European link double-ring buckle body forge piece forming process

A forming process and forging technology, applied in the field of European-style link double-ring buckle body forgings forming technology, can solve the problems of high cost, low material utilization rate, large kinetic energy consumption of forging equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

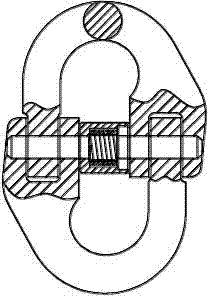

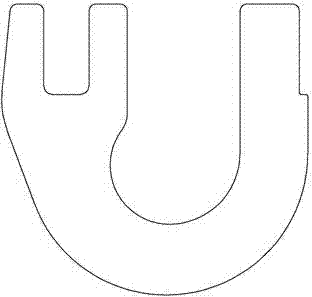

[0024] European link double ring buckle forgings such as figure 2 shown. The basic shape of the forging is U-shaped, and one end of the U-shaped is split in the middle to form a fork. On the whole, the volume distribution of forgings is large at both ends and small in the middle section, and the distribution is asymmetric.

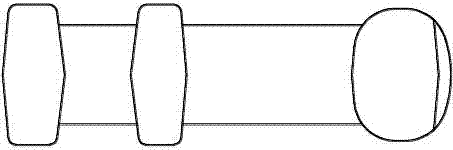

[0025] According to the characteristics of forgings, the focus of the forging process is the billet making process. The main function of the billet making process is to distribute the volume of raw materials reasonably, so as to reduce material waste and improve material utilization; reduce the forming force of subsequent processes and reduce the main equipment Kinetic energy consumption, saving energy. When selecting the billet making process, it is necessary to take into account the stability, operability, process automation and matching of the entire production line. In summary, the proposed process plan is cross wedge rolling, bending, die forging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com