Continuous baked pancake production line capable of adjusting thickness

An adjustable and production line technology, applied in the direction of dough sheeting machine/rolling machine/rolling pin, baking, baking workshop, etc., can solve the problems of cumbersome operation and shut down the production line, so as to reduce the number of use and avoid the level of The effect of turning around and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

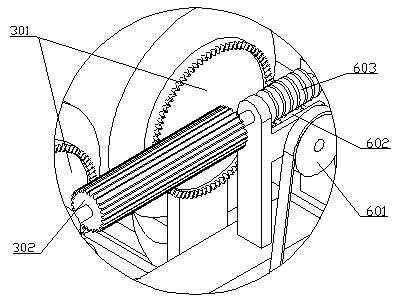

[0037]see Figure 1 to Figure 7 , the embodiment of the present invention provides a continuous pancake production line with adjustable thickness, including a feeding cylinder 1 arranged in sequence from top to bottom, a pressing unit and a conveying unit, a pancake unit 9 arranged on the conveying unit, and a driving press The power drive unit of the noodle unit and the transfer unit, which also includes an adjustment unit arranged on one side of the noodle pressing unit and connected to the noodle pressing unit;

[0038] The surface pressing unit, the power drive unit and the regulating unit are provided with a case 10 outside.

[0039] The specific features of the present invention are also that the pressing unit includes a first pressing roller 201 whose rotating shaft is rotatably matched with the cabinet 10, and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com