Aluminium powder wax pill for automobile engine thermoregulator

A thermostat and engine technology, applied in the field of expansion materials, can solve the problems of copper powder wax pellets in the thermostat, the service life and manufacturing cost are not ideal, the forming weight accuracy cannot be guaranteed, and the proportion of copper powder is large, so as to reduce labor costs and kinetic energy consumption, saving manufacturing process costs, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

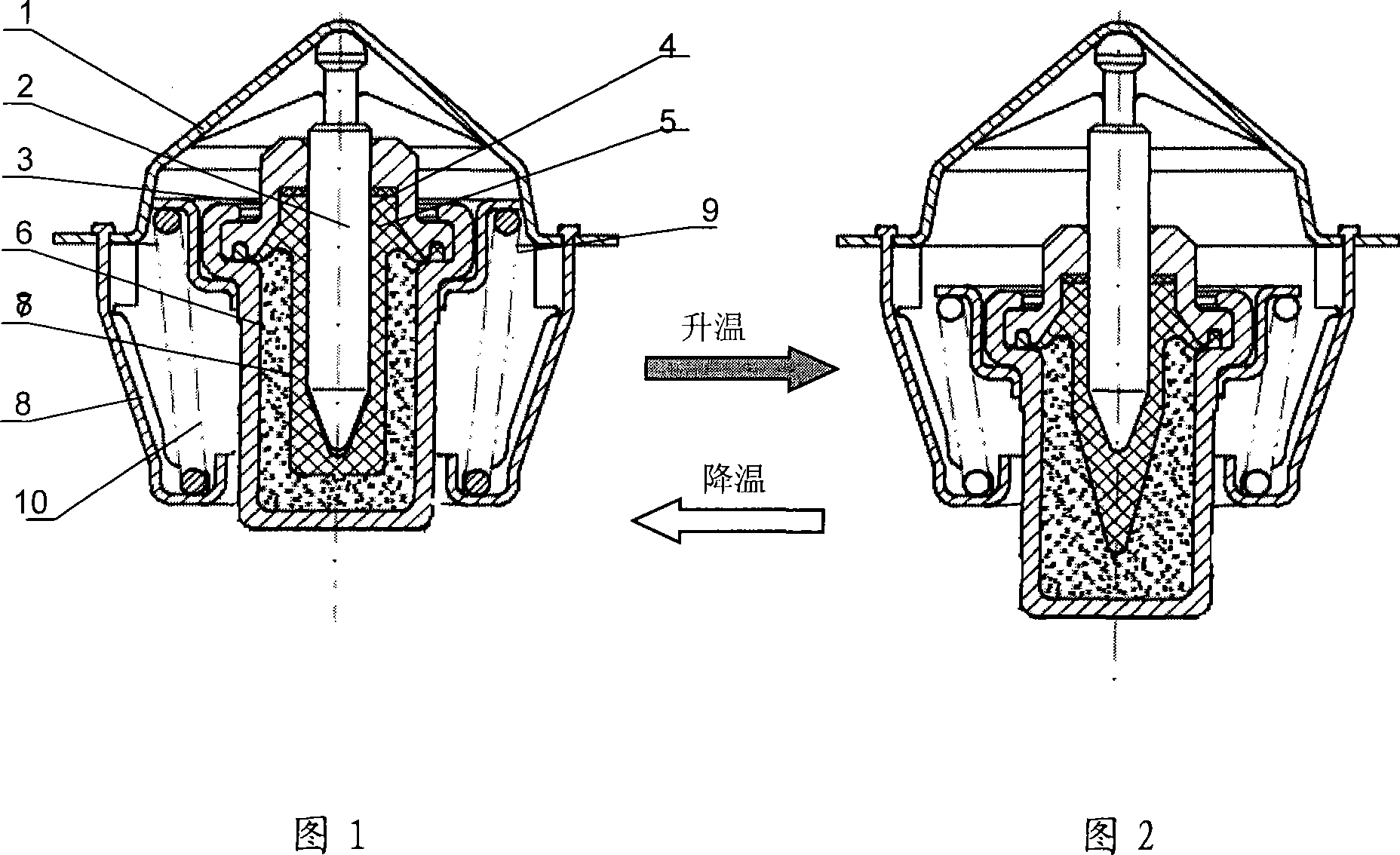

[0019] Embodiments of the present invention are described below in conjunction with the accompanying drawings:

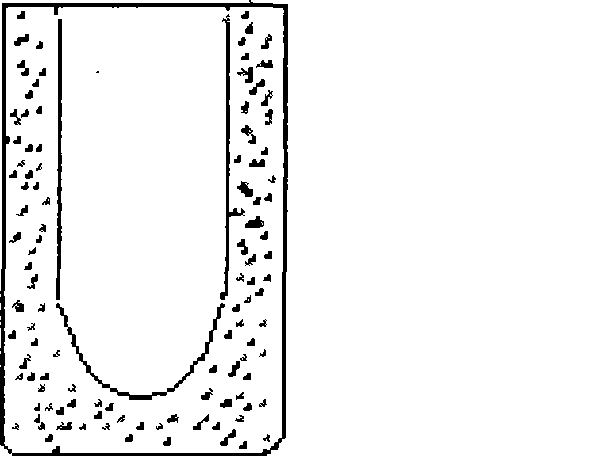

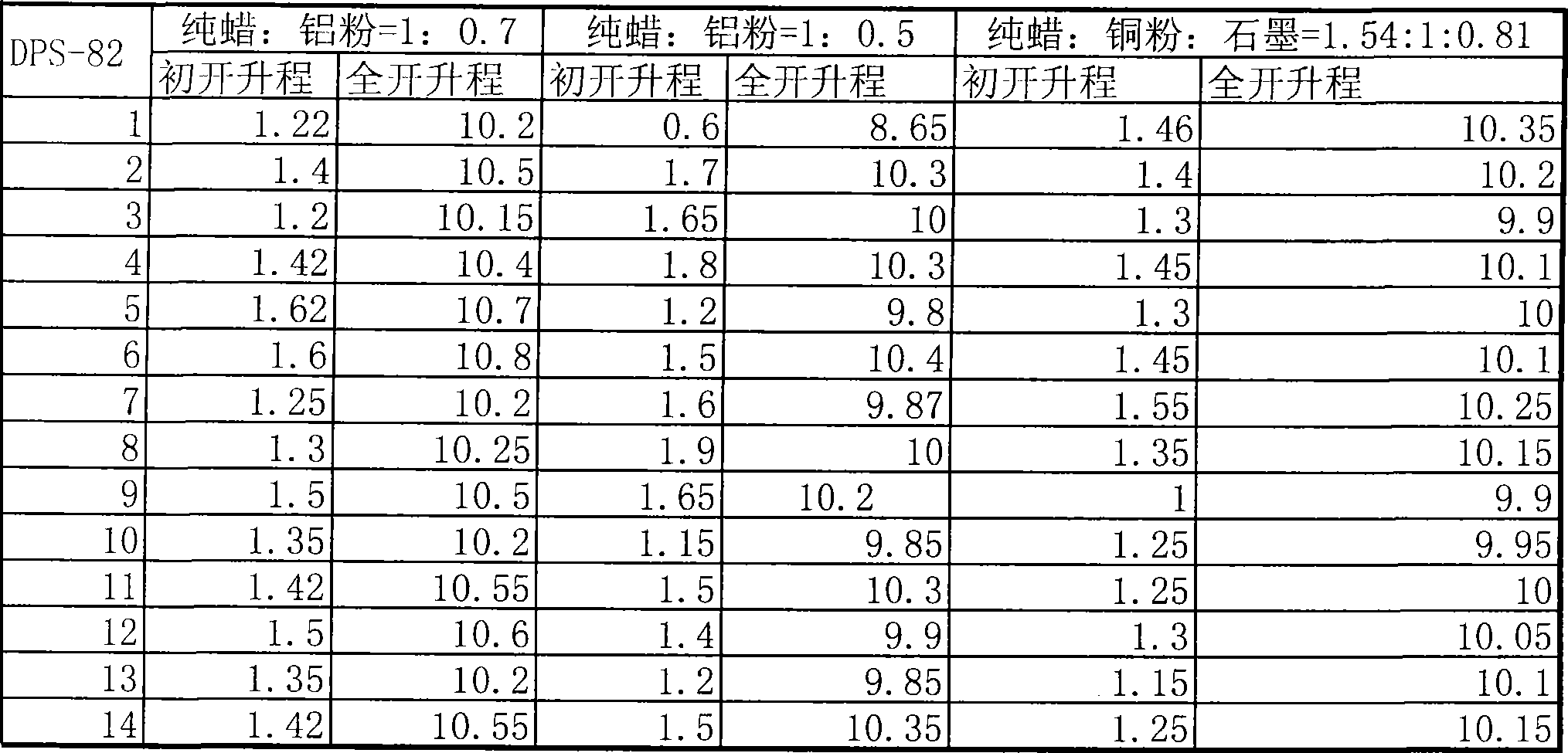

[0020] The aluminum powder wax pill 7 described in this embodiment is a mixture of aluminum powder and paraffin wax, and its shape is a cylinder with blind holes. The weight ratio of the paraffin wax to the aluminum powder is 1:0.4, 1:0.5, 1:0.7 or 1:1, the purity of the aluminum powder is 90%, 92%, 94%, 96%, 98% or 98.5%, and the mesh number is 300 mesh, 325 mesh, 400 mesh, 450 mesh, 500 mesh or 600 mesh. The shape of the aluminum powder particles is spherical or flake. The paraffin is composed of CnH2n+2 linear isoparaffin mixture.

[0021] The manufacturing process of the wax pellets described in this embodiment is: weighing of paraffin wax and aluminum powder, melting wax, mixing and stirring of aluminum powder and paraffin wax, cooling the mixture of aluminum powder and paraffin wax, pulverizing the cooled mixture, and Perform injection molding. Due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com