Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178results about How to "Reduce release force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing soft magnet silicon-aluminium magnetic powder core

InactiveCN1622236ADoes not affect electromagnetic performanceReduce curing stressInorganic material magnetismInductances/transformers/magnets manufactureAl powderBreaking strength

The production process of soft magnetic Fe-Si-Al powder core includes the steps of compounding magnetic powder in different sizes, surface treatment, mixing magnetic powder, insulating agent, adhesive and demolding agent, molding, curing, magnetic heat treatment, soaking and surface coating. The present invention has the advantages of: breaking strength after curing in radial direction of 7-12 kg, less surface stripping, small demolding force, final breaking strength in radial direction of 17-24 kg, no influence of the insulating lacquer on electromagnetic performance and capability of realizing automatic production.

Owner:王锋 +1

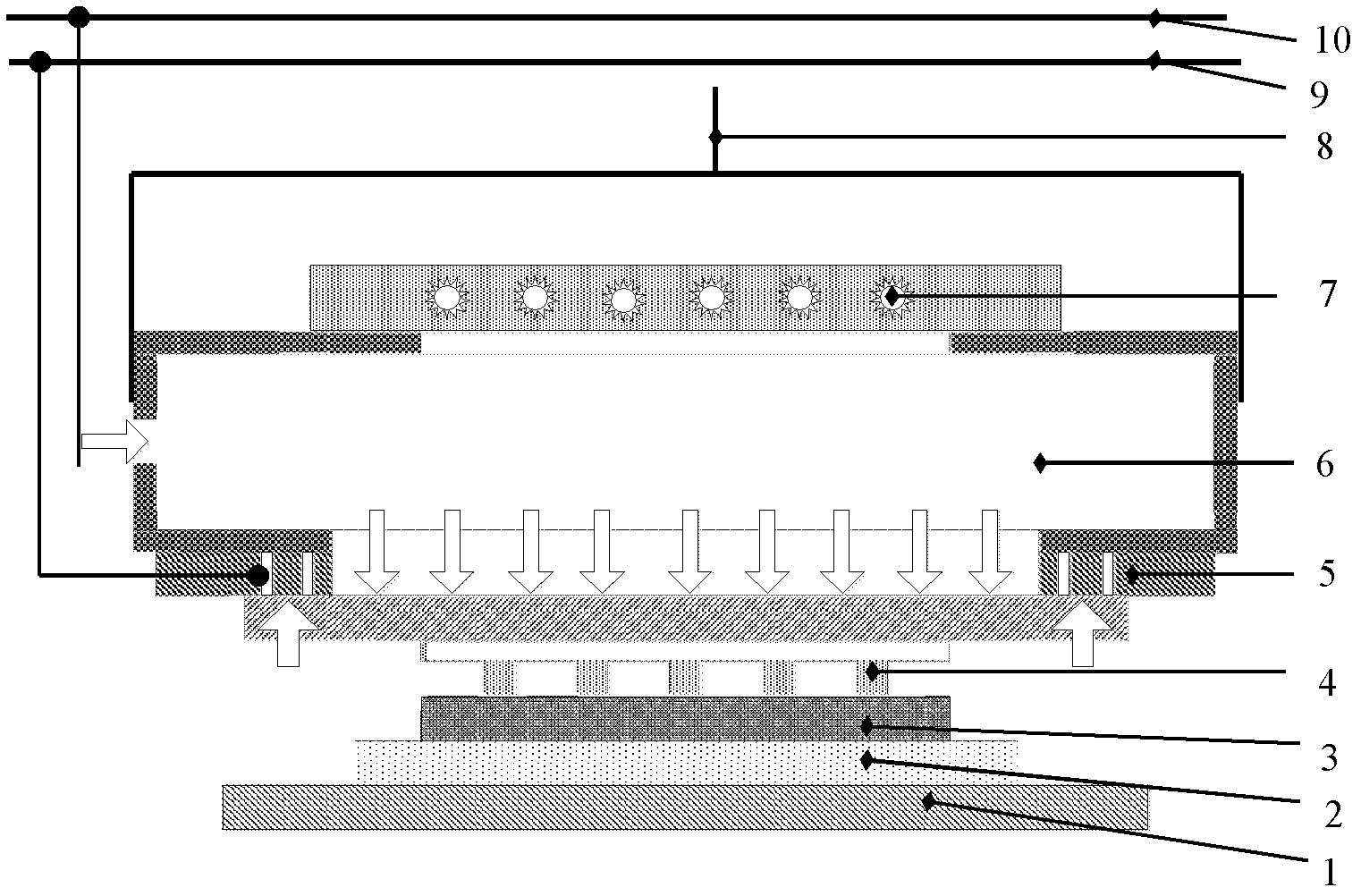

Device and method for large-area nano imprinting photoetching

ActiveCN102591143AHigh elastic modulusHigh complex precisionPhotomechanical apparatusNano structuringFluid control

The invention discloses a device and a method for large-area nano imprinting photoetching. A fluoropolymer-based thin film structure composite soft mould is introduced, and a gas assisting pressing mode and a mould micro-feed pressure pressing mode are adopted in the imprint process. The demoulding is carried out on the basis of low surface energy of a fluoropolymer base by a two-time solidifying and revealing type demoulding method, and thus the large area demoulding can be realized by small demoulding power. The device and the method for the large-area nano imprinting photoetching, disclosed by the invention, realize that a large-area nano-structure can be manufactured on various kinds of substrates, such as uneven (bent, cocked or stepped) substrates, curved substrates, or fragile substrates, and have the obvious advantages of high complex precision, large imprinting area, high efficiency, and low cost and a mould is long in service life. The device and the method for the large-area nano imprinting photoetching are suitable for LED (light emitting diode) nano-imaging technology and manufacturing of optical devices (such as optical lenses), butterfly solar condensers, micro-fluid control devices and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

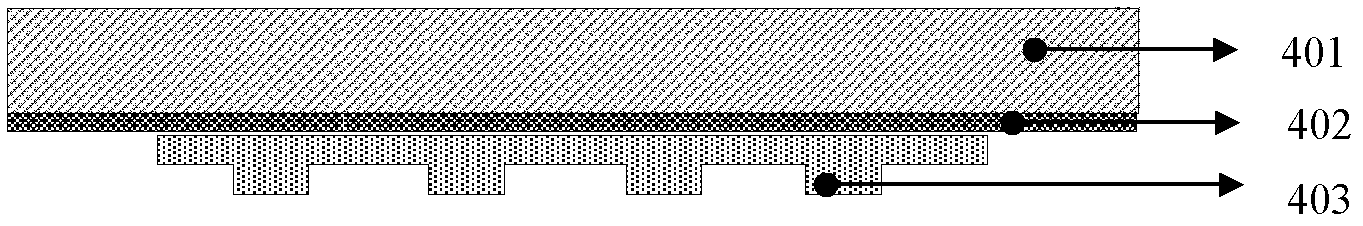

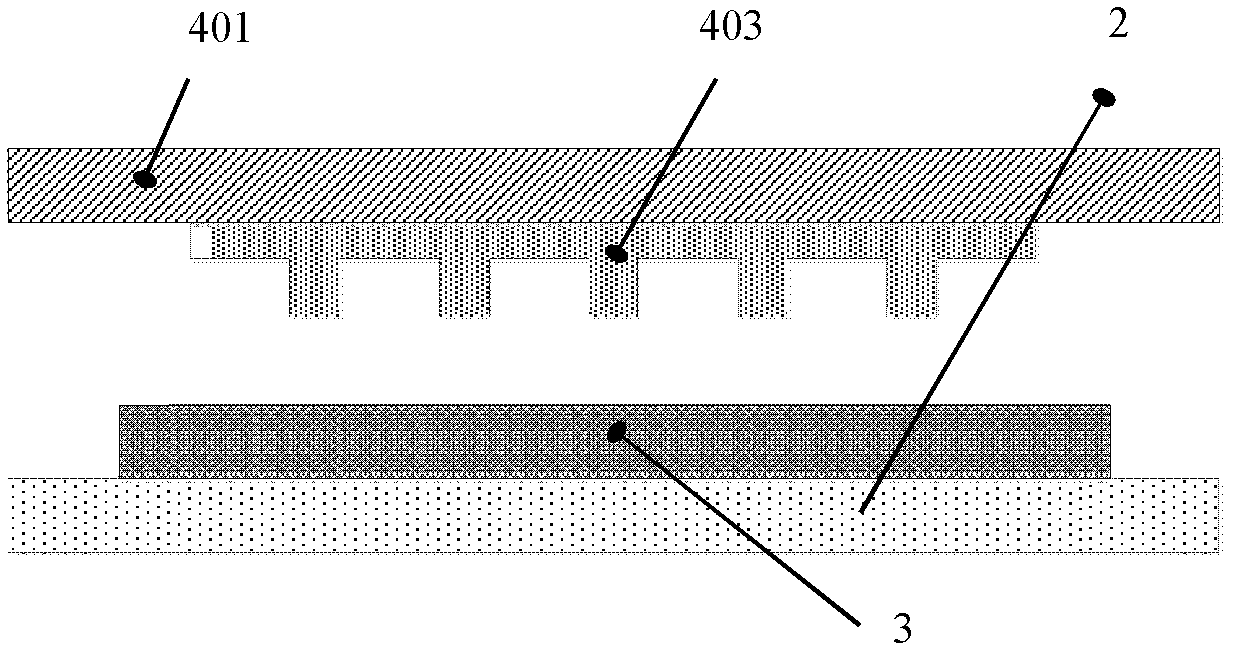

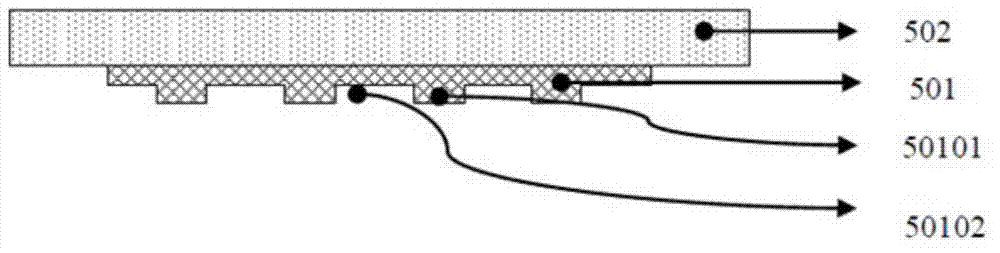

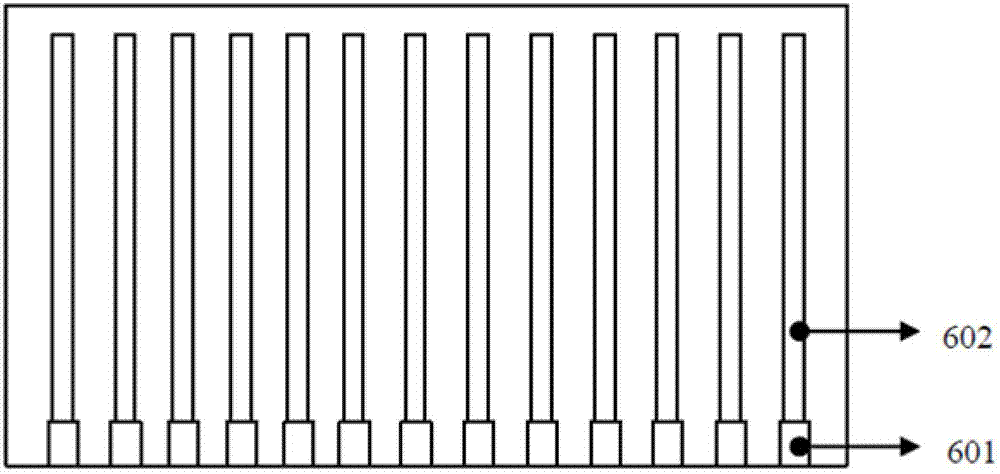

Nanometer impression device and nanometer impression method for high-brightness light-emitting diode (LED) graphics

ActiveCN102866582AReduce defectsGood removal effectNanoinformaticsPhotomechanical exposure apparatusSolubilityGraphics

The invention discloses a nanometer impression device and a nanometer impression method for high-brightness light-emitting diode (LED) graphics. The nanometer impression device comprises a wafer bearing platform, a vacuum sucking disc, a substrate, a ultraviolet light cured nanometer impression slushing compound and the like. A die is a thin film elastic composite flexible die and comprises a graphical layer and a supporting layer, wherein the graphical layer has the characteristics of water solubility, thin-film structure, elasticity and high transparency, and the die is manufactured by adopting a rolling impression process. The nanometer impression method for achieving high-brightness LED graphics based on the device comprises the steps of (1) pre-processing, (2) impression, (3) curing, (4) demoulding, (5) post-processing and (6) transferring of impression graphics. By means of the nanometer impression device and the nanometer impression method, a large-area, high-aspect-ratio micro-nanometer structure is efficiently manufactured on an unsmooth surface or a curved surface substrate or a fragile substrate with low cost. The nanometer impression device and the nanometer impression method are suitable for large-scale manufacture of optical devices, three-dimensional miniature batteries, micro-electromechanical system (MEMS) devices, photovoltaic devices, anti-reflecting layers, self-cleaning surfaces and the like and are especially suitable for the LED graphics and industrial-grade large-scale production of wafer-level splicing-free micro-optical devices.

Owner:兰红波

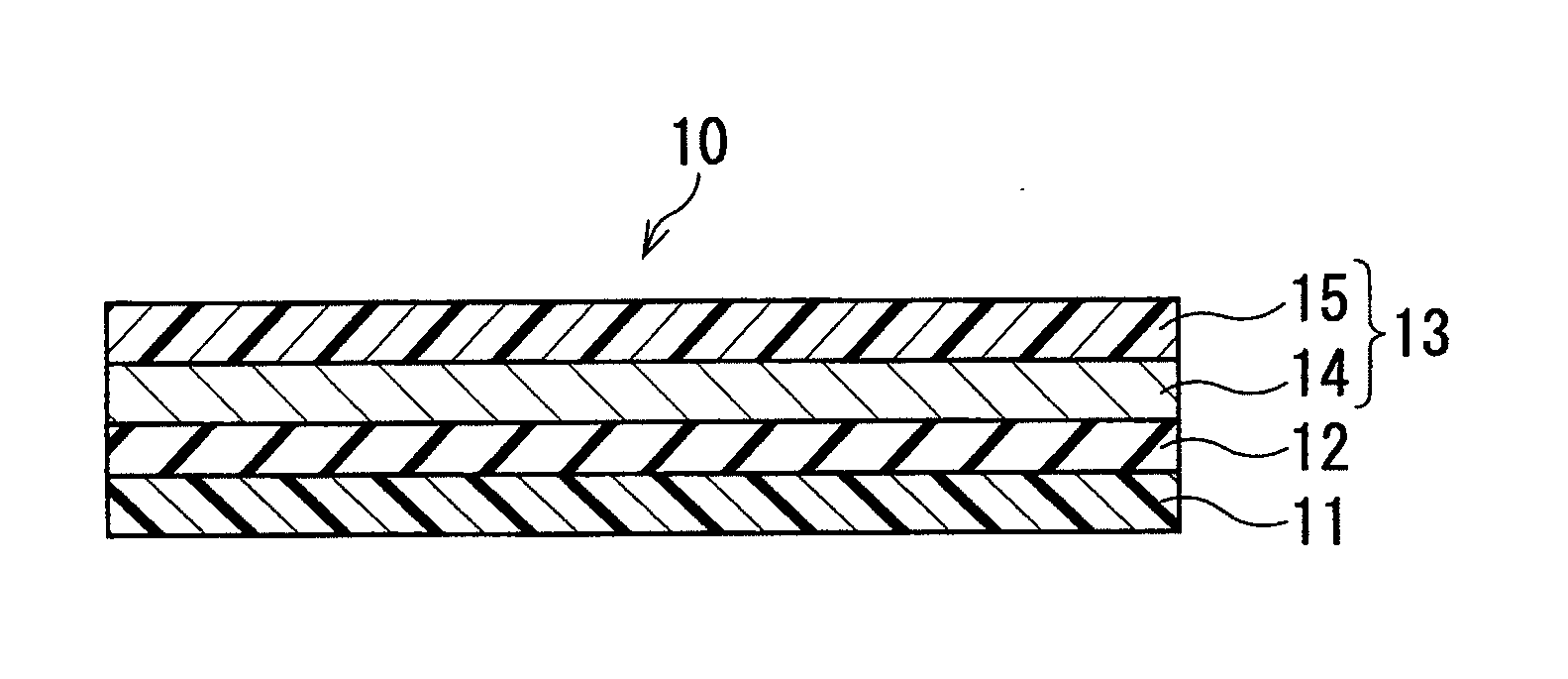

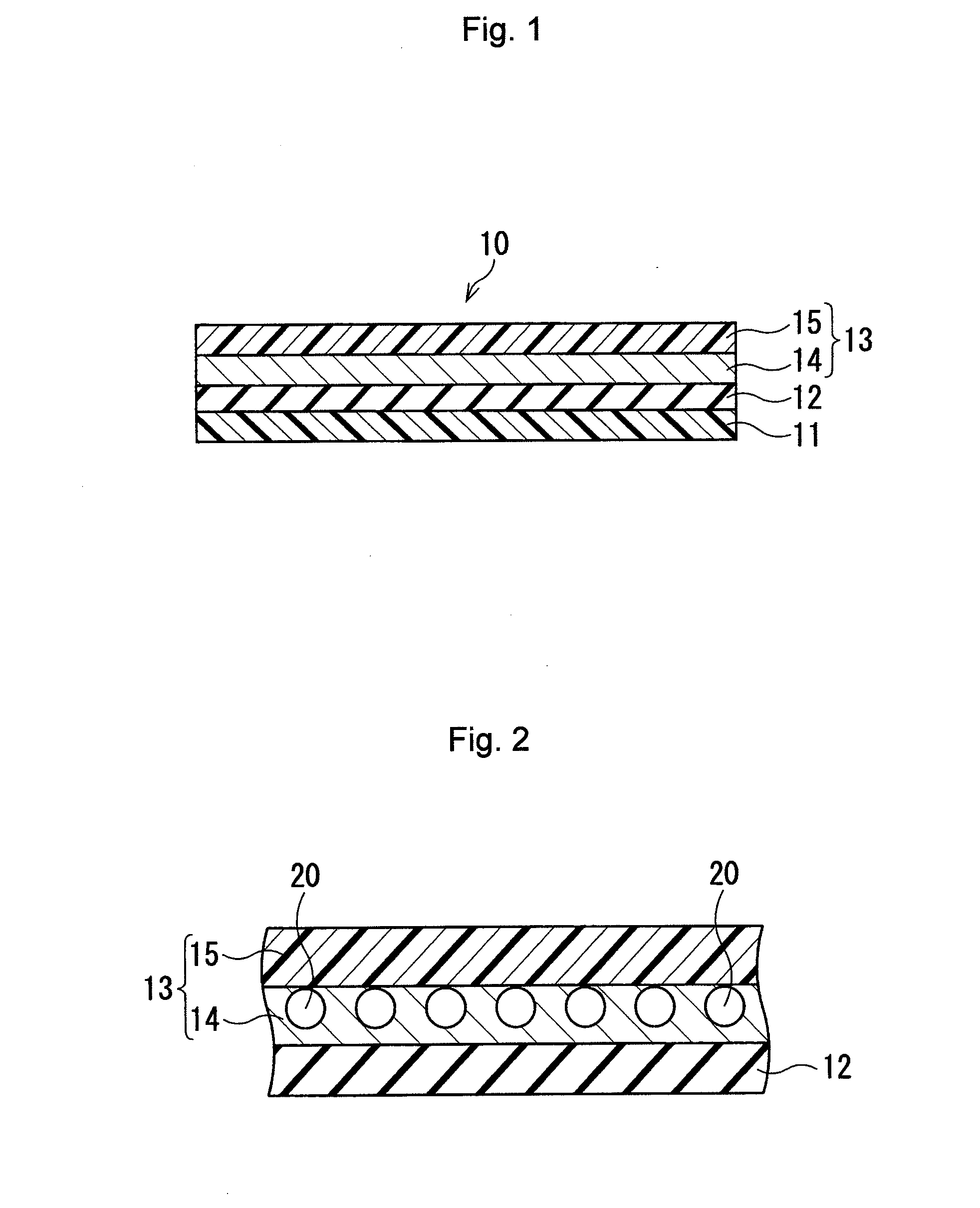

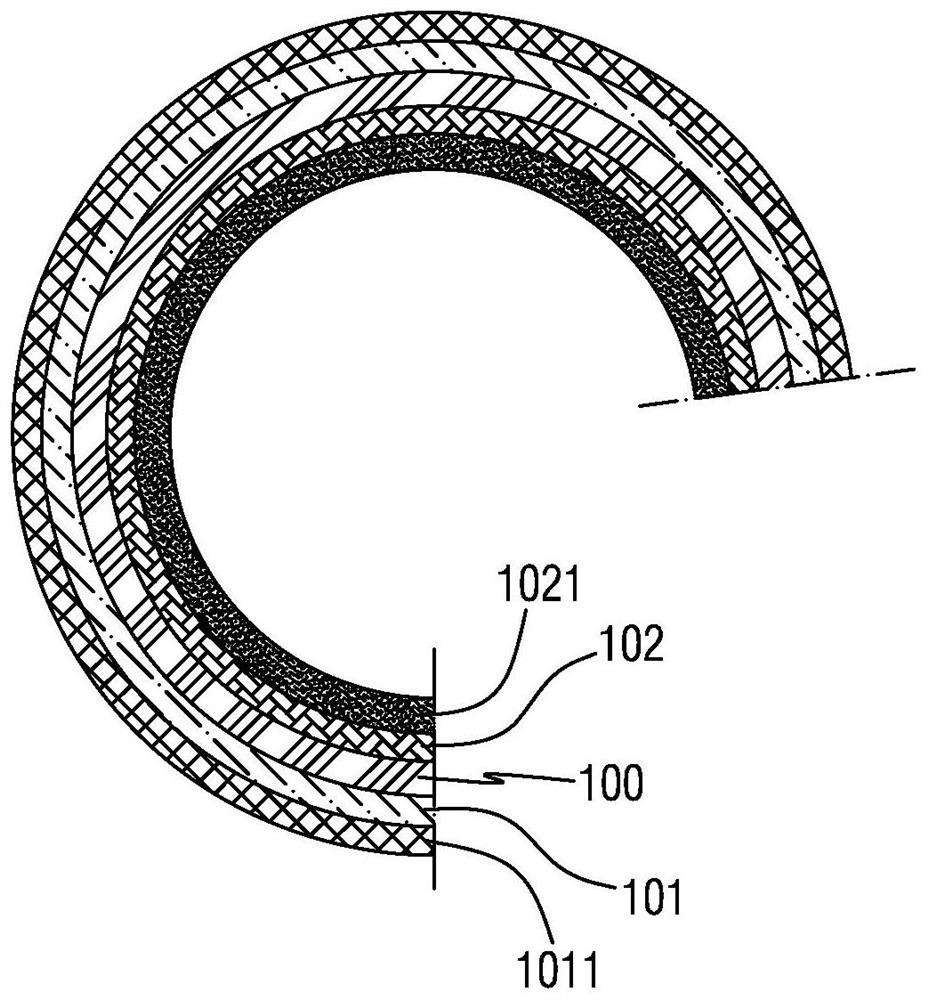

Adhesive sheet and release sheet

ActiveUS20070224378A1Reduce warpageReduce the impactAdhesive articlesSynthetic resin layered productsBiomedical engineeringRelease agent

There is provided an adhesive sheet comprising an adhesive base sheet, an adhesive layer, and a release sheet laminated in sequence from the adhesive base sheet. The release sheet comprises a release agent layer and a release base material laminated in sequence from the adhesive layer. A release force between the release sheet and the adhesive layer is decreased by an external stimulus.

Owner:LINTEC CORP

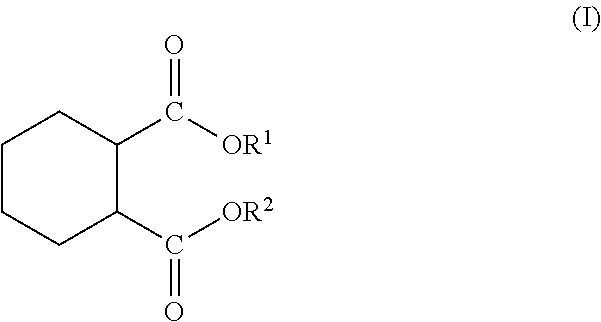

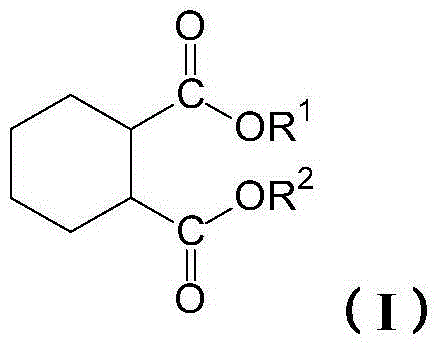

Thermoplastic polyurethanes composition and preparation processes thereof

This invention is directed to a thermoplastic polyurethanes composition comprising polyether-based thermoplastic polyurethane and 1,2-cyclohexane dicarboxylic acid ester and preparation processes thereof. The thermoplastic polyurethane composition has a good mold release behavior in injection molding without undesirably significant shrinkage and surface blooming of final product.

Owner:BASF SE

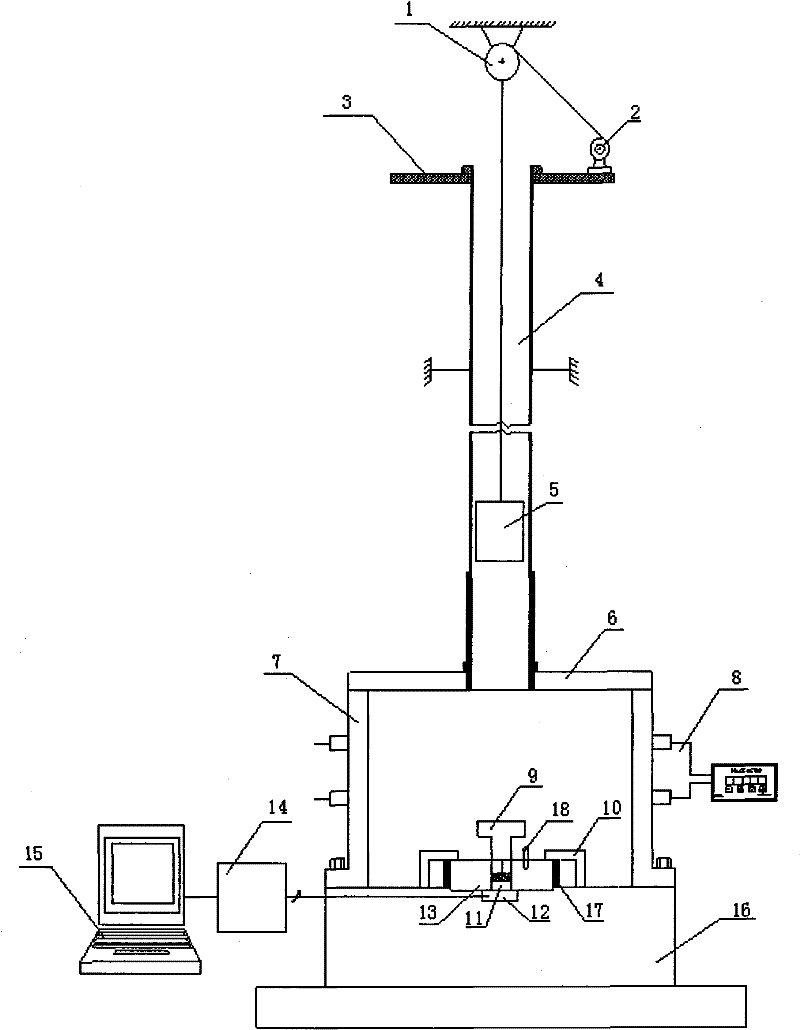

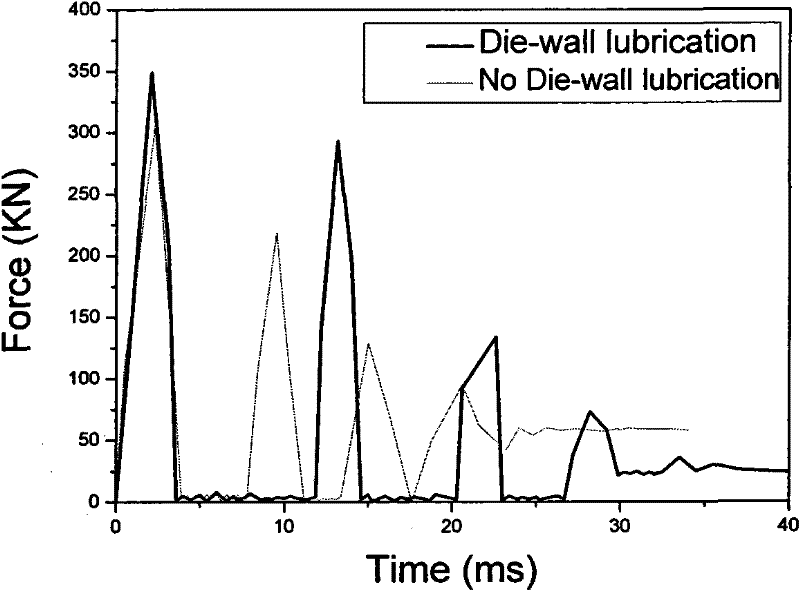

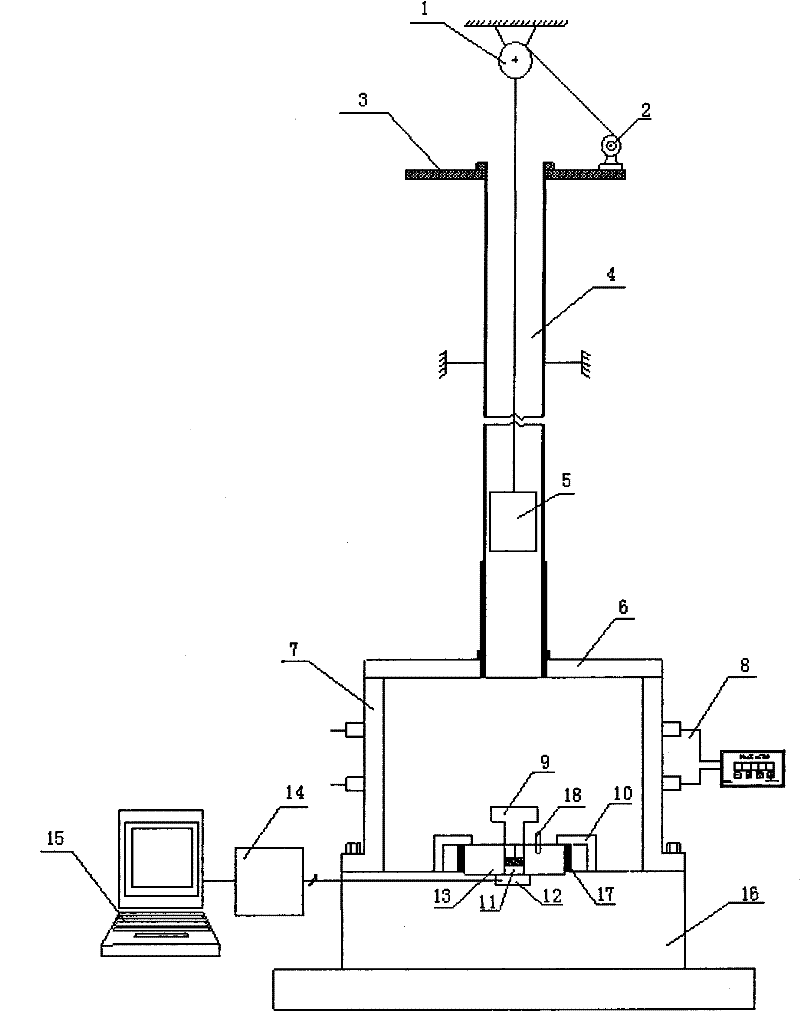

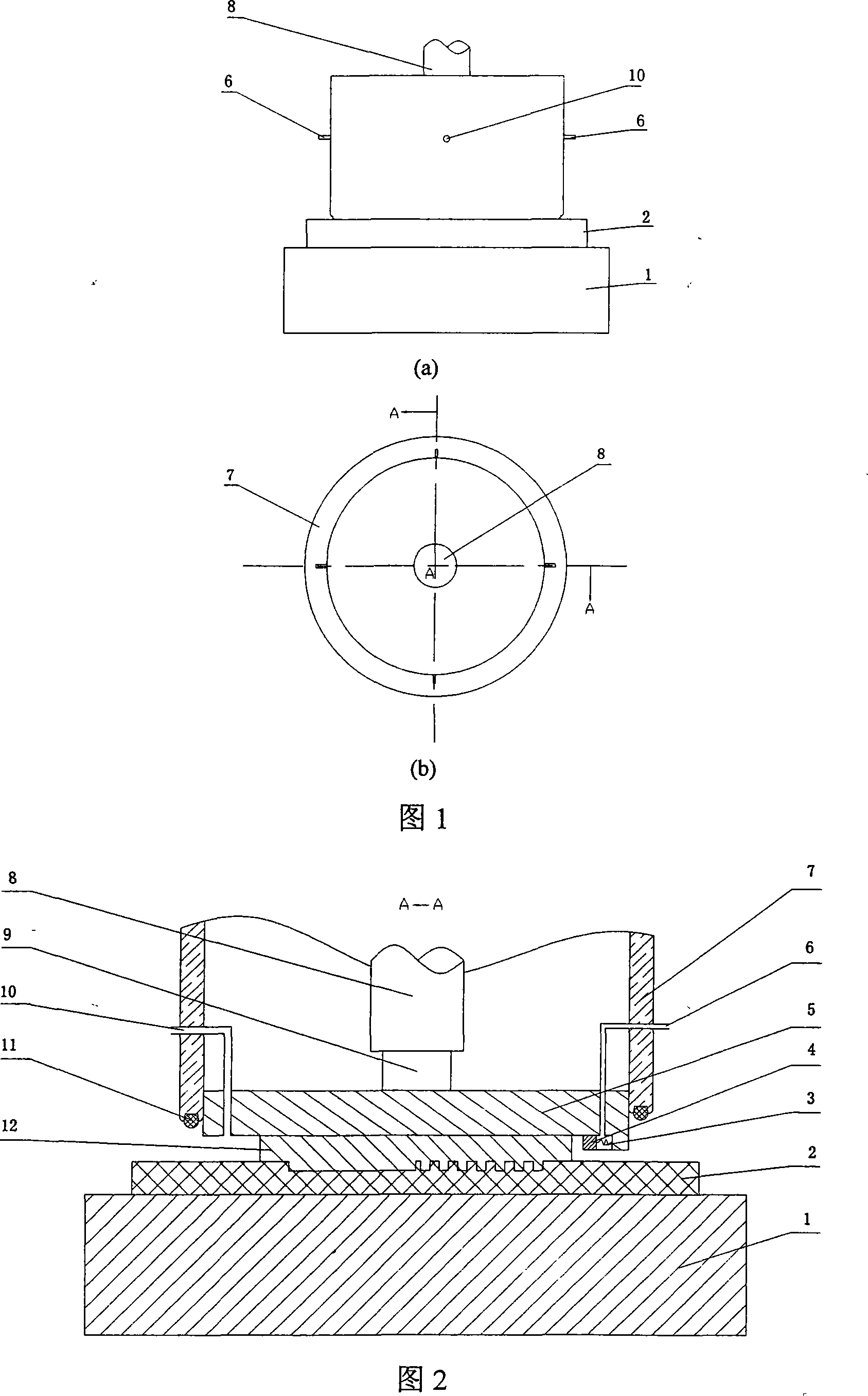

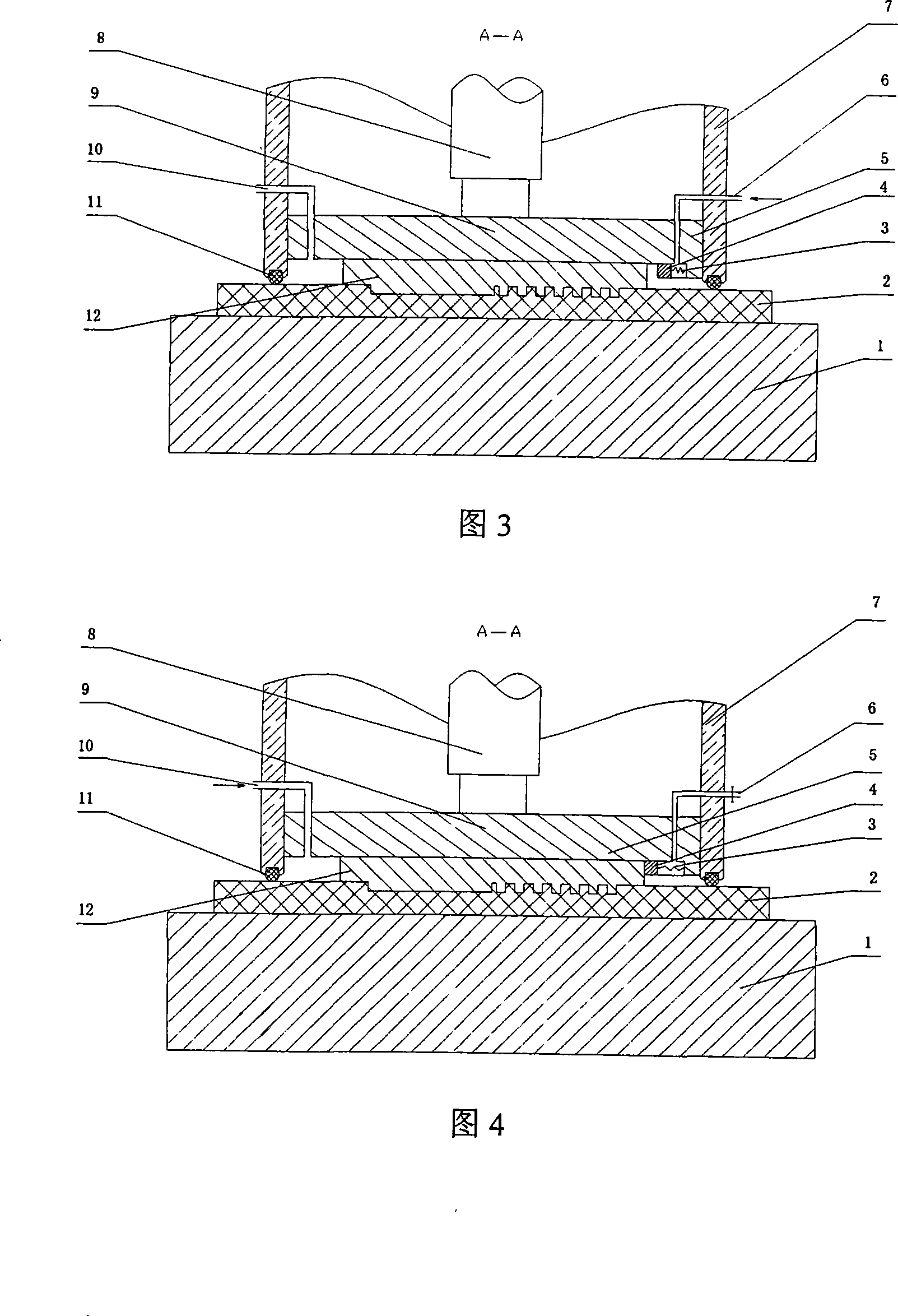

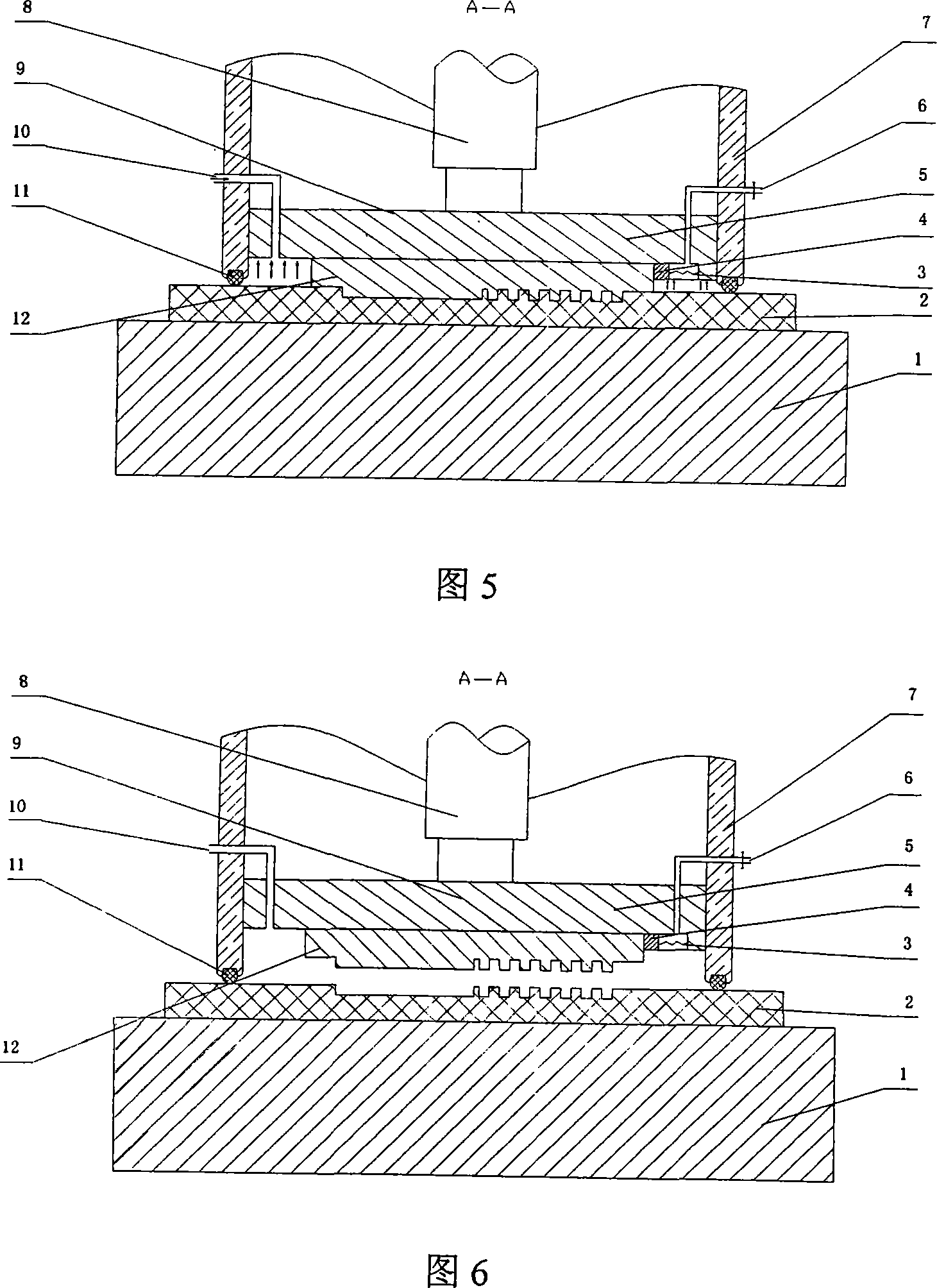

High speed pressing and forming method of warm powder and device thereof

InactiveCN101745638AIncrease the speed of warm pressingPromote particle rearrangementShock waveIntegrated technology

The invention discloses a high speed pressing and forming method of warm powder and a device thereof. The method is an integrated technology of warm-pressing as well as high speed pressing and forming, takes the gravitational potential energy of a drop hammer as pressing energy, a punch hammer falls down to impact on an upper punch to transfer the energy to the powder so as to rapidly and densely form the powder. The punch hammer rope of the device for carrying out the method is connected with a motor by a pulley installed above a guide cylinder and is kept to freely and vertically move in the guide cylinder; a speedometer is symmetrically installed on the two sides of a side die plate; a heating ring is directly sleeved on a die; a pressure sensor is contacted with the lower die punch and is connected with a data acquisition card; and the data acquisition card is connected with a computer by a USB interface. The pressing graph of a shock wave is displayed on the computer, and the maximum value of an impact force and the time impacting on the powder can be directly read from the graphs; and the invention has simple structure, convenient use, reliability and practicability as well as relative low price, is particularly suitable for colleges and universities as well as research and development institutions.

Owner:SOUTH CHINA UNIV OF TECH

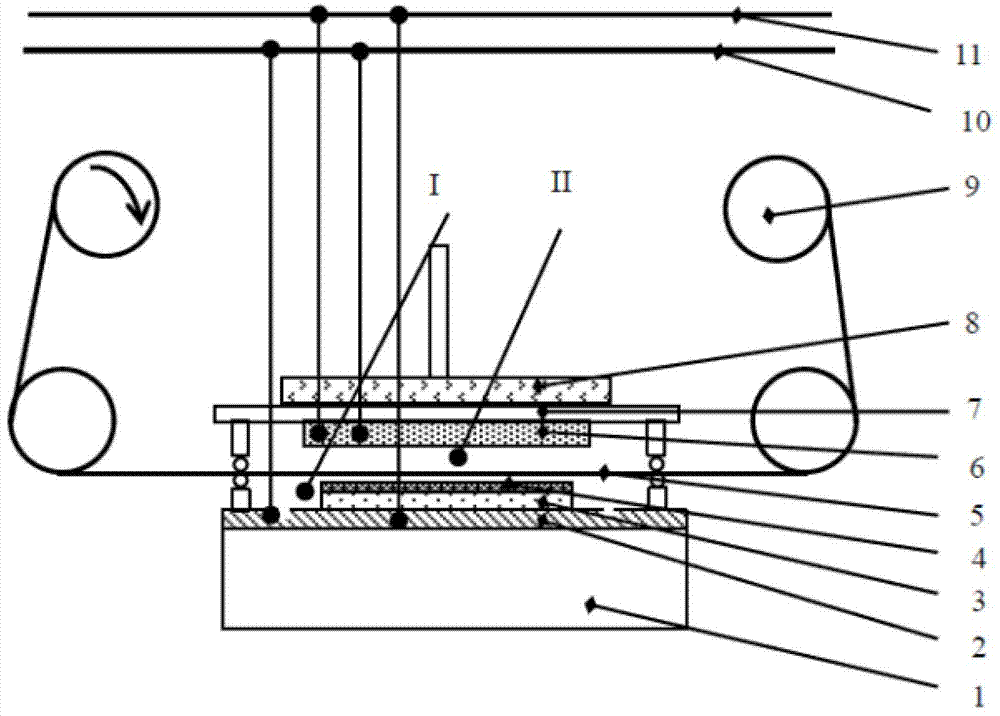

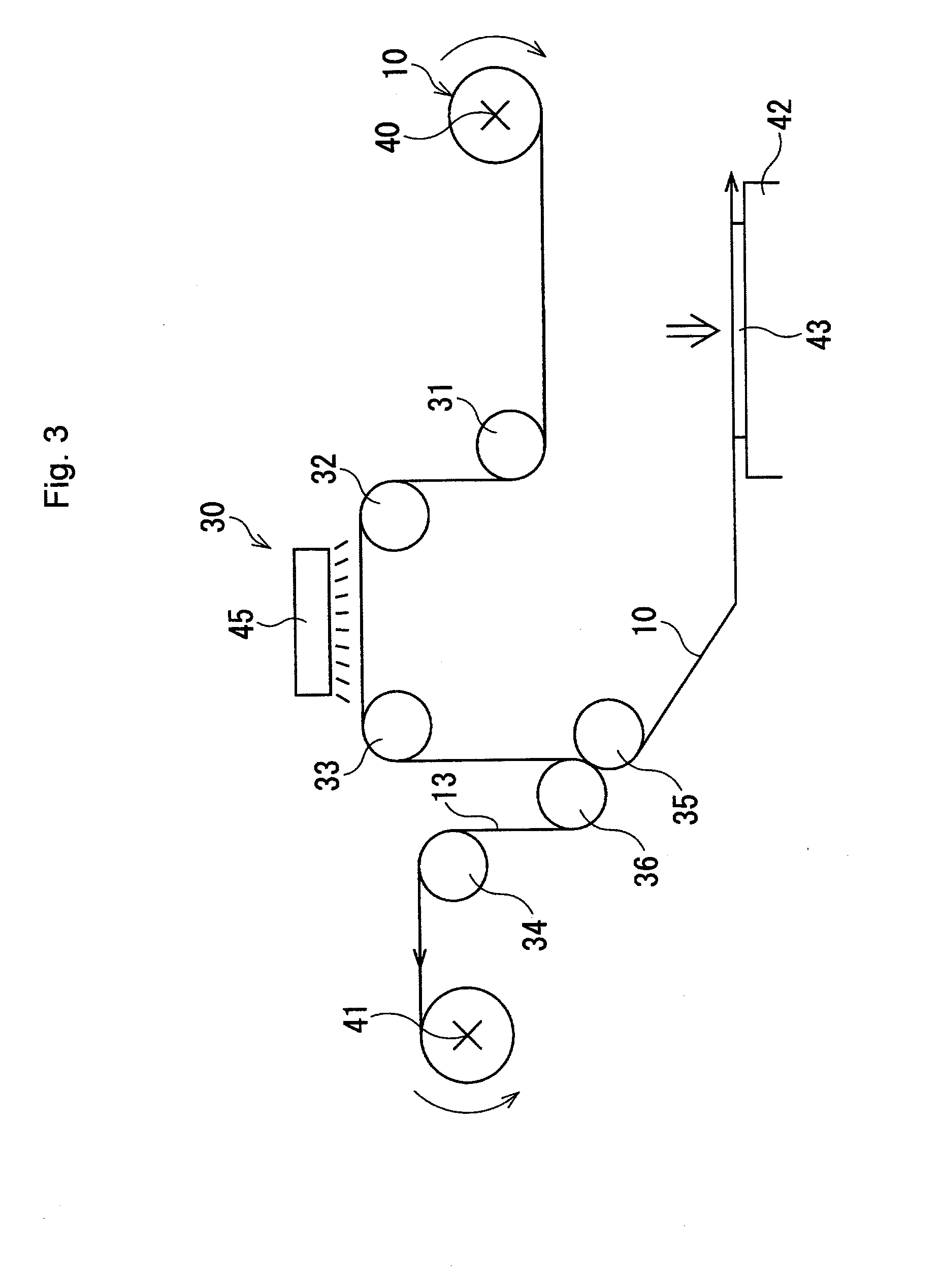

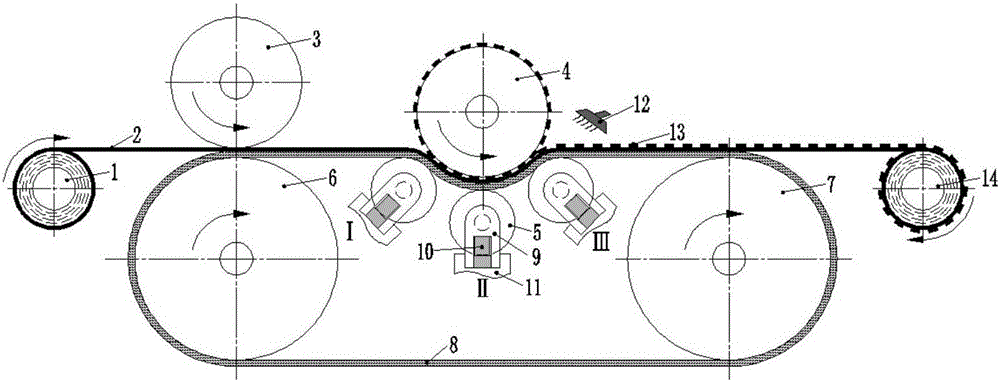

Reel-to-reel hot roller coining forming method for micro-nano structure on surface of polymer

The invention relates to a reel-to-reel hot roller coining forming method for a micro-nano structure on the surface of polymer. The reel-to-reel hot roller coining forming method comprises the steps that a polymer material is conveyed to a preheat roller from an unreeling device, preheated to the attaching temperature and attached to a base band in a hot pressing mode; the polymer material attached to the base band is conveyed to the position between a mold roller and a pressure roller and heated to the coining temperature through the mold roller heated in advance, and then a mold cavity is filled with the polymer material through the action of the pressure roller; mold filling and supersonic vibration assembly starting are conducted at the same time, and the reel-to-reel hot roller coining process is completed with assistance of supersonic vibration; the polymer material is conveyed out from the position between the mold roller and the pressure roller, and then cooled and separated from the position inside the mold roller; and after demolding is completed, a polymer product is continuously cooled, separation of the polymer product and the base band is achieved, and finally reeling is conducted. According to the reel-to-reel hot roller coining forming method for the micro-nano structure on the surface of the polymer, the reel-to-reel hot roller coining process is improved through supersonic vibration, the mold filling process is accelerated, the duplication precision is improved, and the demolding force and demolding deformation are reduced; and the reel-to-reel hot roller coining forming method is advanced.

Owner:SHANGHAI JIAO TONG UNIV

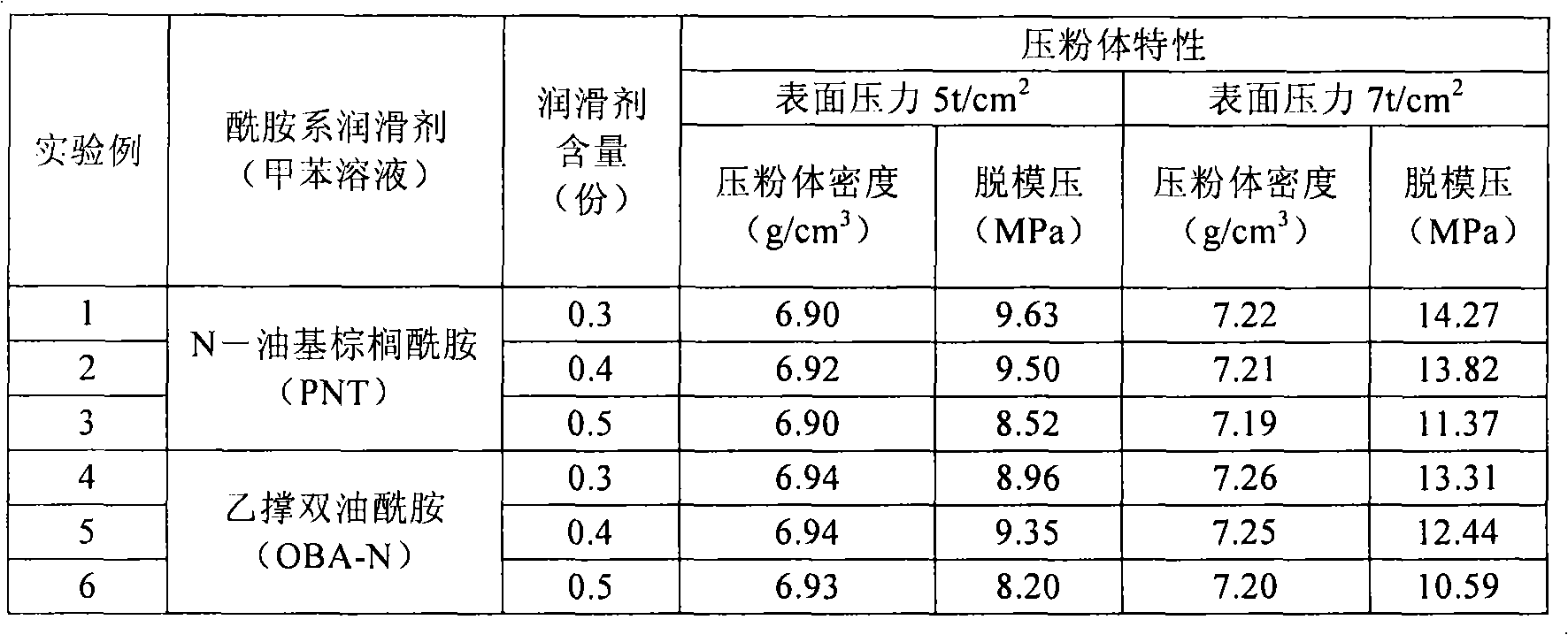

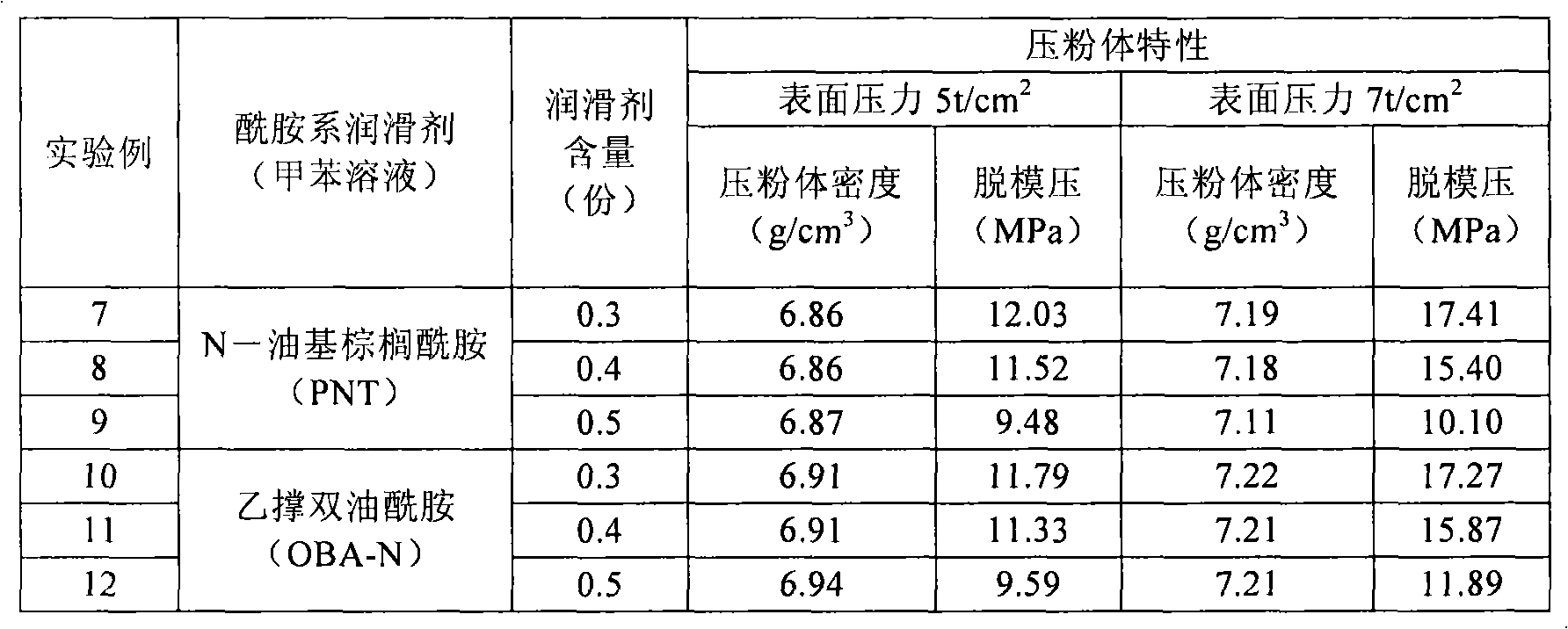

Method for producing powder mixture for powder metallurgy, and method for producing sintered body

InactiveCN101920335AReduce release forceHigh manufacturing densityTransportation and packagingMetal-working apparatusHigh densityPowder mixture

The present invention provides a method for producing a powder mixture for powder metallurgy, which allows production of a green compact having both high density and high lubricity (low demolding force). The method, according to the present invention, for producing a powder mixture for powder metallurgy including an iron-base powder, a mechanical characteristic-improving powder and a lubricant, the method includes the steps of: mixing the iron-base powder and / or the mechanical characteristic-improving powder with an amide-based lubricant solution; removing a solvent in the solution; and coating the surface of the iron-base powder and / or the mechanical characteristic-improving powder with an amide-based lubricant.

Owner:KOBE STEEL LTD

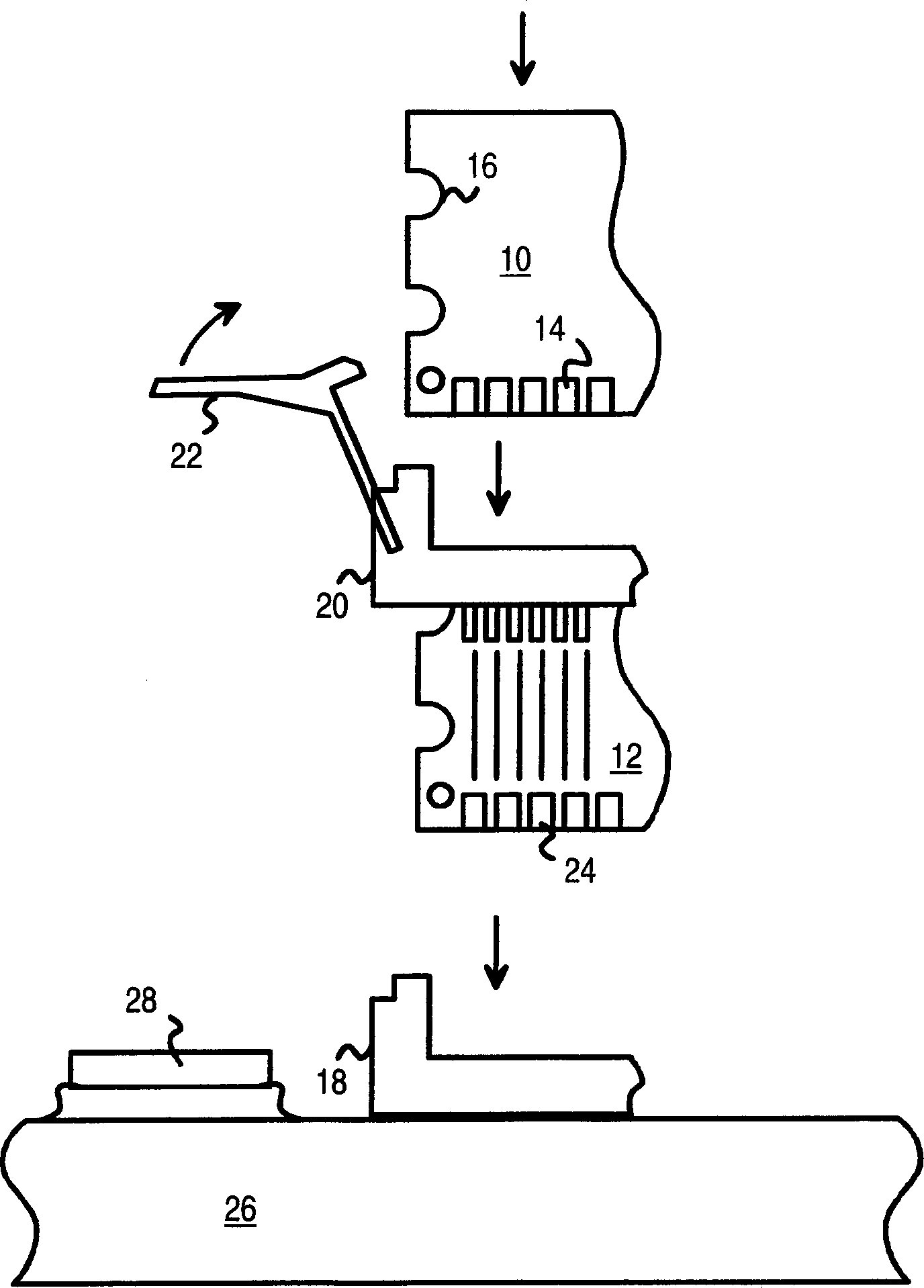

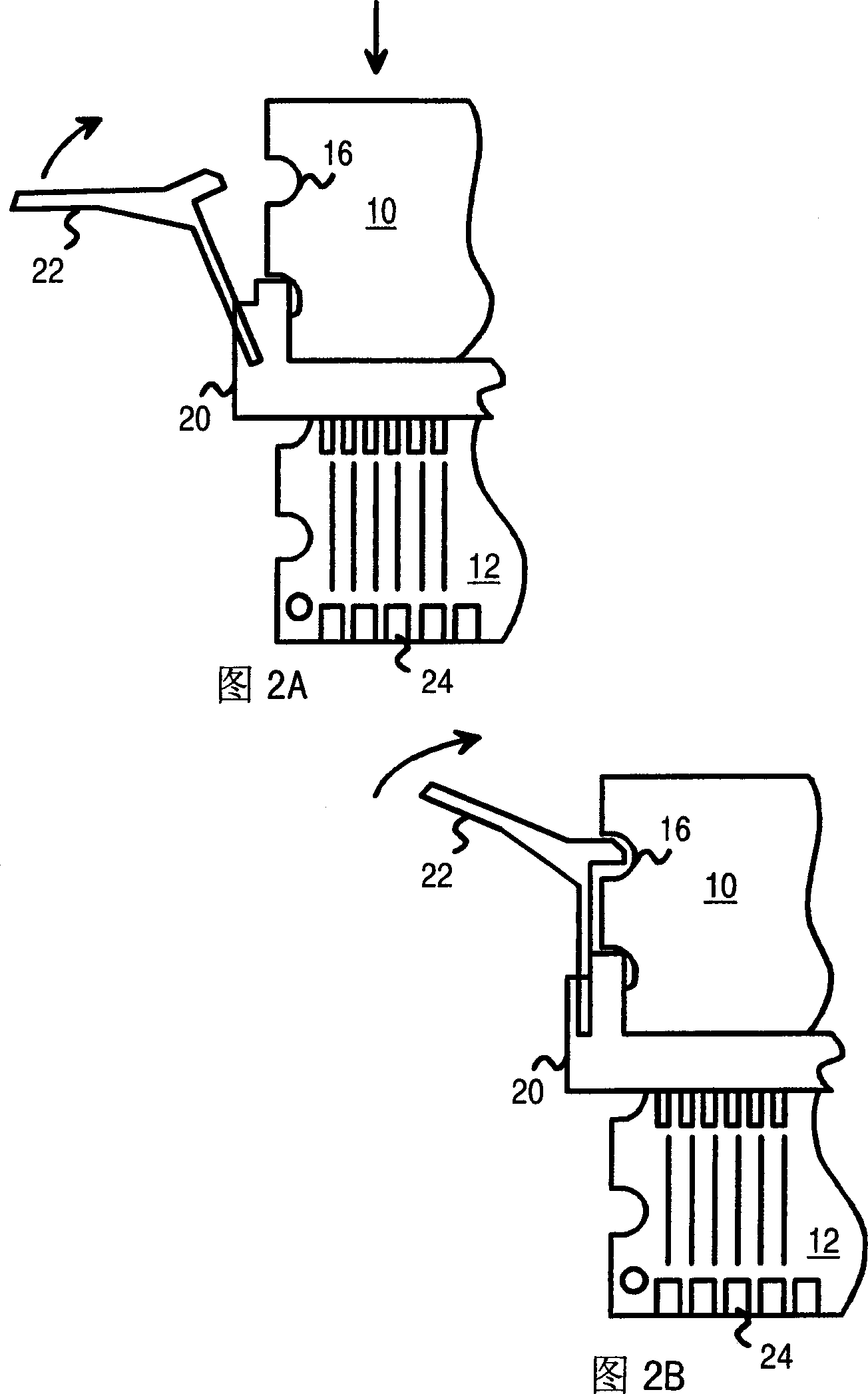

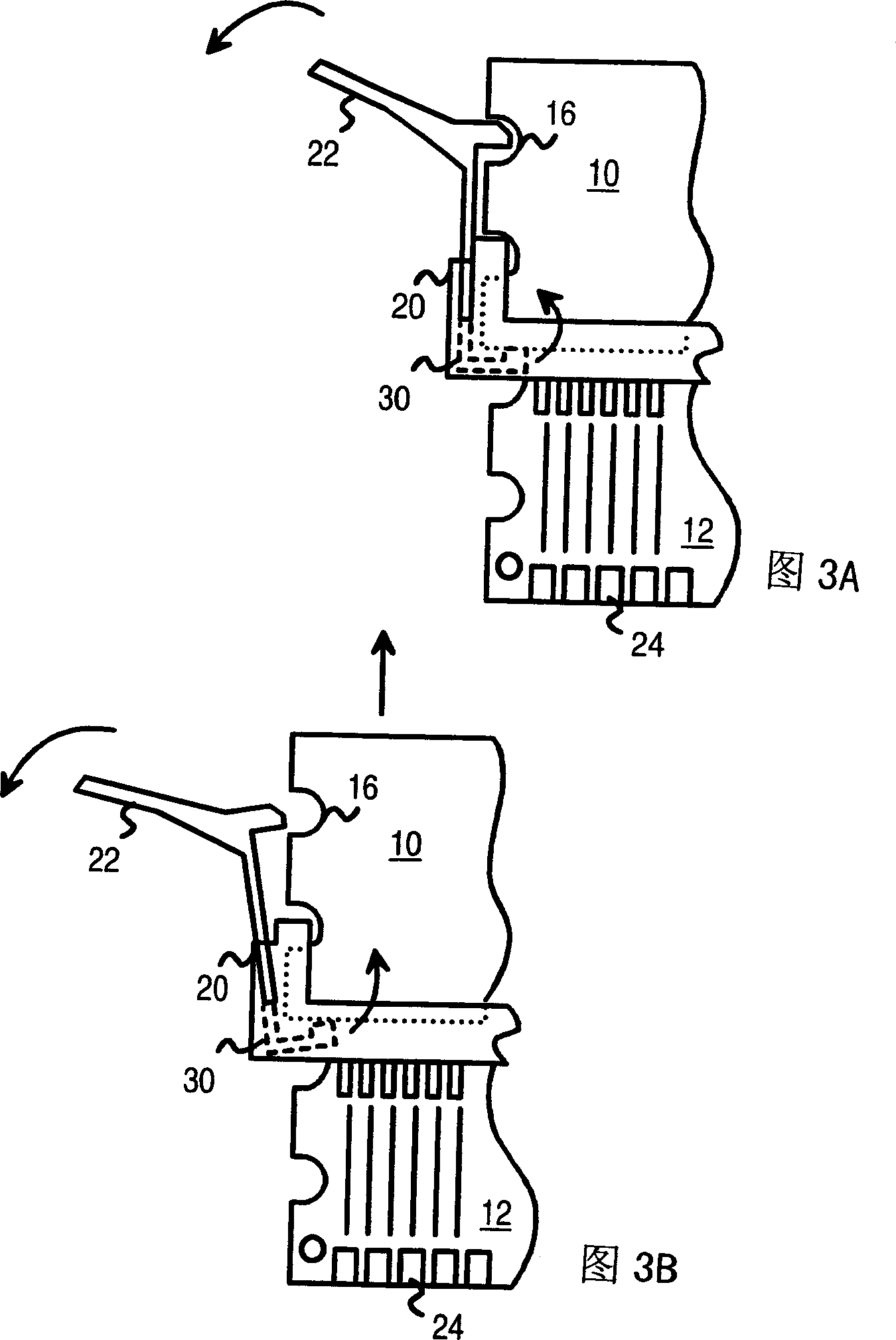

Memory module testing socket and instrument

ActiveCN1780056AReduce release forceElectronic circuit testingCoupling device detailsExpansion cardTester device

Since the notch mesher on the lever handle engages with the notch on the memory module and applies downward pressure, the memory module slot needs to be reduced in force. As the lever handle rotates around the axis the notch mesher is forced to move downwards, causing the notch on the memory module to be applied downward pressure so that the memory module is inserted into the memory module slot on the expansion card on the motherboard of the personal computer. The lever handle releaser arm is pushed downwards during the removal of the memory module. When the releaser arm is pushed downwards, the bottom of the releaser in the memory module slot rotates upward around the releaser pivot. The bottom of the up-turning releaser pushes upwards the front where the memory module is inserted to force the memory module to eject from the memory module slot. Both release and insertion forces can be reduced.

Owner:KINGSTON TECHNOLOGY (SHANGHAI) CO LTD

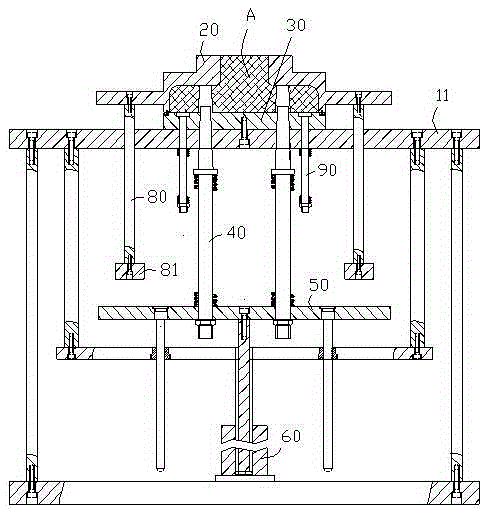

Pneumatic micro-nano imprint demoulding structure

InactiveCN101249938AReduce distortionReduce deformation and even damageNanostructure manufactureMicro nanoEngineering

The invention discloses a nano imprint demoulding structure based on air driving, wherein a polymer clamping casing is arranged on a work bench, a mould plate is arranged at the lower end of the clamping casing, a plunger is arranged on the upper end surface of the mould plate, a sleeve is fixedly connected with the clamping casing, the sleeve and the plunger move from up to down, thereby the mould plate can move from up to down in the clamping casing, a sliding passage arranged on the lower end surface of the mould plate is provided with a spring and a slide block, a mould clamping air passage connected to the clamping casing is led into the slide passage via the mould plate, thereby the slide block can slide in the slide passage on the lower end surface of the mould plate, a demoulding air passage is switched in from the clamping casing and passes through the mould plate, and a sealing ring is arranged on the lower end surface of the clamping casing. The nano imprint demoulding structure is capable of demoulding smoothly, and stress of the polymer and the mould is uniform, further damages of the microstructure imprinted can be reduced to the minimum, the mould can be protested, and the cost of imprinting can be reduced.

Owner:ZHEJIANG UNIV

Thermoplastic polyurethanes composition and preparation processes thereof

InactiveCN104379672ALower glass transition temperatureReduce release forceDicarboxylic acidCyclohexane

This invention is directed to a thermoplastic polyurethanes composition comprising polyether-based thermoplastic polyurethane and 1,2-cyclohexane dicarboxylic acid ester and preparation processes thereof. The thermoplastic polyurethane composition has a good mold release behavior in injection molding without undesirably significant shrinkage and surface blooming of final product.

Owner:BASF SE

Releasing agent and application method thereof

InactiveCN104759578AHigh strengthAvoid breakingFoundry mouldsFoundry coresGranularitySurface roughness

The invention belongs to the technical field of casting, and particularly relates to a releasing agent and an application method thereof. The invention aims at solving the technical problems that the existing releasing agent is difficult in demolding and pollutes the environment. The releasing agent consists of machine oil and silica powder; the granularity of the silica powder is 600 to 2500 meshes, and the content of SiO2 is more than 99.5 percent. The invention also provides an application method of the releasing agent. By adopting the releasing agent, the flatness and smoothness of the surface of a coating outer layer can be guaranteed, excellent surface roughness is guaranteed, the demolding force is reduced, and the transfer rate of the coating is approximately 100 percent.

Owner:SOUTHWEST UNIV

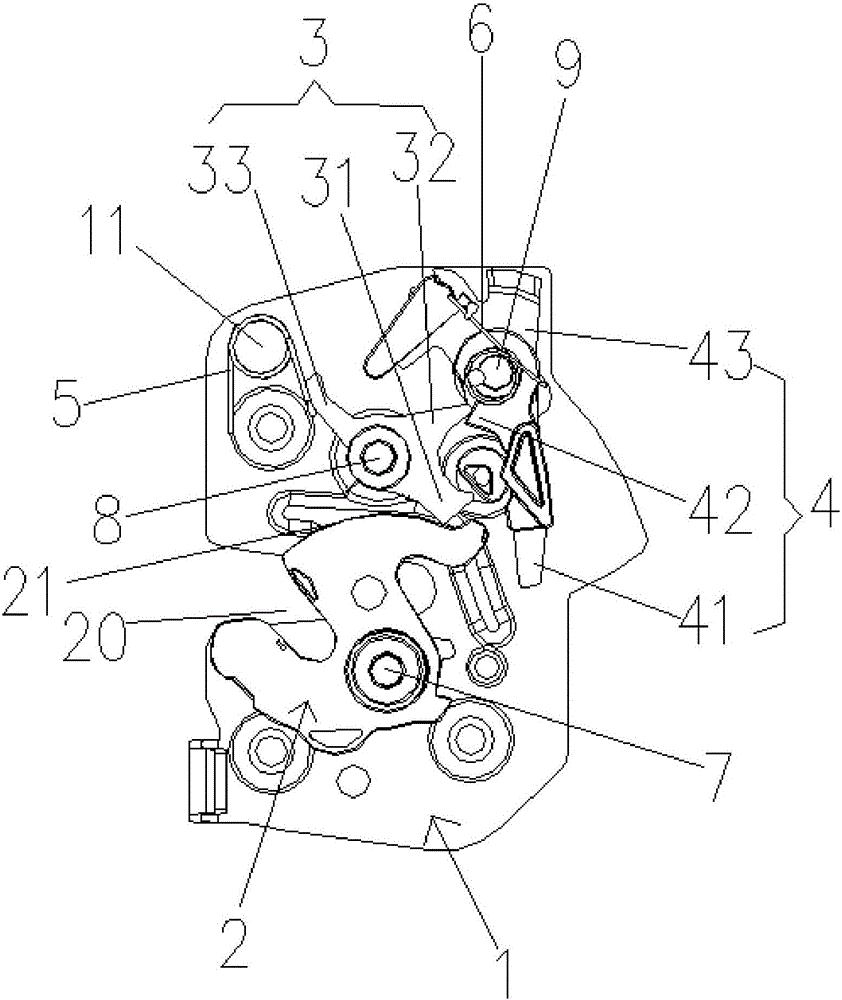

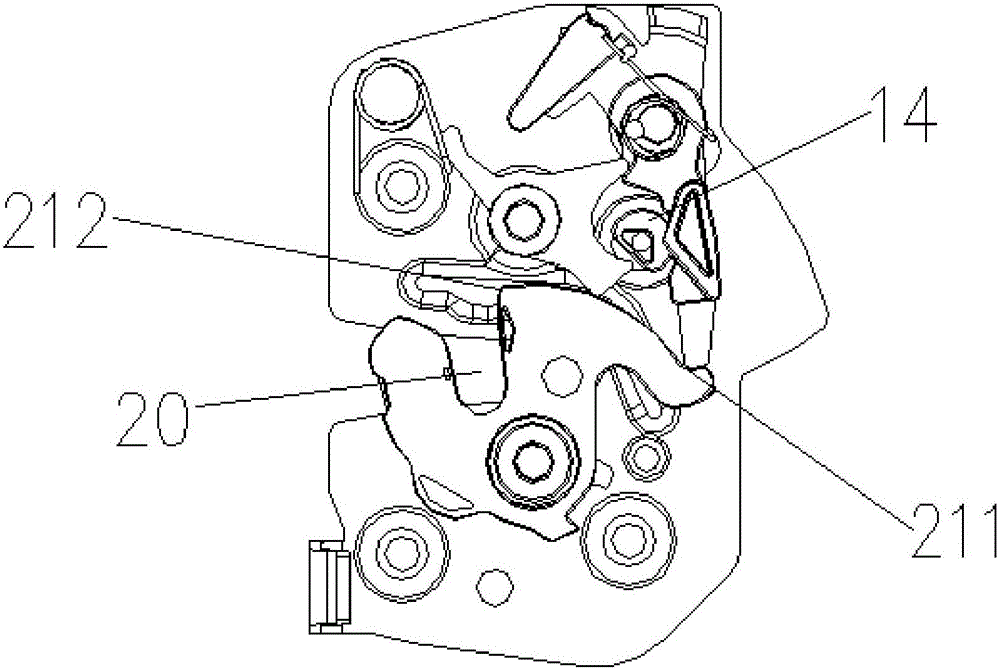

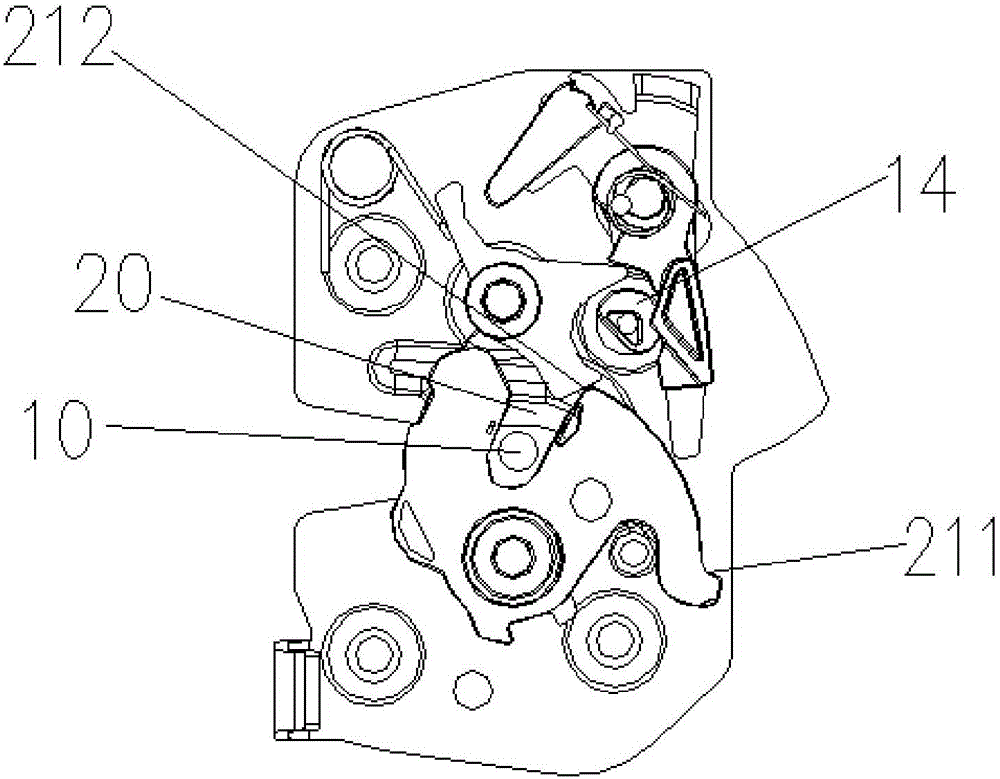

Double-pawl automobile door clock mechanism

ActiveCN105863408AImprove lock strengthImprove the sound of opening and closing doorsNoise-prevention/anti-rattling lockingMechanical engineeringEngineering

The invention discloses a double-pawl automobile door clock mechanism which comprises a base plate, a clamping plate, a first pawl, a second pawl, a first pawl reset spring and a second pawl reset spring. The clamping plate, the first pawl and the second pawl are installed on the base plate and can rotate around a first axis, a second axis and a third axis respectively. The clamping plate is provided with a U-shaped clamping groove capable of being clamped to an automobile body locking pin. The clamping plate is provided with a circular arc face located on the side of the U-shaped clamping groove. The circular arc face is provided with a semi-locking meshed position and a full-locking meshed position. The first pawl is provided with a first extending arm, a second extending arm and a third extending arm which are extended in an integrated mode. The second pawl is provided with a meshed arm capable of abutting against and being separated from the circular arc face and capable of being positioned to the semi-locking meshed position. The first extending arm abuts against the circular arc face and can be positioned on the full-locking meshed position. The first pawl reset spring and the second pawl reset spring are in elastic abutting connection with the first pawl and the second pawl respectively. The second pawl is provided with a protrusion. The second extending arm can be movably located on the two sides of the protrusion. The door lock release force is reduced, and door opening and closing sound is lowered.

Owner:MAGNA AUTOMOTIVE PARTS (SUZHOU) CO LTD

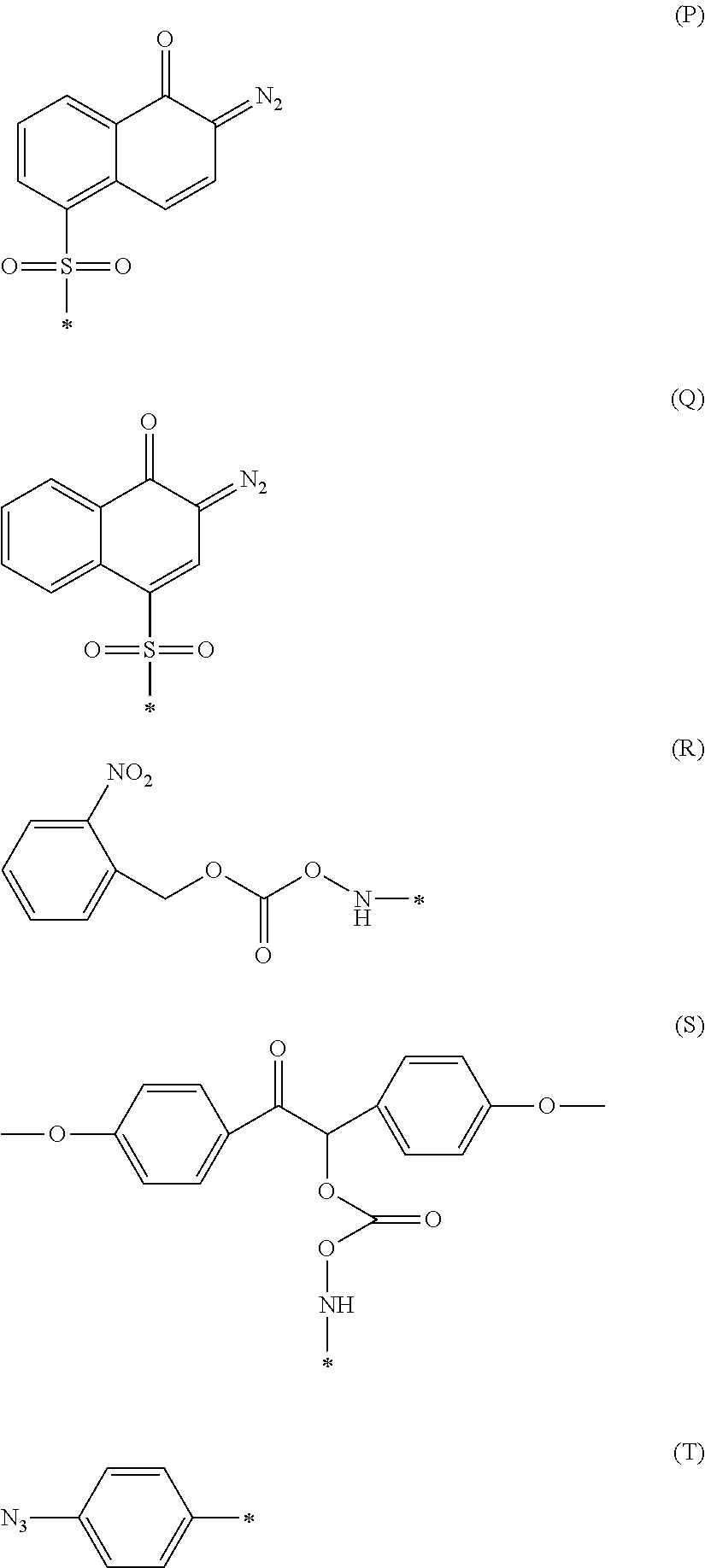

Photosensitive gas generating agent and photocurable composition

ActiveUS20150368433A1Reduce release forcePhotocurableOrganic chemistryOrganic compound preparationLight exposureProduct gas

A photocurable composition excellent in the effect of reducing the mold releasing force even in a small amount of light exposure, and a photosensitive gas generating agent contained in the photocurable composition are provided.The photosensitive gas generating agent is a compound having a photostimulation responsive gas generating group to generate a gas by photostimulation, a perfluoroalkyl group and a polyalkyleneoxy group to link the photostimulation responsive gas generating group and the perfluoroalkyl group. The photocurable composition contains the photosensitive gas generating agent.

Owner:CANON KK

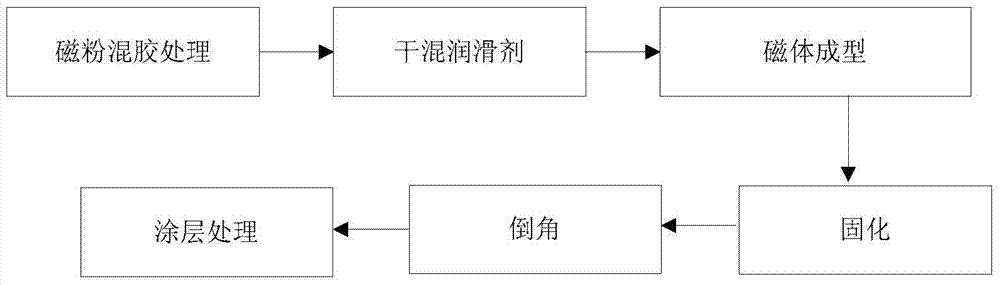

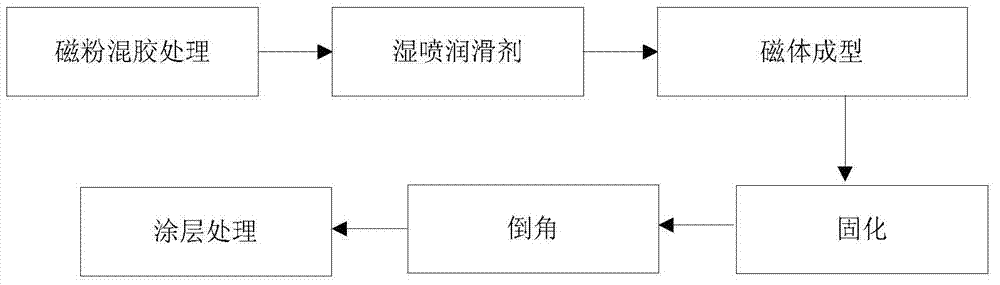

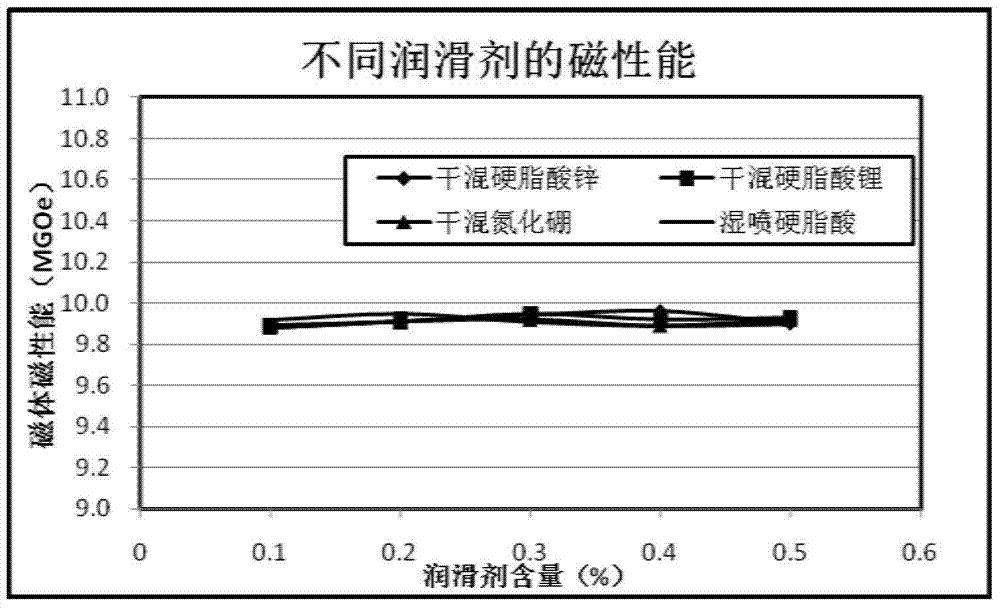

Bonded permanent magnet and production method thereof

ActiveCN103762069AEvenly distributedUniform magnet performanceInorganic material magnetismInductances/transformers/magnets manufactureEpoxyDry mixing

The invention discloses a bonded permanent magnet and a production method thereof. The production method includes S1, mixing rare earth magnetic powder with thermoset epoxy resin to acquire mixed rubber powder; S2, mixing the mixed rubber powder with lubricant in wet, and drying to acquire rare earth bonded magnetic powder; S3, forming the rare earth bonded magnetic powder to acquire bonded magnetic powder. The rare earth magnetic powder mixed with thermoset epoxy resin is mixed with the lubricant, a wet-mixing method replaces dry-mixing lubricant method to form a layer of even lubricant wrapping film on the surface of the mixed rubber powder, so that binding force of the mixed rubber powder and the lubricant is increased, the problem that the mixed rubber powder is separated from the lubricant during the mixed rubber powder feeding process is solved, so that the distribution of the lubricant in the mixed rubber powder is even. Compared with the method utilizing dry-mixing lubricant method to prepare the bonded permanent magnet, the bonded permanent magnet production method can produce bonded permanent magnet has similar magnet property, crushing strength and high magnet forming property, and greatly reduce magnet knockout press.

Owner:MAGNEQUENCH (TIANJIN) CO LTD

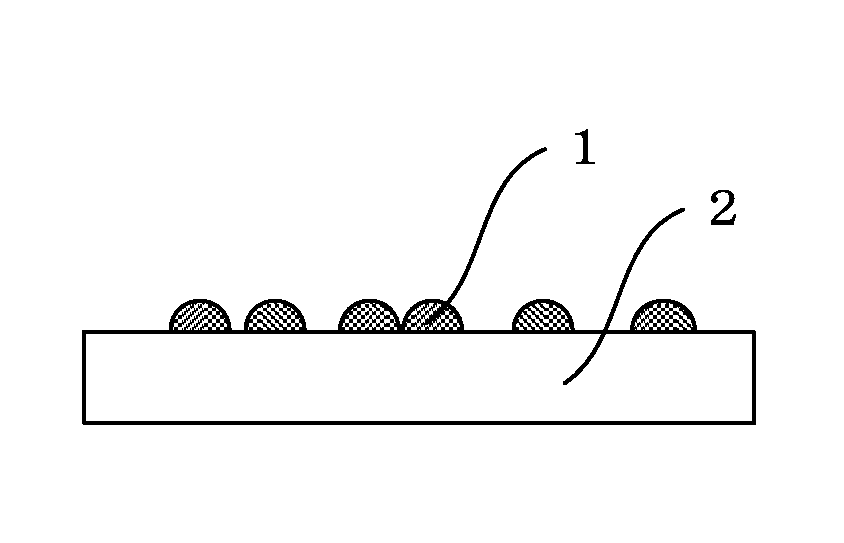

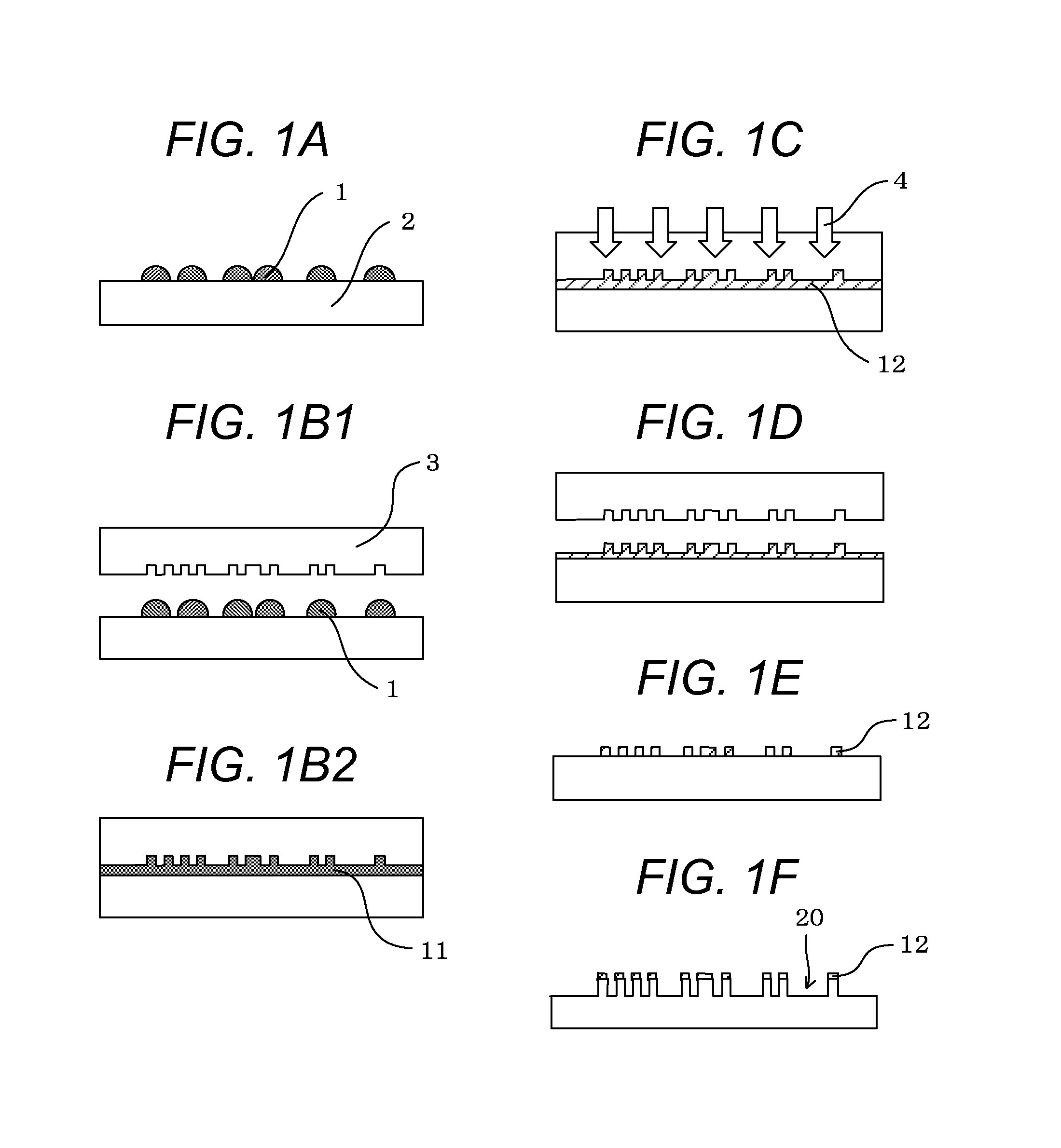

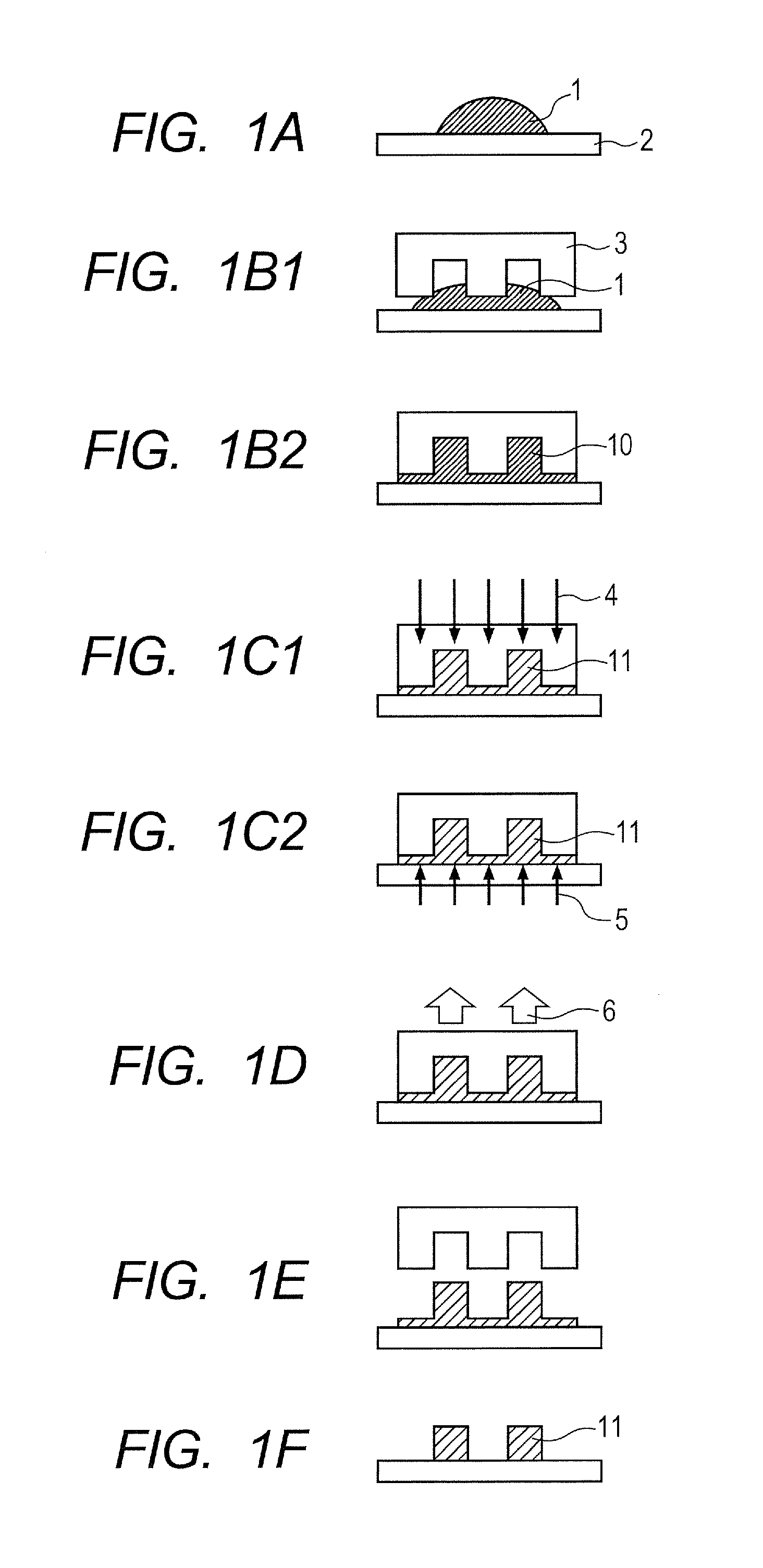

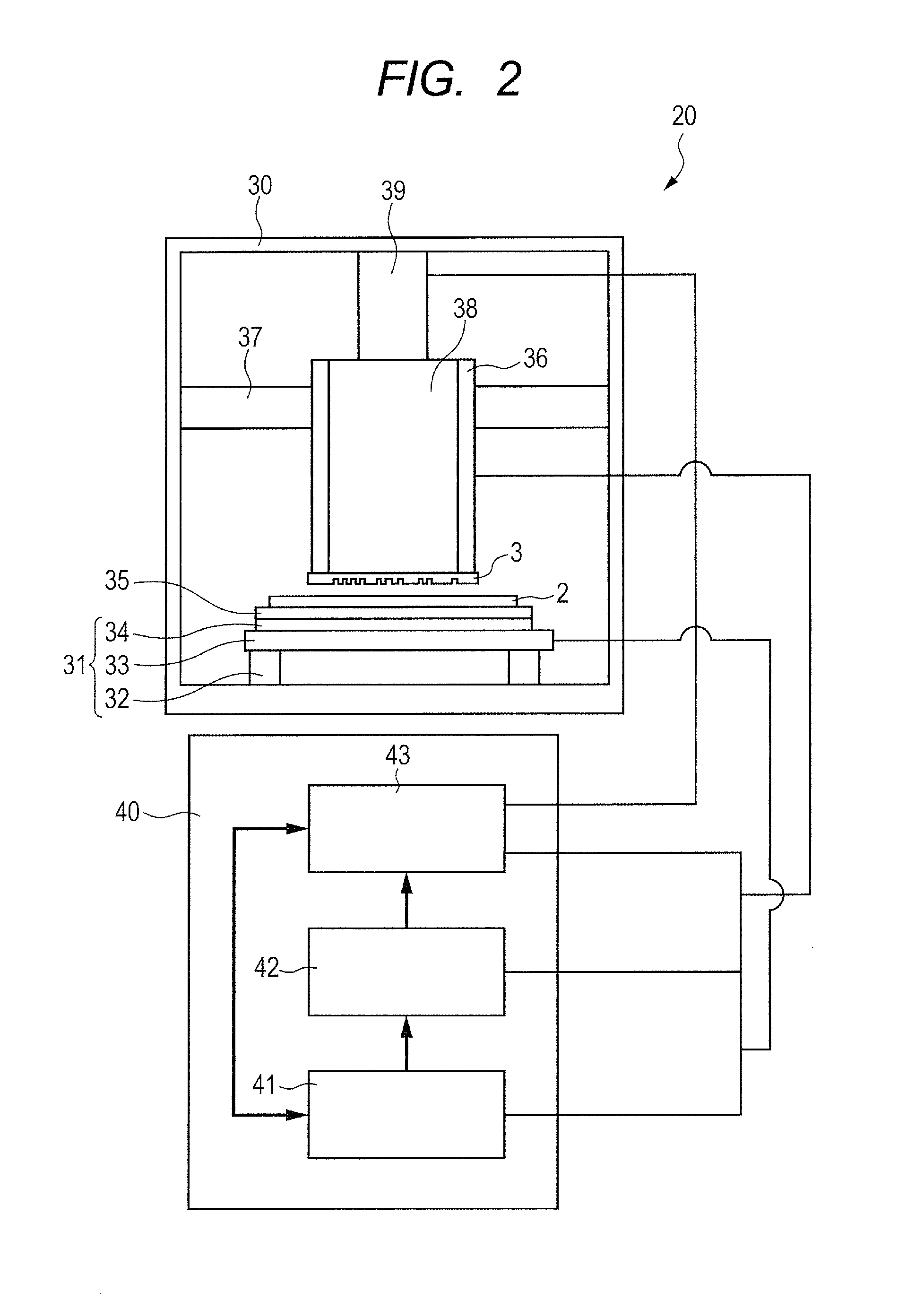

Resin production method and resin production apparatus

ActiveUS20150140227A1Reduce release forcePhotomechanical apparatusPretreated surfacesRadiation exposureChemistry

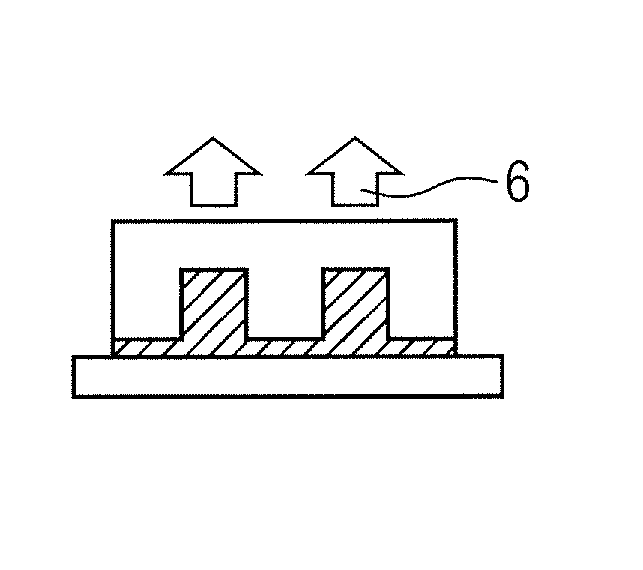

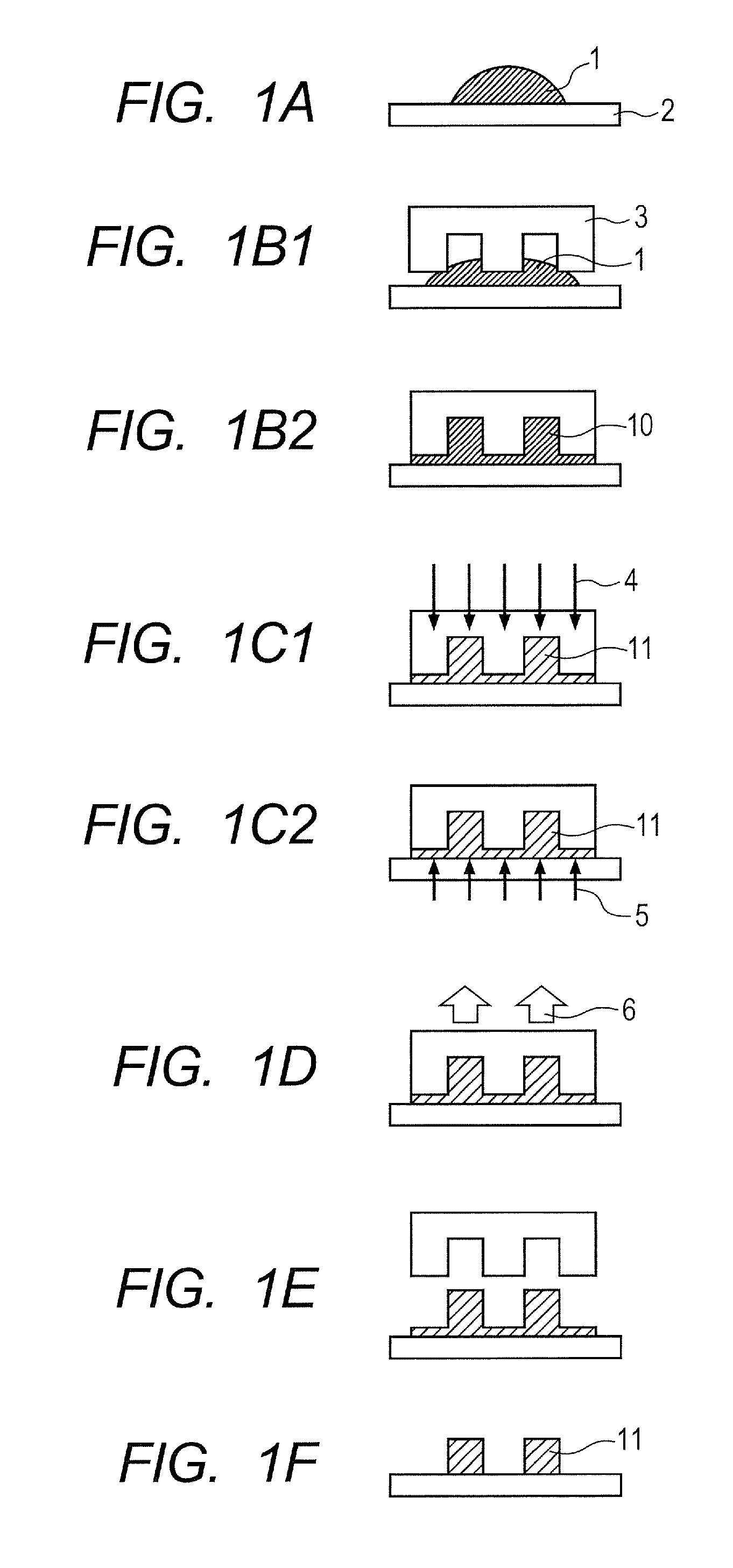

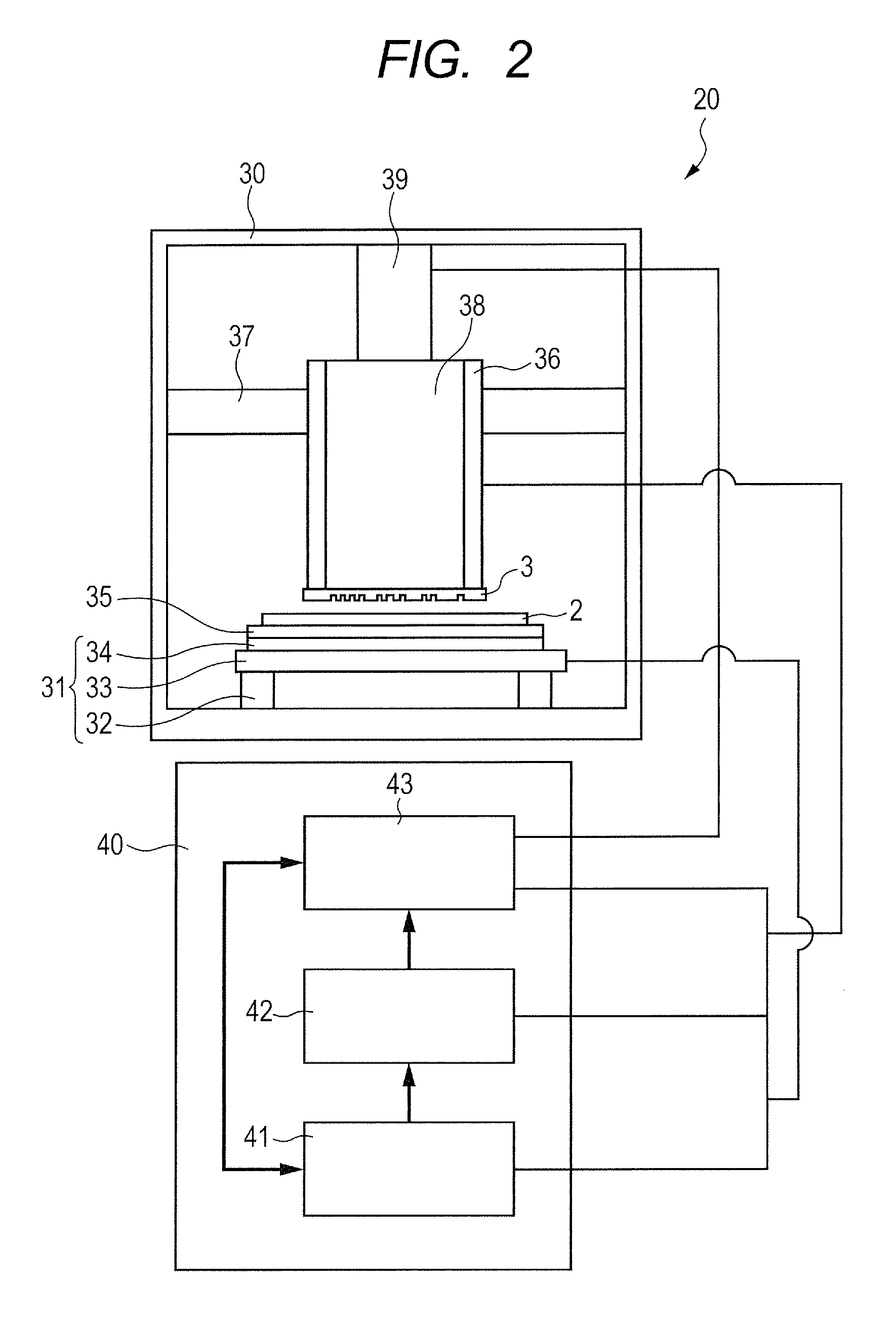

Provided is a resin production method in which a mold release force applied between a mold and a curable resin is reduced in a resin production method using a nano-imprint method. The resin production method includes an arrangement step of arranging a curable composition (1) on a substrate (2); a contacting step of bringing a mold (3) into contact with the curable composition (1); a curable composition curing step of curing the curable composition (1) by irradiating the curable composition (1) with a radiation or heating the curable composition (1) while keeping the curable composition (1) in contact with the mold (3); a tensile stress generation step of generating a tensile stress (6) in a direction of spacing the substrate (2) and the mold (3) away from each other to such a degree that the mold (3) and the curable composition (1) are not spaced away from each other when the curable composition (1) is cured; and a mold release step of releasing the curable composition (1) and the mold (3) from each other.

Owner:CANON KK

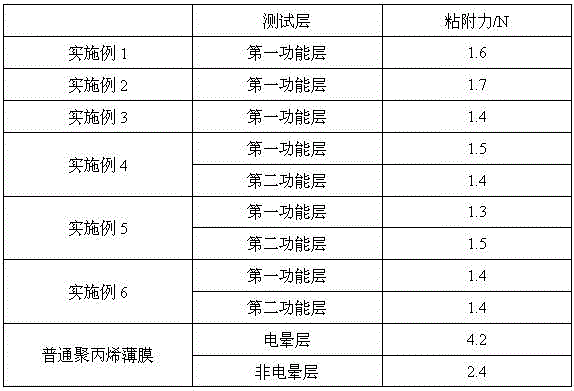

Release film free of silicon coating and preparation method of release film free of silicon coating

ActiveCN106113830ACompact structureEasy to peelLamination ancillary operationsSynthetic resin layered productsMachining processPolypropylene

The invention belongs to the technical field of high-polymer materials and particularly relates to a release film free of silicon coating and a preparation method of the release film free of silicon coating. The release film is in a three-layer structure comprising a first functional layer, a middle layer and a bottom layer or the first functional layer, the middle layer and a second functional layer. By adoption of homo-polypropylene and calcium carbonate master batch as main raw materials, the three-layer release film is structurally compact and easy to strip and is small in release force and more effective on the basis that adhesive surface characteristics are guaranteed against influences, and the problem of generally high release transferring of conventional light release films is solved; in addition, a silicon coating procedure is avoided, so that cost is saved; due to avoiding of toxic and volatile solvents and the like in a processing process, environment pollution is prevented, and harms to operators are reduced.

Owner:河北首发新材料科技有限公司

Casting mould structure capable of pulling core firstly and then ejecting

ActiveCN105290331AReduce manufacturing costExtend your lifeFoundry mouldsFoundry coresHydraulic cylinderMolten metal

The invention provides a casting mould structure capable of pulling a core firstly and then ejecting. The casting mould structure comprises a rack as well as a movable mould, a fixed mould, a movable core rod, an ejector board and a hydraulic cylinder which are arranged on the rack, wherein the movable mould and the fixed mould are arranged up and down; the movable mould and the fixed mould are in mutual contact and form a mould cavity; when the mould works, molten metal is firstly poured into the mould cavity from a sprue of the movable mould, and then, the ejector board is pulled down by virtue of the hydraulic cylinder to drive the movable core rod to move downwards and separate from a through hole of a product, so that shrinkage stress is released; after a product is molded, the movable mould and the product are ejected sequentially through a top mould rod and an ejector rod; and the casting mould structure is suitable for mould opening of the product with the through hole, so that the product with the through hole is prevented from a cracking phenomenon during mould opening.

Owner:安徽熠辉新材料有限公司

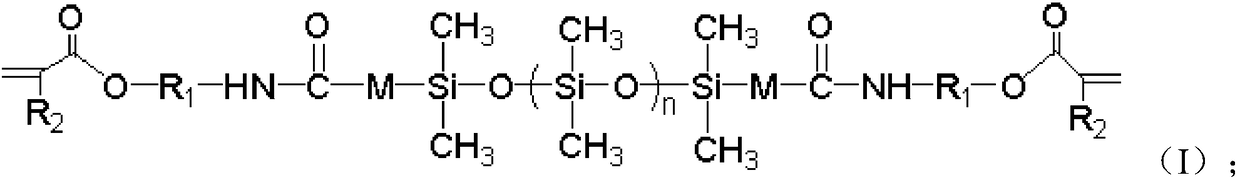

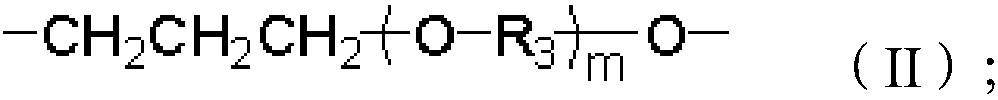

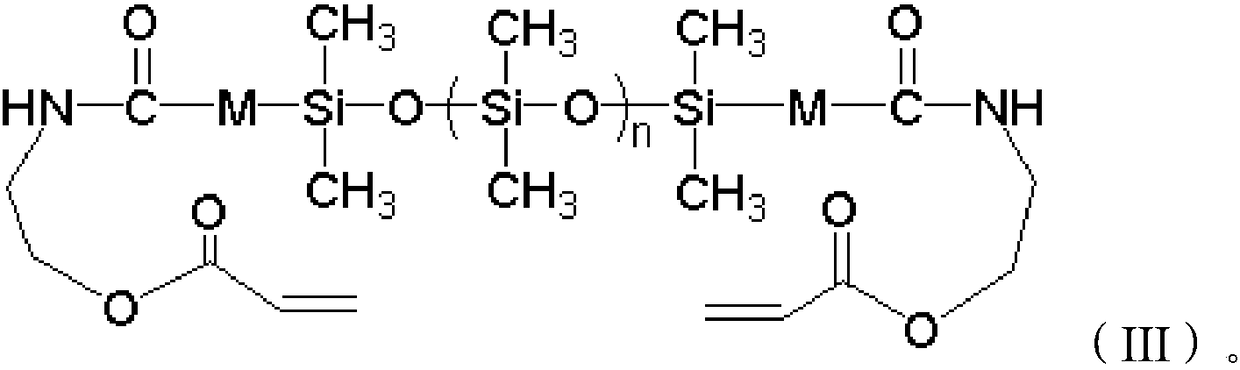

Organic silicon resin as well as preparation method and application thereof

The invention discloses an organic silicon resin as well as a preparation method and the application thereof and belongs to the technical field of organic silicon resins. The organic silicon resin isof a structure of formula (I) as shown in the specification, in the formula, n is greater than or equal to 50; R1 is alkylene; R2 is hydrogen or methyl; M is of a structural formula (II) as shown in the specification, in the formula, m is greater than or equal to 1; R3 is alkylene. The organic silicon resin is relatively low in viscosity, rapid in photo-curing speed, good in filming property and in addition simple in preparation process; when the organic silicon resin is adopted as a host resin of a release agent, the properties of the release agent can be improved, and the release force of afilm formed after the release agent is cured can be reduced.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

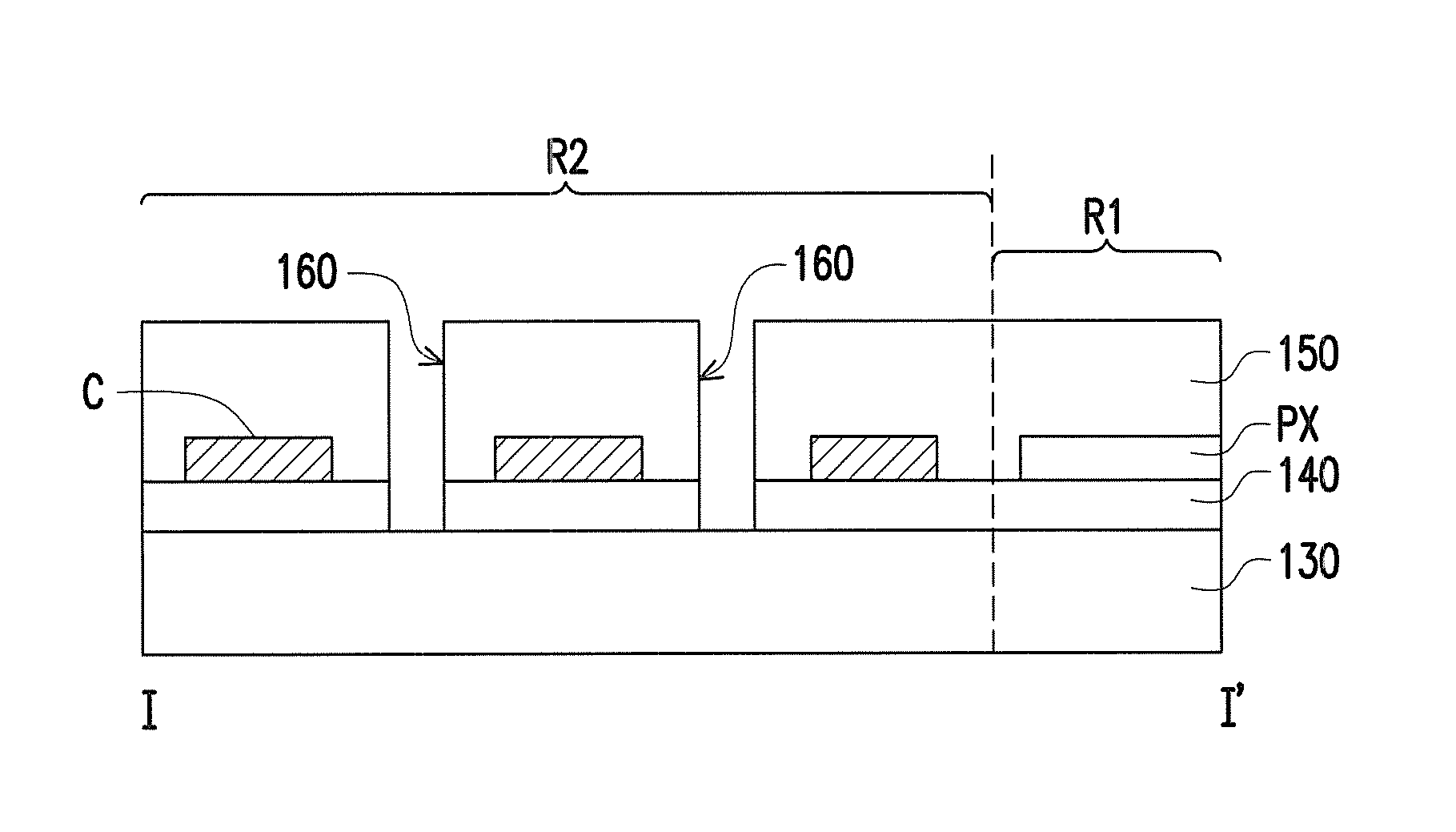

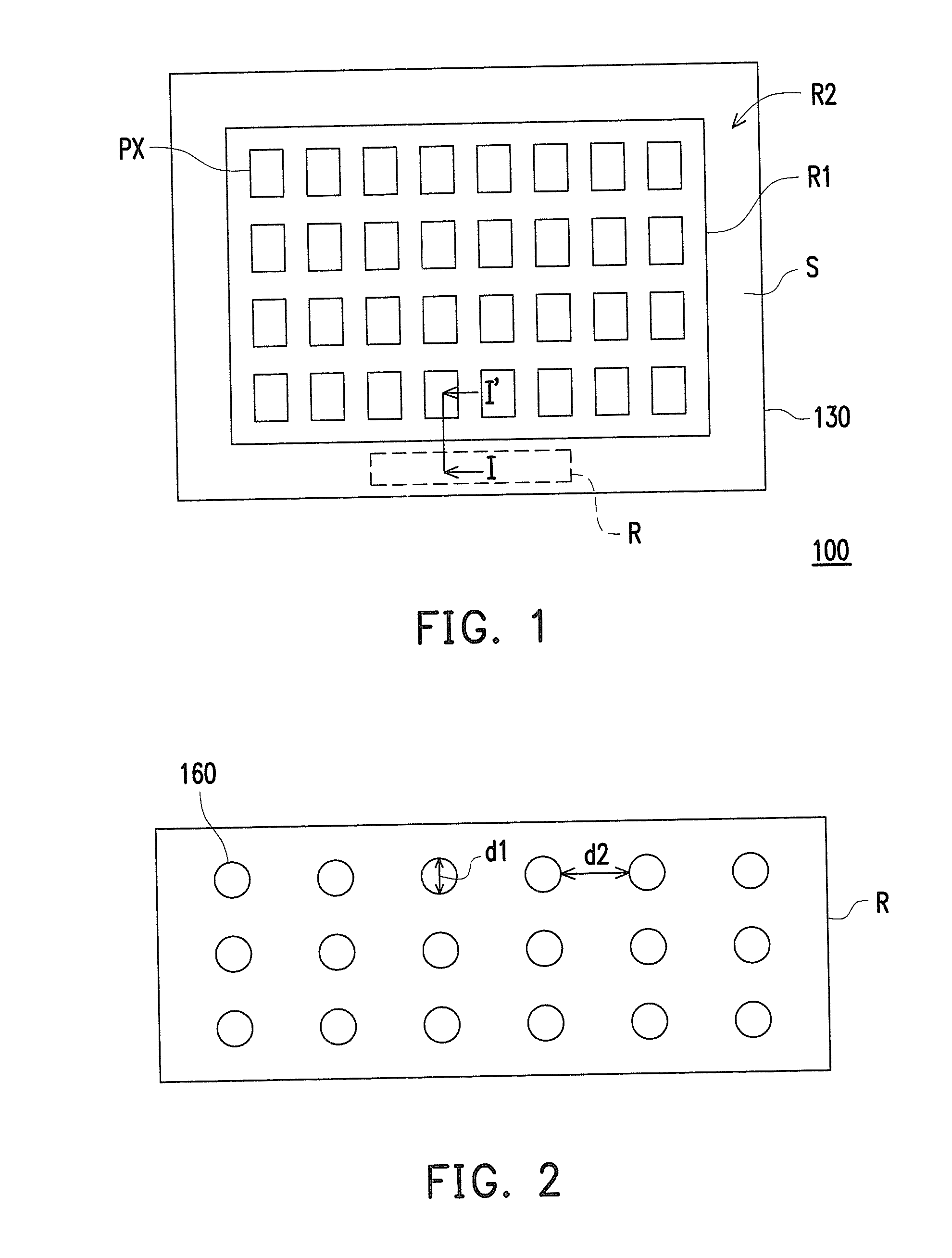

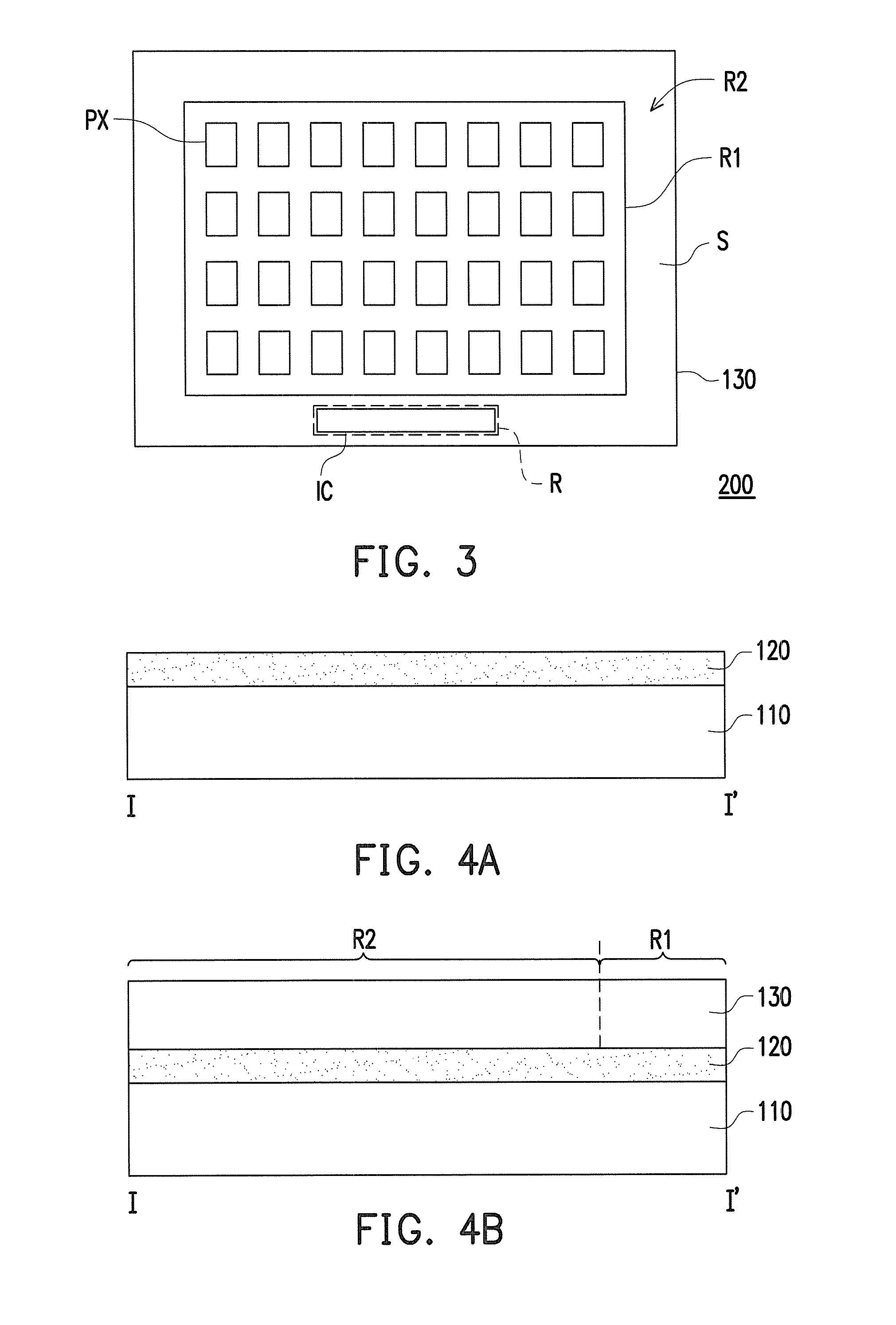

Display panel and method for fabrication thereof

ActiveUS20150214503A1Reduce release forceIncrease success rateSolid-state devicesSemiconductor/solid-state device manufacturingProtection layerPixel array

A display panel is provided. The display panel includes a substrate, a pixel array, a peripheral circuit, and a protective layer. The substrate includes a display region and a non-display region. The pixel array is located in the display region of the substrate. The peripheral circuit is located in the non-display region. The protective layer is located in the display region and the non-display region. The peripheral circuit and the pixel array are covered by the protective layer. The protective layer in the non-display region has a plurality of openings, which expose the substrate. The apertures of the openings is between 1 μm and 1 mm, and the spacing between the openings is 10 μm and 1 cm.

Owner:AU OPTRONICS CORP

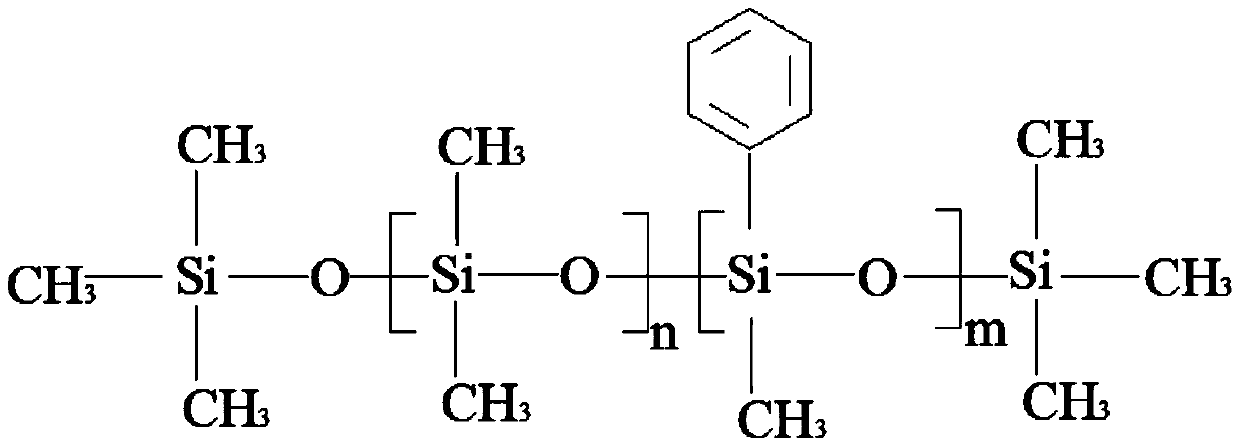

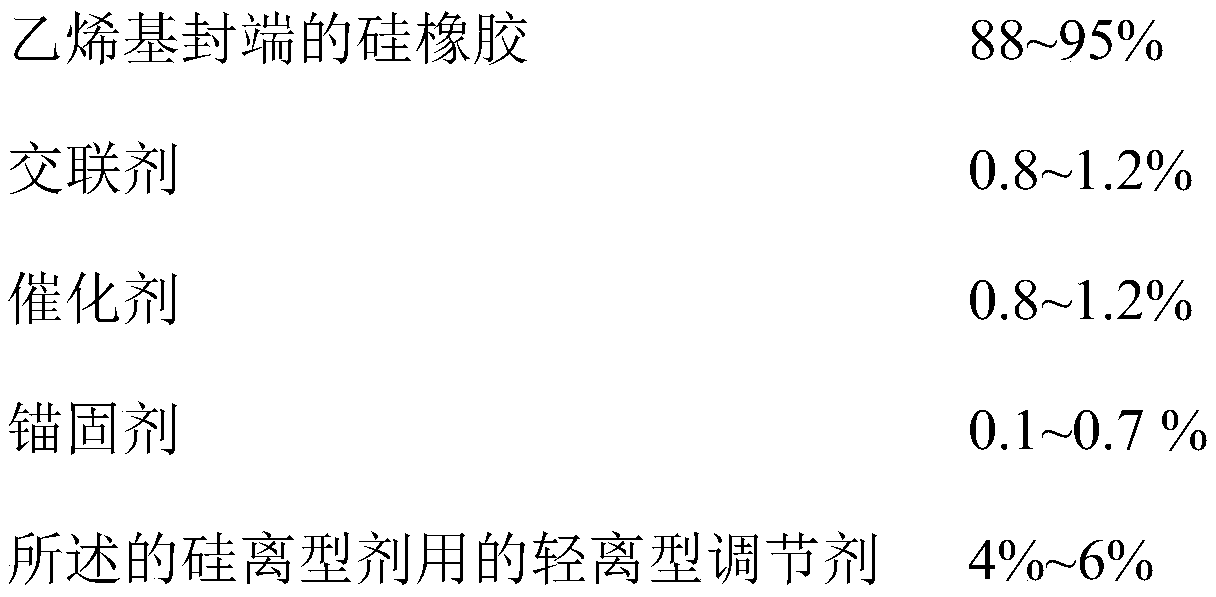

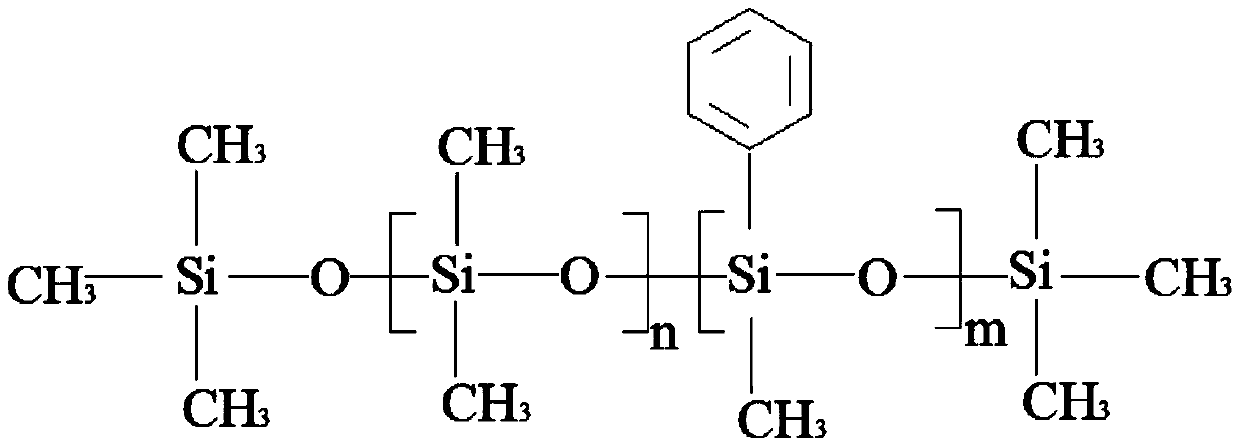

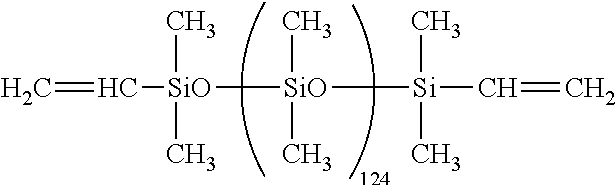

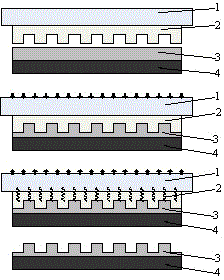

Light release regulator for silicon release agent, and synthesis method and application thereof

InactiveCN110643213AImprove residual adhesionIncrease steric hindranceCoatingsMethyl benzeneAcid catalysis

The invention provides a light release regulator for a silicon release agent. The light release regulator is methyl phenyl silicone oil which is an acid catalytic polymerization product of hexamethyldisiloxane, octamethylcyclotetrasiloxane and 2,4,6-trimethyl-2,4,6-triphenylcyclotrisiloxane. The invention also provides a synthesis method of the light release regulator for the silicon release agent, and a formula composition applied to the silicon release agent. The silicon release agent obtained by using the light release regulator for the silicon release agent has good performance indexes: the release force is small, the release force after aging is close to the release force measured immediately, and the residual adhesion rate can reach 90% or above.

Owner:广东鼎立森新材料有限公司

Silicone release coating composition and low release force emulsion silicone release coating for films and papers having cured release coating

ActiveUS20170145256A1Reduce release forceMaintain good propertiesPaper coatingEmulsion paintsPolymer scienceActive agent

A silicone release coating composition comprises:(A) 100 weight parts of an organopolysiloxane fluid having a viscosity at 25° C. of 50 to 10,000 mPa·s and an alkenyl content of 0.10 to 3.0 wt %;(B) 0.5-40 weight parts of a diorganopolysiloxane represented by the average structural formula (1):Rc3SiO(RbRcSiO2 / 2)n1(Rc2SiO2 / 2)n2SiRc3 (1)wherein Rb is an alkenyl group; Rc is an alkyl group or a phenyl group; n1 provides an alkenyl content of 0.05 to 0.80 wt. %; n2 is at least 1; and n1+n2 provides this component with a viscosity at 25° C. of 5,000 to 150,000 mPa·s;(C) an organohydrogenpolysiloxane that has a viscosity at 25° C. of 1 to 1,000 mPa·s, at least two silicon-bonded hydrogen atoms in each molecule, and an alkyl group or a phenyl group for its silicon-bonded organic groups;(D) a hydrosilylation reaction catalyst in a catalytic amount;(E) a surfactant;(F) water; and(G) an inhibitor.

Owner:DOW SILICONES CORP +1

Solventless release coating organopolysiloxane composition and sheet-form substrate having cured release coating

ActiveUS20160244636A1Reduce release forceFlat surfaceCoatingsFilm/foil adhesive release linersPolymer sciencePtru catalyst

This invention relates to solventless release coating organopolysiloxane composition and sheet-form substrate having cured release coating, providing a solventless release coating organopolysiloxane composition having a viscosity of 50 to 3,000 mPa s, comprising (A) 100 parts of an organopolysiloxane fluid having a viscosity at 25° C. of 10 to 1,000 mPa s and alkenyl content of 0.10 to 3.0 wt %; (B) 0.5 to 15 parts of a diorganopolysiloxane having a viscosity at 25° C. of 10,000 to 150,000 mPa s, and 0.05 to 0.30% of alkenyl groups at the pendant position of its siloxane-chain and trialkylsiloxy-terminals; (C) a prescribed quantity of an organohydrogenpolysiloxane; and (D) a hydrosilylation reaction catalyst. Also, a cured release coating-bearing sheet-form substrate that has a cured coating from this solventless release coating organopolysiloxane composition is provided.

Owner:DOW SILICONES CORP +1

Cold seal release films and methods of making same

ActiveUS20080032141A1Good release effectHigh retention rateFilm/foil adhesivesSynthetic resin layered productsEngineeringOxidative treatment

A cold seal release film including a cold seal release layer employing a silicone oil slip agent therein. The release layer is oxidatively treated to a level to reduce the cold seal release force by at least 25%, as compared to the cold seal release force without oxidative treatment of the release layer. A method of forming the cold seal release film with an improved cold seal release layer as described above also forms a part of the present invention.

Owner:APPLIED EXTRUSION TECH

Demolding method in nanoimprint technology process

InactiveCN105319838AImprove release qualityReduce release forcePhotomechanical apparatusAdhesive materialsComposite material

The invention discloses a demolding method in a nanoimprint technology process. The demolding method comprises the following steps: firstly, coating a substrate with a nanoimprint adhesive material to form an imprint adhesive layer; secondly, pressing a template into the imprint adhesive layer; thirdly, transmitting an ultrasonic wave to the template by an ultrasonic transmitting device at the upper part of the template after the imprint adhesive layer is cured and fixed, so as to assist separation of the template and the imprint adhesive layer; and finally removing the template and finishing the demolding process. Compared with the prior art, the problems that the molded nanoimprint structure is serious in deformation, overlarge in tear force and demolding force and the like due to cohesion force of the template and the adhesive layer in the demolding process of a nanoimprint technology are solved; imprinted pattern transferring and photoetching are completely consistent; the demolding force is effectively reduced; the demolding success rate is greatly improved; and large-scale industrial production is realized.

Owner:SHANDONG UNIV OF SCI & TECH

Resin production method and resin production apparatus

ActiveUS9475229B2Reduce release forcePhotomechanical apparatusSemiconductor/solid-state device manufacturingChemistry

Provided is a resin production method in which a mold release force applied between a mold and a curable resin is reduced in a resin production method using a nano-imprint method. The resin production method includes an arrangement step of arranging a curable composition (1) on a substrate (2); a contacting step of bringing a mold (3) into contact with the curable composition (1); a curable composition curing step of curing the curable composition (1) by irradiating the curable composition (1) with a radiation or heating the curable composition (1) while keeping the curable composition (1) in contact with the mold (3); a tensile stress generation step of generating a tensile stress (6) in a direction of spacing the substrate (2) and the mold (3) away from each other to such a degree that the mold (3) and the curable composition (1) are not spaced away from each other when the curable composition (1) is cured; and a mold release step of releasing the curable composition (1) and the mold (3) from each other.

Owner:CANON KK

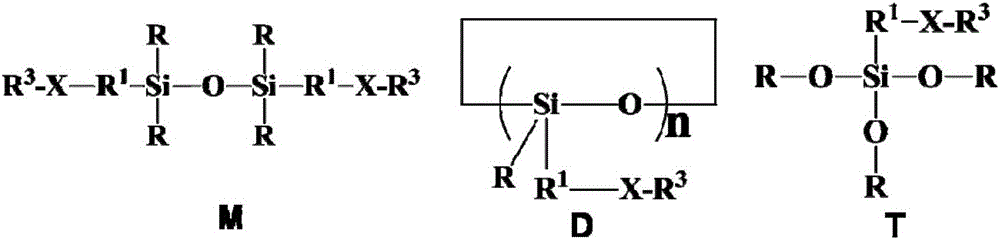

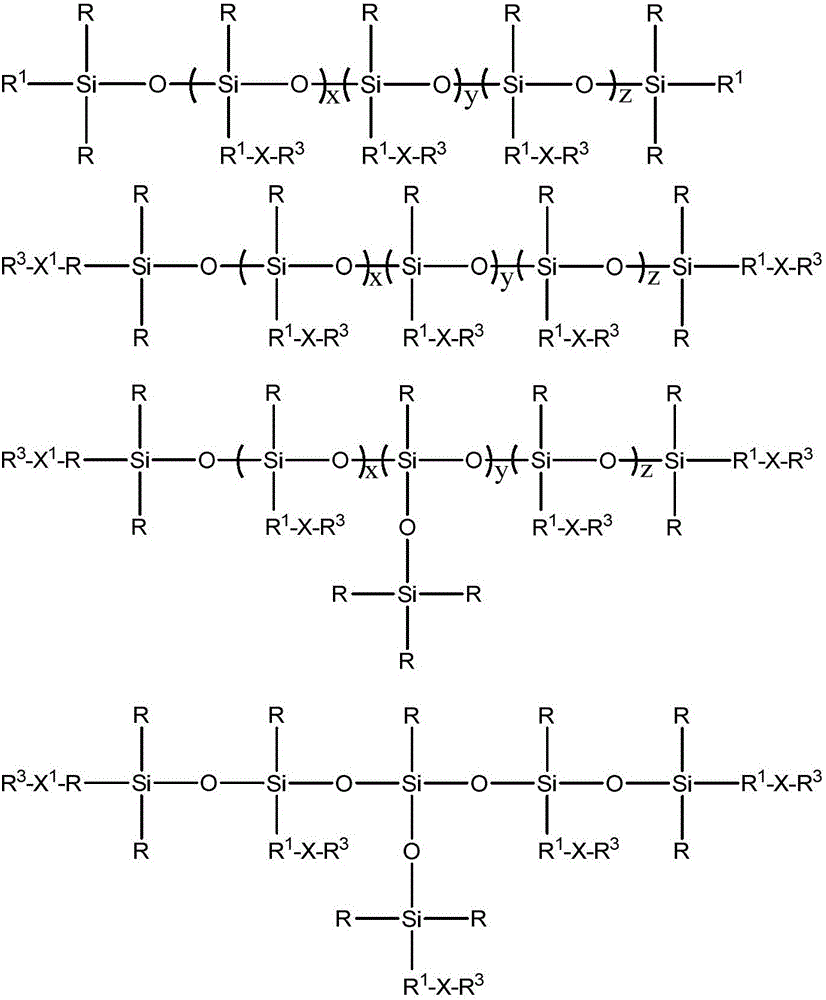

Fluorine-containing alkenyl polysiloxane, preparation method thereof and application

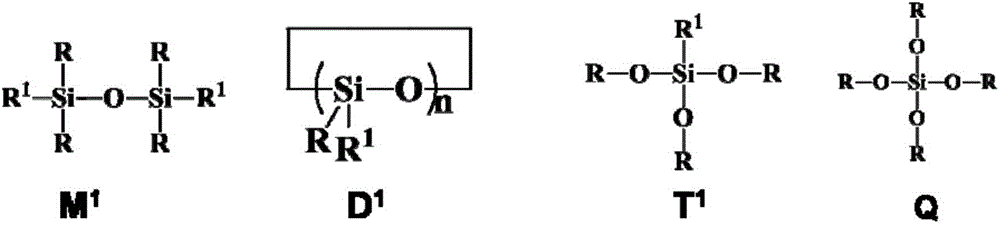

The invention belongs to the field of material chemical synthesis, and discloses fluorine-containing alkenyl polysiloxane, a preparation method thereof and an application. The preparation method for the fluorine-containing alkenyl polysiloxane mainly comprises the following steps: (1) under the action of a solvent and a catalyst, enabling alkenyl siloxane units M1, D1 and T1 to react with a nucleophilic reagent of a fluorine-containing chain segment R3X, and purifying the obtained reaction liquor after the reaction is ended, thereby obtaining fluorine-containing alkenyl polysiloxane M, D and T; and (2) enabling at least one of D and T and at least one of D1, T1 and Q to generate hydrolytic condensation reaction under the action of the catalyst, adding M or M1 to generate end capping reaction after the reaction is ended, and purifying the reaction product to obtain the fluorine-containing alkenyl polysiloxane with a line-type or a body-type structure. The fluorine-containing alkenyl polysiloxane is added, so that a solvent-free organic polysiloxane composite forms a surface with lower surface energy, and therefore, a fluoride-containing siloxane anti-adhesion coating with lower release force is obtained.

Owner:国科广化(南雄)新材料研究院有限公司 +2

Method for Producing Bonds

ActiveUS20120251757A1Reduce release forceEffective preventionAdhesive processesLamination ancillary operationsAdhesion forcePull off force

The invention relates to a method for producing a bonding of two substrates of which at least one is transparent and of which at least one has a surface having a surface energy (measured according to test method C) of 40 mN / m at maximum, comprising the use off a double-sided adhesive product having a first and a second adhesive surface, wherein the first adhesive surface is covered by a first separating layer and the second adhesive surface is covered by a second separating layer, wherein the pull-off force of the first separating layer from the first adhesive surface, AZK1, is less than the pull-off force of the second separating layer from the second adhesive surface, AZK2, and wherein the ratio of adhesion force of the fresh bond of the first adhesive surface on a surface having a surface energy (measured according to test method C) of 40 mN / m at maximum (KKfresh, measured according to test method B) to the pull-off force (measured according to test method A) of the second separating layer from the second adhesive surface, KKfresh: AZK2, equals at least 13.5, comprising the following step: (a) removing the first separating layer from the first adhesive surface and bringing the first adhesive surface into contact with the surface having a surface energy (measured according to test method C) of 40 mN / m at maximum.

Owner:TESA SE

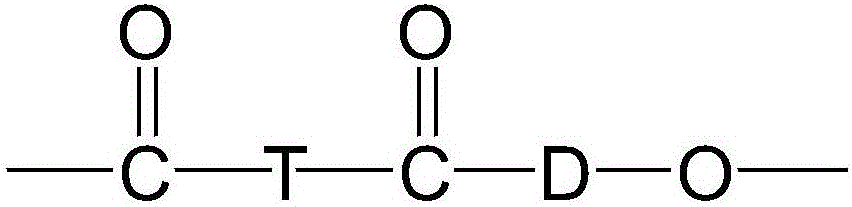

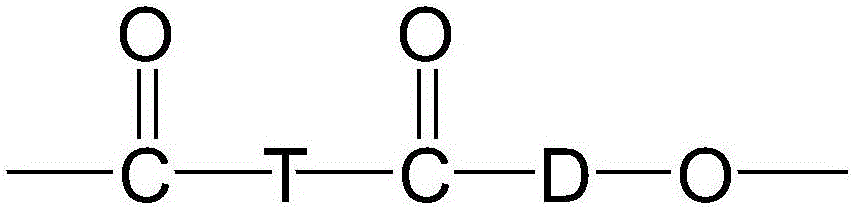

Release film for AB adhesive films

PendingCN113621323AImprove release forceReduce release forcePolyurea/polyurethane coatingsFilm/foil adhesive release linersPolymer scienceFilm base

The invention discloses a release film for AB adhesive films. The release film comprises a release film base material and a release agent layer coating the surface of the release film base material. The invention provides three release films with a unified solution suitable for AB adhesive films. Alkyl acrylates with different chain lengths are used as active monomer diluents, and the alkyl acrylates with different chain lengths are used to adjust the release force, so that the release films can be prepared by adopting an approximate content ratio and the same process, and the research and development and manufacturing costs are reduced.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

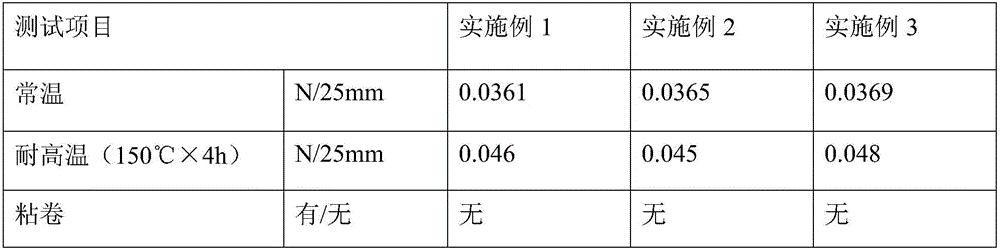

High-temperature-resistant composite release film

InactiveCN106166863ACompact structureEasy to peelSynthetic resin layered productsIsolation effectElastomer

The invention discloses a high-temperature-resistant composite release film, which comprises a release film layer, an adhesive layer and a high-temperature-resistant resin film layer, wherein the release film layer is obtained by co-extrusion process of two thermoplastic resin materials; the adhesive layer is formed by coating one surface of the release film layer with an adhesive; and the high-temperature-resistant resin film layer is glued on the adhesive layer. The three-layer high-temperature-resistant composite release film has a compact structure and is easy to peel off. On the basis of not influencing characteristics of rubber surface, release force is low. A fluorine-containing material is selected for the high-temperature-resistant resin film layer. At the high temperature of 200 DEG C, the high-temperature-resistant resin film layer can never be decomposed or react with the release layer or the adhesive layer. The release film has excellent anti-sticking and isolation effects, and has dimensional stability at high temperature. The release layer adopts an organosilicon elastomer adhesive and the thickness is controlled. Then, there is no residue on the release layer.

Owner:SUZHOU KECHUANG ELECTRONICS MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com