Pneumatic multi-station linkage drilling and boring clamp for lifting lug portion processing

A multi-station, ear technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor processing quality, complicated procedures and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

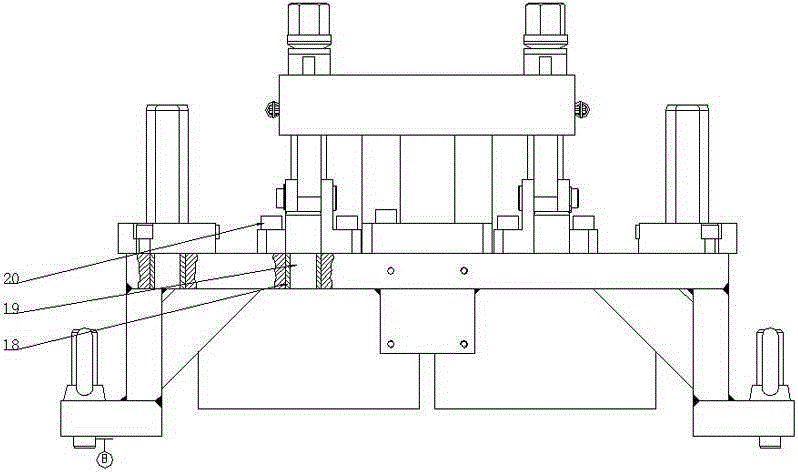

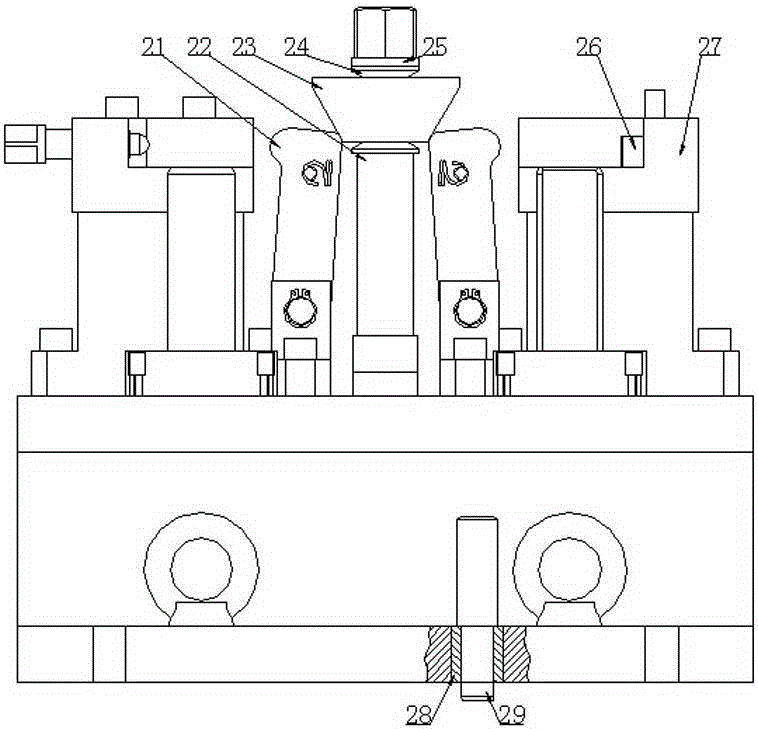

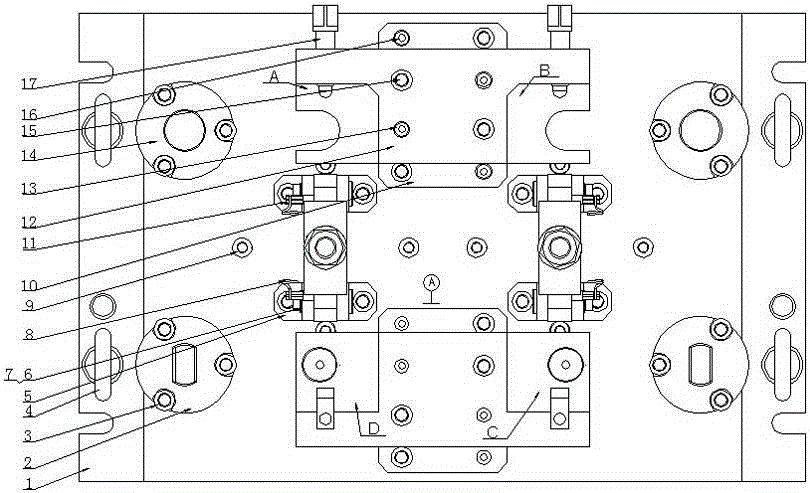

[0018] like figure 1 , figure 2 , image 3 , Figure 4 As shown in the pneumatic multi-station linkage drilling and boring fixture for the processing of the lifting lug ear of the present invention, the piston of the cylinder 30 is stretched downward to drive the pin shaft 22 and the pressing block 23 to move downward, and the pressing block 23 is in contact with the pressing plate 21 when moving downward. Make contact, and press the pressing plate 21 to rotate around the hinge shaft 6 through the inclined surfaces on both sides, so as to compress the parts on both sides, and the spherical washers 24 on the upper and lower sides of the pressing block 23 adjust the pressing block 23 during the pressing process , realizing the pressing balance of the pressing plates 21 on both sides. After the work is completed, the piston of the cylinder 30 moves upwards, driving the pin shaft 22 and the pressing block 23 to move upwards, the pressing block 23 and the pressing plate 21 begi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com