Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve release force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft-magnetic composite material and process for making magnetic conduction component by using same

InactiveCN1700368AWiden your optionsLow costInorganic material magnetismInductances/transformers/magnets manufactureLubricationCalcium carbonate

This invention relates to soft magnetic compound materials, which are characterized by the following: the said materials comprise iron material, isolation agent and lubrication agent with their weight percentage as 92-99 úÑ, 0.5-5 úÑ , 0.5-3 úÑ; the said iron material is powder material, which comprise deoxidized powder, atomized iron powder, hydroxide powder and iron alloy with iron of 80-99.8úÑ; Particle distribution of 20-500; the said isolation agent adopts nanometer calcium carbonate powder or ceramics powder or magnetic oxidation power; the said lubrication is micro powder. The process comprises the following steps: mixing, shaping, solidifying and stainless processing.

Owner:罗计添 +2

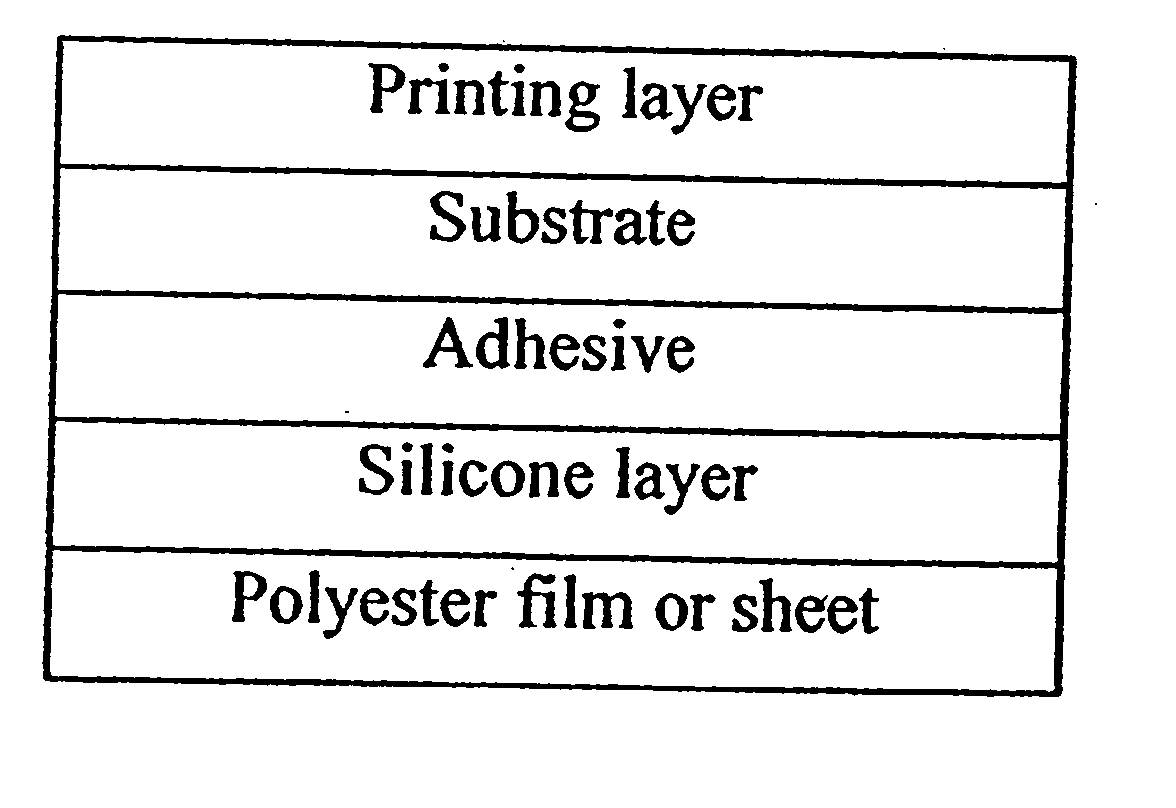

Silicone release polyester film

InactiveUS20050118443A1High viscosityLow viscositySynthetic resin layered productsRecord information storagePolyesterAdhesive

The invention illustrates herein several tests among various manufacturing methods and tests carried out by the inventors according to the method of manufacturing a silicone release polyester film. It should be noted that the technical spirit of the invention shall not be limited or restricted thereby, and can be modified and carried out variously by those skilled in the art. As described in the above, the silicone release polyester film according to the invention is very good in stabilization for pass-the-time and also very good in the property of rub-off after thermal ripening by improving adhesiveness between the polyester layer and the silicone layer by olgano resin having the vinyl radical in the silicone film layer. By improving easiness of release destruction behavior with the adhesive used for release by containing the olgano resin having the vinyl radical in hexenyl polysiloxane, the silicone release polyester film can be used for electronics and the field requiring uniform release. The silicone release polyester film according to the invention can solve the problems of weakened adhesiveness on an adhesive layer combined with the silicone layer resulting from silicone transfer in a process and of bad printing on the surface opposite to the adhesive layer, by allowing the property of minimized silicone transfer in which the content of silicone residue is below 10% by means of excellent silicone hardening.

Owner:TORAY SAEHAN

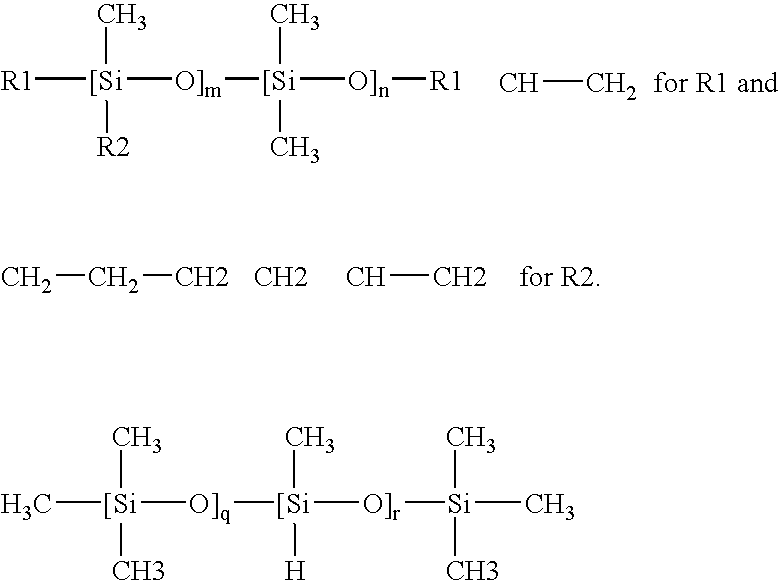

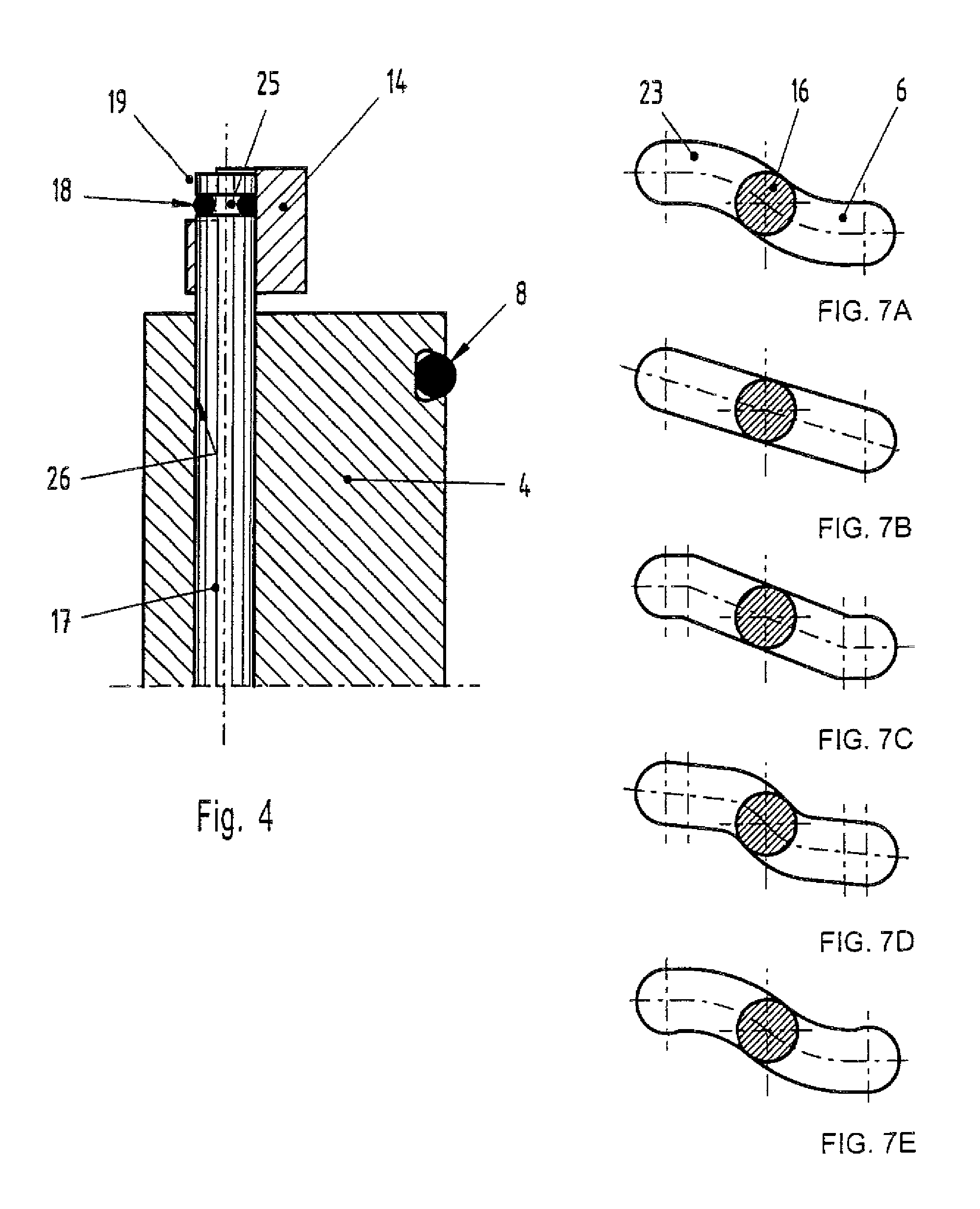

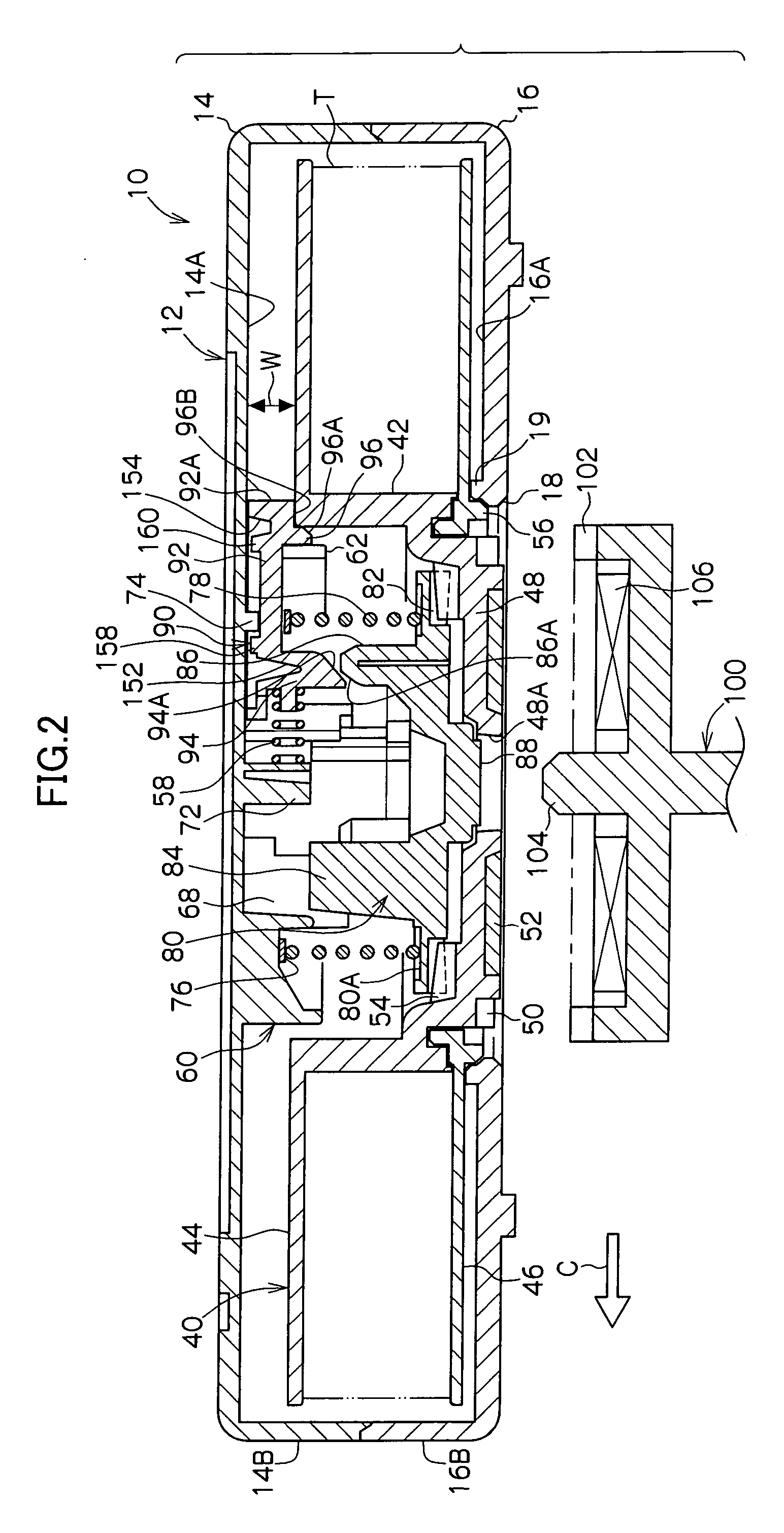

Valve mechanism for a vacuum valve

ActiveUS7341237B2Equal force transmission capabilityImprove carrying capacityOperating means/releasing devices for valvesSlide valveEngineeringVALVE PORT

A valve mechanism having at least one movable valve member for sealing of a valve opening in a housing. Movements of the individual movable valve members are accomplished essentially parallelly to, and perpendicularly to, the seat surface of the valve during the opening and closing of the valve. In order to achieve high forces and low wear in the movement carried out with aid of a slot guide which guide serves to transmit forces during, and in the direction of, the opening and closing, the slot guide comprises slots which are formed in a drive plate, which slots cooperate with and overlap complementary slots in the movable valve members.

Owner:BOSCH HUBERT

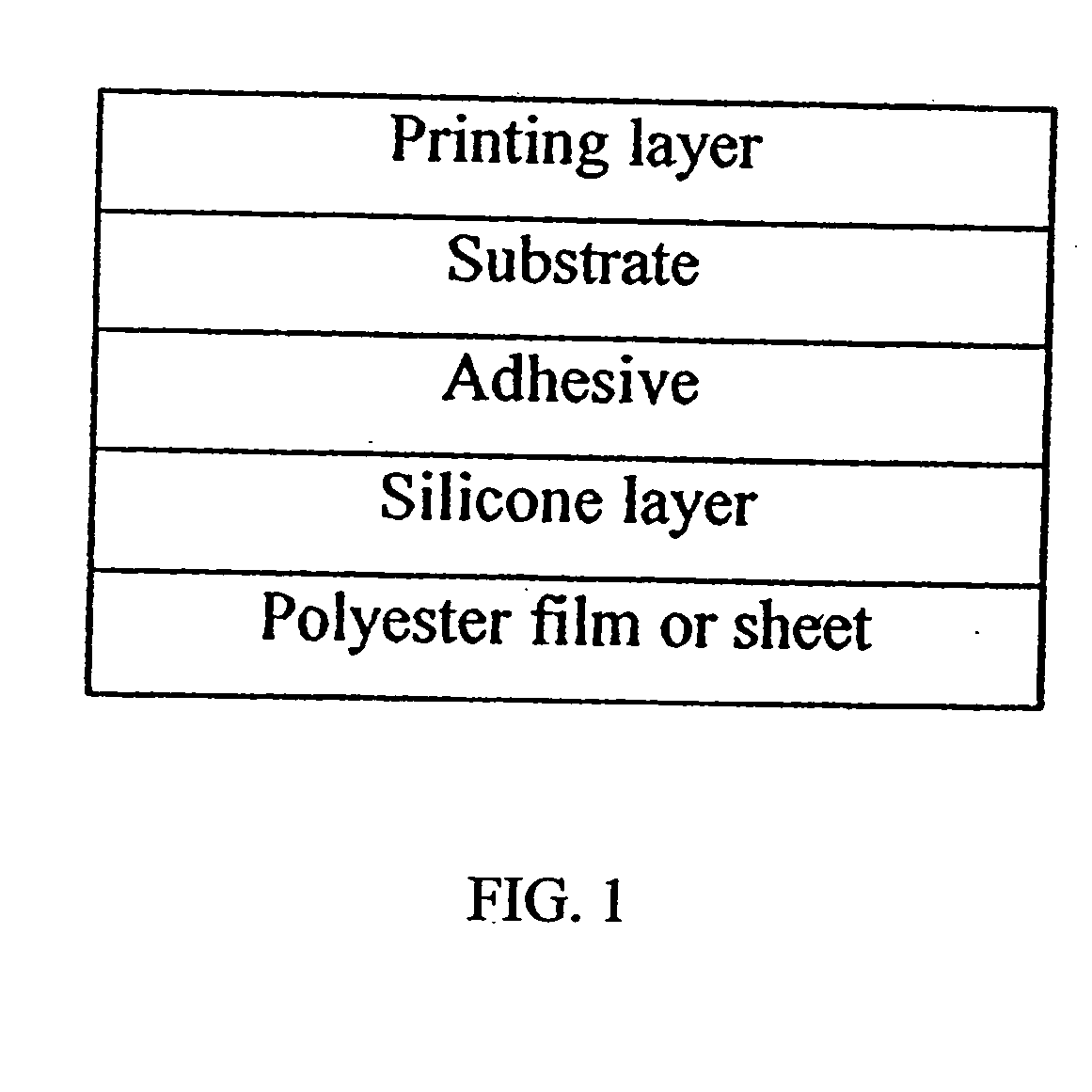

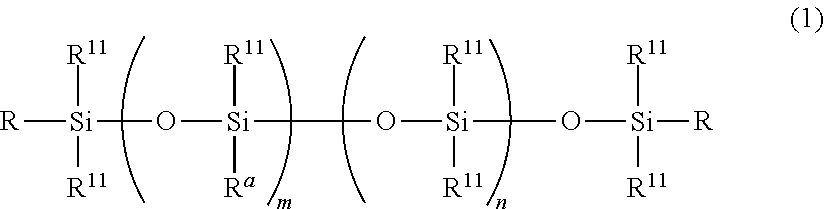

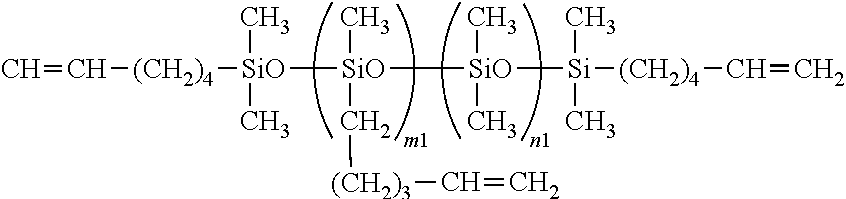

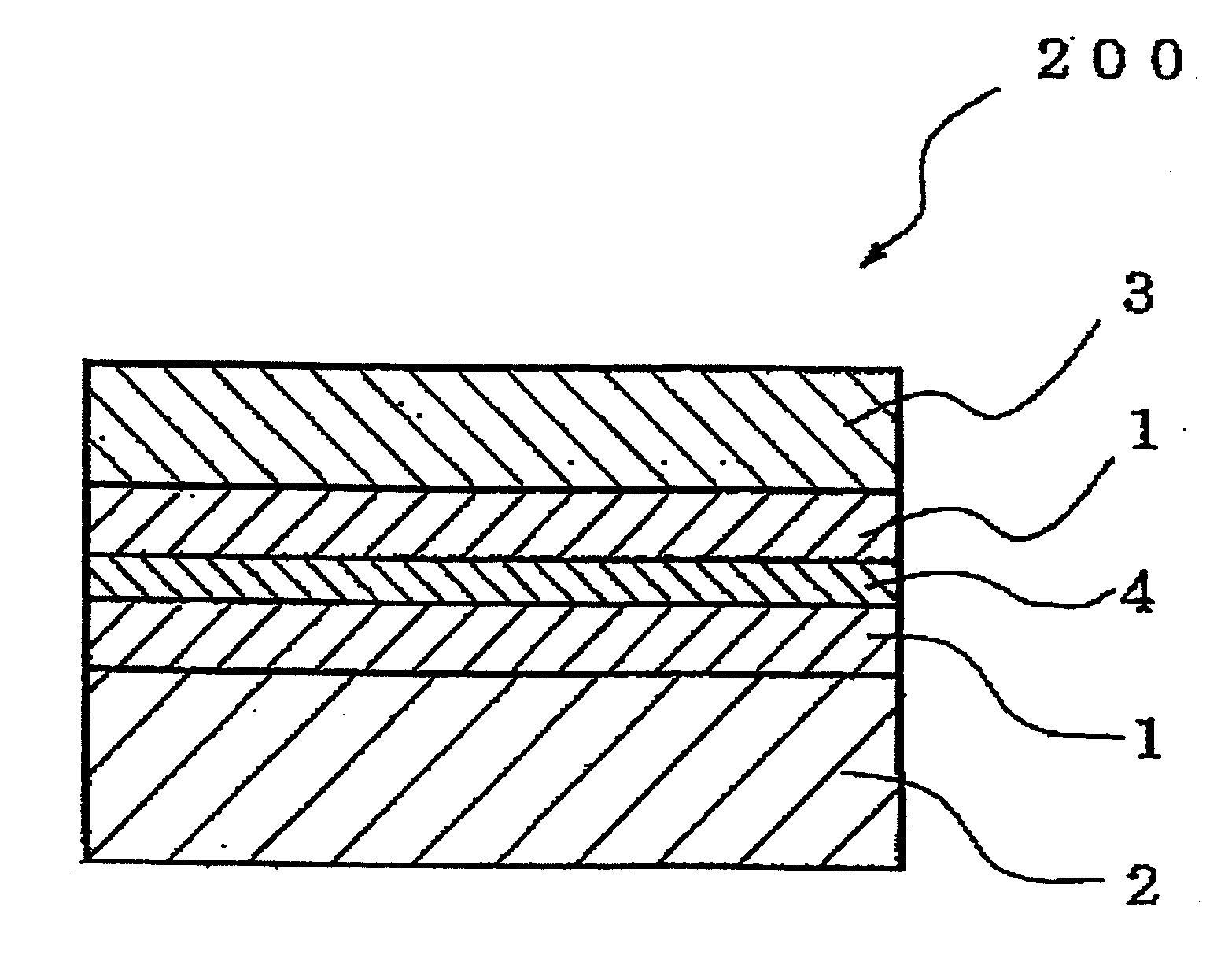

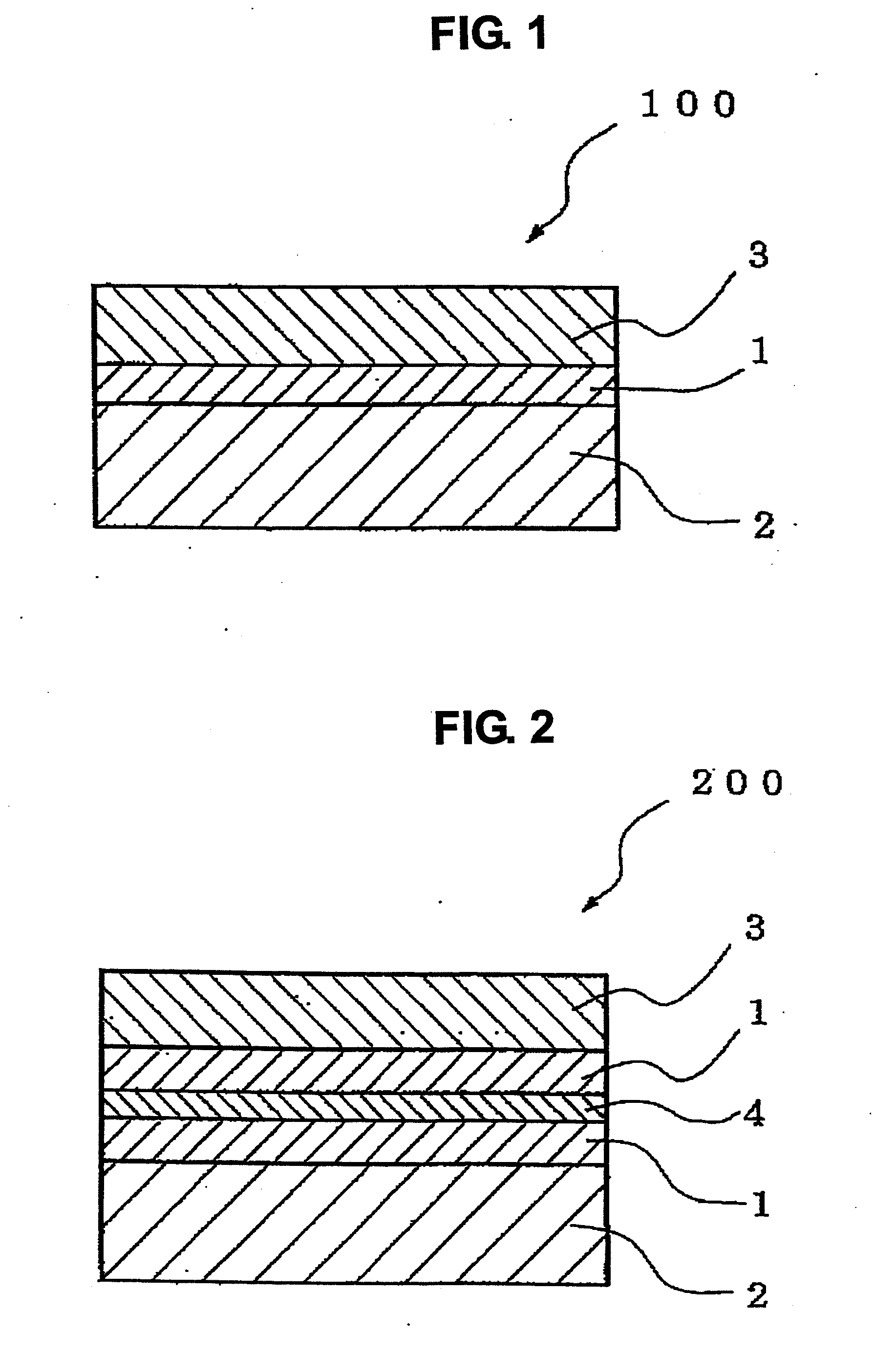

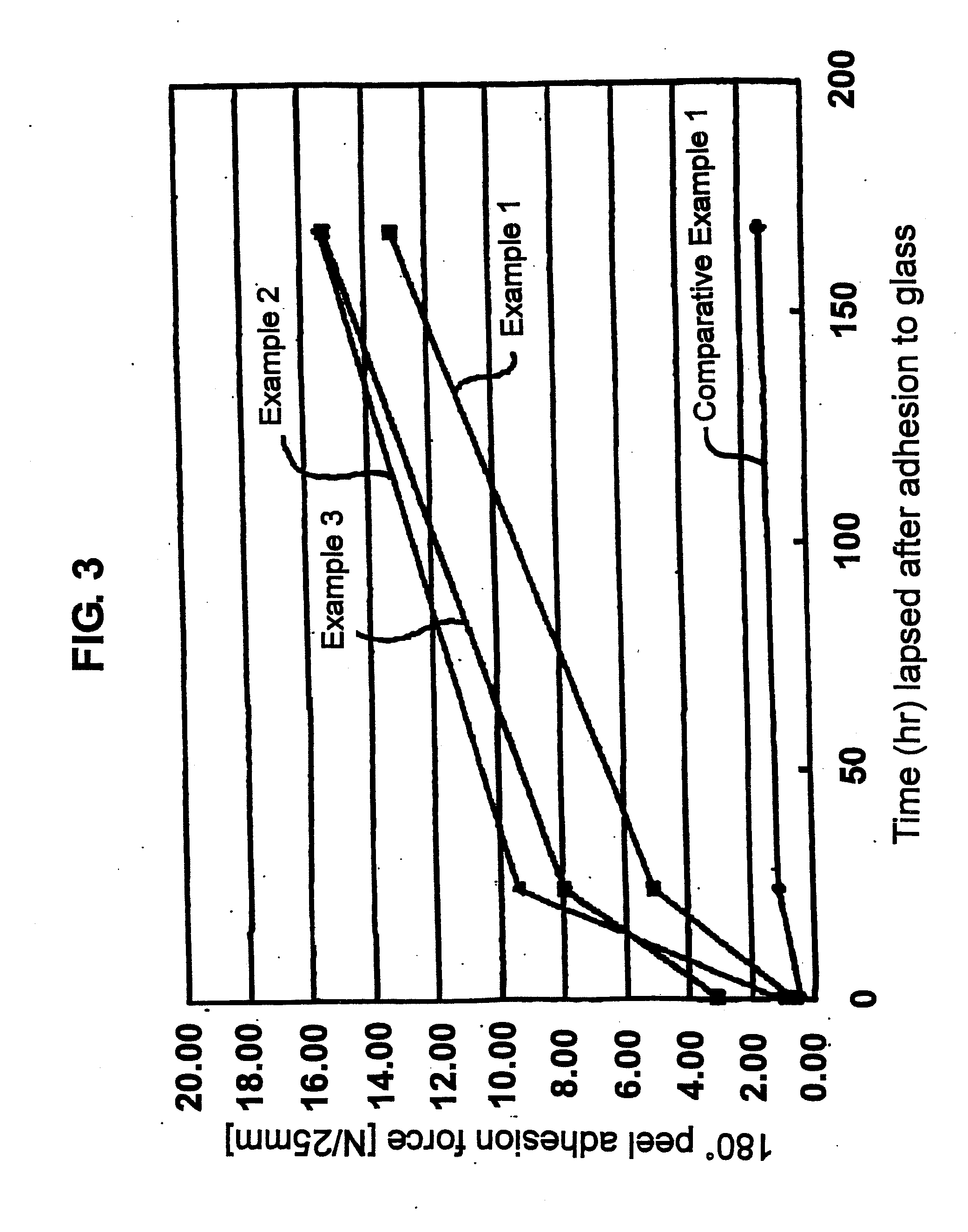

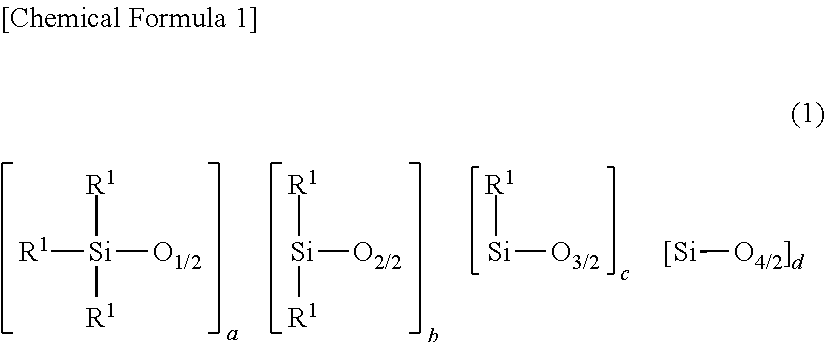

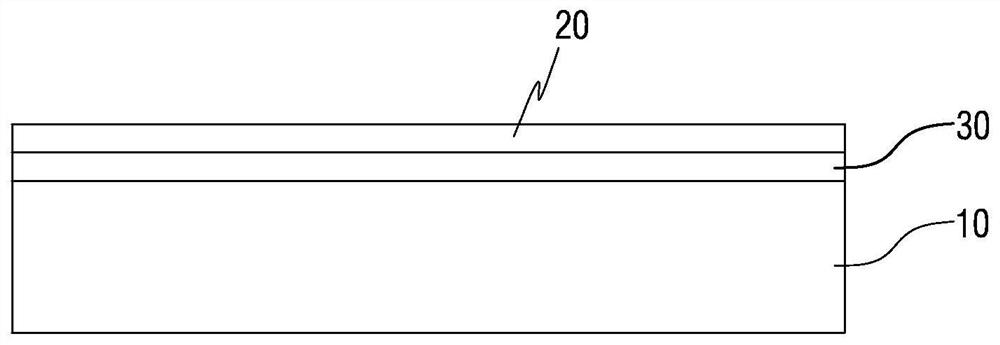

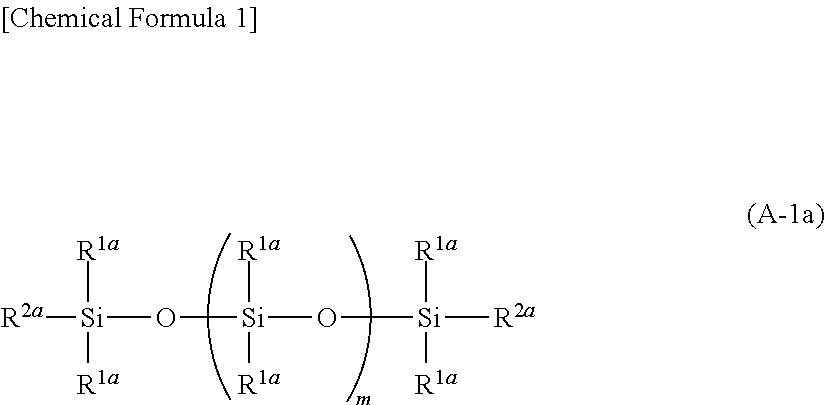

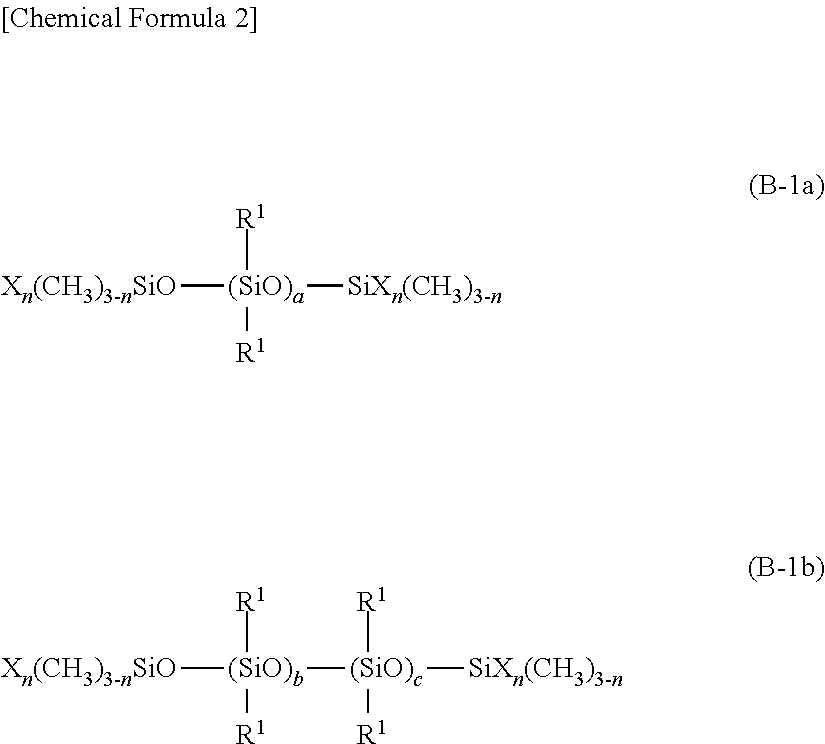

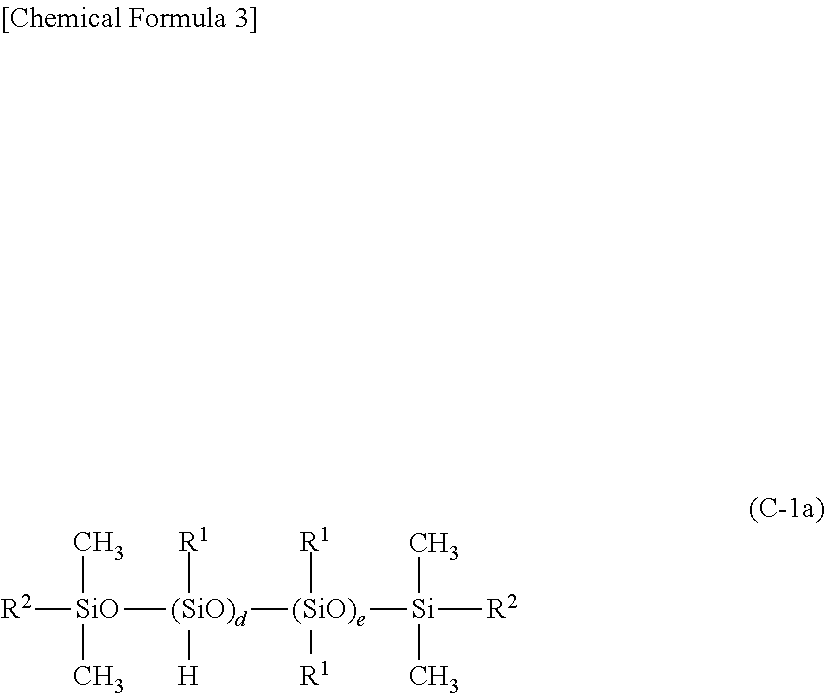

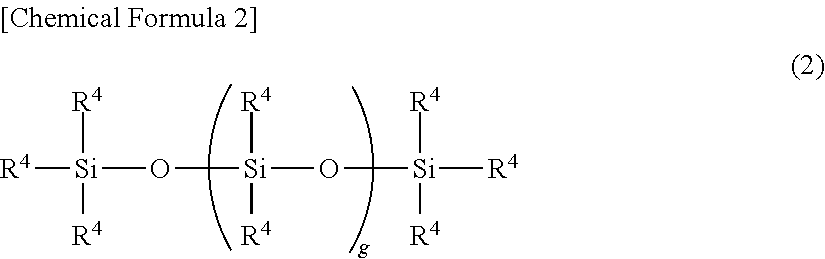

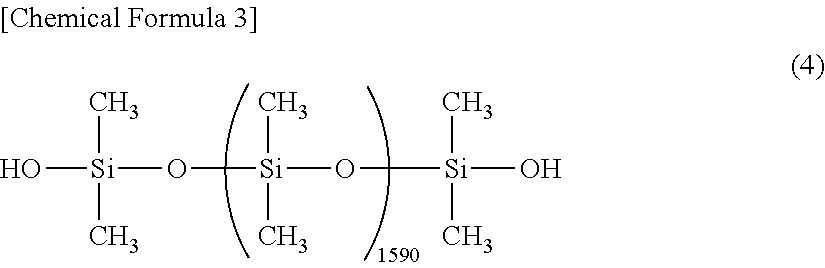

Curable organopolysiloxane composition, sheet-like article having a cured layer formed from said composition, and laminate

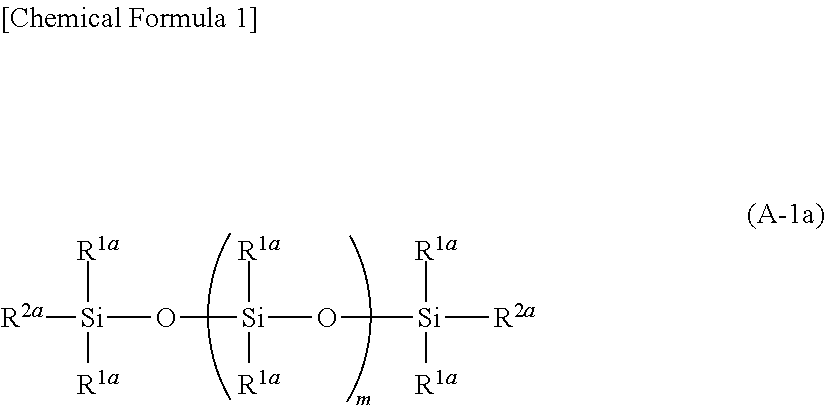

InactiveUS20150284590A1Improve release forceLittle changeFilm/foil adhesivesLayered productsOrganic solventHydrosilylation

A curable organopolysiloxane composition comprising: (A) at least one type of gum-like or liquid organopolysiloxane having a viscosity of not less than 20 mPa·s, a content of the vinyl(CH2═CH—) part of higher alkenyl groups being in a range of 2.0 to 5.0% by mass; (B) an organopolysiloxane resin formed essentially from R13SiO1 / 2 units and SiO4 / 2 units, a molar ratio of the R13SiO1 / 2 units to the SiO4 / 2 units being from 0.5 to 2.0 and a content of the vinyl(CH2═CH—) part of alkenyl groups being less than 1.0% by mass; (C) an organohydrogenpolysiloxane; (D) a hydrosilylation reaction catalyst; and, optionally, (E) an organic solvent. In such a composition, a mass ratio of the component (A) to the component (B) is in a range of 2 / 8 to 8 / 2.

Owner:DOW CORNING TORAY CO LTD

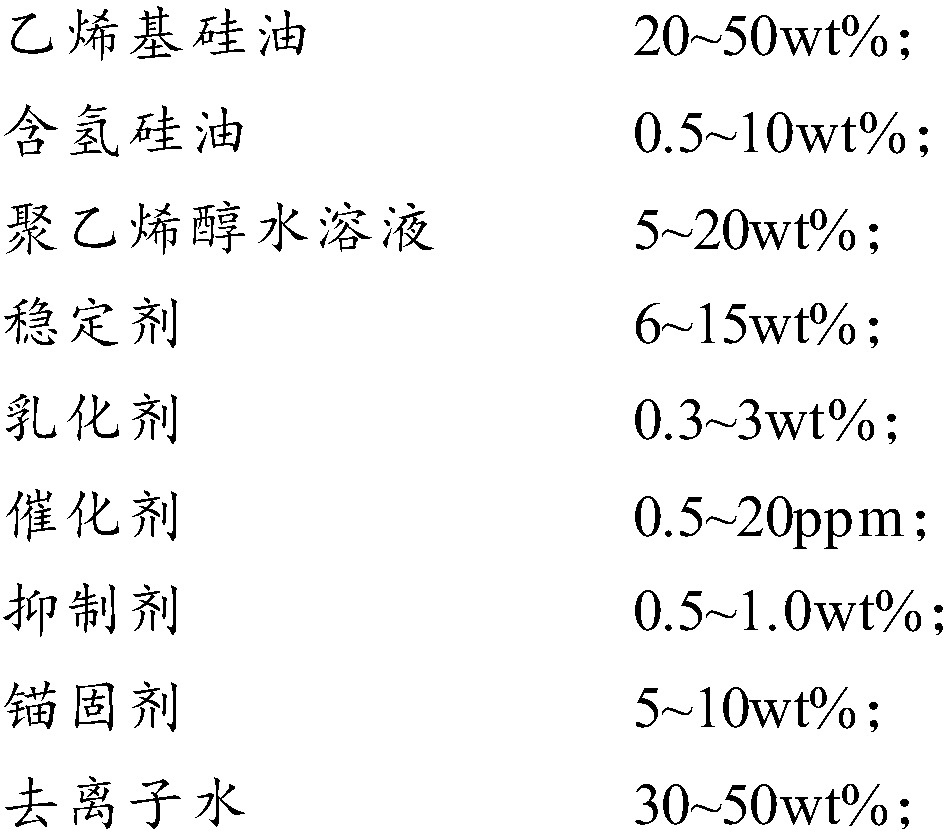

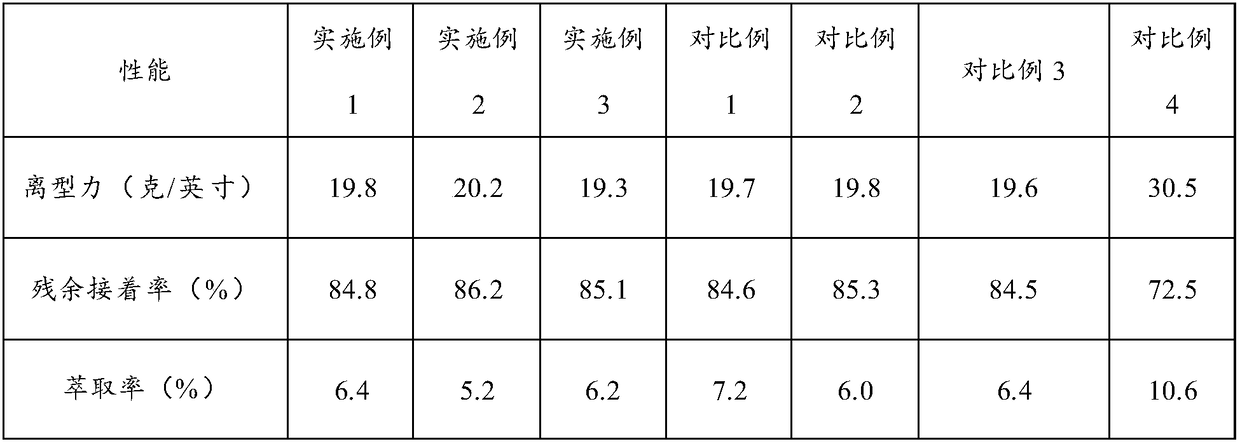

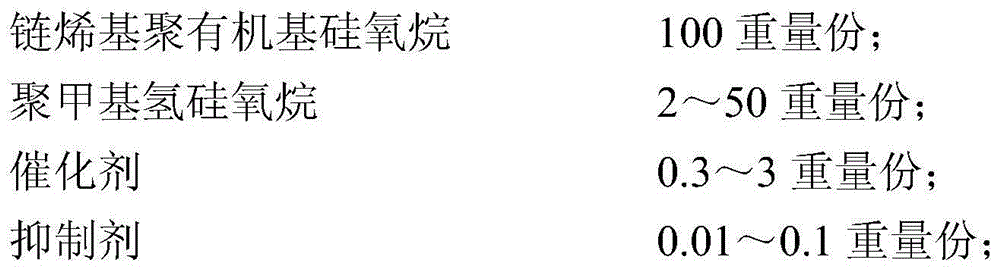

Emulsion type release agent and preparation method thereof

The invention provides an emulsion type release agent. The emulsion type release agent is prepared from the following raw materials of 20 to 50wt% of vinyl silicone oil, 0.5 to 10wt% of hydrogen-containing silicone oil, 5 to 20wt% of polyvinyl alcohol water solution, 6 to 15wt% of a stabilizer, 0.3 to 3wt% of an emulsifier, a 0.5 to 20 ppm catalyst, 0.5 to 1.0wt% of an inhibitor, 5 to 10wt% of ananchoring agent, and 30 to 50wt% of deionized water, wherein the molar ratio of the hydrogen group in the hydrogen-containing silicone oil to the vinyl group in the vinyl silicone oil is (2.0 to 3.5):1. The emulsion type release agent is a safe and environment-friendly type emulsion type release agent with the advantages that the curing speed is quick, the anchoring property is good, the release force is light, and the grafting rate of residue is high.

Owner:杭州崇耀科技发展有限公司 +1

Release agent composition for plastic mold and component using the same

InactiveCN1799805AReduce % DefectiveImprove release forceCeramic shaping apparatusLubricant compositionPolymer scienceActive agent

There is provided a novel nonflammable release agent composition for a plastic mold containing: (a) a hydrofluoroether; (b) fluorine oil; and (c) a fluorine-based surfactant, in which the content of the ingredient (a) is 50 wt % or more. The composition is lowly toxic, noncombustible, and more chemically stable than a conventional one, and brings together high persistence of releasability and sufficient durability.

Owner:CANON KK

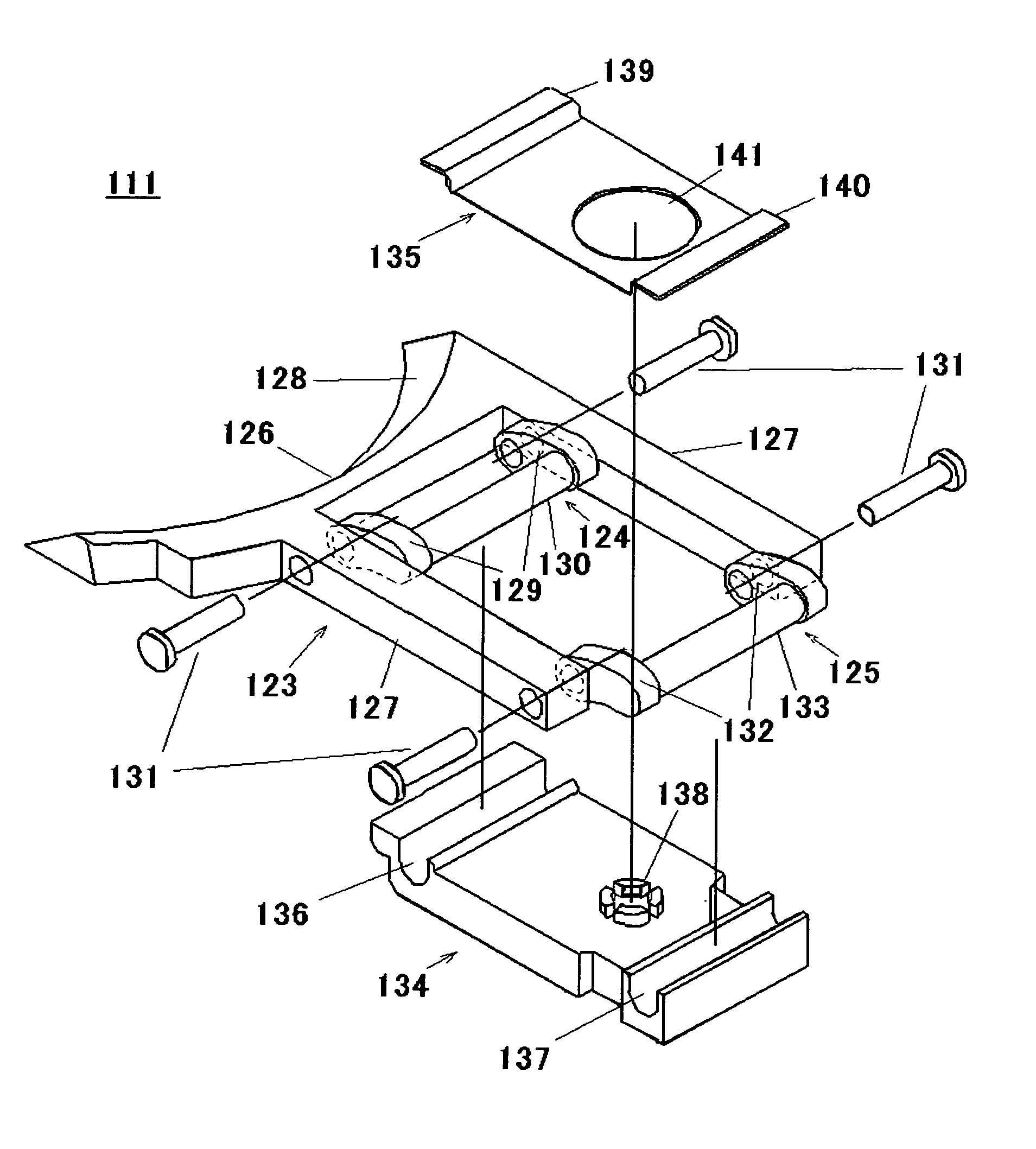

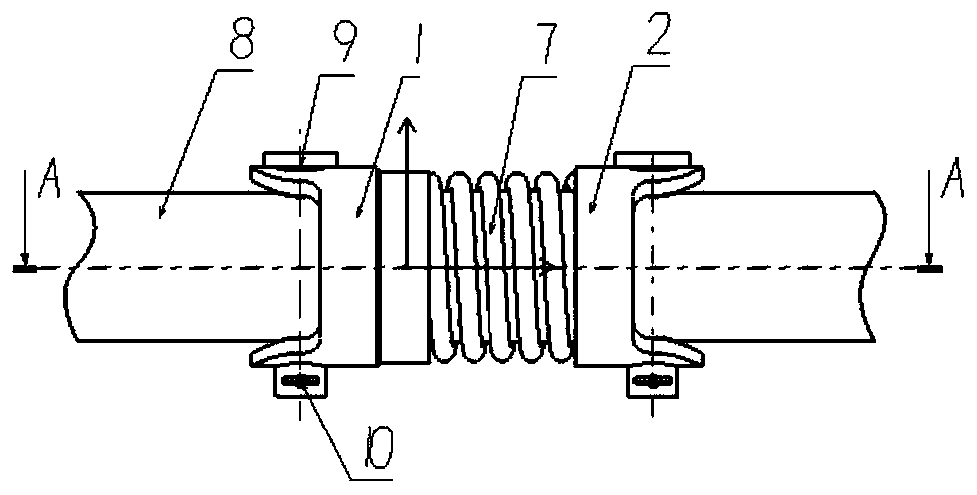

Recording tape cartridge

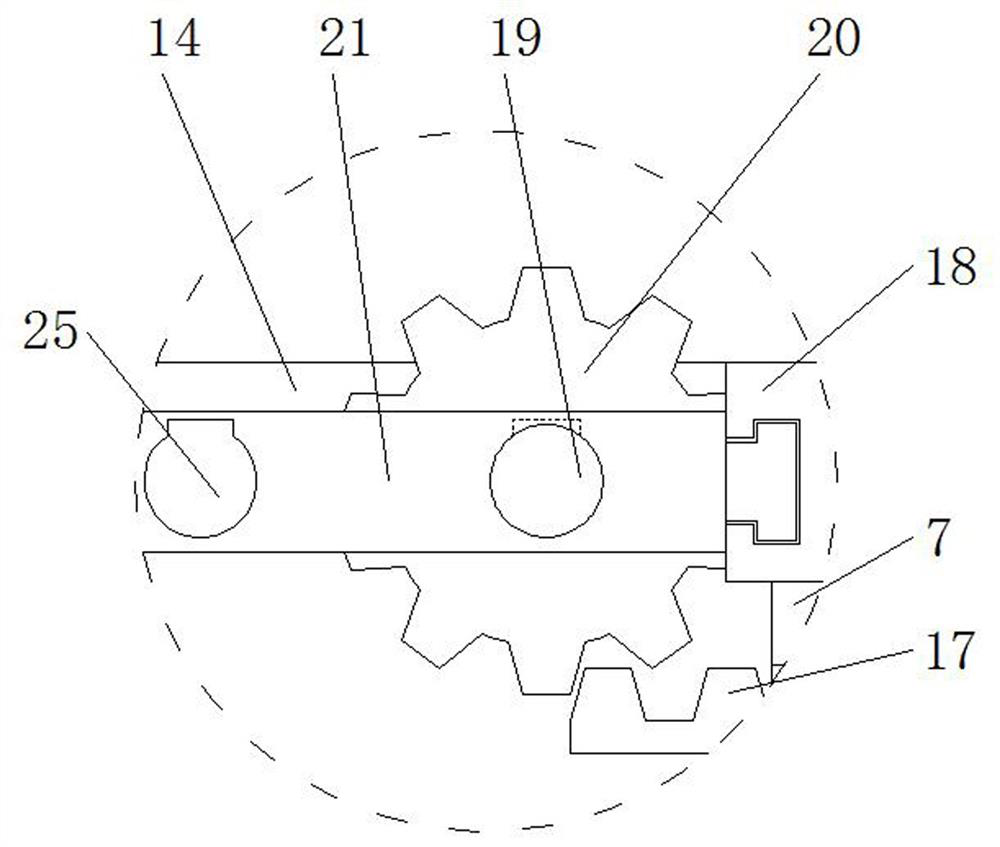

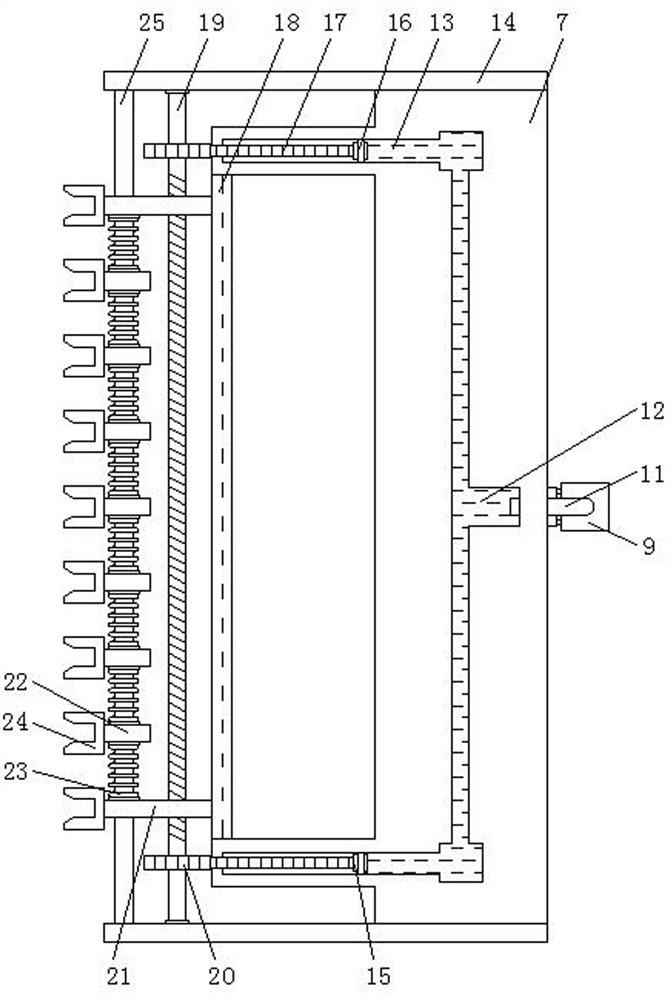

ActiveUS20060231659A1Minimize fluctuationReduce wearPicture changing apparatusRecord information storageGear wheelCoil spring

In a recording tape cartridge, a compression coil spring urges a reel downward via a brake member. Due to the biasing force of the spring, a gear of the brake member securely meshes with a gear inside a reel hub preventing the reel's inadvertent rotation. The biasing force urges lock members outward in a radial direction from the center of a mount or the reel. Engagement portions of the lock members engage with an upper edge of the hub. The outer side surfaces of the engagement portions press against the inner peripheral surface of the hub, and ends of the engagement portions at a further outer side than the body portions intervene between the upper surface of an upper flange and the inner surface of a top plate to prevent rotation of the reel and to control movement of the reel in either a radial or an axial direction.

Owner:FUJIFILM CORP +1

Transparent adhesive sheet for flat panel display, and flat panel display

InactiveUS20110250460A1Superior flexibilityHigh adhesive forceGlass/slag layered productsThin material handlingFlat panel displayDistortion

The invention provides a transparent adhesive sheet for a flat panel display, which does not permit delamination on the adhesion surface to the glass plate even if a stress such as distortion, bending and the like is applied to the display, and does not produce bubbles in the boundary with the glass plate. The transparent adhesive sheet for a flat panel display comprised of a cured product of a composition comprising (A) a polyoxyalkylene based polymer having at least one alkenyl group in one molecule, (B) a compound having an average of not less than 2 hydrosilyl groups in one molecule, and (C) a hydrosilylation catalyst.

Owner:NITTO DENKO CORP

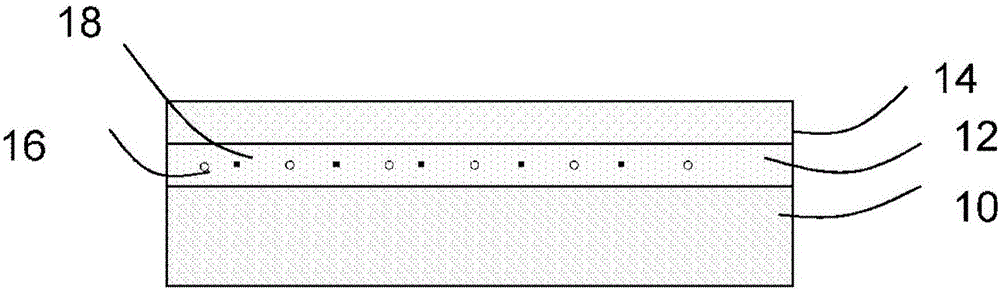

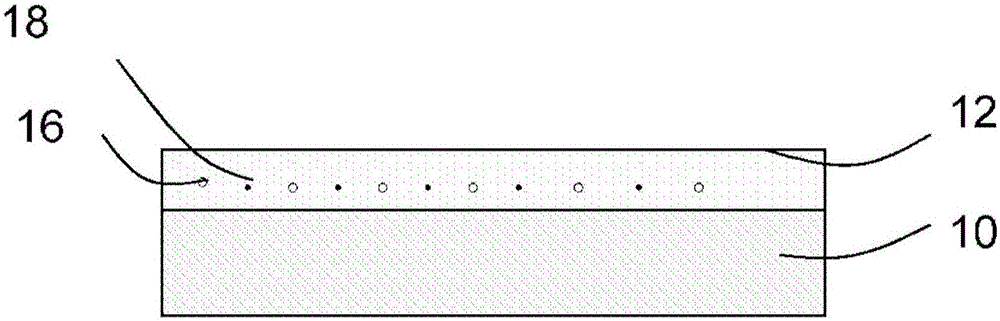

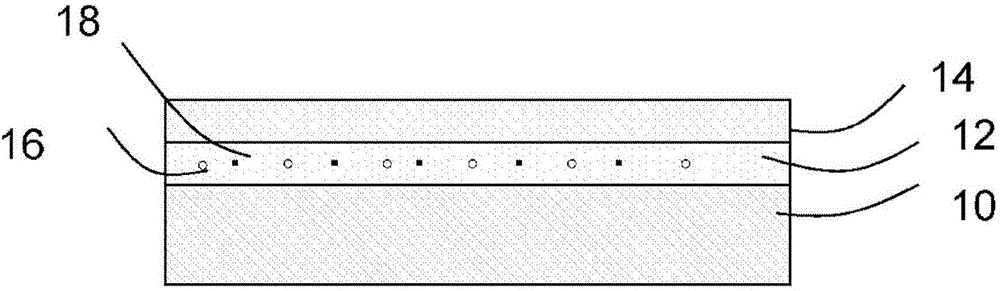

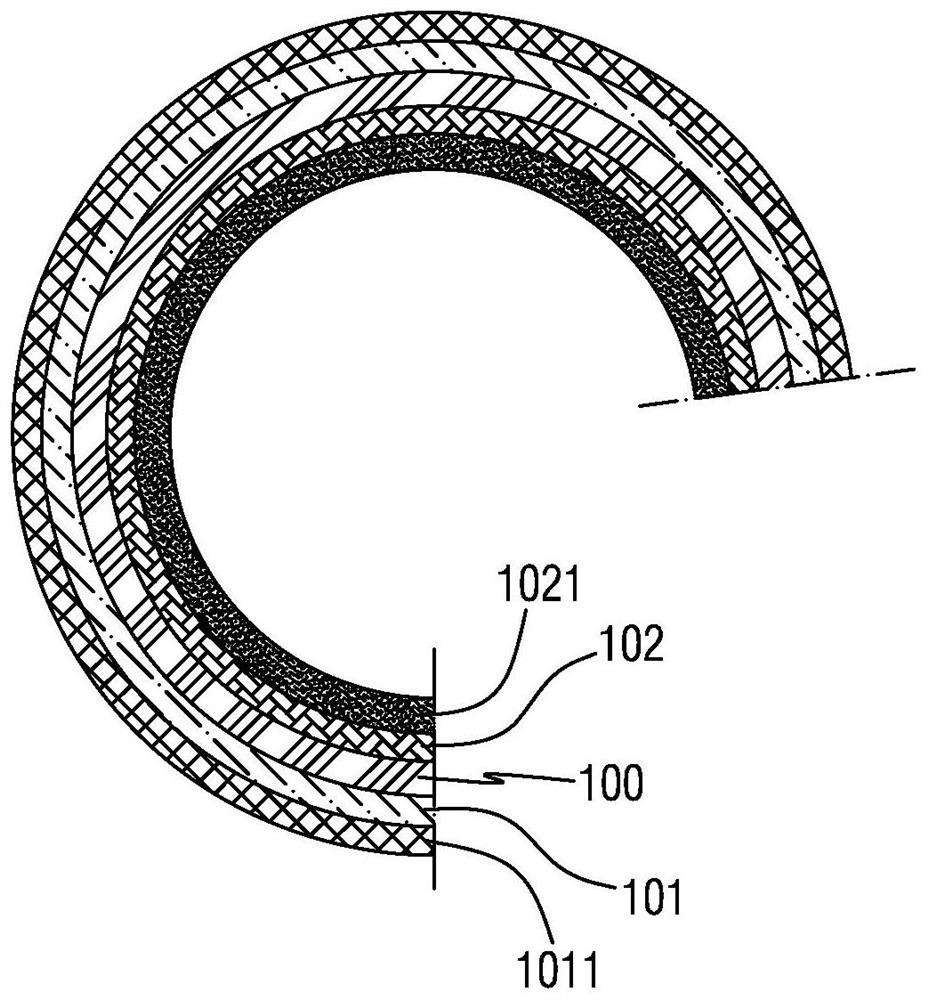

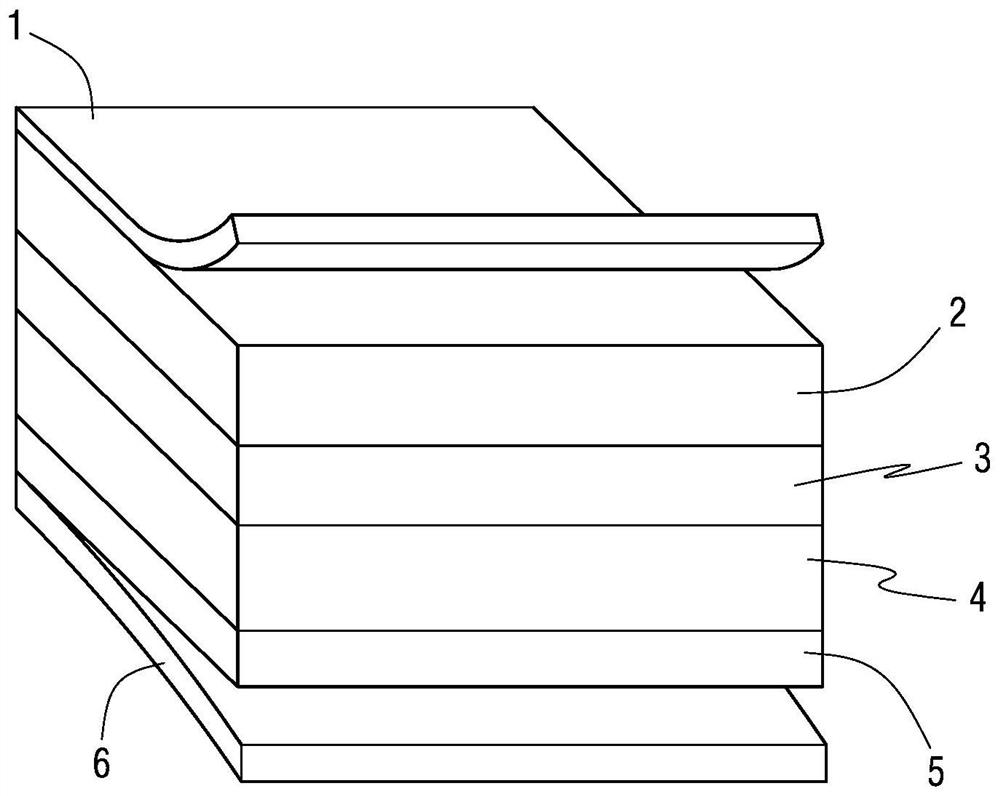

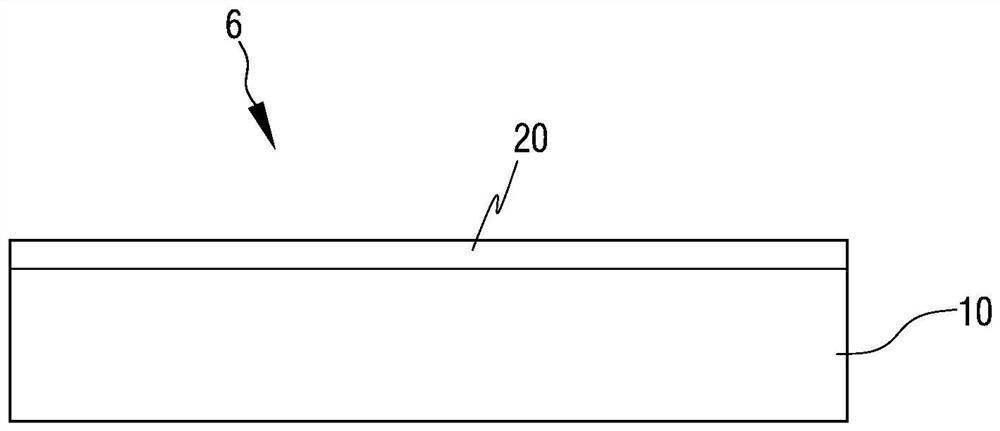

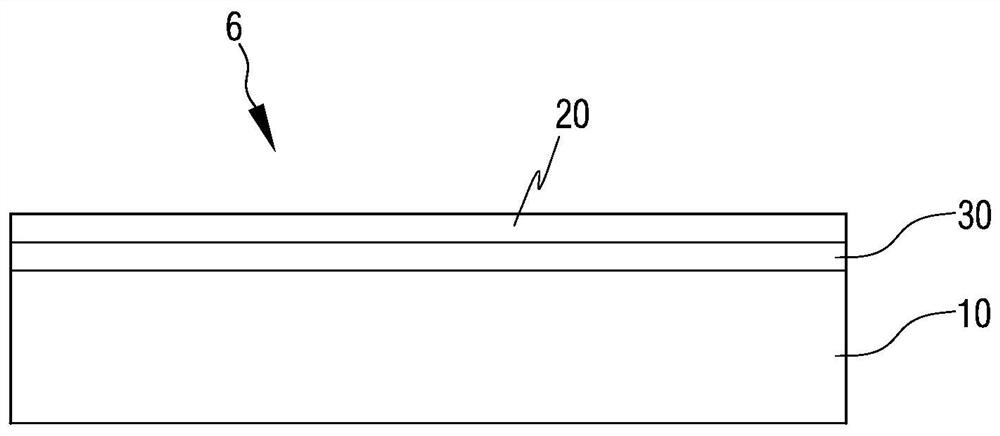

Separable type flexible substrate and manufacturing method thereof

InactiveCN106252269AImprove release forceImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingSilane compoundsDiamine

The invention provides a detachable flexible substrate and a manufacturing method thereof, which includes a support carrier; a release layer attached to the support carrier, which includes polyimide, silane, which constitute the main structure of the release layer compound and siloxane compound, the silane compound accounts for 1-10wt% of the total weight of the release layer, the siloxane compound accounts for 5-45wt% of the total weight of the release layer, and the polyimide consists of diamine and Formed by the reaction of dianhydride; a polyimide layer is formed by the reaction of diamine and dianhydride, which is attached to the release layer, wherein the siloxane compound is used to improve the contact between the polyimide layer and the The release force of the release layer, the silane compound is used to improve the adhesion between the release layer and the support carrier, so that the adhesion between the release layer and the support carrier is greater than the adhesion between the polyimide layer and the release layer degree, so that the polyimide layer can be peeled off from the release layer, while the release layer is still attached to the support carrier.

Owner:TAIMIDE TECH

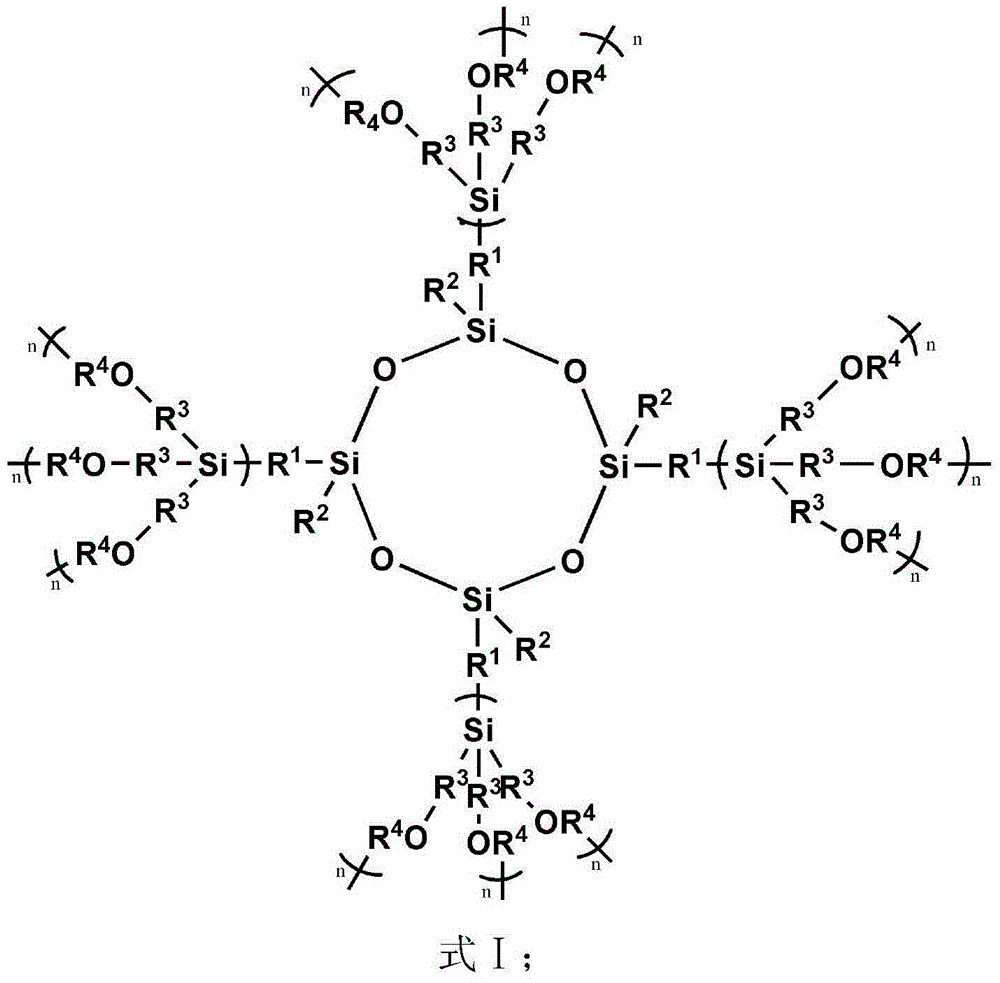

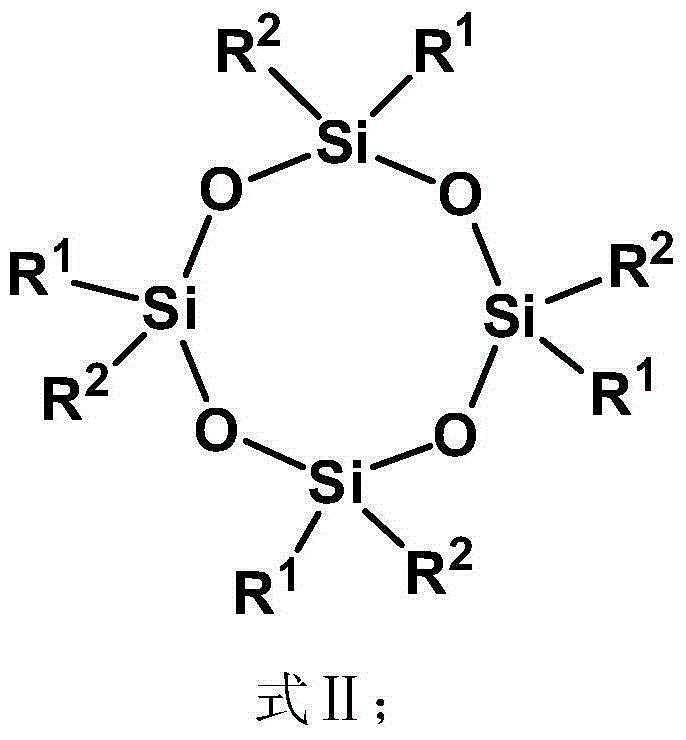

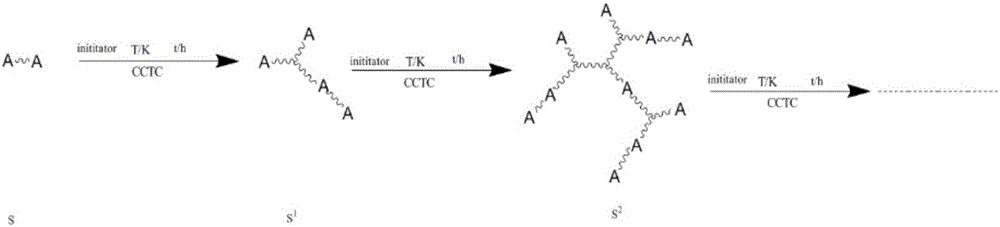

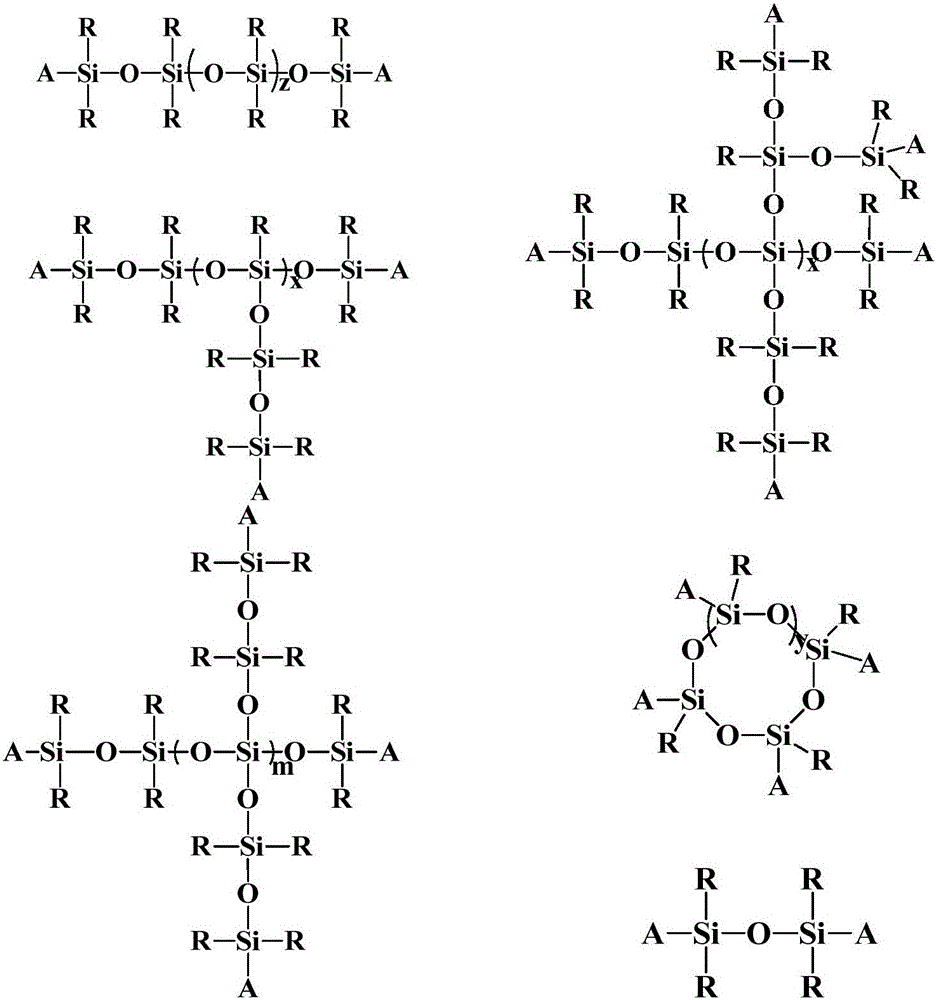

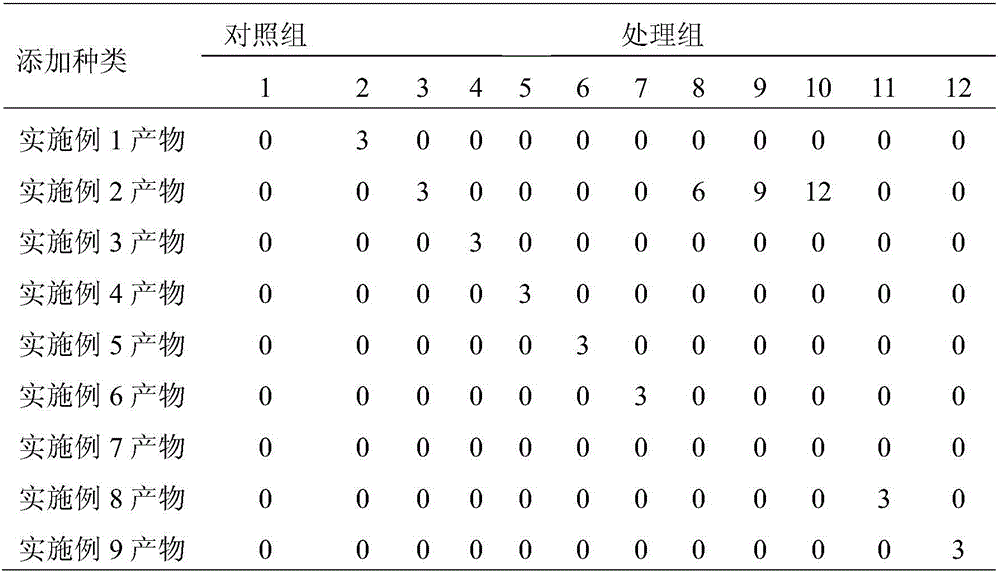

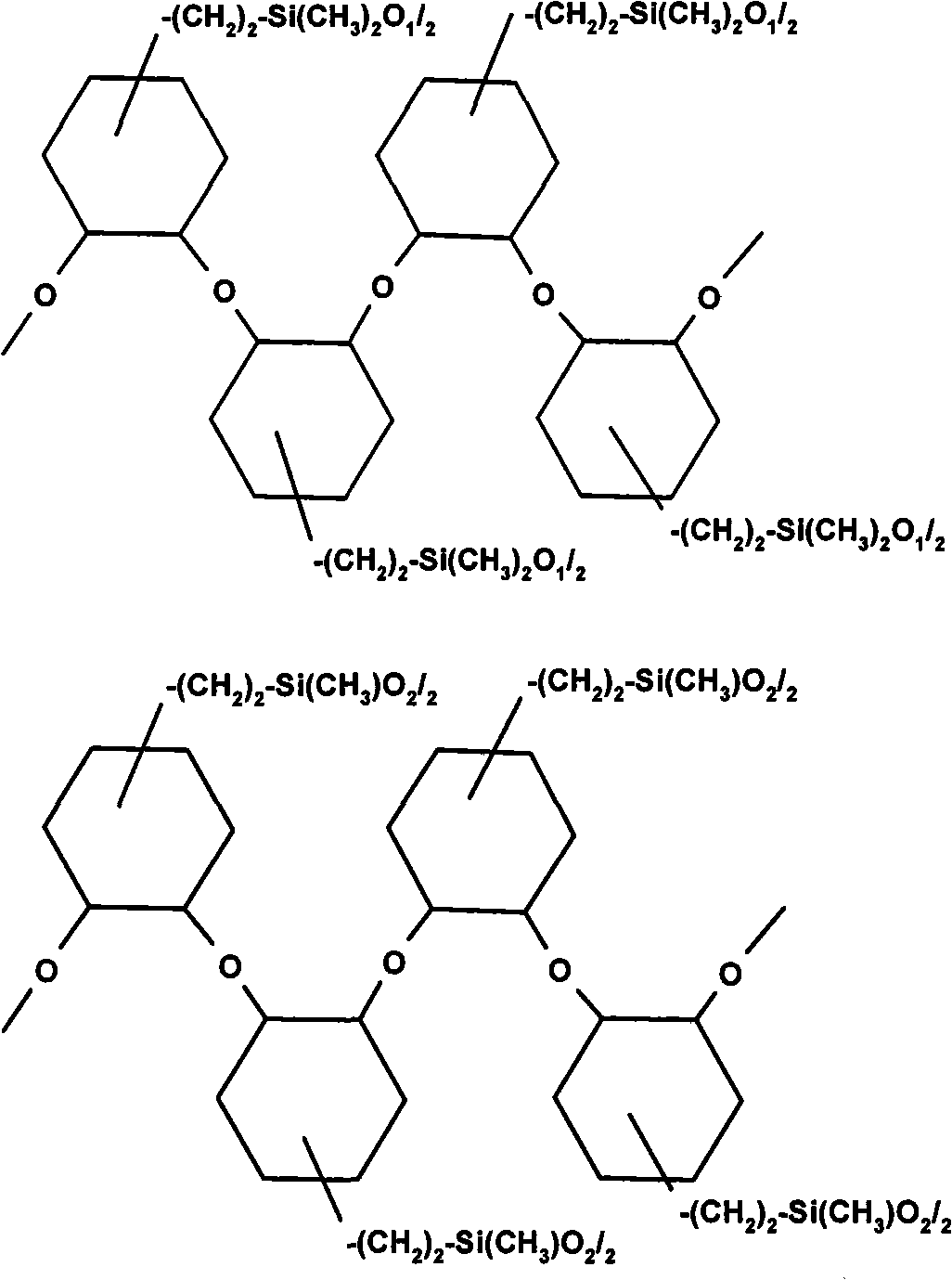

Spherical dendritic organic silicon macromolecule, preparation method thereof and application

The invention belongs to the field of chemical synthesis, and particularly relates to a spherical dendritic organic silicon macromolecule, a preparation method thereof and an application. The structural formula of the spherical dendritic organic silicon macromolecule is indicated in a formula I. The spherical dendritic organic silicon macromolecule is synthesized by a two-step circulation method, and then the synthesized spherical dendritic organic silicon macromolecule serves as a cross-linking compensation point and is applied to a solvent-free polysiloxane compound SL. The two-step circulation method includes hydrosilylation and nucleophilic substitution. Active sites capable of diverging are led into annular siloxane in the hydrosilylation. The nucleophilic substitution aims to lead in more cross-linking reaction sites and ensure that the solvent-free polysiloxane compound obtains a curing coating with a perfect cross-linking network structure when cured on a sheet substrate, so that stable performance of an anti-adhesion coating is ensured.

Owner:国科广化(南雄)新材料研究院有限公司 +2

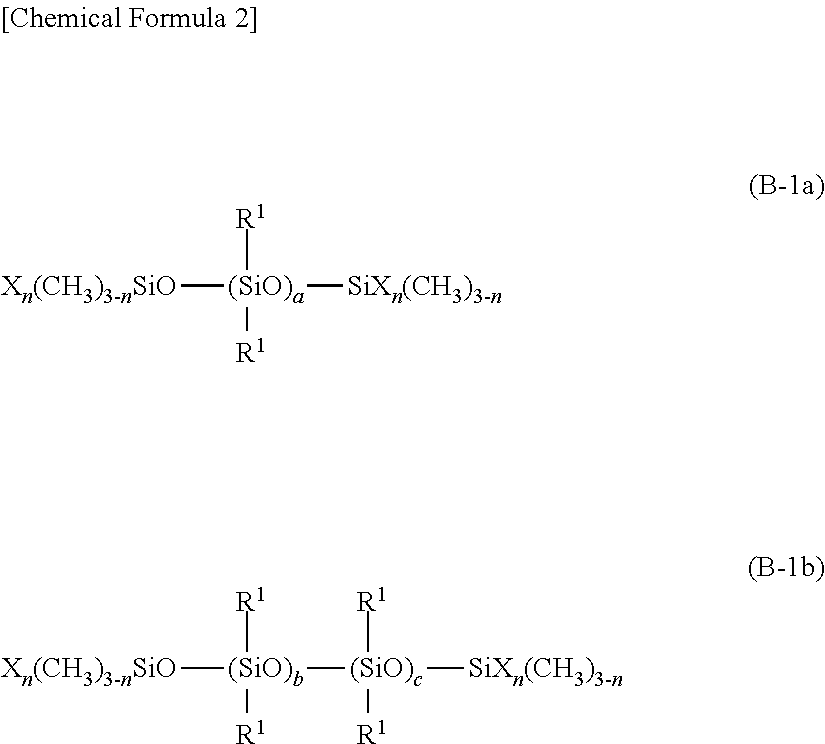

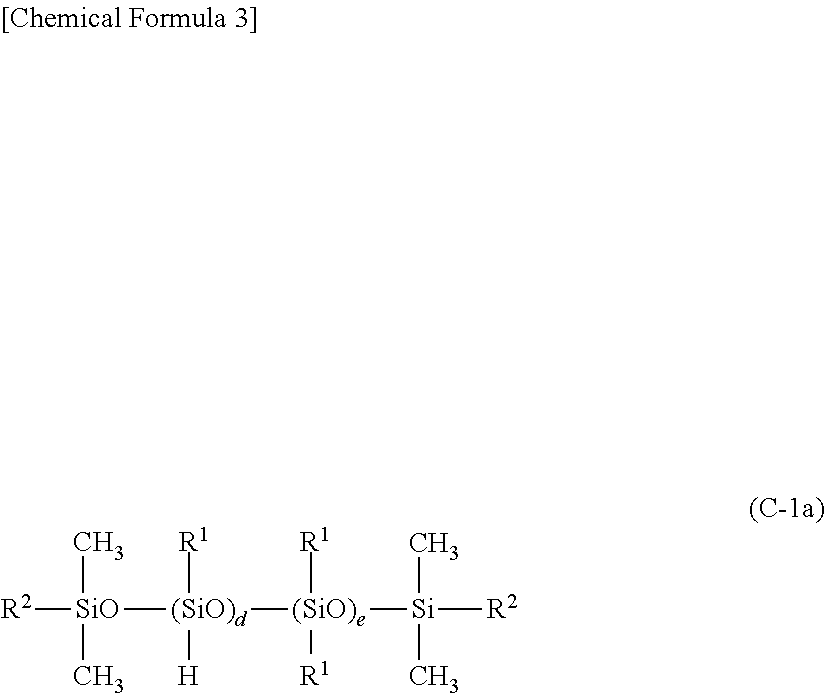

Release agent composition for silicone adhesive, release film, and laminate

ActiveUS20180086915A1Improve release forceNon-macromolecular adhesive additivesOther chemical processesOrganic groupFluorine containing

Provided is a release agent composition for silicone adhesives in which organopolysiloxane having a specific structure is added, as a heavy release component, to a release agent composition for silicone adhesives that includes organopolysiloxane modified with a fluorine-containing organic group.

Owner:SHIN ETSU CHEM IND CO LTD

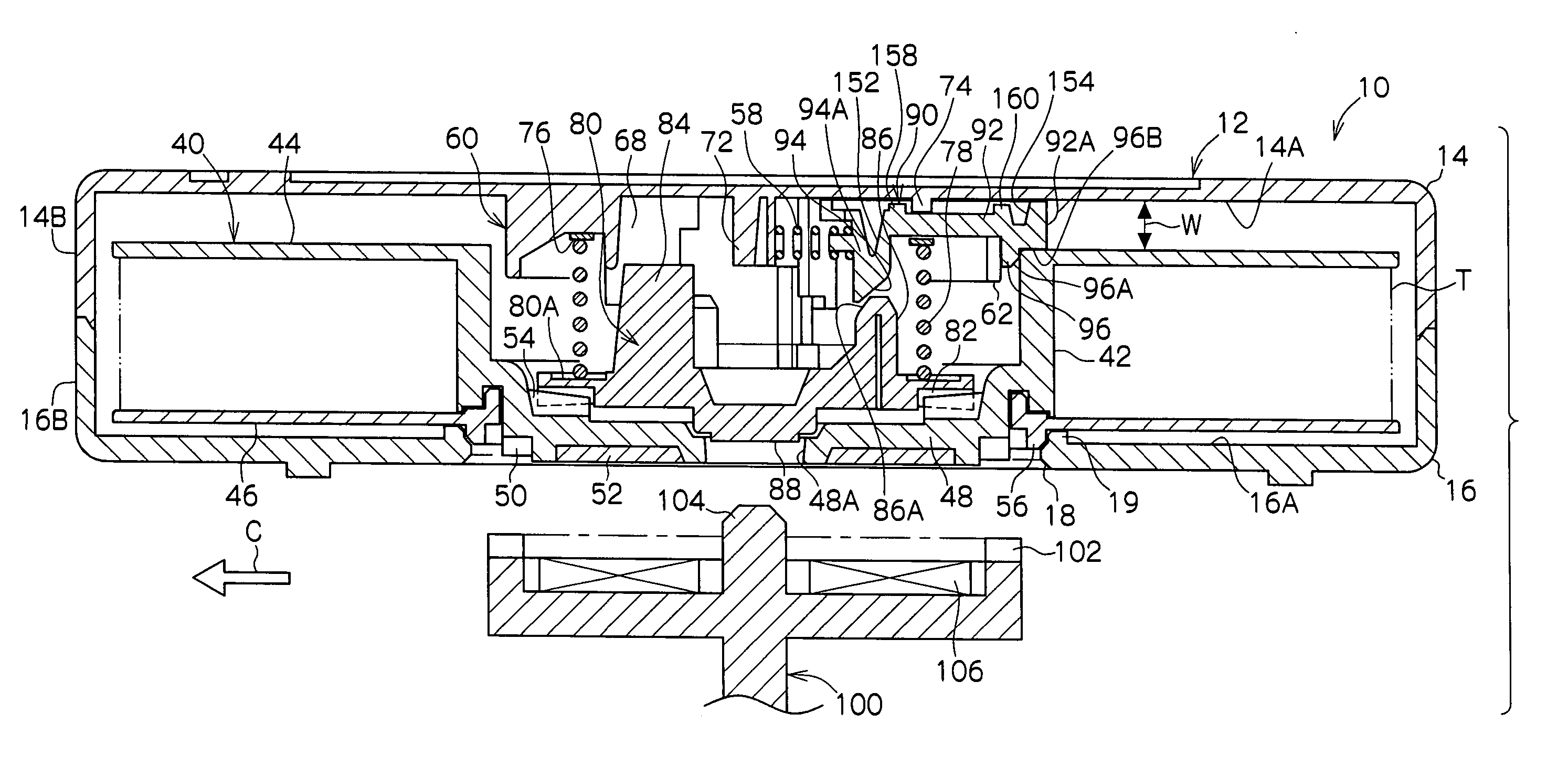

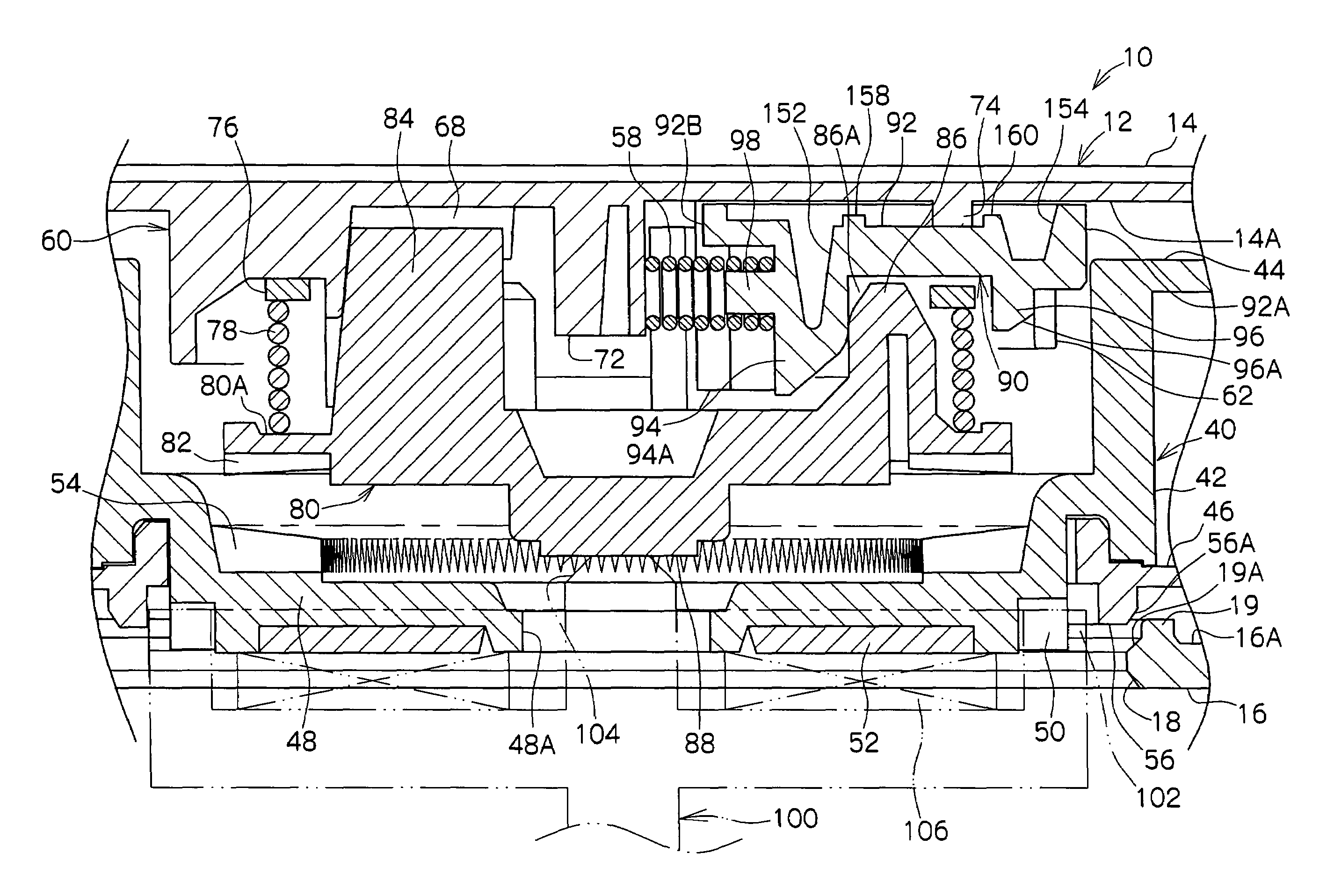

Recording tape cartridge

ActiveUS7322540B2Reduce wearImprove the immunityPicture changing apparatusRecord information storageCoil springFlange

In a recording tape cartridge, a compression coil spring urges a reel downward via a brake member. Due to the biasing force of the spring, a gear of the brake member securely meshes with a gear inside a reel hub preventing the reel's inadvertent rotation. The biasing force urges lock members outward in a radial direction from the center of a mount or the reel. Engagement portions of the lock members engage with an upper edge of the hub. The outer side surfaces of the engagement portions press against the inner peripheral surface of the hub, and ends of the engagement portions at a further outer side than the body portions intervene between the upper surface of an upper flange and the inner surface of a top plate to prevent rotation of the reel and to control movement of the reel in either a radial or an axial direction.

Owner:FUJIFILM CORP +1

High release force type release film with smooth silicone oil surface and production process of high release force type release film

The invention discloses a high release force type release film with a smooth silicone oil surface and a production process of the high release force type release film. The high release force type release film comprises a base material and the silicone oil surface attached to the base material, wherein the silicone oil surface comprises the following components in parts by weight: 45-60 parts of a solvent, 18-22 parts of a release agent, 0.5-1 part of a curing agent, 0.1-0.5 part of a release force regulator and 1-3 parts of a cross-linking agent; the solvent is obtained by mixing a solvent D-30 and a solvent IPA according to the ratio of 3:2, the release agent is obtained by mixing lubricating silicon grease, fluororesin and microcrystalline wax according to the ratio of 2:1:0.1, and the cross-linking agent is obtained by mixing diisocyanate and gleditsia sinensis extract according to the ratio of 20:1. The release film is high in release force, and good in uniformity, further has the smooth and stable silicone oil surface, is weak in viscosity, and can be applied to molten solid hot melt glue surfaces, thermosetting adhesive and the like.

Owner:FOSHAN WEILIXIN ELECTRONICS MATERIAL

Release film for AB adhesive films

PendingCN113621323AImprove release forceReduce release forcePolyurea/polyurethane coatingsFilm/foil adhesive release linersPolymer scienceFilm base

The invention discloses a release film for AB adhesive films. The release film comprises a release film base material and a release agent layer coating the surface of the release film base material. The invention provides three release films with a unified solution suitable for AB adhesive films. Alkyl acrylates with different chain lengths are used as active monomer diluents, and the alkyl acrylates with different chain lengths are used to adjust the release force, so that the release films can be prepared by adopting an approximate content ratio and the same process, and the research and development and manufacturing costs are reduced.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

Emulsion-based high release additive for release sheet, emulsion composition for release sheet, and mold release sheet

The present invention relates to an emulsion-based high release additive for a release sheet, the additive being characterized by being obtained by dispersing in water a condensation product (A) obtained by subjecting the following to a dehydration condensation reaction: (A-1) a polydiorganosiloxane which has an average degree of polymerization of 100-300,000 and which has one or more hydroxyl groups or hydrolyzable groups per molecule; and (A-2) a polyorganosiloxane resin, which contains (SiO4 / 2) units and (R3SiO1 / 2) units (in the formulae, the R groups each represent independently a monovalent hydrocarbon group having 1-12 carbon atoms and not having an aliphatic unsaturated bond or an alkenyl group having 2-6 carbon atoms) as primary components, in which the molar ratio of (R3SiO1 / 2) units relative to (SiO4 / 2) units is 0.6-1.2 and in which the total content of hydroxyl groups and hydrolyzable groups is not lower than 2.1 mass % and lower than 10.0 mass %. The present invention can obtain a silicone cured coating film having a high release force by adding the additive to a curable composition for a release sheet such as a release paper or release film, coating the same on a variety of base materials and curing.

Owner:SHIN ETSU CHEM IND CO LTD

Reactive hyperbranched siloxane resin as well as preparation method and application thereof

The invention belongs to the field of chemical synthesis and discloses reactive hyperbranched siloxane resin as well as a preparation method and application thereof. The reactive hyperbranched siloxane resin is mainly prepared according to the following steps: adding a chain transfer catalyst, an initiating agent and a raw material monomer provided with an active group into a reaction vessel, reacting for 0.5-5 hours at the temperature of 50-100 DEG C, and purifying the obtained reaction product, so that the required reactive hyperbranched siloxane resin is obtained. The reactive hyperbranched siloxane resin obtained through chain transfer catalytic reaction has the advantages that structure surface active groups only contain double bond and influence of formation of hydroxyl groups in condensation reaction is avoided; the obtain reactive hyperbranched siloxane resin contains a large amount of double bond active groups which can participate in reaction of solvent-free polyorganic-based siloxane composite and change structure of a crosslinking system, so that a release layer with excellent performance is obtained.

Owner:国科广化(南雄)新材料研究院有限公司 +2

Silicone-self-adhesives, method for the production thereof, complexes using same and uses

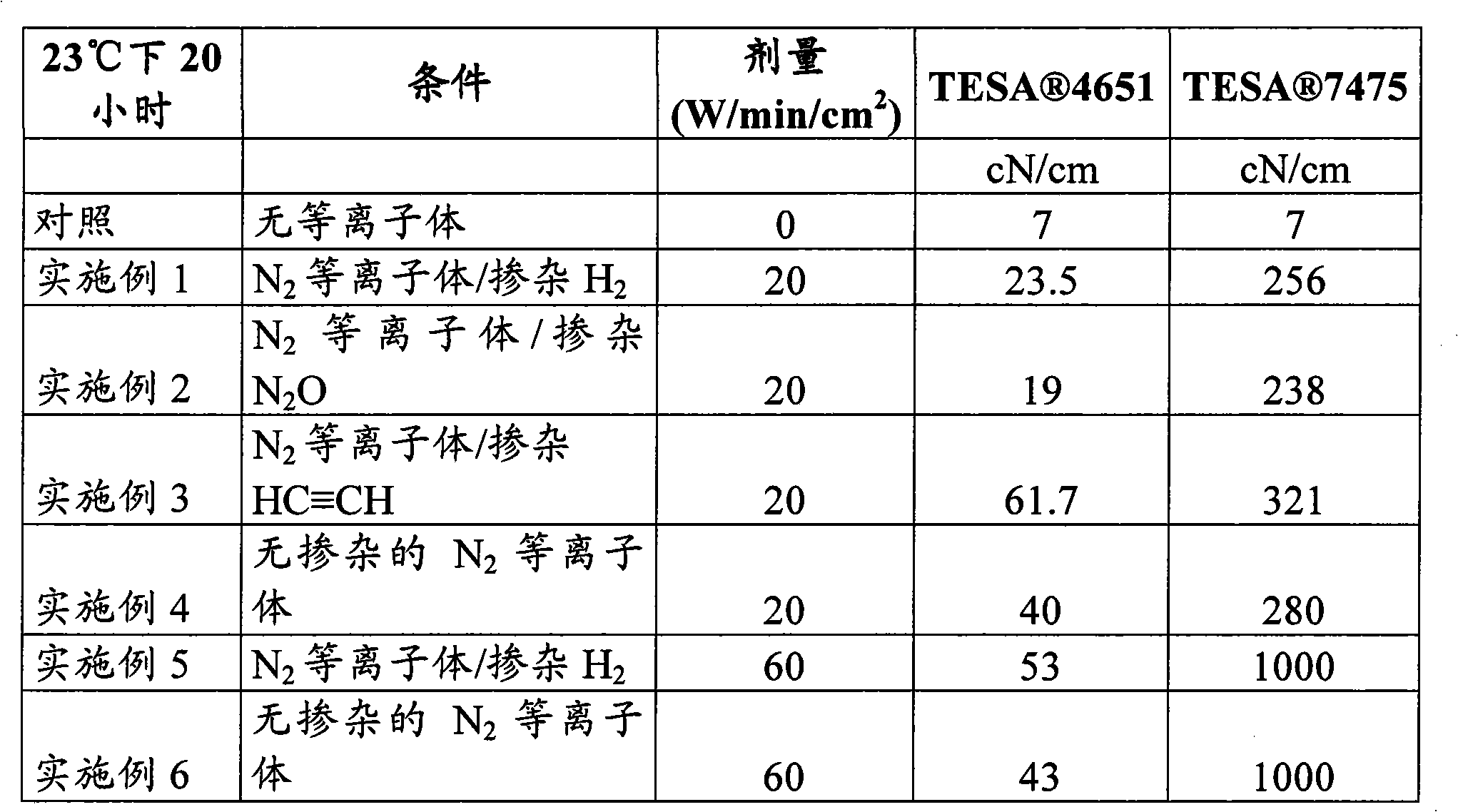

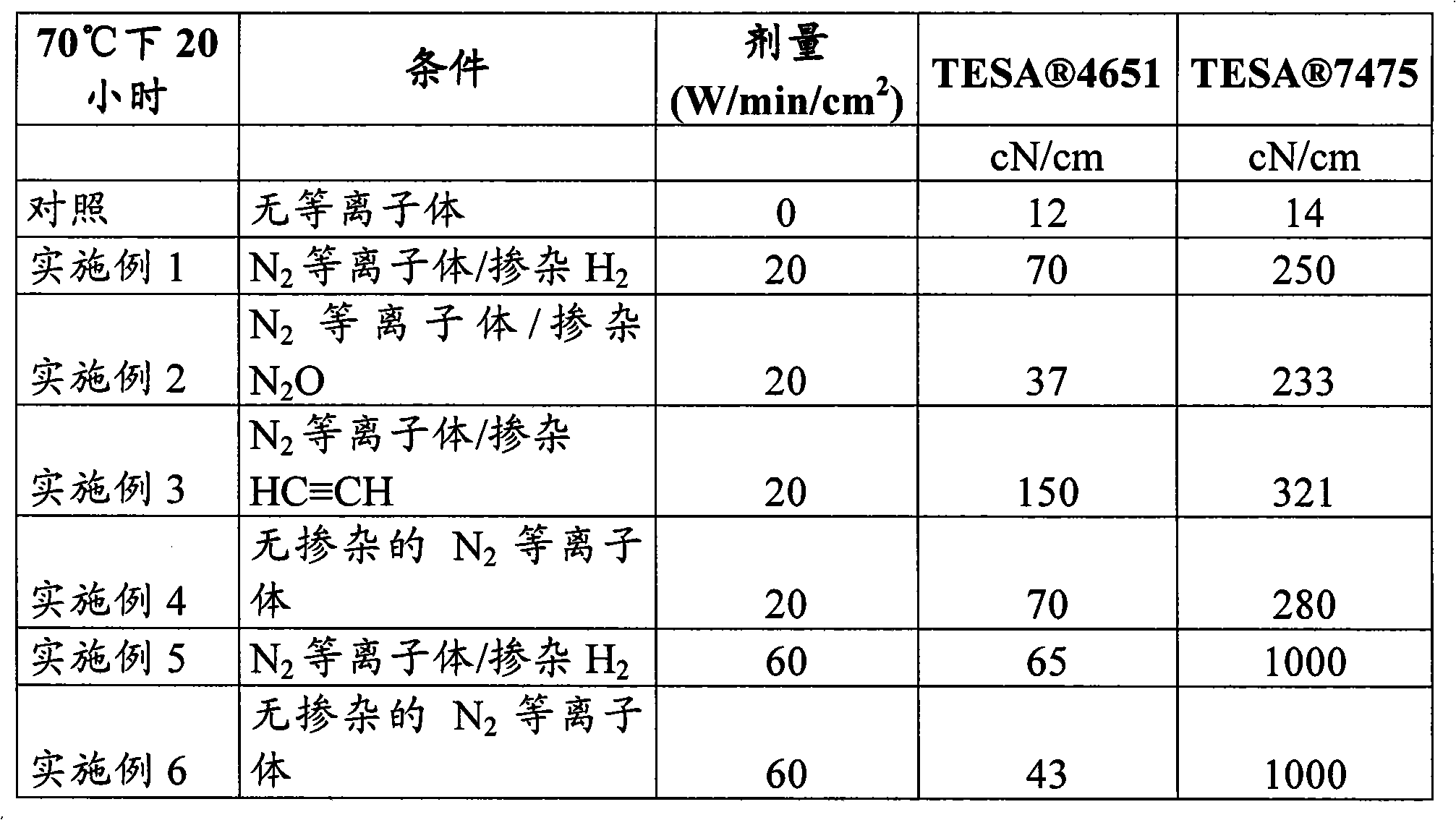

ActiveCN101932638AAvoid or minimize the use ofEasy to implementAdhesivesThin material handlingPolymer scienceAdhesive

Method for preparing a substrate comprising an anti-adhesive silicone coating obtained from an anti-adhesive silicone composition based on crosslinked silicone oil(s) with adhesion properties that are modified compared with the initial properties thereof, in which provision is made for a substrate at least partly coated with an anti-adhesive silicone coating and the anti-adhesive silicone coating is cold-plasma-treated, approximately at atmospheric pressure, in an optionally doped nitrogen atmosphere or in an optionally doped carbon dioxide atmosphere, substrate at least partially coated with an anti-adhesive silicone composition, silicone-self-adhesive complex and uses.

Owner:BLUESTAR SILICONES FRANCE SAS

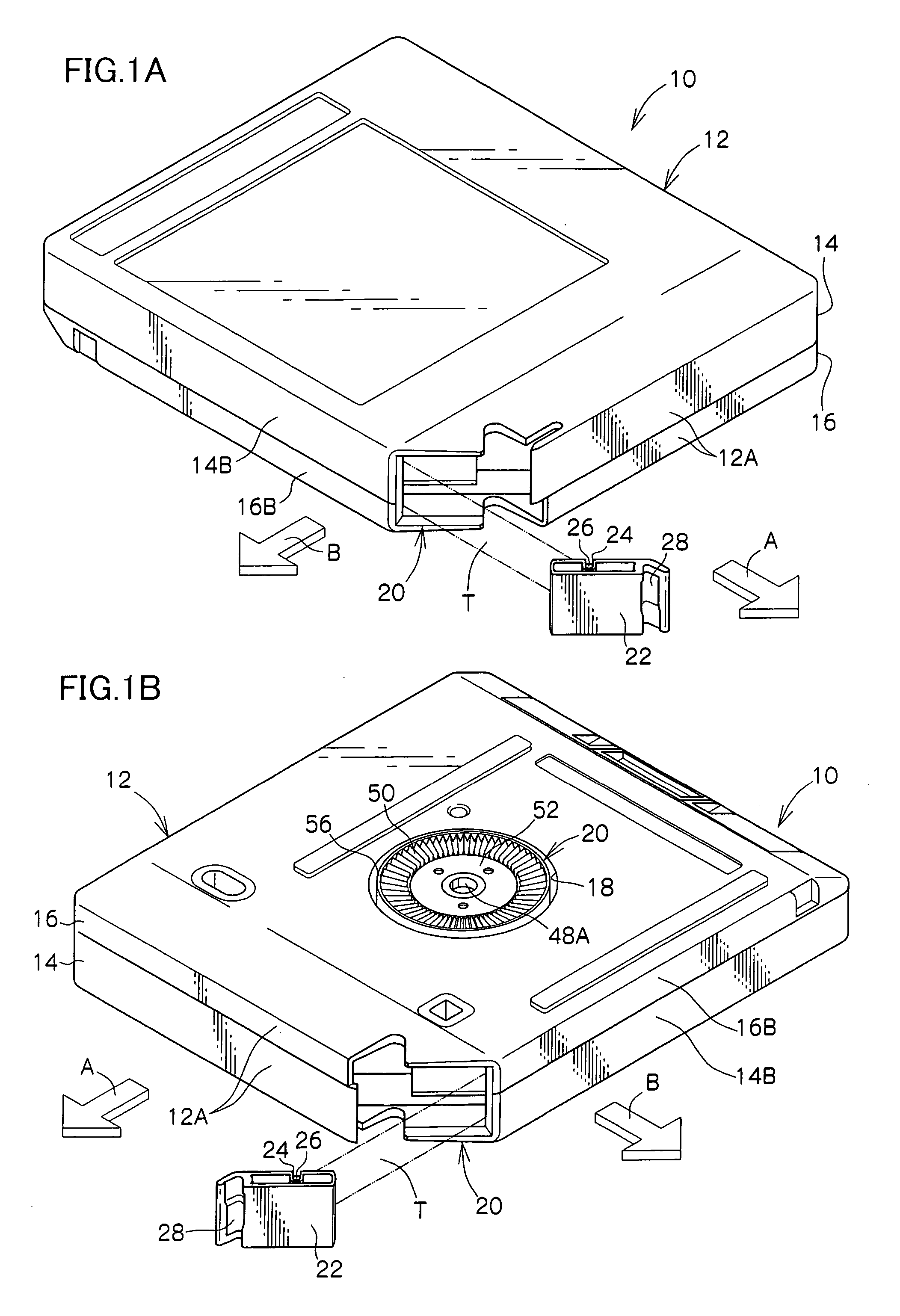

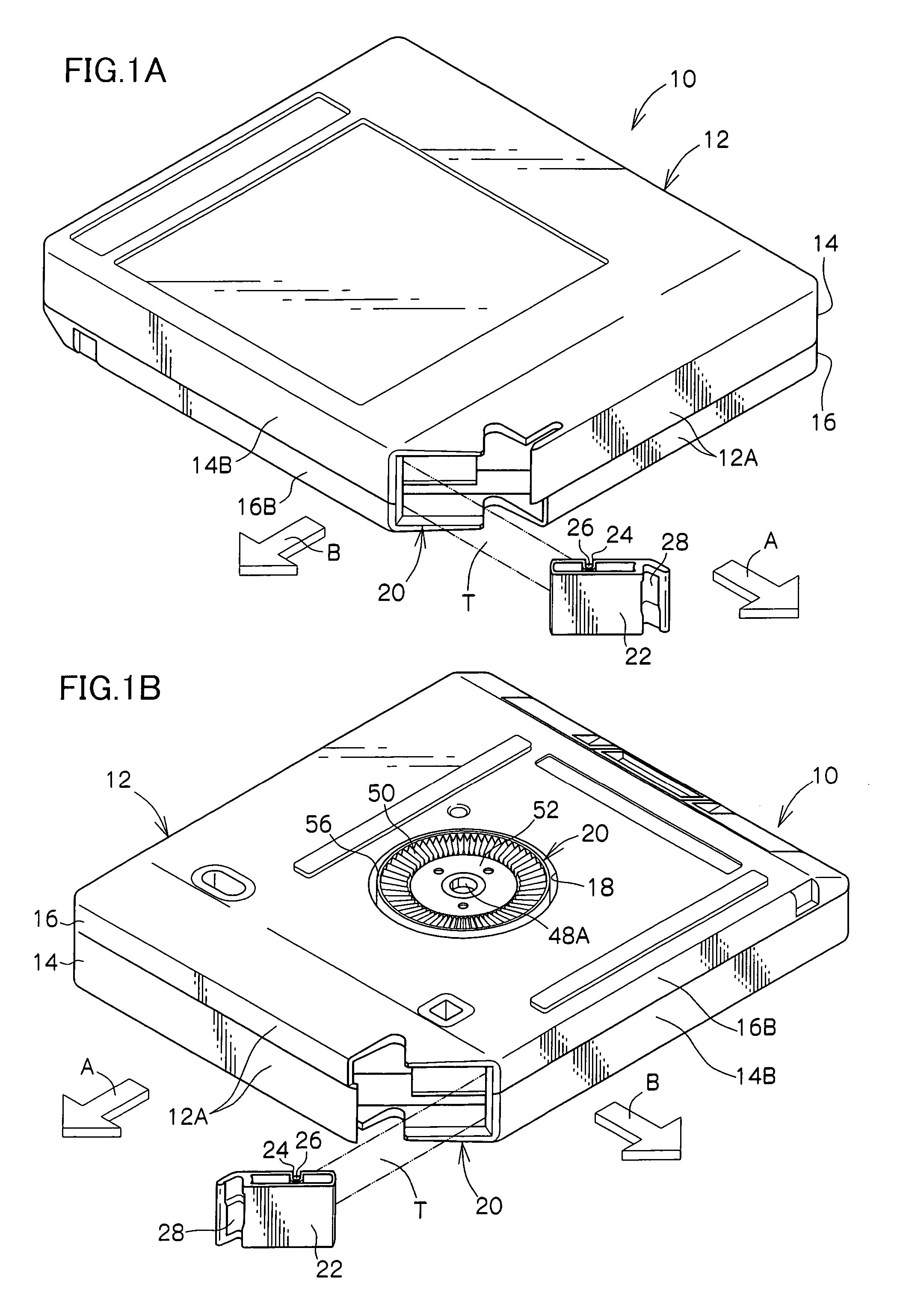

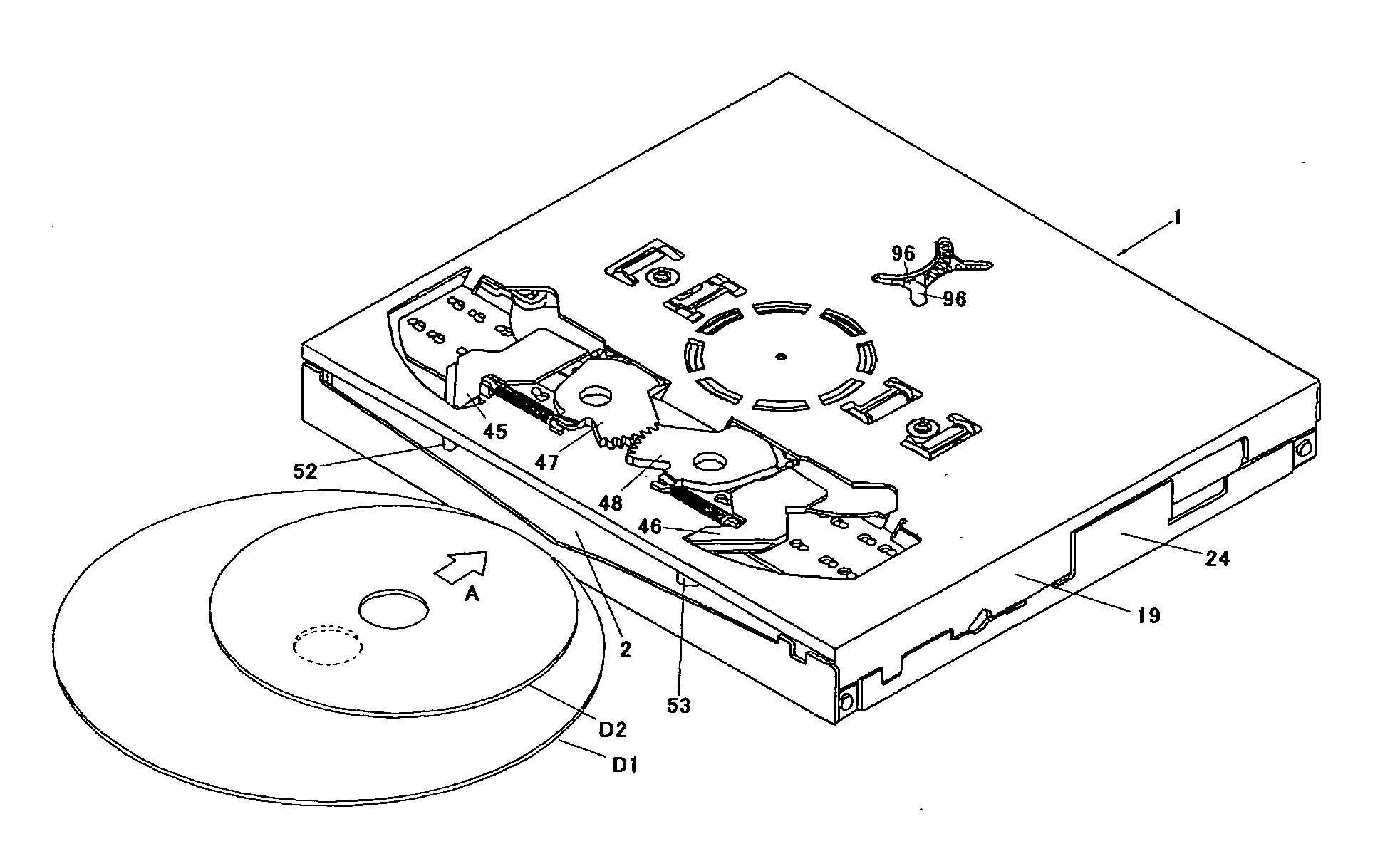

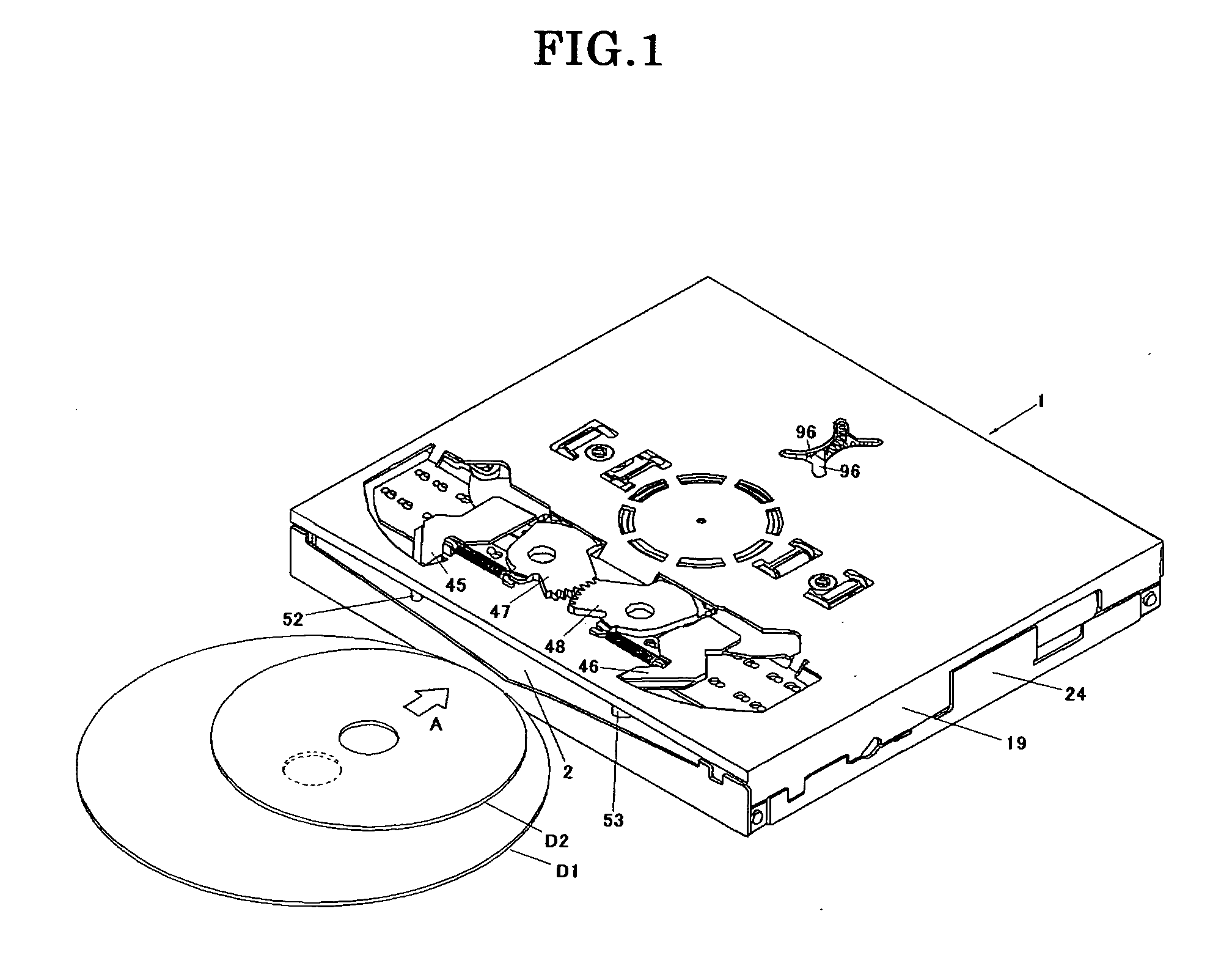

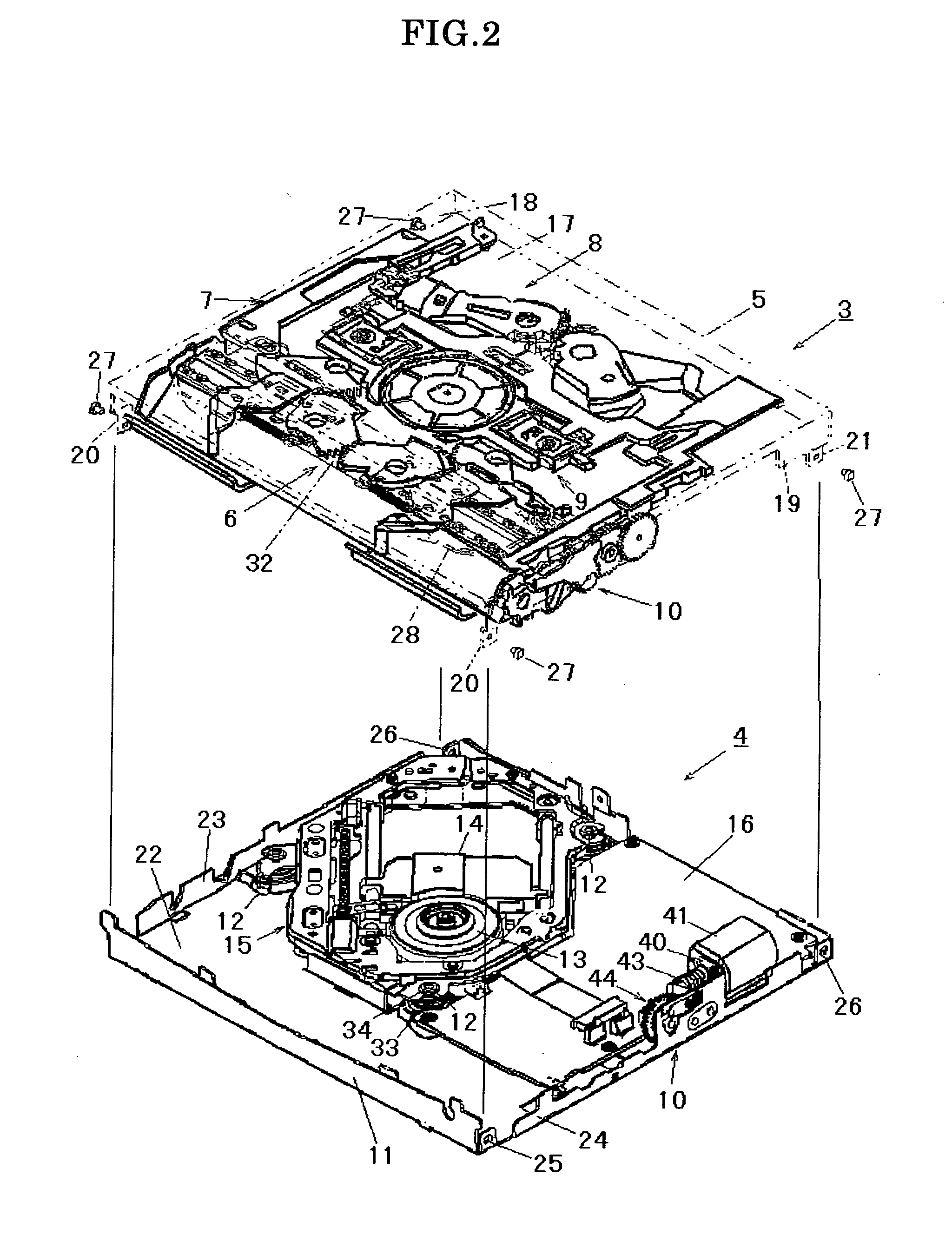

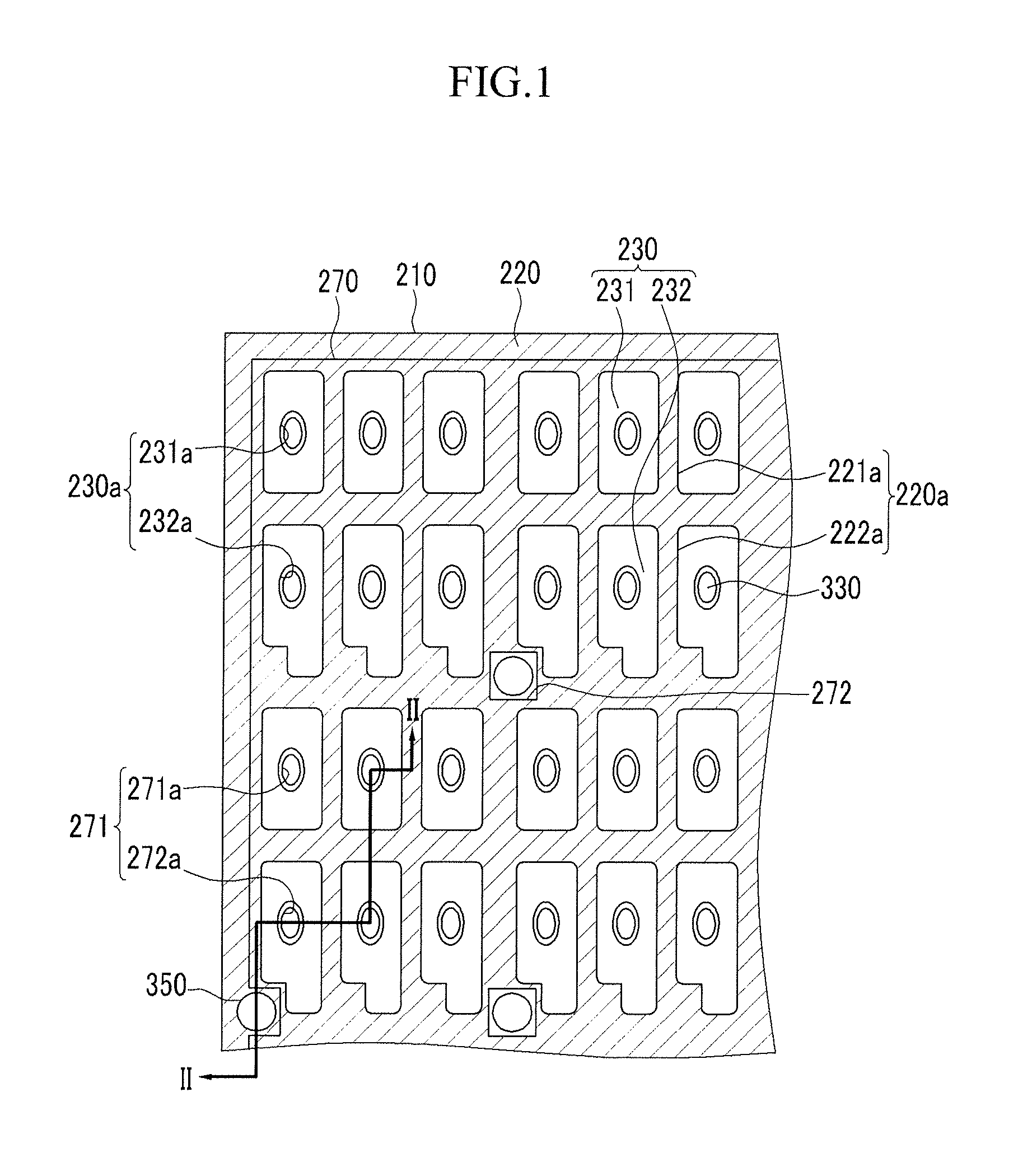

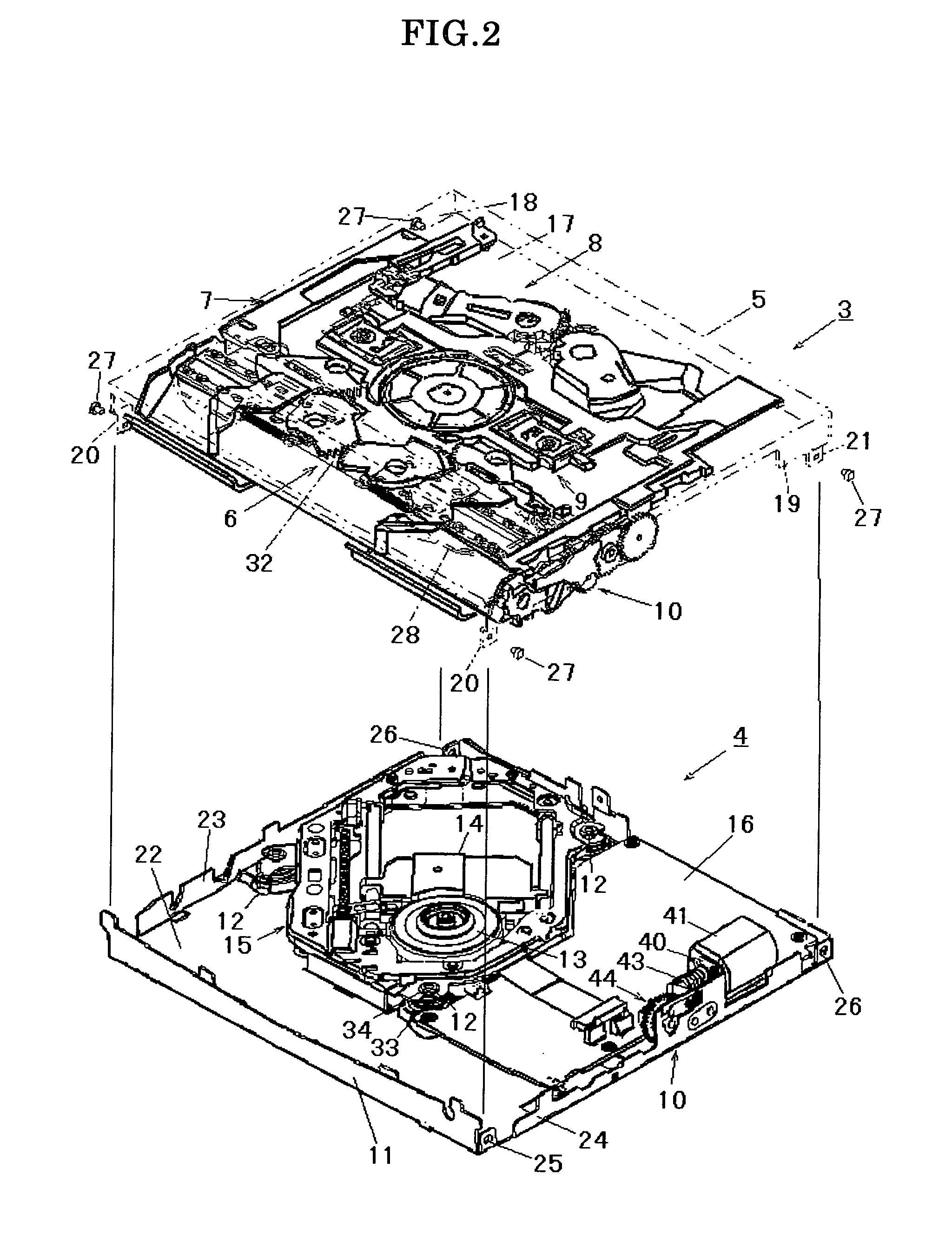

Clamping apparatus for a disc player

InactiveUS20080229338A1Advantageous effect of stablyEasy to separateRecord information storageRecord carrier contruction detailsMagnetic tension forceRotational axis

The present invention relates to a clamping apparatus for a disc player which is able to accurately release a clamper from a turntable while improving miniaturization and thinning. The clamping apparatus for the disc player where the turntable and the clamper clamp a disc by magnetic force comprises a clamper releasing means having a pair of linking mechanisms arranged in symmetrical positions across the axial line of the clamper, and each linking mechanism has a front linking member and a rear linking member with the ability to freely rotate with the frame by centering two rotational axes placed on a single flat surface that is orthogonal to the axial line, and a clamper releasing member which is axially supported at each rotating end of the front linking member and the rear linking member; the mutually opposing ends of both clamper releasing members are moved with a circular trajectory by synchronously rotating the front linking member and the rear linking member, and the ends of both clamper releasing members are engaged to the outer periphery of the clamper, releasing the clamper from the turntable.

Owner:TANASHIN DENKI CO

Release film containing 4-methyl-1-pentene polymer and preparation method thereof

ActiveCN112810273AImprove pass rateSimple manufacturing methodLamination ancillary operationsSynthetic resin layered productsChemistryPolymer chemistry

The invention discloses a release film containing a 4-methyl-1-pentene polymer. The release film is characterized by sequentially comprising an outer film layer, a core film layer and an inner film layer from top to bottom, wherein the outer film layer is prepared by blending a 4-methyl-1-pentene polymer and a probenazole grafted and modified 4-methyl-1-pentene polymer according to a mass ratio of (3-5): 1; the core film layer is prepared by blending probenazole / allyl pentafluorobenzene / 2,4-diphenyl-4-methyl-1-pentene copolymer and hyperbranched polyethylene fiber according to a mass ratio of 100 to (5-10); and the inner film layer is prepared by blending the 4-methyl-1-pentene polymer and the probenazole grafted and modified 4-methyl-1-pentene polymer according to a mass ratio of 1: (2-4). The invention also discloses a preparation method of the release film containing the 4-methyl-1-pentene polymer. The release film containing the 4-methyl-1-pentene polymer, disclosed by the invention, is good in release property, high temperature resistance, weather resistance and flame retardance and excellent in comprehensive performance, performance stability and mechanical properties.

Owner:苏州市新广益电子股份有限公司

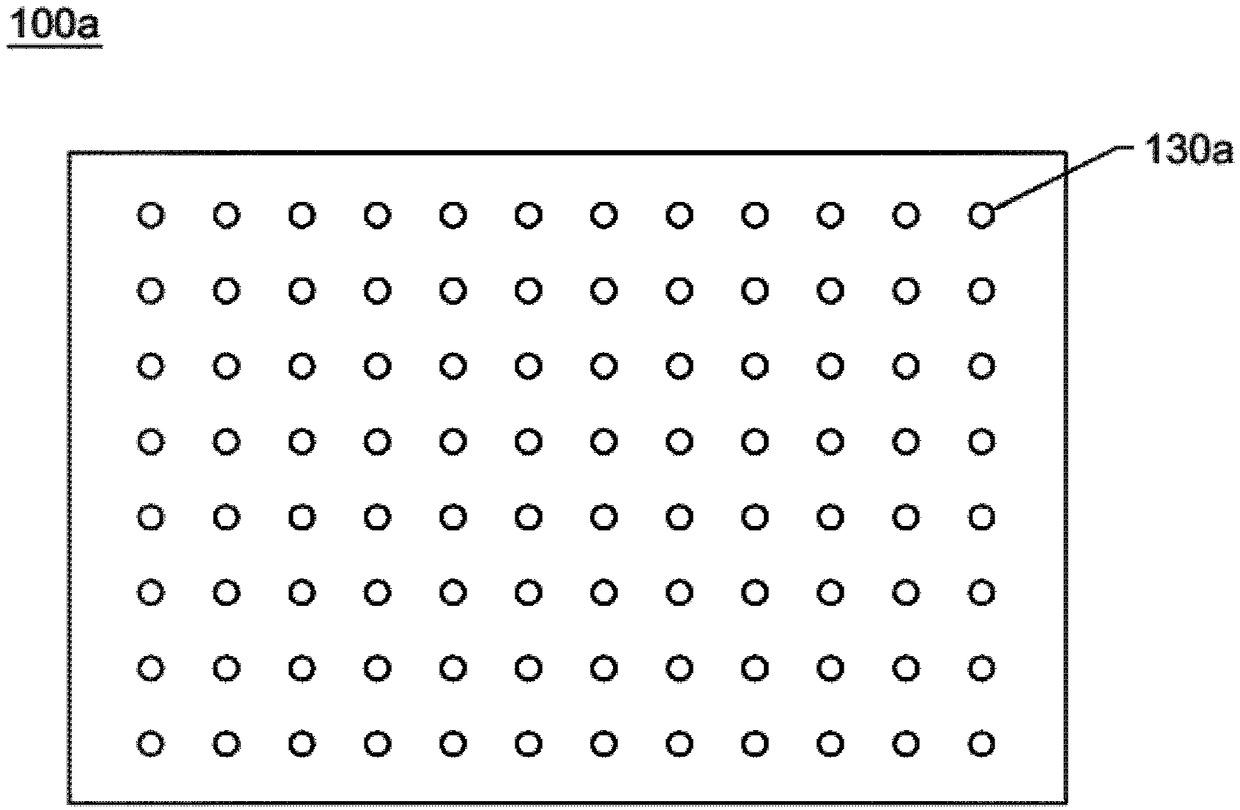

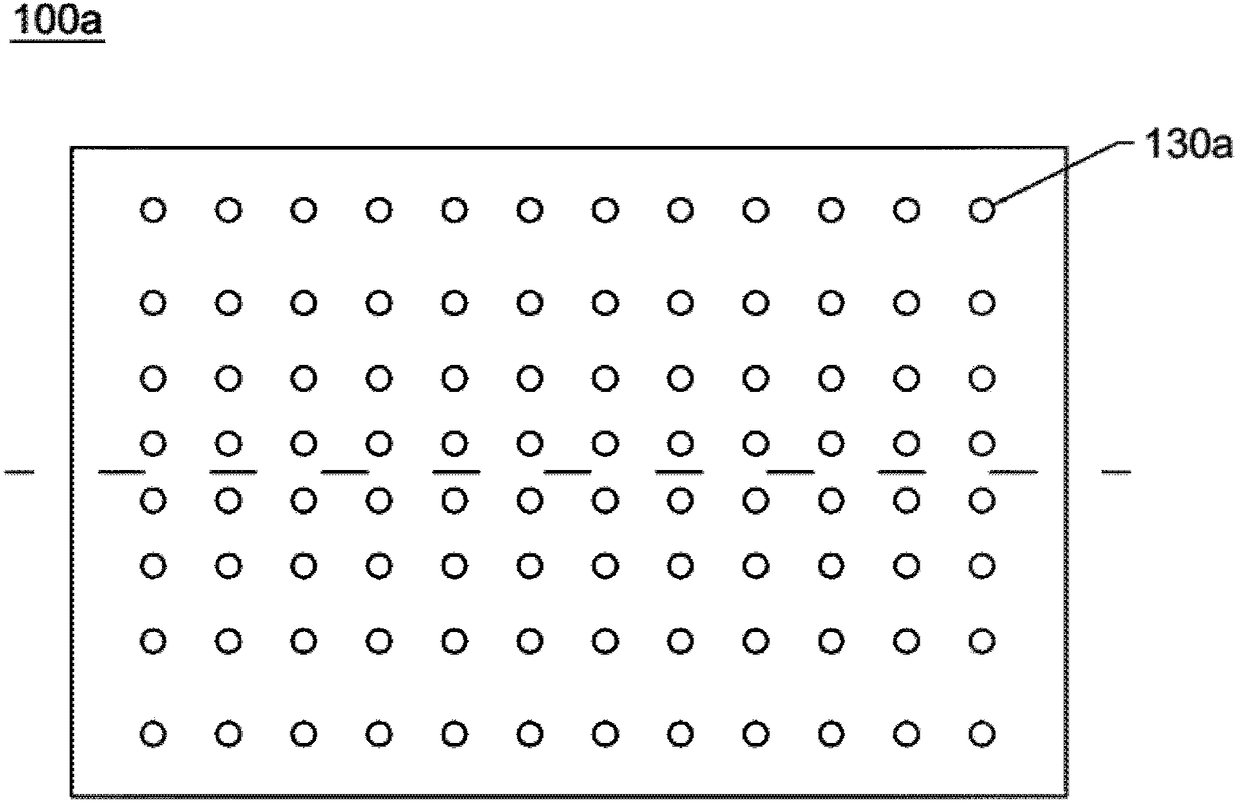

Release paper for food baking

PendingCN108978331AImprove release forceImprove securityPaper/cardboardRelease paperCooking & bakingBiochemical engineering

The embodiments of the invention provide release paper for food baking, wherein the release paper can meet the safety requirements of food baking, can provide good release effect, and further can ensure gas permeability. According to the embodiments of the invention, the release paper for food baking is provided, and comprises a bottom paper layer and a release layer, wherein the release layer isformed by curing a an aqueous release agent, the release paper is provided with gas holes, and the gas holes penetrate through the release paper.

Owner:오리온푸드컴퍼니리미티드

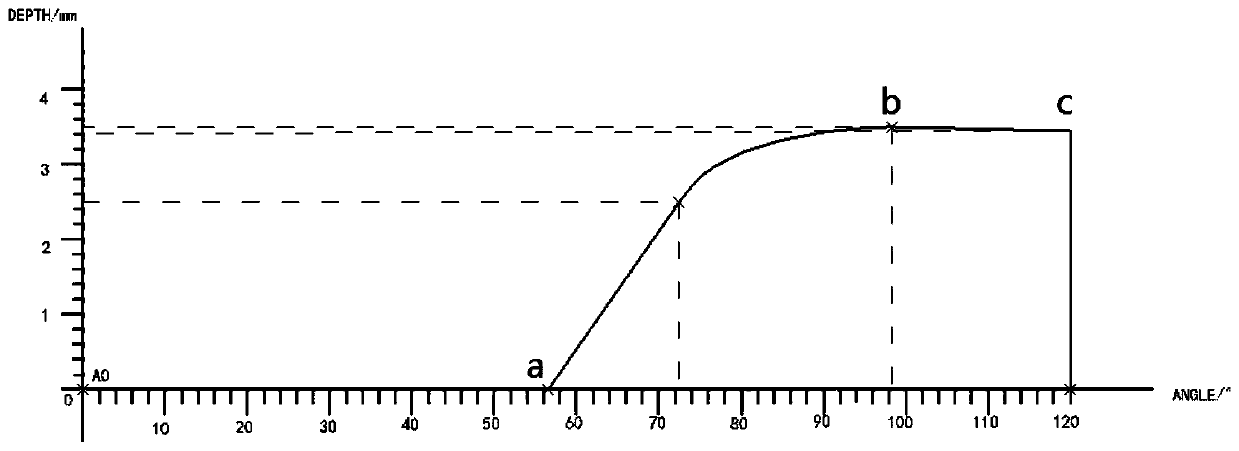

Release film with release force lightened after UV illumination and coating device thereof

ActiveCN112246527AGuaranteed uptimePrevent leakageLiquid surface applicatorsSynthetic resin layered productsChemistryPolythiophene

The invention discloses a release film with release force lightened after UV illumination and a coating device thereof. The release film comprises a release film body, wherein the release film body comprises a base material layer and a first release layer, an antistatic layer is arranged between the base material layer and the first release layer, the upper surface of the first release layer is coated with a DMPA layer, the upper surface of the DMPA layer is coated with a second release layer with an adjustable area, the antistatic layer is a polythiophene macromolecule conductive layer, and the base material layer is a PET layer. According to the release film, compression springs are sequentially extruded, and the elastic force of the compression springs can push fixing plates to move, sothat the front and rear fixing plates slide towards the middle, all clamping seats are driven to uniformly move towards the center point position, all coating roller mounting mechanisms are driven touniformly move towards the center point position, the number of coating rollers in contact with the release film is adjusted, then the dosage of an adhesive release agent can be adjusted, the releaseforce of the produced release film is adjusted, and the production adaptability of a production device to different release films is improved.

Owner:TOP TECH SUBSTRATES CO LTD

Heavy release additive for release sheet, polyorganosiloxane composition for release sheet, and release sheet

A heavy release additive for a release sheet comprises a condensation reaction product of dehydrative condensation reaction between (A) a polydiorganosiloxane of average polymerization degree of 500 to 10,000 and has at least one hydroxy or hydrolysable group per molecule and (B) a polyorganosiloxane resin composed of a (SiO4 / 2) unit and a (R3SiO1 / 2) unit (wherein R's independently represent a C1-12 monovalent hydrocarbon group or a C2-6 alkenyl group each having no aliphatic unsaturated bond), has a ratio of the (R3SiO1 / 2) unit to the (SiO4 / 2) unit of 0.6 to 1.2 by mole, and contains the hydroxy group and the hydrolysable group in the total content of 2.1 mass % or more and less than 10.0 mass %. The heavy release additive can have the effect of achieving an extremely great peel force compared with cases in which no additive is added.

Owner:SHIN ETSU CHEM IND CO LTD

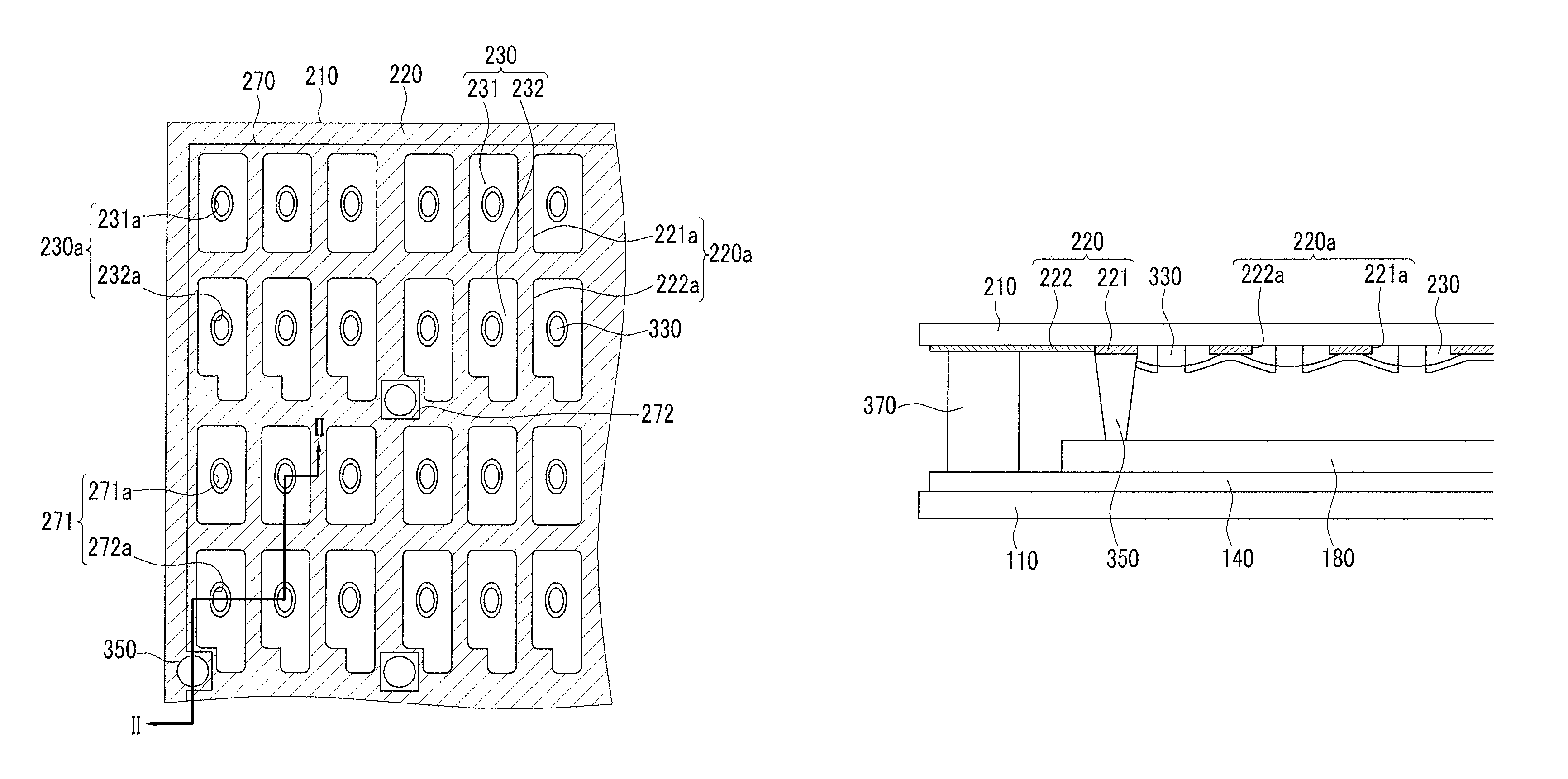

Color filter array panel, manufacturing method thereof, and liquid crystal display including the same

InactiveUS8451406B2Simple manufacturing processPrevent and reduce occurrenceWave amplification devicesMountingsLiquid-crystal displayColor filter array

A color filter array panel includes: a substrate; a light blocking member on the substrate; a color filter on the substrate and partially overlapping the light blocking member, and having an opening exposing the substrate; a protective member in the opening; and a common electrode on the light blocking member and the color filter, and having a cut portion at a position corresponding to the opening.

Owner:SAMSUNG DISPLAY CO LTD

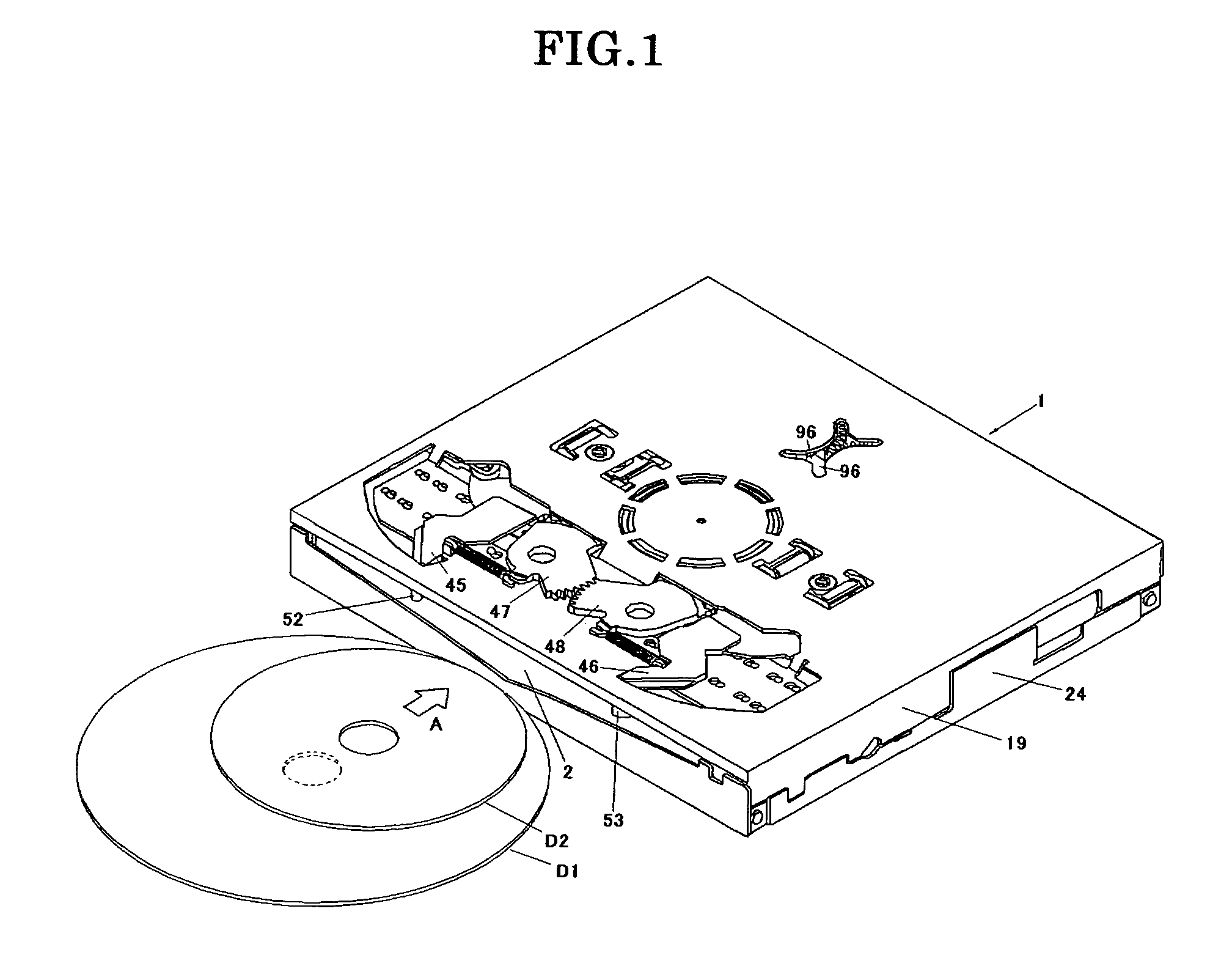

Clamping apparatus for a disc player

InactiveUS8001558B2Thinning and miniaturizationReduce exerciseRecord information storageRecord carrier contruction detailsRotational axisMagnetic tension force

The present invention relates to a clamping apparatus for a disc player which is able to accurately release a clamper from a turntable while improving miniaturization and thinning. The clamping apparatus for the disc player where the turntable and the clamper clamp a disc by magnetic force comprises a clamper releasing means having a pair of linking mechanisms arranged in symmetrical positions across the axial line of the clamper, and each linking mechanism has a front linking member and a rear linking member with the ability to freely rotate with the frame by centering two rotational axes placed on a single flat surface that is orthogonal to the axial line, and a clamper releasing member which is axially supported at each rotating end of the front linking member and the rear linking member; the mutually opposing ends of both clamper releasing members are moved with a circular trajectory by synchronously rotating the front linking member and the rear linking member, and the ends of both clamper releasing members are engaged to the outer periphery of the clamper, releasing the clamper from the turntable.

Owner:TANASHIN DENKI CO

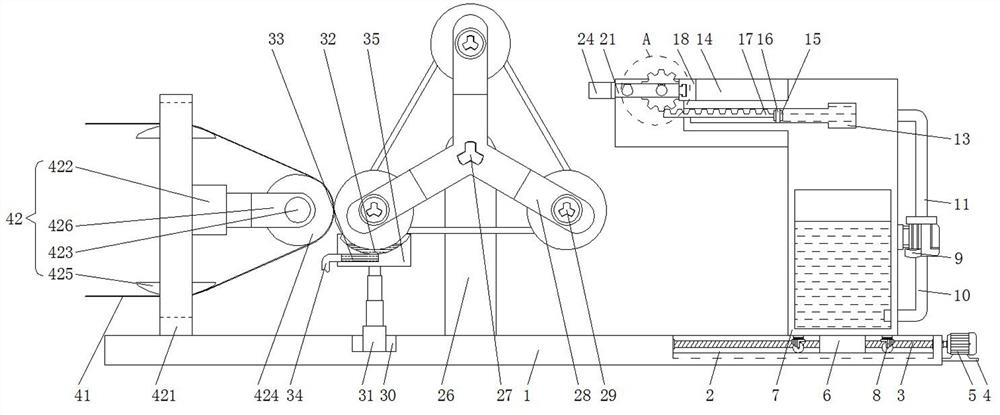

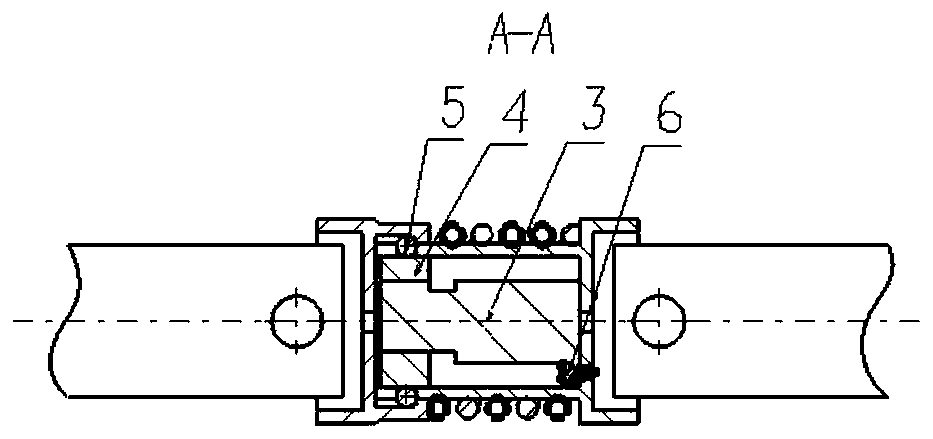

Automatic parachute fall off mechanism of unmanned aerial vehicle

The invention discloses an automatic parachute fall off mechanism of an unmanned aerial vehicle. The automatic parachute fall off mechanism is composed of fall off joint connectors, a rotary electromagnet, a rotary guide rail, a spring, a parachute belt, a parachute belt shaft and a cotter pin. The automatic fall off mechanism is connected to the parachute belt through an upper fall off joint connector and a lower fall off joint connector, and the parachute belt is connected with the unmanned aerial vehicle. When the unmanned aerial vehicle parachutes and lands, a control circuit controls therotary electromagnet to drive the rotary guide rail to rotate, so that the ball falls into an arc-shaped groove of the guide rail to fall off, the constraint of the ball on the fall-off joint upper connector and the fall-off joint lower connector is relieved; after the ball falls off, the spring release force is increased to separate the fall-off joint upper connector from the fall-off joint lower connector, and parachute throwing is completed. The rotary electromagnet and the rotary guide rail are designed, the rotary electromagnet is used for driving the rotary guide rail to rotate to achieve ball falling, and an unlocking structure and the unlocking process are simplified. The automatic parachute fall off mechanism is simple in structure, convenient to install and capable of safely andreliably achieving separation of the parachute and the unmanned aerial vehicle.

Owner:XIAN AISHENG TECH GRP

Emulsion-based high release additive for release sheet, emulsion composition for release sheet, and mold release sheet

The present invention relates to an emulsion-based high release additive for a release sheet, the additive being characterized by being obtained by dispersing in water a condensation product (A) obtained by subjecting the following to a dehydration condensation reaction: (A-1) a polydiorganosiloxane which has an average degree of polymerization of 100-300,000 and which has one or more hydroxyl groups or hydrolyzable groups per molecule; and (A-2) a polyorganosiloxane resin, which contains (SiO4 / 2) units and (R3SiO1 / 2) units (in the formulae, the R groups each represent independently a monovalent hydrocarbon group having 1-12 carbon atoms and not having an aliphatic unsaturated bond or an alkenyl group having 2-6 carbon atoms) as primary components, in which the molar ratio of (R3SiO1 / 2) units relative to (SiO4 / 2) units is 0.6-1.2 and in which the total content of hydroxyl groups and hydrolyzable groups is not lower than 2.1 mass % and lower than 10.0 mass %. The present invention can obtain a silicone cured coating film having a high release force by adding the additive to a curable composition for a release sheet such as a release paper or release film, coating the same on a variety of base materials and curing.

Owner:SHIN ETSU CHEM IND CO LTD

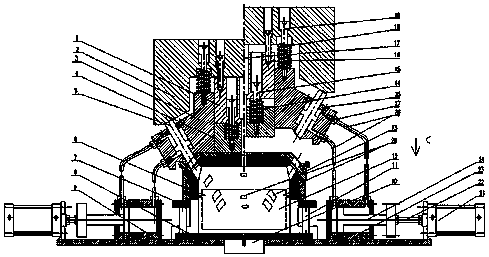

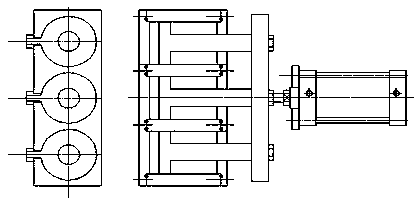

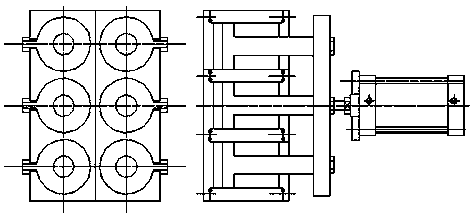

Forging and inclined window hole punching composited die

PendingCN109719246AAvoid deformationAvoid quality problemsRimsForging/hammering/pressing machinesEngineeringMechanical engineering

The invention belongs to the technical field of forging dies, and particularly relates to a forging and inclined window hole punching composited die. The composite die comprises an upper die seat, a connecting sleeve, an upper die sliding sleeve, a pressing plate, a window inclined punch, a central punch, a first connecting screw, a first spring, a second connecting screw, a second spring, a hydraulic auxiliary system, a lower de and a bottom plate. The bottom surface of the pressing plate of the composite die is a plane, so that deformation of the front forming surface is avoided; meanwhile,hydraulic power is added to the window inclined punch, the pressure for inclined hole punching is increased, and the quality problem is avoided; besides, the demolding force is increased, by the aid of a multi-split synchronous hydraulic device, synchronization of multiple window inclined punches can be well realized, simultaneous demolding of the punches can be realized, the processes of punchingof hub blank inclined windows and separation from the window inclined punches are performed simultaneously in the very small space of a wheel, and the structure is ingenious.

Owner:CITIC DICASTAL

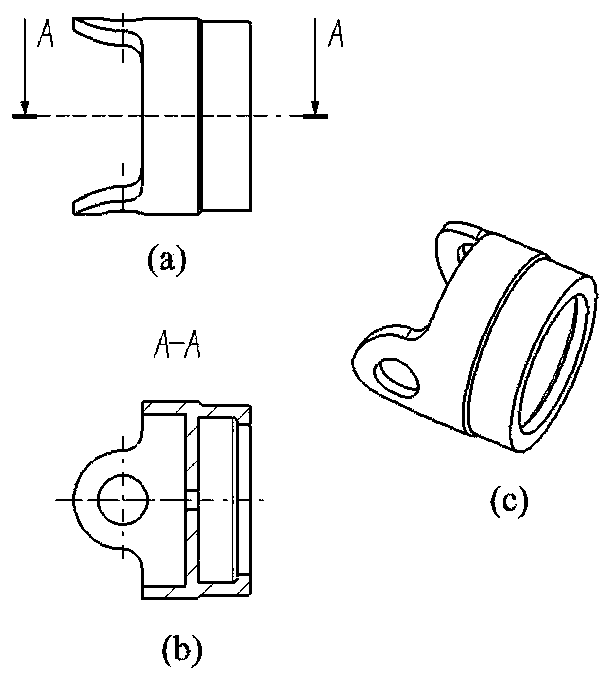

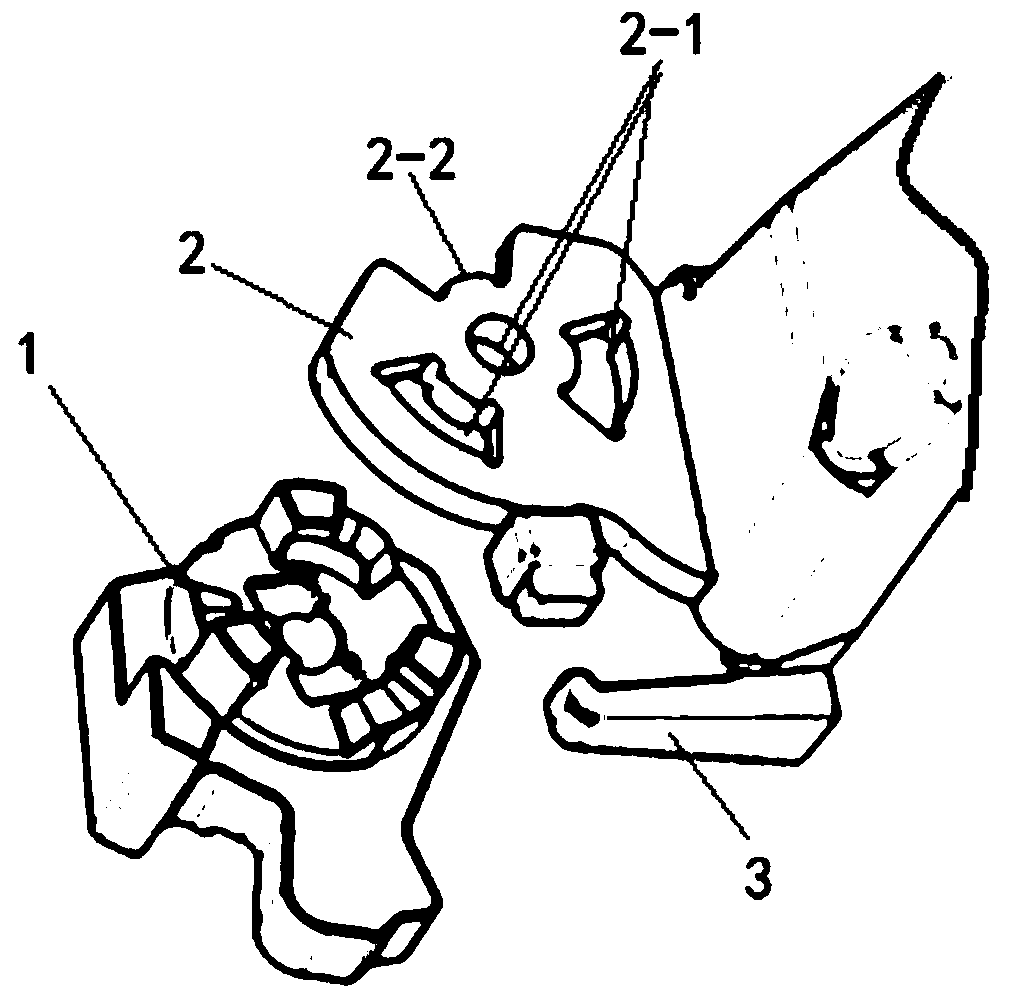

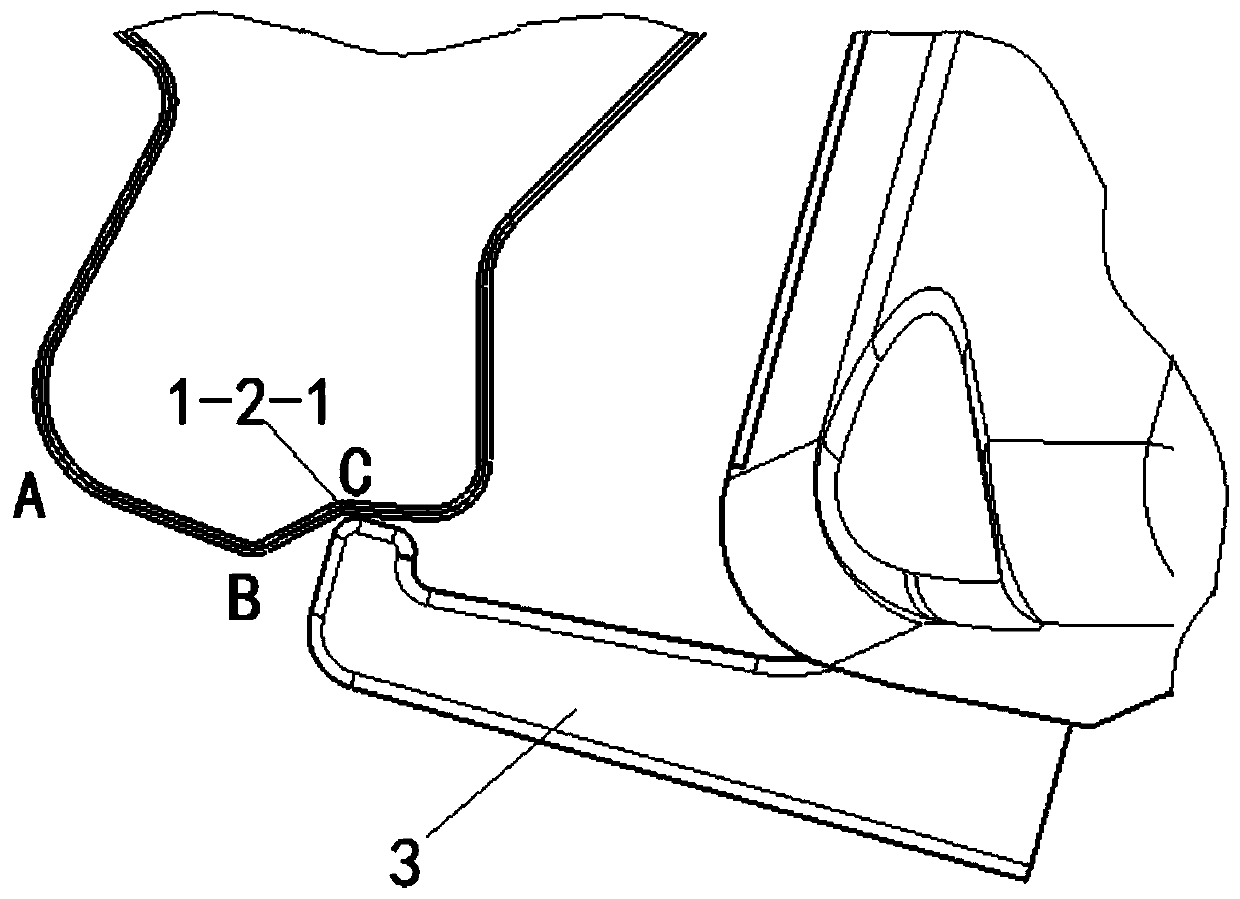

Structure for improving handle loosening force of automobile steering column

The invention relates to the technical field of automobile steering column structures, in particular to a structure for improving a handle loosening force of an automobile steering column. A cam clamping structure and a handle stand bar are fixed to the end, matching a climbing cam, of a handle. A sliding pair I is fixed on the front surface of a cam bottom plate; a sliding pair II is fixed to thelower side edge of the cam bottom plate, a clamping foot is fixed to the side edge of the lower left corner of the cam bottom plate. The sliding pair I is composed of a circular truncated cone and three climbing bosses fixed to the surface of the circular truncated cone, a through hole is formed in the circle center of the circular truncated cone, and a mounting hole and a climbing notch are formed in the cam clamping structure. The sliding pair II is a U-shaped block with a concave structure at the bottom; and the handle stand bar is in contact with the bending part of the bottom of the U-shaped block. According to the invention, the sliding pair II is newly designed; under the condition that the locking force of the handle is basically unchanged, the loosening force of the handle is greatly increased, the requirements for the locking force of the handle and the NVH performance of a system are met, and the requirements of part of customers with high requirements are met.

Owner:BOSCH HUAYU STEERING SYST CO LTD

Release film for polaroid

ActiveCN112661995AImprove adhesionPut an end to the phenomenon of pulling upPolyurea/polyurethane coatingsPolymer scienceMeth-

The invention discloses a release film for a polaroid. The release film comprises a release film base material and a release agent layer coated on the surface of the release film base material, and the release agent layer is prepared from an ultraviolet light curing release agent prepared from the following raw materials in parts by weight: 60-140 parts of polybutadiene polyurethane, 45-85 parts of polyacrylate resin, 10-25 parts of hydroxypropyl methacrylate, 25-55 parts of a trifluoroethyl methacrylate active monomer diluent, 25-55 parts of an octadecyl methacrylate active monomer diluent and 1-5 parts of 2-hydroxy-2-methyl-1-phenyl-1-acetone serving as an initiator. The ultraviolet curing release agent is an ultraviolet curing release agent without a silicone oil component, high-temperature baking is not needed, no silicone oil seeps out, and the phenomenon that the PAS adhesive is pulled up due to transfer of the silicone oil component is completely eradicated.

Owner:JIANGSU SHUANGXING COLOR PLASTIC NEW MATERIALS

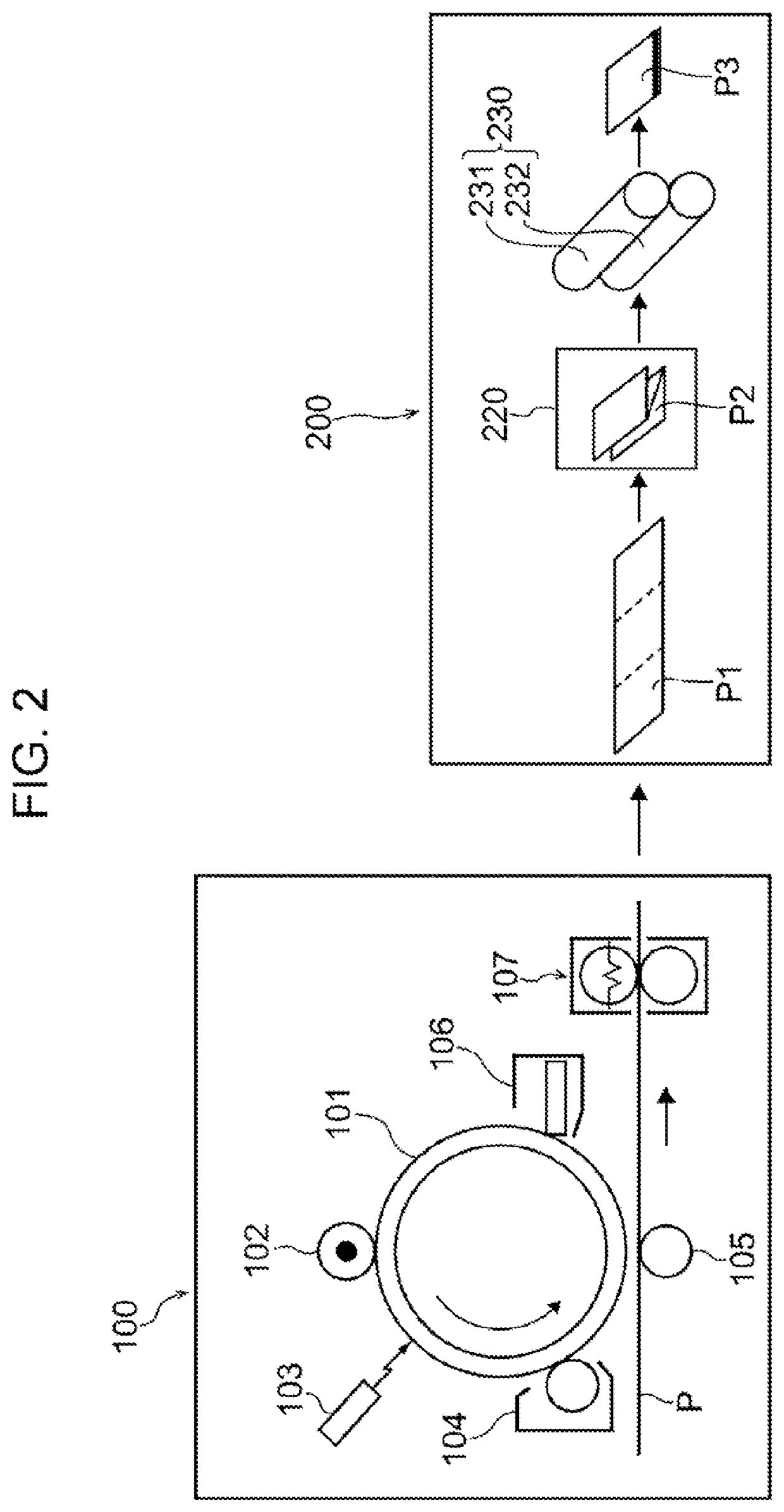

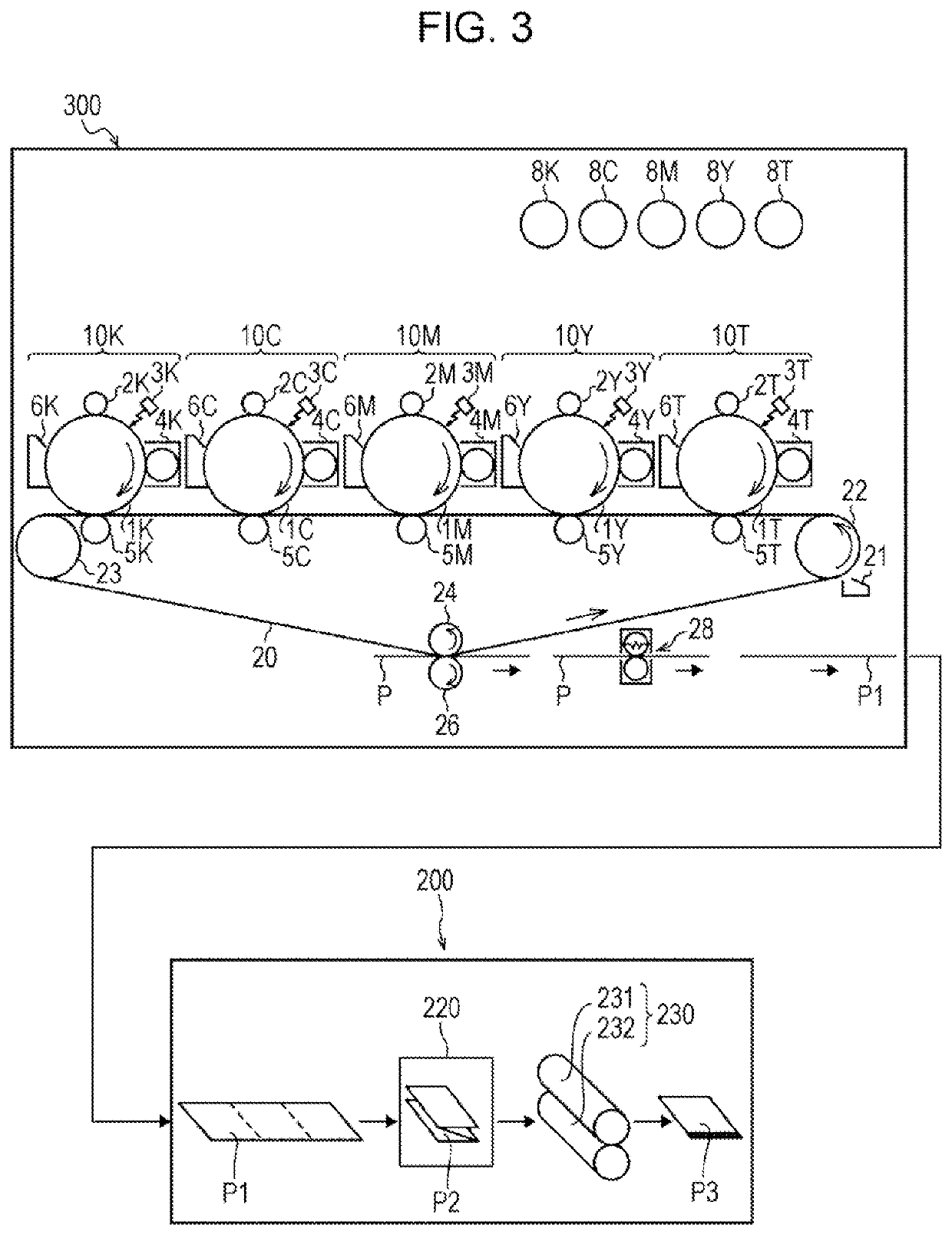

Pressure sensitive adhesive particle, adhesive material, apparatus for producing printed material, method for producing printed material, printed material, sheet for producing printed material, and method for producing sheet for producing printed material

PendingUS20220228036A1Small viscosityImprove release forceLaminationLamination apparatusPolymer scienceAdhesive materials

A pressure sensitive adhesive particle includes a sea-island structure constituted by a sea containing a resin A and islands containing a resin B1 and a resin B2, in which a viscosity of the resin B1 at 100° C. is smaller than a viscosity of the resin B2 at 100° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com