Shell side multi-chamber multi-layer fixed bed reactor

A technology of fixed bed reactor and multi-layer bed, applied in the direction of chemical/physical process, chemical instrument and method, etc., can solve the problems of high equipment operation cost, less reaction waste heat, large output energy consumption, etc., to improve heat exchange Efficiency, saving operating costs, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

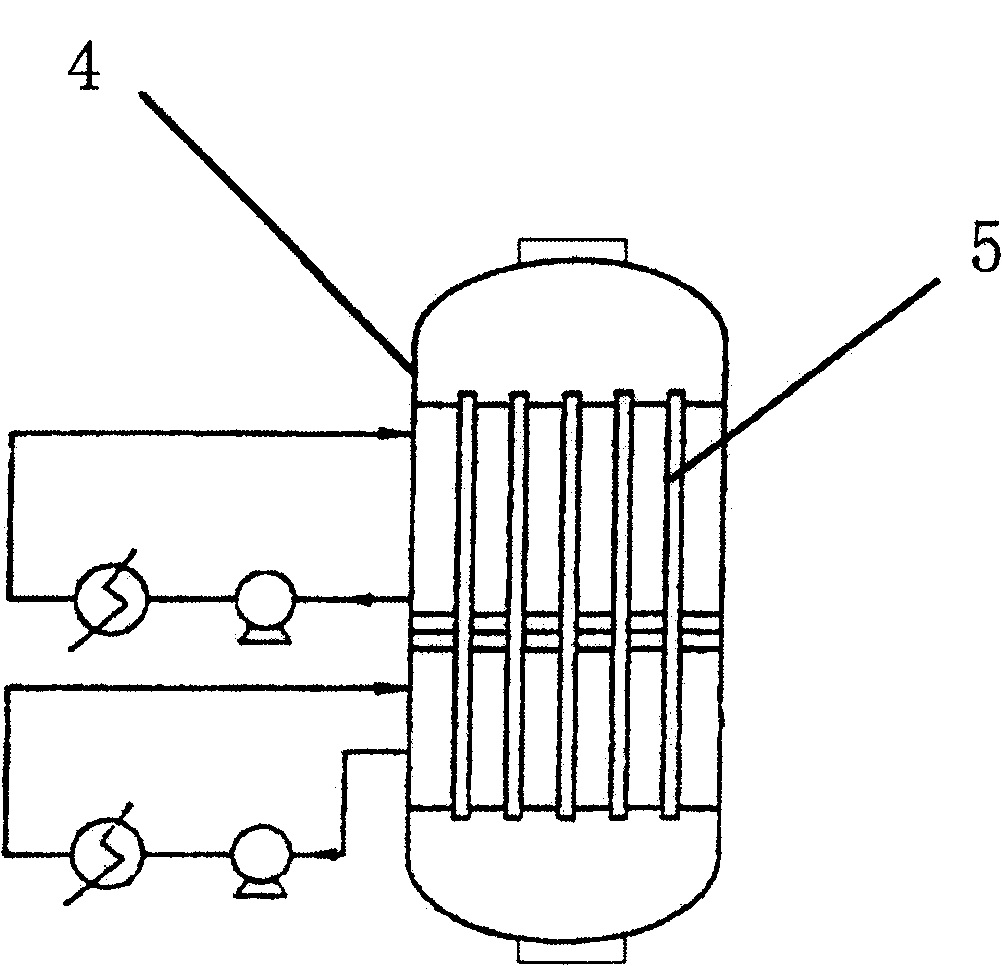

[0034] see figure 1 , At present, the shell-and-tube fixed-bed reactor adopts the structure of one chamber on the shell side, which consumes a lot of energy per unit of output, low effective utilization rate, and high equipment operating cost; it is easy to cause heat concentration and it is difficult to remove it uniformly; And the residual heat of reaction is too little to be fully utilized.

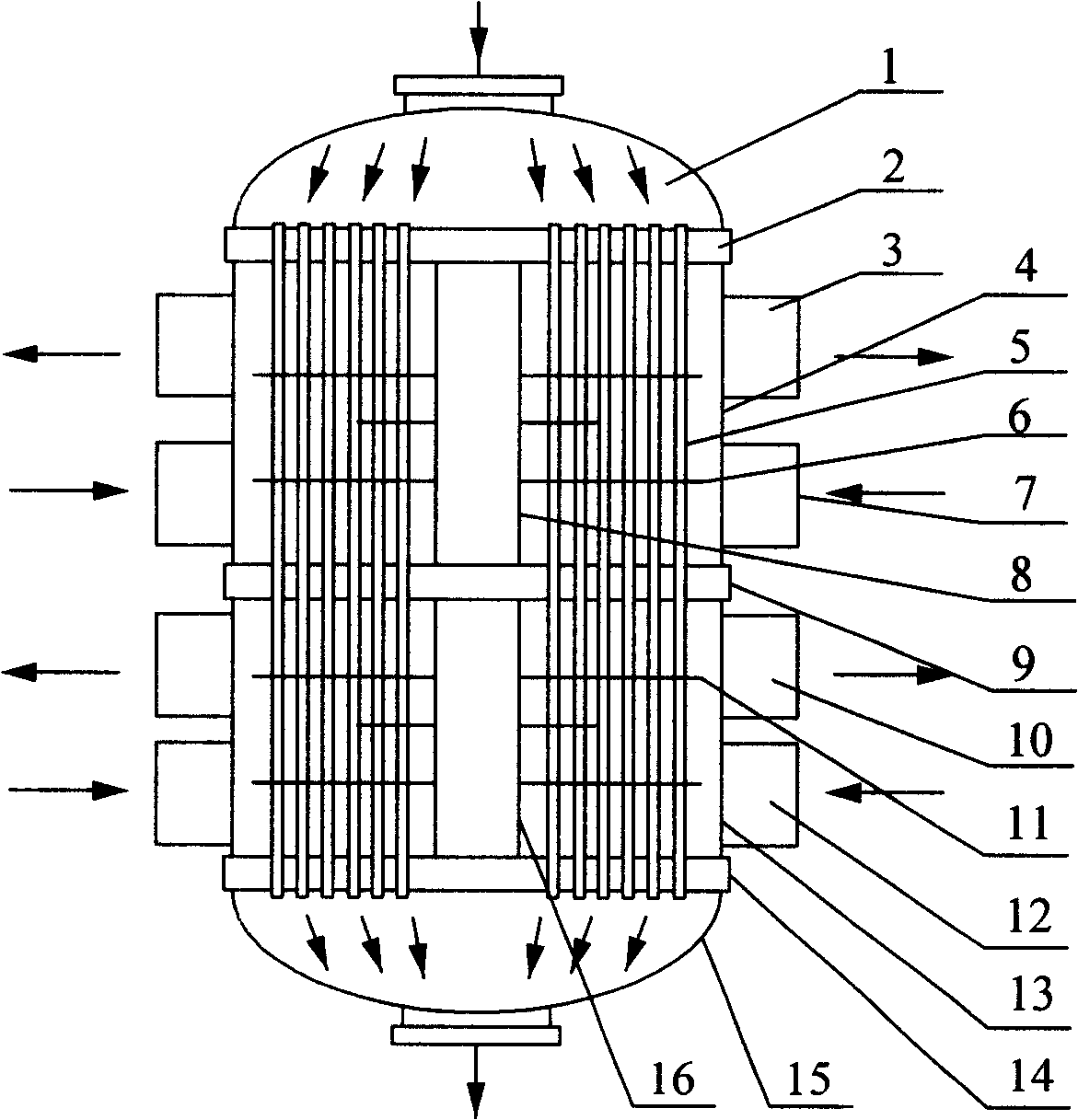

[0035] see figure 2 , image 3 , further elaborating on the structure implemented by the present invention: this tubular fixed-bed reactor includes an upper head tube box 1, an upper tube plate 2, a first section shell 4, a reaction tube 5, and a first section shell side baffle 8. The middle tube sheet 9, the second section shell 13, the lower tube sheet 14, the lower head tube box 15, the second section shell side baffle 16, etc. constitute the main body of the reactor, and the first section shell 4 is provided with The first section of the upper ring road 3 and the first section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com