Guide arm side bending forming method

A guide arm, bending forming technology, applied in the field of guide arm side bending forming, can solve the problems of high labor intensity, inability to meet the needs of large quantities of guide arms, specialization, high quality and high efficiency, and high labor costs, so as to reduce decarbonization and kinetic energy consumption, good comprehensive economic benefits, and the effect of reducing process auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

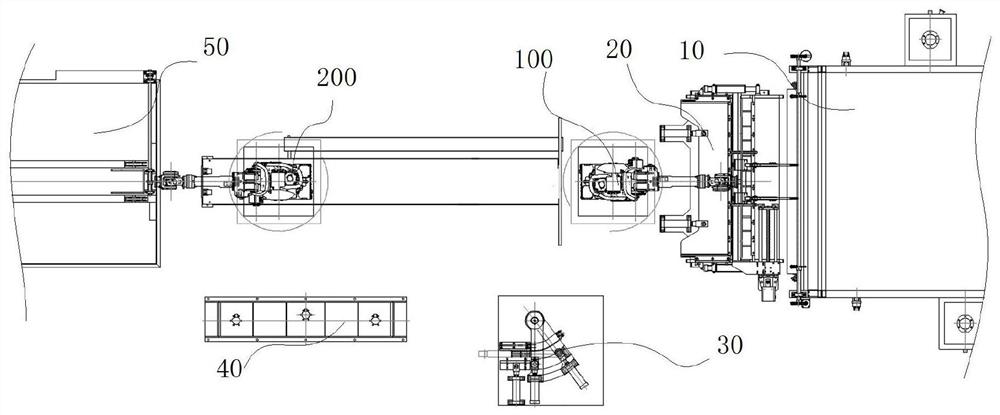

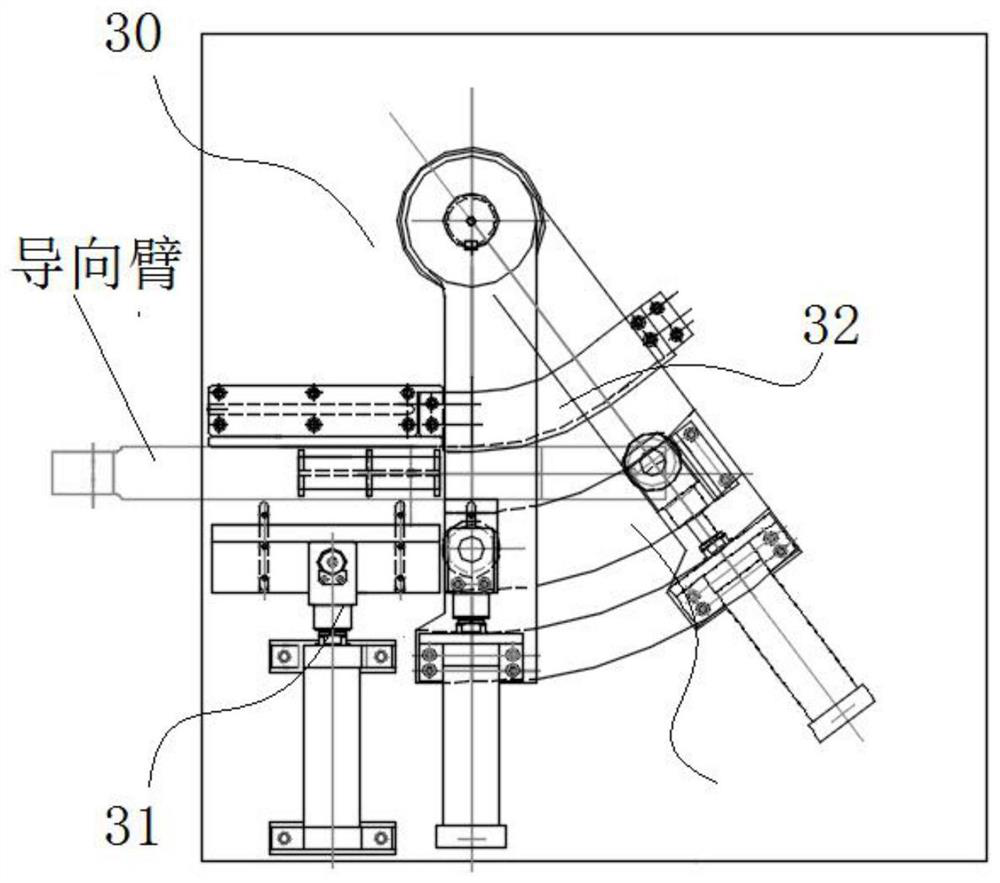

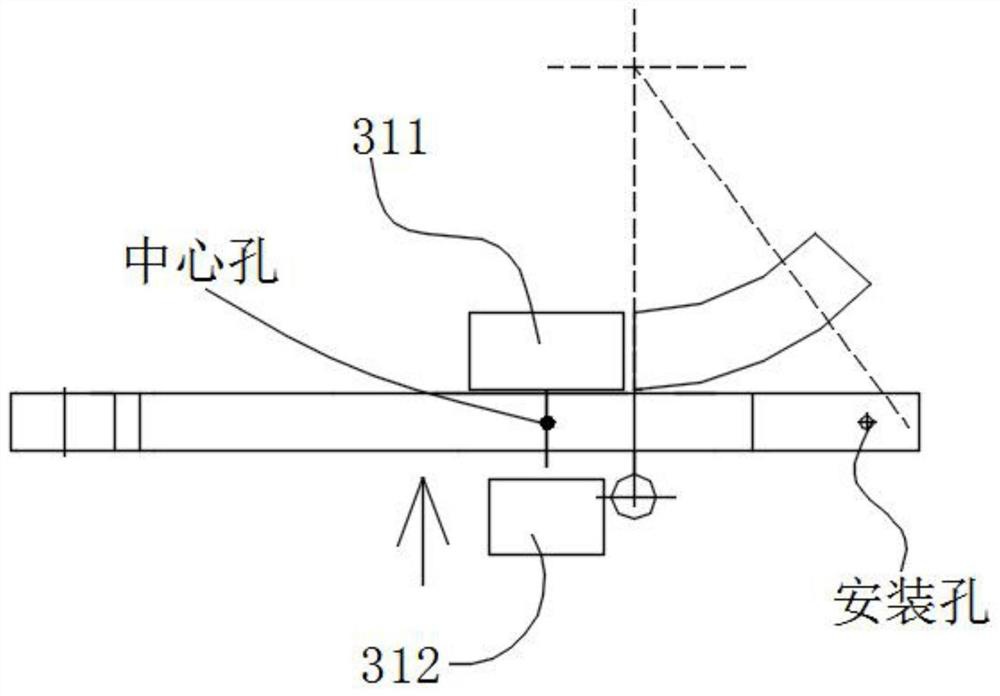

[0031] This embodiment provides a method for side bending processing of the guide arm, see Figure 1-Figure 2 , where the processing equipment used includes a walking quenching furnace 10, a positioning device 20, a side bending machine 30, a hydraulic forming machine 40 and a quenching oil tank 50, and placing the guide arms on each processing equipment is completed by a manipulator , the specific processing includes the following steps:

[0032] The first step: put the guide arm in the step-type quenching heating furnace 10, and the guide arm will gradually heat up after being placed in the step-type quenching heating furnace 10. When the temperature of the guide arm rises to 920 ° C ~ 950 ° C, The guide arm is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com