Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Reduce kinetic energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment process for desulfurized wastewater

InactiveCN101486517ASmall footprintLow construction costSludge treatment by de-watering/drying/thickeningWaste water treatment from gaseous effluentsFlocculationWastewater

The invention discloses a desulfurized wastewater treatment process. Firstly, NaOH or lime milk is added into the acidic desulfurized wastewater so as to adjust the pH value to be 8 to 9; then, the desulfurized wastewater is pumped into an electric flocculation treatment device by a pumpp, effluent after electric flocculation treatment enters an inclined pipe settling tank so as to be further treated, and then the treated wastewater reaching the standard is discharged or reused. The scruff discharged by the electric flocculation treatment device and the settled sludge discharged by the inclined pipe settling tank enter a sludge thickening tank so as to be further concentrated; the concentrated sludge is pumped into a sludge dewatering machine so as to be dried; and the dried sludge is shipped out for disposal, and the supernatant in the thickening tank and the filter-press fluid in the dewatering machine flow back to a regulating reservoir. The treatment process is characterized by simple flow and good treatment effect.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

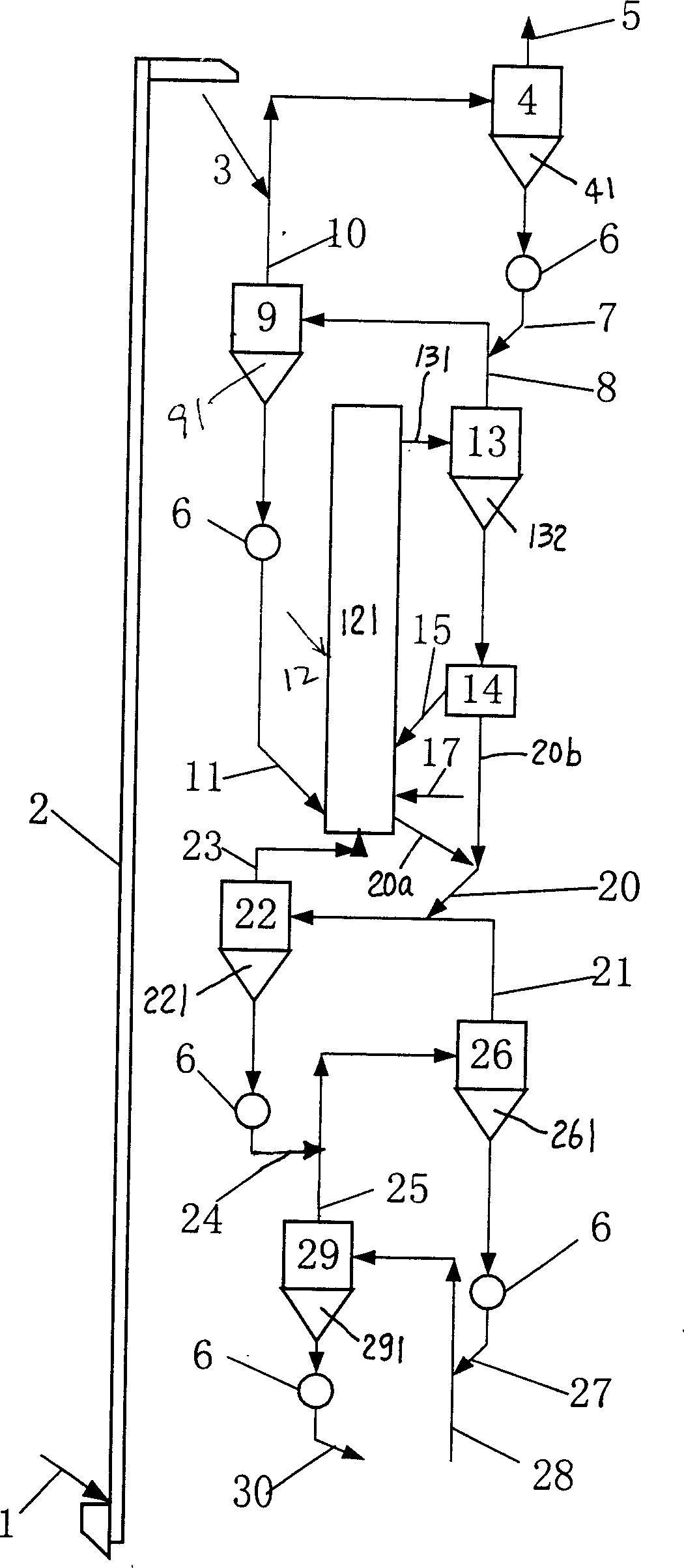

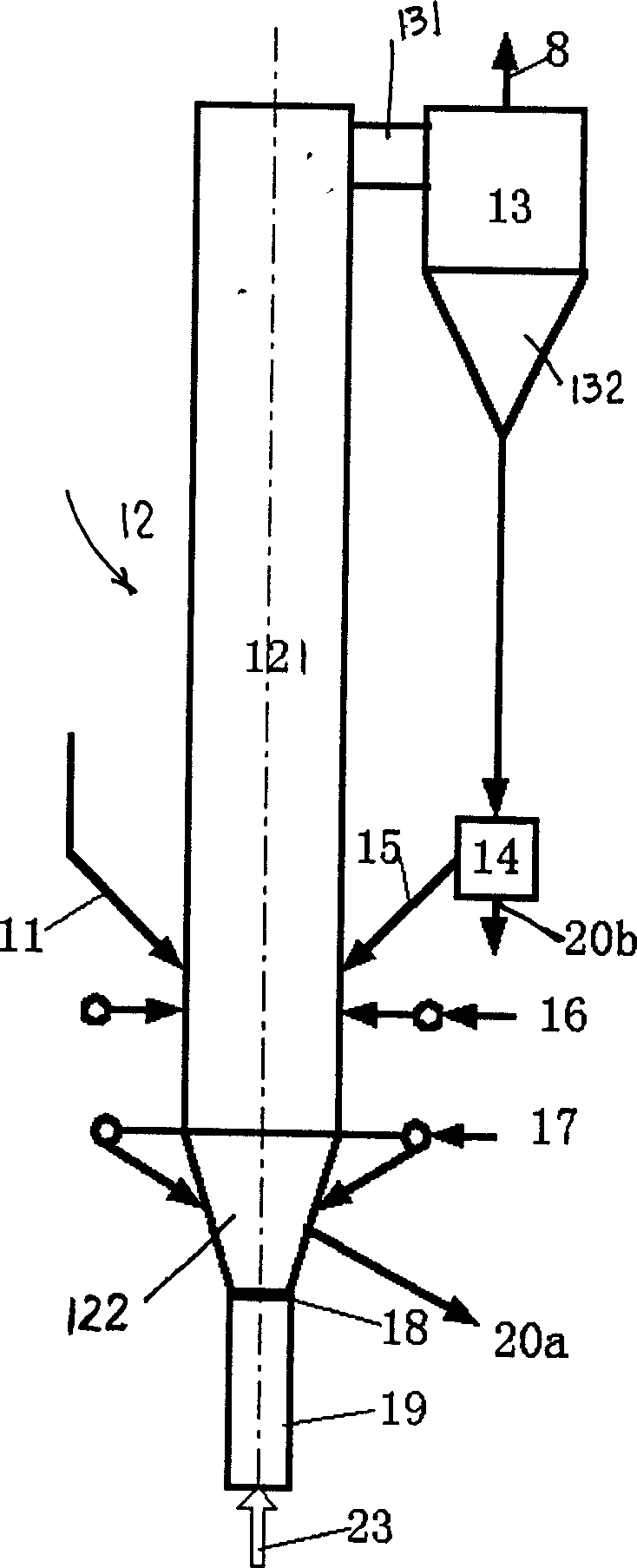

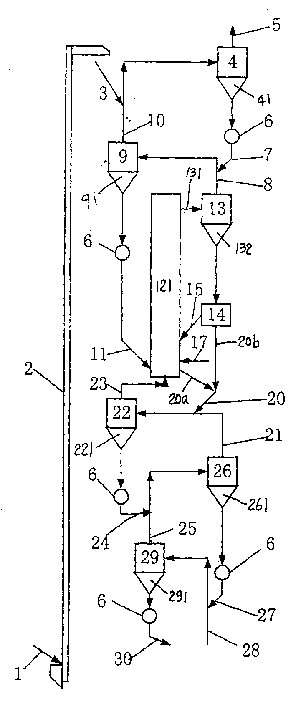

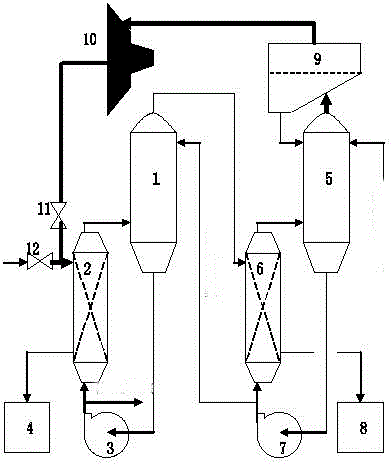

Rapid cycled fluidized calcining procedure for superfine kaolin and equipment

InactiveCN1600687AIncrease productivityImprove thermal efficiencyPigmenting treatmentAluminium silicatesCycloneEngineering

The invention relates to superfine Kaolin calcining process and device, the prodn, method includes; preheating kaolin raw powder material, then putting it in fluidization calcining furnace from the bottom, at same time, sending fuel into the furnace, preheated primary air is sent from plenum under the furnace burns with the fuel and to form a reducibility atmosphere calcining area in the lower section, the volume content of CO+H2 in reduction area is 0-10 percent, secondary air is sent from top of the reduction area to burn residual CO+H2 completely, airflow speed is 1-6m / s in the furnace, raw powder material is in fluidization, kaolin is circularly burned for 0.3-3 hours in temp. 700-1100 deg.C, then is sent into cyclone cooling system to be cooled to obtain superfine kaolin by mixer-grinding and depolymerizing.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

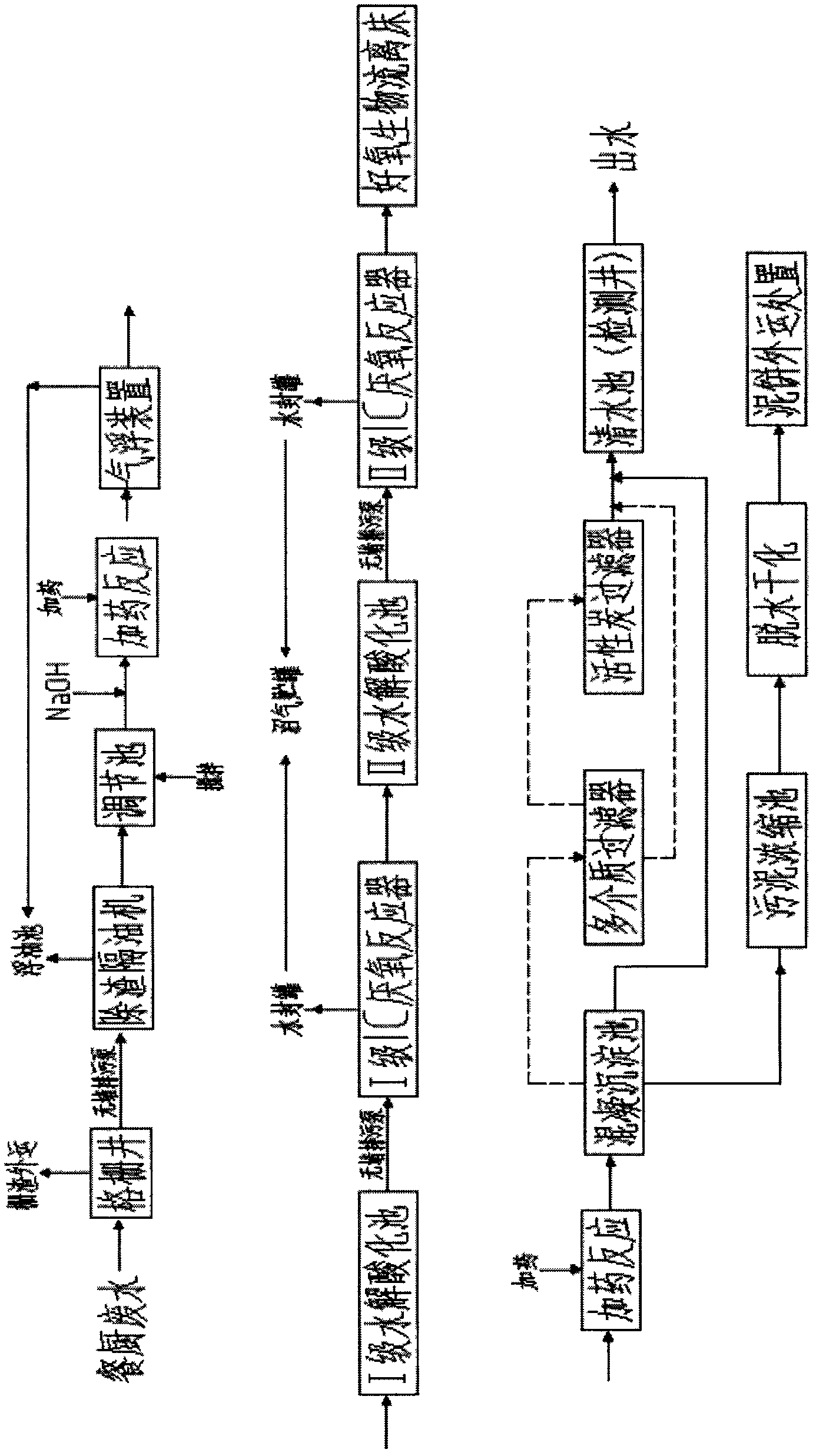

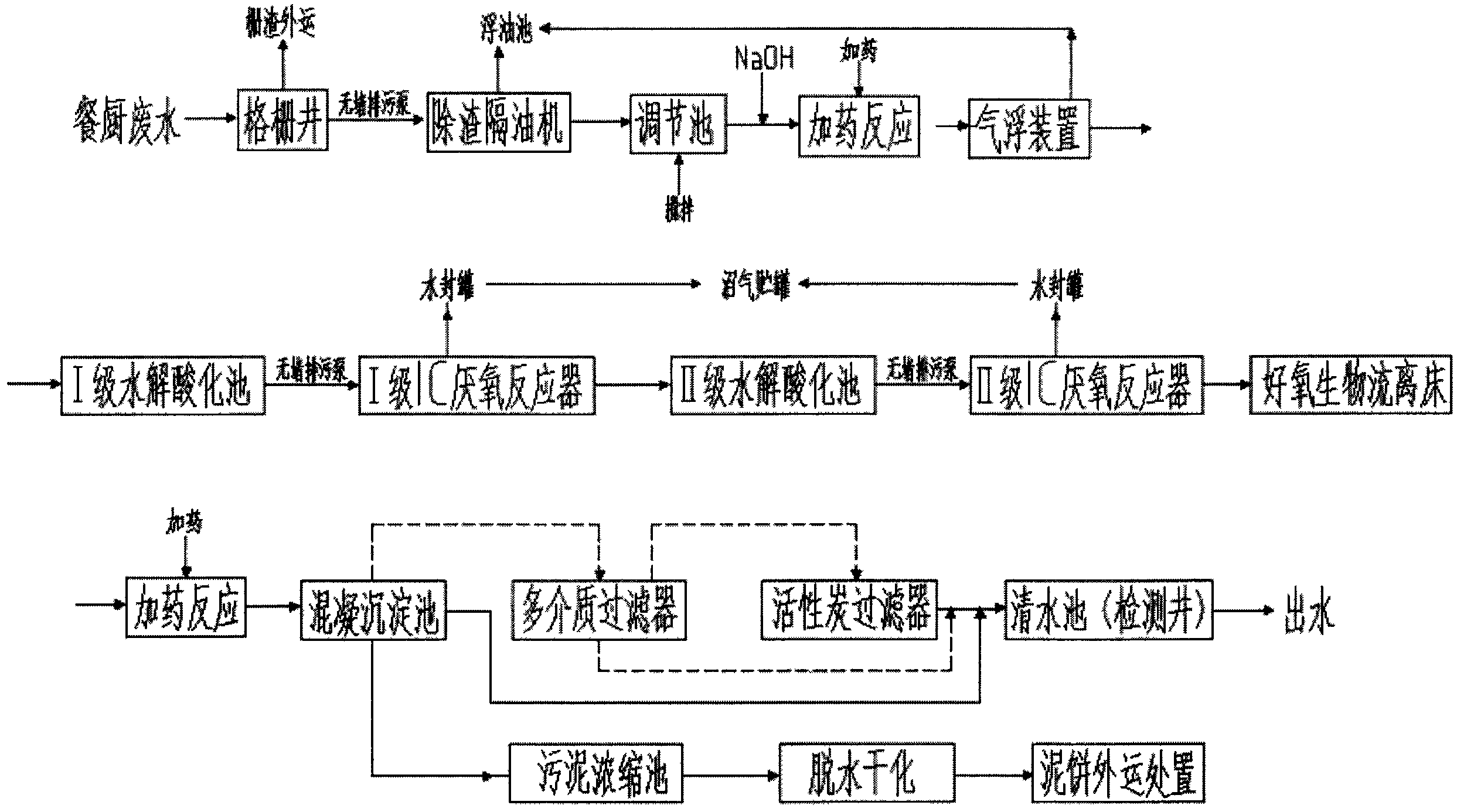

Treatment method of secondary wastewater of kitchen waste

ActiveCN102603117AReduce productionReduced processing system difficultyMultistage water/sewage treatmentFlocculationChemical oxygen demand

The invention discloses a treatment method of secondary wastewater of kitchen waste. The treatment method comprises the following steps of: (1) carrying out materialization pretreatment on kitchen wastewater to remove floater, animal or vegetable butter, oil and SS (suspended matter) in the wastewater; (2) carrying out the two-stage hydrolysis acidification-IC (internal circulation) anaerobic reaction treatment and biochemical treatment of an aerobiont separation bed on the wastewater; and (3) carrying out flocculation and precipitation on the biochemically-treated wastewater to discharge, and concentrating, dewatering and drying precipitate. The wastewater discharged by using the method reaches The people's Republic of China national standard of sewage comprehensive discharge standard (third-level discharge standard); through two-stage hydrolysis acidification-IC anaerobic reaction treatment, the gross removing rate of CODcr (chemical oxygen demand) can reach more than 92%, and carbon source does not needed to be supplied in the midway of the reaction, so that the normal running of equipment can be guaranteed.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

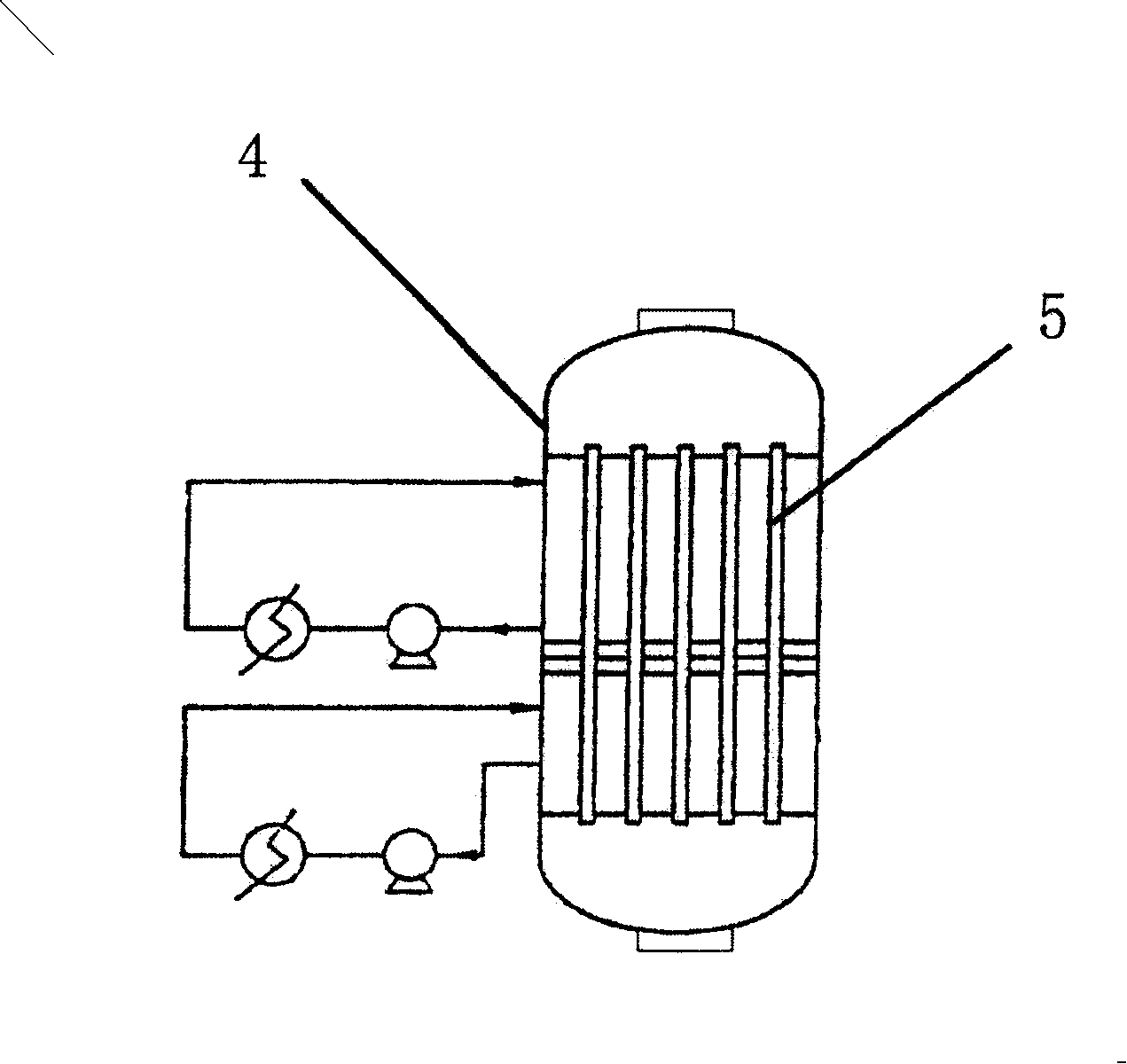

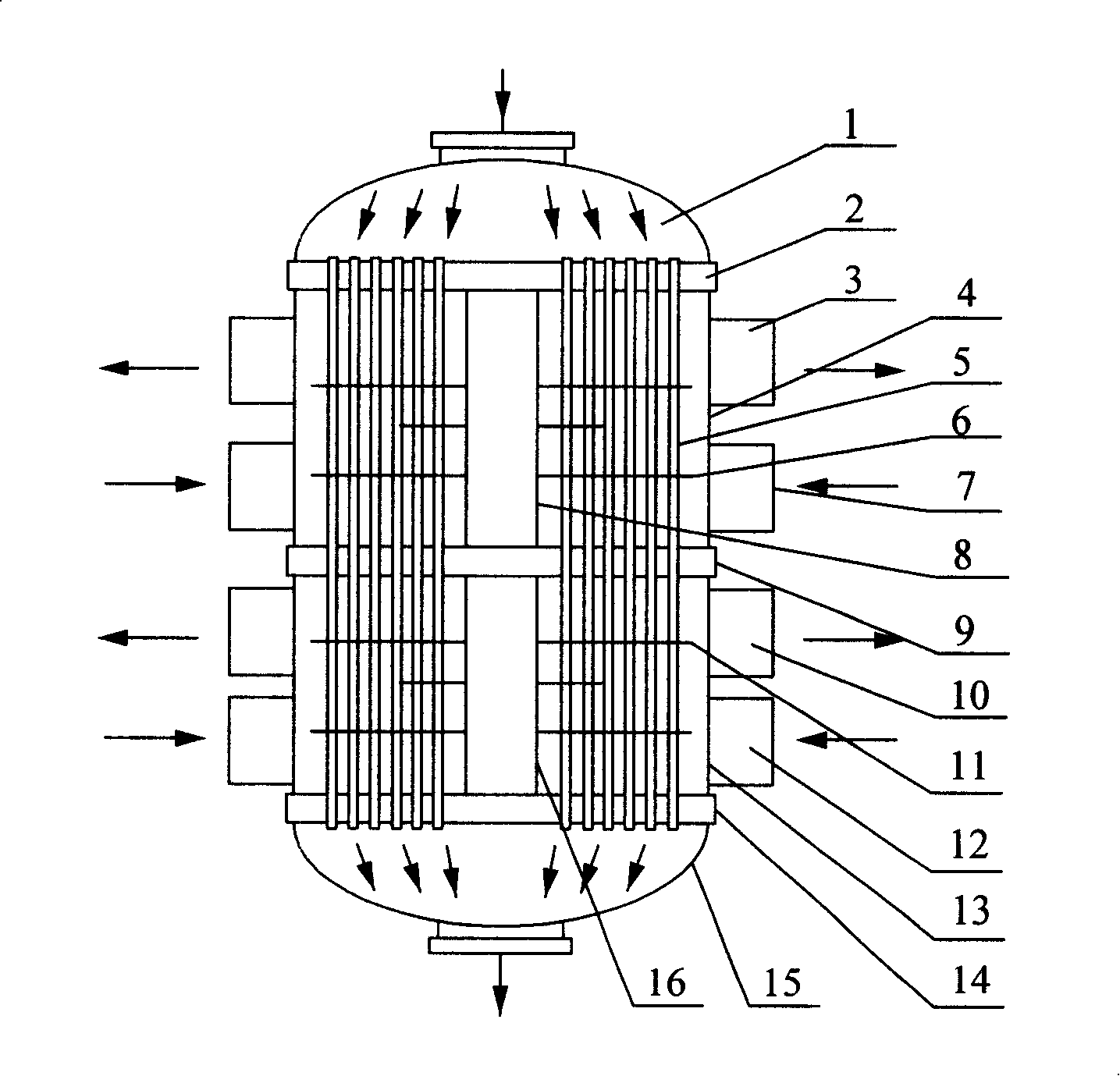

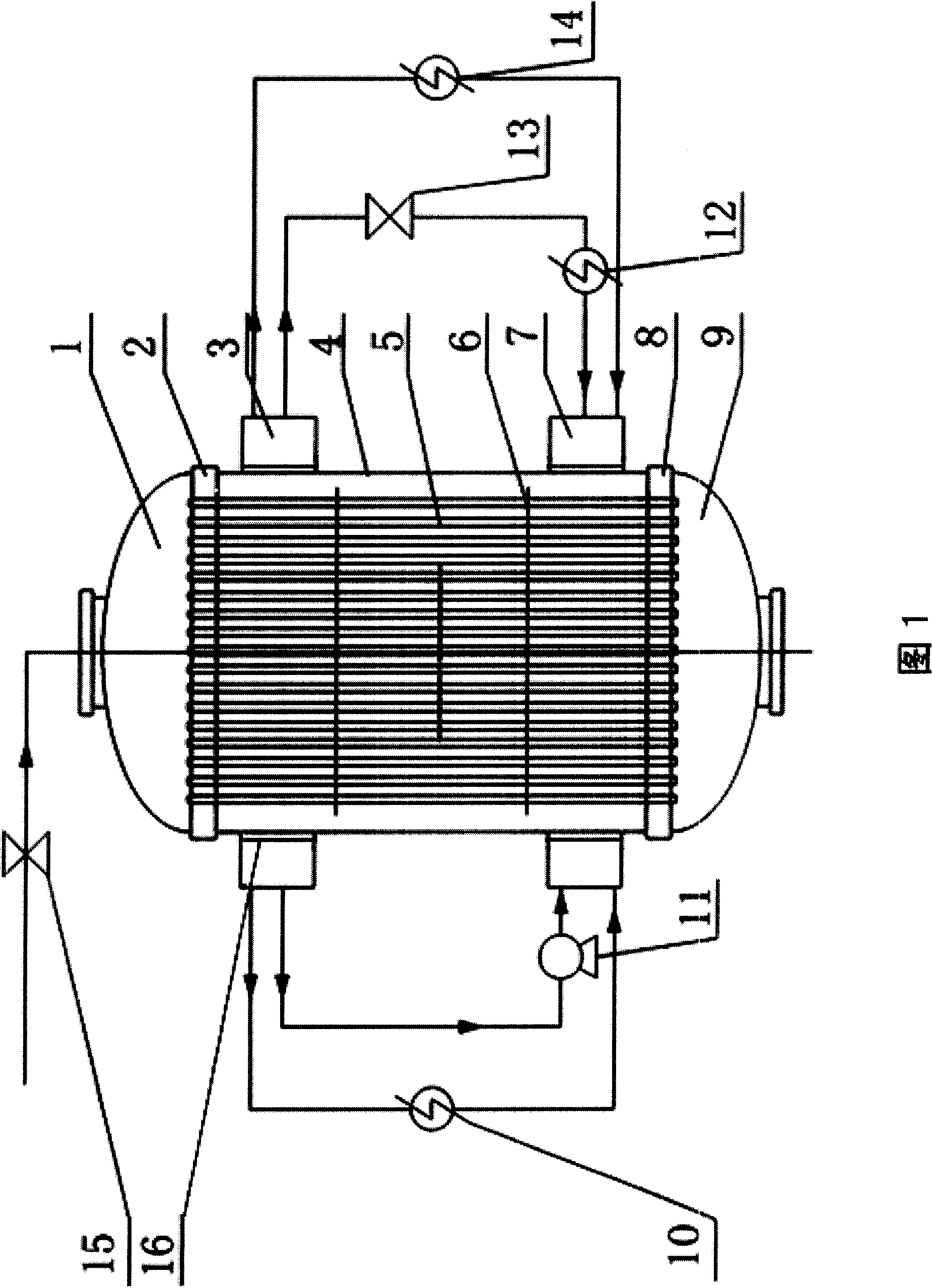

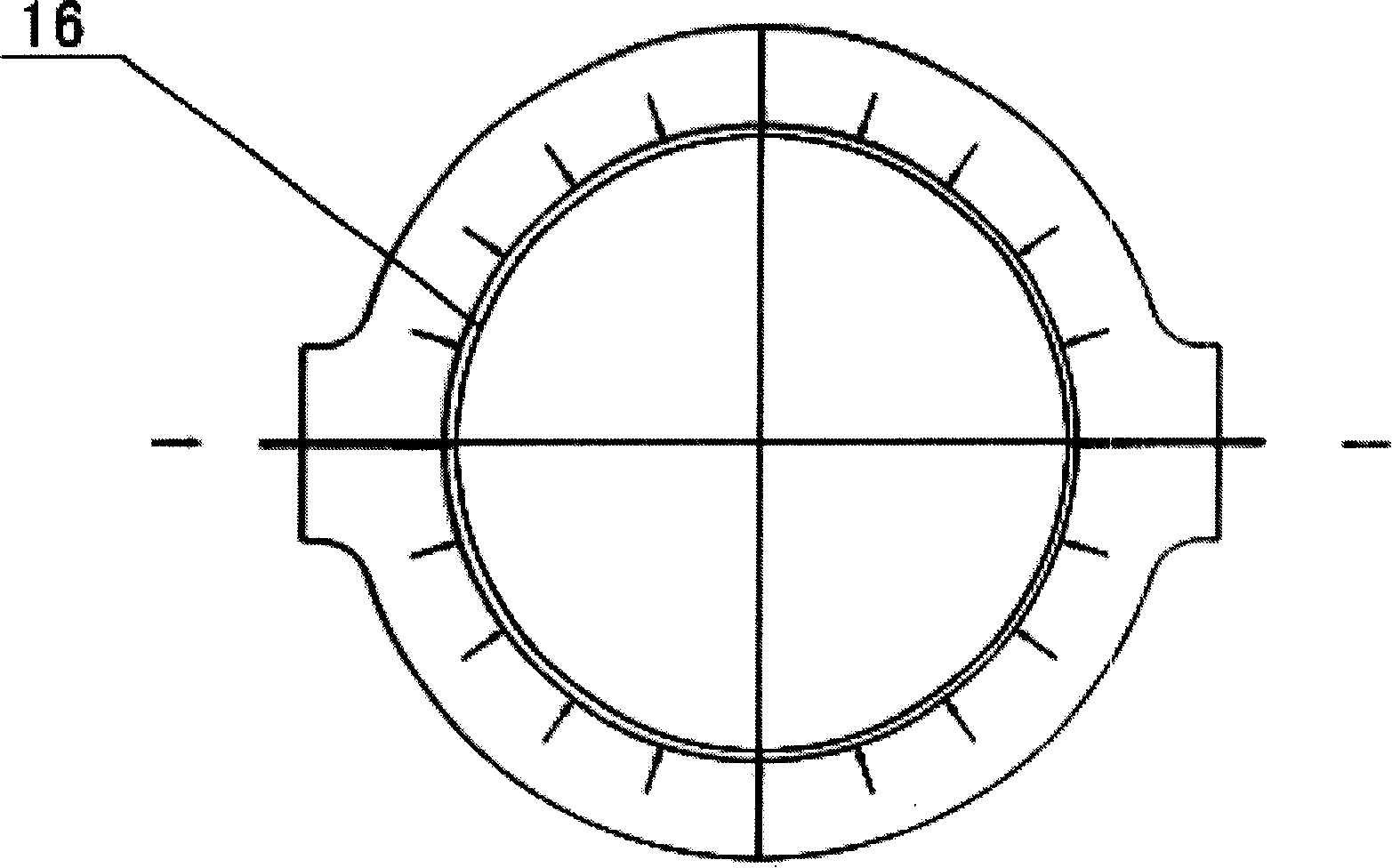

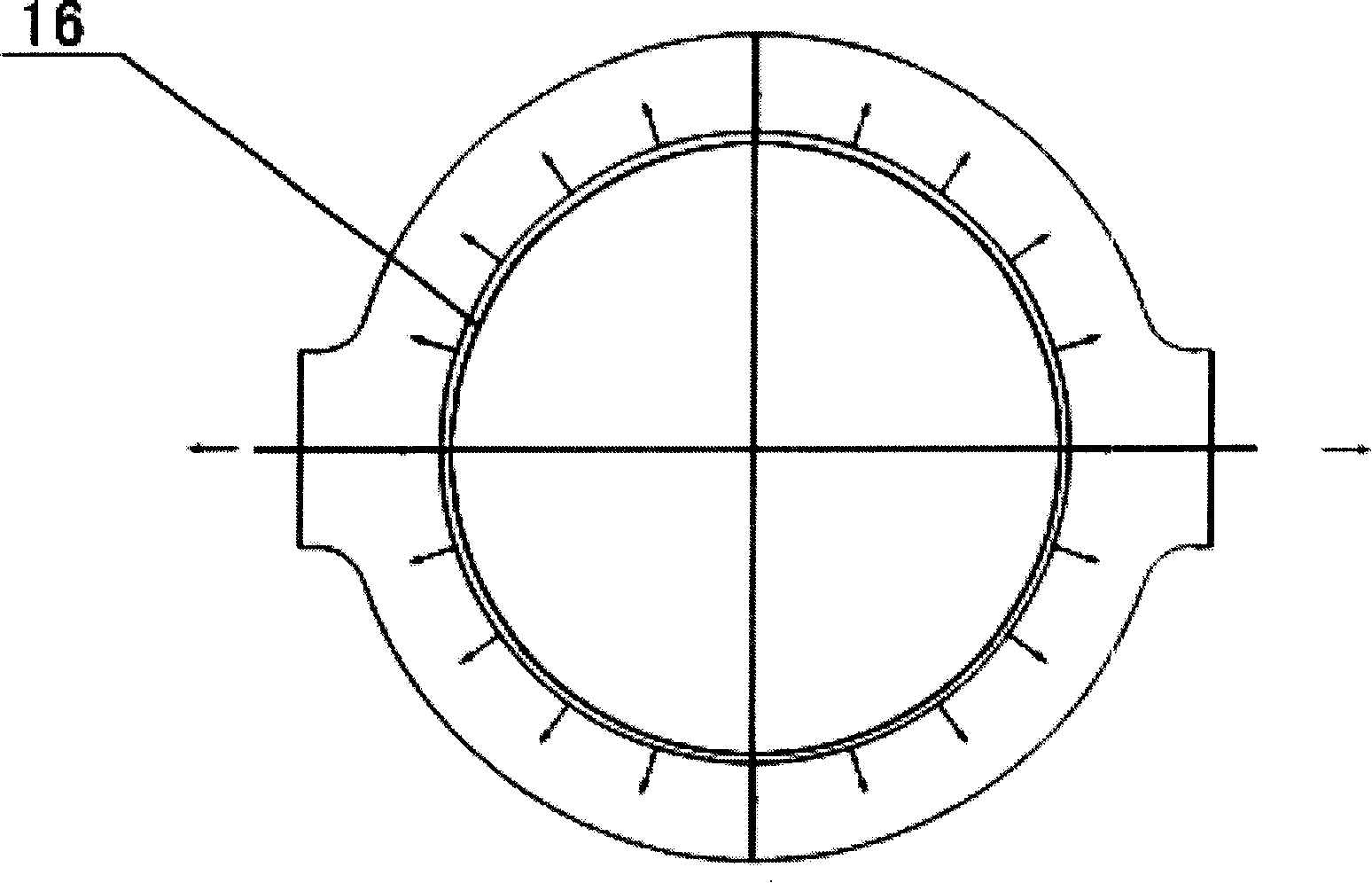

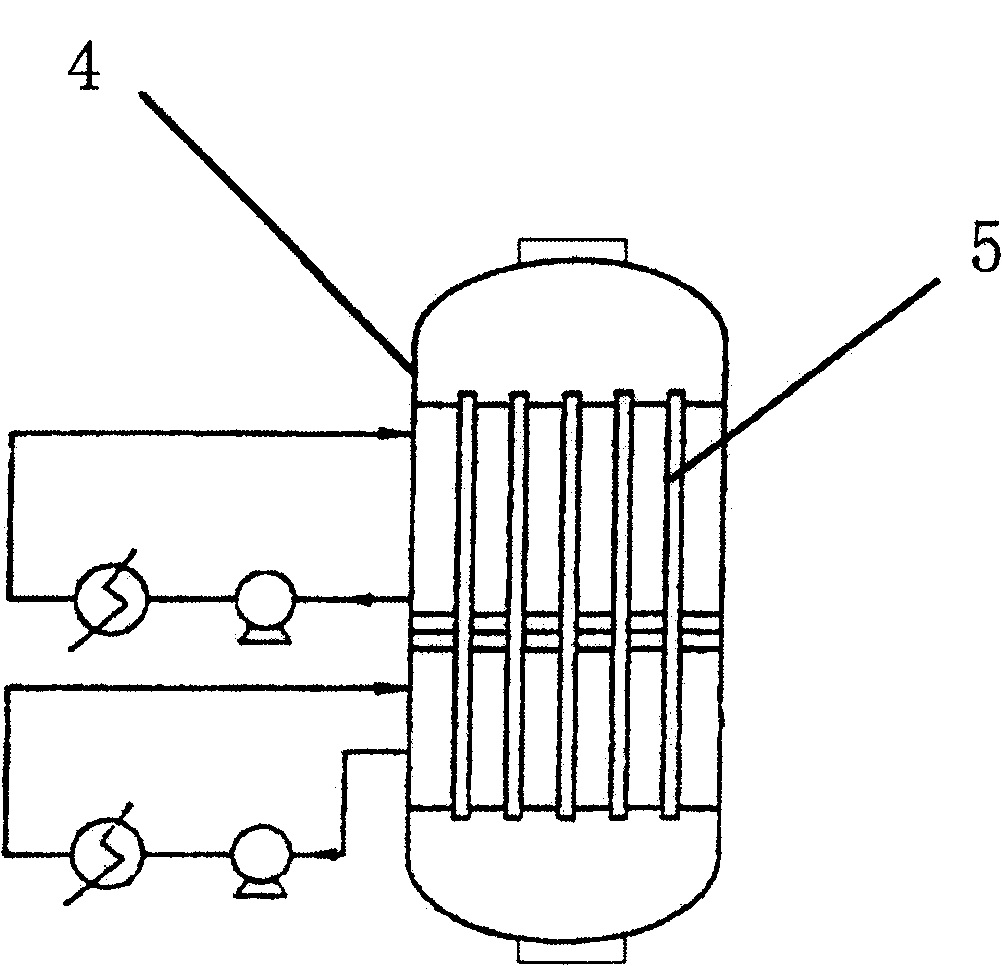

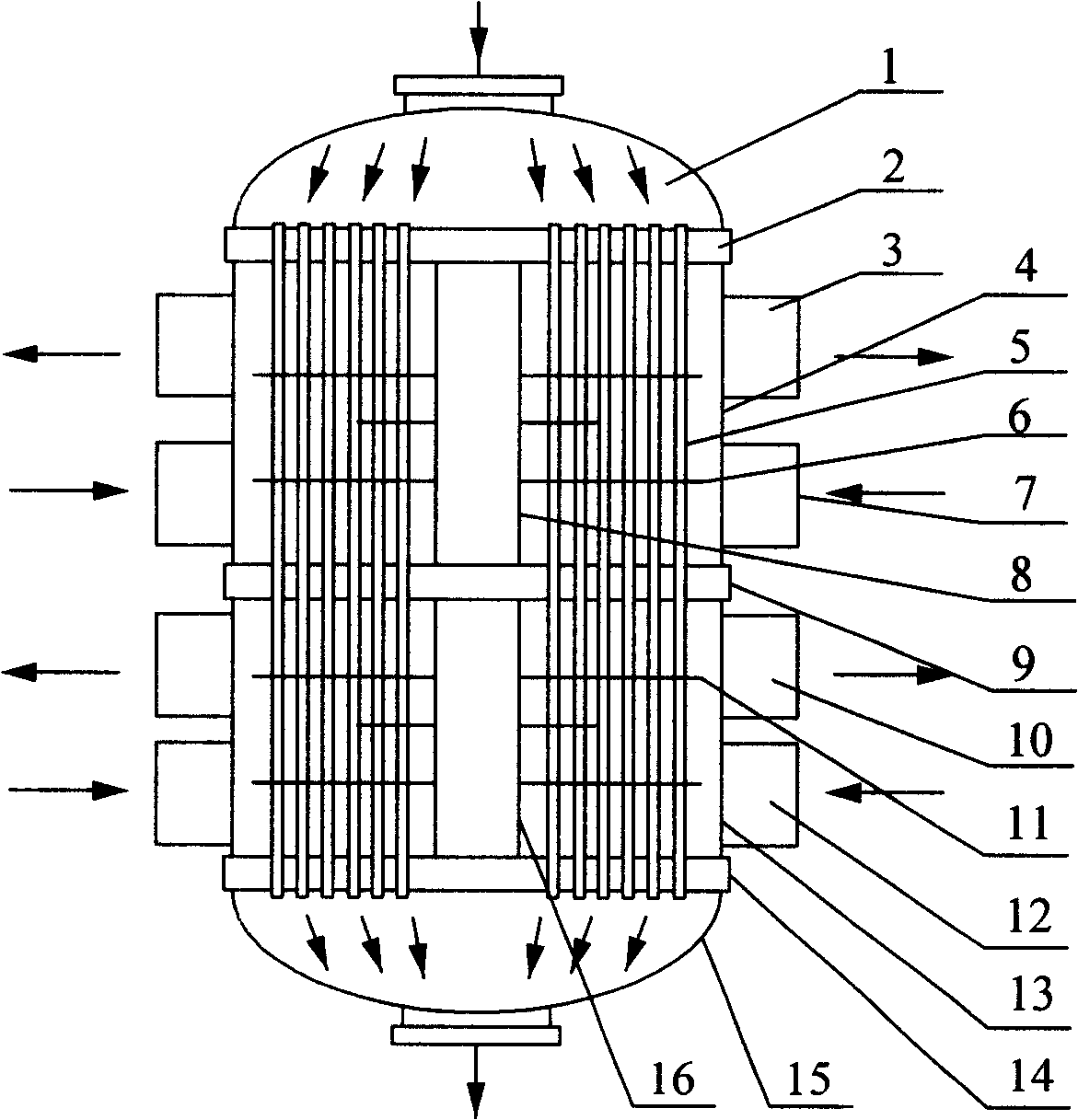

Shell pass multi-cavity type multi-layer bed fixed bed reactor

ActiveCN101209402AUniform accessReduce kinetic energy consumptionChemical/physical processesFixed bedEngineering

The invention relates to a multi-layered fixed-bed reactor, a shell side of which has a plurality of chambers. Currently, all the fixed-bed reactors with shells and tubes adopt a shell-side structure as a chamber, thus causing uneven heat transfer, insufficient heat exchange and worse utilization of residual heat. The shell of the invention is composed of an upper shell and a lower shell, and between an upper cannular plate and a lower cannular plate inside each shell, two shell-side baffles are arranged along the shell axial direction and divide the shell into three chambers, and reaction tubes as well as three semicircular traverse baffles are arranged inside the chambers at the two sides, thus forming cross current and parallel flow as a flow form of heat-exchanging mediums between tubes. Under the condition of existing equipments, the capacity of manufacturing large-scale reactors is doubled by the invention; the reactors are applicable for catalysts with high load and have balanced reaction, even heat transfer and sufficient heat exchange and the utilization of residual heat is more complete.

Owner:西安航天华威化工生物工程有限公司

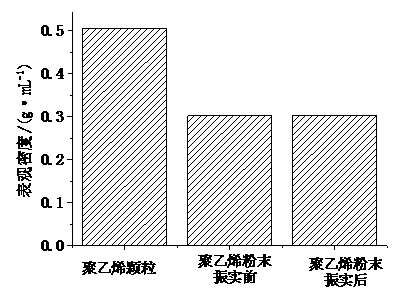

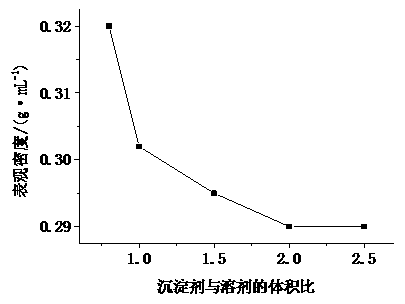

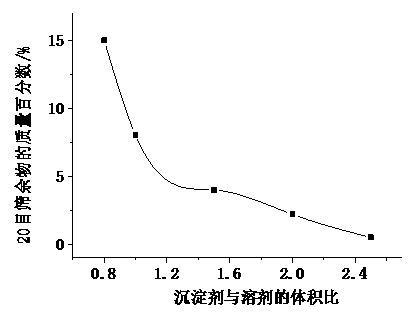

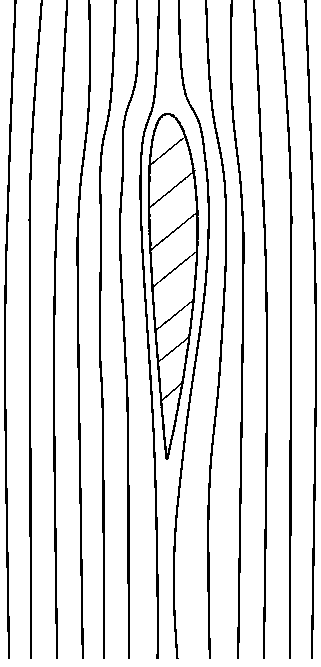

Polyolefin powder capable of uniform mixing with plant small piece and preparation method thereof

InactiveCN103214722AReduce weightWell mixedPowdery paintsHydrocarbon polymer adhesivesPolyolefinPlant roots

The invention relates to a polyolefin powder capable of uniform mixing with plant small pieces and a preparation method of the polyolefin powder. The powder comprises the ingredients of polyethylene, polypropylene, polystyrene or the mixture of the three, the particle size of the powder is 100nm-1mm, apparent density is 0.18g / mL-0.40g / mL, and the uniform mixing of the powder with the small pieces of plant root, stem, trunk, leaf, and seed case can be achieved through a mixing medium. The preparation process of the powder comprises the following steps of: mixing solid materials in various forms with a special solvent, heating the mixture for dissolution, carrying out thermo-precipitation using a special precipitant, carrying out separation, rolling homogenization and dispersion, separating the solvent and the precipitant for recycling, drying the resulting product, and grinding the dried product. The whole preparation process has the characteristics of material recycling, less volatile matter, strong environment protection and the like; the prepared powder can be applied to preparing an environment-friendly composite material which is further applied to fabricating a container, furniture, a finishing material, a toy and the like; and the prepared powder can be used as raw material for powder coating and a hot melt adhesive material which is easy in uniform coating.

Owner:JIUJIANG UNIVERSITY

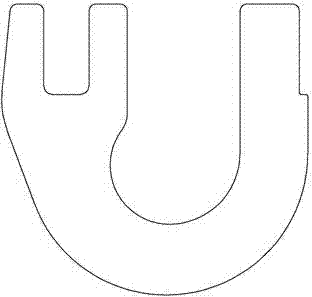

Wheat tillage limiting sowing machine

ActiveCN103477740AReduce kinetic energy consumptionImprove germination rateSpadesPloughsFertilizerAgricultural engineering

The invention provides a wheat tillage limiting sowing machine, comprising a tillage limiting device, a ridge forming device, a trenching sowing device, a compacting machine and a rack, wherein the tillage limiting device is used for deep tillage of a sown part, and comprises two groups of crankshafts, a connecting rod, a tillage limiting rod and a shovel, and the ridge forming device adopts upper layer of dry soil for ridge forming. When tillage is carried out, each group of crankshafts drives the corresponding shovel to vertically move for deep tillage through the corresponding connecting rod and the corresponding tillage limiting rod, then a shovel of the ridge forming device makes arc-shaped movement downwards to sow the upper layer of dry soil into a ridge forming transmitter for ridge forming under the action of the crankshafts, the connecting rod and a ridge forming rod, and afterwards the trenching sowing device and the compacting machine are used. According to the wheat tillage limiting sowing machine, the front of each wheat trenching sowing device is provided with one shovel of the ridge forming device and one shovel of the tillage limiting device, and only after the soil at the sown parts is subjected to deep scarification and the upper layer of dry soil is removed for ridge forming, trenching fertilizer application, sowing and compacting can be carried out.

Owner:全椒县全动机械有限公司

Remediation method for polluted soil

InactiveCN109622596ACompact processReduce kinetic energy consumptionContaminated soil reclamationIonPh balance

The invention discloses a remediation method for polluted soil. The remediation method comprises the following main steps of crushing, screening, spraying, heating sterilization and the like to remediate the polluted soil. Compared with a traditional remediation method for soil pollution, the remediation method for the polluted soil has the advantages that a treatment process is improved, and dustreduction and medicament addition in a soil treatment process are achieved through spraying; medicinal steam and pressure which are generated during heating sterilization are utilized to realize soilsterilization; by adding medicinal liquid and mixing the liquid uniformly, metal ion chelation and acid-base pH balance in the polluted soil are realized. The adopted treatment approaches of the method are hardly influenced by pollutant types and environmental conditions and have a wide application field. The method has the advantages of good effect, high operability and good social and environmental benefits.

Owner:王忠良

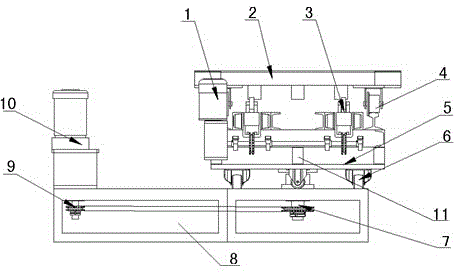

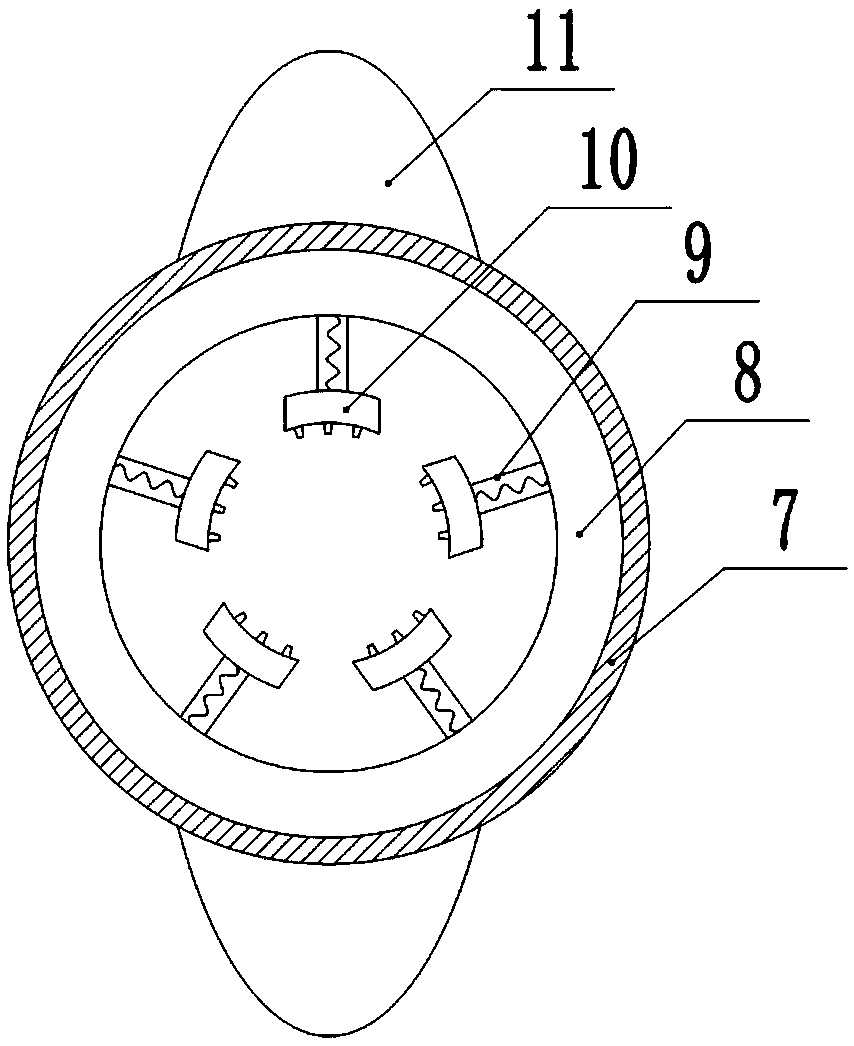

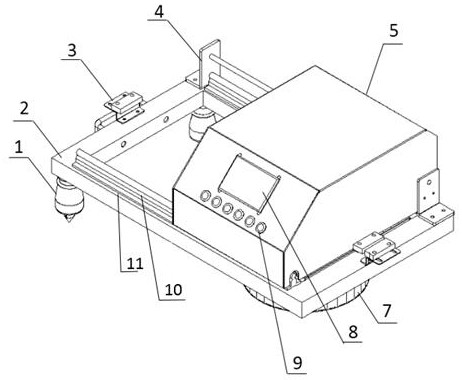

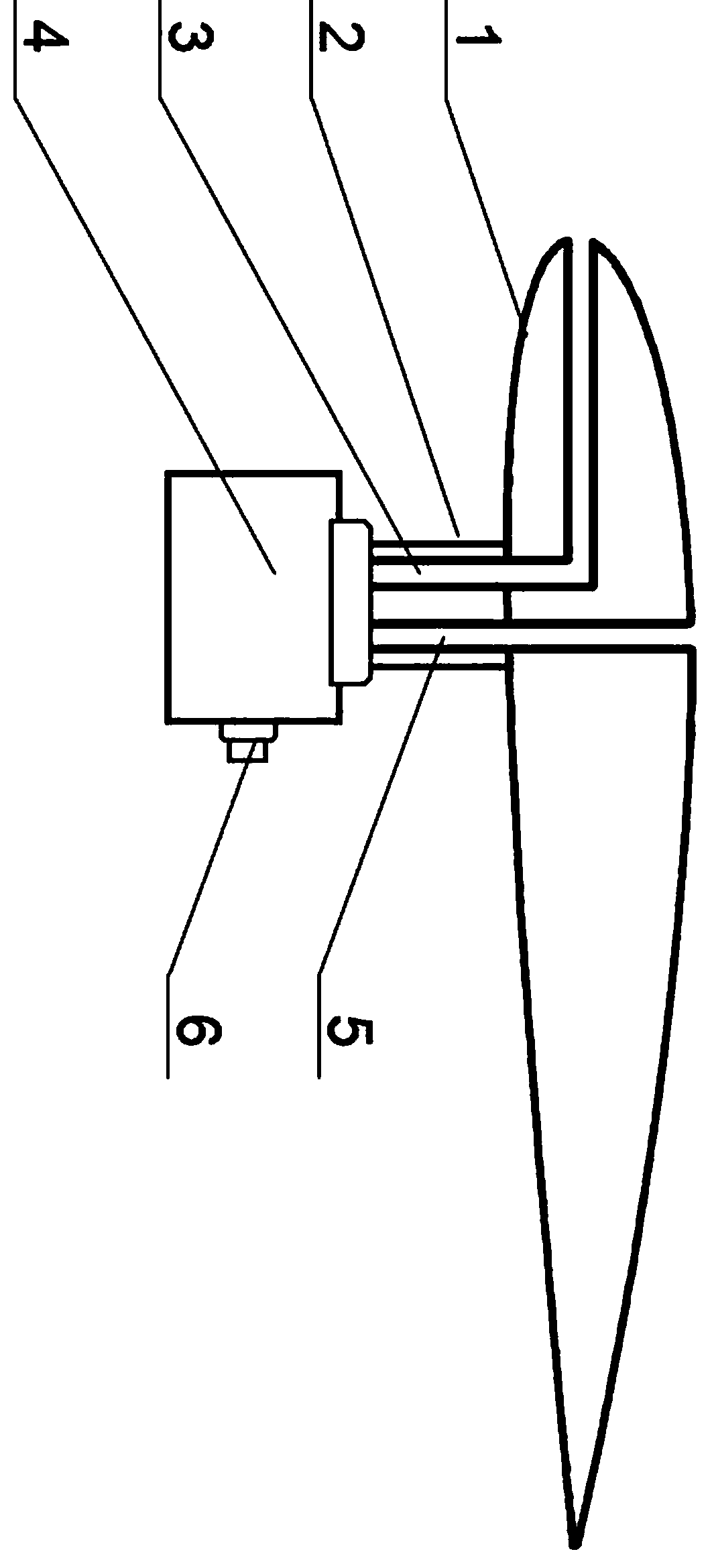

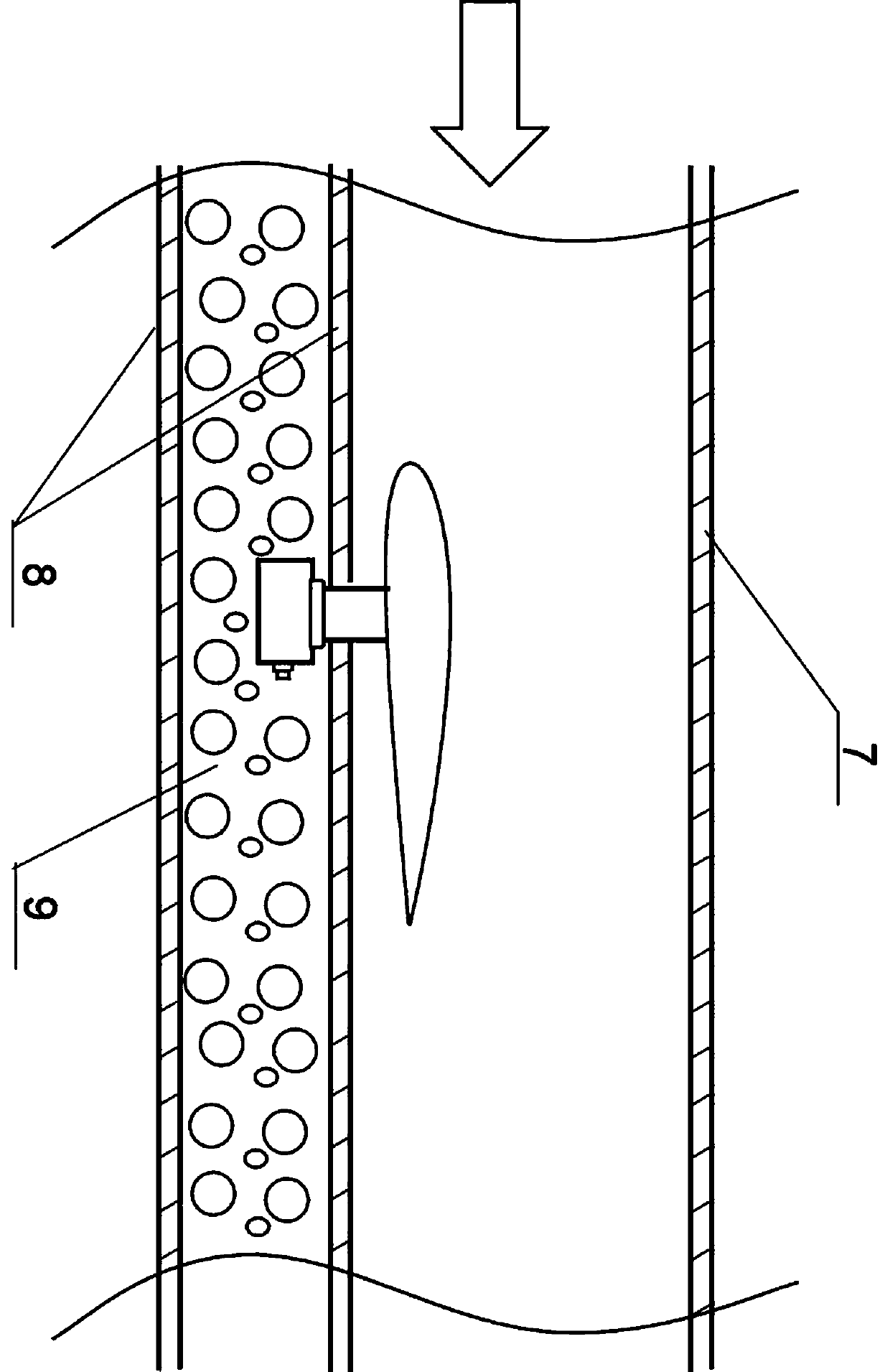

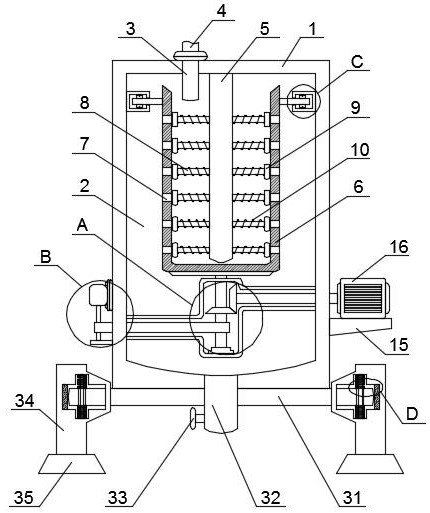

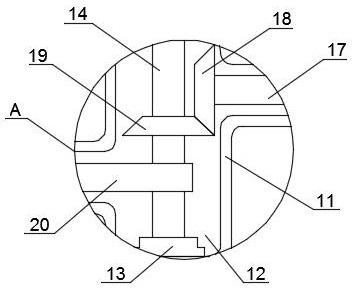

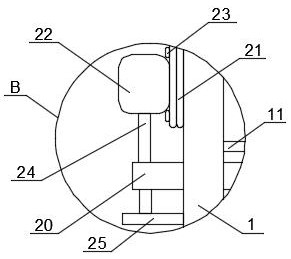

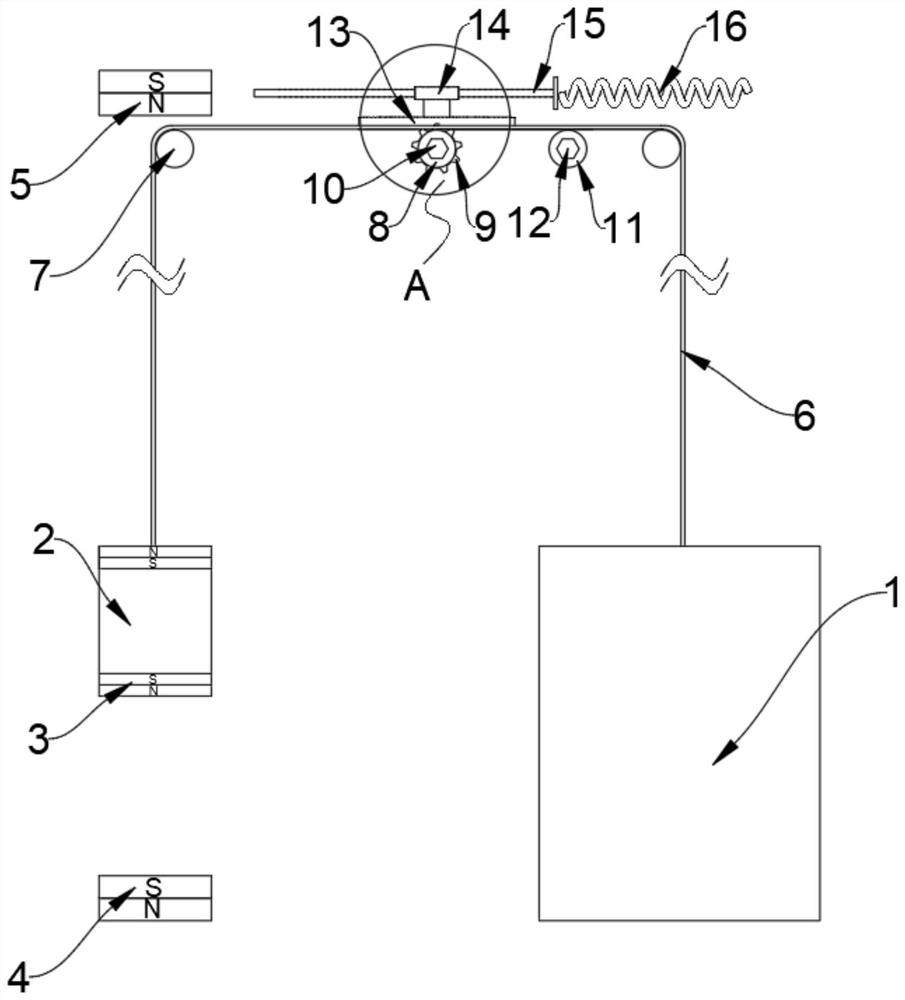

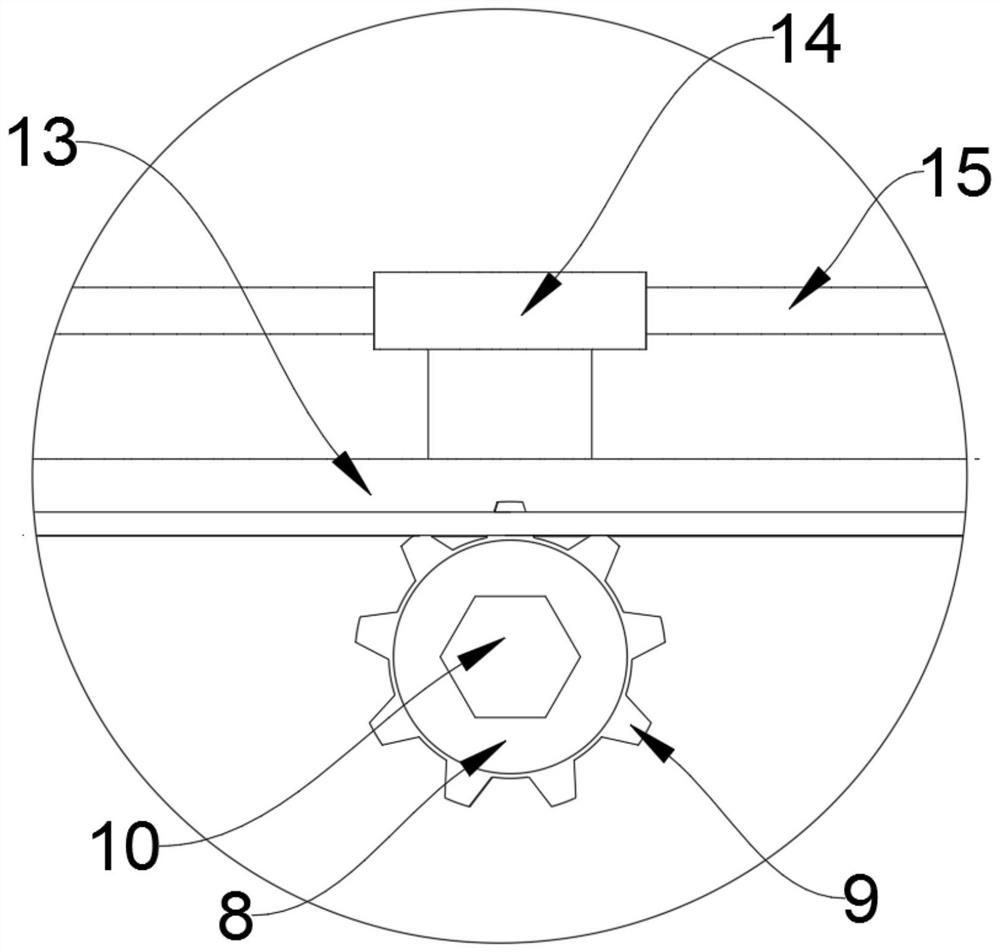

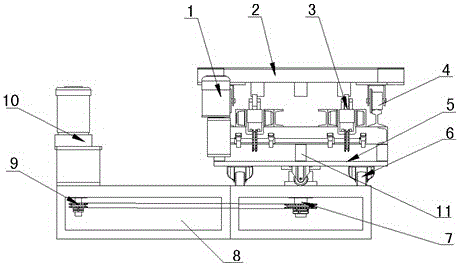

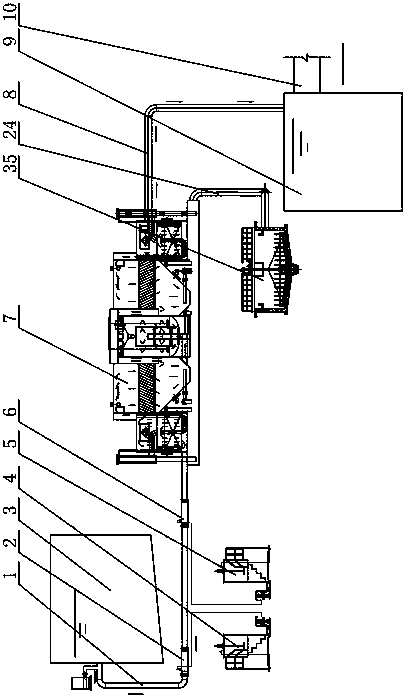

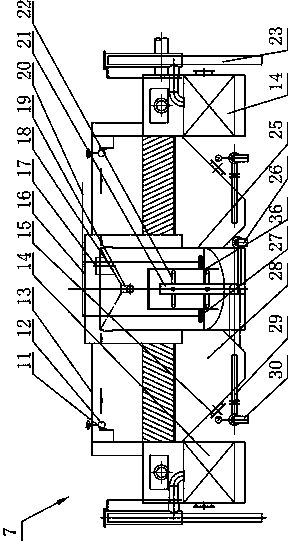

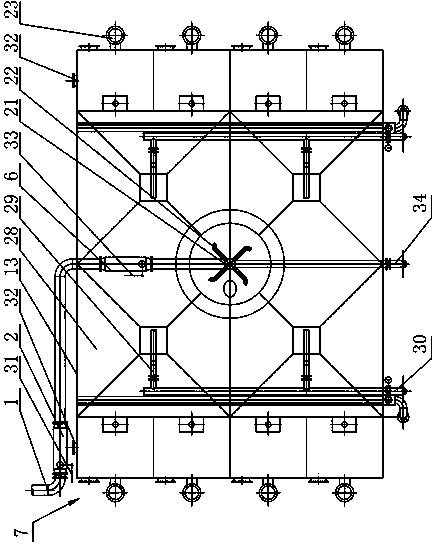

Turntable for vacuum lens coating machine

ActiveCN104651795AReduce wearReduce kinetic energy consumptionVacuum evaporation coatingSputtering coatingRotational axisRotary stage

The invention relates to a turntable for a vacuum lens coating machine. The vacuum lens coating machine comprises a pushing motor (1), a material trolley (2), one-way pushers (3), an upper support (4), the turntable (5), bearing wheels (6), a rotation stop assembly (7), a base (8), a sprocket chain (9), a rotating motor (10) and a rotating shaft (11). The vacuum lens coating machine is characterized in that the rotation stop assembly (7) is arranged on the rotating shaft (11), the rotating motor (10) is used for driving the turntable (5) to rotate to the 180-degree position through the transmission of the sprocket chain (9), and the one-way pushers (3) on two sides are used for pushing the material trolley (2) to the next station by the simultaneous driving of the pushing motor (1) and the sprocket chain so as to transfer a lens on a coating rack of the vacuum lens coating machine. By adopting the turntable provided by the invention, the consumption of kinetic energy can be saved, the abrasion between related parts can be reduced, the coated lens can be rotated stably in the whole coating process, and the coating quality can be improved further.

Owner:DANYANG DINGXIN MASCH EQUIP CO LTD

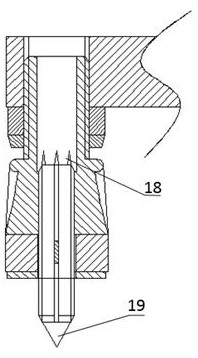

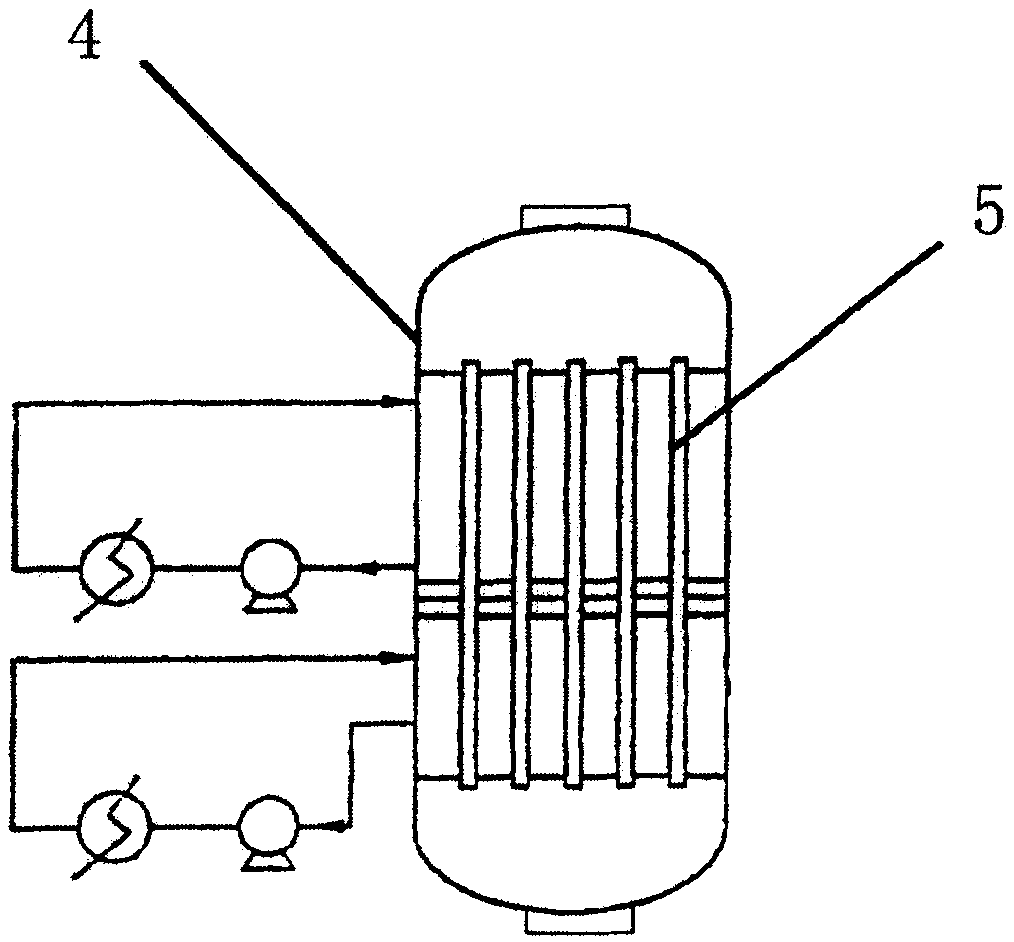

Copper alloy antivacuum adding Zircomium engineering technology equipment and technological process thereof

The invention discloses a device for non-vacuum zirconium doping engineering in a copper alloy and the process thereof. The device comprises an induction melting furnace (1), a seal mechanism (2), a casting tube (3), a protective cover (4) and a crystallizer (5). The seal mechanism (2) is fixed on one side of the upper part of the induction melting furnace (1) through bolts. The casting tube (3) is fixed at the bottom at the other side of the seal mechanism (2). The crystallizer (5) is inserted into the lower end of the casting tube (3) through the protective cover (4). The process includes the following steps: loading, sealing, melting, refining, argon gas introduction, Zr doping, casting and testing, wherein the casting step is implemented by using the furnace, the casting tube and the crystallizer.

Owner:LUOYANG COPPER PROCESSING GROUP

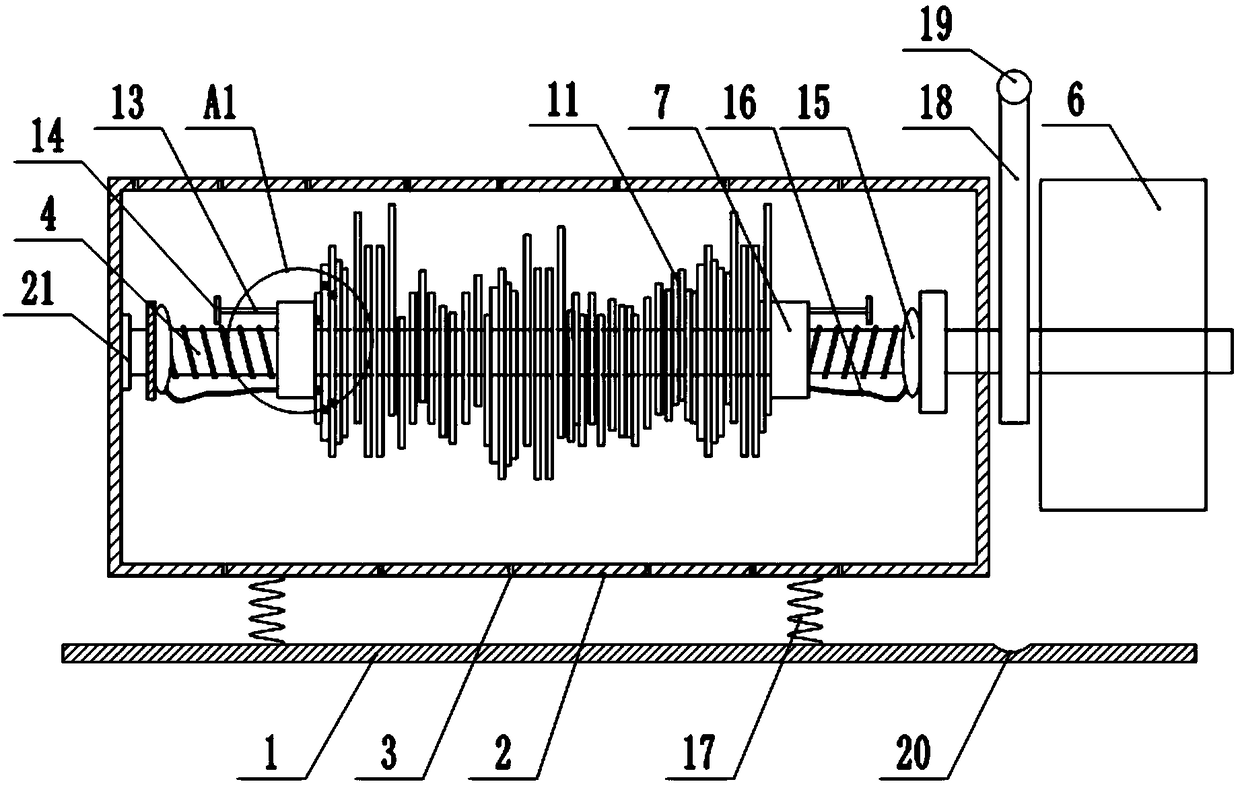

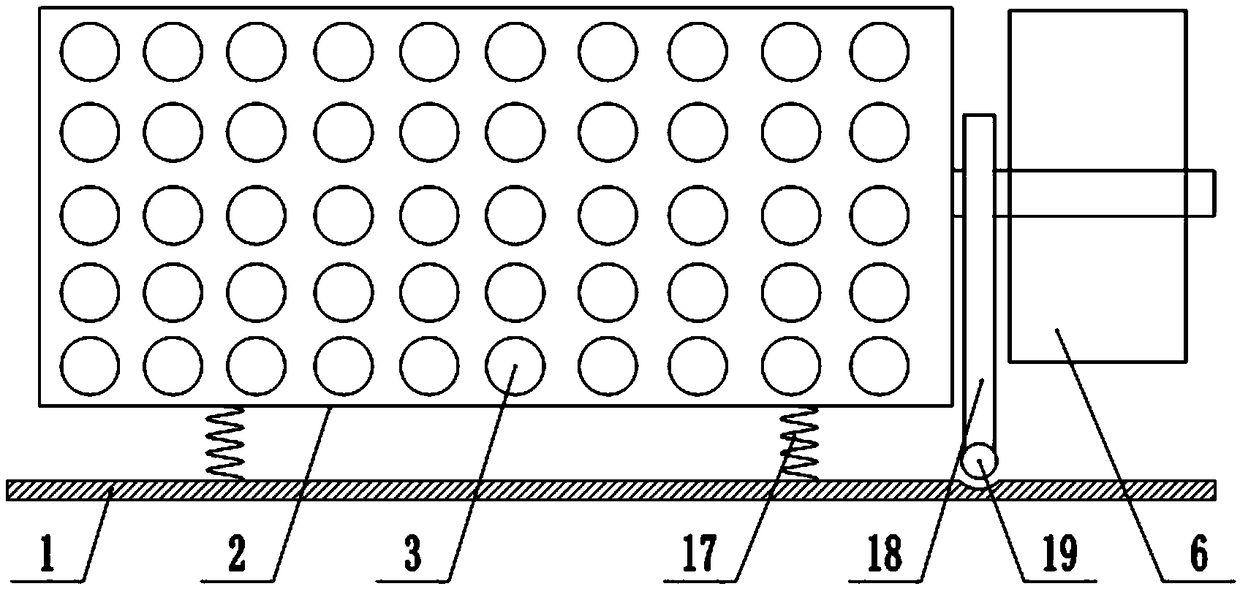

Environment-friendly noise removing device

The invention relates to an environment-friendly noise removing device which comprises a base and a shell. The shell is provided with a plurality of noise removing holes, a two-way lead screw is rotationally connected to the interior of the shell, the middle of the two-way screw is provided with a smooth portion, one end of the two-way lead screw penetrates through the shell and is fixedly connected with multiple rotary blades, the two ends of the two-way lead screw are in threaded connection with nuts, supporting air bags are arranged on the inner walls of the nuts, multiple abutting rods areevenly distributed on the supporting air bags, the free ends of the abutting rods are all face towards the circle centers of the nuts, the free ends of the abutting rods are fixedly connected with abutting blocks, the multiple abutting blocks can abut against each other and are spliced into a circular ring, and the abutting blocks are provided with threads. The two-way lead screw is sleeved witha noise removing air bag set which comprises multiple noise removing air bags, each noise removing air bag is provided with a reset spring, every two adjacent noise removing air bags have the height difference, first air guide pipes are arranged between the noise removing air bags at the two ends of the noise removing air bag set and the supporting air bags in a communicating mode, and the noise removing air bags are provided with air outlets. Noise produced by an air outlet of an air conditioner can be reduced.

Owner:宁波清智环保科技有限公司

Synchronous carbon and nitrogen removing reactor

ActiveCN105060465AHigh microbial biomassReduce productionTreatment using aerobic processesSustainable biological treatmentChemical oxygen demandBiological filter

The invention discloses a synchronous carbon and nitrogen removing reactor which is suitable for the treatment of waste water with high ammonia nitrogen and low carbon and nitrogen ratio, in particular for the treatment of kitchen waste water, an anaerobic digestion solution and the like which are similar to the waste water with high ammonia nitrogen and low carbon and nitrogen ratio. The synchronous carbon and nitrogen removing reactor mainly comprises a cylindrical inner cylinder body and a cylindrical outer cylinder body which are coaxial, wherein an aeration device, a jet device, filler, an effluent weir and the like are arranged in the cylinder bodies; biological filter as a carrier is distributed in the inner cylinder; flow-separated ball filler as a carrier is put into the outer cylinder; after the anaerobic digestion solution with the high ammonia nitrogen is treated by the reactor, the removal rate of the ammonia and the nitrogen can reach 75 to 90 percent, and the removal rate of CODCr (Chemical Oxygen Demand) can reach 55 to 65 percent.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Soil carbon flux measurement device

ActiveCN110824140BStrong representativeStrong movement precisionEarth material testingMicrocomputerSample plot

The invention discloses a soil carbon flux measuring device. The device comprises an air storage cylinder (7), a base (2), a rack (4), a movable air storage cylinder cover (12), a cylinder cover lifting device (13), a cylinder cover translation device (15), a sensor, a display and a system control microcomputer, an air storage cylinder is formed by combining an upper fixed cylinder body (16), a lower movable cylinder body (17) and a thin elastic sleeve (24) sleeving the two cylinder bodies, the lower movable cylinder body is defined by a plurality of arc-shaped surface sliding pieces which arelongitudinally and circumferentially arranged, and each arc-shaped surface sliding piece can be adjusted in an up-down telescopic mode along with unevenness of a sample plot. The device is speciallyused for measuring the carbon flux of the soil, and has the advantages of strong adaptability to the surface condition of the ample plot to be measured, high sealing performance, strong representativeness of collected and extracted sample gas, conformity to design requirements, low error and the like. Power transmission of translation or vertical lifting of the device is carried out under the two-dimensional condition, positioning is accurate, the joint closing performance is good, and faults and damage are not likely to happen.

Owner:ZHEJIANG FORESTRY UNIVERSITY

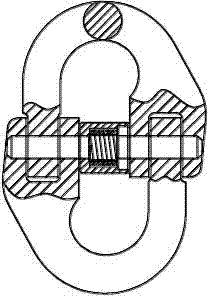

European link double-ring buckle body forge piece forming process

The invention discloses a European link double-ring buckle body forge piece forming process. The process includes the following steps that 1, feeding is conducted, rod materials are cut into segmented blanks I; 2, heating is conducted, the blanks are heated; 3, the weight conservation principle is followed, a cross wedge rolling machine is adopted to make blanks, and the rolled blanks II are thick in the two ends and thin in the middles; 4, a bending die is adopted to bend the blanks II into blanks III, the bending degree of the blanks III is equal to that of a final forming forge piece of a buckle body; 5, primary forging is conducted on the blanks III in a primary forging die; 6, finish forging is conducted; 7, edge cutting is conducted; 8, reshaping is conducted. According to the process, the blanks are made through the cross wedge rolling machine, the blanks II are thick in the two ends and thin in the middles, and reasonable weight or size distribution is conducted on raw materials, so that waste of materials is reduced, that is, generated burrs are reduced, the material utilization rate is increased, meanwhile, in the forging process, the forging forming pressure is required, the kinetic energy consumption of a main machine is lowered, and energy is saved.

Owner:SHANDONG SHENLI RIGGING

Mixing material separation and dust-reduction device and application thereof

The invention discloses a mixing material separation and dust-reduction device and application scenarios thereof. The device comprises a multi-channel bionic swirler and an ejector, wherein the multi-channel bionic swirler comprises an overflow tube, a swirl chamber, a shrinking hopper and a sample discharge tube, which are fixedly connected with each other from top to bottom; bionic non-smooth units are distributed on the inner wall surface of the multi-channel bionic swirler; an inlet channel is disposed at the upper end of a side wall of the swirl chamber; the ejector comprises a spray nozzle, a mixing chamber, a throat tube and a diffusion chamber; one end of the spray nozzle is connected with a high-pressure pump, and the other end of the spray nozzle stretches into the interior of the mixing chamber; the mixing chamber is connected with the overflow tube in a closing manner; two ends of the throat tube are respectively connected with the mixing chamber and the diffusion chamber in a closing manner; and the diffusion chamber is connected with a dust-reduction box through a pipeline. The device is mainly used in scenarios in which a large amount of dust is generated such as drilling, geotechnical engineering, grouting engineering, geological disaster control engineering, mining, tunnel piercing and the like, and is capable of solving the technical problems that the existingdevice is low in separation efficiency on mixing materials, unsatisfactory in dust-reduction effect, serious in abrasion, short in service life and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

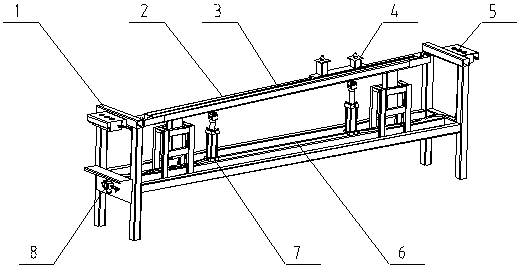

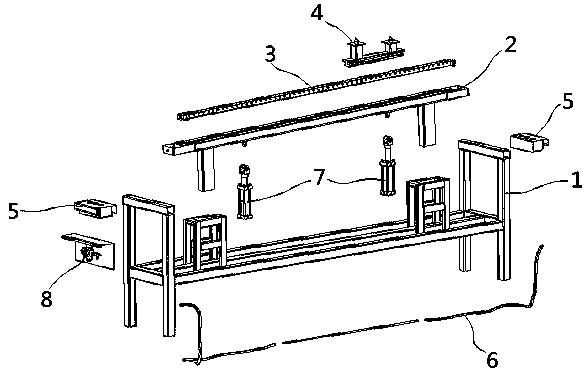

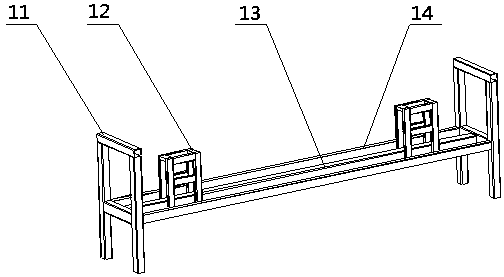

Part reciprocating conveying platform

InactiveCN108296680ASolve the problems of low efficiency and high manual labor intensity in the transfer processAchieve forwardingWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to a part reciprocating conveying platform. The part reciprocating conveying platform comprises a main frame and a conveying mechanism arranged on the main frame, the conveying mechanism can do up-down inclination angle motion relative to the horizontal plane so that conveyed parts can move from one end of the conveying mechanism to the other end of the conveying mechanism under the action of gravity. A lateral inclination preventing structure is arranged between the conveying mechanism and the main frame. The conveying mechanism comprises a conveying rail and a part storage frame which are matched through a guide rail slide bock pair. The conveying rail is longitudinally arranged on the main frame and can do up-down inclination angle motion relative to the horizontalplane. The two ends of the main frame are provided with control panels correspondingly so that the inclination angle, relative to the horizontal plane, of the conveying mechanism can e controlled. The part reciprocating conveying platform is simple in structure and low in cost, and the problems that a welding manual production line welding procedure assembly part conveying process is low in efficiency, and the labor intensity is high are solved.

Owner:CHERY AUTOMOBILE CO LTD

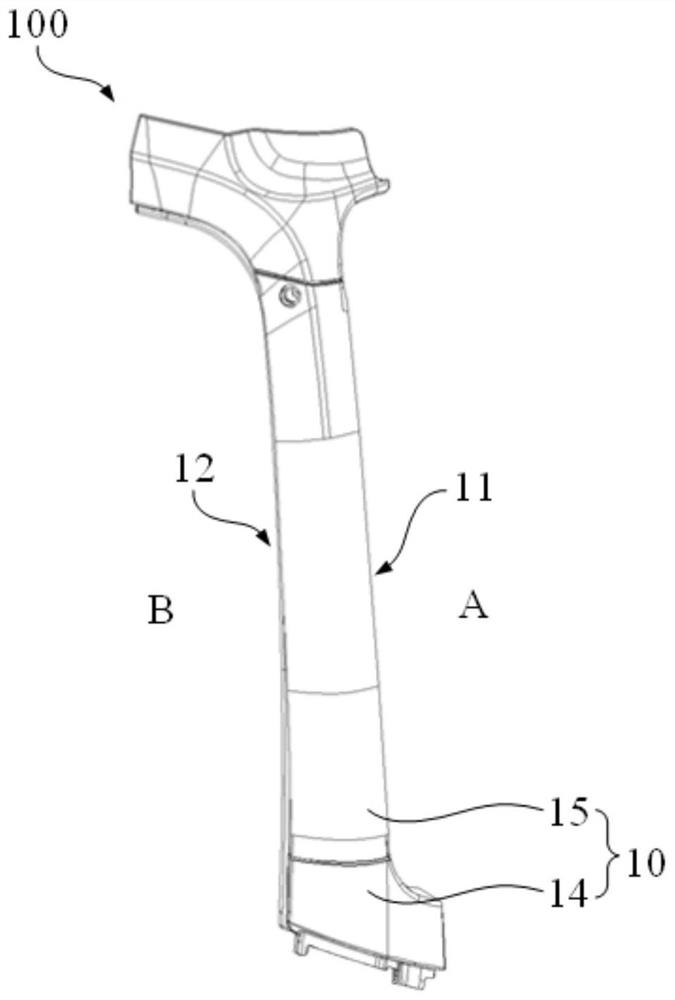

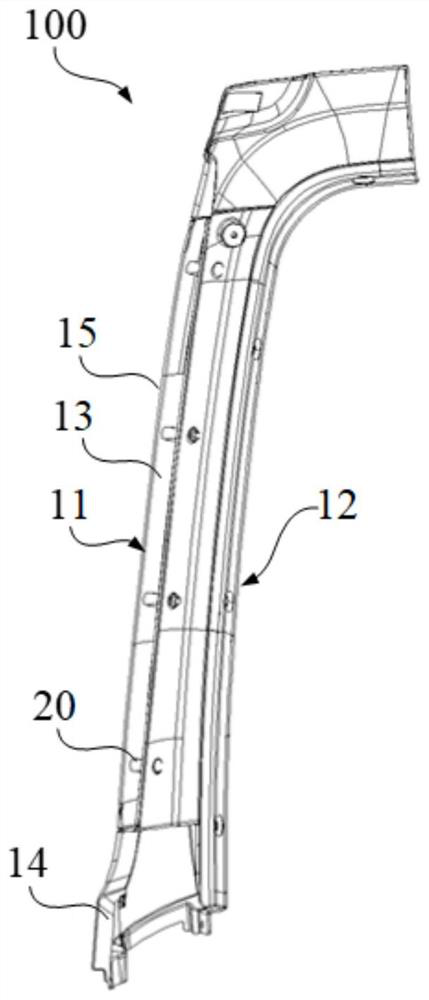

A-pillar exterior trimming panel and a vehicle

PendingCN113022463AImprove fuel economyReduced separation areaAerodynamics improvementVehicle body streamliningStructural engineeringVehicle driving

The invention relates to an A-pillar exterior trimming panel and a vehicle, the A-pillar exterior trimming panel is arranged on the outer side of an A pillar of the vehicle, the vehicle further comprises a front windshield window and a side window which are located on the two sides of the A pillar, the A-pillar exterior trimming panel comprises an exterior trimming panel body, and the exterior trimming panel body is provided with an air inlet, an air outlet and a flow guide channel communicating with the air inlet and the air outlet; the air inlet is formed in the side of the front windshield window, and the air outlet is formed in side of the side window. According to the A-pillar exterior trimming panel and the vehicle, when passing through the surface of the A pillar, airflow is exhausted from the air outlet through the flow guide channel from the air inlet of the exterior trimming panel body, the air outlet is formed in the side of the side window, and therefore the airflow can be concentrated to be tightly attached to the side window to be accelerated, the separation area of the airflow at the A pillar is reduced, kinetic energy consumption is reduced, and the fuel economy of the vehicle is further improved; in addition, the body-in-white of an original vehicle cab does not need to be changed, the design is improved only for the A-pillar exterior trimming panel, and therefore the A-pillar exterior trimming panel can be applied to different vehicle types, the manufacturing cost is low, the design period is short, and meanwhile maintenance is more convenient.

Owner:FAW JIEFANG AUTOMOTIVE CO

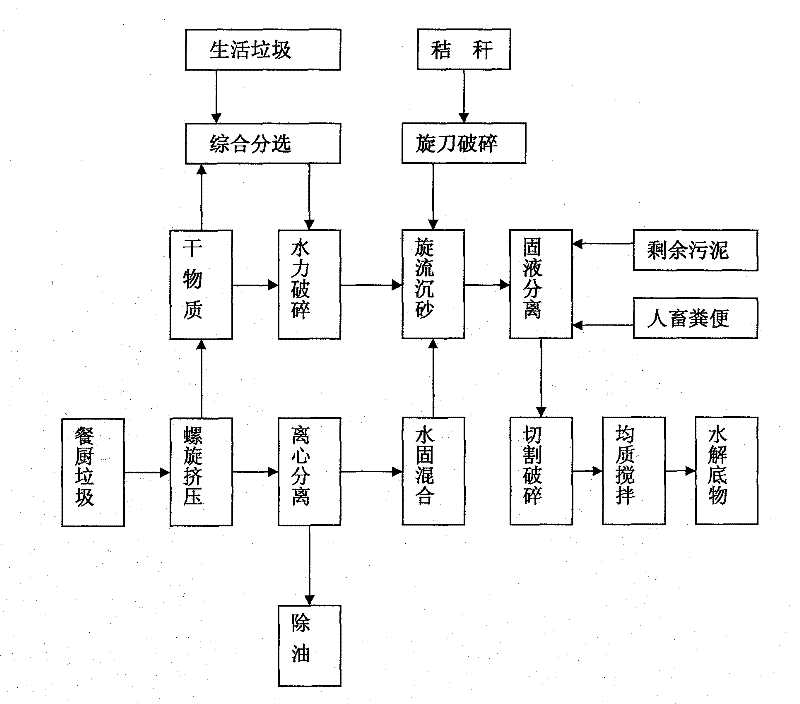

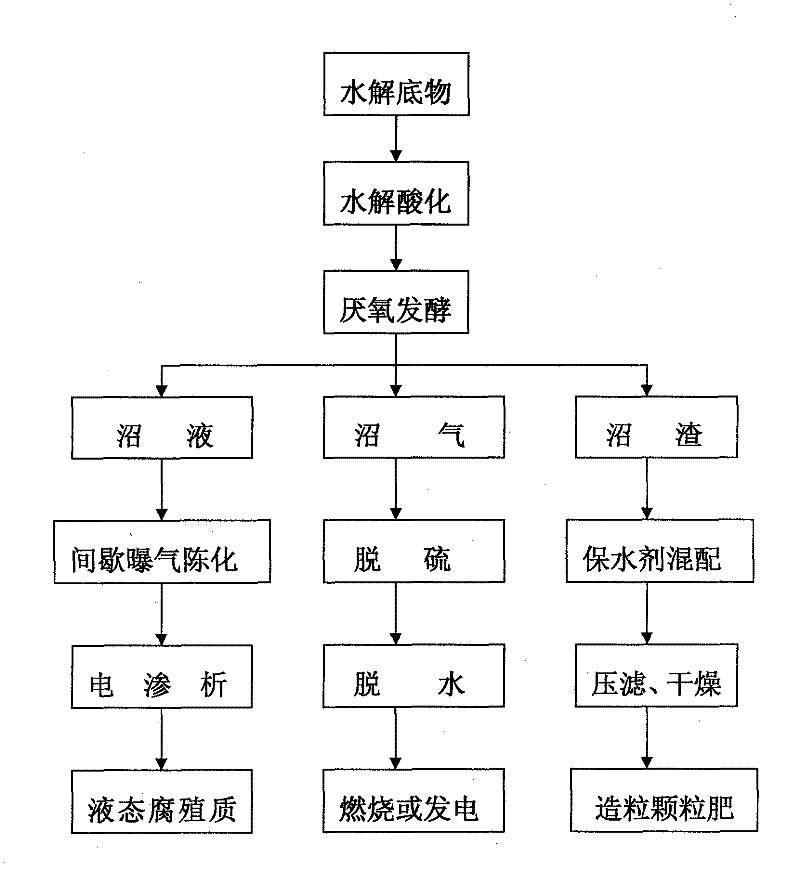

Organic solid waste combined anaerobic fermentation method

InactiveCN101337838BReduce consumptionImprove mass transfer efficiencyBio-organic fraction processingClimate change adaptationSludgeCombined method

The invention discloses a combined anaerobic fermentation method of organic solid wastes. The organic solid wastes used for the combined anaerobic fermentation include domestic wastes, excess sludge, feces, kitchen waste, straws, etc. The method comprises the following steps: carrying out different pre-processing processes to obtain organic materials with a granularity less than 5 mm; passing through a cutting pump, adjusting the C / N ratio, adjusting the water content, etc. to obtain a homogeneous fermentation substrate with a solid holdup of 2 to 10%; hydrolyzing and acidifying the fermentation substrate in the presence of a hydrolase; fermenting for a period of 15 to 25 days under the condition of stirring at a middle temperature of 32-38 DEG C to obtain biogas, which can be used for energy supply or output of a system; aging and desalting the biogas liquid to obtain a liquid humic acid fertilizer; and processing the biogas residues to a granular humic acid fertilizer. The fermentation substrate has proper C / N ratio to obviate feedback suppression of the substrate during the fermentation of a single material and simultaneously can enhance the hydrolysis effects of celluloses, lignin, hemicelluloses, etc. The method has the advantages of easy flow pattern control, low energy consumption, and no generation of sewages, and can obtain the high-quality biogas fluid and the high-quality granular humic acid fertilizer.

Owner:鄂尔多斯市城市矿产研究开发有限责任公司

Double-effect evaporation final-effect vapour system

InactiveCN104888482ANo lossEnsure normal start and stopMultiple-effect evaporationThermal energyAutomatic control

The invention relates to a double-effect evaporation final-effect vapour system. According to the double-effect evaporation final-effect vapour system, a discharge pipe arranged on the lower part of a I-effect slurry flash chamber is communicated with a feed inlet of a I-effect slurry circulating pump; a vapour outlet pipe arranged on the top part of the I-effect slurry flash chamber is communicated with a vapour inlet of a final-effect slurry heater; a feed outlet of the I-effect slurry circulating pump is communicated with a feed inlet arranged on the lower part of a I-effect slurry heater; a discharge pipe arranged on the upper part of the I-effect slurry heater is communicated with a feed inlet of the I-effect slurry flash chamber; a liquor condensate pipe of the I-effect slurry heater is communicated with a I-effect liquor condensate collecting tank; a discharge pipe arranged on the lower part of a final-effect slurry flash chamber is communicated with a feed inlet of a final-effect slurry circulating pump; a feed outlet of the final-effect slurry circulating pump is communicated with a feed inlet arranged on the lower part of the final-effect slurry heater; a discharge pipe arranged on the upper part of the final-effect slurry heater is communicated with a feed inlet of the final-effect slurry flash chamber; and a liquor condensate pipe of the final-effect slurry heater is communicated with a final-effect liquor condensate collecting tank. Process flow is simple; automatic control is adopted; thermal energy of final-effect discharged vapour is used effectively; energy waste is reduced; no polluted water is generated; environmental pollution is avoided; production cost is reduced; and productivity is increased.

Owner:江苏瑞和化肥有限公司

Fixed bed reactor for producing maleic anhydride by benzene process with annual production capacity of 20 000 tons

InactiveCN101182316AEven heat transferUniform accessOrganic chemistryChemical/physical/physico-chemical stationary reactorsFixed bedAnnual production

The present invention relates to a chemical reactor group using benzene as a raw material for maleic anhydride production, and the annual production capacity of the chemical reactor group is twenty thousand tons of the maleic anhydride. In China, the maximum annual production capacity of a single piece of the device using the benzene as the raw material for the maleic anhydride production is ten thousand tons per year, and a salt-melting cycling pump used for moving heat is all adopted in one piece. The reactor group in ten thousand tons per year has the problems as follows: firstly, the production capacity of the single piece of device is limited, which can not meet the requirement of the market development; secondly, when the device is used, the energy consumption of unit output is large, the effective utilization rate is low, and the equipment operation cost is high; thirdly, one piece of salt-melting cycling pump is used for moving heat, which causes that the heat concentrated and can be hardly moved out; fourthly, the reaction waste heat is too little, which can not be used completely.

Owner:西安航天华威化工生物工程有限公司 +1

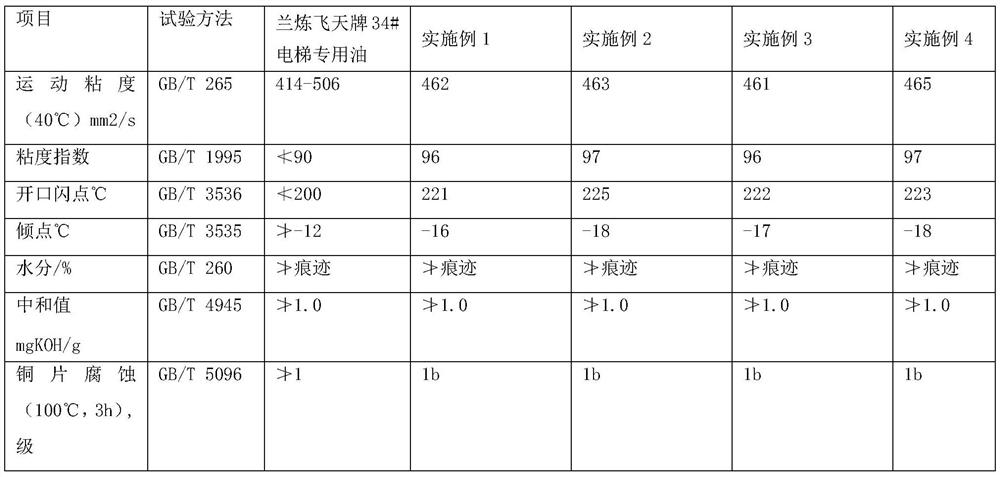

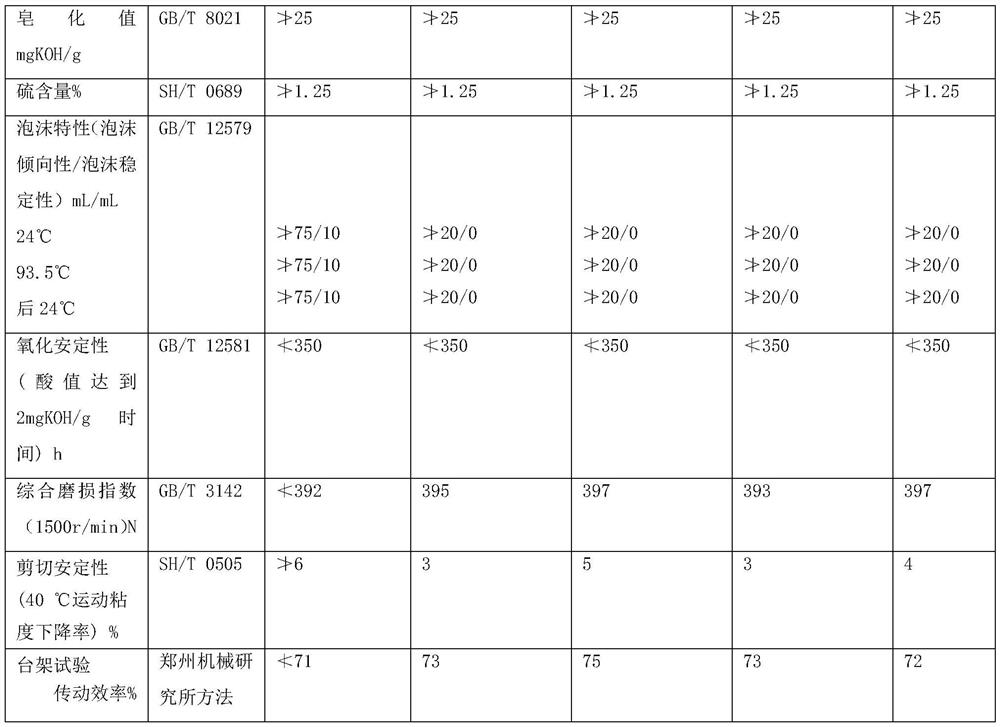

Special multi-effect oil for elevator traction machine, and preparation method thereof

InactiveCN112011395AImprove solubilityNot easy to evaporate lossLubricant compositionProcess engineeringViscosity index

The invention provides a special multi-effect oil for an elevator traction machine. The special multi-effect oil is prepared from 150BS bright oil, an extreme pressure anti-wear agent, an antioxidant,an antirust agent, a friction modifier, a viscosity index improver, a pour point depressant and an antifoaming agent. The invention further provides a preparation method of the special multi-effect oil for the elevator traction machine. Materials are economical and durable, energy is saved, friction is reduced, the transmission efficiency is high, corrosion to a worm gear copper part is reduced to the maximum extent while excellent extreme pressure abrasion resistance and high bearing capacity are ensured, and the lubricating requirement of a medium-low-speed elevator traction machine in China is met. Moreover, the production process is simple, and the intermiscibility among the components is good.

Owner:上海中孚油品集团有限公司

Flow guiding type wing-shaped flow measuring device

PendingCN109974797AReduce disturbanceReduce shockVolume/mass flow by differential pressureEngineeringStreamflow

The invention relates to a flow guiding type wing-shaped flow measuring device, which comprises a wing-shaped flow measuring device body, wherein the wing-shaped flow measuring device body consists ofa primary device and a secondary device; the primary device comprises a wing-shaped thin plate and a positioning bracket; the wing-shaped thin plate is fixed on the positioning bracket; a full-pressure taking pipe and a static-pressure taking pipe penetrate through the wing-shaped thin plate and the positioning bracket and are connected with a wind pressure transmitter of the secondary device; adata output interface is arranged on the wind pressure transmitter; and a data receiving interface is arranged on a controller. The flow guiding type wing-shaped flow measuring device is simple in structure and reasonable in design, can accurately measure the flow of wind, and is convenient to adjust the wind quantity in the cabin in time.

Owner:JIANGSU UNIV OF SCI & TECH

Sludge-blockage-preventing desliming machine for sewage treatment

InactiveCN112174249AReduce usageDehydration fastWater/sewage treatment by centrifugal separationSludge treatmentSpiral bladeSewage treatment

The present invention discloses a sludge-blockage-preventing desliming machine for sewage treatment, which comprises a shell, a fixed bottom plate is fixedly connected to the outer bottom wall of theshell, and supporting columns are arranged at the two ends of the fixed bottom plate in a sleeving mode. In the rapid dewatering process, the fixed shaft and the inner barrel rotate relatively, at themoment, the connecting rod and the spiral blade are matched to stir sludge in an overturning mode and scatter the sludge, the dewatering quality of the sludge is greatly improved, and along with rotation of the inner barrel, the sludge scraping plate continuously scrapes off the sludge on the inner side wall of the inner barrel. According to the sludge dewatering device, sludge is effectively prevented from being accumulated in the dewatering holes of the inner barrel to form blockage, and the sludge dewatering efficiency can be improved; meanwhile, the pressure springs and the fixing columnsare matched to damp the fixing bottom plate in the vertical direction, and the buffer pads buffer the fixing bottom plate in the horizontal direction; the two components are combined to release forceand buffer vibration generated by working of the desliming machine, damping of the desliming machine is achieved, and therefore stability of the desliming machine in the working process is guaranteed, and potential safety hazards are reduced.

Owner:张雷昌

Elevator energy-saving control method and energy-saving elevator

ActiveCN112723048AReduce consumptionReduce kinetic energy consumptionElevatorsBuilding liftsStatistical analysisEnergy conservation

The invention discloses an elevator energy-saving control method and an energy-saving elevator. The elevator energy-saving control method comprises the following steps of: according to no-load stop scheduling basis of the elevator, calculating the elevator use requirements of each floor in a historical time period before the current day, determining the floor with the most elevator use requirements in each historical time period, taking the floor with the most elevator use requirements as the no-load stop floor of the elevator, and when the elevator is standby, dispatching the elevator to stop at the floor to wait for a carrying instruction. According to the elevator energy-saving control method and the energy-saving elevator provided by the invention, based on statistical analysis, the invention provides the elevator scheduling control method which takes energy conservation as a main part, takes the waiting time length of people waiting for the elevator into consideration and introduces the dynamic waiting time, so that the aim of minimizing the waiting time of people waiting for the elevator can be achieved, the elevator calling service can be responded immediately, the calling service can be completed at the highest speed, and the highest convenience is provided for people waiting for the elevator.

Owner:SHUNDE POLYTECHNIC

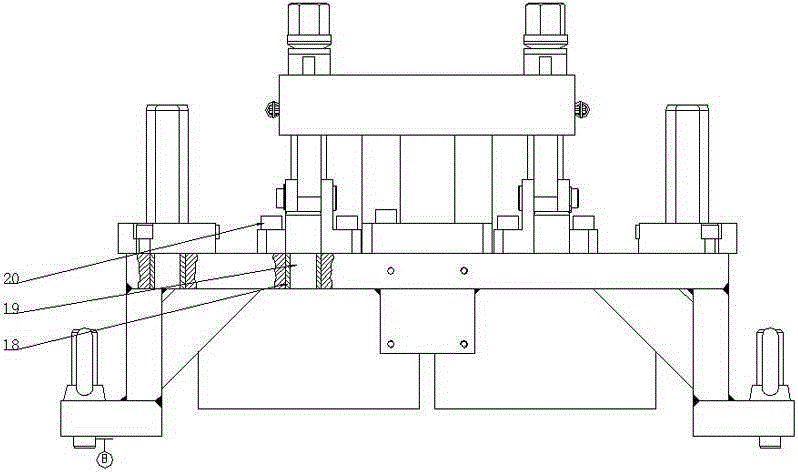

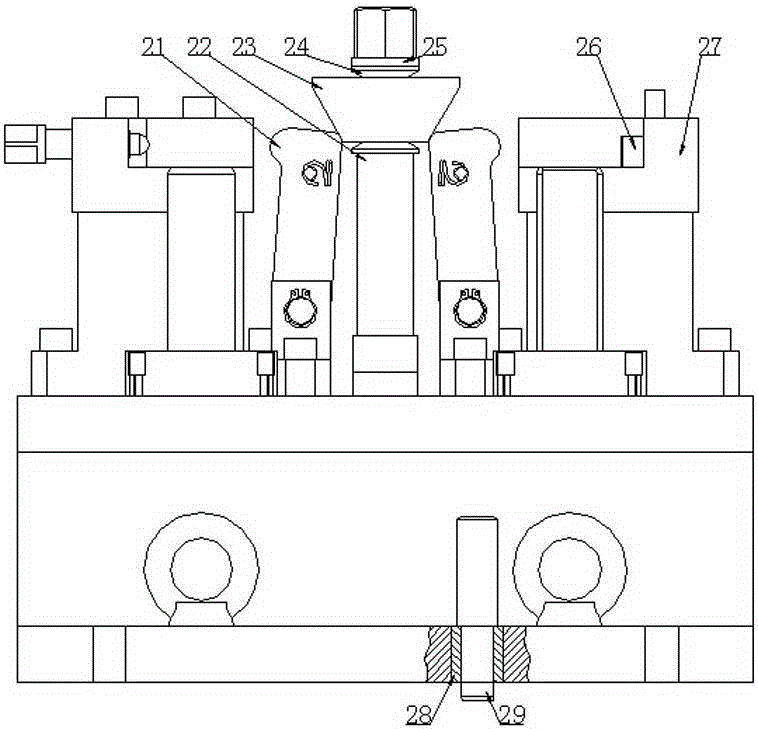

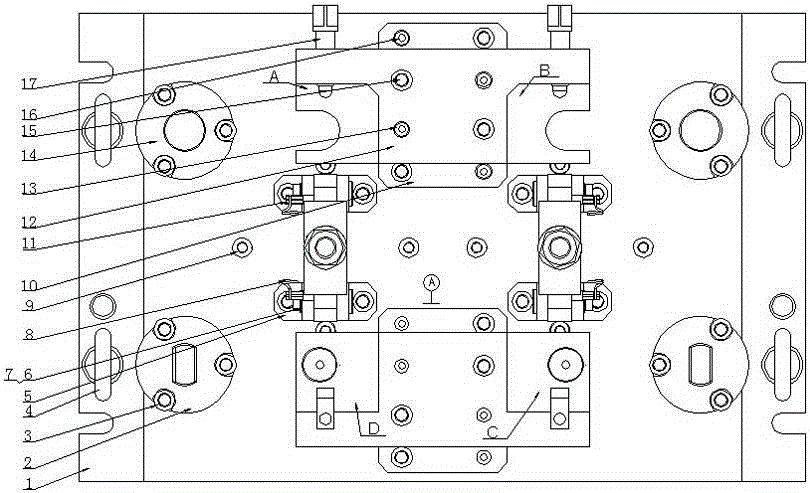

Pneumatic multi-station linkage drilling and boring clamp for lifting lug portion processing

InactiveCN106624909AImprove processing efficiencyReduce kinetic energy consumptionWork clamping meansPositioning apparatusProcess efficiencyEngineering

The invention provides a pneumatic multi-station linkage drilling and boring clamp for lifting lug portion processing. The clamp comprises a base; air cylinders are arranged on the base through a supporting seat; pressing blocks are arranged on the lower portions of pistons of the cylinders; a hinge pin is arranged at the lower ends of the pressing blocks; pressing plates are symmetrically arranged on the two sides below the pressing blocks; hinge shafts are arranged at the bottom of the pressing plates; and tension springs are arranged on the two sides of each pressing plate. After the working procedures are merged, processing efficiency is improved, kinetic energy consumption of equipment, regular maintenance, and labor cost are significantly reduced, and material links and material frame transporting are reduced.

Owner:DONGFENG SHIYAN AUTO FORGED STEEL

Rotary table for lens vacuum coating machine

ActiveCN104651795BReduce wearReduce kinetic energy consumptionVacuum evaporation coatingSputtering coatingElectric machineSprocket

Owner:DANYANG DINGXIN MASCH EQUIP CO LTD

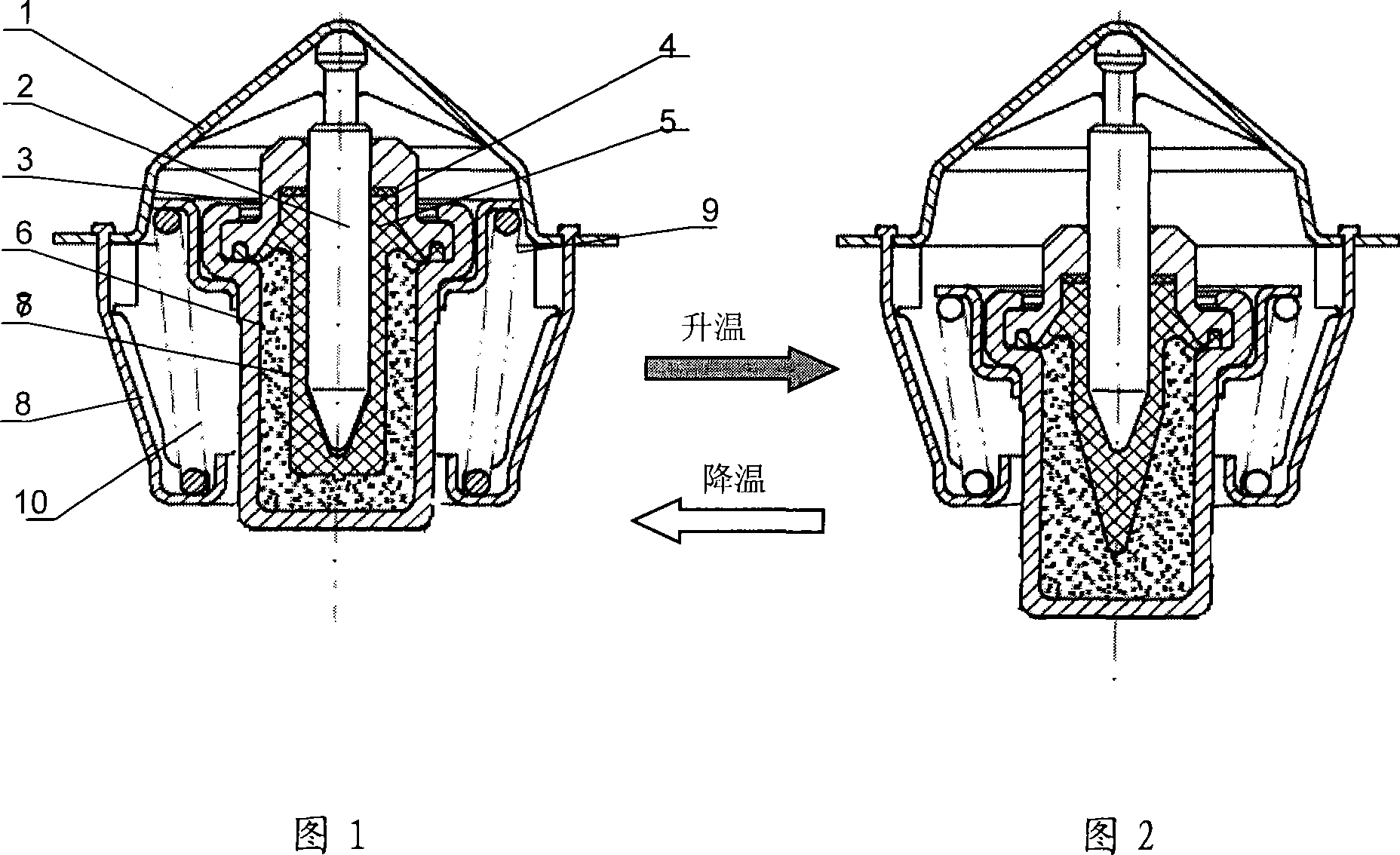

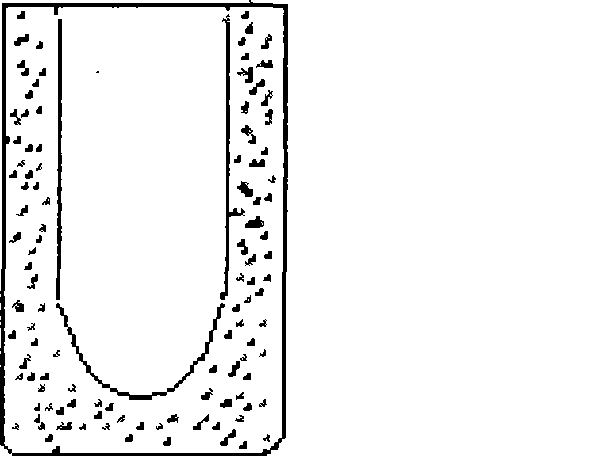

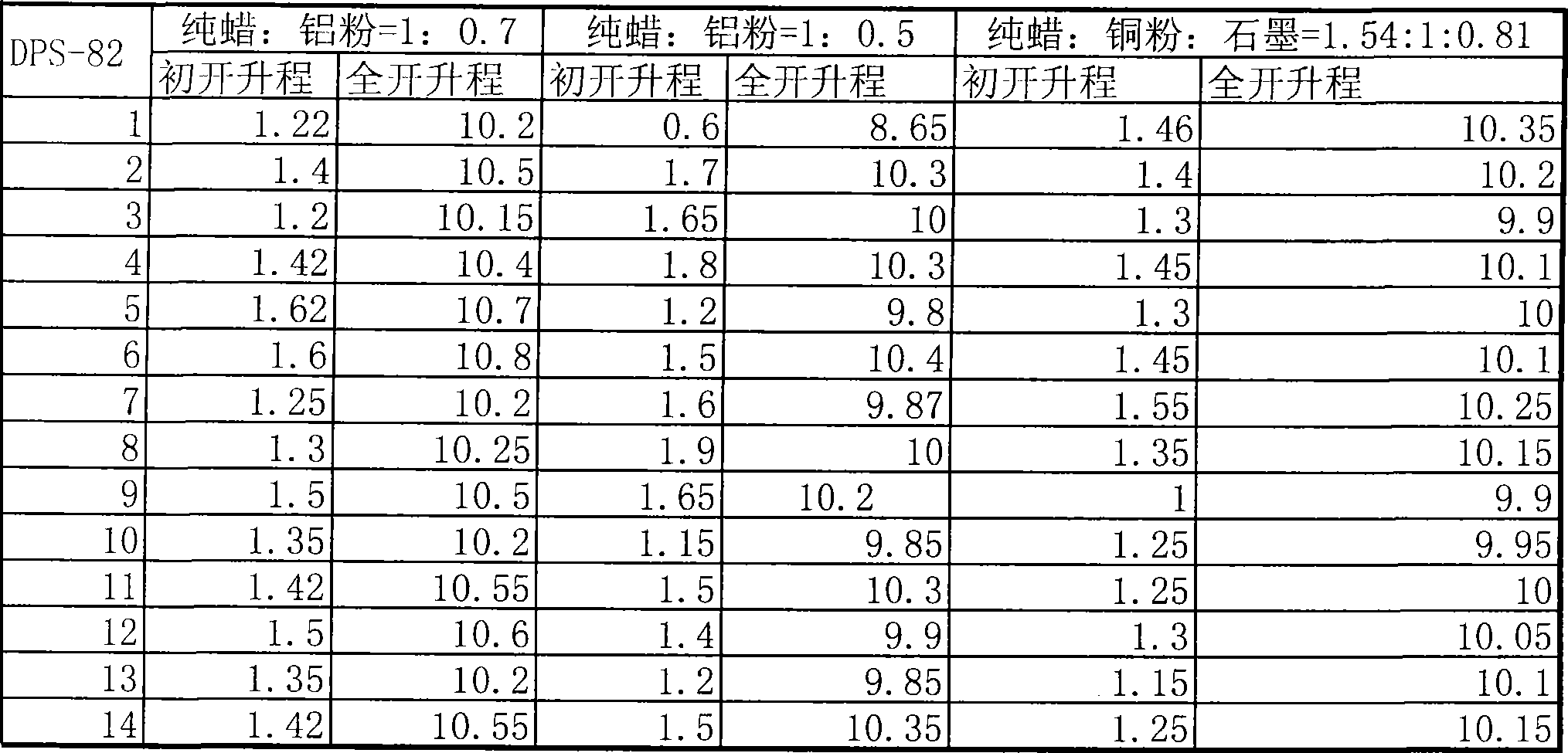

Aluminium powder wax pill for automobile engine thermoregulator

InactiveCN101418125AImprove liquidityImprove consistencyCoolant flow controlMachines/enginesParaffin waxSolubility

The invention relates to an aluminum powder wax-wrapped pill for a thermoregulator of an automobile engine, which is characterized in that the wax-wrapped pill is a mixture of aluminum powder and paraffin wax, and takes the shape of a cylinder provided with a dead hole; and the weight ratio of the paraffin wax to the aluminum powder is 1 to 0.4-1. The aluminum powder wax-wrapped pill not only can sensitively sense the temperature variation of the engine but also is difficult to separate after being subjected to thermal expansion and cold shrinkage for tens of thousands times due to the characteristic of light specific gravity of the wax-wrapped pill, so that the service life of the thermoregulator is prolonged. Simultaneously, because the aluminum powder used is flaky aluminum powder and the solubility and the fluidity of the aluminum powder are superior to those of other metalloid such as copper powder, the aluminum powder is easy to form when being mixed with the paraffin wax, and the weight precision is easy to control; and the aluminum powder wax-wrapped pill has the advantages of low cost, high profit and long service life.

Owner:DONGFENG FUJI THOMSON THERMOSTAT

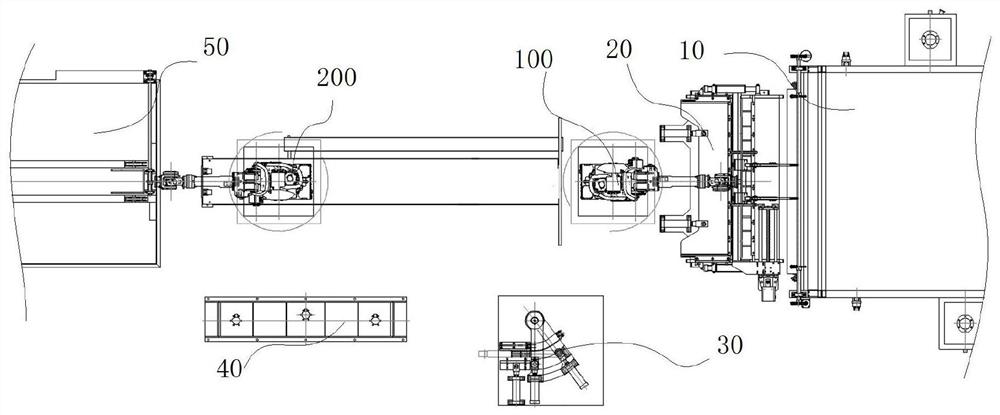

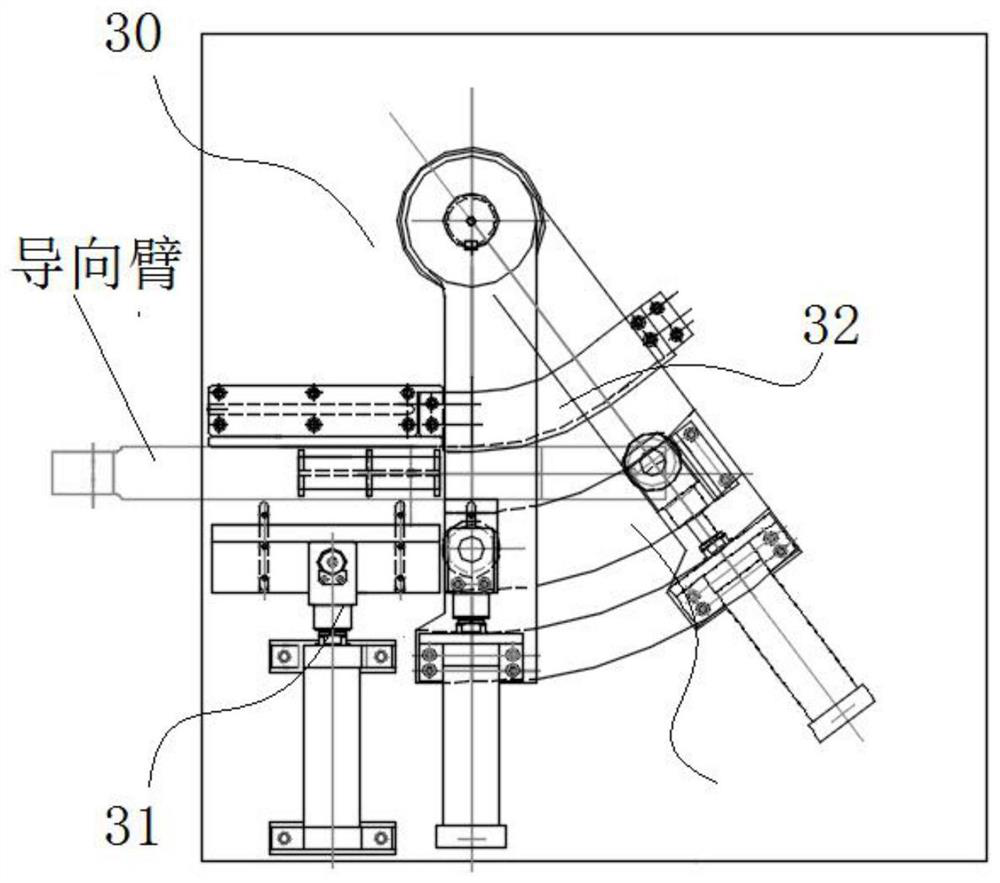

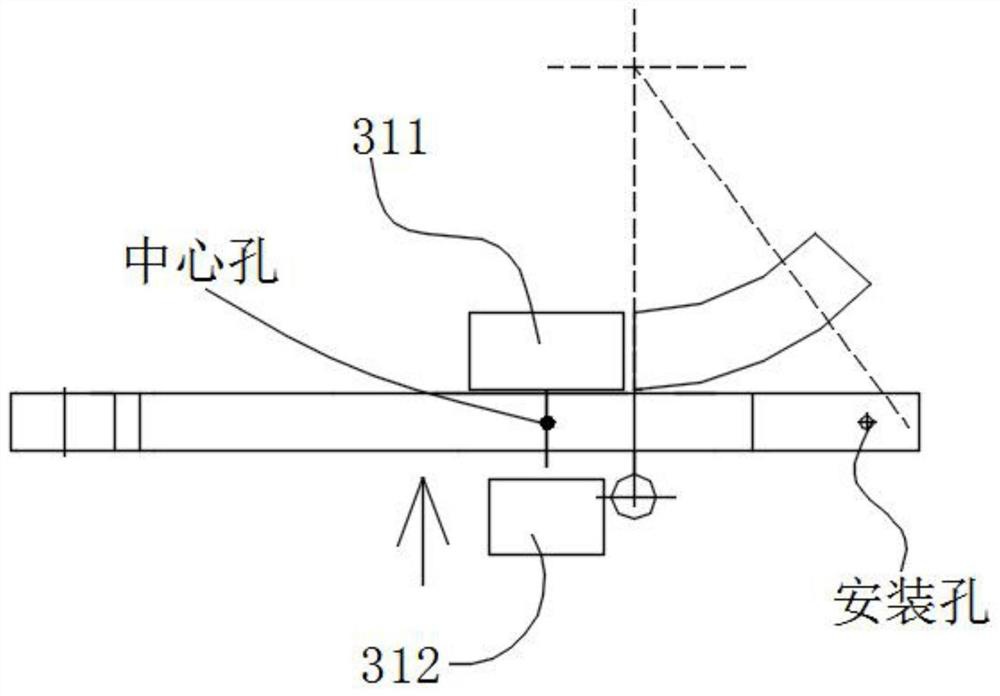

Guide arm side bending forming method

ActiveCN111974878AReduce decarbonizationReduce kinetic energy consumptionFurnace typesVehicle componentsMolding machineEconomic benefits

The invention discloses a guide arm side bending forming method, and relates to the field of air suspension guide arm manufacturing. The guide arm side bending forming method comprises a marching-typeheating furnace, a positioning device, a side bending machine, a hydraulic forming machine and an oil quenching tank, and can realize batch production, moreover, multi-directional forming is completed at a time through quenching heating, heating decarburization is reduced, the quality is stable, the machining efficiency is high, energy consumption is reduced, the production cost is low, the automation degree is high, and the guide arm side bending forming method has better comprehensive economic benefits, and is convenient to popularize.

Owner:东风汽车底盘系统有限公司

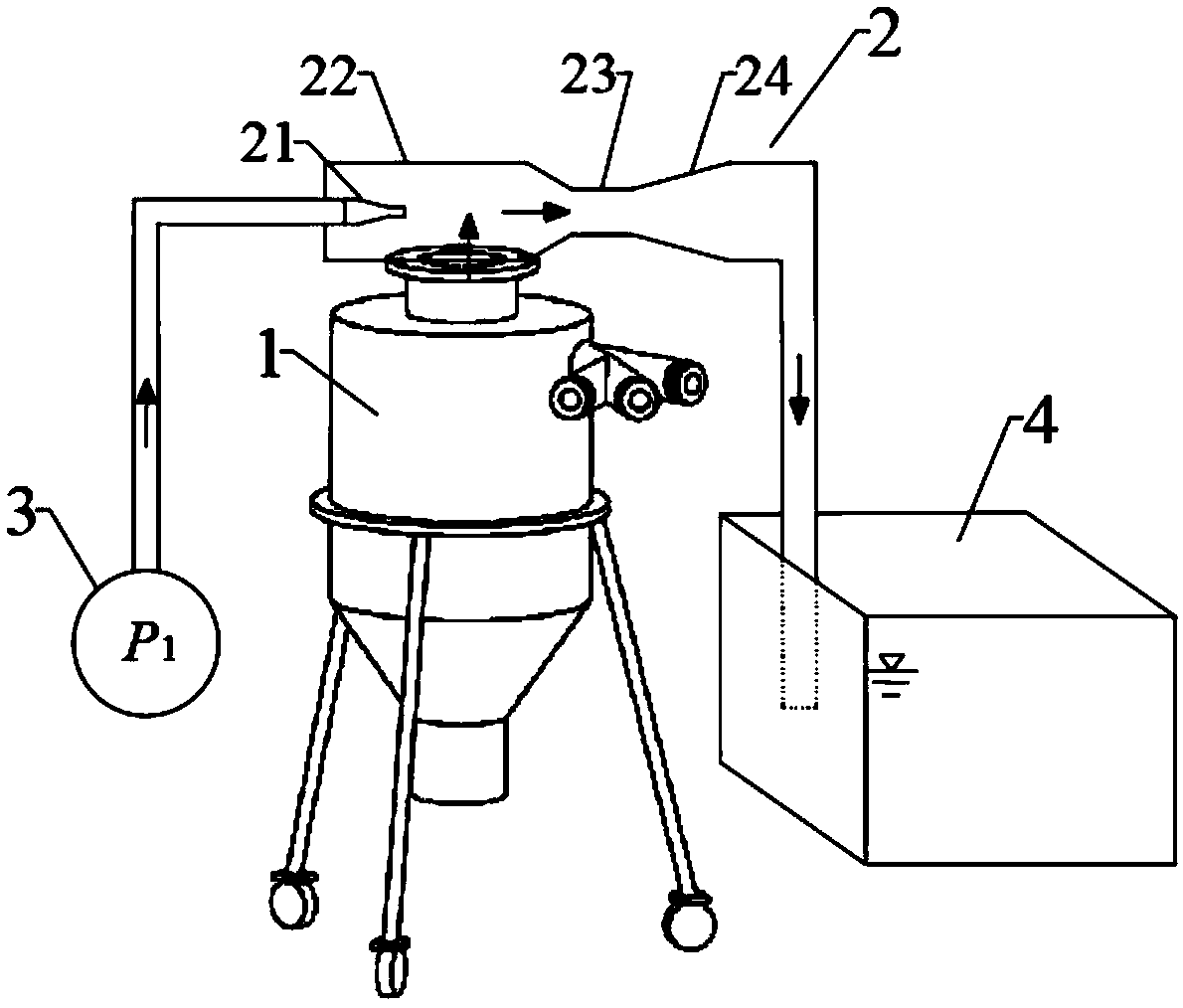

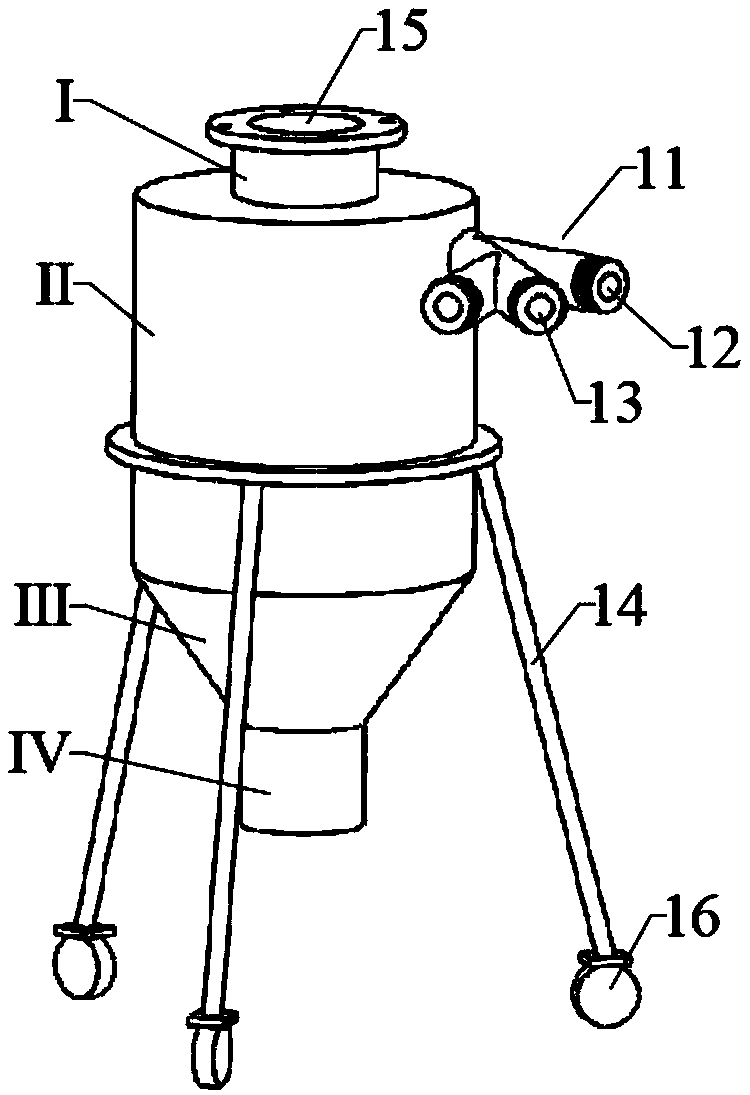

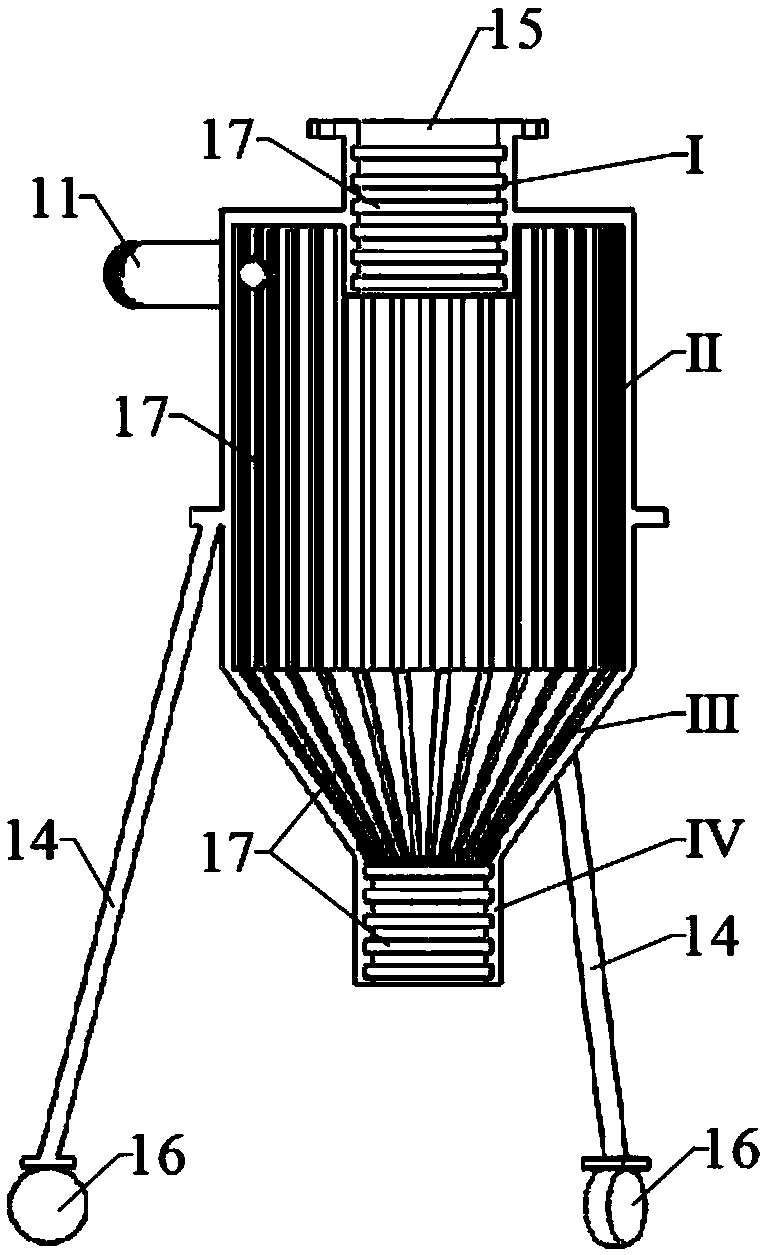

Integrated complete equipment for water quality purification treatment

ActiveCN103922506BGood removal effectMature Stable Continuous RemovalMultistage water/sewage treatmentChemical oxygen demandOperating energy

The invention relates to integrated complete equipment for water quality purification treatment. The equipment comprises a water cooling pool, wherein a water inlet lifting pump and a water inlet pipe are arranged on one side of the water cooling pool, and the water inlet pipe is provided with a first pipeline mixer and a second pipeline mixer at an interval; the output end of the second pipeline mixer is connected with an efficient floating, clarifying and self-flushing and filtering integrated machine and the output end is provided with an output water pipeline and an output mud pipeline; the output water pipeline is connected with a clean water pool, a first clean water pool is provided with a discharge opening, and the output mud pipeline is connected with a sludge concentration pool. The equipment provided by the invention can more maturely, stably and continuously remove all organic matters such as SS (Suspended Solids), oil, chroma and suspended solids, COD (Chemical Oxygen Demand), turbidity and the like in various types of surface raw water, underground water and reuse water of sewage by means of a working principle of the integrated machine combining efficient floating, clarifying, filtering and self-flushing process technical structures, so that the effluent treatment effect is improved, the investment and occupied areas are saved, the power lift of second-level flow is reduced, the pipe valve is shortened, and the operating energy consumption is reduced and the cost of the added chemicals is lowered.

Owner:JIANGSU NEW EPOCH ENVIRONMENTAL PROTECTION

Shell side multi-chamber multi-layer fixed bed reactor

ActiveCN101209402BUniform accessReduce kinetic energy consumptionChemical/physical processesFixed bedEngineering

Owner:西安航天华威化工生物工程有限公司

Shell pass multi-cavity type fixed bed reactor

ActiveCN101209401BUniform accessReduce kinetic energy consumptionChemical/physical processesFixed bedProcess engineering

Owner:西安航天华威化工生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com