Forging and inclined window hole punching composited die

A compound mold and punching window technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as limited demoulding ability, inconsistent punch operation, troublesome process, etc., to achieve Increase the force of demoulding, avoid quality problems, and facilitate the effect of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

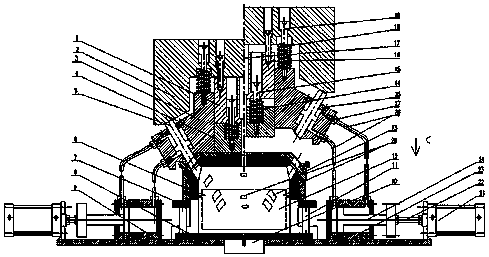

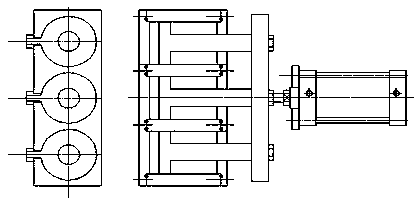

[0024]A compound mold for forging oblique window holes, including an upper mold base 2, a connecting sleeve 1, an upper mold sliding sleeve 3, a pressure plate 4, a window oblique punch 5, a central punch 17, a first connecting screw 15, and a first spring 14 , the second connecting screw 19, the second spring 18, two left and right hydraulic auxiliary systems, the lower mold 6, the base plate 9, the tray 7, the lower supporting plate 8, the ejector rod 10, the guide post 11, the waste slide plate 12, the bolt 16, The upper mold base 2 includes a circular top surface and a side wall extending downward around the top surface, and the side wall has a certain thickness; the connecting sleeve 1 is a columnar structure, and the connecting sleeve 1 is fixedly connected to the top surface of the upper mold base 2 by bolts 16. The bottom; the pressing plate 4 is a columnar structure, and the bottom surface of the pressing plate 4 is a plane; the central punch 17 is arranged in the conn...

Embodiment 2

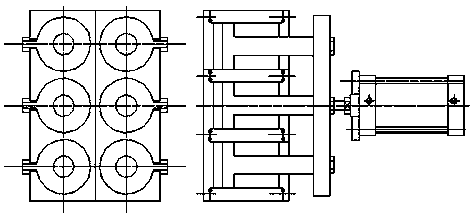

[0031] In the compound mold for forging oblique window holes provided in this embodiment, the wheel hub blank needs to punch six oblique window holes, and a hydraulic auxiliary system is used, combined with the attached image 3 As shown in , one of the main piston rods in the hydraulic auxiliary system drives the six distribution piston rods of the six sub-hydraulic cylinders to move up and down the six window oblique punches 5 through the hydraulic power of the hydraulic oil. Wherein said lower mold 6 is hollow, and is divided into upper and lower two parts, and upper part diameter is small, and lower part diameter is big; Described lower mold 6 circumference is evenly provided with 3 square empty slots, and lower supporting plate 8 is arranged on the bottom plate, The lower supporting plate 8 is located in the lower space of the lower mold 6, and the circumference of the lower supporting plate 8 is fixedly provided with a guide post 11 at a position corresponding to the squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com