Roll crusher

A technology of roller crusher and crushing teeth is applied in the field of building material crushing, which can solve the problems of hard damage of crushing teeth, easy wear of crushing teeth, weak local force strength of crushing teeth, etc., so as to reduce the probability of damage and facilitate replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

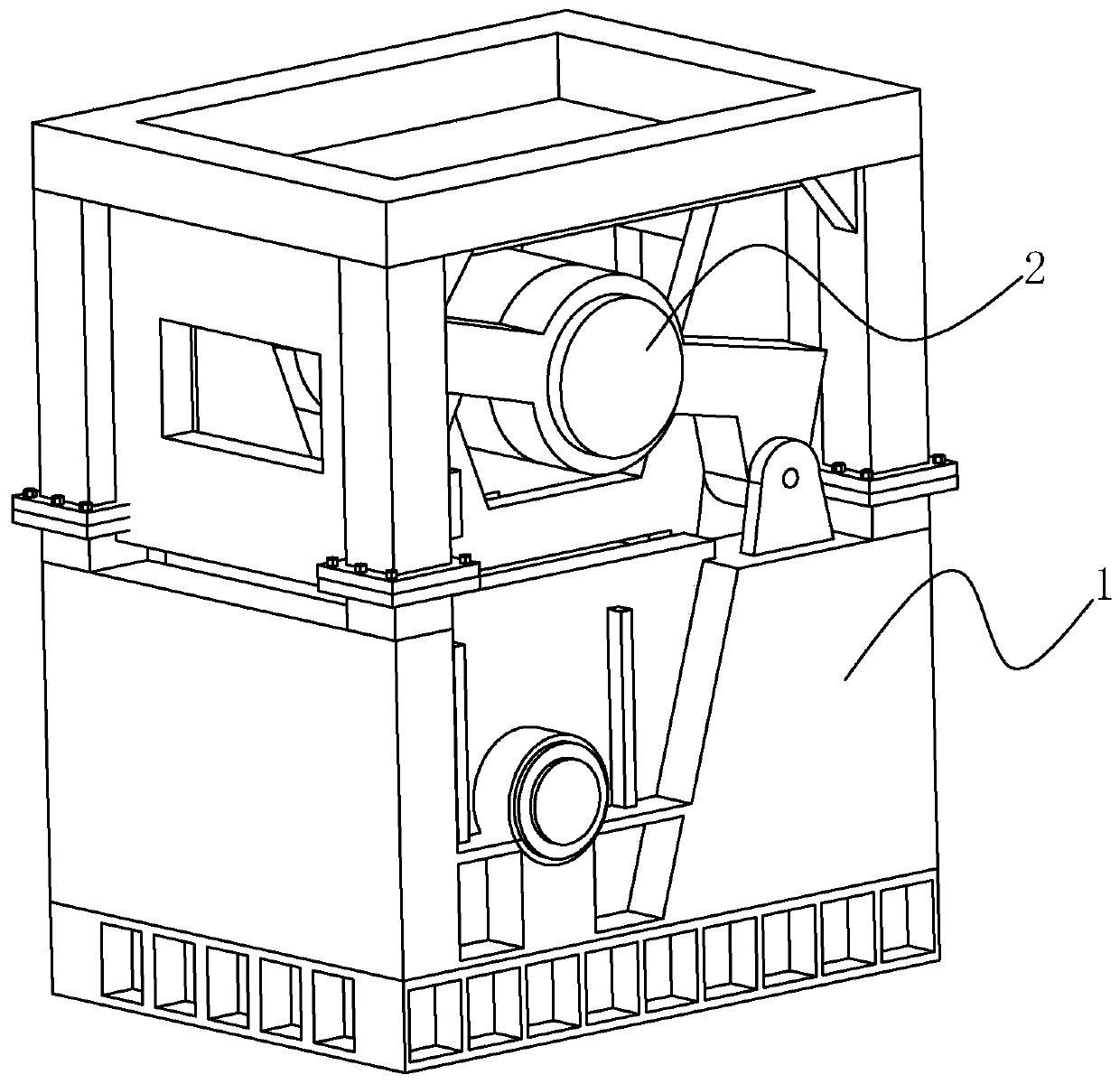

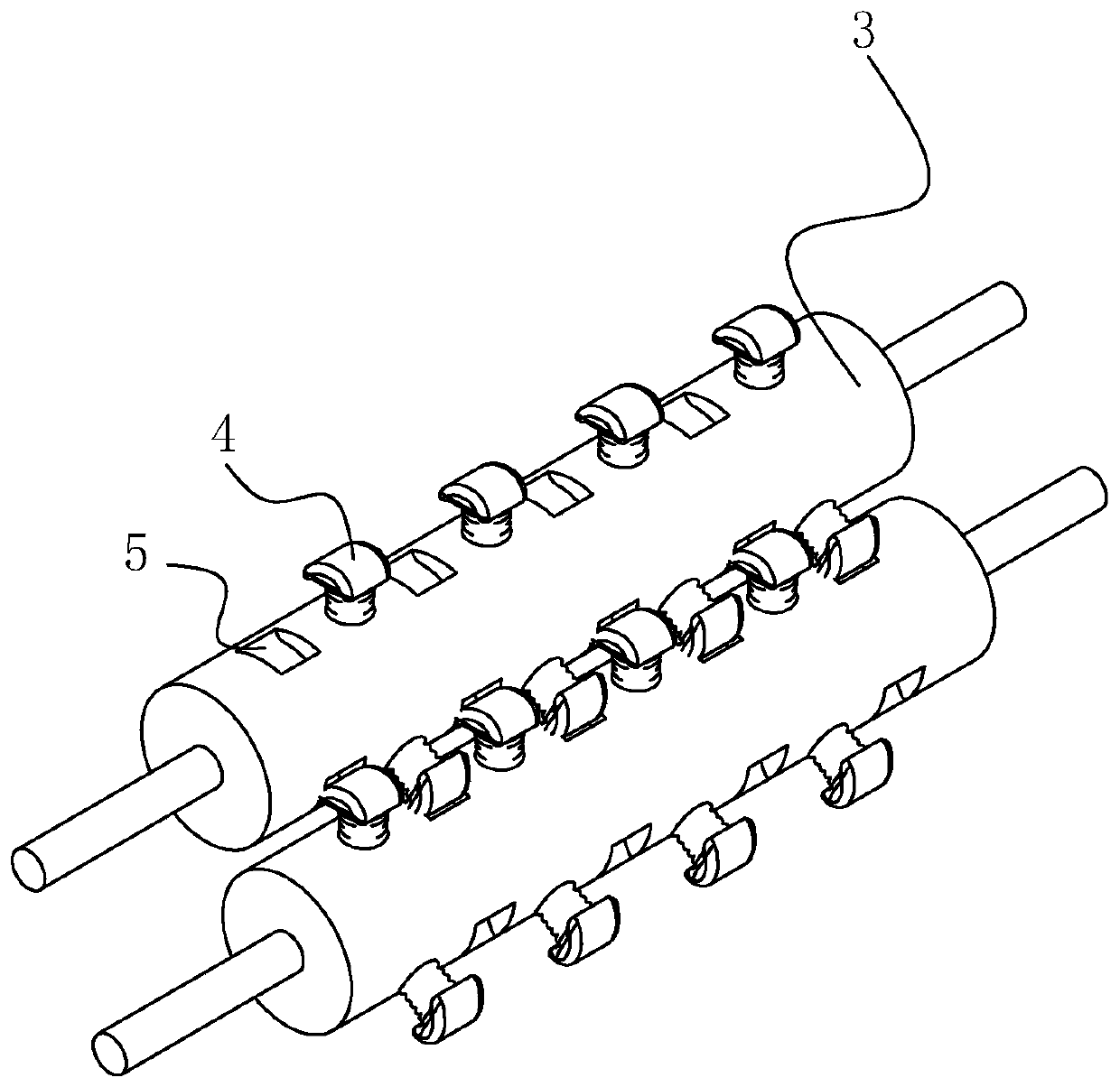

[0032] Embodiment one: roller mill, such as figure 1 and figure 2 As shown, the crushing chamber 2 driven by the motor through the pulley is installed on the frame 1, and the rollers 3 are installed in the crushing chamber 2. The rollers 3 are arranged in groups, which can be set in two or more groups for multiple crushing. Each group of rollers 3 cooperate with each other, and a plurality of crushing teeth 4 are installed on the surrounding surface of each roller 3, and a pit 5 is provided at the same time for the crushing teeth 4 on the matching roller 3 to extend in, thereby crushing the material.

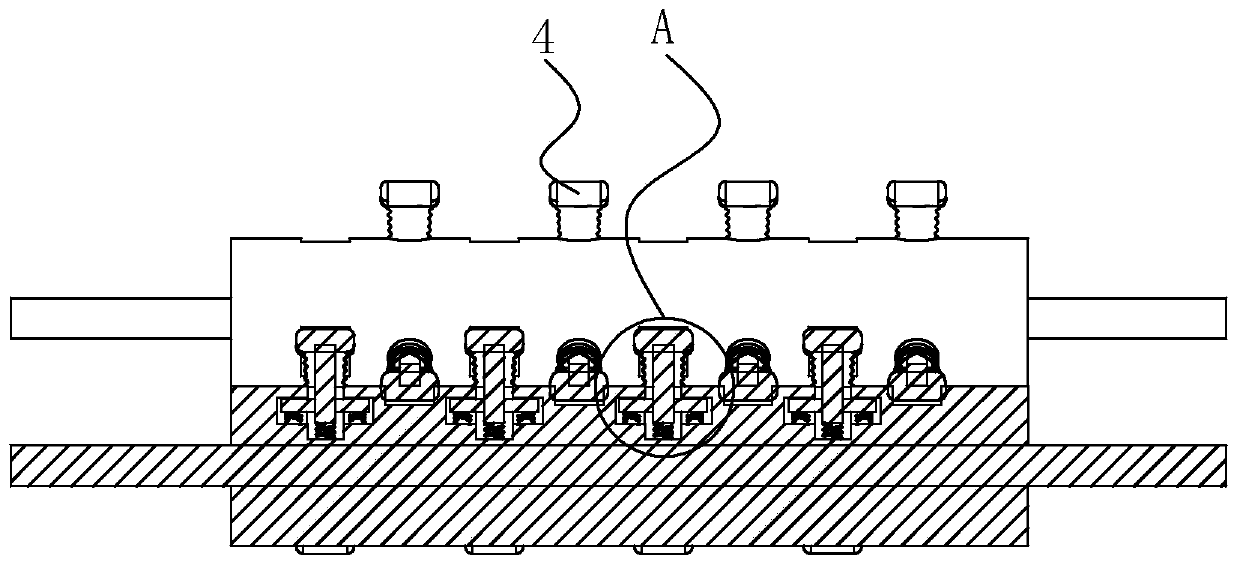

[0033] When installing the crushing teeth 4, the crushing teeth 4 are installed in a detachable manner. First, an installation groove 6 is provided on the surrounding surface of the roller 3. The crushing teeth 4 can be directly stuck in the installation groove 6, and fixed by interference fit. In this way, when disassembly is needed in the later stage, the crushing teeth 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com