Separable type flexible substrate and manufacturing method thereof

A technology of flexible substrates and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as high cost and cumbersome manufacturing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

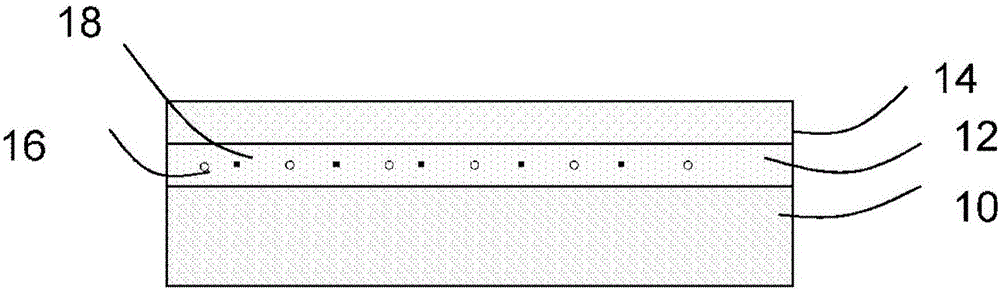

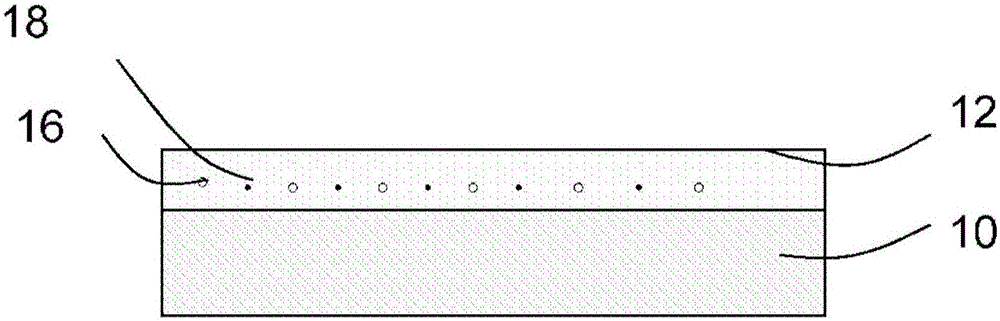

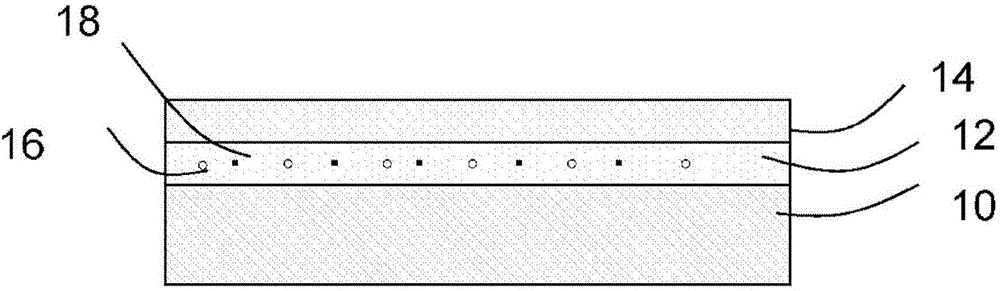

[0029] A method for preparing a releasable flexible substrate.

[0030] Preparation of the first polyamic acid solution

[0031] Put 52.63 grams of ODA and 440 grams of DMAc as a solvent into a three-necked bottle, and then add 57.4 grams of PMDA after stirring until completely dissolved, wherein the monomer accounts for 20 wt% of the total weight of the reaction solution. Then, keep stirring at 25° C. and react for 25 hours. After the reaction, 1 wt % silane compound and 10 wt % siloxane compound are added to obtain the first polyamic acid solution.

[0032] Preparation of the second polyamic acid solution

[0033]Put 71.67 g of TFMB and 412.5 g of DMAc as a solvent into a three-neck flask, stir until completely dissolved, then add 65.84 g of BPDA, wherein the monomer accounts for 25 wt% of the total weight of the reaction solution. Then, the second polyamic acid solution can be obtained by continuously stirring and reacting at 25° C. for 25 hours.

[0034] Polyimide layer...

Embodiment 2

[0040] The steps of Example 1 were repeated, but the components of the first polyamic acid solution were changed to 3 wt% silane compound and 10 wt% siloxane compound.

Embodiment 3

[0042] The steps of Example 1 were repeated, but the components of the first polyamic acid solution were changed to 5 wt% silane compound and 10 wt% siloxane compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com