Copper alloy antivacuum adding Zircomium engineering technology equipment and technological process thereof

A technology of technical equipment and process method, which is applied in the field of copper alloy non-vacuum zirconium engineering technical equipment, can solve the problems of human toxic surrounding environment, inclusions, pollution, etc., achieve significant economic benefits of scale, reduce consumption costs, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Production alloy grade: QCr0.6-0.4-0.05 Specification: 210×620mm billet process:

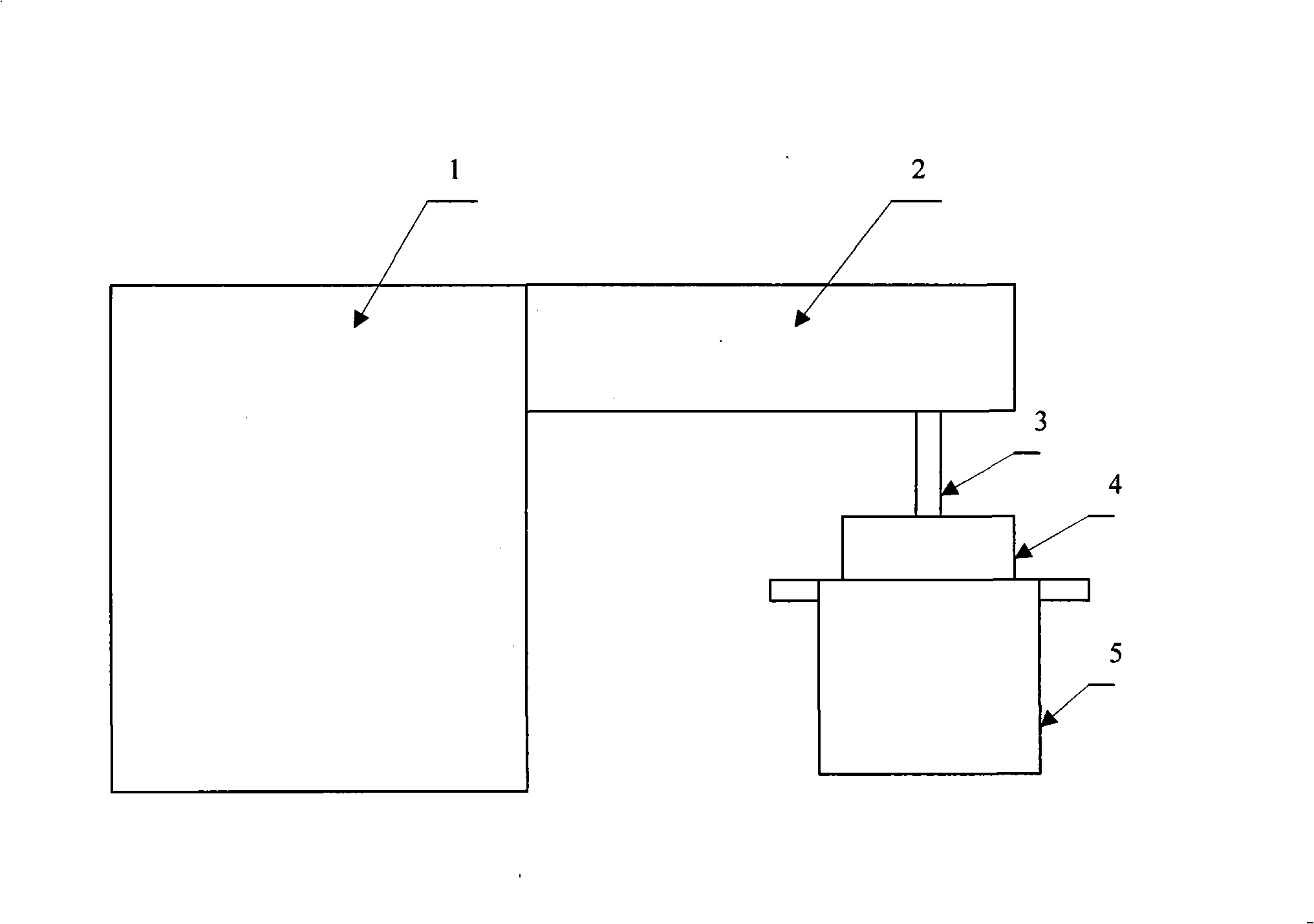

[0020] Adoption: batching is carried out according to the weight ratio, put into the induction melting furnace 1 successively for melting, and the furnace is covered with a compound flux, and the melting temperature is 1200-1400°C for melting; and then refined at 1150°C-1350°C for 10-60 minutes for heat preservation After that; open the sealed furnace cover and add Cu-Cr intermediate alloy and cover the furnace cover for melting; fill the furnace with high-purity protective gas for protection: then open the sealed furnace cover and add it in the form of Cu-Zr intermediate alloy, cover After the furnace cover is melted, casting is carried out. During the casting process, the melt is poured into the crystallizer 5 from the pouring pipe 3 through the protective cover 4 with the protective gas through the sealing tool 2 protected by the protective gas from the melting furnace, and the crystall...

Embodiment 2

[0022] Production alloy grade: QCr0.6-0.4-0.05 Specification: 210×620mm process:

[0023] Adoption: batching is carried out according to the weight ratio, put into the induction melting furnace 1 successively for melting, and the furnace is covered with a compound flux, and the melting temperature is 1200-1400°C for melting; and then refined at 1150°C-1350°C for 10-60 minutes for heat preservation Finally; open the sealed furnace cover and add pure metal Cr and cover the furnace cover for melting; fill the furnace with high-purity argon: then open the furnace cover and add pure metal Zr, cover the furnace cover and melt; carry out casting , during the casting process, the melt flows from the melting furnace 1 through the sealing tool 2 protected by high-purity argon, from the pouring tube 3 through the protective cover 4 with protective gas into the crystallizer 5, and the protective cover is placed on the upper part of the crystallizer. The flux is used as the lubricant in th...

Embodiment 3

[0025] Bolts are used to fix the sealing device on the upper side of the induction melting furnace, and a pouring tube is fixed at the bottom of the other end of the sealing device, and the lower end of the pouring tube is inserted into the crystallizer through the protective cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com