayered productsWaferingSingle crystal

The present invention is a method for producing a bonded wafer, comprising at least: bonding a base wafer serving as a support substrate to a bond wafer made of a silicon single crystal via an insulator film or directly bonding the wafers to provide a bonded wafer; and reducing a thickness of the bond wafer to form a thin film made of the silicon single crystal on the base wafer, wherein the thickness of the bonded wafer is reduced based on at least surface grinding while measuring the thickness of the bond wafer, and surface grinding with respect to the bond wafer is stopped when the thickness of the bond wafer reaches a target thickness. As a result, the method for producing a bonded wafer enabling a silicon single crystal thin film to precisely have a desired film thickness, a bonded wafer, and a surface grinding machine enabling a silicon single crystal thin film to precisely have a desired film thickness are provided.

Owner:SHIN-ETSU HANDOTAI CO LTD

Mask and fabrication method thereof and application thereof

ActiveUS7648804B2Improve uniformityReduce manufacturing costPhotomechanical apparatusSemiconductor/solid-state device manufacturingPhase shiftedTransmittance

A mask including a transparent substrate, a semi-transparent layer and a film layer is provided. The transparent substrate at least has a first region, a second region and a third region. The semi-transparent layer covers the second region and the third region of the transparent substrate and exposes the first region. The film layer covers the halftone layer disposed at the third region, to make the transmittance of the third region lower than that of the second region. The halftone layer and the film can be made of phase shift layers, to form a phase shift mask. Besides, several fabrication methods of the mask are also disclosed to form the above-mentioned mask.

Owner:AU OPTRONICS CORP

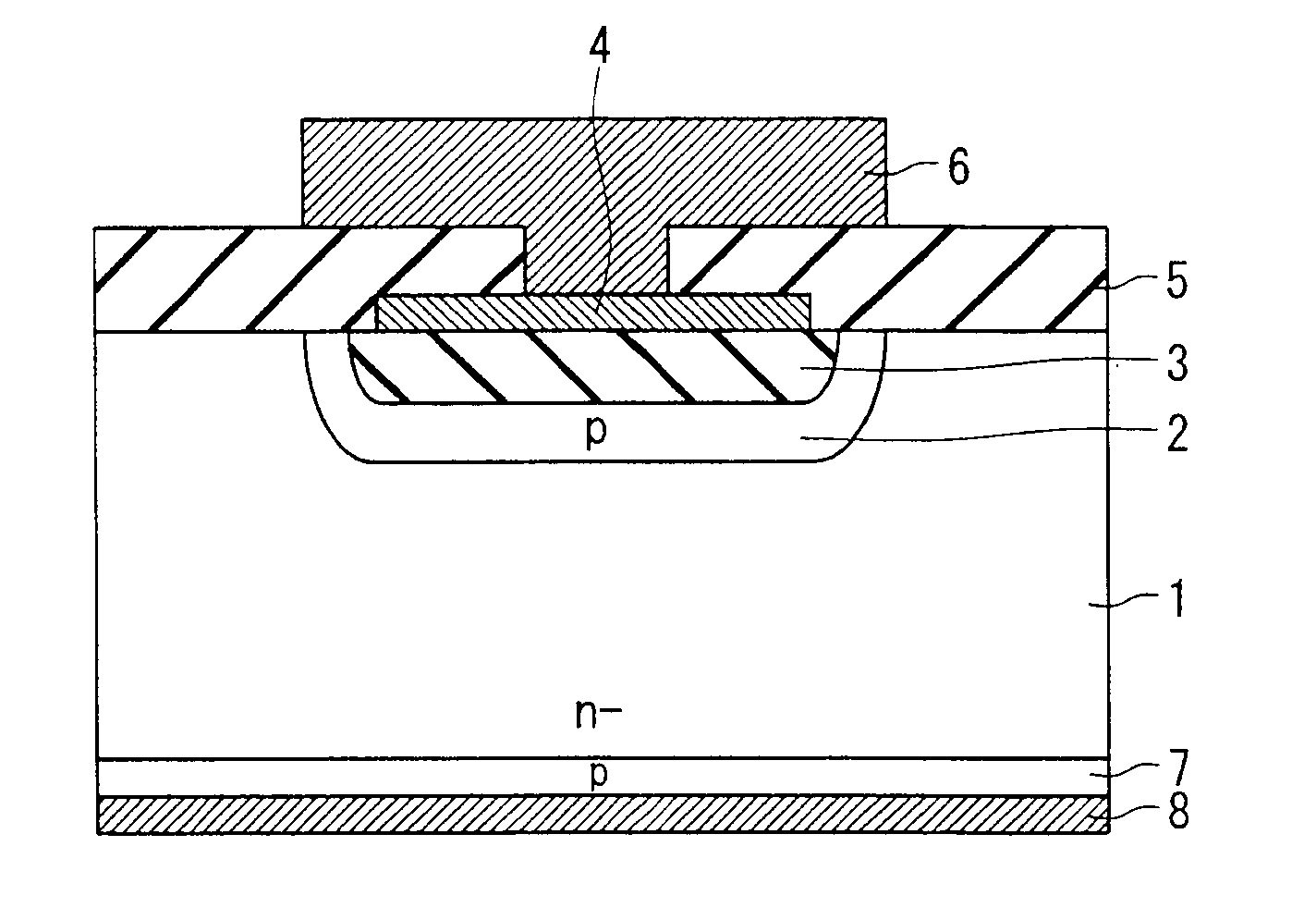

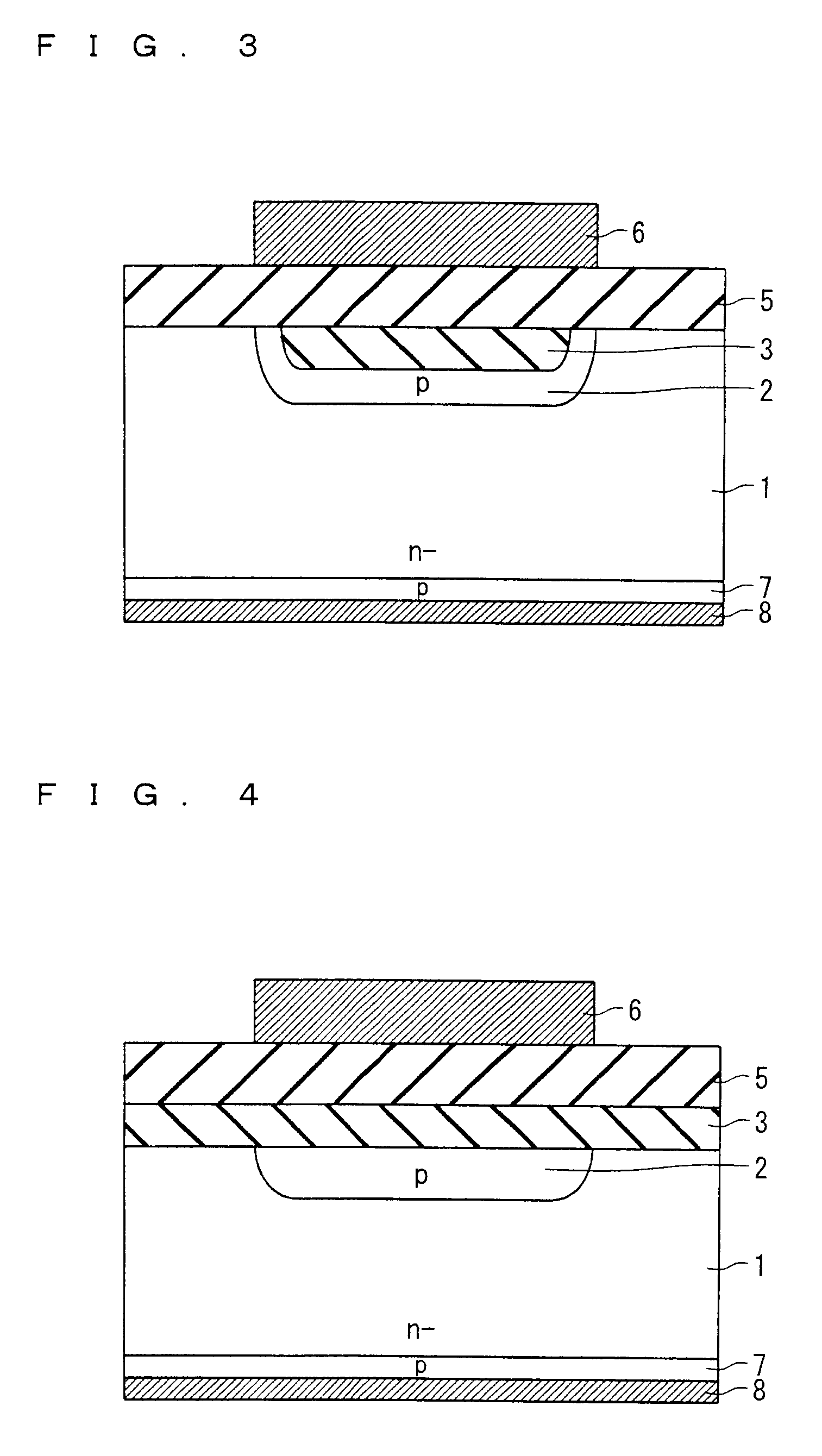

Power semiconductor device

ActiveUS8552428B2Reduce unevennessReduce uneven thicknessSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSemiconductor

Owner:MITSUBISHI ELECTRIC CORP

Imprinting apparatus, imprinting method, and article manufacturing method

ActiveUS9946173B2Reduce uneven thicknessReduce unevennessPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineering

Owner:CANON KK

Shell of ring-in-ring casting of K4169 high-temperature alloy

InactiveCN108788015ASmall coefficient of thermal expansionGuaranteed dimensional accuracyFoundry mouldsFoundry coresSurface layerThermal expansion

Owner:SHANGHAI WANZE PRECISION CASTING CO LTD

Method of controlling a drug release rate

A method of controlling the drug release rate of a drug coated endovascular stent by depositing a drug material layer on the stent and then modifying the drug material using gas cluster ion beam irradiation to create a carbon matrix with interstices containing the original drug. The rate at which the drug elutes through the interstices can be controlled by processing parameters. Multiple layers may be employed to create time varying release rates.

Owner:EXOGENESIS CORP

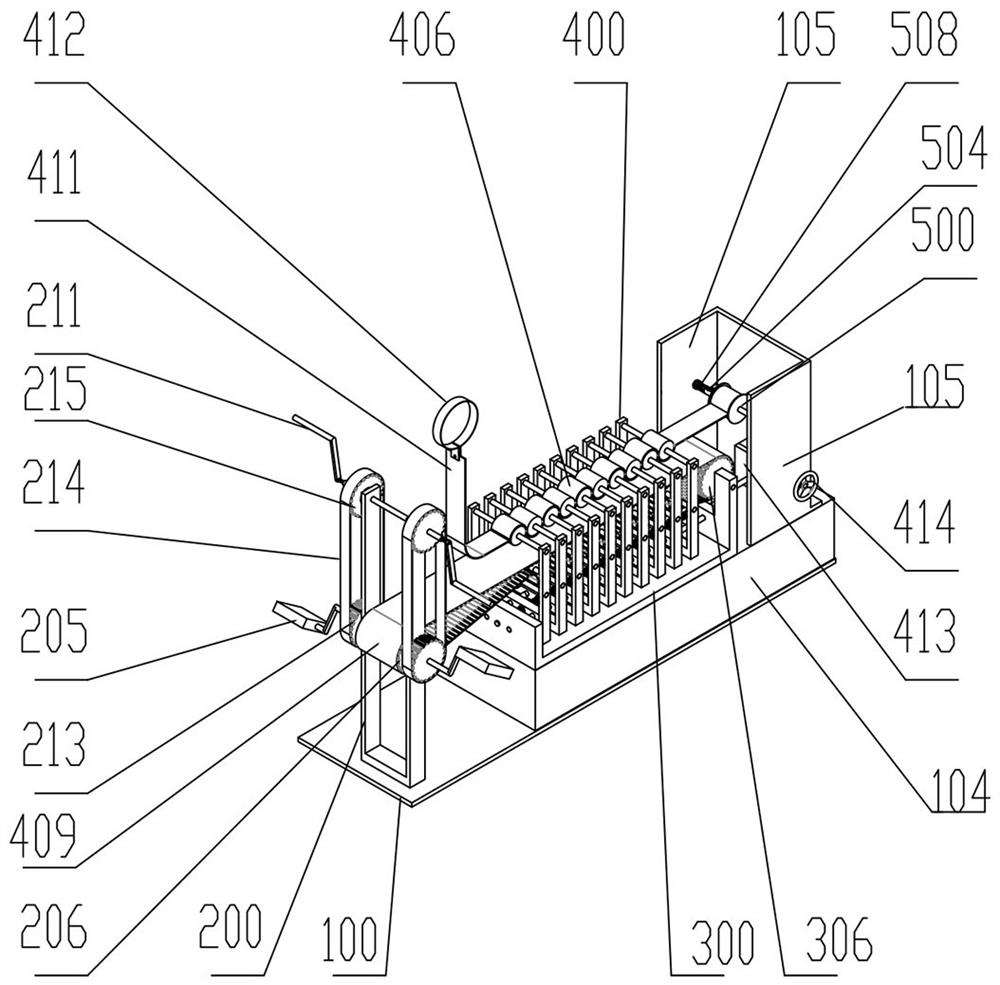

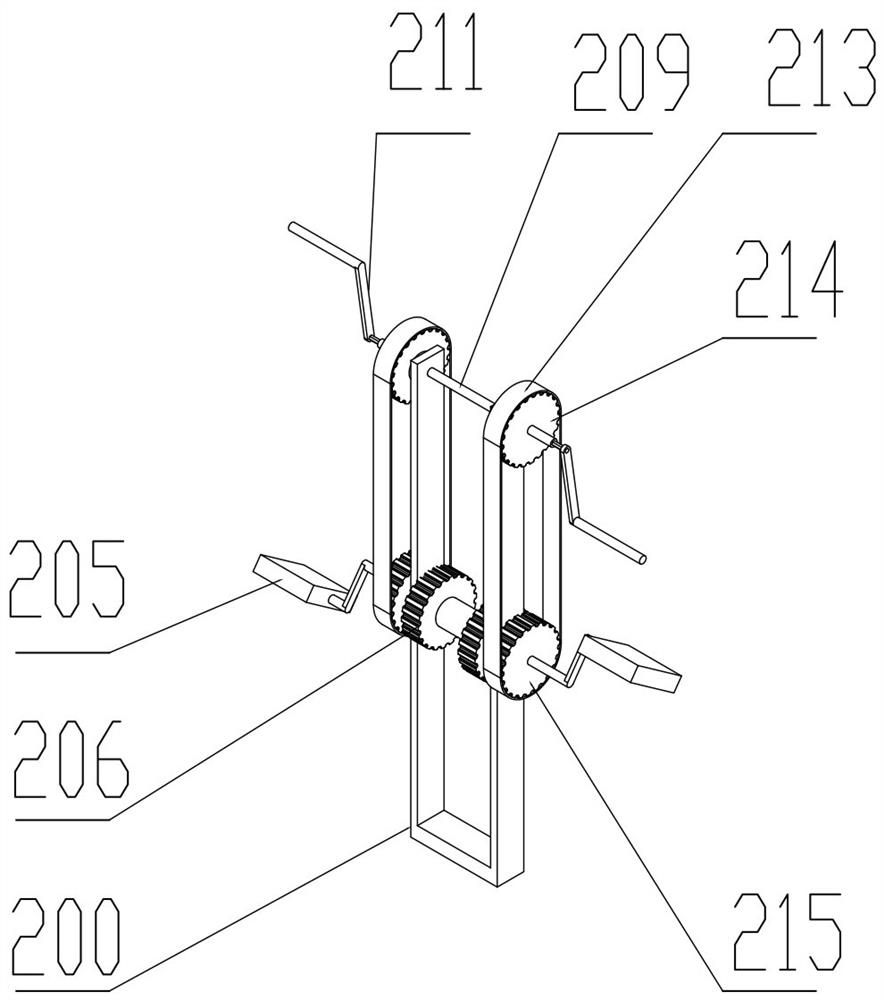

Continuous baked pancake production line capable of adjusting thickness

ActiveCN109673693ARealize dynamic adjustmentAffect uniformityDough-sheeters/rolling-machines/rolling-pinsBaking plantsEngineeringManufacturing line

The invention discloses a continuous baked pancake production line capable of adjusting thickness, and belongs to the technical field of food processing machines. The continuous baked pancake production line capable of adjusting the thickness is characterized by comprising a material feeding cylinder, a dough pressing unit and a conveying unit which are successively arranged from top to bottom, abaked pancake unit arranged on the conveying unit, and a power driving unit for driving the dough pressing unit and the conveying unit; the continuous baked pancake production line further comprises an adjusting unit arranged at one side of the dough pressing unit and mutually connected with the dough pressing unit; and a machine case is arranged outside the dough pressing unit, the power drivingunit and the adjusting unit. The continuous baked pancake production line capable of adjusting the thickness provided by the invention has the beneficial effects of being capable of dynamically adjusting the thickness of a baked pancake, and being uniform in thickness of the baked pancake, high in operation efficiency, low in energy consumption, and convenient to operate.

Owner:徐州花千树农业发展有限公司

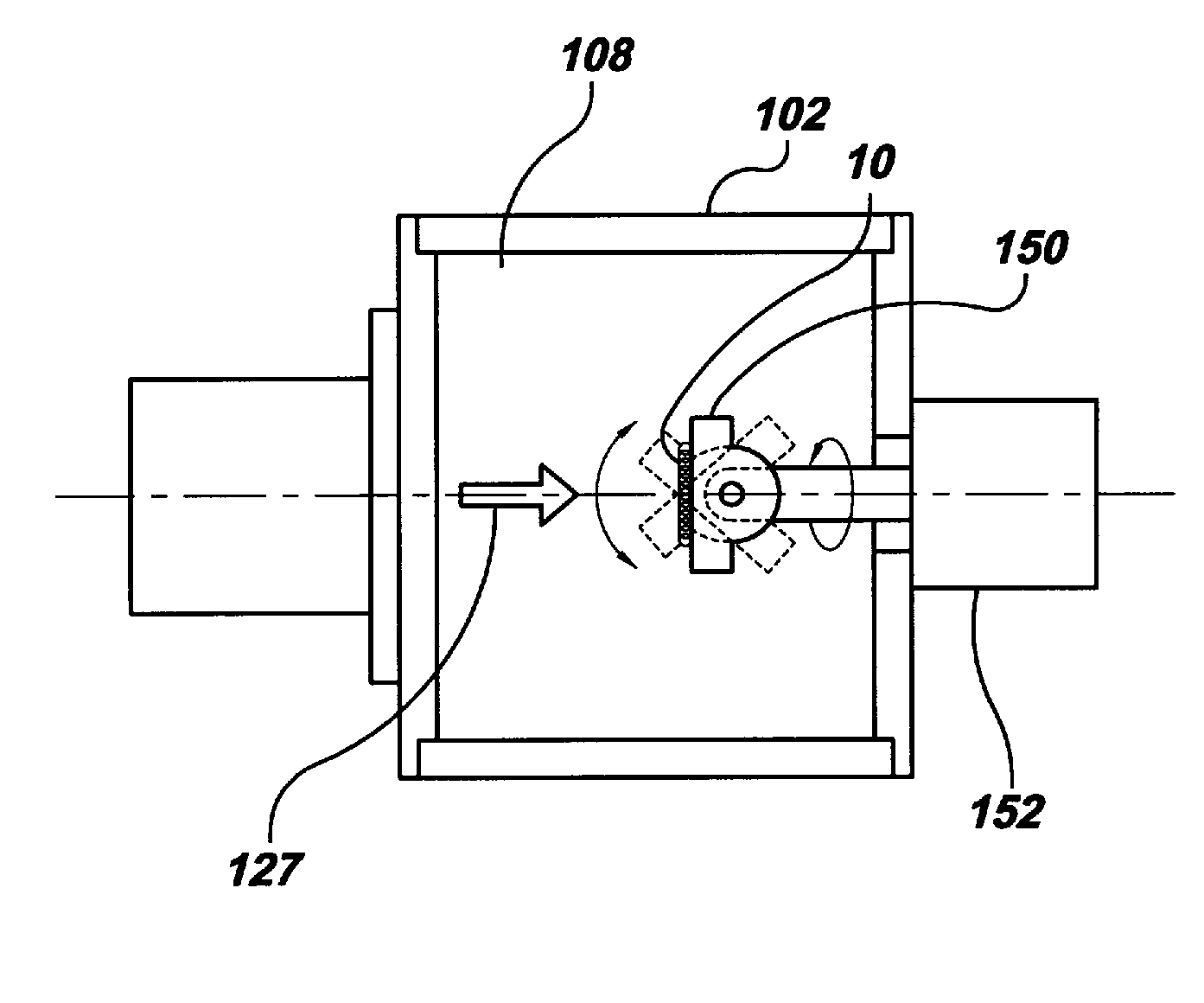

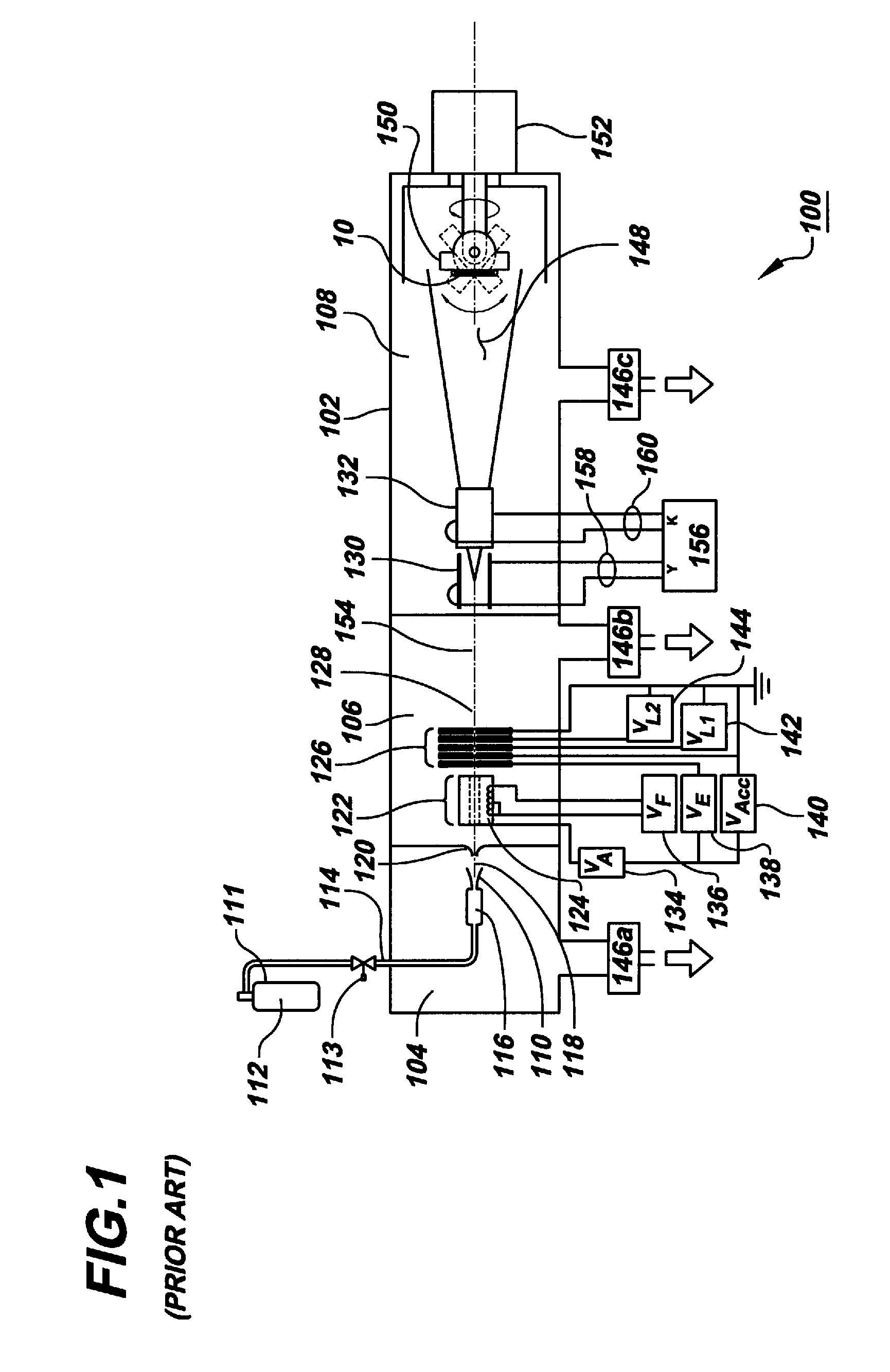

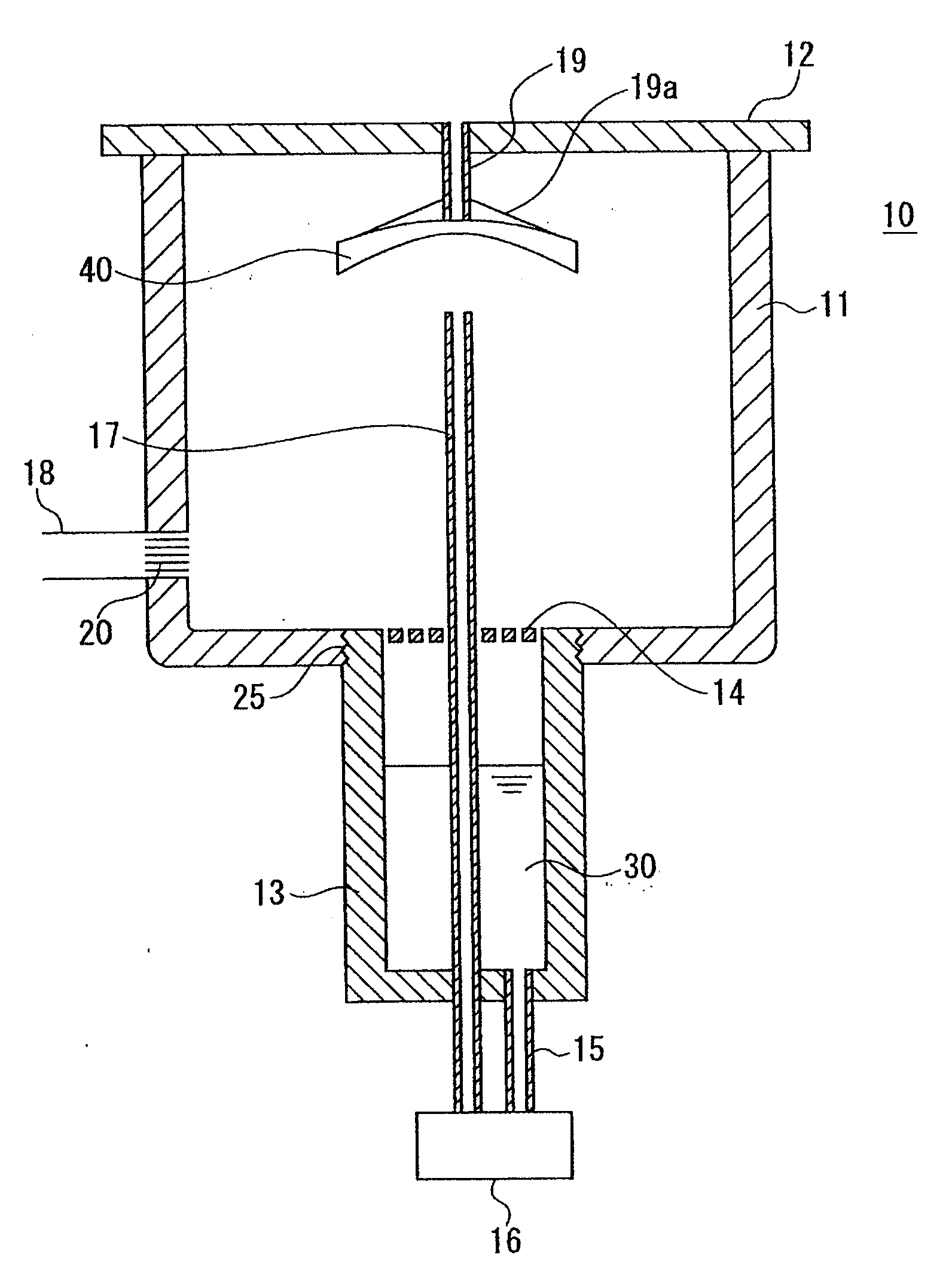

Coater and method of manufacturing plastic lens

InactiveUS20110008533A1Avoid treatmentReduce uneven thicknessSpraying apparatusVacuum evaporation coatingReducerEngineering

A coating device includes a treatment tank capable of being hermetically-sealed, a substrate holder contained in the treatment tank, a rotation mechanism for rotating the substrate holder, a nozzle for spraying a coating material to a substrate held by the substrate holder, and a partial pressure reducer for reducing partial pressure of a volatile component derived from the coating material inside the treatment tank. The coating device not only prevents dust from entering a treatment tank by sealing the treatment tank hermetically, but also reduces unevenness in thickness of the coating film in the case where the coating treatment is performed to a plurality of lenses.

Owner:HOYA CORP

A graphite disc base

ActiveCN107058978BReduce uneven thicknessEasy to spreadSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGraphiteComputer science

Owner:HC SEMITEK ZHEJIANG CO LTD

Multifunctional fitness device and operation method

InactiveCN113559461AReduce CatonReduce curlingResilient force resistorsFrictional force resistorsVehicle frameCrank

The invention discloses a multifunctional fitness device and an operation method. The device comprises a bottom plate, an outer roller carrier, an outer roller, a frame, pedals, a first synchronous wheel, a crank, a third synchronous wheel, a second synchronous belt, a fourth synchronous wheel, a distance adjusting seat, a guide rod, a shaft, a second synchronous wheel, a second synchronous wheel hole, a lead screw, a nut, a roller seat, a roller, a connecting rod, a first synchronous belt, a pull belt, a turbine speed reducer, a winding drum, a winding shaft, a transmission shaft, a spring, a rotating shaft and a nut. The outer side of the bottom plate is fixedly connected with a hood, the left side of the bottom plate is fixedly connected with the frame, the middle of the frame is provided with a frame groove, the upper portion of the frame is provided with a pedal hole, the upper portion of the pedal hole is provided with a crank hole, the middle of the pedal hole is provided with a pedal shaft, the pedal shaft penetrates through the pedal hole, the pedal shaft is rotatably connected with the pedal hole and rotates in the pedal hole, and the two sides of the pedal shaft are fixedly connected with the pedals. A first synchronizing wheel is arranged in the middle of the frame groove.

Owner:JIAMUSI UNIVERSITY

Flat fluorescent lamp

InactiveCN101170048AIncrease brightnessImprove uniformityGas discharge lamp detailsCapacitanceGas-discharge lamp

A flat fluorescent lamp is disclosed. The flat fluorescent lamp comprises a gas discharge chamber, a fluorescent substance, a discharge gas, and a plurality of first and second electrodes. The fluorescent substance is disposed on an inner surface of the gas discharge chamber and the discharge gas is filled in the gas discharge chamber. An electrode pair includes the first and the second electrodes. The first and the second electrodes are disposed on different planes so that the discharge area formed between the first and the second electrodes is larger than that formed between the two electrodes on a same plane to perform better efficiency of luminance.

Owner:DELTA OPTOELECTRONICS +1

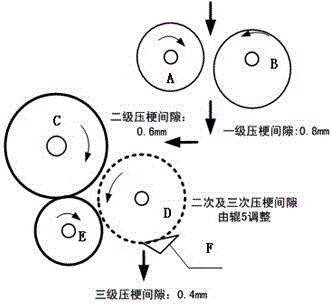

Method and apparatus for tobacco stem stagewise sheeting by microwave expansion

InactiveCN106036988AReduce the problem of large thickness reboundNot prone to sticking roller phenomenonTobacco treatmentMicrowaveEngineering

The invention provides a method and apparatus for tobacco stem stagewise sheeting by microwave expansion. The method includes: subjecting microwave-expanded tobacco stems (150%-180% in expansion) to primary stem sheeting, with tobacco sheet thickness being 0.8-1 mm after primary stem sheeting, performing secondary stem sheeting then to obtain thickness of 0.5-0.7 mm, and performing tertiary stem sheeting after secondary stem sheeting to obtain stem sheets having a thickness of 0.2-0.4 mm after triple stagewise stem sheeting. A press roller A and a press roller B form a primary sheeting unit, a press roller C and a press roller D form a secondary sheeting unit, and a tertiary sheeting unit is composed of press rollers D and E. The microwave-expanded tobacco sheets are produced by means of stagewise decrease from great thickness to little thickness, roller sticking rarely occurs during stem pressing by microwave expansion, the obtained stem sheets are uniform in thickness, subsequent shred productivity is significantly improved, few dregs occur, and stem slivers rarely form.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

a zro 2 twip steel mold powder for automobile and its application

The invention discloses ZrO2-contained vehicle TWIP steel continuous casting crystallizer protection slag and application thereof. The protection slag consists of the following oxide components in percentage by mass: 20-40% of CaO, 8-20% of SiO, 13-30% of Al2O3, 5-12% of Na2O, 1-6% of Li2O, 3-16% of BaO, 2-8% of MnO2, 4-13% of F-, 1.5-3.5% of ZrO2, 1.3-2.4 of (CaO+BaO) / Al2O3, 1.9-2.5 of CaO / SiO2, and 1.6-2.2 of Al2O3 / SiO2. The protection slag can be preferably applied to the continuous casting process of TWIP steel with 15-25 mass% of Mn and 2-4 mass% of Al.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com