Release film for AB adhesive films

A technology of release film and adhesive film, which is applied in the direction of film/sheet adhesives, adhesives, film/sheet release liners, etc., can solve problems such as no solution provided, and achieve excellent release performance and attached The effect of high force and low release force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

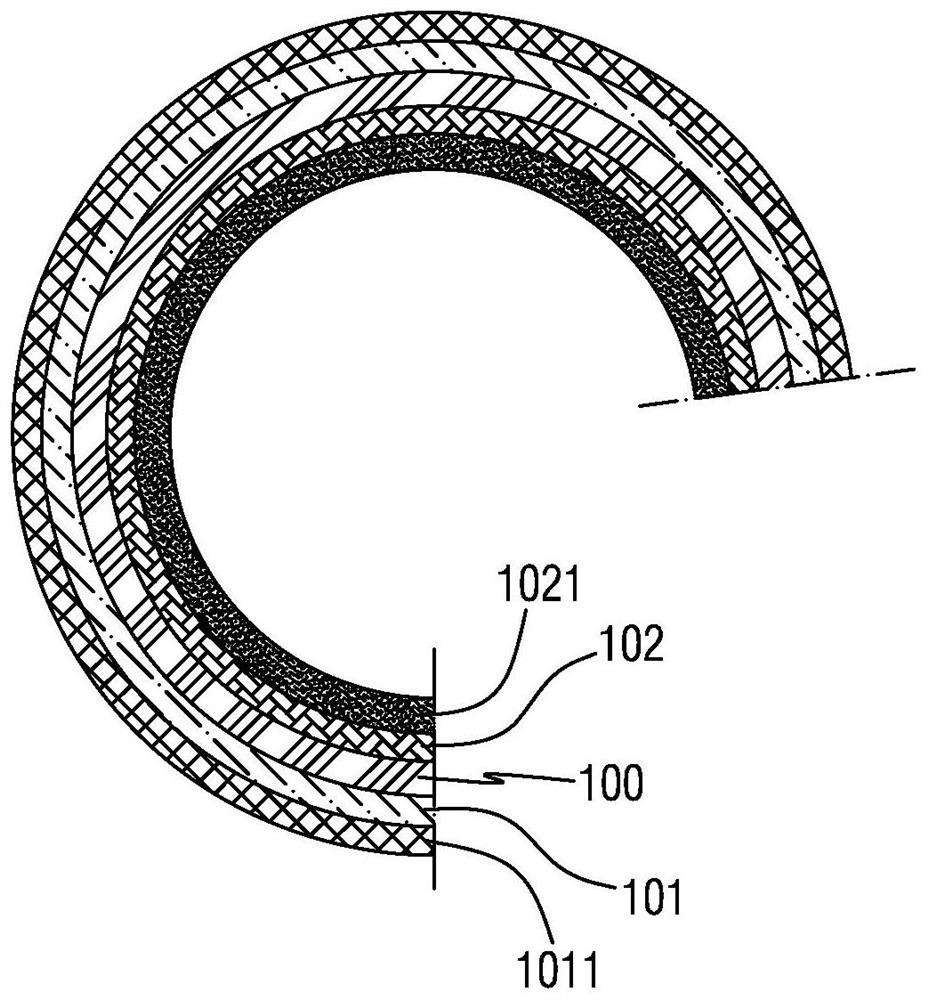

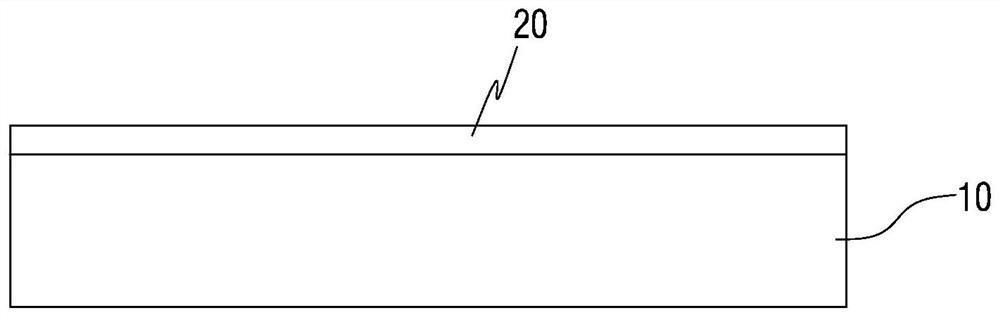

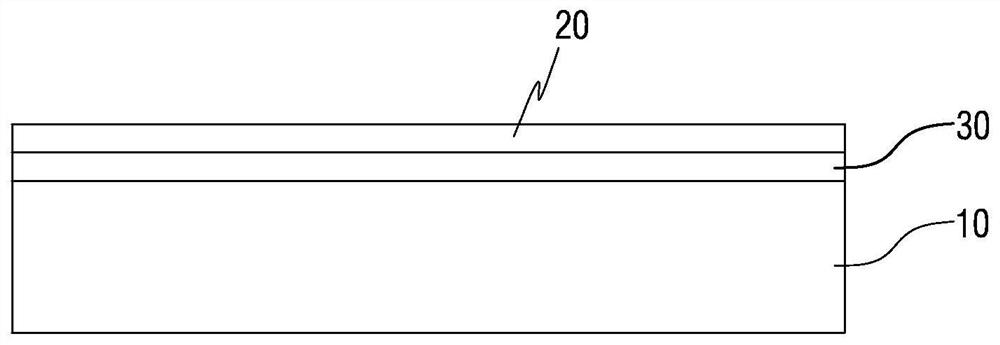

[0024] This embodiment provides a suitable for attaching to figure 1 The high-viscosity layer on the surface of the shown high-viscosity layer 102 has a release film with light release force, and its specific structure can be as follows figure 2 As shown, including the release film substrate 10 and the release agent layer 20 coated on the surface of the release film substrate 10, the release agent layer 20 is prepared from the following parts by weight of raw materials Dosage made from:

[0025] 60-140 parts by weight of polybutadiene polyurethane, 45-85 parts by weight of polyacrylate resin, 10-25 parts by weight of hydroxypropyl methacrylate, 25-55 parts by weight of trifluoroethyl methacrylate active Monomer diluent, the active monomer diluent of 2-methyl-2-acrylic acid behenyl ester of 20-25 parts by weight, the initiator of 1-5 parts by weight is 2-hydroxyl-2-methyl-1 -Phenyl-1-propanone.

[0026]The release agent in Example 1 is a UV-curable release agent without sil...

Embodiment 2

[0028] This embodiment provides a suitable for attaching to figure 1 The low-viscosity layer on the surface of the shown low-viscosity layer 101 has a release film with medium release force, and its specific structure can be as follows figure 2 As shown, including the release film substrate 10 and the release agent layer 20 coated on the surface of the release film substrate 10, the release agent layer 20 is prepared from the following parts by weight of raw materials Dosage made from:

[0029] 60-140 parts by weight of polybutadiene polyurethane, 45-85 parts by weight of polyacrylate resin, 10-25 parts by weight of hydroxypropyl methacrylate, 25-55 parts by weight of trifluoroethyl methacrylate active Monomer diluent, the stearyl methacrylate active monomer diluent of 20-25 weight parts, the initiator of 1-5 weight part is 2-hydroxyl-2-methyl-1-phenyl-1- acetone.

[0030] The release agent in Example 2 is a UV-curable release agent without silicone oil components. It does...

Embodiment 3

[0032] This embodiment provides a suitable for attaching to figure 1 The surface of the shown high-viscosity layer 101 has a release film with medium release force for the high-viscosity layer, and its specific structure can be as follows figure 2 As shown, including the release film substrate 10 and the release agent layer 20 coated on the surface of the release film substrate 10, the release agent layer 20 is prepared from the following parts by weight of raw materials Dosage made from:

[0033] 60-140 parts by weight of polybutadiene polyurethane, 45-85 parts by weight of polyacrylate resin, 10-25 parts by weight of hydroxypropyl methacrylate, 25-55 parts by weight of trifluoroethyl methacrylate active Monomer diluent, the dodecyl methacrylate active monomer diluent of 20-25 parts by weight, the initiator of 1-5 parts by weight is 2-hydroxyl-2-methyl-1-phenyl-1- acetone.

[0034] The release agent of Example 3 is a UV-curable release agent without silicone oil component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com