Method for growing large-size silicon carbide single crystal

A silicon carbide single crystal, large-size technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problem of large-size silicon carbide single crystals without providing process parameters, and reduce the uneven heat generation. The effect of low overall cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: The specific structure of this application for growing a large-sized silicon carbide single crystal growth device:

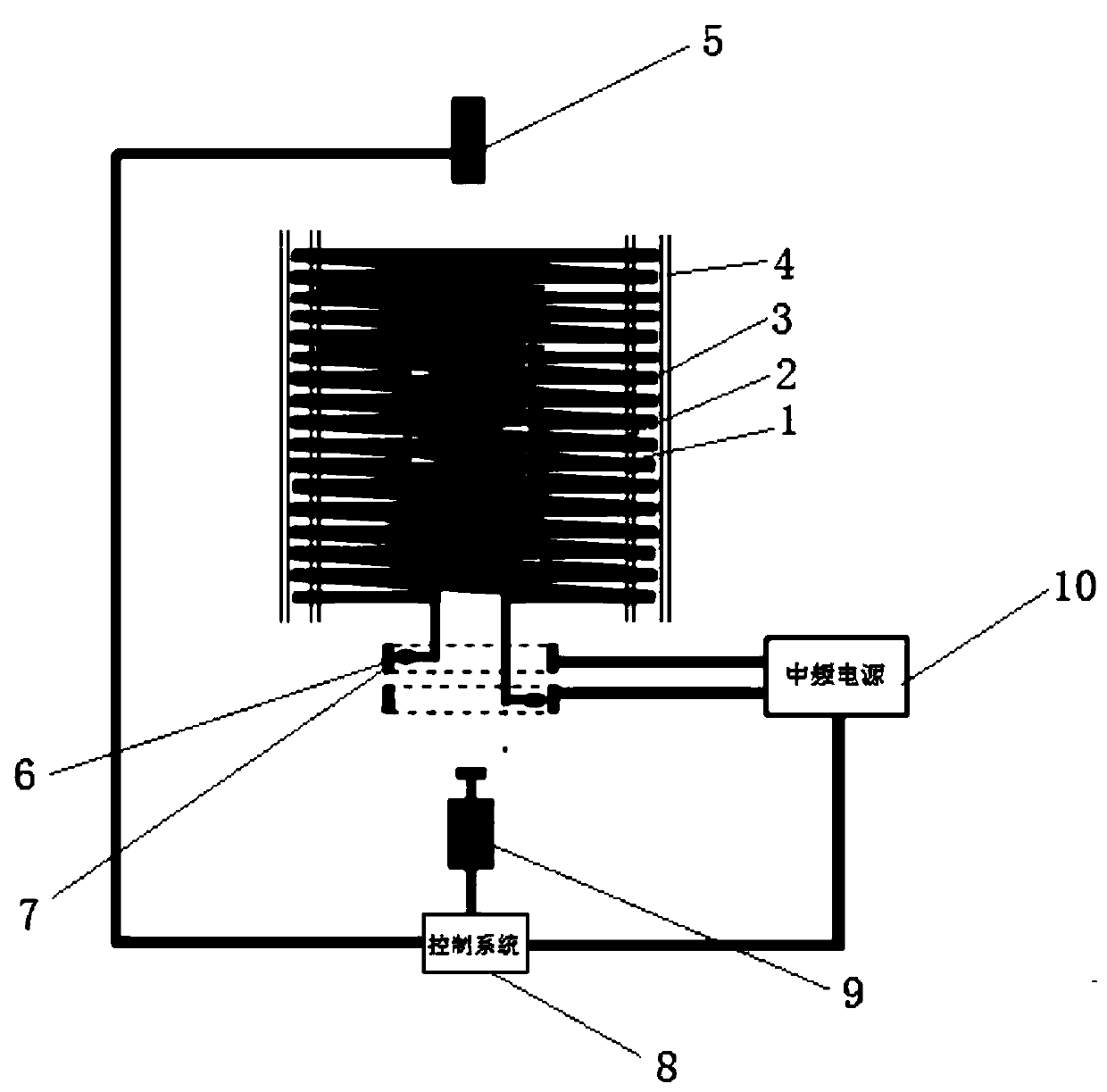

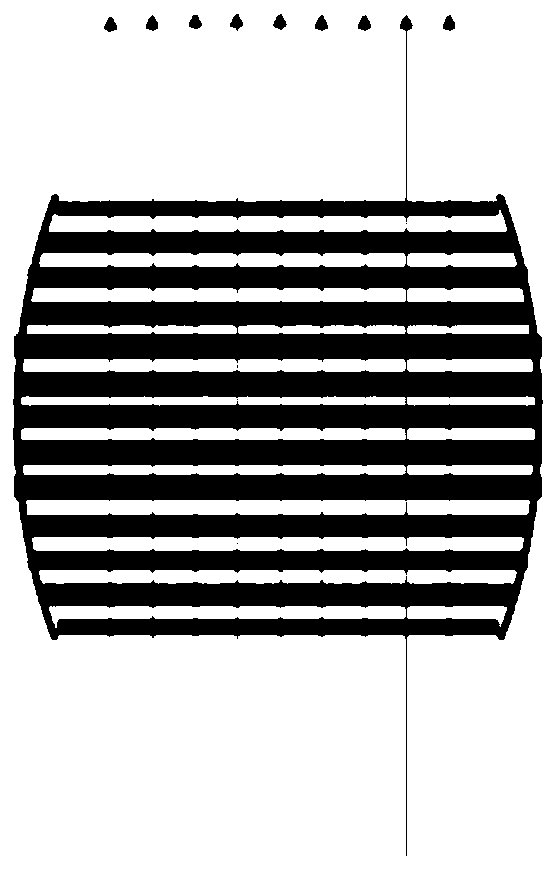

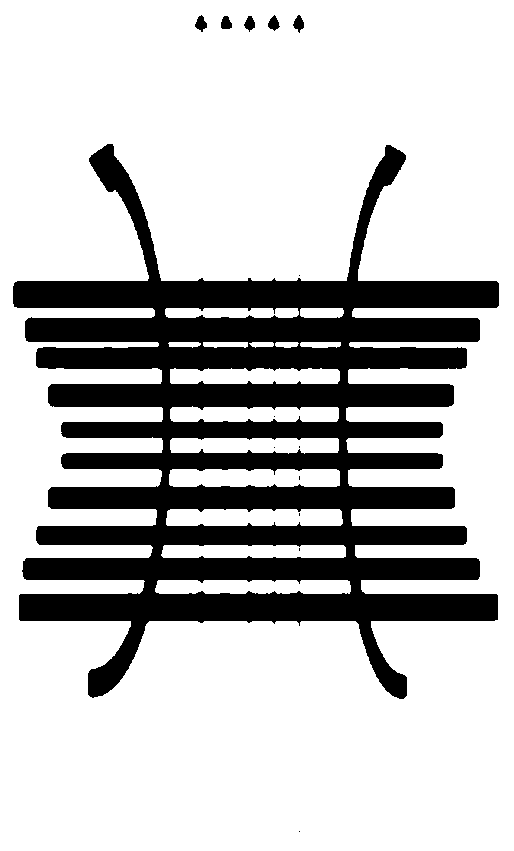

[0038] Such as figure 1 As shown, the silicon carbide single crystal growth device used to grow large-sized silicon carbide single crystals includes: a crystal growth chamber, a first quartz tube 2, an induction coil 3, and a second quartz tube 4. The crystal growth chamber is used for growing large-sized silicon carbide single crystals. Crystal; an induction coil 3, which is wound and arranged outside the first quartz tube 2, is used to heat the crystal growth chamber, and increases the magnetic field generated by the induction coil 3 by reducing the turn spacing of the coil and increasing the ratio of the coil height to the coil diameter uniformity, thereby improving the distribution uniformity of the temperature field in the crystal growth chamber; the induction coil 3 also rotates around the first quartz tube 2 through the provided rotating...

Embodiment 2

[0046] Example 2: Growth of silicon carbide single crystal

[0047] According to an embodiment of the present application, a growth method for growing a large-sized silicon carbide single crystal includes:

[0048] (1) Assembly stage: place raw materials and seed crystals in the crystal growth chamber, i.e. the graphite crucible 1, and place insulation felts on the bottom and sides of the growth device, and replace the atmosphere in the crystal growth chamber with a protective gas atmosphere;

[0049] (2) Heating and heating stage: the growth device is evacuated, and then a protective gas is introduced, and the absolute pressure in the growth device is maintained at 0.8×10 4 -1.2×10 4 Pa; the control system controls the power supply of the intermediate frequency power supply, and at the same time turns on the temperature measuring device, and starts to rotate the induction coil, and the induction coil rotates at a speed of 3-30r / min until the crystal growth chamber reaches 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com