Emulsion type release agent and preparation method thereof

A release agent and emulsion type technology, applied in the field of emulsion release agent and its preparation, can solve the problems of residual adhesive force, no mention of foaming performance of anchoring working fluid, no mention of release force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

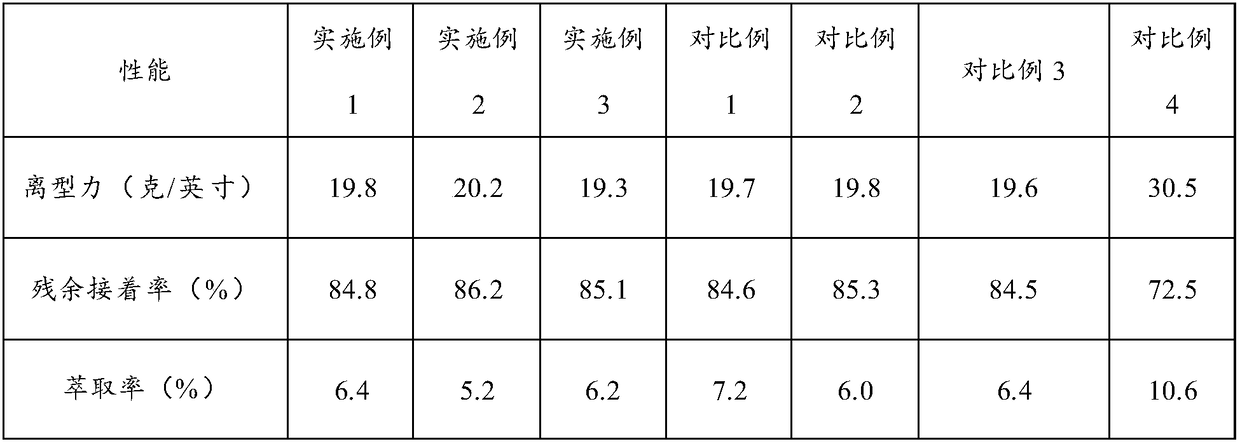

Examples

preparation example Construction

[0050] The application also provides a preparation method of emulsion type release agent, comprising the following steps:

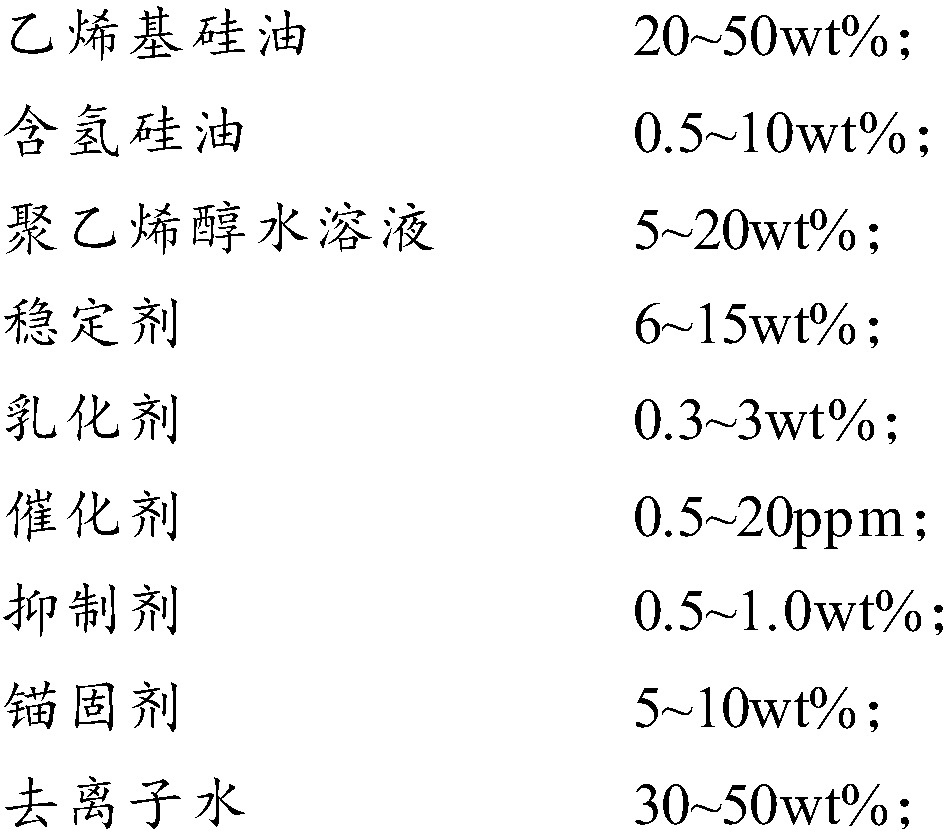

[0051] 20-50wt% vinyl silicone oil, 0.5-10wt% hydrogen-containing silicone oil, 5-20wt% polyvinyl alcohol aqueous solution, 6-15wt% stabilizer, 0.3-3wt% emulsifier, 0.5-1.0wt% Add 30-50wt% deionized water after mixing the inhibitor and 5-10wt% anchoring agent, and homogenize after phase inversion to obtain component A;

[0052] Mix 5-20wt% vinyl silicone oil, 60-2520ppm catalyst, 10-20wt% polyvinyl alcohol aqueous solution and 0.3-3wt% emulsifier, add 30-50wt% deionized water, and homogenize after phase inversion , get B component;

[0053] Mix component A, component B and deionized water in a mass ratio of 20:1:100 to obtain an emulsion release agent.

[0054] In the process of preparing emulsion-type release agent, firstly prepare component A according to the above ratio, that is, vinyl silicone oil, hydrogen-containing silicone oil, polyvinyl alcohol...

Embodiment 1

[0061] 40wt% of vinyl-terminated vinyl silicone oil with a viscosity of 500cps and a mass content of vinyl group of 1.2%, 3wt% of a hydrogen-containing silicone oil with a viscosity of 25cps and a mass content of hydrogen group of 0.6%, a viscosity of 40cps, a degree of alcoholysis of 88%, and a molecular weight of 100000~ 120000 polyvinyl alcohol aqueous solution 8wt%, water-based alkyd resin (brand YG-AK337) 9wt%, polyether modified silicone oil (brand 7123) 0.5wt%, 3-methyl-1-butyn-3-ol 0.5wt %, vinyltriethoxysilane 5.0wt%, and add it into a high-speed disperser to disperse evenly, then slowly add deionized water 34wt%, after the phase inversion is completed, transfer it to a high-pressure homogenizer at 30MPa for 3 times to obtain group A Minute;

[0062] 15wt% of vinyl-terminated vinyl silicone oil with a viscosity of 500cps and a vinyl mass content of 1.2%, 1560ppm of a platinum-vinylsiloxane complex, 15wt of a polyvinyl alcohol aqueous solution with a viscosity of 40cps...

Embodiment 2

[0067] 39.5wt% of vinyl-terminated vinyl silicone oil with a viscosity of 500cps and a vinyl mass content of 1.2%, 3.5wt% of a hydrogen-containing silicone oil with a viscosity of 25cps and a hydrogen-based mass content of 0.6%, a viscosity of 40cps, an alcoholysis degree of 88%, and a molecular weight of 100000~120000 polyvinyl alcohol aqueous solution 8wt%, water-based alkyd resin (brand YG-AK337) 9wt%, polyether modified silicone oil (brand 7123) 0.5wt%, 3-methyl-1-butyn-3-ol 0.5wt%, vinyl triethoxysilane 5.0wt%, add in the high-speed disperser and disperse evenly, then slowly add deionized water 34wt%, after the phase inversion is completed, transfer to the high-pressure homogenizer for 3 times at 30MPa to obtain A component;

[0068] 15wt% of vinyl-terminated vinyl silicone oil with a viscosity of 500cps and a vinyl mass content of 1.2%, 1560ppm of a platinum-vinylsiloxane complex, 15wt of a polyvinyl alcohol aqueous solution with a viscosity of 40cps, an alcoholysis degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com