Net-knot-free screen printing plate

A kind of technology without net knot and screen, applied in screen printing machine, rotary printing machine, printing and other directions, can solve the problems such as difficulty in graphic drawing and film alignment, unsuitable for mass production, production efficiency restriction, etc. Achieve the effect of eliminating the influence of the net knot on the ink, improving the photoelectric conversion efficiency, and improving the printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

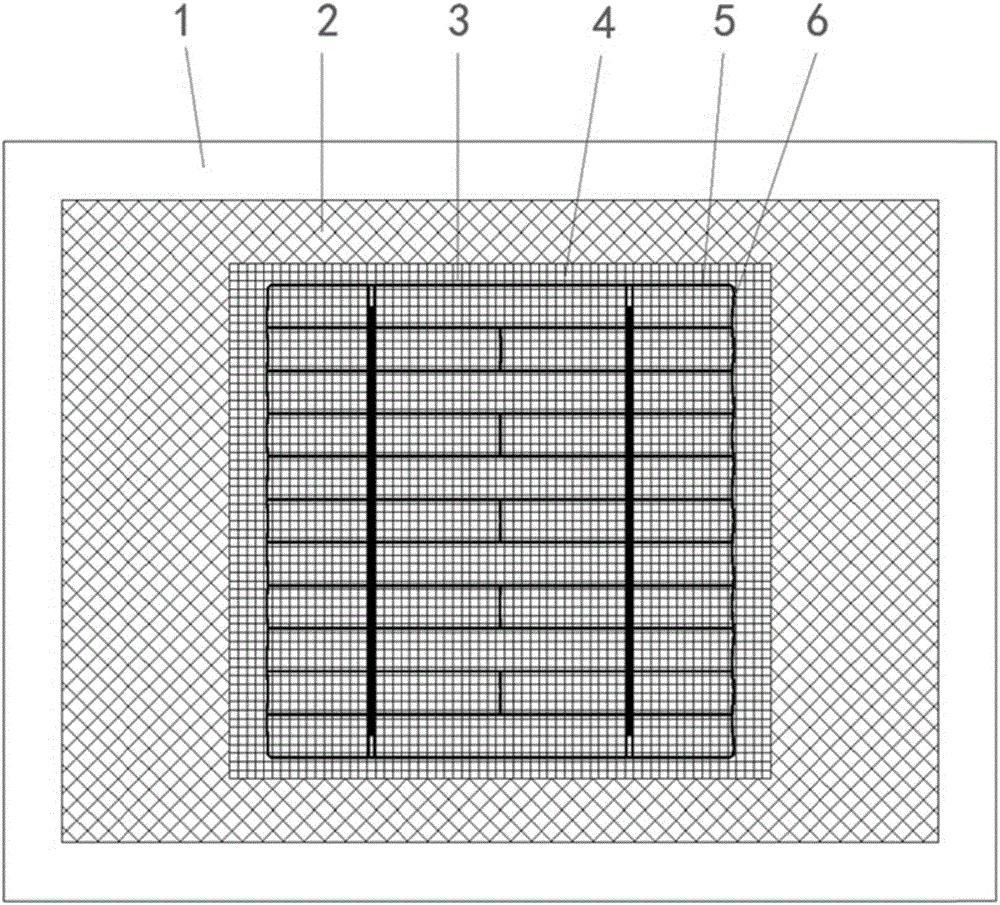

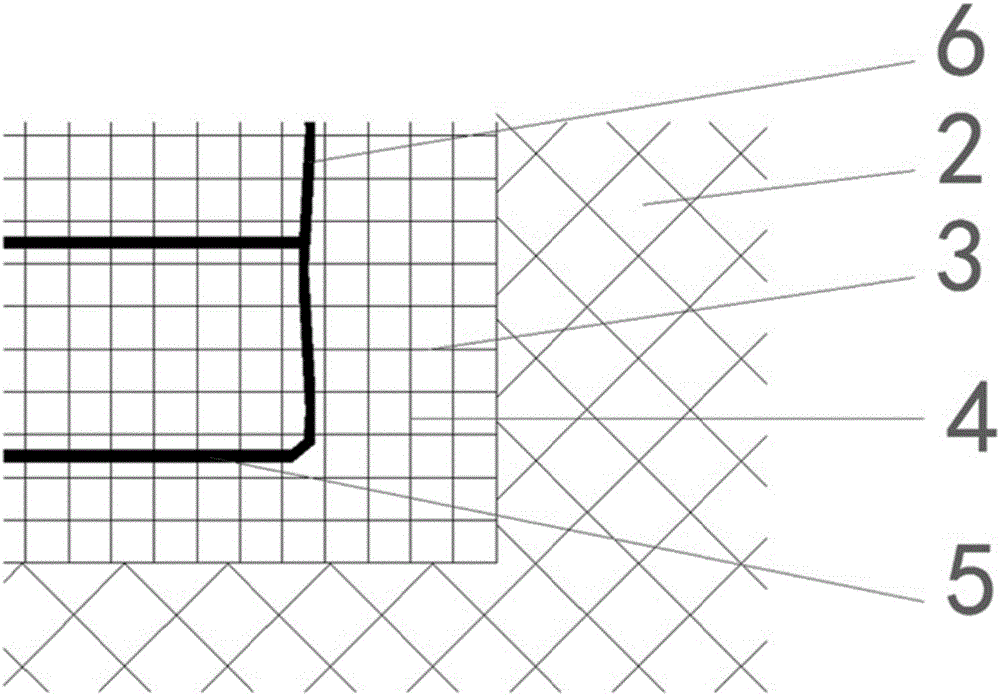

[0022] A kind of knotless screen plate provided by the invention, such as Figure 1-2 As shown, including the screen frame 1, the screen frame 1 is provided with several warp threads 3 and weft threads 4 obtained by stretching the wire mesh, the warp threads 3 and the warp threads 3 are arranged in parallel, the weft threads 4 and the weft threads 4 are arranged in parallel, and the warp threads 3 and weft 4 are vertically arranged, and the contact between warp 3 and weft 4 and screen frame 1 is fixed by bonding or compounded with polyester screen 2 to form a composite net and then bonded to screen frame 1. Make sure that the screen frame 1 is parallel or perpendicular to the warp 3 and weft 4, so as to avoid the problem of position deviation; the middle part of the screen fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com