Turntable for vacuum lens coating machine

A technology of vacuum coating machine and rotary table, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of low production efficiency, high average energy consumption per single piece, and it is difficult to meet modern scale production, etc. problems, to achieve the effect of reducing kinetic energy consumption and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

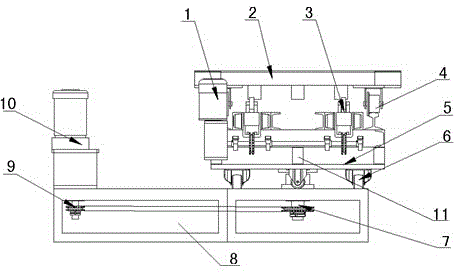

[0008] Depend on figure 1 Known, a lens vacuum coating machine Turntable , consisting of a pusher motor 1, a material trolley 2, a one-way pusher 3, an upper bracket 4, a rotating table 5, a load wheel 6, a rotation limit assembly 7, a base 8, a sprocket chain 9, a rotating motor 10, and a rotating shaft 11, the base 8 is fixed with a sprocket chain 9 transmission mechanism, the base 8 is provided with a rotating table 5 through two load wheels 6, the rotating table 5 can be rotated by the rotating shaft 11, and the rotating shaft 11 is located on the rotating shaft. The middle of the table 5 is connected with the chain, the rotary table 5 is provided with two upper brackets 4 and two one-way pushers 3, the material trolley 2 is fixed on the upper bracket 4, and the pushing motor 1 is placed on the ground. The rotary shaft 11 is provided with a rotation limit assembly 7, and the rotating motor 10 drives the rotary table 5 to rotate 180° through the transmission of the sprock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com