Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Reduce hard damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

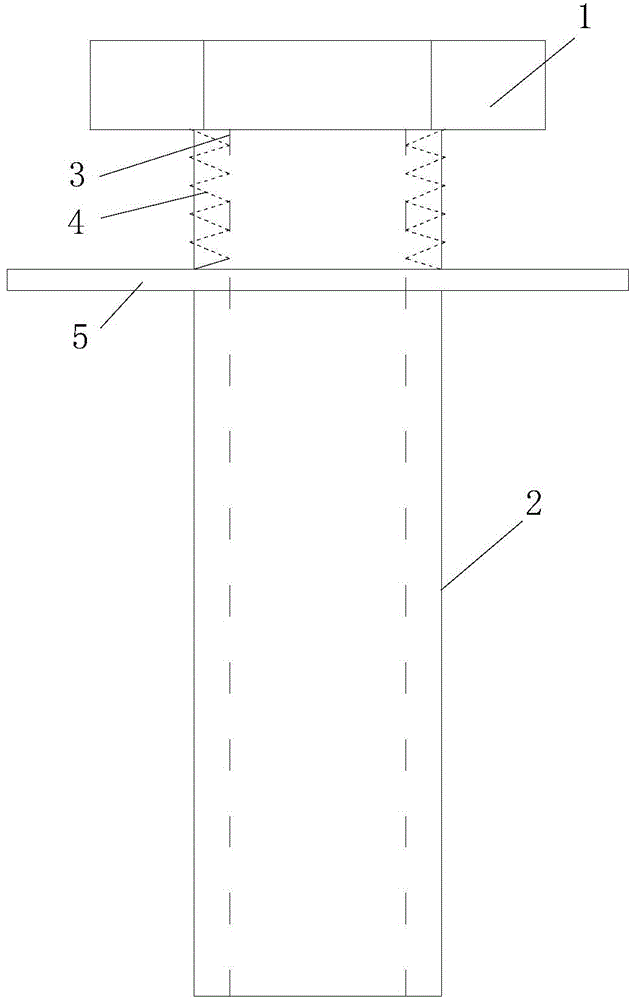

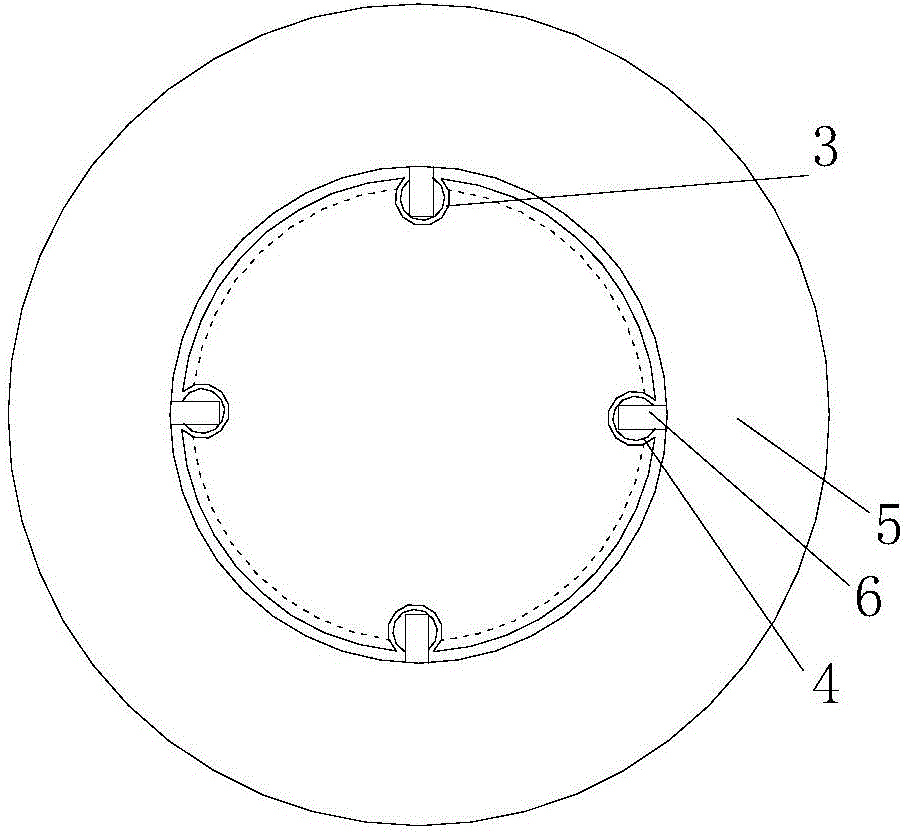

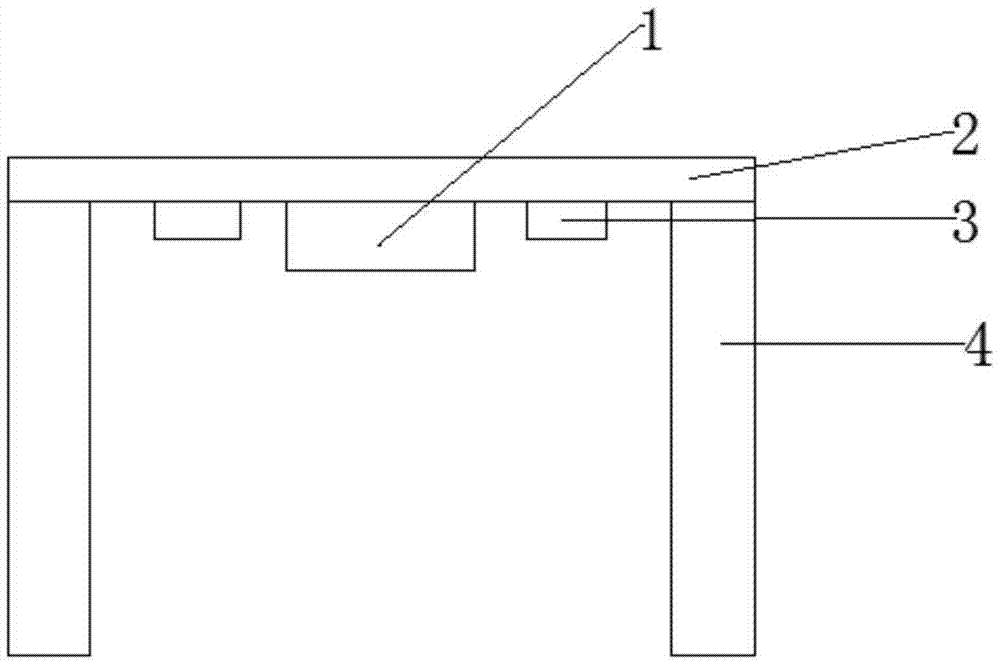

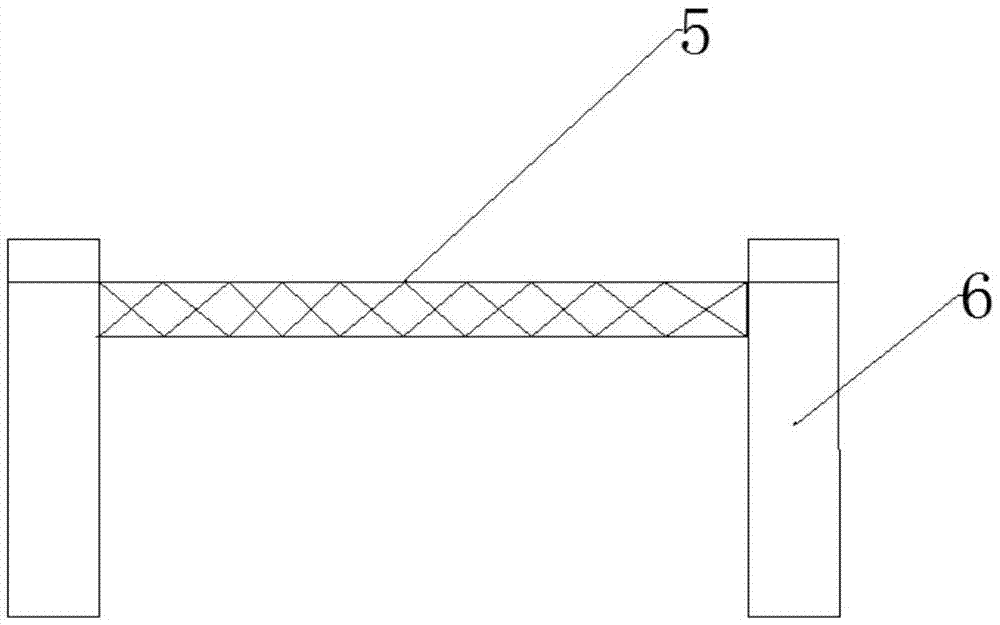

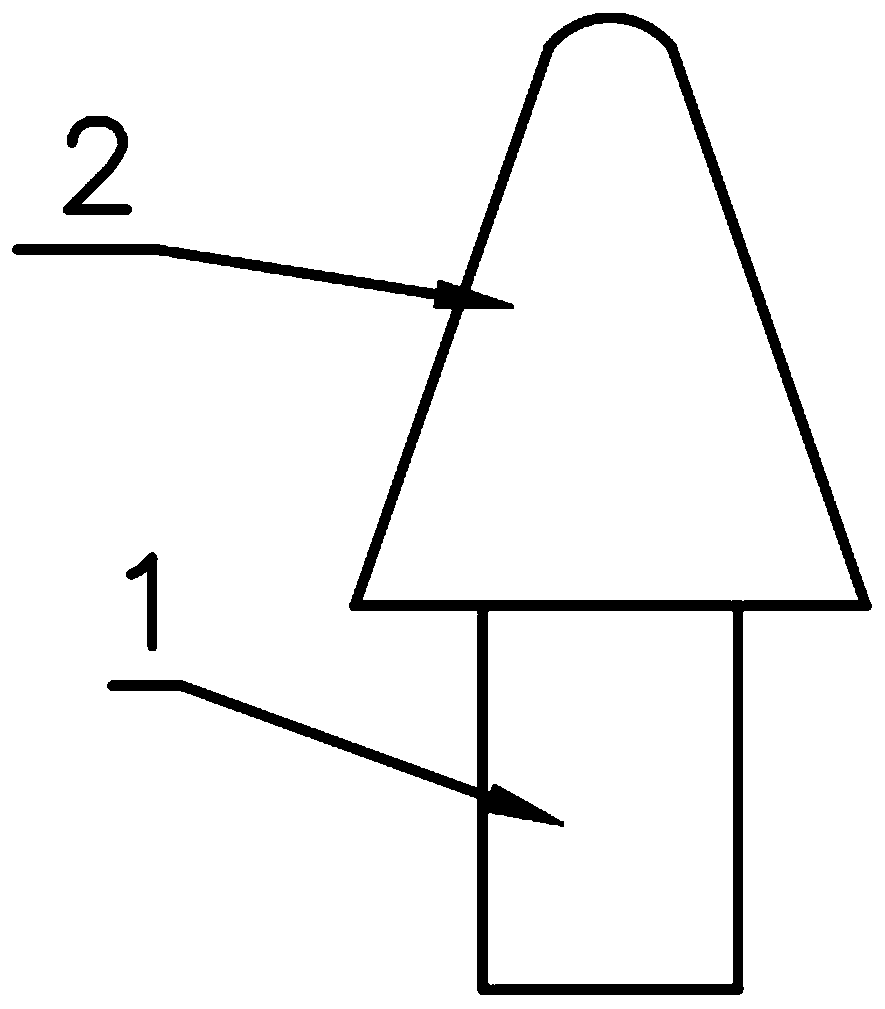

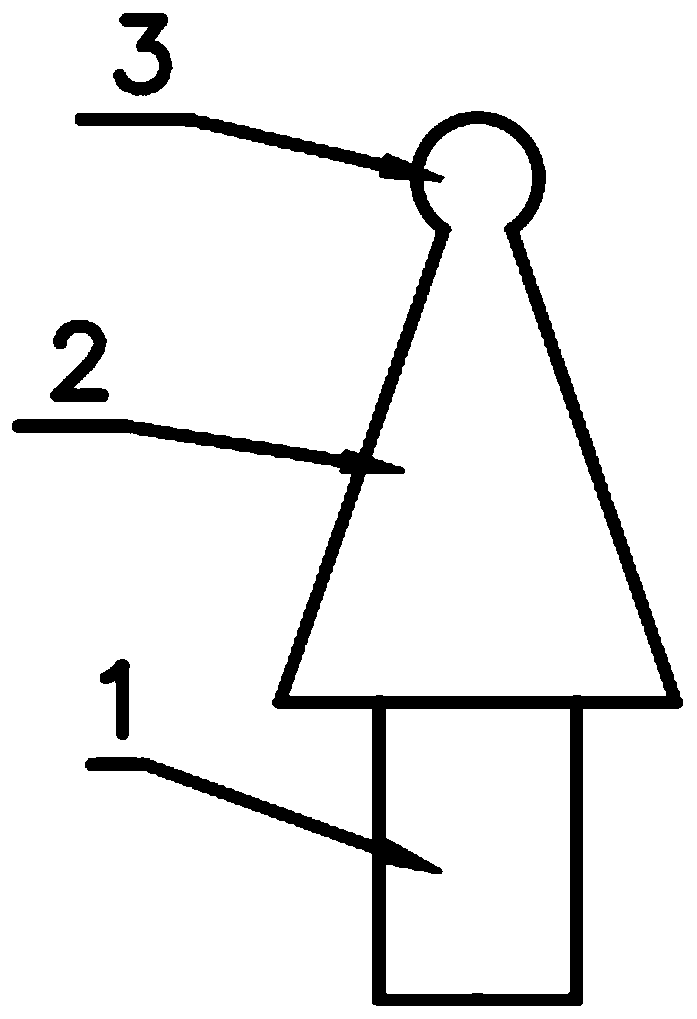

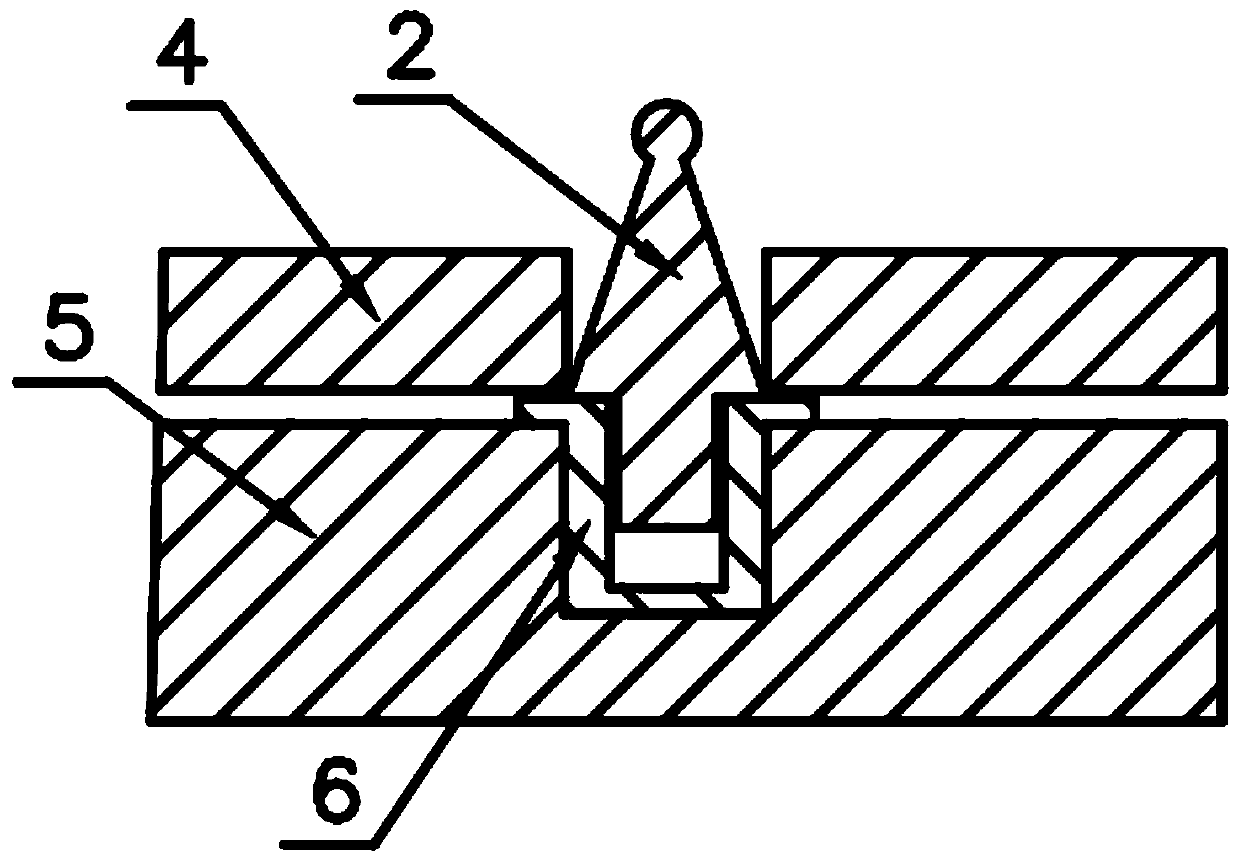

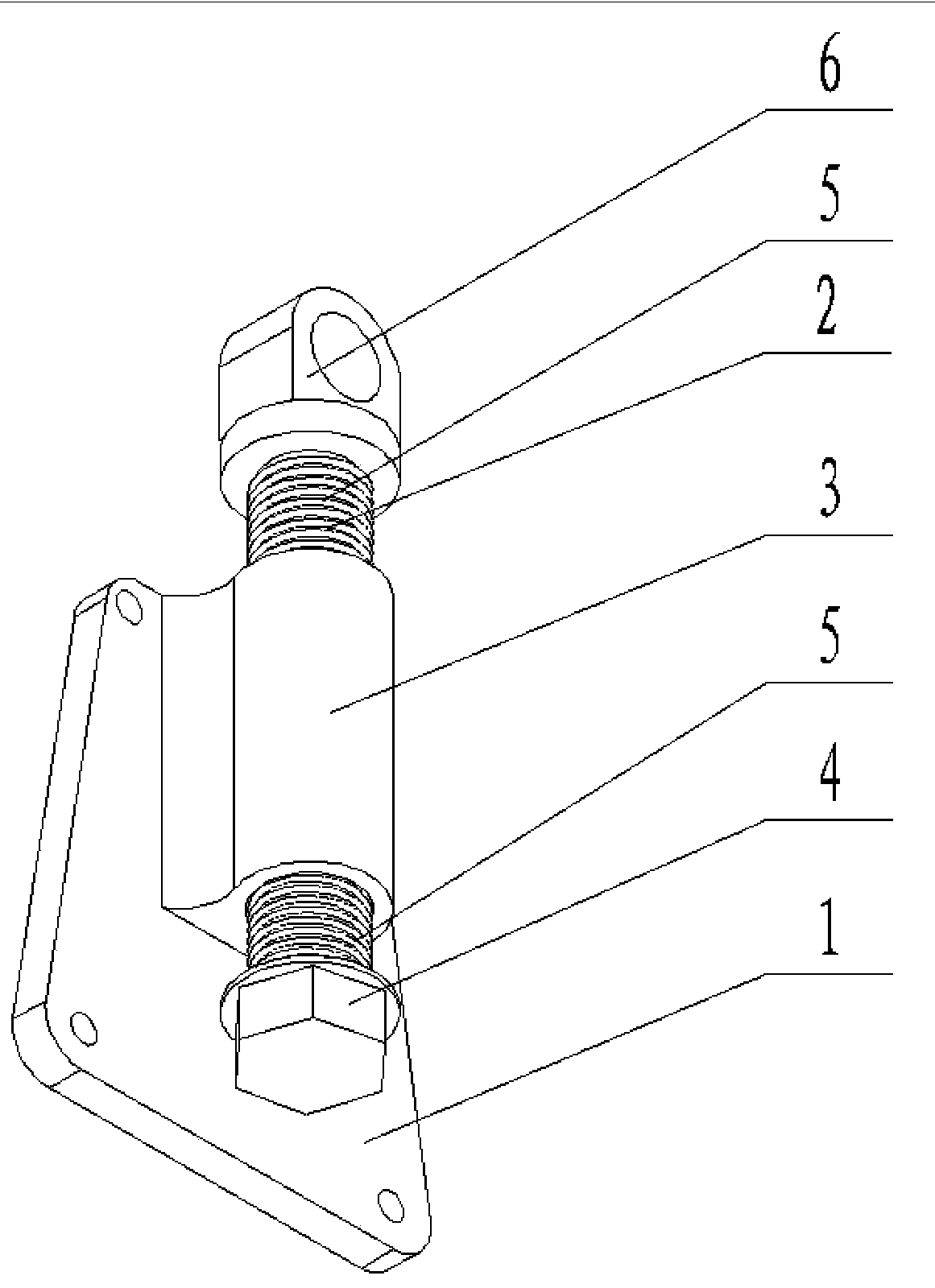

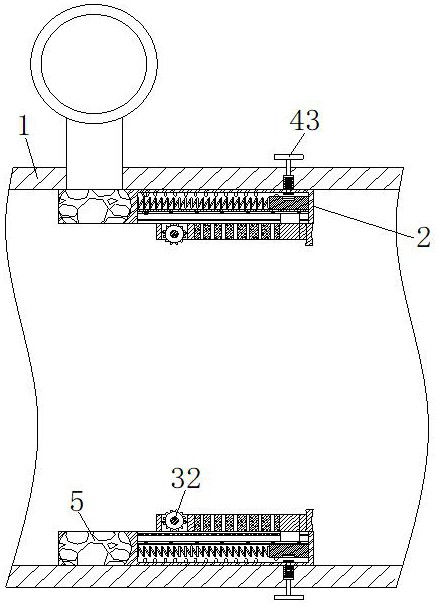

Connecting bolt

The invention relates to the technical field of firm connecting pieces, in particular to a connecting bolt. The connecting bolt comprises a bolt head, a threaded rod integrated with the bolt head, and a gasket which sleeves the threaded rod, wherein a plurality of circular notches are opened in the peripheral wall of the threaded rod in the axial line direction, an elastic component is arranged in each circular notch, and press blocks for pressing the elastic components in the circular notches are firmly arranged on the gasket. A plurality of elastic components are assembled in the circular notches in a one-to-one correspondence mode, the gasket sleeves the threaded rod, the press blocks on the gasket compress the elastic components, when connecting spare parts, the gasket contacts with the spare parts, and the firm connection is realized through screwing down the threaded rod; by means of the elastic components, there is a certain elasticity between the gasket and bolt head, and then the hard damage of the gasket to the spare parts is lowered.

Owner:常州市永达紧固件有限公司

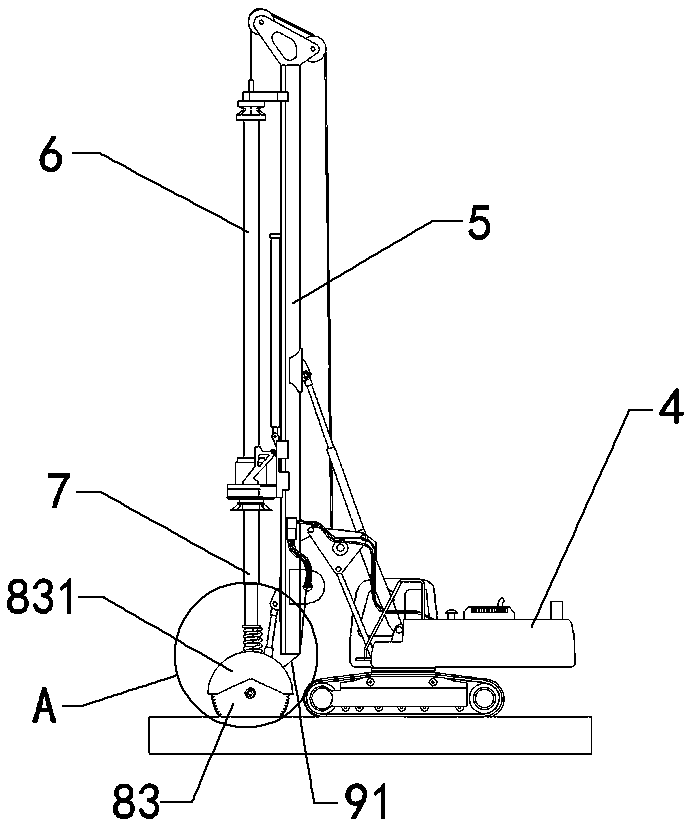

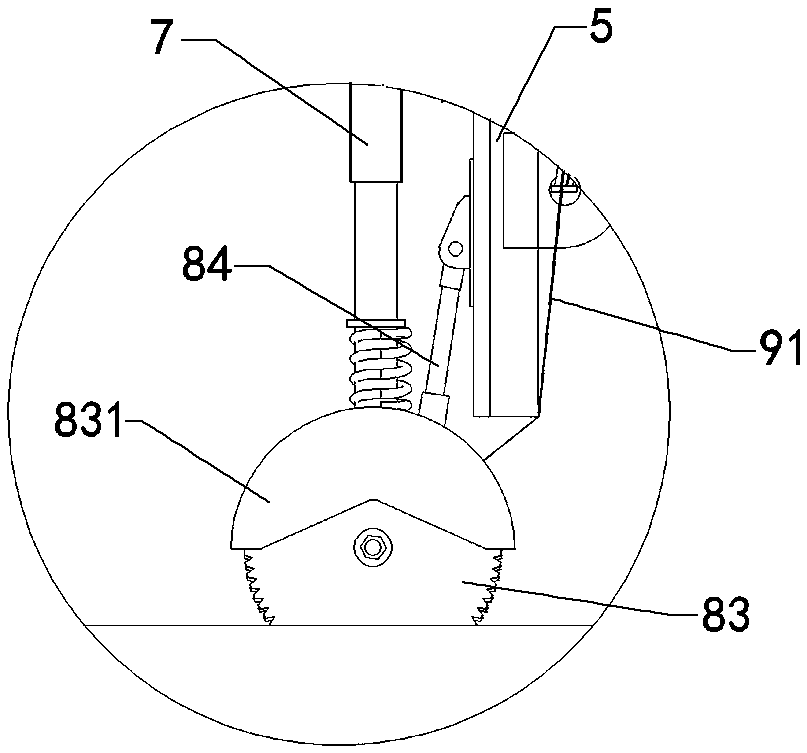

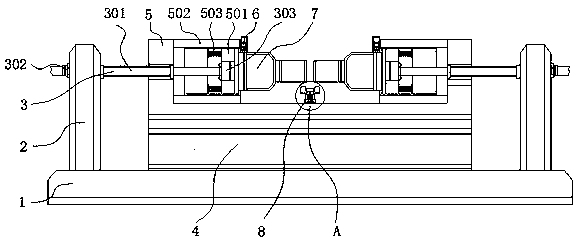

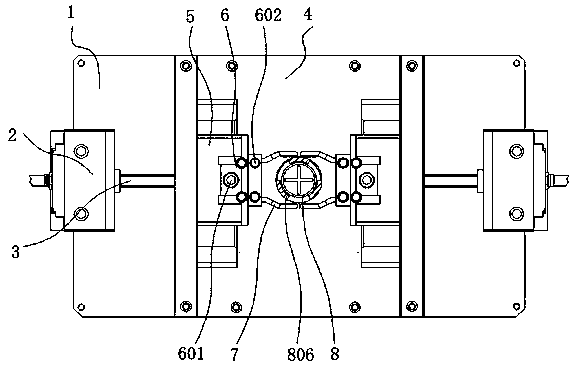

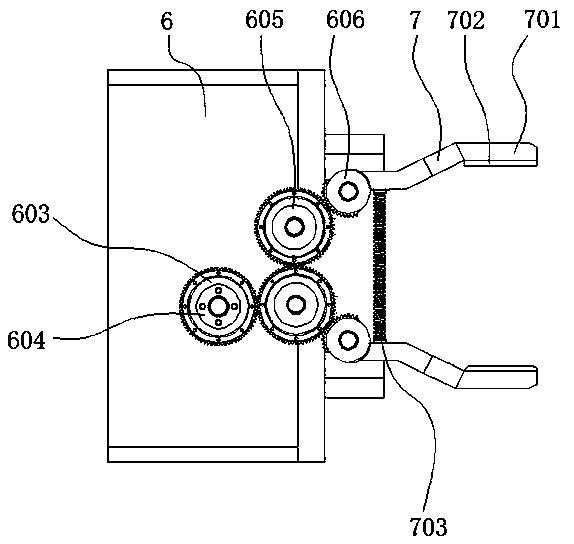

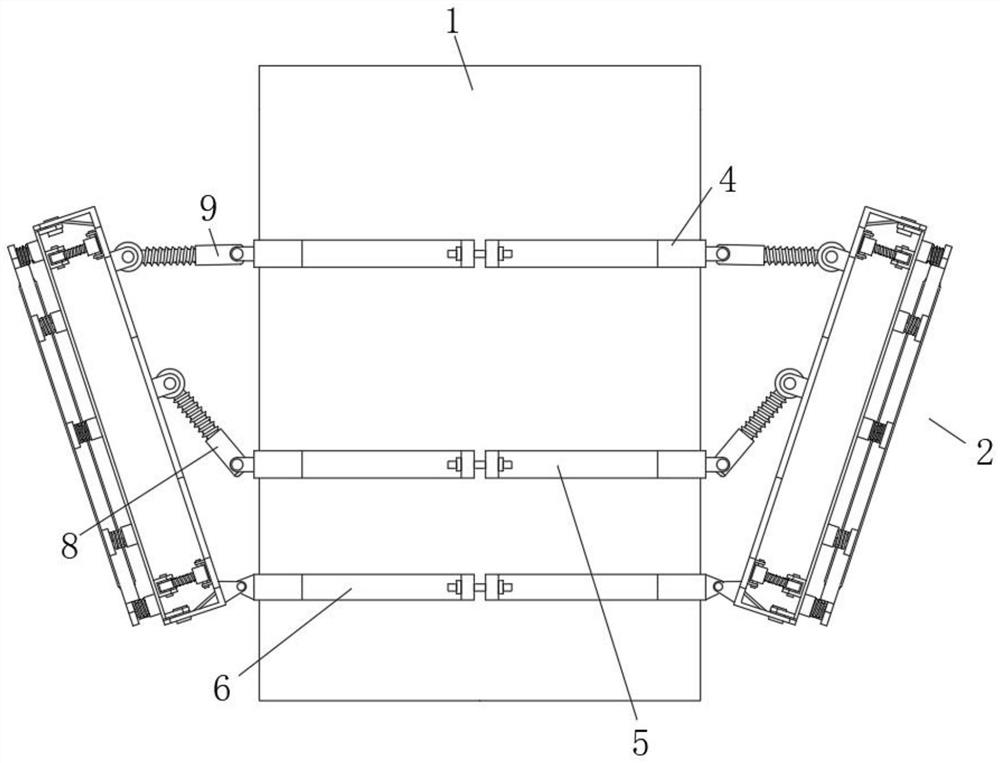

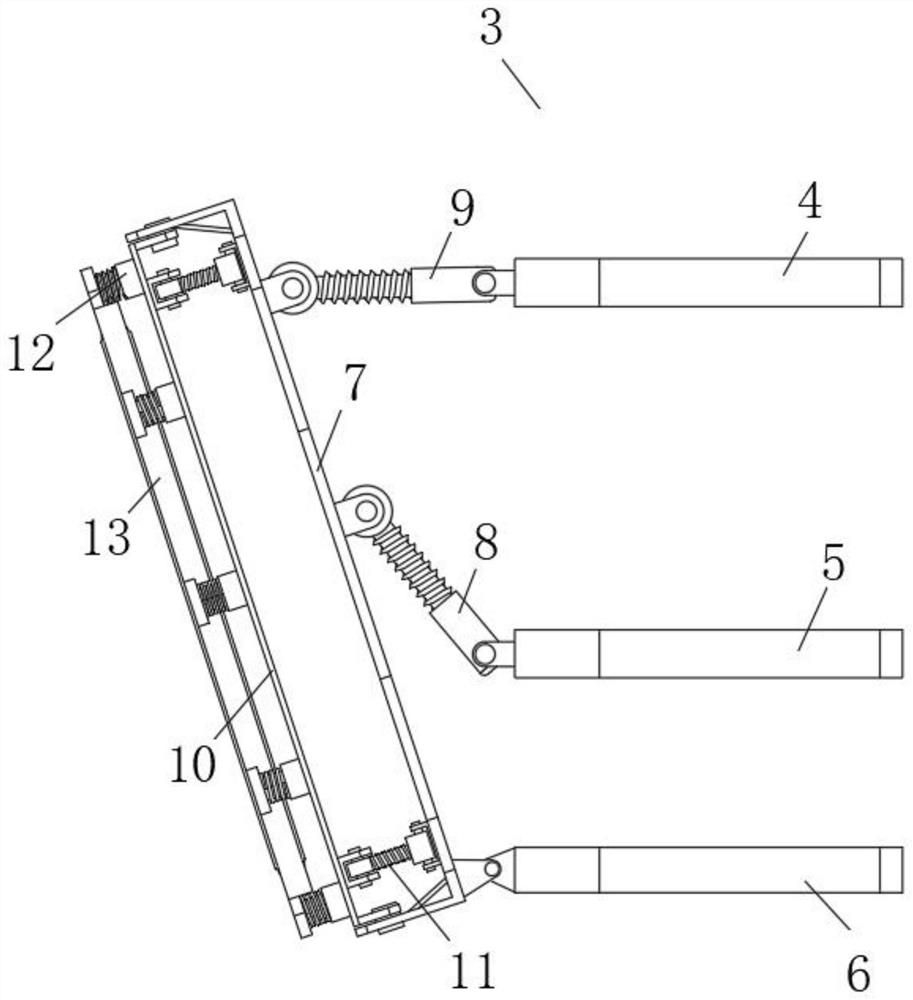

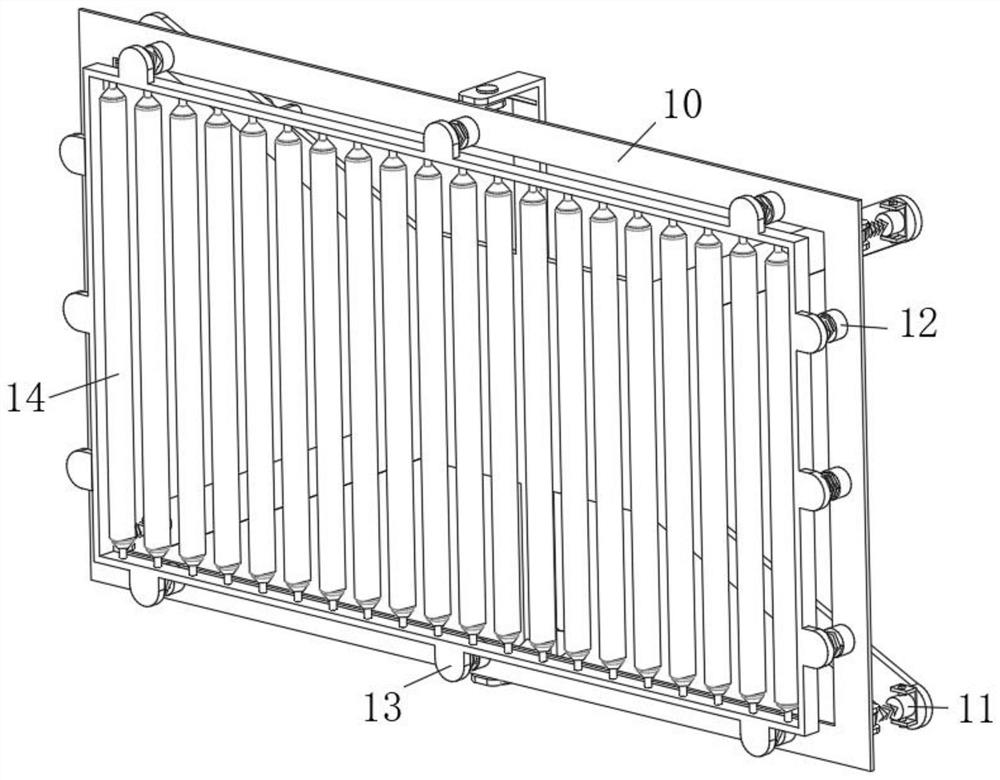

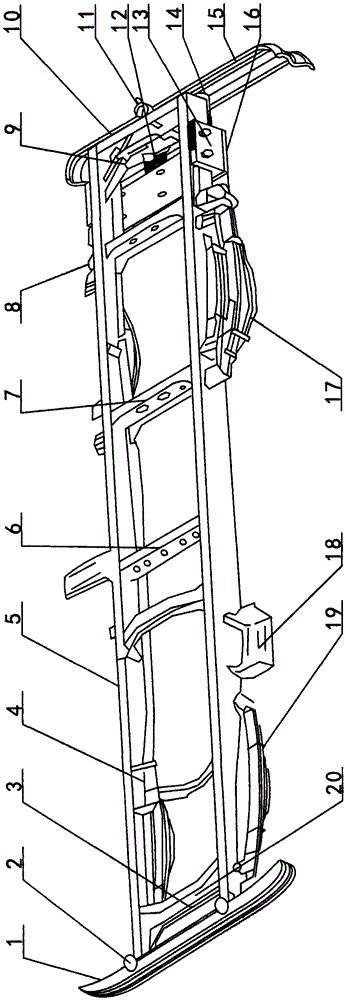

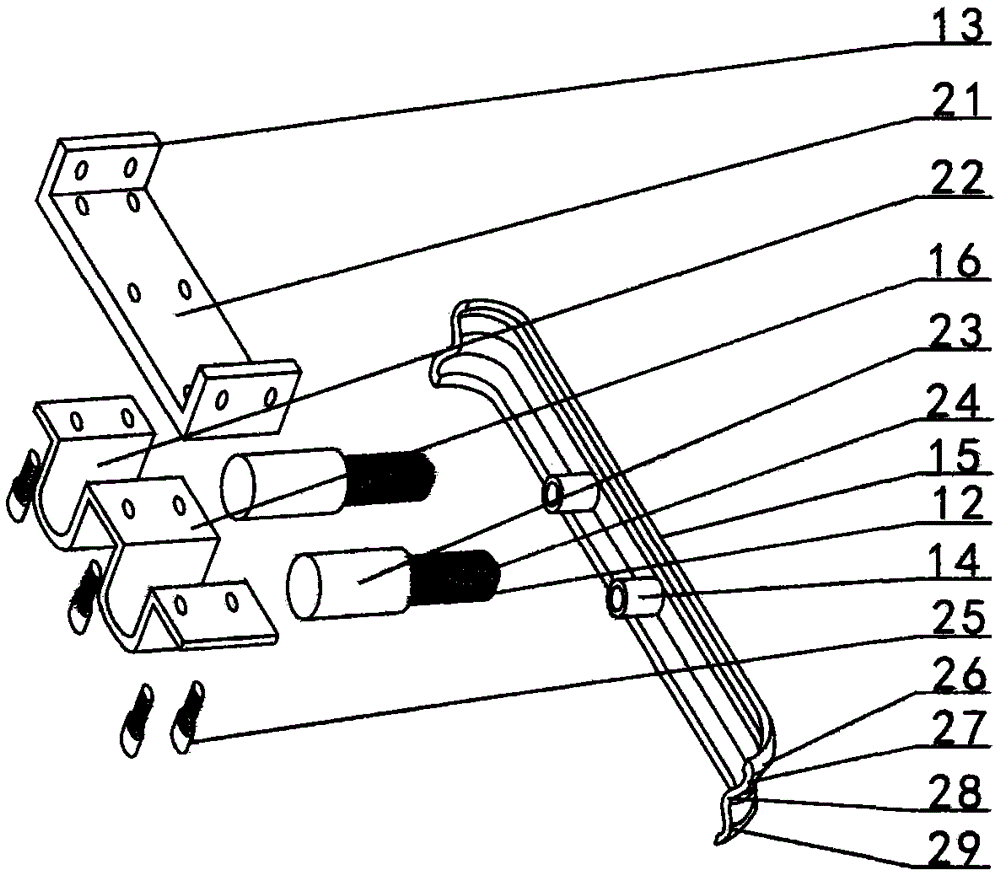

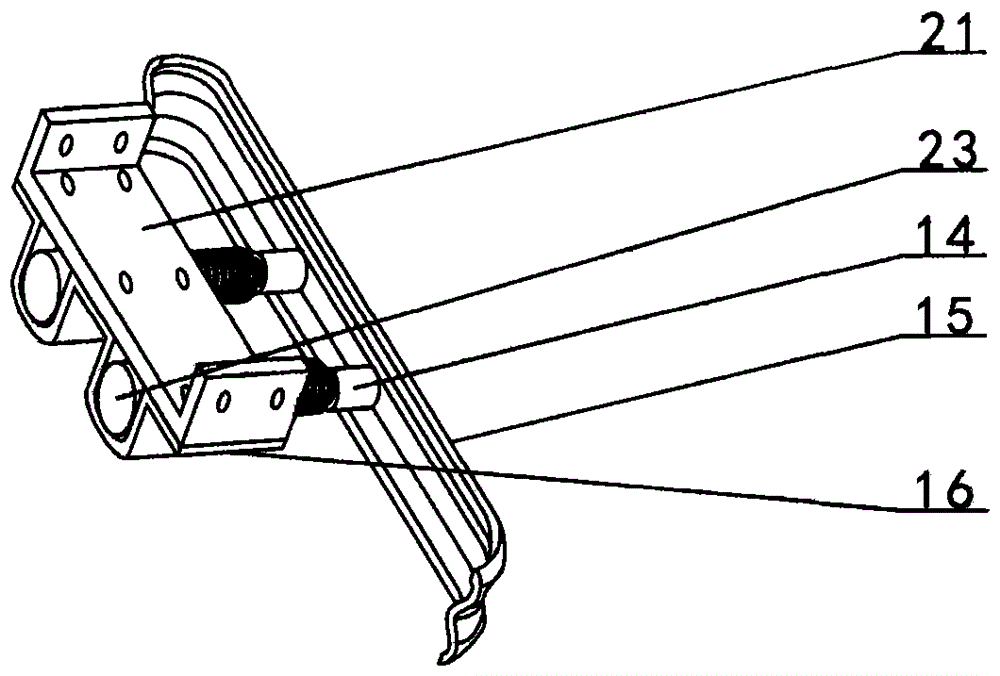

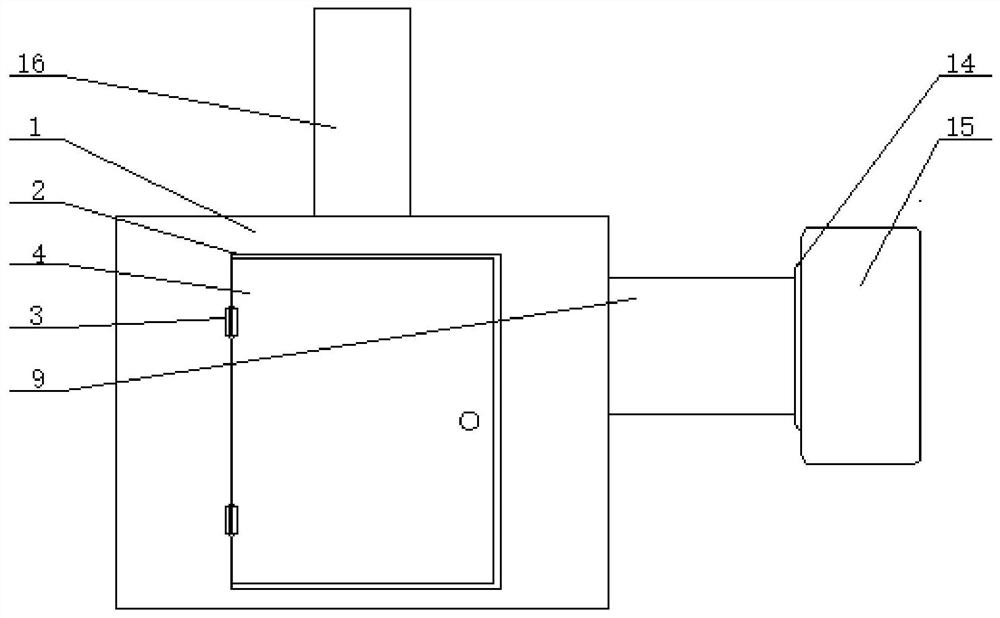

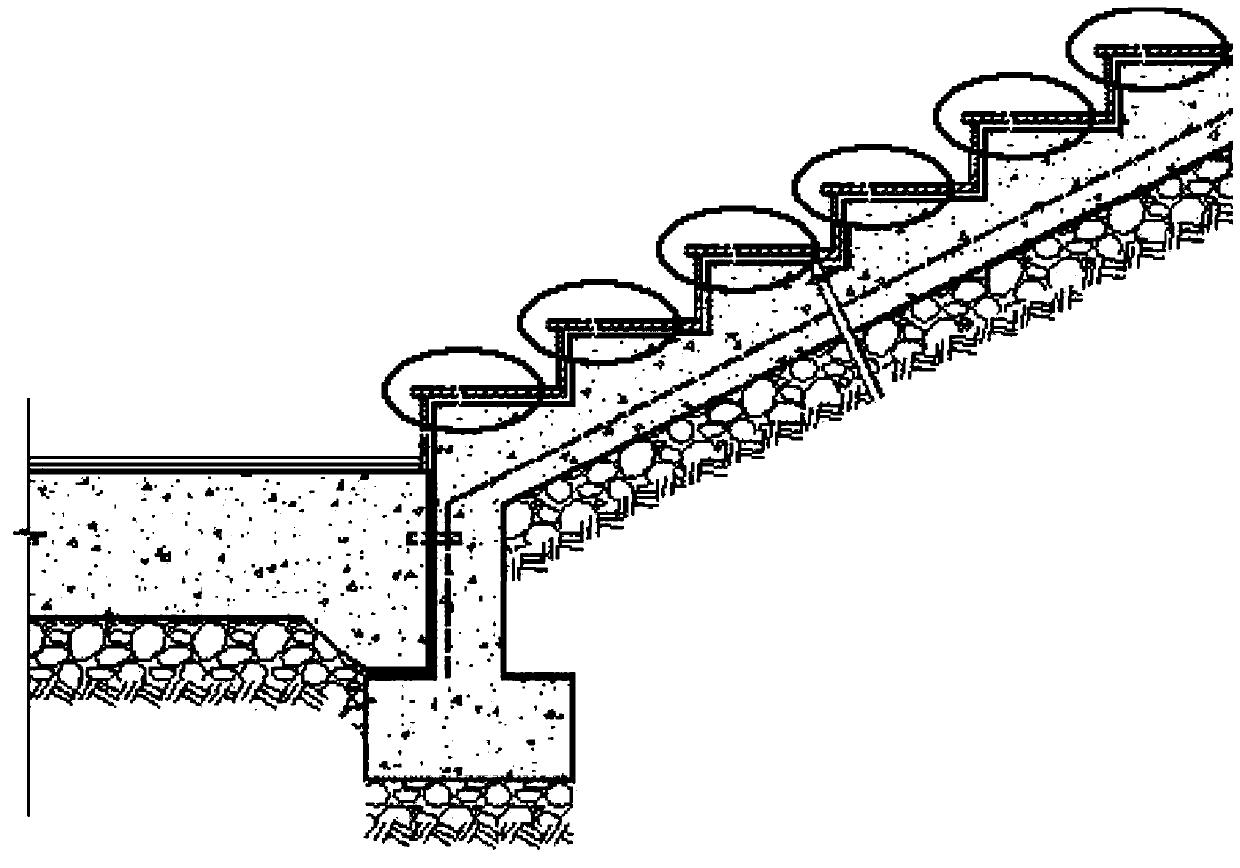

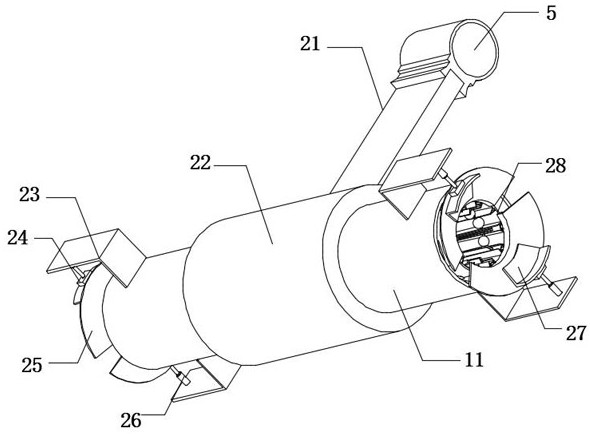

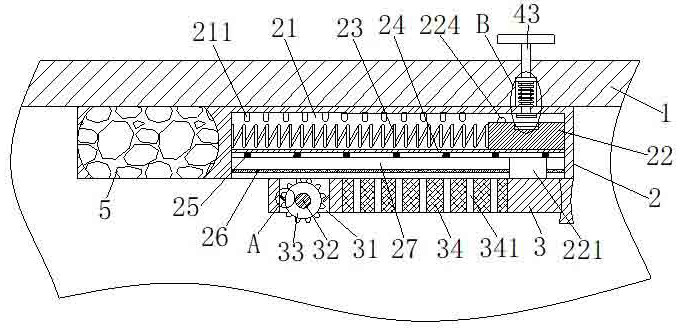

Square pile wire cutting device and mechanical excavation method of hard rock stratum square pile

PendingCN107803942AReduce difficultyReduce hard damageWorking accessoriesStone-like material working toolsWire cuttingStructural engineering

The invention relates to the technical field of excavation of square piles, and discloses a square pile wire cutting device and a mechanical excavation method of a hard rock stratum square pile. The method comprises the following steps that site leveling is carried out; measuring and paying off are carried out; circular pile hole construction is performed; a rotary drilling machine is utilized, and a round pile hole is excavated in the middle of the square pile until the design depth of the pile hole is reached; square pile hole contour line cutting is carried out, wherein the square pile wirecutting device is used for performing layer-by-layer cutting along the square pile hole contour line, the cutting depth of each time is 500-1000 mm, rocks in the square pile hole is cut into multipleblocky stones with smaller size; slag removal of the square pile hole is carried out, wherein the rotary drilling machine is utilized, the block stones in the square pile hole are crushed, lifted anddischarged, and the first layer of excavation is completed; and the step 4 and the step 5 are repeated, and cutting and slag removal are performed layer by layer until the design depth of the squarepile hole is reached. According to the square pile wire cutting device, the mechanical degree is high, construction precision is high, construction quality is stable, control is easy, and constructionefficiency is high.

Owner:中国建筑土木建设有限公司

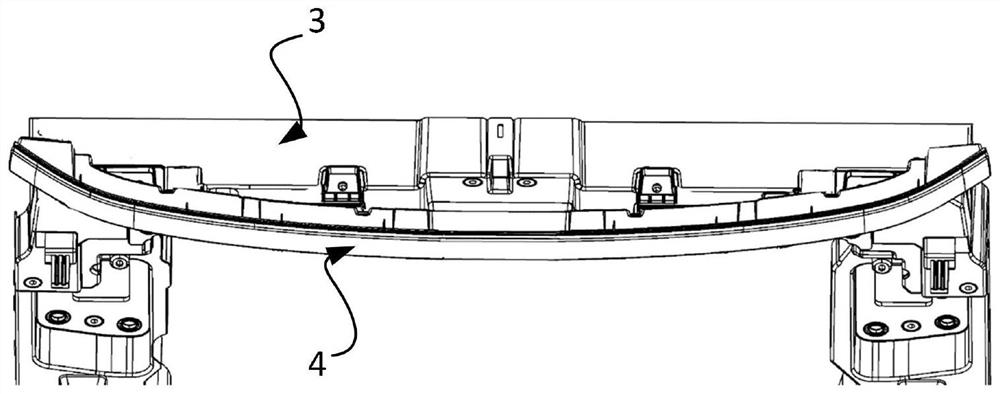

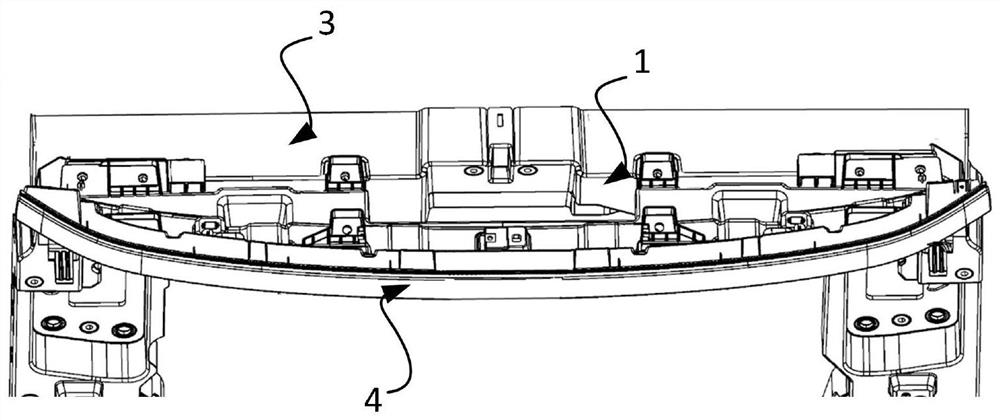

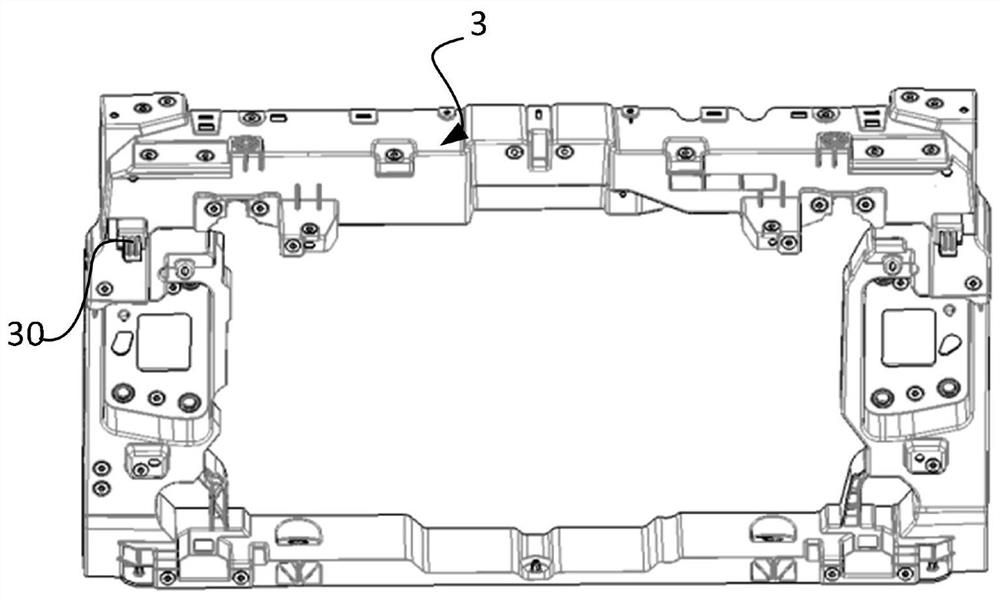

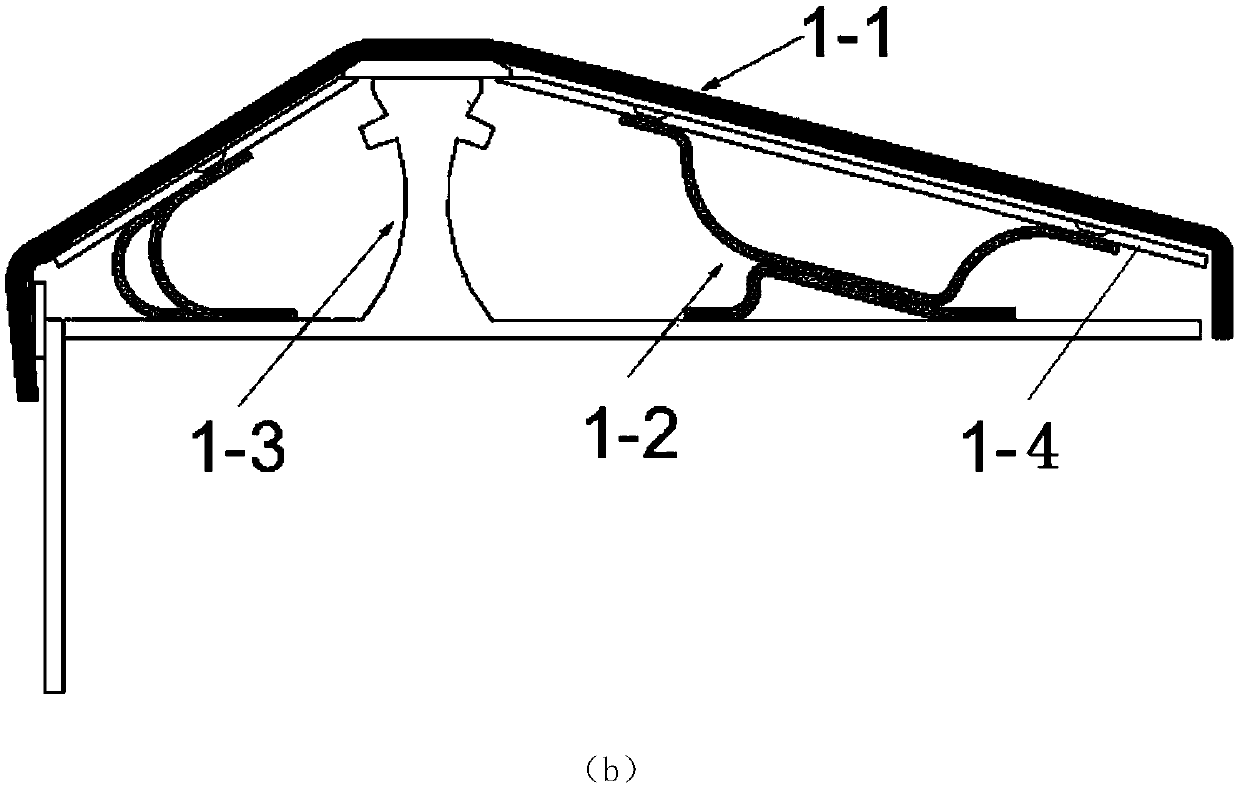

Front through lamp assembly

ActiveCN113147568APrevent fallingAvoid hard collisionNuclear energy generationPedestrian/occupant safety arrangementPedestrianSupport plane

The invention relates to a front through lamp assembly, which relates to the technical field of automobile bodies. The front through lamp assembly comprises a front end frame, a front bumper, a fragile support frame and a front through lamp, wherein the front end frame is provided with an abutting piece; a crumple space is formed between the front bumper and the front end frame; a fragile support frame is contained in the crumple space, and the two sides of the support frame are connected with the front end frame and the front bumper respectively; an inserting opening penetrating through the support frame is formed in the support frame; the front through lamp is connected with the support frame through the front bumper. When the pedestrian collides with the vehicle, the abutting piece is used for penetrating through the inserting opening and abutting against the front bumper so as to support the front bumper. When a pedestrian collides with a vehicle, the support frame can crumple and deform in the crumple space and drive the front through lamp to move backwards, so that the front through lamp assembly does not cause hard injury to thighs of the pedestrian, and the pedestrian can be effectively protected.

Owner:VOYAH AUTOMOBILE TECH CO LTD

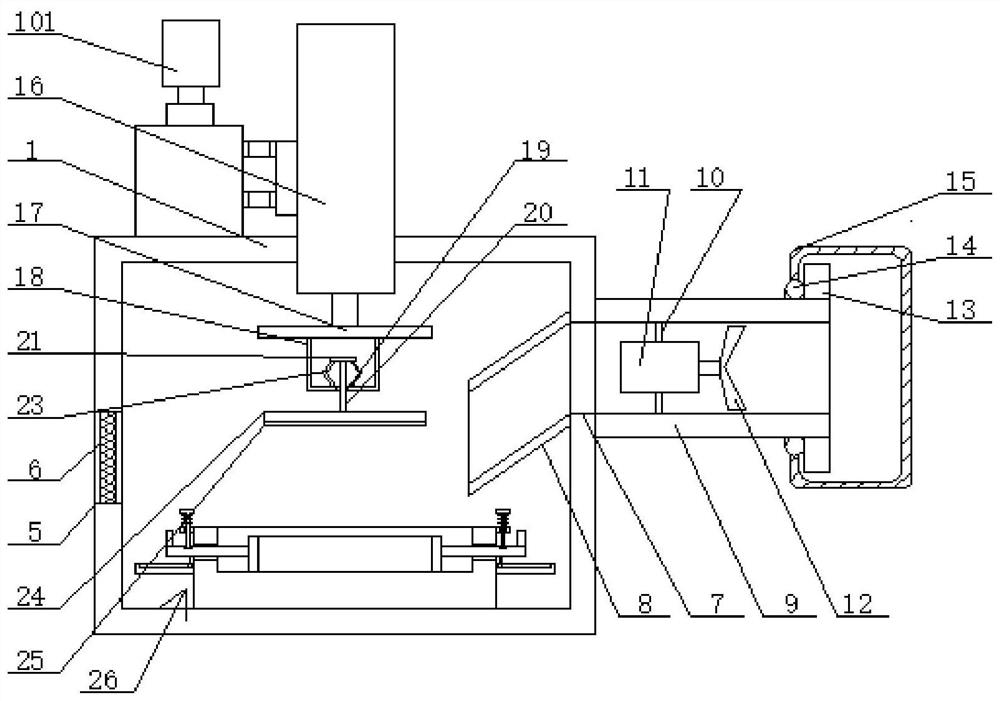

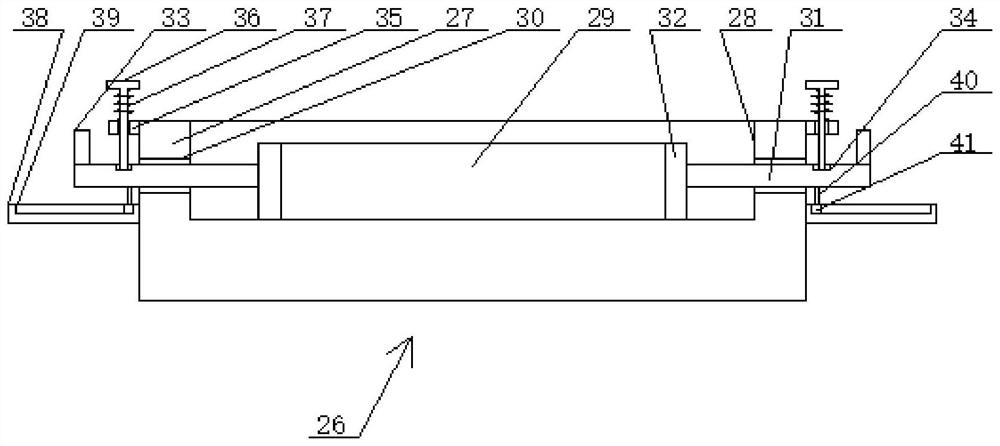

Clamping device with anti-wear structure and used for nut machining

InactiveCN110497222AEasy to useAvoid damagePositioning apparatusMetal-working holdersEngineeringAir compressor

The invention relates to a clamping device with an anti-wear structure and used for nut machining. The clamping device with the anti-wear structure and used for nut machining comprises a base and a bearing table, wherein a support block is connected to the upper end of the base, and a transversal rotation structure is installed at the middle part of the inner side of the support block; the bearingtable is arranged at the middle part of the upper end of the base, and slide assemblies are connected to the two sides of the top end of the bearing table; a transmission structure is installed at one side of the top end of each slide assembly, and clamping mechanisms are distributed at one side away from the bearing table, of each transmission structure; and a support mechanism is arranged at the top end of the middle part of the bearing table. According to the clamping device with the anti-wear structure and used for nut machining, a transversal transmission structure, a hydraulic rod, a hydraulic oil connection pipeline and an installation block are arranged, and the hydraulic rod, the hydraulic oil connection pipeline and the installation block are arranged in the transversal transmission structure; a user starts a hydraulic cylinder while needing the clamping mechanisms to move to the right; through an air compressor, hydraulic oil flows into the hydraulic rod from the hydraulicoil connection pipeline, and the hydraulic rod stretches to drive a slide block to move to the right side along the inner wall of a slide rail.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

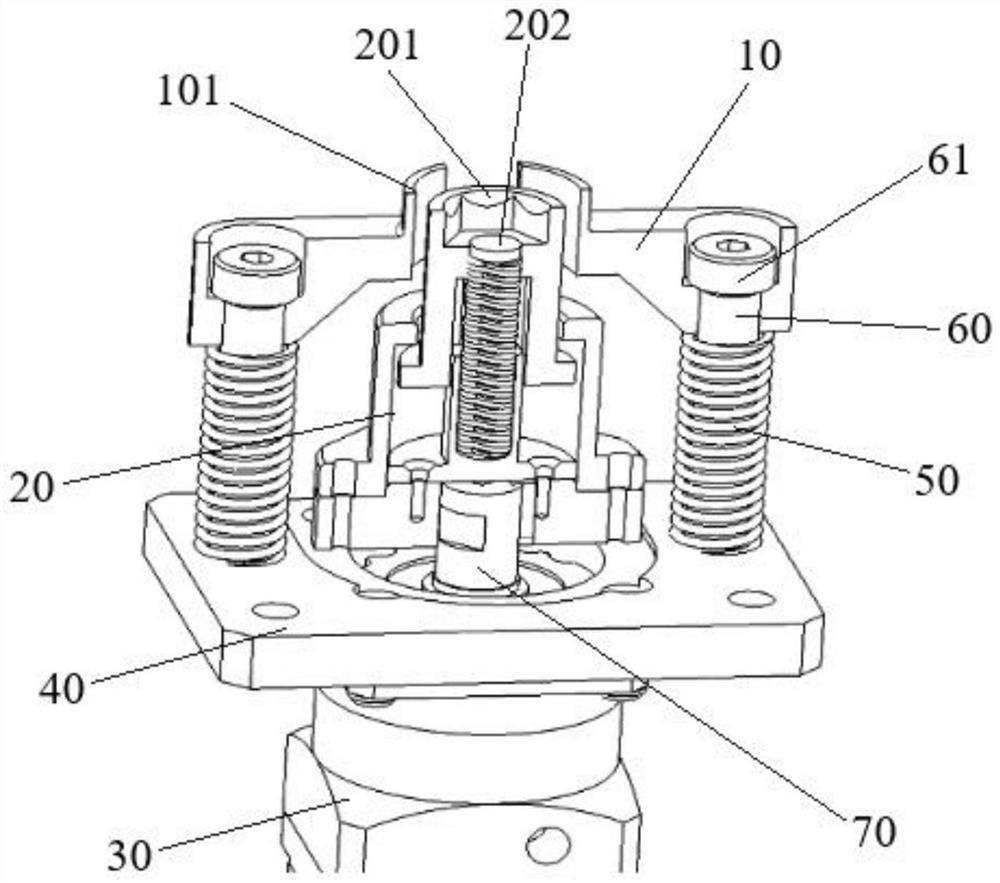

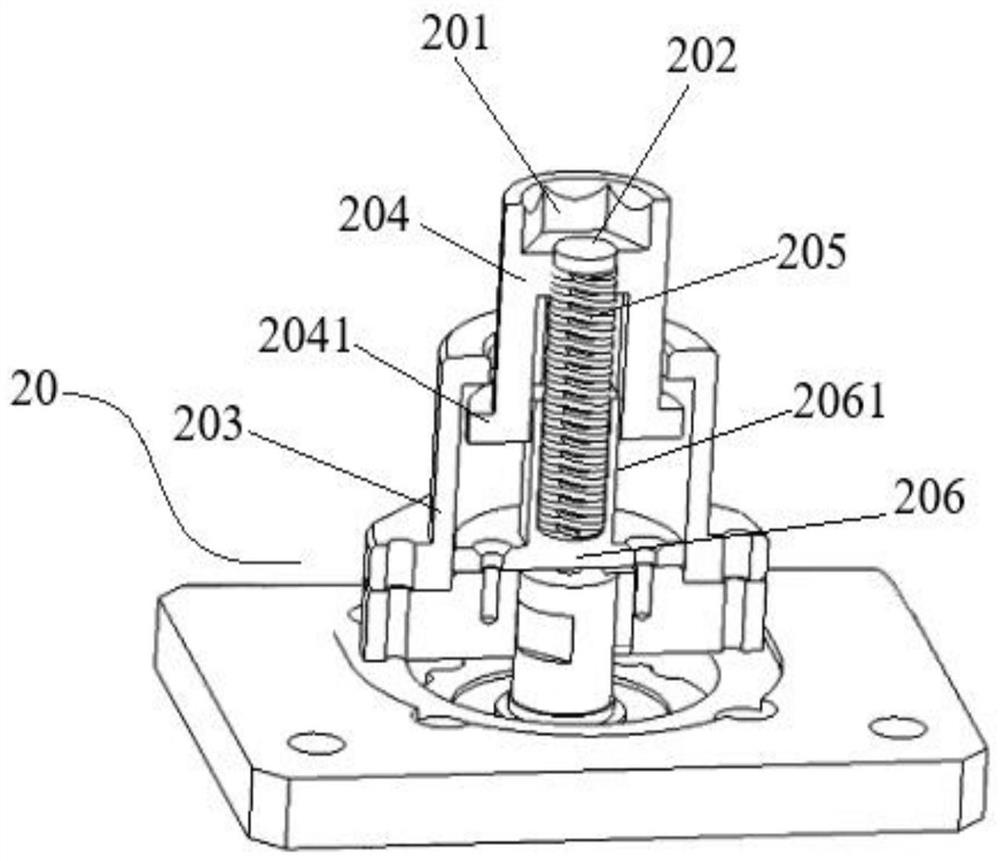

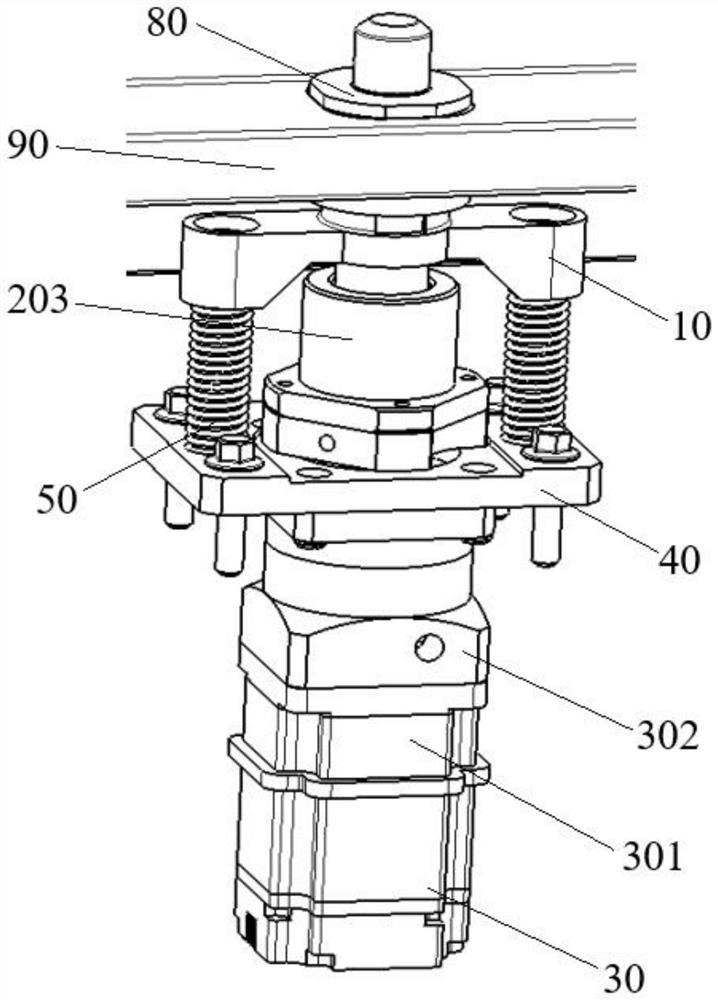

Unlocking device

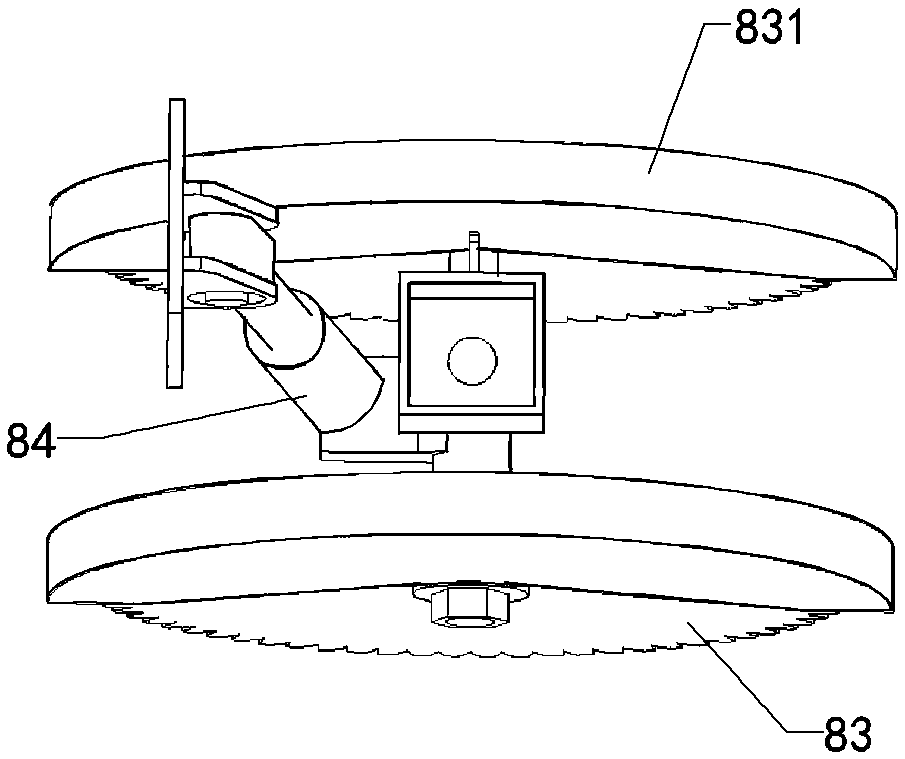

PendingCN112060892AWith jacking functionWith screw functionCharging stationsElectric propulsion mountingElectric machineryEngineering

The invention provides an unlocking device which comprises a jacking mechanism, a screwing mechanism and a motor. The motor is used for driving the screwing mechanism, the jacking mechanism is arranged on the outer side of the screwing mechanism, the screwing mechanism is connected with a mounting plate, and an elastic piece is arranged between the jacking mechanism and the mounting plate. The jacking mechanism can axially move relative to the screwing mechanism, the jacking mechanism is provided with a jacking part, and the height of the highest point of the jacking part is larger than that of the highest point of the screwing mechanism. The unlocking device has a jacking function, can unlock the anti-unlocking device of the locking device, has a screwing function, can achieve locking andunlocking operation of the locking device after the anti-unlocking device is unlocked, also has a torque dynamic real-time detection function, and can analyze and judge the tightening and unlocking processes under the action of a torque sensor.

Owner:ZHEJIANG JIZHI NEW ENERGY AUTOMOBILE TECH CO LTD +1

Flexible anti-collision sheath of telegraph pole

ActiveCN111560890AReduced risk of breakageReduce hard damageRoadway safety arrangementsMechanical engineeringUtility pole

Owner:国网黑龙江省电力有限公司佳木斯供电公司 +1

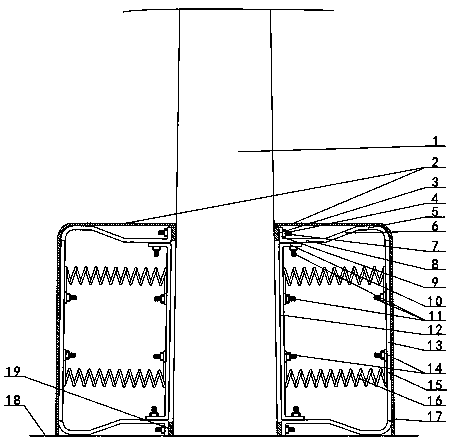

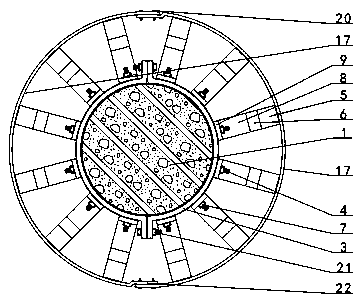

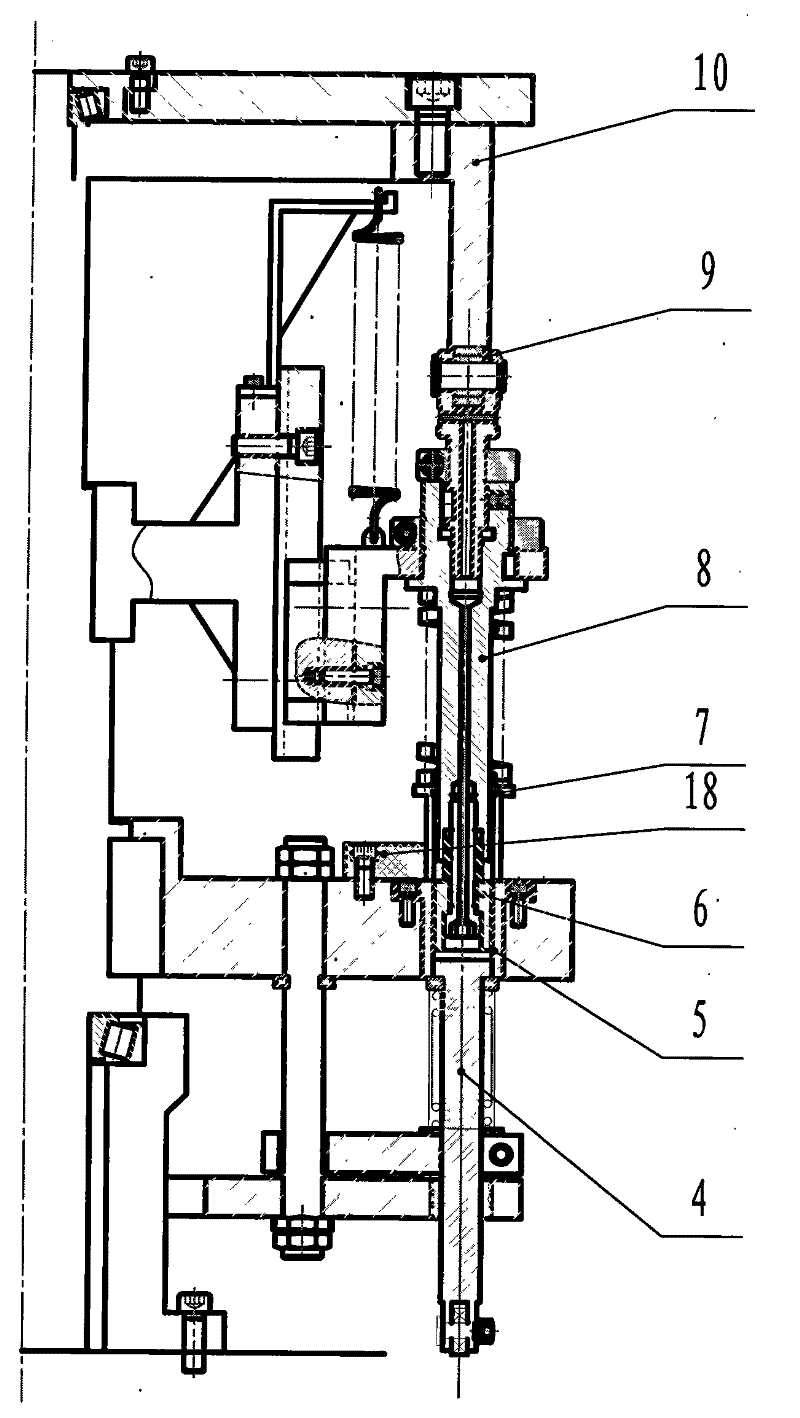

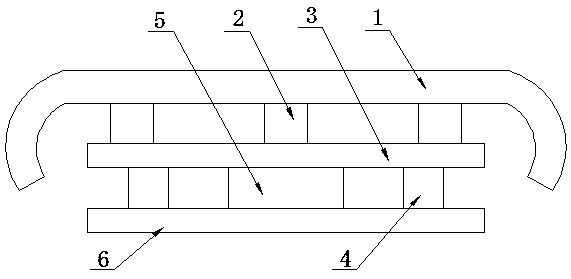

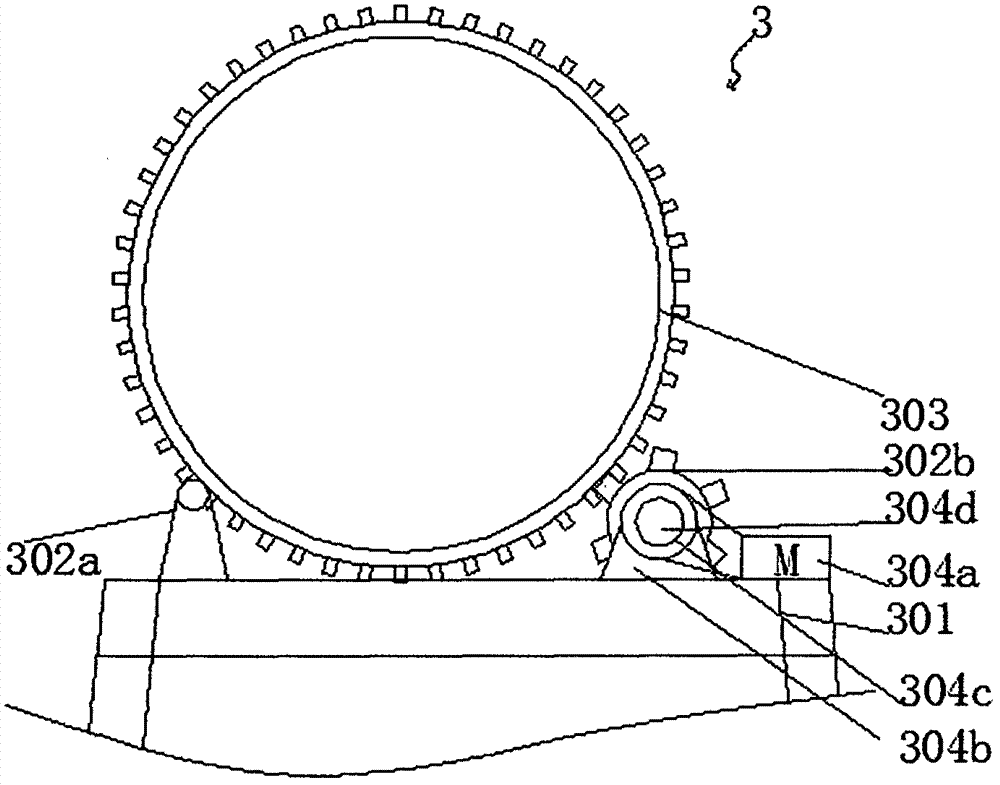

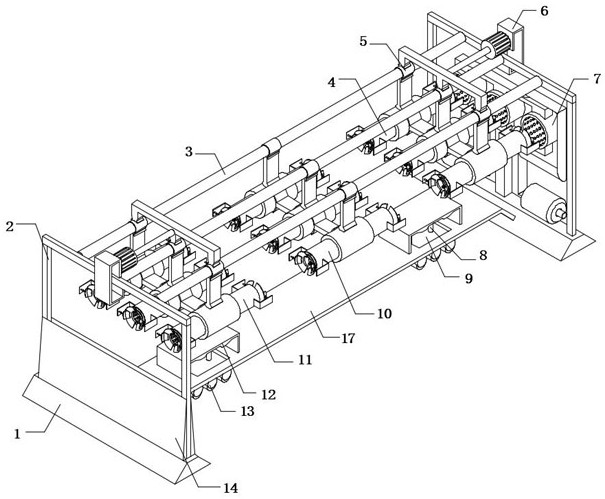

Rotary drawing machine

The invention discloses a rotary drawing machine for the production of aluminum anti-fake bottle cap, which comprises three parts, including a cap feeding part, a rotary drawing part and a cap returning part, wherein the cap feeding part is composed of a driving plate gear (11), a cap incoming driving plate (13) and a positioning disk (18); the rotary drawing part is composed of a motor gear (1),a mainshaft gear (2), a mainshaft (3), an upper rotator (16), a lower rotator (17), a core holder (8), a rolling bearing (9), a rolling guide rail (14), an upper cam (10), a material returning unit (4), a lower cam (12), a female die (5), a pressing ring (7), a male die (6) and a connecting block (22); and the cap returning part is composed of a tension spring (15), the material returning unit (4), the lower cam (12), a cap exiting driving plate (19) and an upper rotator bending plate (23); the rotary drawing machine greatly reduces the high noise phenomenon of equipment and achieves the advantages of fast production speed, high efficiency, small weight of equipment and small floor area, and the bottle caps are sequentially arrayed after being drawn, and accordingly, can be directly subject to the next procedure of knurling and cushioning, in addition, the rotary drawing machine simultaneously diminishes the possibility that the bottle caps are polluted by oil from the equipment and can also effectively lower mechanical damage of the equipment to human body.

Owner:LIPENG PACKING YANTAI CITY

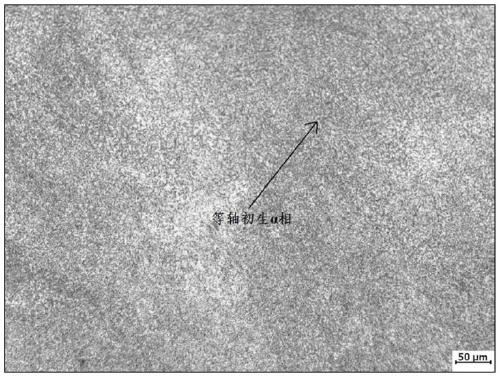

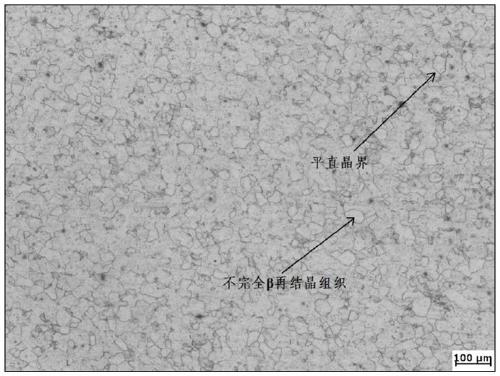

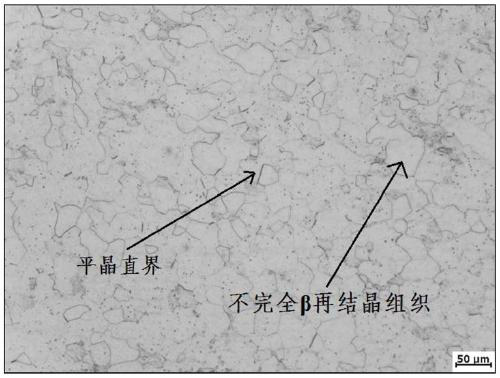

Preparation method of ultrahigh strength titanium alloy hot-rolled bar

The invention discloses a preparation method of an ultrahigh strength titanium alloy hot-rolled bar. The preparation method comprises the following steps: S1, heating the ultrahigh strength titanium alloy hot-rolled bar to the temperature which is 15-20 DEG C lower than the beta phase transformation point temperature, and carrying out thermal insulation; and S2, heating the ultrahigh strength titanium alloy hot-rolled bar after thermal insulation treatment to the temperature which is 10 DEG C higher than the beta phase transformation point temperature, and carrying out multi-pass rolling to obtain the ultrahigh strength titanium alloy hot-rolled bar. According to the preparation method, a beta grain structure is obtained on the surface layer of the ultrahigh strength titanium alloy hot-rolled bar through two-step heating, so that impact of the ultrahigh strength titanium alloy hot-rolled bar to a roller is reduced during the rolling process, and abrasion of production equipment is lowered; the beta grain structure in the ultrahigh strength titanium alloy hot-rolled bar is fully crushed through multi-pass rolling to obtain the demanded equiaxed structure, and an overheated structureis not generated on the basis of lowering the rolling deformation resistance, so that the ultrahigh strength titanium alloy hot-rolled bar has excellent structure uniformity and performance uniformity to have excellent tensile strength and elongation.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Automobile anti-collision beam capable of reducing collision kinetic energy

The invention discloses an automobile anti-collision beam capable of reducing collision kinetic energy. The automobile anti-collision beam comprises an anti-collision beam cross beam. Multiple evenly-distributed energy absorption boxes are arranged at the bottom end of the anti-collision beam cross beam, a bearing plate is arranged at the bottom ends of the energy absorption boxes, buffer assemblies are symmetrically arranged on the two sides of the bottom end of the bearing plate, a damping mechanism is arranged in the middle of the bottom end of the bearing plate, and the bottom end of the buffer assembly and the bottom end of the damping mechanism are connected with a mounting plate. The damping mechanism comprises a first base plate located at the top end of the mounting plate, an opengroove is formed in the middle position of the top of the first base plate, a first rocker and a second rocker are arranged in the open groove, the end, away from the second rocker, of the first rocker is connected with a first rotary shaft, and the first rotary shaft stretches into the first base plate. The automobile anti-collision beam has the beneficial effects that through the arrangement ofthe buffer assembly and the damping mechanism, impact force can be effectively dispersed and buffered and decomposed, the impact force is weakened, losses of a user are minimized while hard injuriesof vehicles and staff are reduced, and the safety protection effect is improved.

Owner:安徽彤上智能科技有限公司

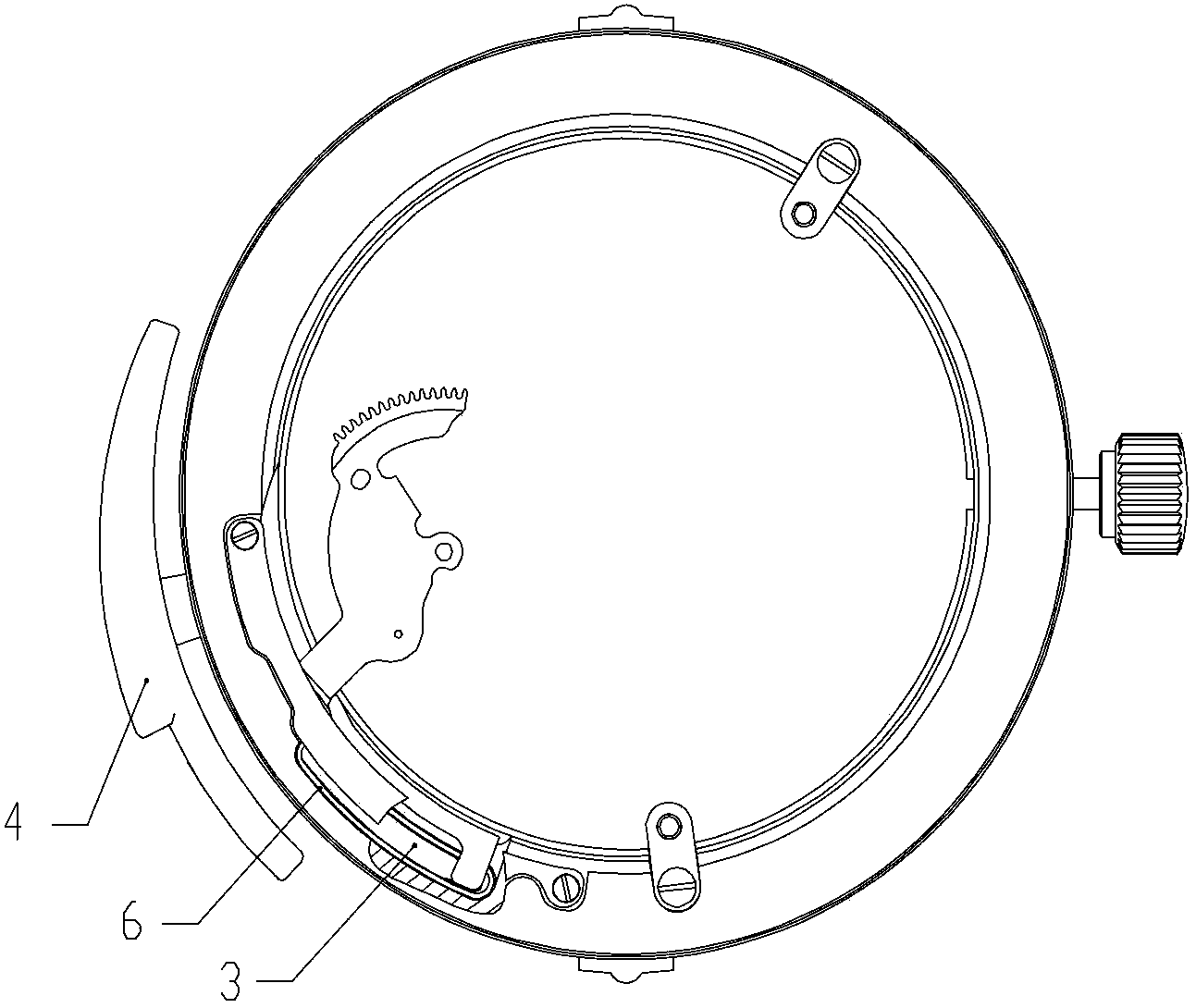

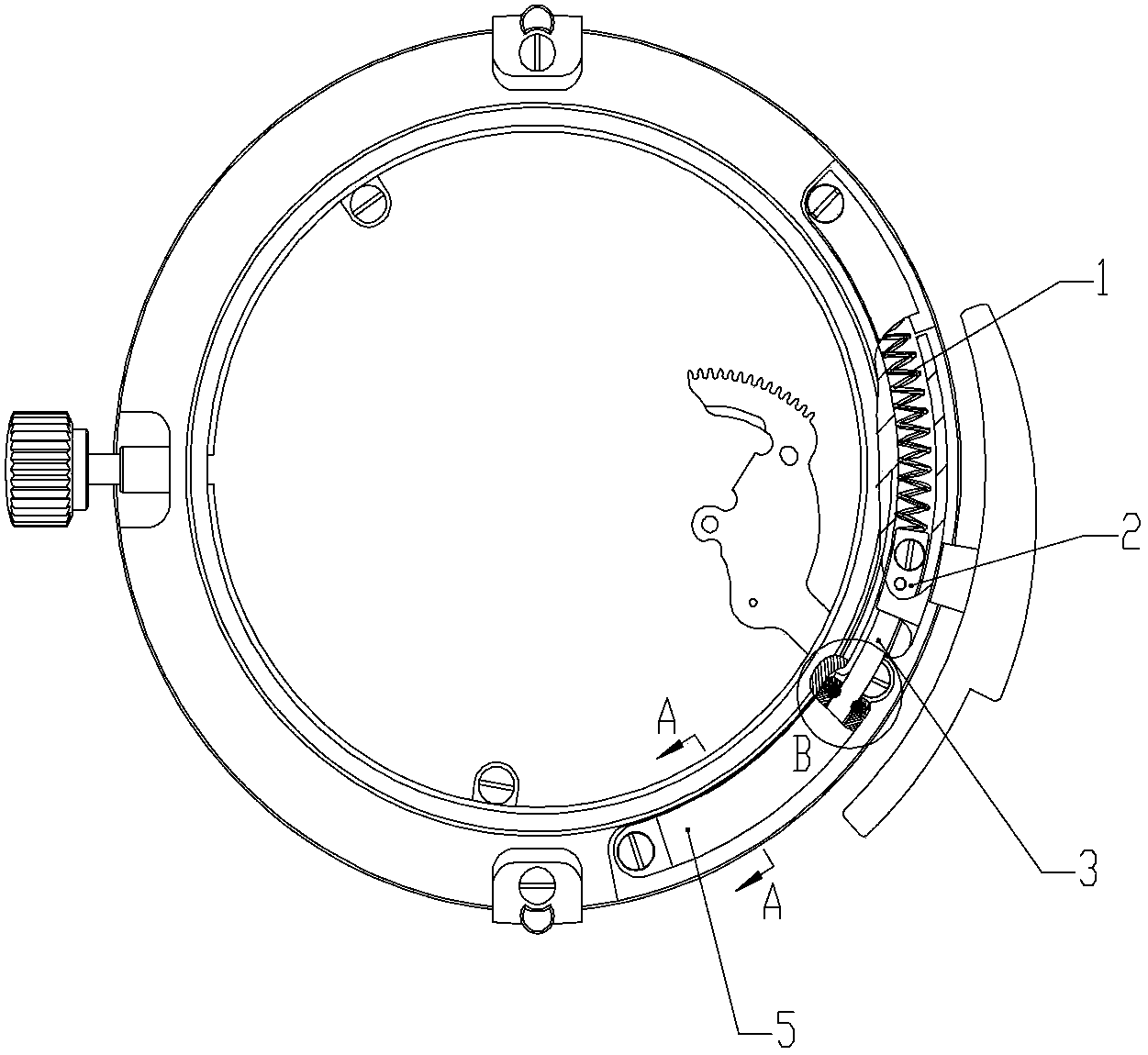

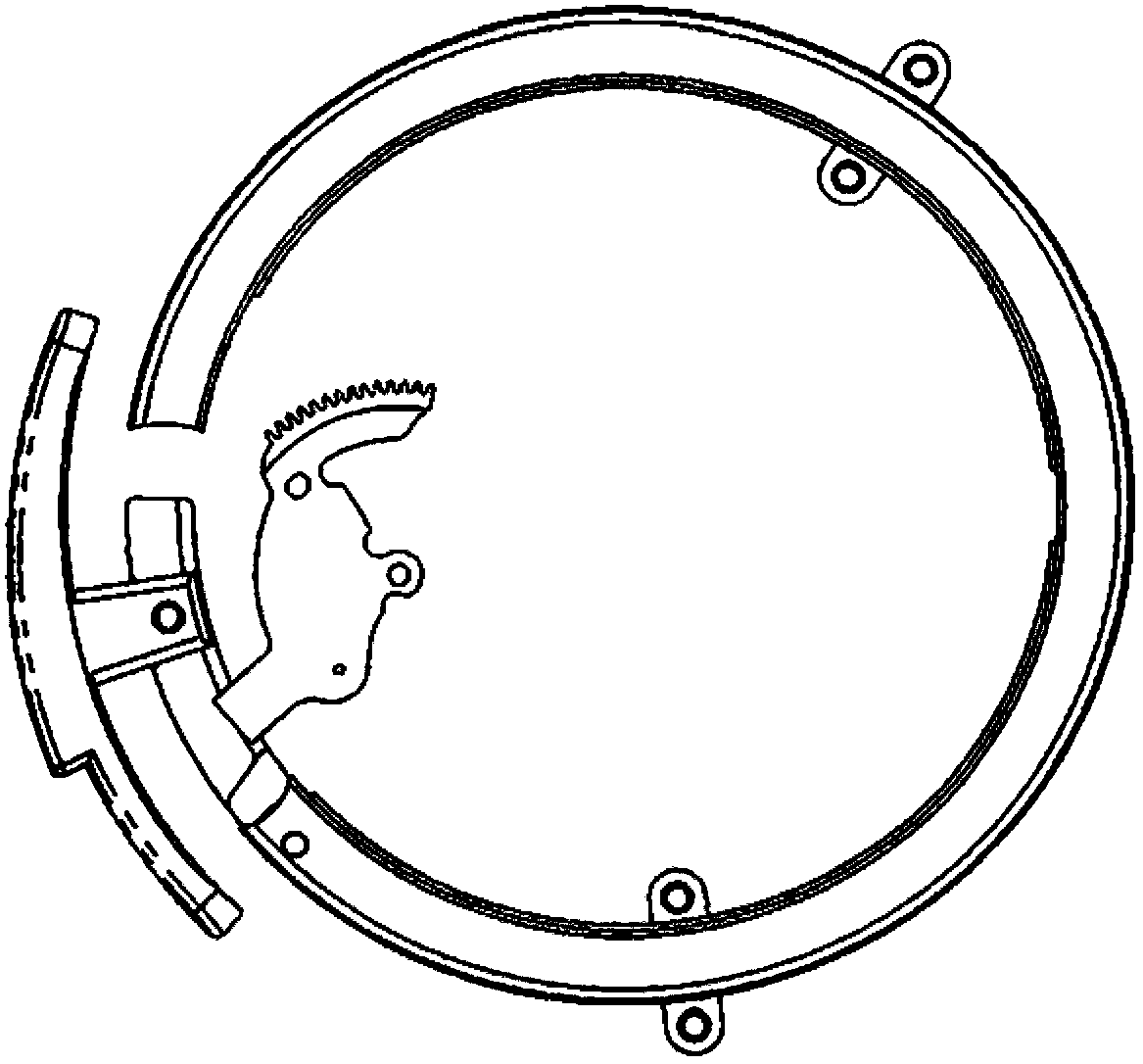

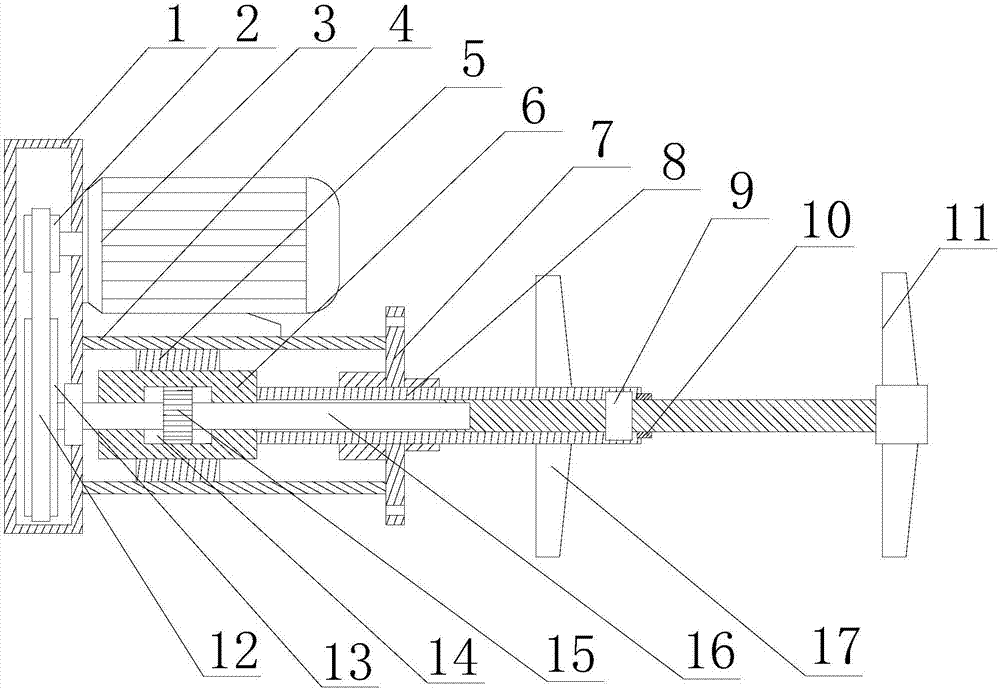

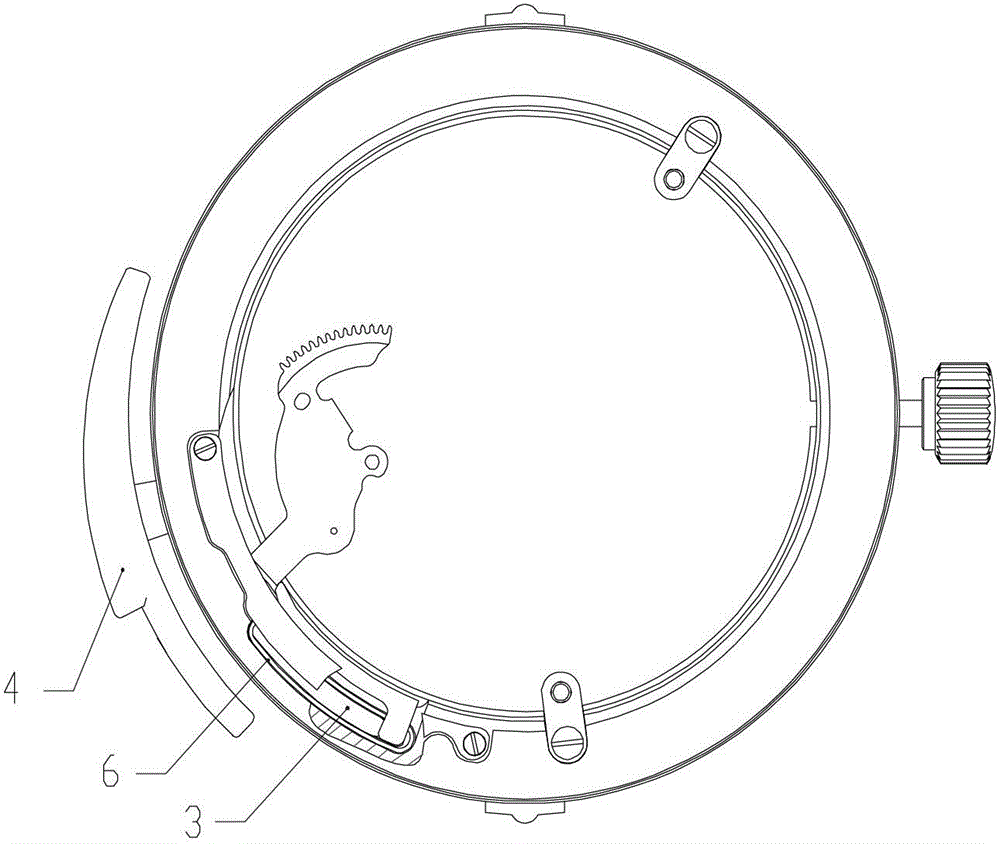

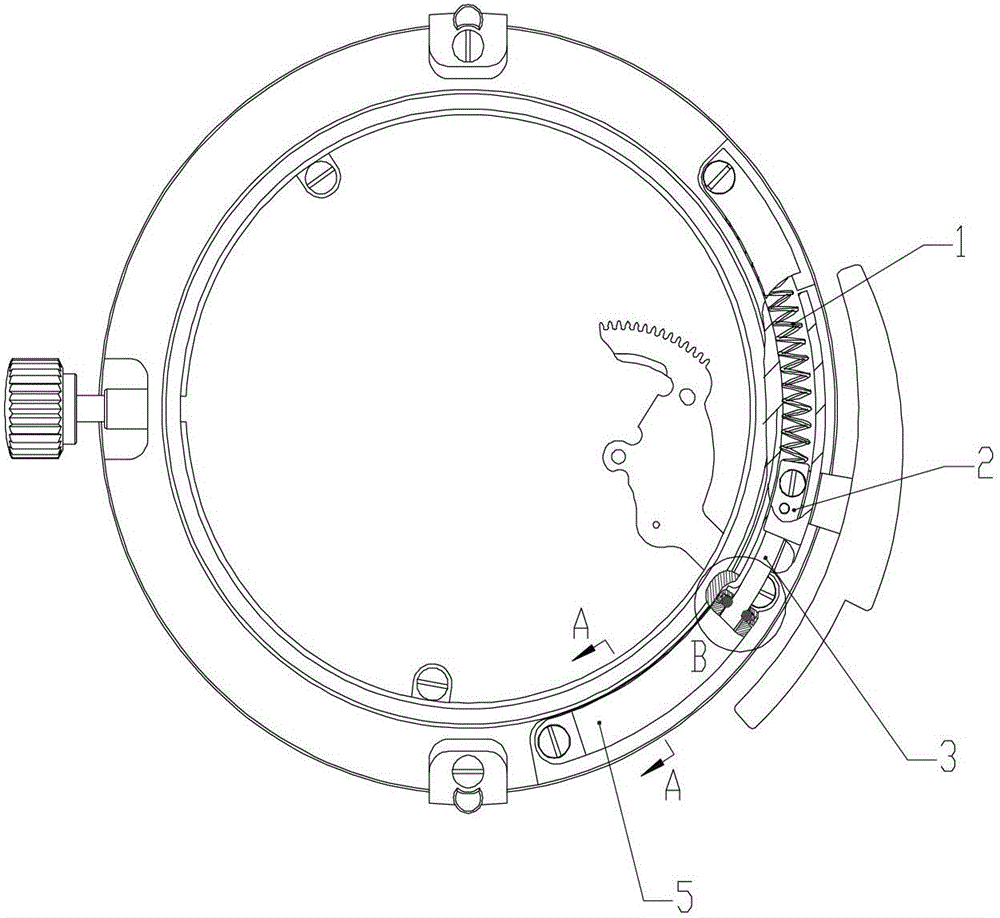

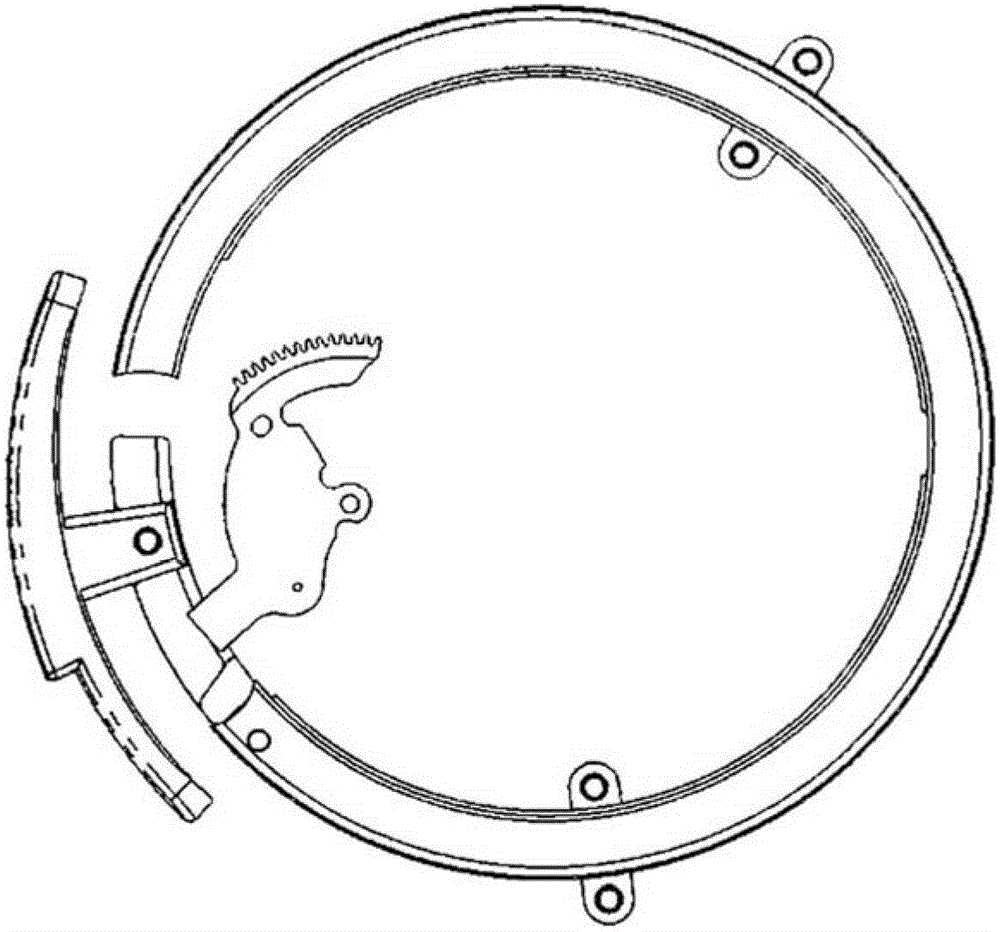

Starting mechanism of mechanical time-telling watch

ActiveCN103472705AGuaranteed to workReduce hard damageAcoustic indicationClockwork casesRubber ringEngineering

The invention discloses a starting mechanism of a mechanical time-telling watch. According to the starting mechanism, a through groove is formed on a spacer ring, and a pull core support is fixed in the through groove of the spacer ring; a connecting sleeve is respectively connected and fixed with one end of a pull core and a square end of a shifting hander as a whole, and the other end of the pull core is a free end; the pull core which is sheathed with a waterproof sealing pipe and a pressure spring penetrates through a connecting block and the pull core support; the pressure spring is arranged in a range of the length of the support; the connecting block is fixedly arranged at a gap formed on the pull core; the pull core penetrates through the connecting block, and the connecting block is fixedly connected with a shafting block; the shafting block in contact with or separated from a movement time-telling starting plate; and upper and lower ends of the exterior of the spacer ring are provided with waterproof rubber rings. The starting mechanism of the invention is advantageous in that: because waterproof rubber rings for sealing are arranged between the spacer ring and a watchcase, and a waterproof sealing pipe is arranged between the spacer ring and the inner pull core, the contact between the exterior and the interior is obstructed from an outermost end, and sealing is carried out from the interior, thereby enabling favorable dustproof and waterproof effects to be achieved. According to the starting mechanism, a sealing box is omitted, which enables a watch with a standard size to be small and thin.

Owner:TIANJIN SEAGULL WATCH CO LTD +1

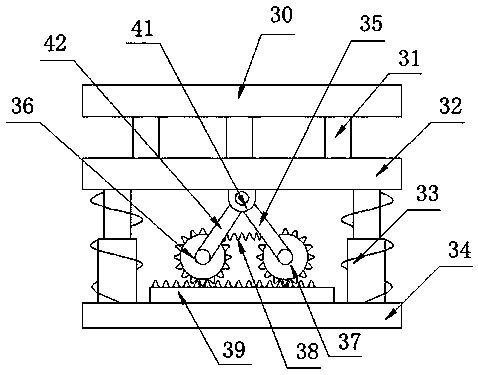

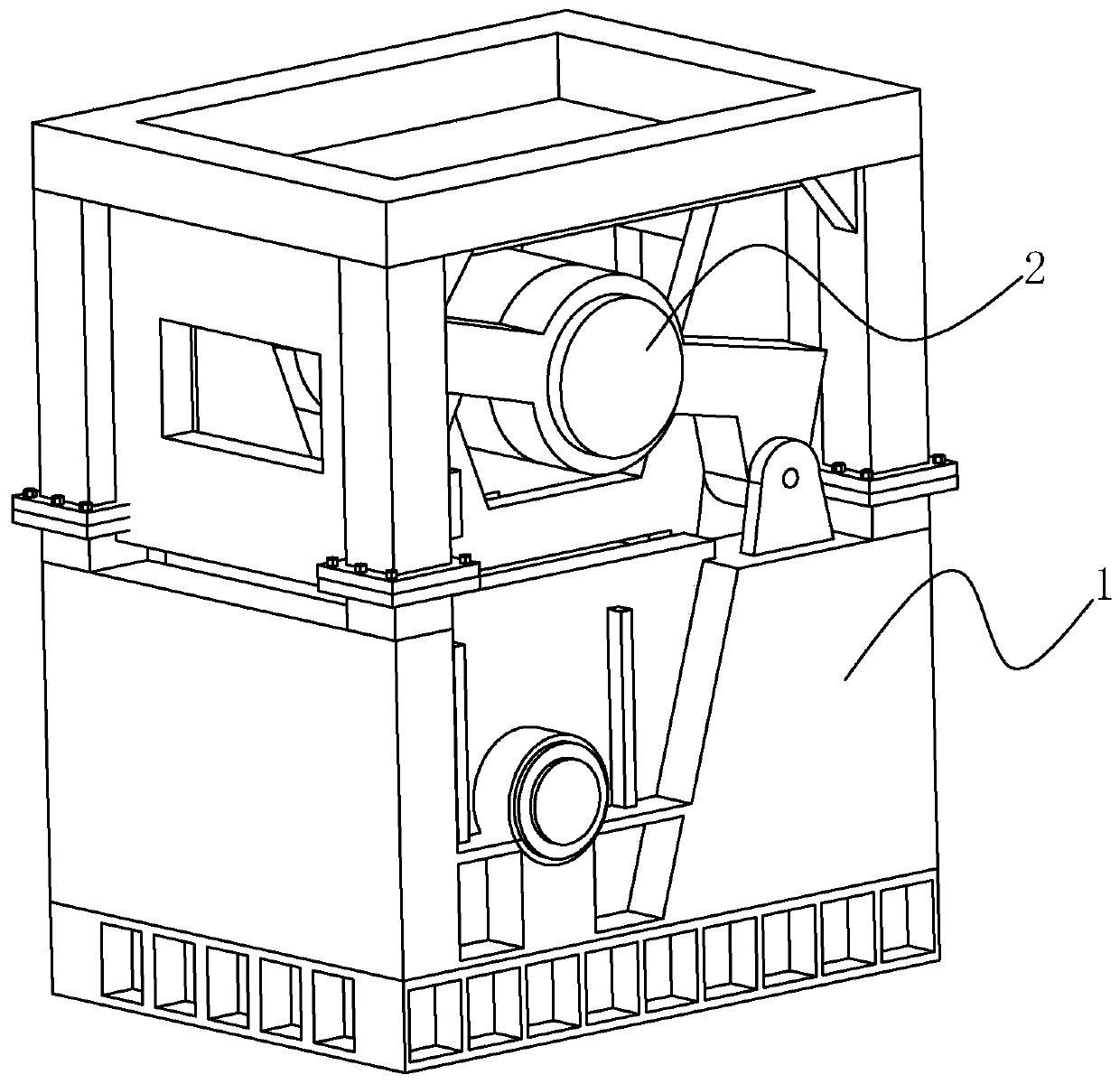

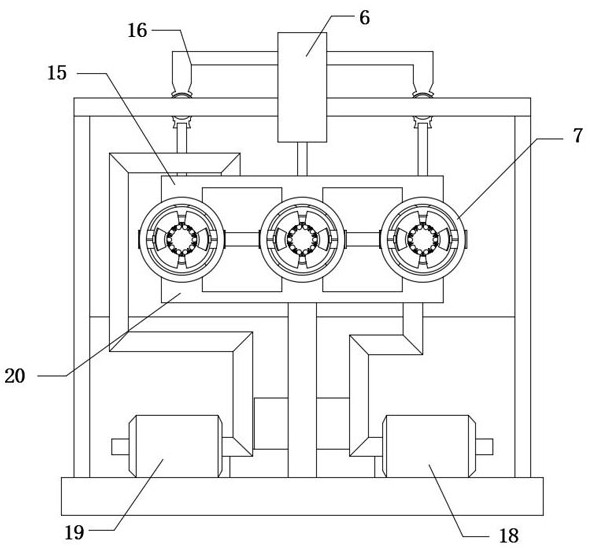

Waste mushroom-stick treatment device

PendingCN107138232AIncrease the crushing areaReasonable structureGrain treatmentsElectric machineryIndustrial engineering

The invention discloses a waste mushroom-stick treatment device which comprises a feeding unit, a smashing unit and a shaftless trommel. The feeding unit comprises a feeding frame 1 and a bin, wherein the feeding frame 1 is in driving connection with a belt 1, and the bin is connected to the end, away from the smashing unit, of the belt 1 in a covering mode. The smashing unit comprises a smashing box, a feeding frame 2 and a smashing motor, wherein the feeding frame 2 is in driving connection with a belt 2, the smashing box is located above the belt 2, and the smashing motor is fixedly connected with one side of the smashing box. The smashing motor is connected with a rotatable smashing device through a belt wheel, and the end, away from the smashing box, of the belt 2 is extended into the shaftless trommel.

Owner:李松君

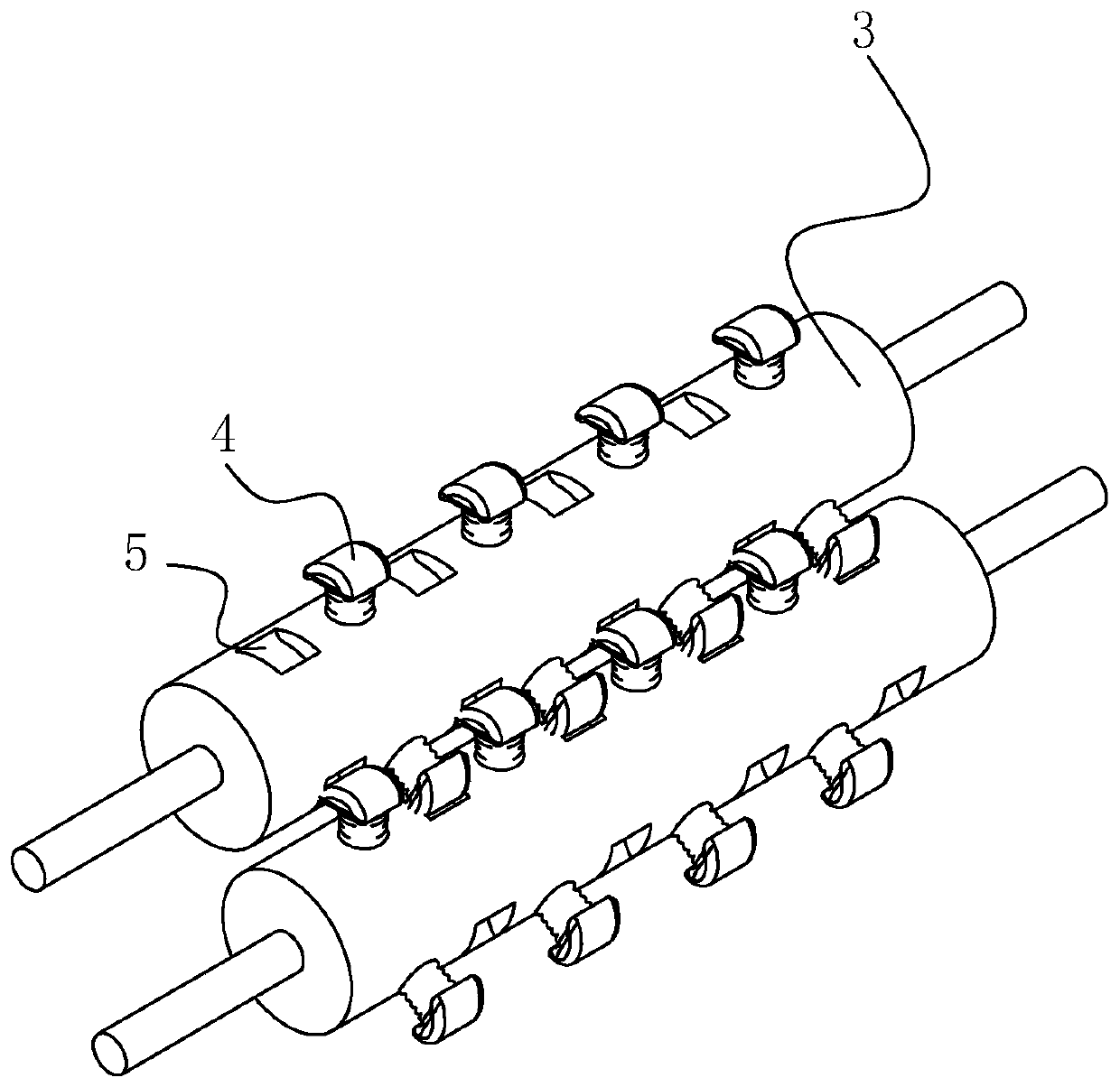

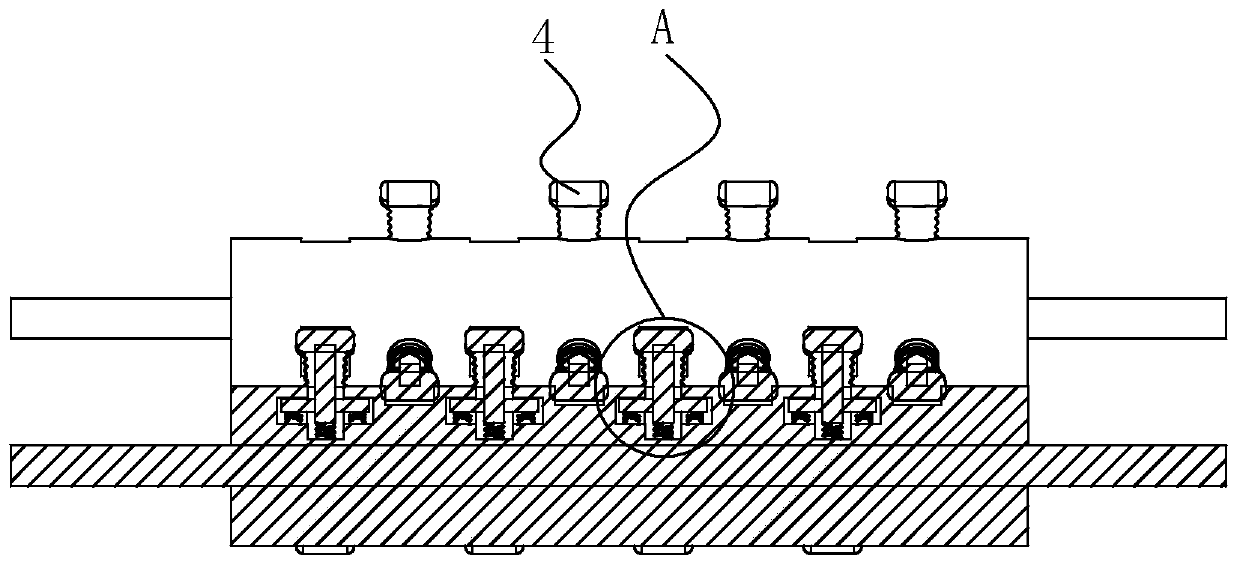

Roll crusher

The invention discloses a roll crusher, relates to the field of building material crushing, and aims at solving the problem that the crushing efficiency is influenced because a roll is liable to be damaged during material crushing of a crusher. The essential of the technical scheme is as follows: the roll crusher comprises at least two rolls which are synchronously and reversely driven, wherein crushing teeth are formed on the surrounding surface of each roll, and pits matched with the crushing teeth are formed in the roll which is matched with the previous roll; and the crushing teeth are detachably and fixedly connected to each roll. According to the roll crusher, the crushing teeth on the surface of each roll are configured to be detachable, so that replacement is facilitated, and thenthe crushing efficiency is increased.

Owner:福建泉州市宝质混凝土有限公司

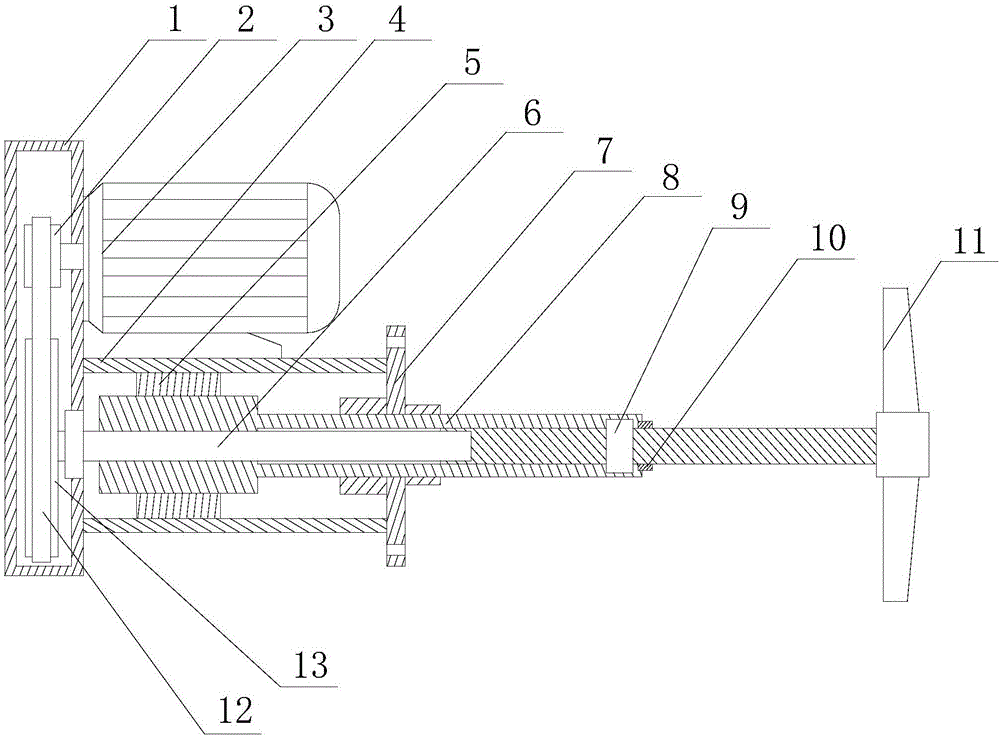

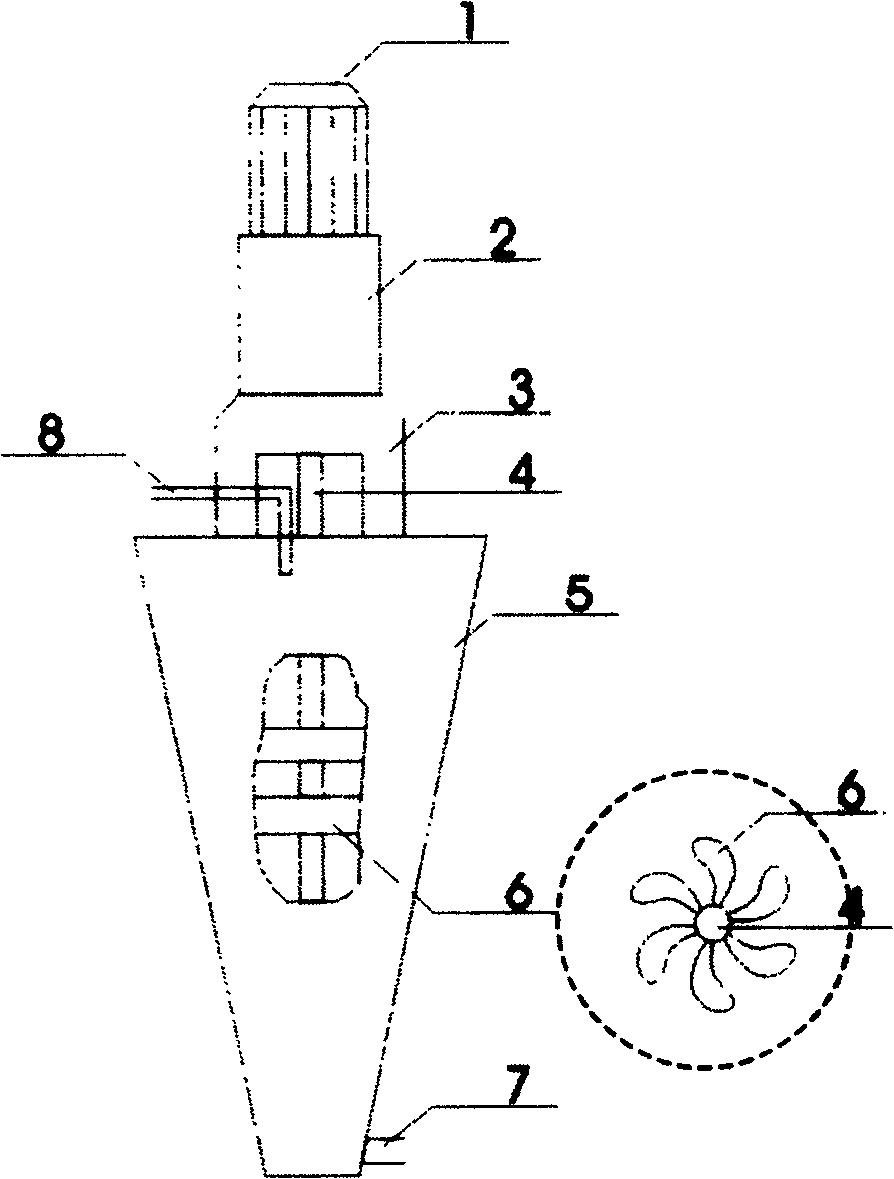

Usage method for stirring device of slurry at bottom of desulfurization tower in thermal power plant

InactiveCN107433152AGuaranteed uptimeAvoid Hard CollisionsTransportation and packagingRotary stirring mixersDrive wheelDrive shaft

The invention discloses a usage method for a stirring device of slurry at the bottom of a desulfurization tower in a thermal power plant. The method comprises the following steps: a fixed cylinder is fixed to the desulfurization tower through a flange plate, blades are placed in the desulfurization tower, an electrical machine is started, a universal driving shaft starts to rotate through linkage of a driving wheel, a belt and a driven wheel, when the universal driving shaft is rotated, a sleeve sleeves most of the universal driving shaft, annular grooves are arranged in the inner circumferential wall of the tail end of the extended segment of the sleeve, and follow-up rings of the universal driving shaft are matched with the annular grooves. According to the invention, in order to solve a problem in the prior art that when the slurry at the bottom of the desulfurization tower is stirred, stirring blades are badly damaged, a stirring and mixing working procedure applicable to slurry with relatively large solid-phase particles is designed, and stirring efficiency of the slurry is improved under the premise that the stirring blades work stably.

Owner:绵阳行之智汇知识产权服务有限公司

Vehicle height limiting system

InactiveCN106894359AReduce property damageReduce personal injury accidentsTraffic signalsRoad signsKeelAutomotive engineering

The invention provides a vehicle height limiting system. It includes a front height limit reminder device and a rear height limit rack. The front height limit reminder device is composed of a height limit infrared measurement module, an LED screen, a cross bar, and a column. The rear height limit frame is composed of a pole and a height limit rope net. At present, most highway height-limiting poles use keel-type height-limiting racks. Although they are strong, they are prone to hard damage when they collide, causing damage to vehicles and the height-limiting racks themselves, and even accidents that cause personal casualties. However, this height limit system can remind super-high drivers to stop in time. When the driver does not process through the front height limit reminder device, the rear height limit pole can stop the vehicle in time, and its traffic limit device is a height limit net, so it can reduce Property damage due to hard collision.

Owner:TIANJIN FEISI JIER TECH DEV

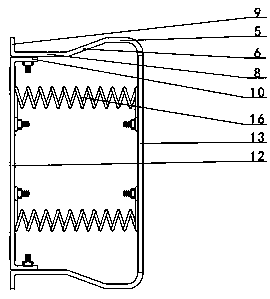

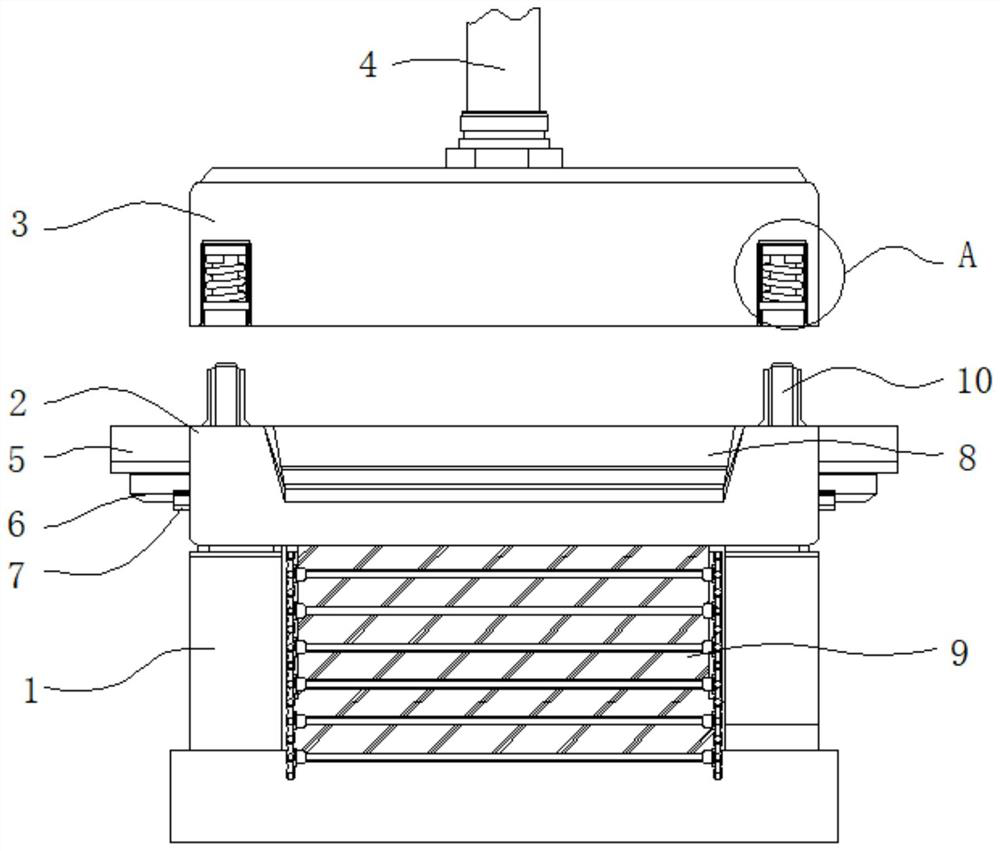

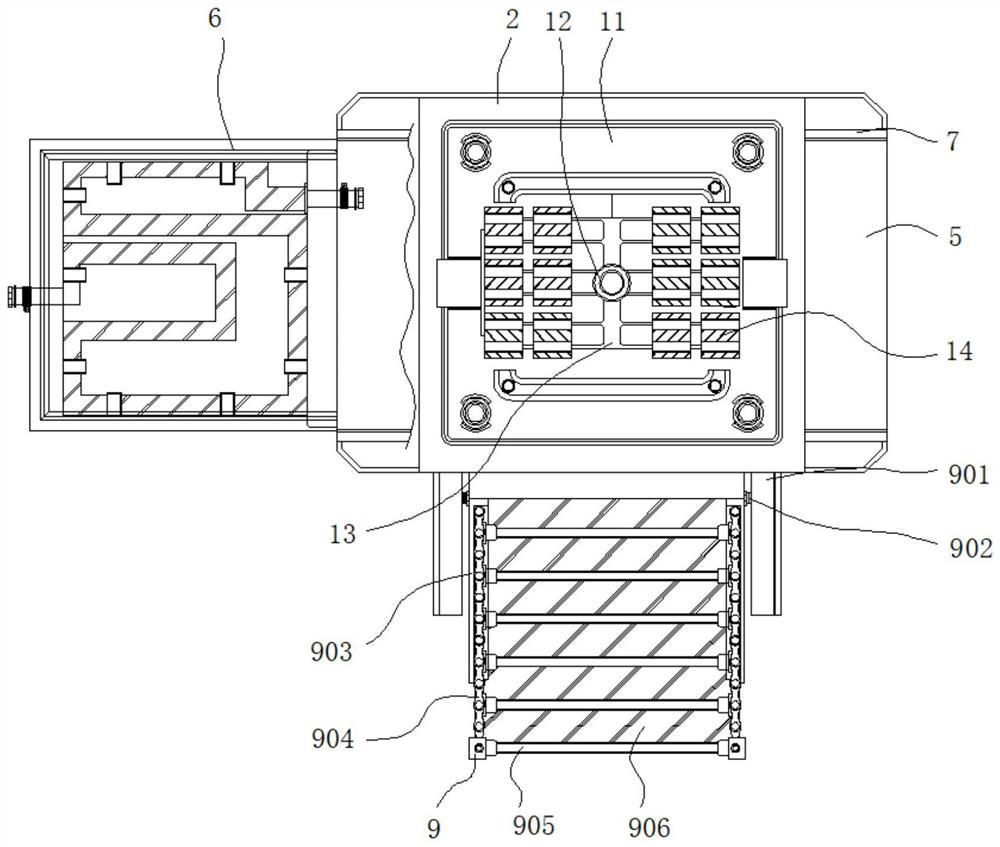

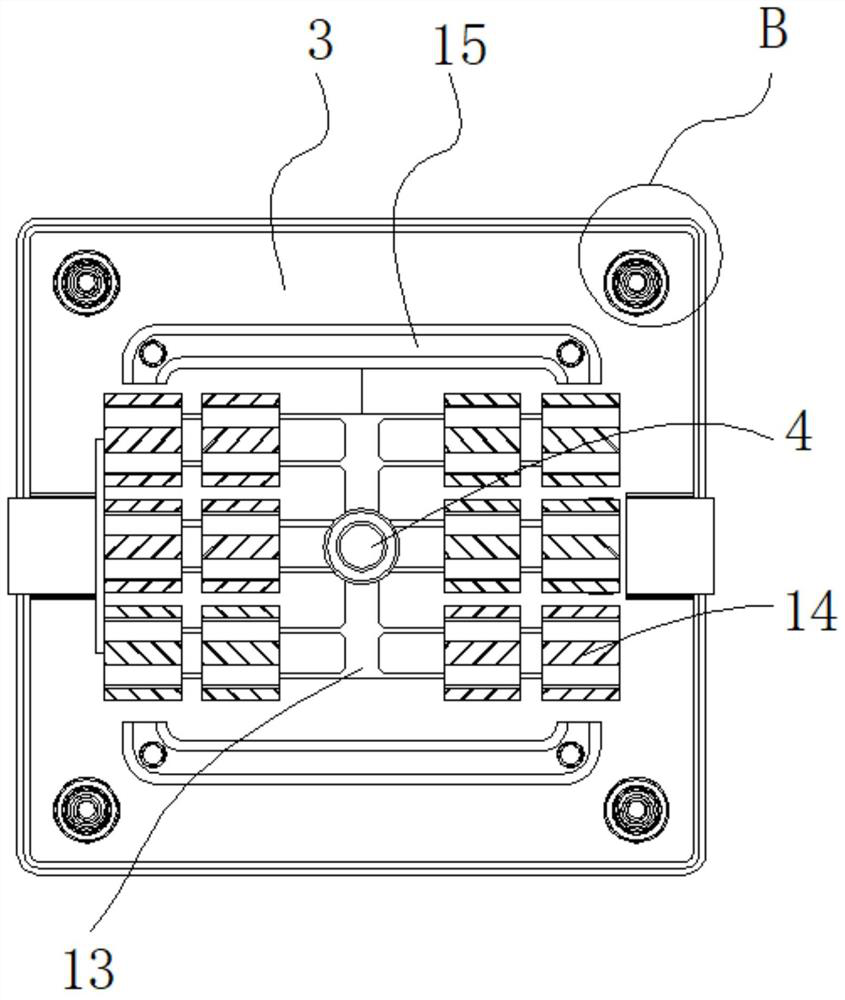

A magnetic core forming mold

ActiveCN112309701BEvenly filledStable structureMagnetic core manufactureMechanical engineeringPhysics

The invention relates to a magnetic core molding die, which includes a machine body and a cooling structure. A lower mold platform is fixed on the top of the upper end of the machine body, and an upper mold platform is arranged on the top of the upper end of the lower mold platform. The top of the upper mold platform is distributed in parallel. There is a material conveying pipeline, side sliding platforms are distributed on both sides of the upper end of the lower mold platform, and guide rails are distributed parallel to the middle part of the lower end of the side sliding platform, the inner wall of the guide rails is slidingly connected with a cooling structure, and the middle part of the lower mold platform The front end is provided with a conveying platform. In the present invention, through the arrangement of the machine body and the lower die table, the machine body and the lower die table are distributed horizontally, and the welded integral structure is formed between the machine body and the lower die table, and the entire machine body and the lower die table are used as the basic fixed structure of the equipment It is connected in the form of welding, which has a stable structure and is not easy to break, and the entire equipment is distributed horizontally, which can effectively ensure that the mold cavity is evenly filled during the pouring process.

Owner:海宁市海铖电子有限公司

A kind of cushioning and protecting component around pier columns used in bridge construction

ActiveCN111648278BImprove crash performanceReduce hard damageBridge structural detailsRoadway safety arrangementsArchitectural engineeringPier

The invention discloses a pier column peripheral buffer protection assembly for bridge construction, and relates to the technical field of bridge protection. The invention includes a pier column body; a protective mechanism is movably installed on the side of the pier column body; the protective mechanism includes two anti-collision assemblies with the same structure and connected to each other through connecting pieces; the anti-collision assembly includes an upper hoop, a middle hoop and a lower hoop. Hoop; the limit frame is hinged on the side of the lower hoop; one surface of the limit frame is hinged with two symmetrically arranged first compressive and tensile members and two symmetrically arranged second compressive and tensile members; two first compressive and tensile members are hinged. The ends of the tension parts far away from the limit frame are hinged with the middle hoop; the ends of the two second compression and tensile parts far away from the limit frame are hinged with the upper hoop. Through the design of the protection mechanism and the anti-collision component, the invention adds a buffer protection device on the basis of the traditional bridge pier column, and then effectively improves the anti-collision performance of the bridge pier column through the layout of the buffer protection device.

Owner:徐保友

Server mainboard assembling guide device

InactiveCN109807609AEliminate work wasteReduce hard damageMetal working apparatusBiomedical engineeringMotherboard

The invention discloses a server mainboard assembling guide device. The server mainboard assembling guide device comprises a positioning column; the positioning column is a cylinder, is in cooperativeconnection with a threaded hole formed in an assembling plate, and is connected with a guide head; the outer surface of the guide head is conical, the upper portion of the guide head is a smooth curved-surface head, and the guide head is matched with a positioning hole formed in a mainboard; and the diameter of the conical bottom surface of the guide head is smaller than or equal to that of the positioning hole of the mainboard. According to the server mainboard assembling guide device, through the positioning guide function, influence brought by a case is relieved, sew holes of a board cardand the mainboard are correctly aligned to a bolt of the case, the board card and the mainboard directly slide down to the correct position along the guide head, and work wasting caused by multiple times of manual adjusting is eliminated; and in addition, through the smooth design of the head of the server mainboard assembling guide device, the hard damage probability of board card components canbe greatly reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

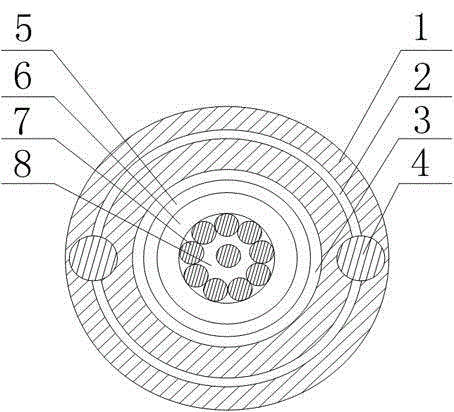

Processing method of bundle pipe type light-duty optical cable

InactiveCN104880793AReduces the chance of severe deformation to damageCompact structureFibre mechanical structuresFiberCopper wire

The invention discloses a processing method of a bundle pipe type light-duty optical cable. First of all, two copper wires and multiple annular reinforced ribs spaced at equal intervals are symmetrically arranged along the axis of a PE sheath in the PE sheath, the multiple annular reinforced ribs are sleeved on the two copper wires along the radial direction of the PE sheath, a tubular-like a support frame is formed in the PE sheath, a center sleeve is fixed at the central portion of the PE sheath, after multiple fibers are arranged in the center sleeve, then the center sleeve is filled up with a fiber paste, the inner wall of the PE sheath is enabled to be fully supported, and thus processing of the optical cable is completed. When the optical cable encounters a corner or an area section with quite large bending amplitude, the PE sheath is deformed and distorted, at the moment, portions disposed inside the PE sheath extrude one another, the tubular frame formed by the copper wires and the reinforced ribs inside the PE sheath is correspondingly deformed in response to borne distortion stress so as to buffer the stress effect transmitted by the PE sheath to the sleeve and reduce the probability that the PE sheath is severely deformed and damaged.

Owner:成都亨通光通信有限公司

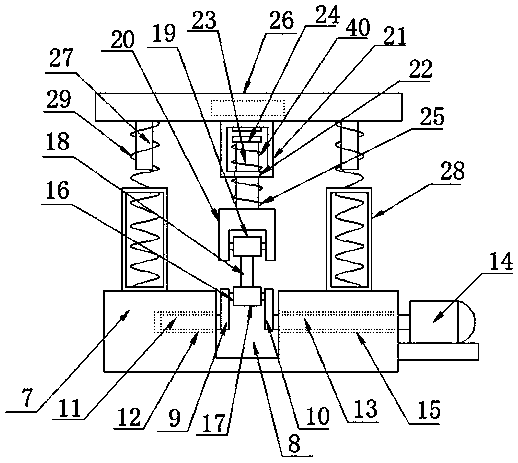

Anti-collision damping device for reversing

InactiveCN104442656BReduce harmEffective protectionUnderstructuresVehicular safety arrangmentsHydraulic cylinderTruck

The invention provides a reversing anti-collision shock reduction device, and relates to a rear anti-collision device of a medium carrier vehicle. A plurality of beams are arranged between two longitudinal girders (5) from front to rear to form a crossbeam of the medium carrier vehicle. A connection plate (21) is fixedly connected with the rear portions of the two longitudinal girders (5). At least two hydraulic cylinders (23) are fixed to the lower portion of the connection plate (21) through a hydraulic cylinder fixing plate (16). Pistons (24) of the at least two hydraulic cylinders (23) are fixedly connected with an anti-collision shock reduction plate (15) on the rear portion to form the reversing anti-collision shock reduction device. According to the reversing anti-collision shock reduction device, the anti-collision shock reduction plate is arranged on the lower portion of the rear end of the crossbeam of the medium carrier vehicle and is protected by the hydraulic cylinders and a spring, the harm, caused by vehicle collision, to the crossbeam can be partially defused, and the situation that a car is plunged in the bottom of a truck and the driver of the car and passengers are dead can be reduced.

Owner:HENAN VOCATIONAL & TECHN COLLEGE OF COMM

An extrusion type electronic circuit board production equipment

ActiveCN108617096BGuarantee the quality of pressingOffset hard resistance forceCircuit board tools positioningMultilayer circuit manufactureStructural engineeringMechanical engineering

The invention discloses extrusion-type electronic circuit board production equipment comprising a processing casing; an inlet is arranged in middle of the front end of the processing casing; hinges are symmetrically fixed on the left side of the front end of the inlet; a door plate is fixedly connected on the right side of the hinges; an air inlet hole is arranged in middle of the left end of theprocessing casing; a leak net plate is fixed on the inner wall of the air inlet hole; an air outlet hole is arranged on the upper side of the right end of the processing casing; an air outlet pipe isfixedly connected on the right port of the air outlet hole; the elastic force of a bevel spring can cancel a hard press force of a pressure plate on multi-layer circuit boards, thus reducing hard damages on the multi-layer circuit boards by the pressure plate in a lamination process; when an exhaust fan rotates to suck air, substrate powders and impurities are discharged onto a cloth boa inner wall; the air can be discharged via cloth bag apertures, thus effectively absorbing the substrate powders and impurities in the processing casing, and ensuring the compacting quality of the multi-layer circuit boards.

Owner:信丰达诚科技有限公司

Mixing device for desulfurization of flue gas generated by thermal power generation

InactiveCN107398199AGuaranteed uptimeAvoid Hard CollisionsGas treatmentRotary stirring mixersDrive wheelFlue gas

The invention discloses a mixing device for desulfurization of flue gas generated by thermal power generation. The mixing device comprises a tank body, a motor and a fixing cylinder, wherein the motor is arranged on the fixing cylinder; a driving wheel is mounted on the extension section of the output end of the motor; the outer circumferential wall of a linking shaft is sleeved by a sleeve; one end of the sleeve penetrates through a flange disc and extends outwards; secondary blades are fixed on the outer circumferential wall of the extension section of the sleeve; the other end of the sleeve is arranged inside the fixing cylinder; a linking column is connected with one end of the sleeve; a cavity is formed inside the linking column; an inner tooth belt is arranged on the inner circumferential wall of the cavity; a gear is arranged on the linking shaft; one end of the linking shaft sequentially penetrates through the cavity and the rear wall of the tank body and extends continuously; a driven wheel is mounted on the extension section of the linking shaft; and main blades are mounted at the tail end of the linking shaft. Aiming at the problem that a conventional stirring blade is seriously damaged, the inventor designs a slurry stirring and mixing procedure which is applicable to relatively large solid-phase granules, namely, on premise that stable operation of stirring blades is ensured, the slurry stirring efficiency is improved.

Owner:绵阳行之智汇知识产权服务有限公司

A starting mechanism of a mechanical timekeeping watch

ActiveCN103472705BGuaranteed to workReduce hard damageAcoustic indicationClockwork casesRubber ringMechanical engineering

Owner:TIANJIN SEAGULL WATCH CO LTD +1

Quality treating method of ceramic frit

This invention discloses a ceramic glaze improving method, including the following procedures: carry out supermicro refining treatment to ceramic glaze, dry the powder after being refined to get the finished product. The good effect of this invention relies in: refining the glaze can greatly shorten the calcining time and also decrease the using amount of glaze. It saves the energy and lowers the cost. And the ceramic calcined has good performance, and the surface glassiness and water absorption are better than the conventional glaze product.

Owner:广西蒙娜丽莎新材料有限公司

Traction head

The invention provides a traction head. The traction head comprises a traction base, a stretching arm, a stretching port, a stretching arm sleeve and support springs, wherein the stretching arm sleeve is welded on the traction base; the main body part of the stretching arm is arranged in the stretching arm sleeve; the stretching port is welded at one end of the stretching arm; a bolt and a nut are assembled at the other end of the stretching arm; the support springs are arranged at the two ends of the stretching arm in a sleeving manner respectively. According to the traction head, the support springs and the movable stretching arm are adopted, so that hard damages between the traction head and a traced machine are reduced; a cast steel material of a reinforced plate is used, so that the traction head is firmer and resistant to wear, and the service life of the traction head is prolonged; the other end of the stretching arm is provided with a thread, and is matched with the bolt and the nut, so that convenience is brought to replacement even the traction head is damaged, time and labor are saved, and resources are saved.

Owner:江苏翔宇灌溉设备有限公司

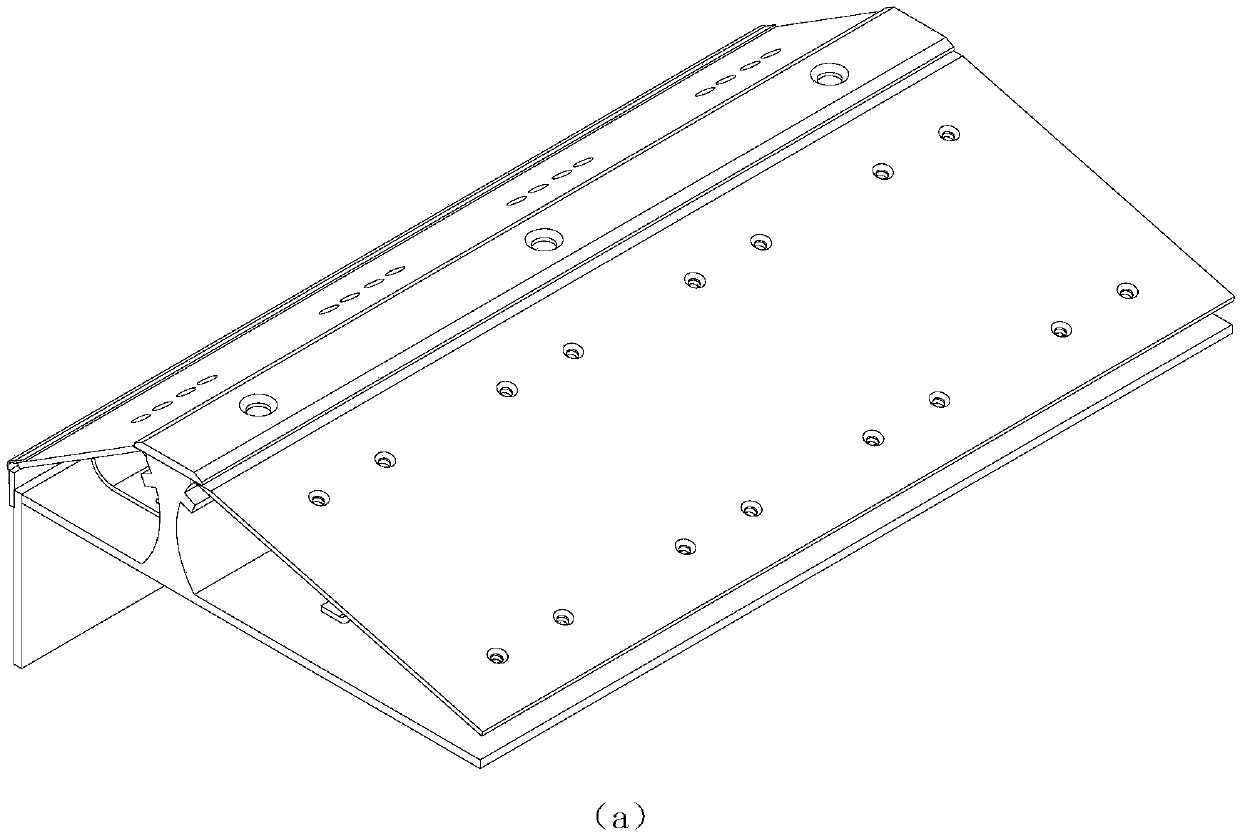

Step decoration seat with buffering, power assisting and knee protecting functions

The invention discloses a step decoration seat with buffering, power assisting and knee protecting functions. The step decoration seat comprises an anti-slip rubber layer, an alloy bearing plate component group, an alloy base plate and a plurality of alloy plate springs. The alloy base plate is fixed to the step surface, the alloy bearing plate component comprises two alloy bearing plates, the alloy bearing plates and the alloy base plate completely cover the step surface to form a roof shape integrally, the whole roof-shaped structure surface is provided with the anti-slip rubber layer and covers the step edge, and the alloy plate springs support the alloy bearing plates. The anti-slip rubber layer forms a first buffering wave face, the bearing plate component group is capable of dispersing stress to a maximum extent, a second buffering wave face is formed after combination with the alloy plate springs, and reverse impact is weakened under the joint action. The bearing plates in slopestructures provide ascending and descending angular support and jointly act with the anti-slip rubber layer, and ascending power assistance and descending resistance can be increased by the gradient.In addition, an ergonomic design is adopted for surfaces of the bearing plates and accords with human skull or kneecap contours to reduce injuries as far as possible.

Owner:杭州李春环境科技有限公司

A kind of straightening equipment for steel wire rope production

ActiveCN113564947BReduce hard damageAvoid damageRope making machinesHydraulic cylinderIndustrial engineering

Owner:南通银龙钢绳有限公司

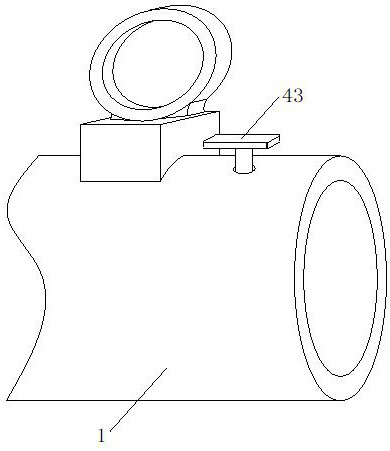

Electromagnetic flowmeter scale cleaning device capable of improving precision

InactiveCN114018347AReduce hard damageImprove efficiencyVolume meteringVolume/mass flow by electromagnetic flowmetersMechanical engineeringElectromagnetic flowmeter

The invention discloses an electromagnetic flowmeter scale cleaning device capable of improving precision. The electromagnetic flowmeter scale cleaning device comprises a flowmeter pipeline, mounting blocks are symmetrically and fixedly mounted on the inner wall of the top and the inner wall of the bottom of the flowmeter pipeline, and a set of paired measuring electrodes are mounted at the left ends of the two mounting blocks in an embedded mode; cleaning mechanisms are arranged in the two mounting blocks, cleaning fluid is led into the flowmeter pipeline by powering off, so that the cleaning fluid drives a cleaning wheel to be close to the bottom surface of the measuring electrode through the cleaning block, and dirt on the bottom surface of the measuring electrode is scraped by a mud scraping convex block with a frosted coating through rotation of the cleaning wheel, part of scraped dirt can be taken away in cooperation with introduced cleaning fluid, due to the fact that the flux of the cleaning fluid changes in real time, the cleaning block can drive the cleaning wheel to rub the measuring electrode left and right back and forth, cleaning work is completed, and hard damage to the measuring electrode can be reduced by arranging the mud scraping protruding block to be made of sponge materials.

Owner:CHINA JILIANG UNIV

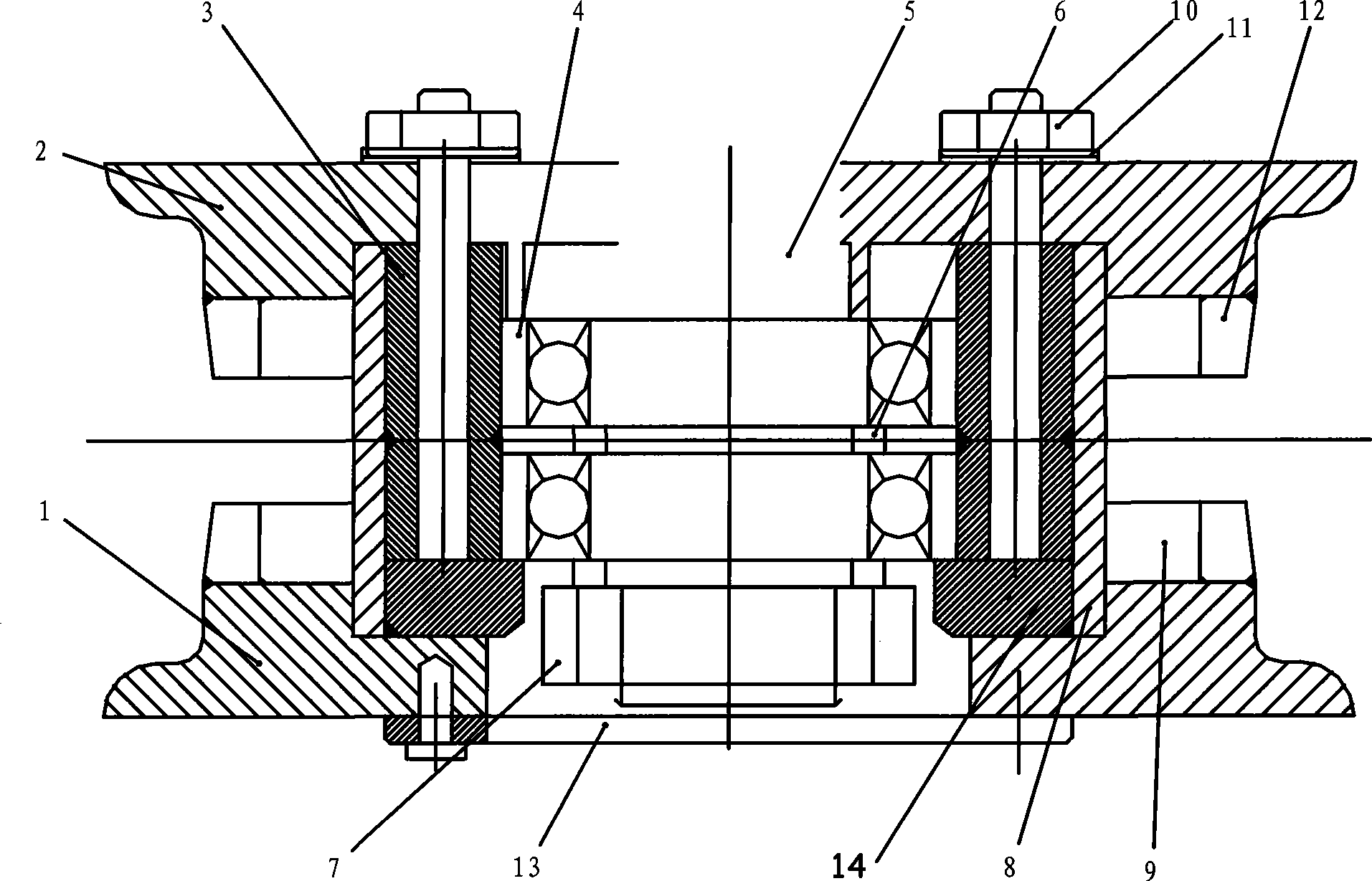

Supporting wheel hub and manufacture method thereof

InactiveCN101391559AEasy to installSolve the problem of difficult movement without tracksHubsBall bearingSteel tube

The invention provides a supporting hub and a manufacturing method thereof, relating to the technical field of the supporting hub which is used for supporting a solid rubber tyre, in particular to a supporting hub which is applicable to the trackless movement of a mine movable substation. The supporting hub comprises an external side hub, an internal side hub, a bearing sleeve, a ball bearing, a shaft, a nut, a steel pipe sleeve, a hub ring, a bolt and a cover plate; the external side hub is arranged correspondingly to the internal side hub; the bearing sleeve is arranged between the external side hub and the internal side hub and connected with the internal side hub by the bolt; the bearing sleeve is internally provided with the ball bearing which is internally provided with the shaft; one side of the shaft close to the external side hub is provided with the nut; the external side of the bearing sleeve is provided with the steel pipe sleeve; the external side of the steel pipe sleeve is provided with the hub ring which is arranged between the external side hub and the internal side hub; one side of the external side hub far away from the internal side hub is provided with the cover plate which is connected with the external side hub by the bolt. The supporting hub achieves the objects that the structure is simple and easy for installation and maintenance and solves the trackless movement problem of the mine substation.

Owner:CHINESE ELECTRICAL EQUIP GRP CO LTD

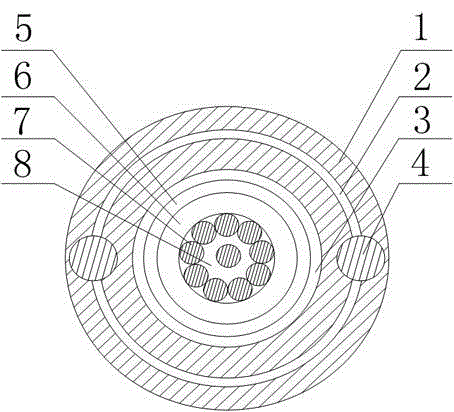

Beam tube type light optical cable

InactiveCN104914528AReduces the chance of severe deformation to damageCompact structureFibre mechanical structuresFiberCopper wire

The invention discloses a beam tube type light optical cable comprising a PE sheath and a central bushing which is arranged at the middle part of the PE sheath. Fiber paste is filled in the central bushing, and multiple optical fibers are fixed in the central bushing. Two copper wires are symmetrically arranged in the PE sheath along the axis of the PE sheath. The beam tube type light optical cable also comprises multiple annular reinforcing ribs which are arranged in the PE sheath. The multiple reinforcing ribs equidistantly sleeve the two copper wires in a spacing way along the radial direction of the PE sheath. The PE sheath deforms and warps when encountering a corner or a regional section with higher degree of bending, all the parts arranged in the internal part of the PE sheath mutually extrude at the time, and a tubular framework formed by the copper wires and the reinforcing ribs in the PE sheath correspondingly deforms according to the affected torsional stress so as to buffer the stress effect of the PE sheath transmitted to the bushing and reduce the probability of severe deformation and even damage to the PE sheath.

Owner:成都亨通光通信有限公司

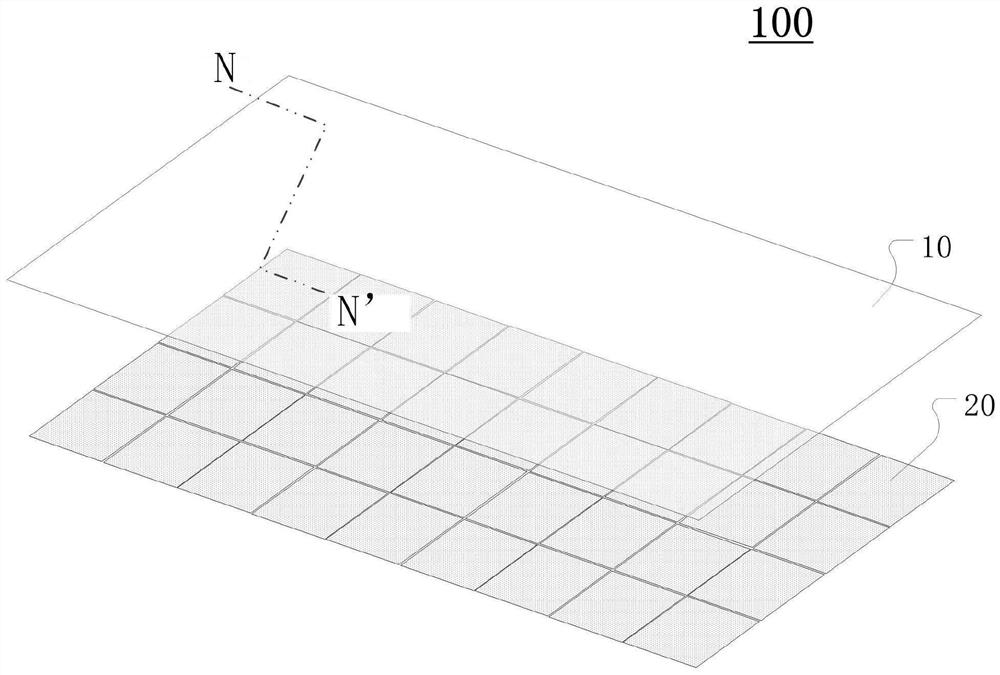

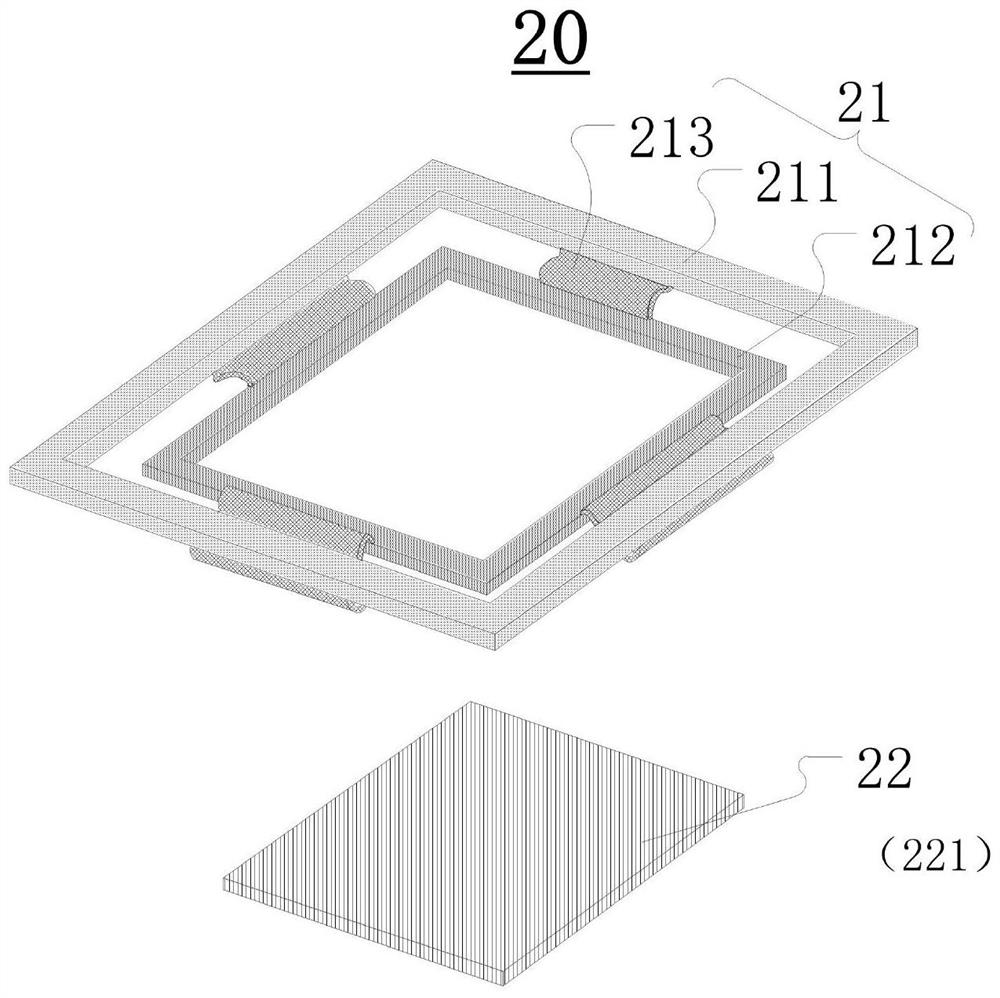

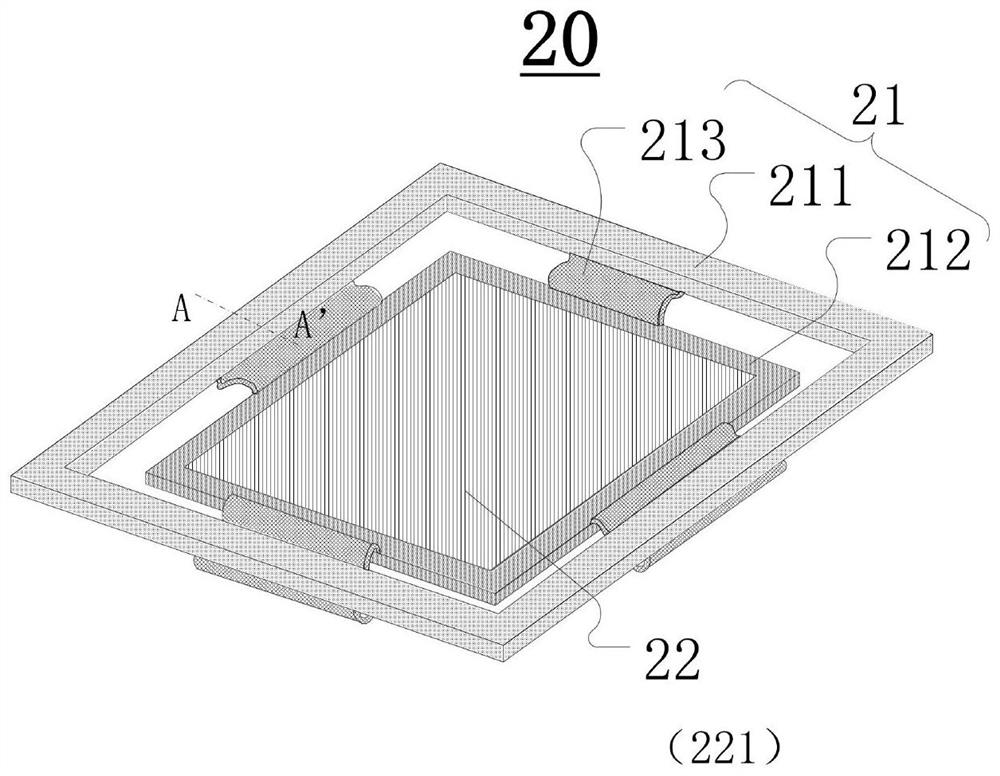

Heat dissipation assembly, display device and assembling method of display device

ActiveCN113450668AReduce hard damageAvoid damageCooling/ventilation/heating modificationsIdentification meansDisplay deviceEngineering

The invention provides a heat dissipation assembly, a display device and an assembling method of the display device, and relates to the technical field of display. The heat dissipation assembly comprises a back plate base body and a heat dissipation module located on one side of the back plate base body, and the heat dissipation module comprises a frame and a heat conduction piece. The frame comprises a first sub-frame, a second sub-frame and an elastic connecting piece; the first sub-frame is fixedly connected with the back plate base body, the elastic connecting piece is connected with the first sub-frame and the second sub-frame, and the heat conduction piece is fixedly connected with the second sub-frame; the orthographic projection of the first sub-frame on the plane where the back plate base body is located surrounds the orthographic projection of the second sub-frame on the plane where the back plate base body is located; the heat dissipation assembly comprises a first state and a second state; in the first state, in the direction perpendicular to the plane where the back plate base body is located, the distance between the heat conduction piece and the back plate base body is H1, and H1 is larger than 0; and in the second state, the heat conduction piece is in contact with the back plate base body. The elastic heat dissipation assembly can be completely attached to the display panel, and damage to the display panel is avoided.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com