Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Increase the crushing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jaw crusher

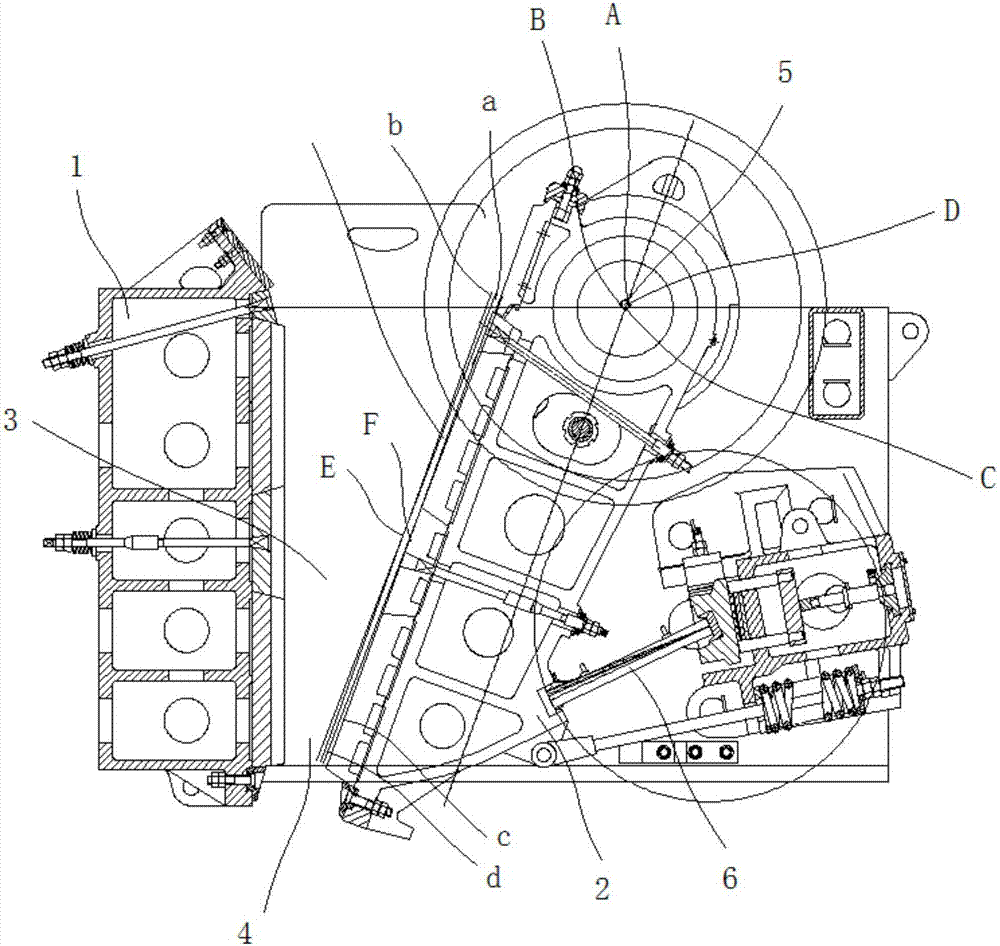

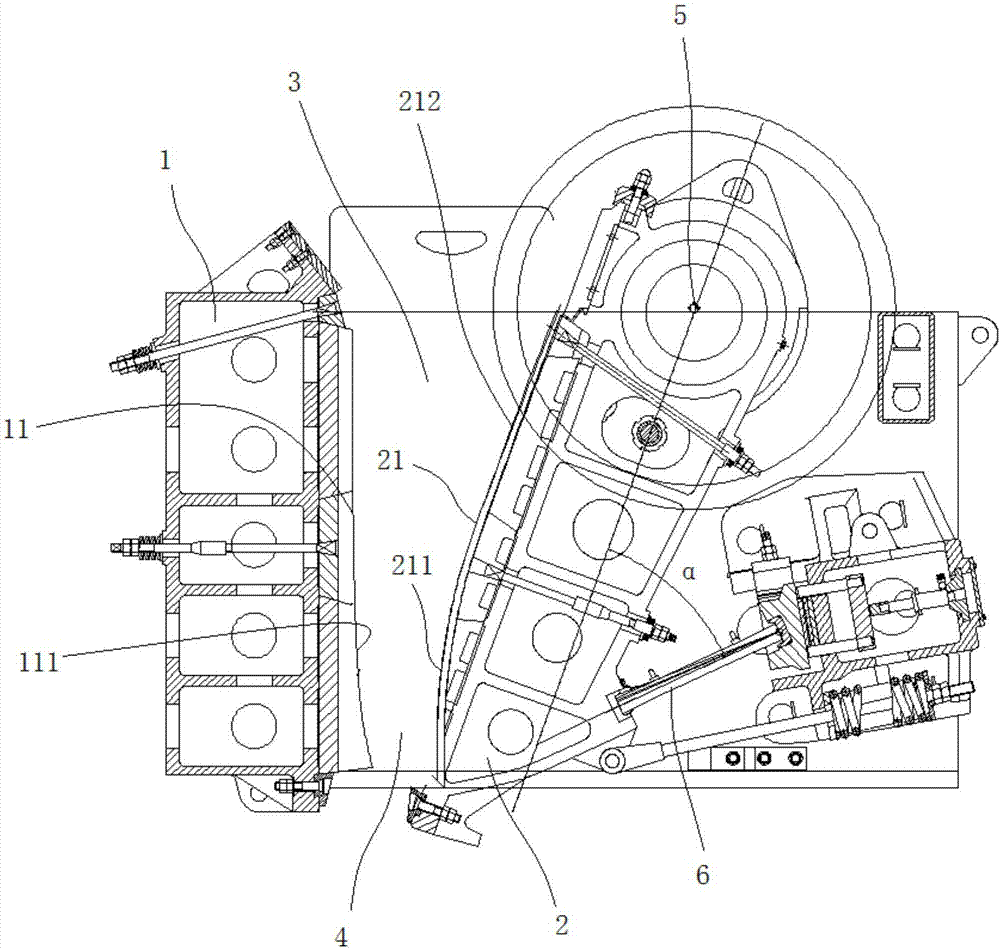

The invention discloses a jaw crusher. The jaw crusher comprises a fixed jaw with a fixed jaw crushing face and a movable jaw with a movable jaw crushing face. A crushing cavity is formed between the movable jaw crushing face and the fixed jaw crushing face. A discharging port is formed in the bottom of the crushing cavity. The movable jaw gets close to or gets away from the fixed jaw under the joint action of a spindle and a toggle plate of the jaw crusher. The position, close to the position of the discharging port, of the movable jaw crushing face is provided with a first hook face crushing face, and the first hook face crushing face deviates and extends in the direction away from the fixed jaw when extending towards the discharging port. When materials in the crushing cavity need to be discharged, the upward force applied to the materials through the first hook face crushing face can be reduced, or the upward force is not applied to the materials any more, and therefore material rising is reduced or the materials do not rise again any more in the material falling process, centralized abrasion on the movable jaw crushing face from the materials is reduced or centralized abrasion on the movable jaw crushing face from the materials cannot be caused, the discharging efficiency is improved, and the movable jaw crushing face is not prone to damage.

Owner:NENGCHENG GRP

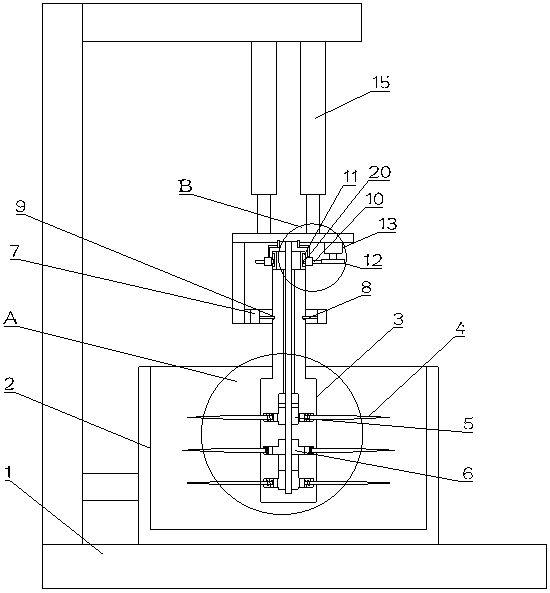

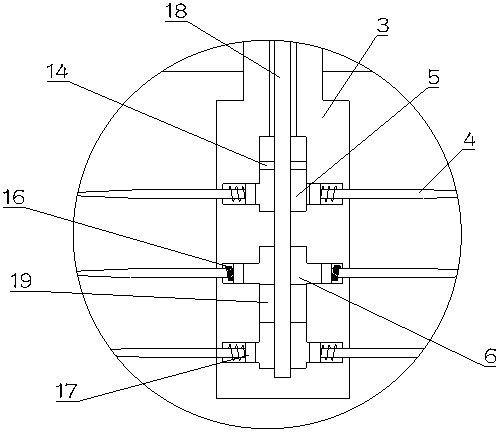

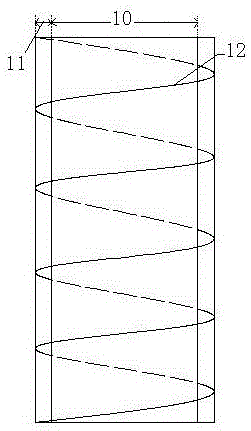

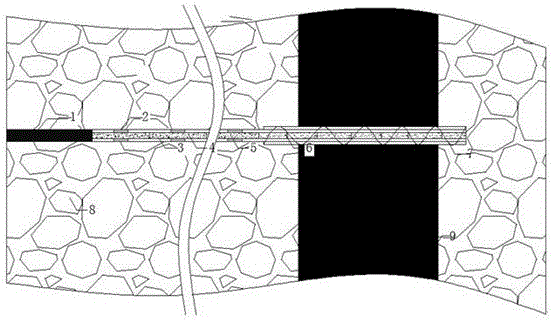

Boring system of rotary dual jet flows under high pressure, and rotary dual jet flows nozzle under high pressure

InactiveCN1959058AIncrease the crushing areaImprove utilization efficiencyLiquid/gas jet drillingEnergy transferJet flow

The present invention relates to a high-pressure rotary double-jet drilling method. It is characterized by simultaneously using rotary jetting method and straight jetting method. Said rotary jetting method can form large energy transfer area zone in targent zone and the straight jetting method can partially form energy transfer area zone in the centre of target zone, the rotary jetting method and straight jetting method are formed into a mutual shearing relationship, the mutual shear of the above-mentioned two jetting methods can produce cavitation action. The high-pressure rotary double-jet nozzle used for said method includes external nozzle and internal nozzle; said internal nozzle is placed in the external nozzle interior. Said invention can make straight jetting method and rotary jetting method be combined together so as to raise utilization efficiency of jetting energy and can drill metal or high-strength non-metal material.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

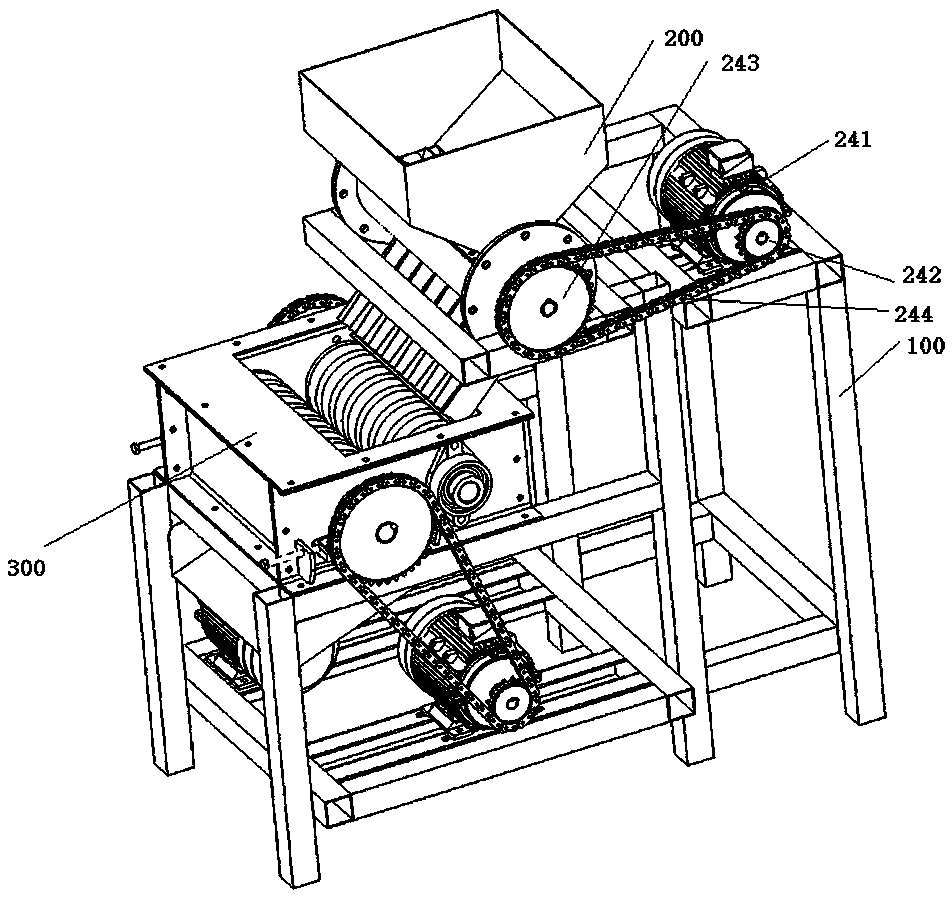

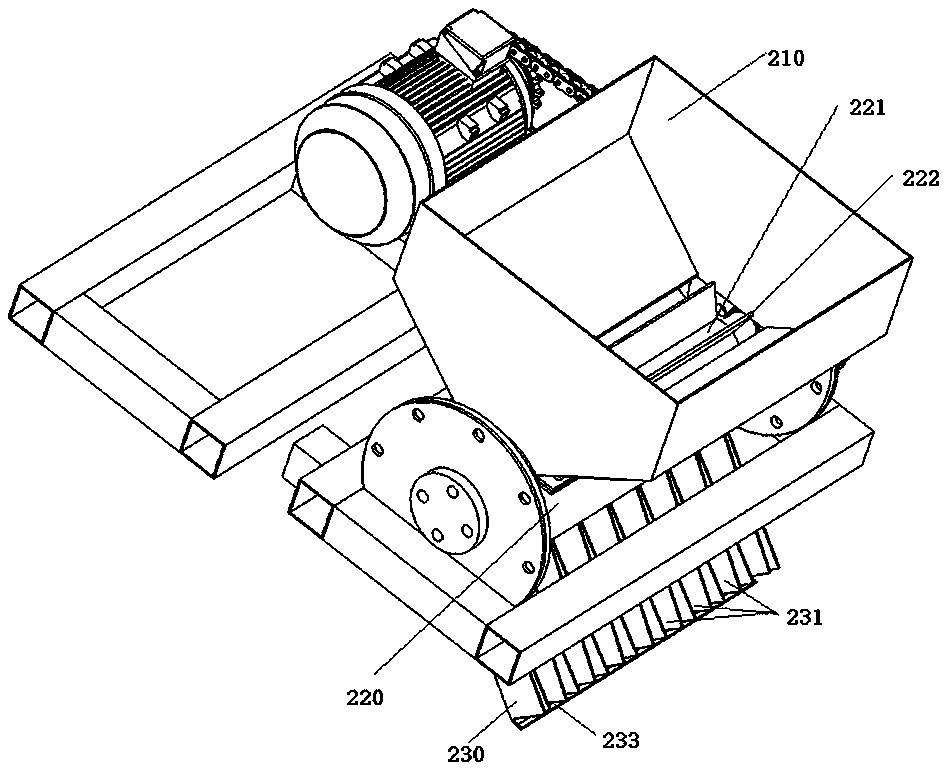

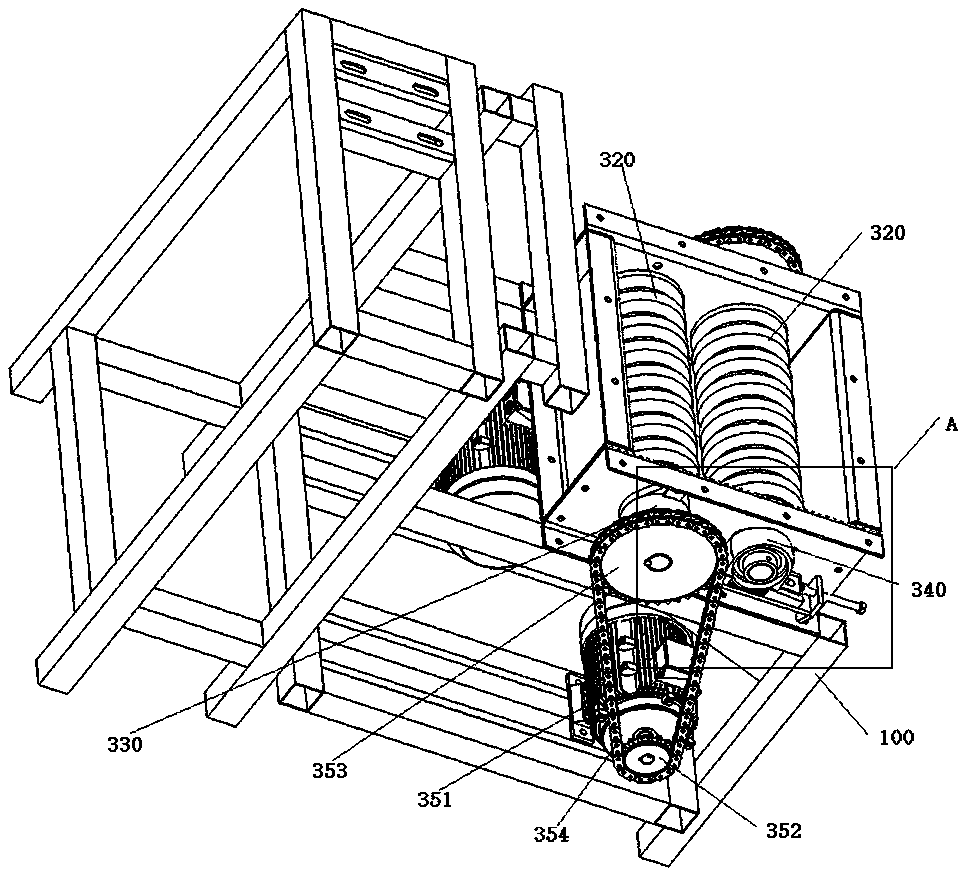

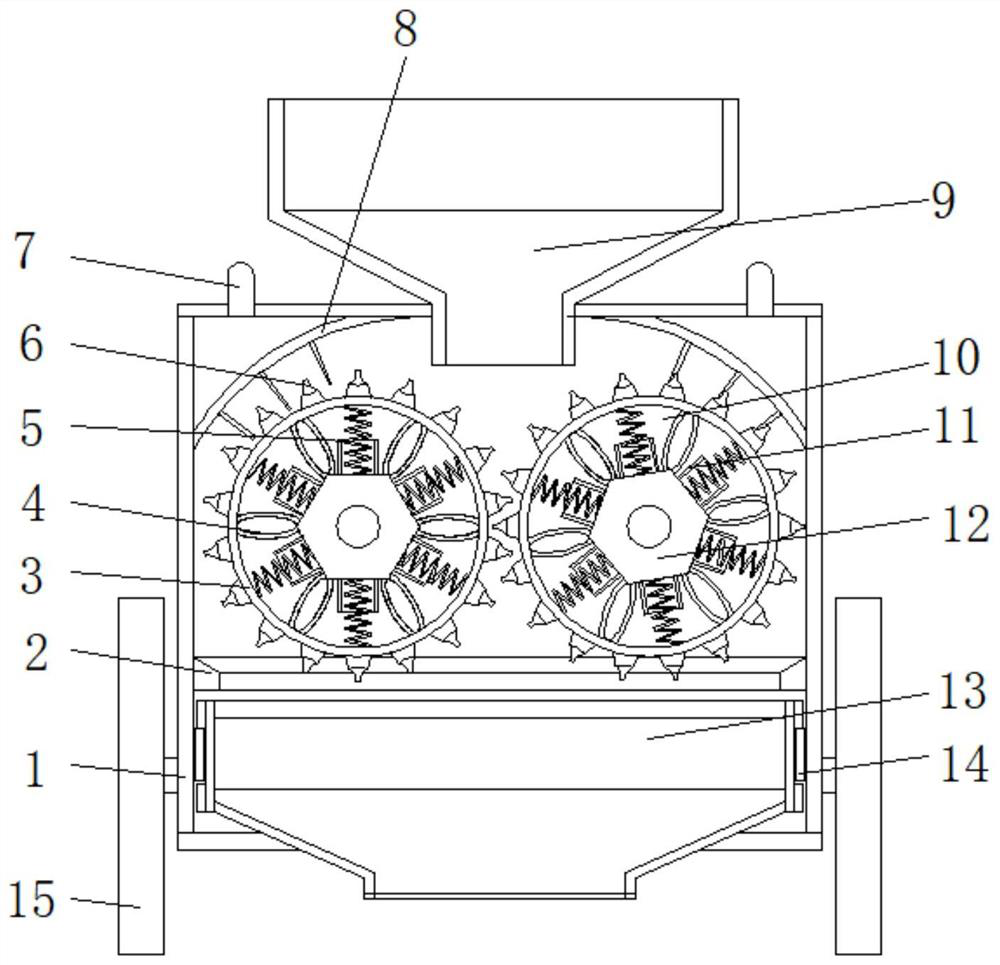

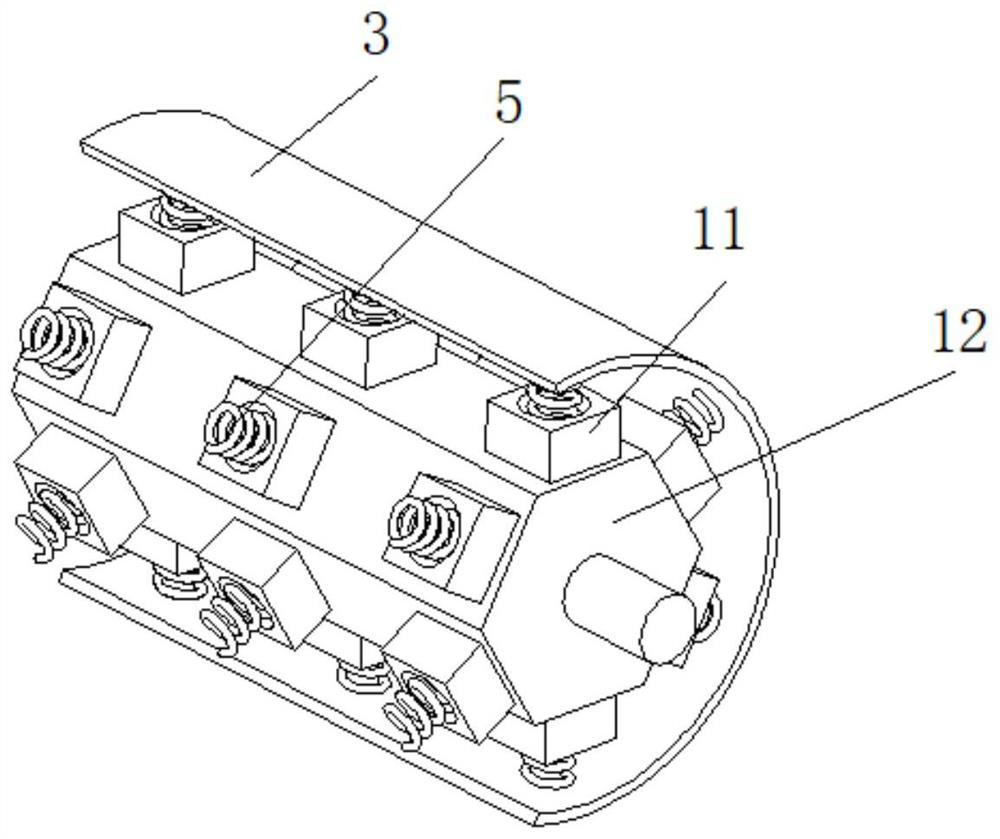

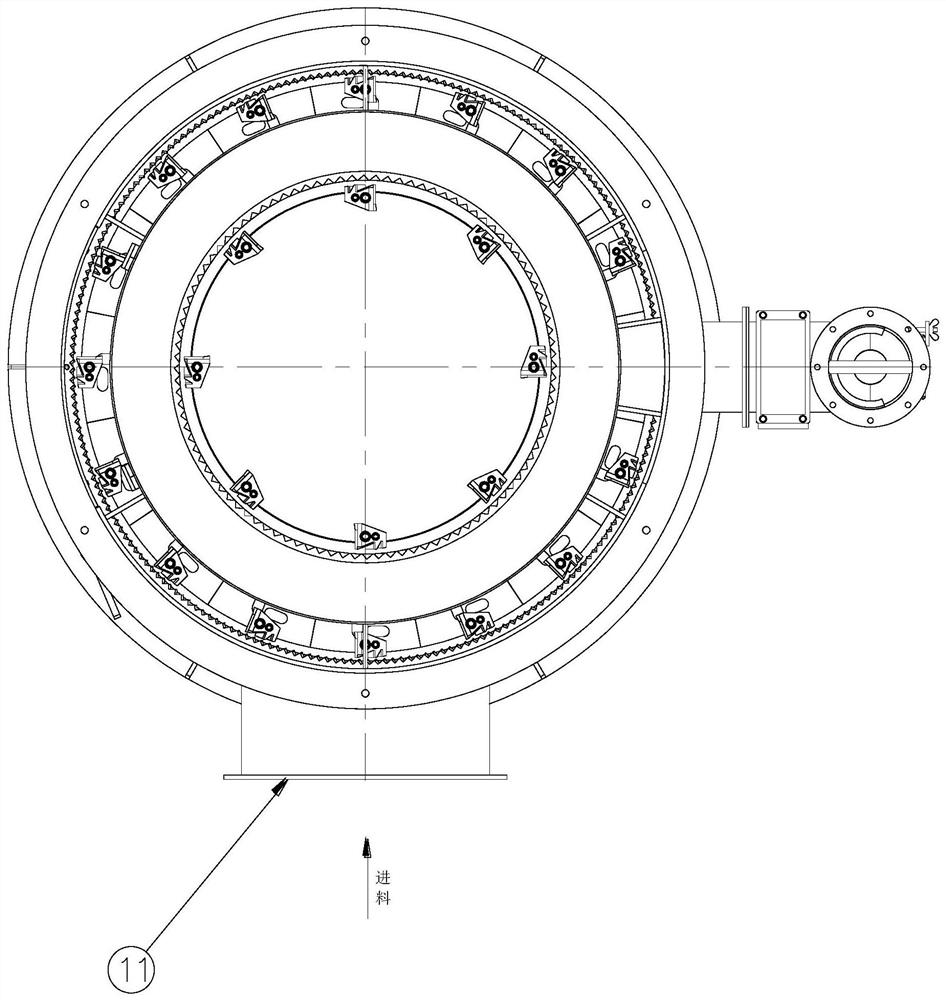

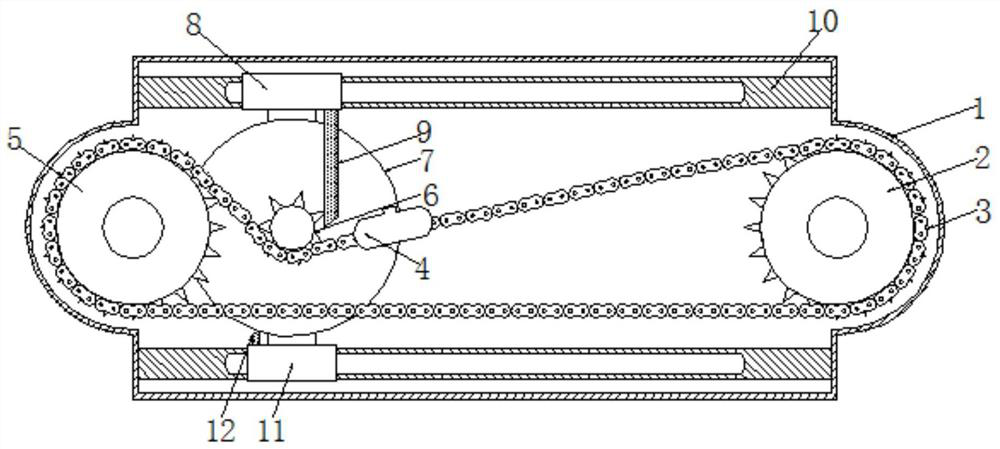

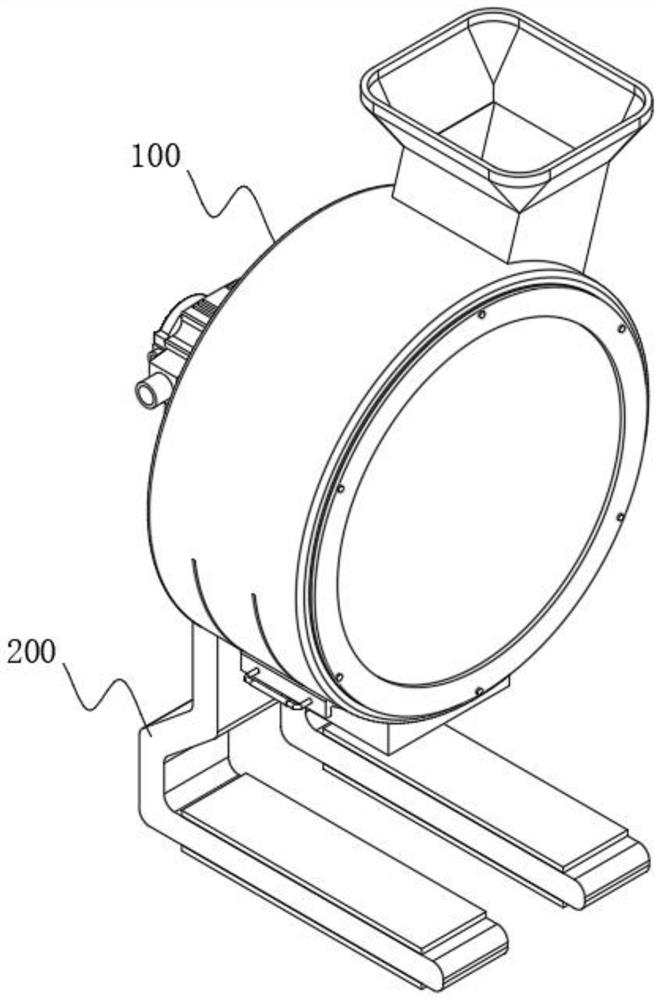

Hull breaking machine based on pretreated walnuts

The invention discloses a hull breaking machine based on pretreated walnuts, and relates to the field of walnut deep processing equipment. The hull breaking machine comprises a rack, an impeller feeding device and an opposite roller extrusion device; the impeller feeding device conducts feeding through an impeller to enable the walnuts to fall into the opposite roller extrusion device orderly, sothat the feeding efficiency is ensured; rollers of the opposite roller extrusion device are structurally optimized, V-shaped annular grooves in the rollers of the opposite roller extrusion device areformed alternately with roller sections to avoid mutual interference of the walnuts and improve the hull breaking efficiency, meanwhile one of the rollers is fixedly arranged, and the other roller isadjustable so as to adapt to hull breaking of the walnuts with different sizes and increase the kernel exposure rate; the impeller feeding device and the opposite roller extrusion device are both driven in a chain transmission mode, the driving speed of the impeller feeding device and the driving speed of the opposite roller extrusion device are matched to enable the materials to be smooth, the work continuity of the hull breaking machine is ensured, and the efficiency is improved; the outer surfaces of the rollers are wrapped with a PVC belt, jumping of the walnuts during falling is reduced,the extrusion efficiency is improved, meanwhile the adaptability of the walnuts in an extrusion work area is improved through the PVC belt, and the high kernel exposure rate is achieved.

Owner:SHIHEZI UNIVERSITY

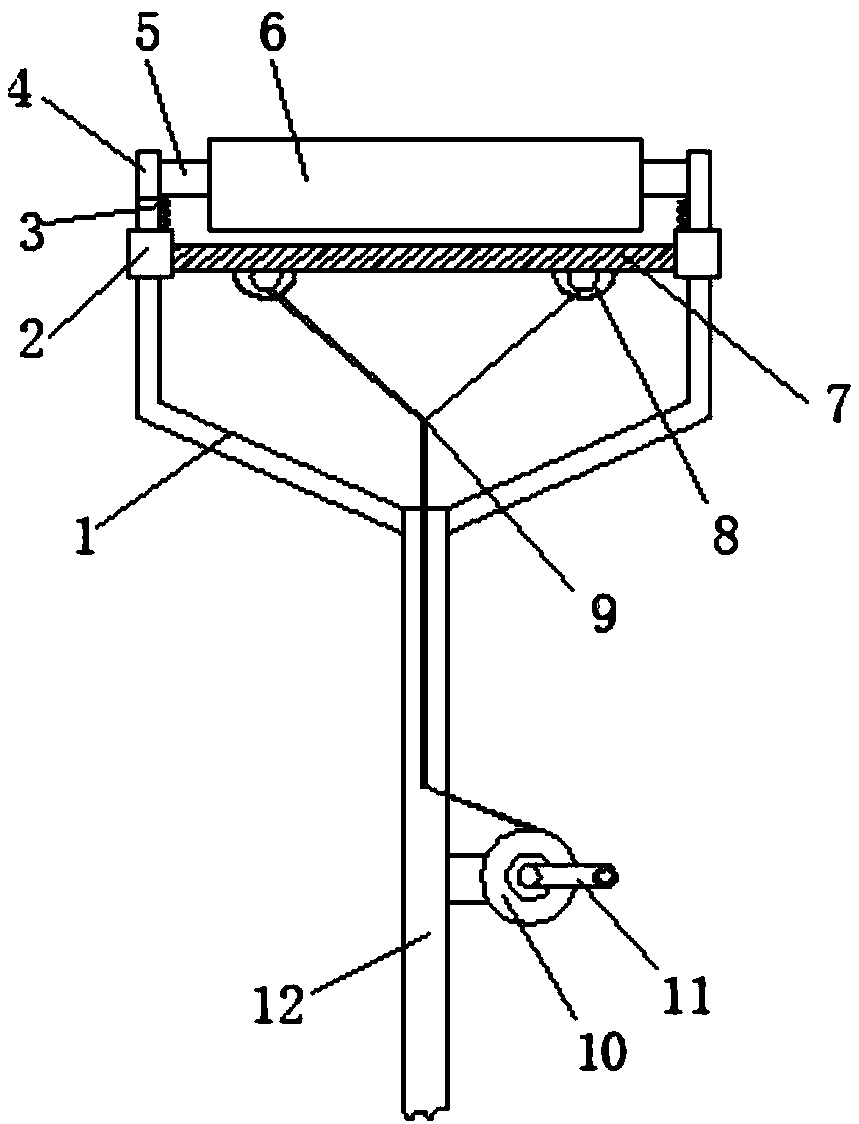

Coating painting device for building decoration

InactiveCN107747390AEven by forceImprove qualityBuilding constructionsArchitectural engineeringEngineering

The invention discloses a paint painting device for architectural decoration, which comprises a U-shaped frame, a rotating shaft is fixed at the top of the U-shaped frame through a fixing tube, and a painting roller is sleeved on the rotating shaft. The tube is fixed with a protective cover, and a fixed ring is welded on the protective cover, and the fixed ring is fixedly connected with the turntable through a connecting rope, and a pole is arranged at the center of the bottom of the U-shaped frame. In the present invention, firstly, a U-shaped frame is used to fix the painting roller. Compared with the traditional L-shaped frame, the force of the pulverizing roller is more uniform during use, and the quality of the paint is improved. Secondly, a protective cover is provided, and the painting roller When rotating, the protective cover can effectively prevent the paint from being thrown out under the action of centrifugal force, making the operation more convenient and hygienic, and the position of the protective cover can be adjusted through the connecting rope, and the position of the protective cover can be adjusted according to the painting angle during painting. The position is adjusted for easy painting by painting roller.

Owner:CHENGDU 5702 TECH CO LTD

Environment-friendly machine applied to glass crushing and reutilization

ActiveCN107999215AEfficient and comprehensive crushingIncrease the crushing areaGrain treatmentsElectric machineryEngineering

The invention discloses an environment-friendly machine applied to glass crushing and reutilization. The environment-friendly machine comprises a crushing bucket; the top wall of the crushing bucket is provided with a feeding opening; the environment-friendly machine applied to the glass crushing and reutilization is simple in structure; waste glass is put into the crushing bucket; an external power supply is started; a motor and a cutter are started for driving a first complete gear to rotate so that a second complete gear rotates reversely, the waste glass positioned on a supporting plate shakes and has full contact with the cutter; meanwhile, a long rod moves up and down to increase the crushing area of the cutter; with the rotation of the long rod and by the acting forces of an electromagnet and a permanent magnet, the permanent magnet shakes under the effect of a third spring, so the crushing area of the cutter is further increased. The environment-friendly machine disclosed by the invention can be used for efficiently and comprehensively crushing the waste glass and improves the work efficiency.

Owner:江苏双兴工贸有限公司

Plastic recycling and reusing device

PendingCN107627495AQuality improvementHigh strengthPlastic recyclingGrain treatmentsEngineeringMechanical engineering

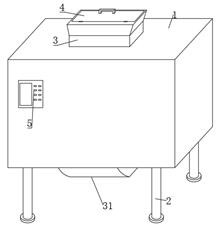

The invention provides a plastic recycling and reusing device, and belongs to the field of plastic processing equipment. The plastic recycling and reusing device comprises a box body. Multiple filterbarrels are arranged at the lower end of the box body. Multiple filter holes consistent in diameter are formed in each filter barrel. Multiple crushing cutters are arranged in the filter holes. The crushing cutters can rotate along the axes of the crushing cutters under drive of a belt wheel. The plastic recycling and reusing device can uniformly crush plastic, then the plastic is used as raw materials to be fed, and recycling and reusing of plastic products are achieved.

Owner:TIANJIN RUILING TECH DEV CO LTD

Grinding disc for waste rubber smashing device

The invention provides a grinding disc for a waste rubber smashing device and relates to a rubber mechanical component. The grinding disc for the waste rubber smashing device comprises a mobile grinding disc and a fixed grinding disc, wherein a gap between the two grinding discs is reduced gradually from a large end to a small end. The large end of the fixed grinding disc adopts wider tooth spaces and deep teeth, and the small end of the fixed grinding disc adopts narrower tooth spaces and shallow teeth. Conical convergence screw teeth are arranged on the smashing surface of the mobile grinding disc; a plurality of linear radial triangular teeth are formed in the smashing surface of the fixed grinding disc and clung to one another tightly. When waste rubber enters the gap between the mobile grinding disc and the fixed grinding disc through a propeller, the waste rubber is cut and ground through smashing teeth on the grinding discs, so that rubber powder is obtained. The cross section of each smashing tooth of the fixed grinding disc is triangular. The grinding disc is simple in structure, convenient to assemble and disassemble, high in smashing efficiency, low in unit energy consumption, smooth in feeding and discharging, uniform in smashing, small in grinding particle size and high in grinding quality.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

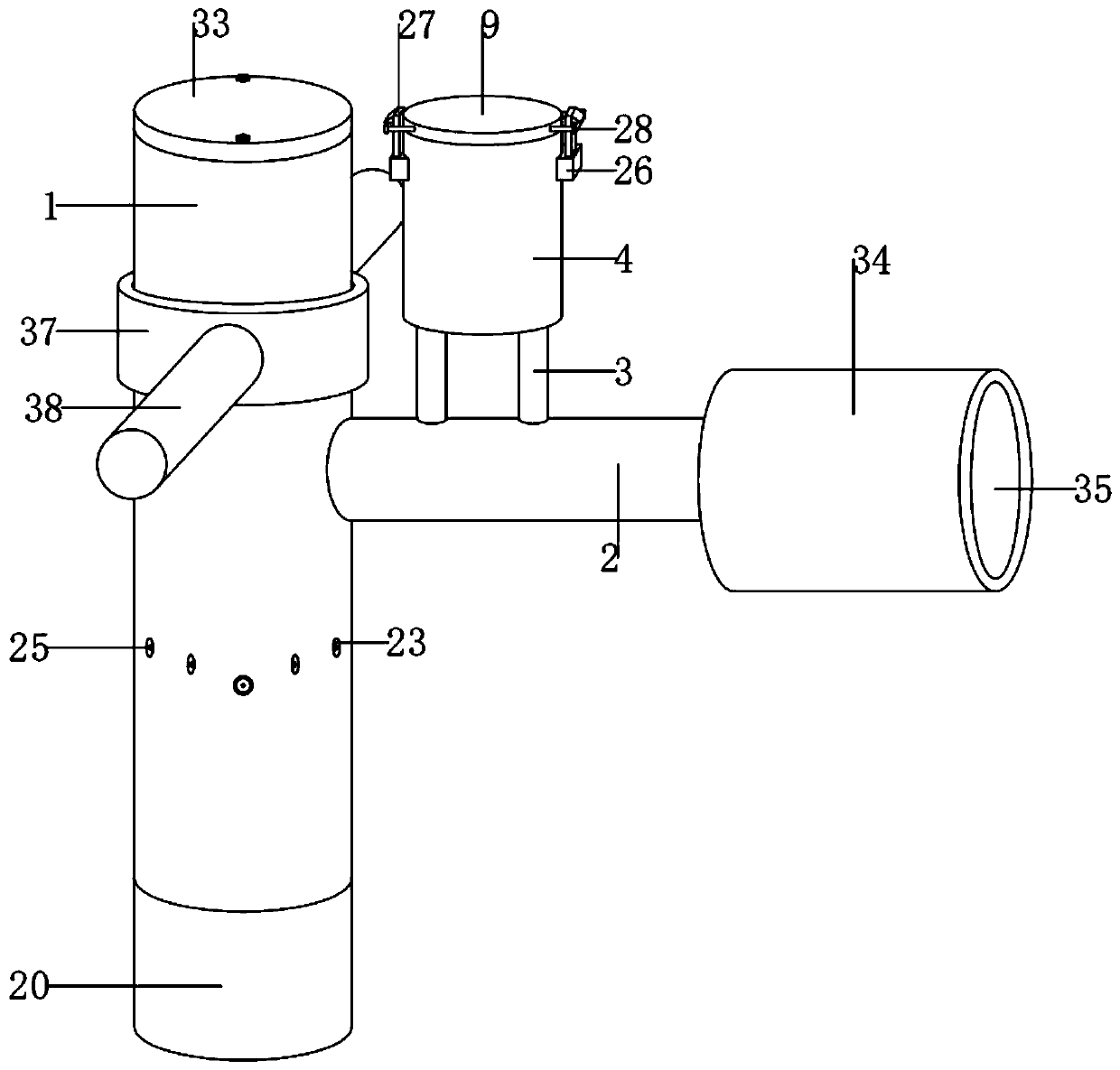

Automatic jet-flow crushing tool for natural gas hydrate solid-state fluidization and mining

InactiveCN111577211AIncrease water pressureImprove airtightnessEarth drilling toolsLiquid/gas jet drillingThermodynamicsEngineering

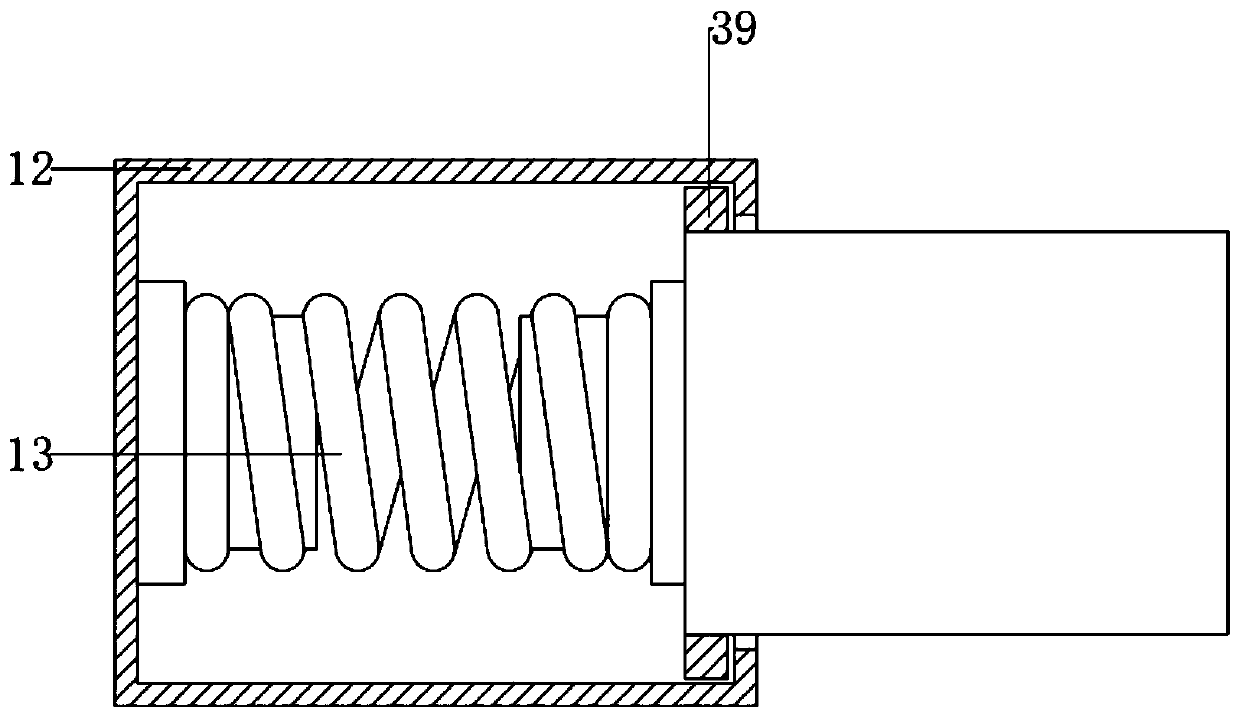

The invention provides an automatic jet-flow crushing tool for natural gas hydrate solid-state fluidization and mining, and belongs to the technical field of natural gas hydrate excavation equipment.The automatic jet-flow crushing tool for natural gas hydrate solid-state fluidization and mining comprises a crushing tube, wherein the right end of the crushing tube is connected to a connecting tubethrough threads; the connecting tube communicates with the crushing tube; the upper end of the connecting tube is fixedly connected to two compression tubes; the compression tubes communicate with the connecting tube; the upper ends of the compression tubes are fixedly connected to a compression barrel; the compression barrel communicates with the two compression tubes; a first rubber plug is connected between the inner walls of the compression barrel in a sliding mode; the upper end of the first rubber plug is fixedly connected to a connecting block; the upper end of the connecting block isfixedly connected to a pressure plate; the upper end of the pressure plate is fixedly connected to three first springs; the upper end of the compression barrel is fixedly provided with a barrel cover;and the three first springs are positioned at the lower end of the barrel cover. The invention aims to solve the problems that pressure generated by jet flow in the prior art is small, crushing efficiency is low, and a crushing tool is difficult to close after crushing is accomplished.

Owner:罗文树

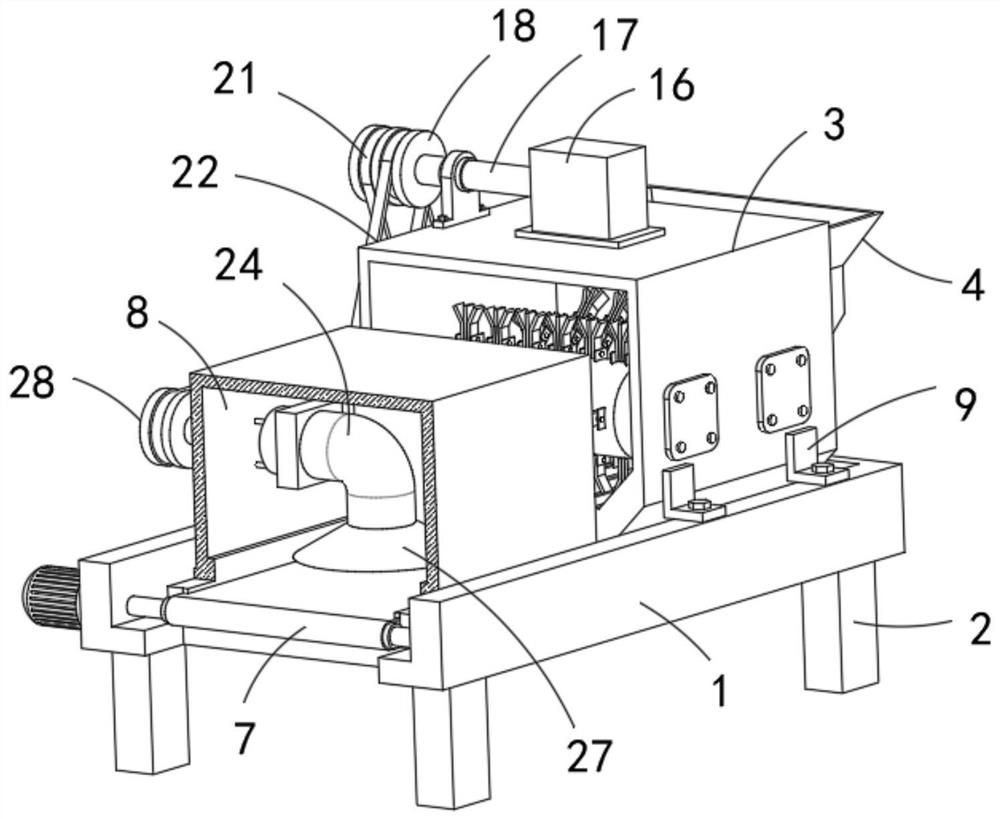

Horizontal pulverizer for waste rubber

ActiveCN104875300AHigh densityImprove crushing effectPlastic recyclingMechanical material recoveryWaste rubberEngineering

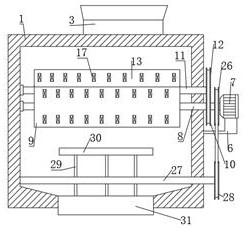

The invention discloses a horizontal pulverizer for waste rubber. The horizontal pulverizer comprises a pulverizer body, wherein the pulverizer body is horizontally arranged; a waste rubber inlet is formed in one side of the upper end of the pulverizer body, and a waste rubber outlet is formed in one side of the lower end of the pulverizer body; the pulverizer body is of a rectangular structure; motors are respectively arranged on both sides of the pulverizer body; pulverizing blades are arranged in the pulverizer body; the pulverizing blades are distributed on the upper and lower inner walls of the pulverizer body; the pulverizing blades are arranged on the upper and lower inner walls of the pulverizer body in an inclined mode; the ends of the pulverizing blades on the upper and lower inner walls of the pulverizer body are staggered. Through the structural arrangement, the intensity of the pulverizing blades is high, the pulverizing effect is good, and the pulverizer body is driven to integrally rotate by the motors, so that the pulverizing effect is greatly enhanced.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Soil improvement method

InactiveCN109220033AReduce resistanceImprove efficiencySoil lifting machinesRotary stirring mixersEngineeringOxygen content

The invention belongs to the technical field of agriculture, and particularly relates to a soil improvement method. An improvement device is adopted in the method. The improvement device comprises a box, and further comprises connecting units, first driving units, a second driving unit, a mixing unit, a material taking unit, a first plate, a second plate, a third plate, a fourth plate and a gas storage chamber. The connecting units, the first driving units, the second driving unit, the mixing unit and the material taking unit mutually cooperate, on the one hand, through clockwise and anticlockwise rotation of stirring plates, an improvement agent and soil are sufficiently and uniformly mixed through the stirring plates, the soil is refined and sufficiently absorbs oxygen, the oxygen content of the soil is ensured, and the improvement effect of the soil is improved; on the other hand, through cooperation of fixing columns, fixing rods and rotary rollers, the bump force borne by the improvement device in the running process is relieved, the improvement device is prevented from being tipped over, and therefore, the stability of the improvement device is improved.

Owner:叶淑源

Garden waste melting machine

ActiveCN112452477AAvoid excessive movementImprove stabilityBio-organic fraction processingGrain treatmentsStructural engineeringWaste treatment

The invention belongs to the technical field of waste treatment, particularly relates to a garden waste melting machine, and aims at solving the problem of low crushing efficiency of an existing melting machine. The garden waste melting machine comprises a box body; a first straight shaft and a second straight shaft are rotatably connected inside the box body; a first rotating roller is fixed on the first straight shaft in a sleeving manner; a second rotating roller is fixed on the second straight shaft in a sleeving manner; a plurality of grooves are formed in the circumferential outer wallsof the first rotating roller and the second rotating roller; a first sliding groove is formed in the inner wall of one side of each groove; first sliding blocks are connected in the first sliding grooves in a sliding manner; moving blocks are fixed on the inner sides of the first sliding blocks and arranged in the grooves; and a crushing knife is fixed on the top of each moving block. According tothe garden waste melting machine, a driving mechanism drives the first straight shaft and the second straight shaft to rotate so as to drive the first rotating roller and the second rotating roller,and the crushing knives move back and forth in the grooves under the action of the centrifugal force and first springs to move and crush waste, so that the crushing dead angles are eliminated, and thecrushing efficiency is improved.

Owner:广东绿润环境科技有限公司

Pasture forage sufficient crushing equipment based on intelligent manufacturing

ActiveCN112825687AThe solution function is relatively simpleConvenient post-crushing workCuttersDrive shaftReciprocating motion

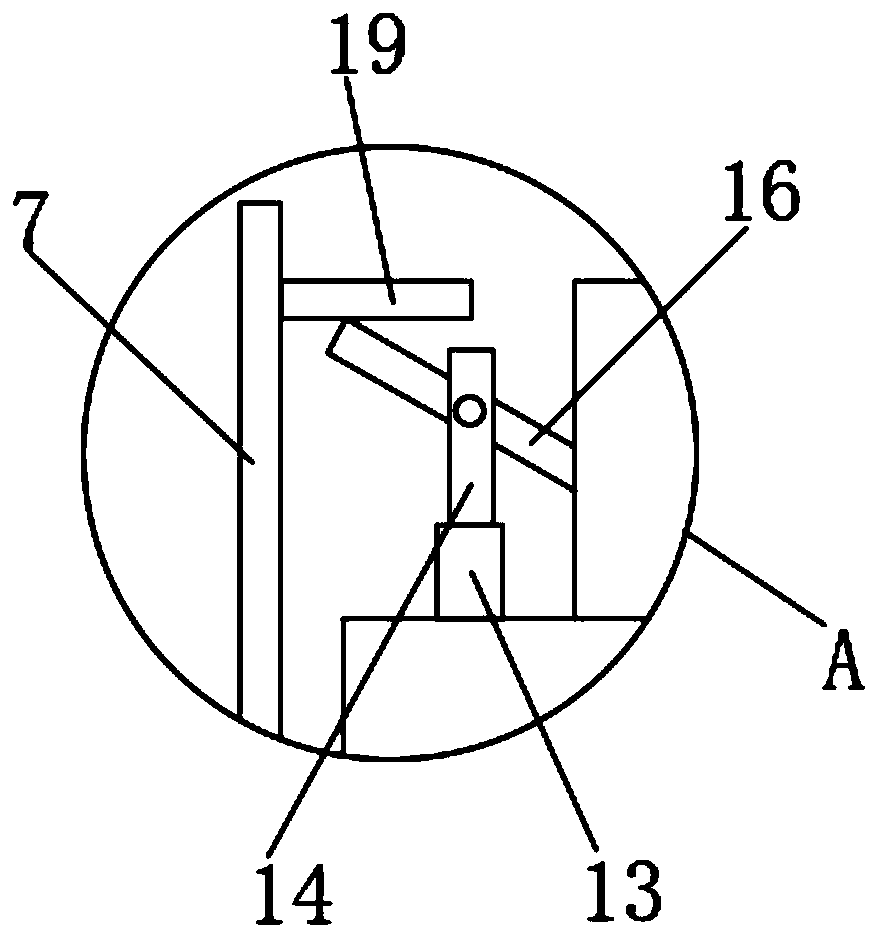

The invention relates to the technical field of intelligent technologies, and discloses pasture forage sufficient crushing equipment based on intelligent manufacturing. The pasture forage sufficient crushing equipment comprises an extrusion bin, a rotating rod is movably connected to the interior of the extrusion bin, a push rod is hinged to the top of the rotating rod, a push block is hinged to the end, away from the rotating rod, of the push rod, and a clamping plate is fixedly connected to the side surface of the push block. According to the pasture forage sufficient crushing equipment based on intelligent manufacturing, through cooperative use of the rotating rod and the clamping plate, before forage is crushed, disordered forage is firstly compacted, later crushing work is facilitated, through cooperative use of a driving shaft and a crushing shaft, during crushing, the crushing shaft can transversely reciprocate, the crushing area is increased, the crushing efficiency is improved, through cooperative use of a driving rod and a sliding block, a baffle can be intermittently controlled to be opened and closed, the intermittent discharging effect is achieved, the crushing efficiency is greatly improved, and function simplification of common crushing equipment is avoided.

Owner:聊城市飓风工业设计有限公司

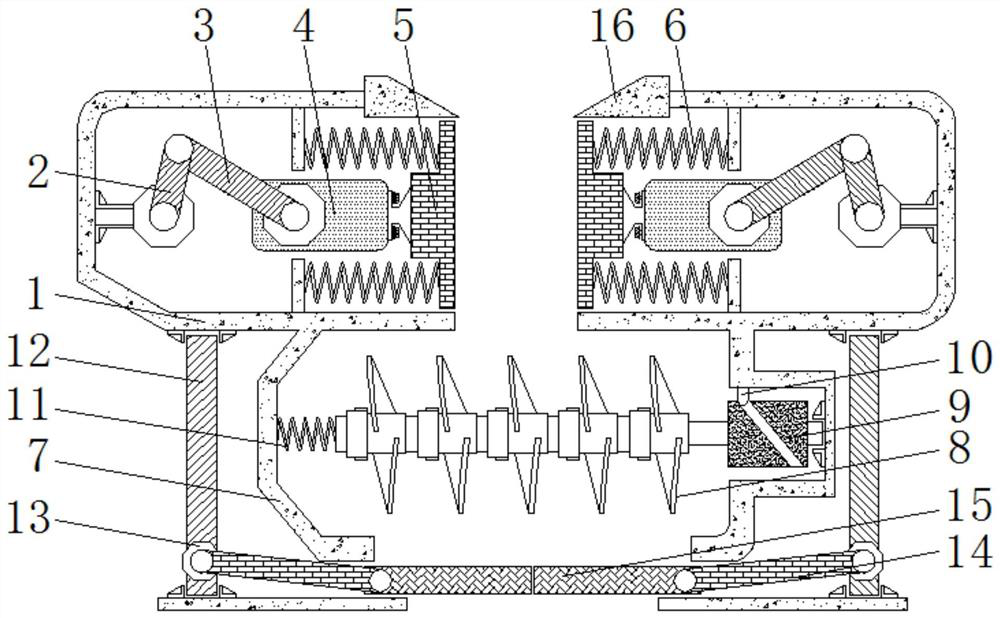

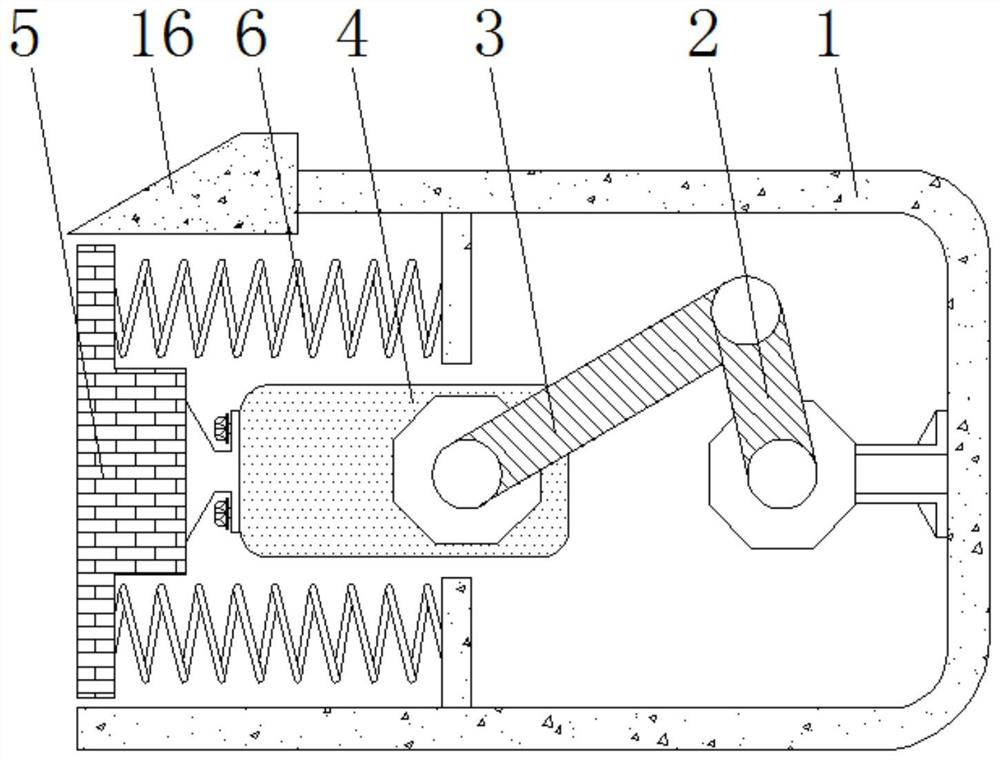

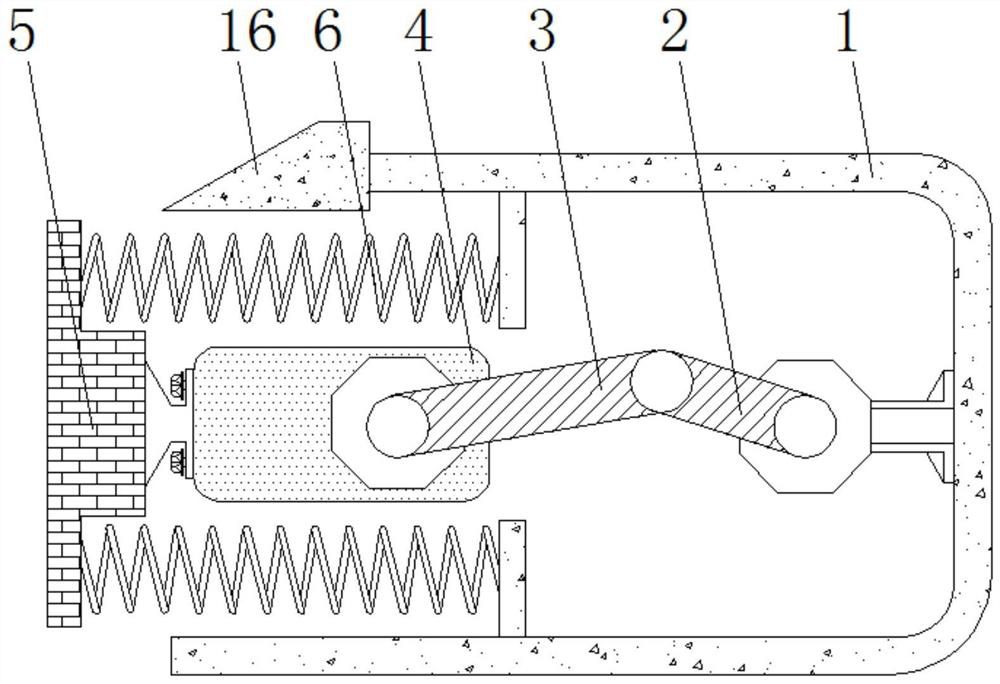

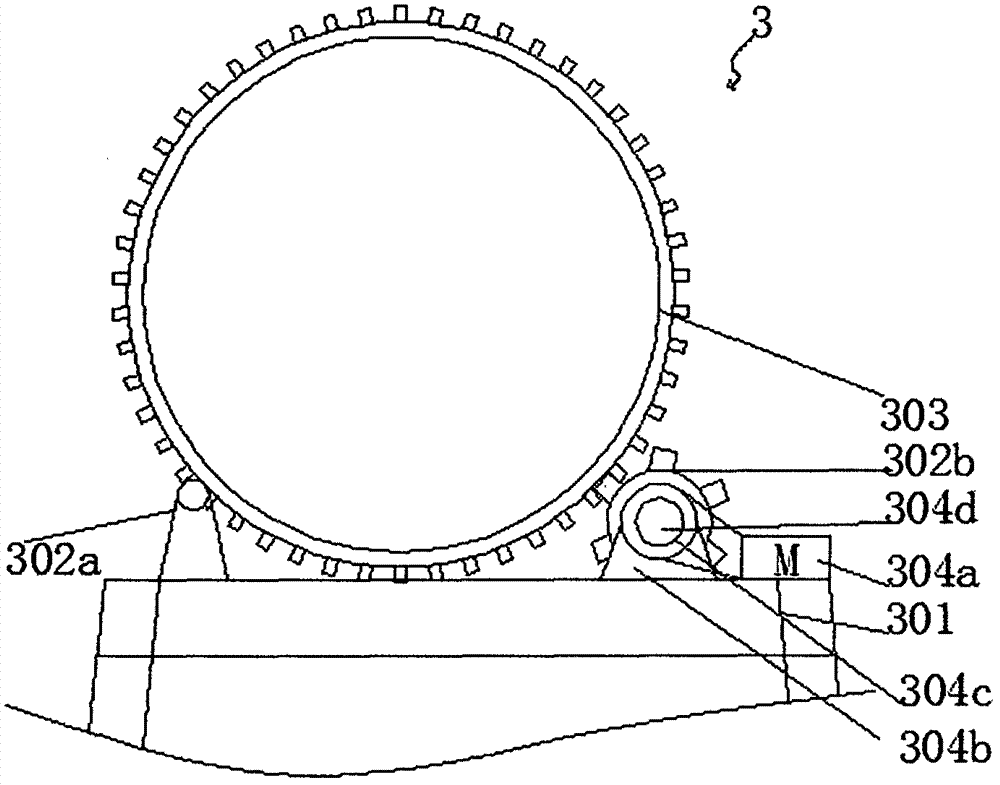

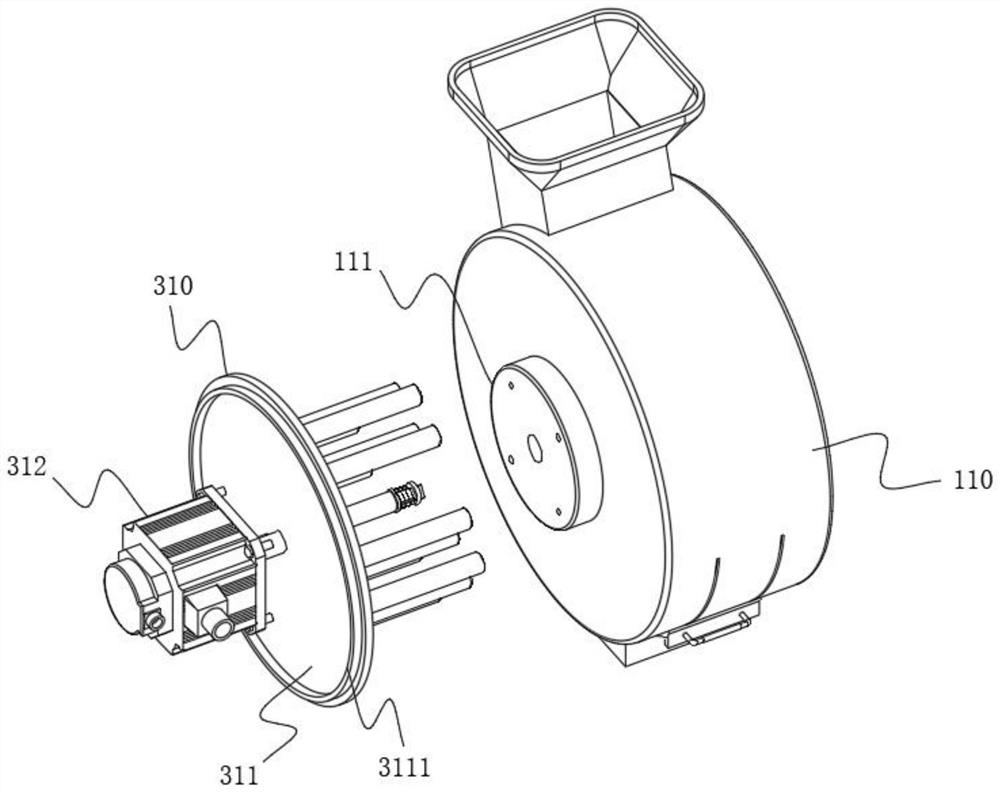

Waste mushroom-stick treatment device

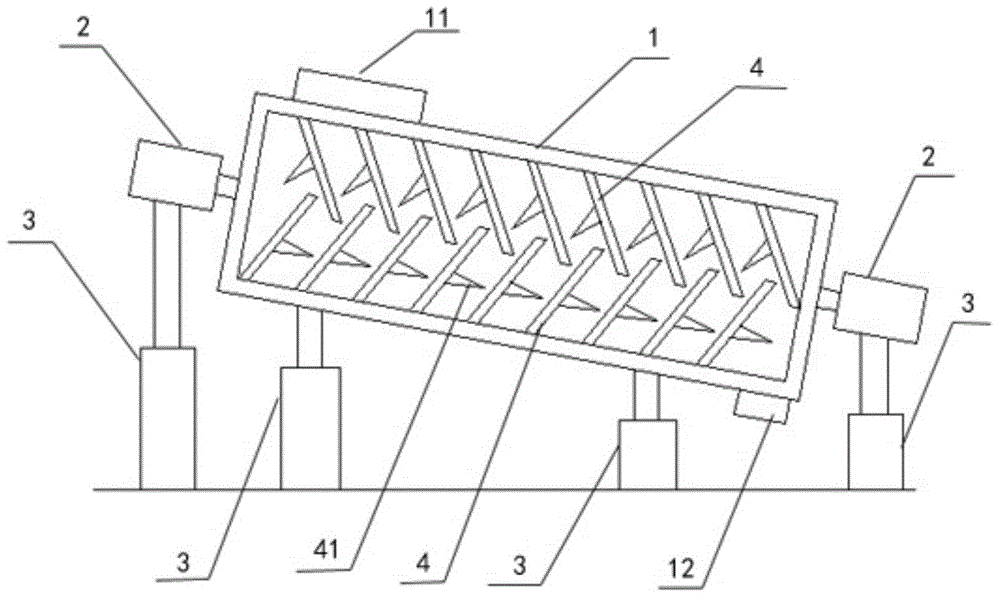

PendingCN107138232AIncrease the crushing areaReasonable structureGrain treatmentsElectric machineryIndustrial engineering

The invention discloses a waste mushroom-stick treatment device which comprises a feeding unit, a smashing unit and a shaftless trommel. The feeding unit comprises a feeding frame 1 and a bin, wherein the feeding frame 1 is in driving connection with a belt 1, and the bin is connected to the end, away from the smashing unit, of the belt 1 in a covering mode. The smashing unit comprises a smashing box, a feeding frame 2 and a smashing motor, wherein the feeding frame 2 is in driving connection with a belt 2, the smashing box is located above the belt 2, and the smashing motor is fixedly connected with one side of the smashing box. The smashing motor is connected with a rotatable smashing device through a belt wheel, and the end, away from the smashing box, of the belt 2 is extended into the shaftless trommel.

Owner:李松君

Suspension type river water heavy metal pollution treatment device and using method thereof

InactiveCN111533231AGood suspensionAdjust depthWater contaminantsWater/sewage treatmentRiver regulationEnvironmental engineering

The invention discloses a suspension type river water heavy metal pollution treatment device and a using method thereof, and belongs to the technical field of river regulation. The suspension type river water heavy metal pollution treatment device comprises a treatment box. A storage box is fixedly connected on the top end of the treatment box, the storage box penetrates through the outer wall ofthe treatment box and extends into the treatment box; a connecting sleeve is fixedly installed on the outer wall of the treatment box, a suspension plate is in threaded connection with the outer wallof the connecting sleeve, two symmetrically-arranged floating balls are movably installed in the treatment box, linkage rods are fixedly connected to the top ends of the floating balls, and the linkage rods penetrate through the outer wall of the top of the treatment box. Uniform distribution of sulfide can be realized, sulfide aggregation can be effectively prevented and treatment of heavy metalions in river water is more comprehensive and thorough, the treatment effect is improved, secondary pollution to river water caused by addition of sulfide can be effectively avoided, and sulfide precipitate can be collected and recovered.

Owner:楼东

Forage grass crushing device for animal husbandry

InactiveCN112369634AAvoid flying situationsGood split effectFeeding-stuffCrop conditionersAnimal scienceElectric machinery

The present invention discloses a forage grass crushing device for animal husbandry. The forage grass crushing device for animal husbandry comprises a box body, a feeding pipe is inserted into an outer wall of a top wall of the box body, a third motor is arranged on an outer wall of one side of the box body, connecting columns are arranged at one end of an output shaft of the third motor, crushingteeth which are annularly distributed at equal intervals are arranged on outer walls of circumferences of the connecting columns, a second motor is arranged on an outer wall of one side of the box body, a threaded lead screw is fixedly connected to an outer wall of one end of an output shaft of the second motor, a threaded sleeve sleeves an outer wall of a circumference of the threaded lead screw, a mounting plate is arranged on an outer wall of a bottom part of the threaded sleeve, and a first motor is arranged on an outer wall of a bottom part of the mounting plate. After forage grass is added into the box body through the feeding pipe, crushing teeth on outer walls of the two connecting columns are engaged with each other to fully crush the forage grass, at the same time, through-holesformed in outer walls of the crushing teeth can enable the forage grass to be inserted into the through-holes, and a crushing effect of the device on the forage grass is improved.

Owner:贾从夫

Adjustable crushing device

InactiveCN105396652AChange the degree of fragmentationSimple structureGrain treatmentsMechanical engineeringEngineering

Owner:太仓圣广仁自动化设备有限公司

Margarya melanoide bait crushing device for fishery

The invention discloses a margarya melanoide bait crushing device for fishery, relates to the technical field of agriculture, and aims to solve the problems that the efficiency is low because margaryamelanoide shells are smashed mainly through manual beating or knocking, and waste is caused because small margarya melanoides are likely to become residues in the treatment process. The device specifically comprises a shell, wherein a plurality of rolling wheels are fixedly installed on the two sides of the shell correspondingly, a feeding hopper is fixedly installed at the top end of the shell,two driving motors are fixedly installed at the end of the shell, and rotating shafts are fixedly installed at the ends of output shafts of the two driving motors correspondingly. According to the device, large margarya melanoides can be extruded to improve a damage degree, the small margarya melanoides are prevented from being missed, ingestion of fishes or lobsters is better facilitated, when the device conducts gathering to enable the bottom ends of crushing cylinders to be separated mutually, the crushing cylinders can rebound to drive crushing teeth to vibrate, attached margarya melanoides are vibrated off, the crushing efficiency is improved, the crushed margarya melanoides are discharged through a discharging hopper mechanism, and the operation is simple and convenient.

Owner:靳彤彤

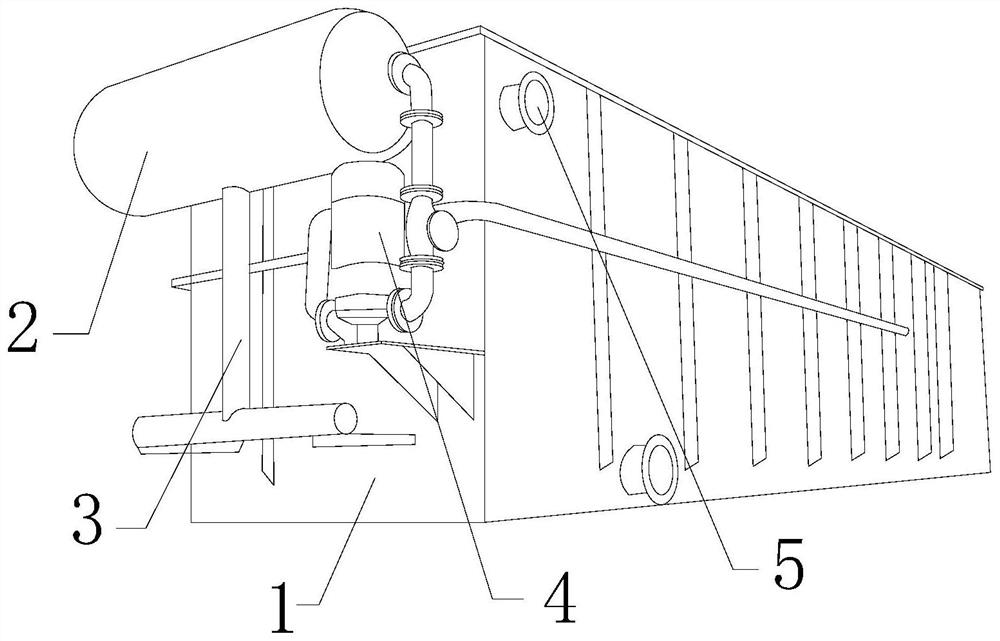

Organic fertilizer pollution-free treatment device and treatment method

PendingCN113154800AImprove finenessIncrease the broken areaDrying chambers/containersGrain treatmentsDrive motorAgricultural engineering

The invention belongs to the technical field of fertilizer processing, and particularly relates to an organic fertilizer pollution-free treatment device. The organic fertilizer pollution-free treatment device comprises a workbench and a plurality of supporting columns, wherein the plurality of supporting columns are fixedly connected to the lower end of the workbench; a rectangular groove is formed in the upper end of the workbench, one side of the rectangular groove extends out of the workbench, and a shell is fixedly connected into the rectangular groove; a supporting mechanism connected with the workbench is arranged on the outer side wall of the shell, a feeding pipe communicating with the interior of the shell is fixedly connected to the side wall of the shell, and the end, away from the feeding pipe, of the shell is of an open structure; and a first rotating shaft and a second rotating shaft which are parallel to each other are rotationally connected to the inner wall of the shell, and breaking mechanisms making contact with fertilizer raw materials are arranged on the outer side walls of the first rotating shaft and the second rotating shaft. According to the organic fertilizer pollution-free treatment device, by using a driving motor, fertilizer can be broken and dried, so that the utilization rate of a power source is relatively increased; and the breaking process and the drying process supplement each other, so that the good breaking effect is beneficial to the subsequent drying effect.

Owner:南京三美农业发展有限公司

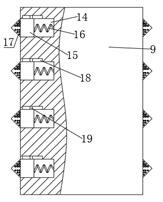

Crushing device for soil improvement

InactiveCN113634337AIncrease the crushing areaAvoid incomplete fragmentationGrain treatmentsSoil treatmentAgricultural engineering

The invention is applicable to the technical field of soil treatment equipment, and provides a crushing device for soil improvement. The crushing device comprises a supporting seat, a crushing cylinder and a crushing part, wherein the crushing cylinder is fixedly arranged on the supporting seat; the crushing part is arranged on the supporting seat; the crushing part comprises a rotating shaft; the rotating shaft can jump up and down in the rotating process; a plurality of crushing cutters are arranged on the surface of the rotating shaft in an array mode; a fixing rod is arranged in the rotating shaft in a sliding mode; the fixing rod is fixedly arranged on the supporting seat; and the fixing rod drives the crushing cutters to extend out intermittently through a transmission mechanism. The crushing device is thorough in crushing and good in crushing effect.

Owner:江苏进化树生物科技有限公司

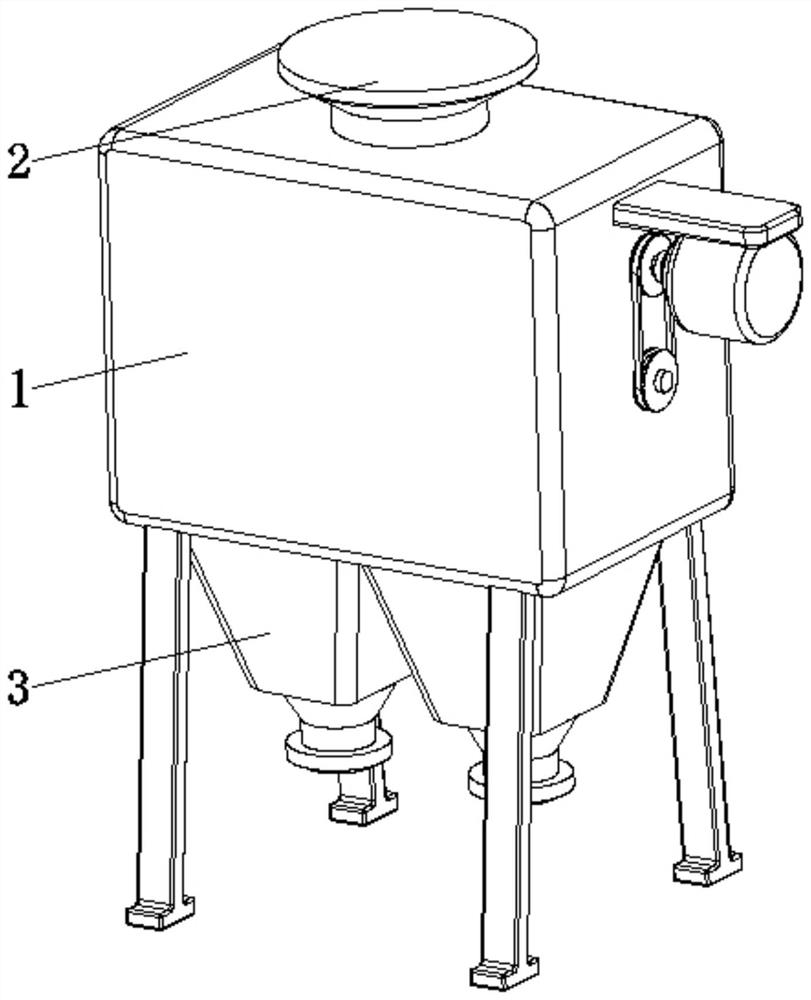

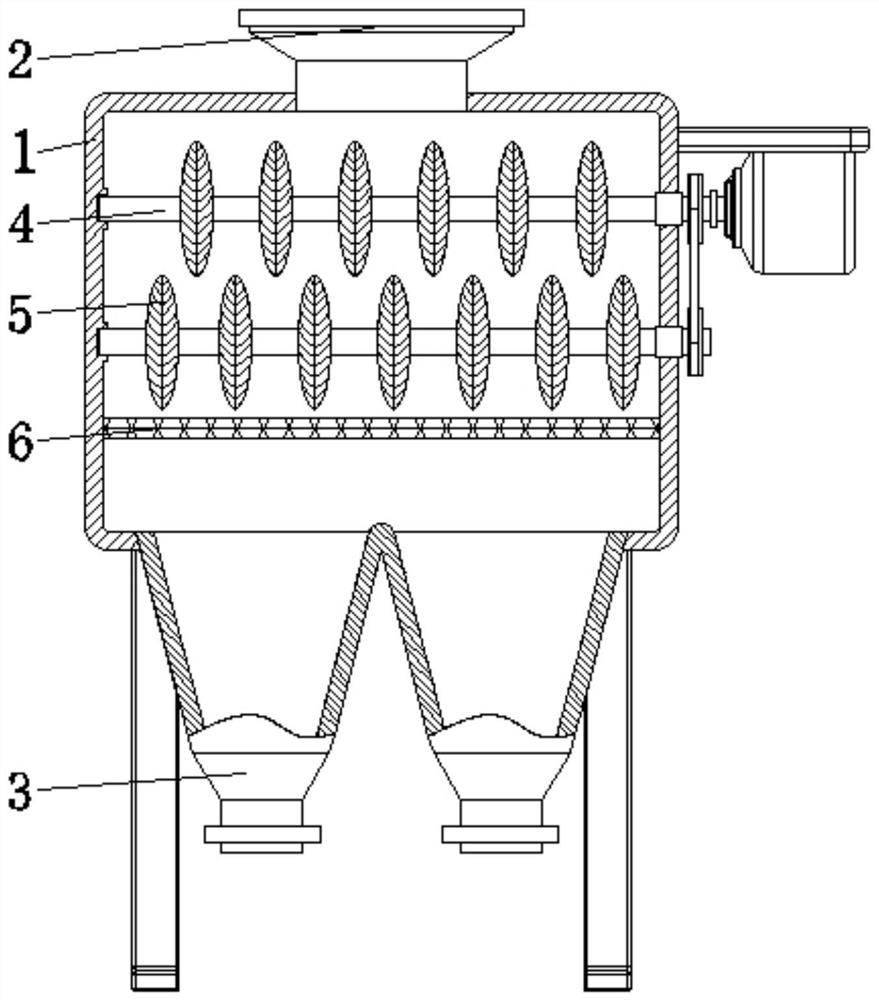

Waste plastic recycling equipment

InactiveCN112917756AQuick smashReduce diffuseUsing liquid separation agentPlastic recyclingDust controlEnvironmental engineering

The invention discloses waste plastic recycling equipment, and relates to the technical field of waste plastic recycling. The waste plastic recycling equipment comprises a crushing chamber, a feeding hopper and discharging ports. The feeding hopper is fixed to the center of the top of the crushing chamber and communicated with the crushing chamber, and the discharging ports are formed in the center of the bottom of the crushing chamber. Driving rotating shafts are rotatably connected to the position, close to the feeding hopper, between the two corresponding sides in the crushing chamber, crushing devices are fixed to the surfaces of the driving rotating shafts, the crushing devices are evenly distributed on the surfaces of the driving rotating shafts and arranged in an up-down staggered mode, and a screen is fixed to the position, close to the crushing devices, of the inner wall of the crushing chamber. According to the waste plastic recycling equipment, the purposes of dust removal and rapid crushing are achieved, dust can be removed in time, dust diffusion is reduced, the human body inhalation amount is reduced, human health is facilitated, pollution to the atmosphere is reduced, meanwhile, crushing is rapid and thorough, and the crushing efficiency and the use performance are improved.

Owner:石岩嘎

A horizontal pulverizer for waste rubber

ActiveCN104875300BHigh densityImprove crushing effectPlastic recyclingMechanical material recoveryWaste rubberEngineering

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Leather leftover material secondary compression utilization equipment

ActiveCN113617793AIncrease the crushing areaBroken fastSolid waste disposalTextile disintegration and recoveryWaste recoveryWaste material

The invention belongs to the field of leather solid waste recovery, and particularly relates to leather leftover material secondary compression utilization equipment which comprises a machine body. A feeding pipe is fixedly connected to the upper surface of the machine body, and a water inlet pipe is arranged at the bottom end of the feeding pipe. According to the leather leftover material secondary compression utilization equipment, through the arrangement of a cleaning mechanism, when crushed materials fall to the upper surface of a partition plate, a water inlet pipe injects water, a transmission shaft drives a rolling shaft to rotate, and a rotating disc does circular motion with the transmission shaft as the circle center along the upper surface of the partition plate; under the driving of the rotating disc, an arc-shaped plate continuously stirs the materials, and a rotating plate is matched, so that the outer surfaces of the materials and the outer surfaces of brush strips make contact and friction faster and more sufficiently, and the cleaning speed and the cleaning effect are improved; and one part of water flow with impurities flows out of a blow-off pipe, and the other part of water flow with the cleaned materials falls down from a screen, so that the problem that when traditional leather is recycled, due to the fact that the number of impurities in the materials is large, the utilization rate is low is solved.

Owner:江门市普德再生资源科技有限公司

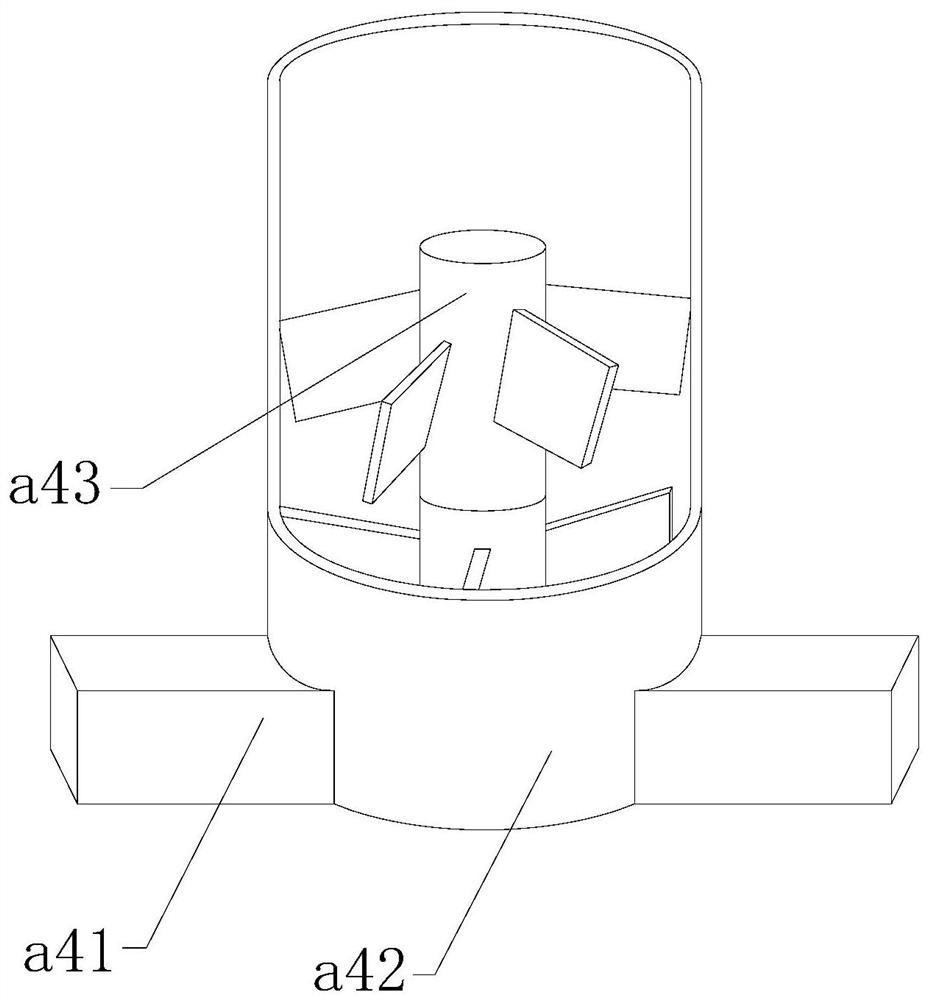

A two-stage ultrafine pulverizer

ActiveCN111686880BAchieve finenessIncrease the crushing areaGrain treatmentsTransport systemProcess engineering

The invention belongs to the technical field of pulverizing equipment, and specifically discloses a two-stage ultrafine pulverizer, comprising a discharge chamber, a pulverization system and an air transport system. A classification system is arranged in the discharge chamber, and a feed pipe is arranged on the pulverization system; It is used for material conveying of the crushing system and the discharge chamber; it is characterized in that the crushing system includes a shunt hood, a coarse crushing device, and a fine crushing device, and the coarse crushing device and the fine crushing device are arranged in sequence along the material movement direction. The invention realizes the requirement that the target particle size can be achieved by the primary crushing process of only one vertical ultrafine pulverizer, which not only improves the crushing efficiency, but also has a good crushing effect on tough materials, and at the same time reduces the traditional secondary crushing. The total energy consumption and total cost of the process have broad application prospects.

Owner:FAMSUN CO LTD

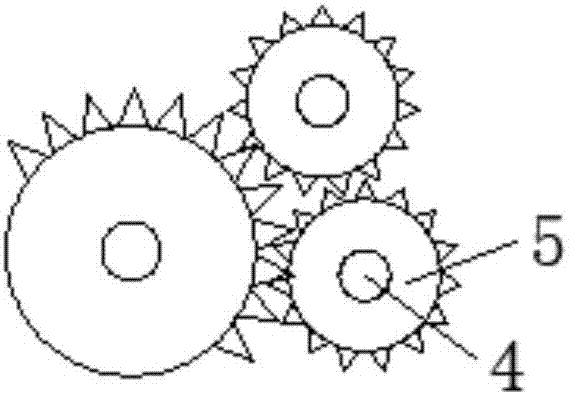

A pavement construction auxiliary crushing equipment that moves left and right to increase crushing efficiency

ActiveCN110670466BImprove crushing efficiencyAffect operationRoads maintainenceGear wheelArchitectural engineering

The invention relates to the technical field of road construction, and discloses a road construction auxiliary crushing equipment that moves left and right to increase the crushing efficiency. The rotation of the three gears causes the crushing rod to rotate. The sawtooth of the crushing rod further breaks the damaged road surface. At the same time, the gravel is easy to splash on the unconstructed road surface. Run, reduce the crushing effect, make the fixed block push the first push rod, cause the crushing rod to move synchronously, make the crushing rod move on the road while rotating, speed up the overall speed of crushing, and move the crushing rod to the end of the movement path At the starting point and the end point, it will temporarily rotate in place to increase the crushing time at both ends of the path, which is convenient for effective crushing, and then the fixed block drives it back and forth, so that the crushing rod can fully crush the road surface, improve the crushing rate, and increase the work. efficiency.

Owner:宁夏鎏铭建设工程有限公司

Crushing tool for powder coating production

InactiveCN114210427AImprove stabilityImprove work efficiencyGrain treatmentsStructural engineeringKnife blades

The invention provides a crushing tool for powder coating production. The crushing tool comprises a base; the first blade is arranged at the bottom of the base; the connecting rod slides on the base, and the bottom end of the connecting rod is fixedly connected with the first blade; the crushing machining tool for powder coating production comprises a base, a connecting rod is arranged on the base, a clamping assembly is arranged on the connecting rod, the clamping assembly comprises two clamping grooves, and the inner surfaces of the two clamping grooves are both slidably connected with clamping rods. The moving assembly drives the clamping assembly to clamp the connecting rod, so that the first blade is stably connected to the base, the limiting assembly limits the first blade, the connecting assembly enables the limiting assembly to be stably connected to the base, the stability of the first blade is improved, and therefore the first blade is fixed to the base.

Owner:HUNAN LIANXIN SCI & TECH CO LTD

Industrial wastewater treatment equipment

InactiveCN111847548AIncrease the crushing areaIncrease the gapSpecific water treatment objectivesTreatment involving filtrationIndustrial wastewater treatmentProcess engineering

The invention discloses industrial wastewater treatment equipment. The equipment structurally comprises a treatment box, a water supply tank, a connecting pipe, a converter and an exhaust port, wherein the connecting pipe is in threaded connection with the front end of the treatment box; the treatment box comprises a box body, an isolation plate, a drainage channel, a treatment device and a drainage pipe; the treatment device is embedded and fixedly connected to the upper position in the box body; and the isolation plate is connected between the treatment devices in a nesting manner. Accordingto the invention, wastewater is introduced into a rotary filtering tank; stirring blades and crushing blades are driven by a rotating shaft to rotate at the same time, particle impurities in water can be impacted by the crushing blades, particle impurities continuously impact on the angle plates of the crushing blades, and blockage of larger particulate impurities in the filter cavity is avoided.Before wastewater treatment, the rotating shaft is clamped on the combining shaft firstly, so that the elastic strip pulls the contact block to be compressed backwards due to compression of the rotating shaft, the rotating shaft is further clamped in the middle section of the elastic strip, the rotating speed is effectively increased, and the treatment performance is improved.

Owner:大连汉唐盛世传媒科技有限公司

An environmentally friendly machine for glass crushing and reuse

ActiveCN107999215BEfficient and comprehensive crushingIncrease the crushing areaGrain treatmentsElectric machineryElectromagnet

The invention discloses an environment-friendly machine applied to glass crushing and reutilization. The environment-friendly machine comprises a crushing bucket; the top wall of the crushing bucket is provided with a feeding opening; the environment-friendly machine applied to the glass crushing and reutilization is simple in structure; waste glass is put into the crushing bucket; an external power supply is started; a motor and a cutter are started for driving a first complete gear to rotate so that a second complete gear rotates reversely, the waste glass positioned on a supporting plate shakes and has full contact with the cutter; meanwhile, a long rod moves up and down to increase the crushing area of the cutter; with the rotation of the long rod and by the acting forces of an electromagnet and a permanent magnet, the permanent magnet shakes under the effect of a third spring, so the crushing area of the cutter is further increased. The environment-friendly machine disclosed by the invention can be used for efficiently and comprehensively crushing the waste glass and improves the work efficiency.

Owner:江苏双兴工贸有限公司

A garden waste recycling machine

ActiveCN112452477BAvoid excessive movementImprove stabilityBio-organic fraction processingGrain treatmentsStructural engineeringMachine

The invention belongs to the technical field of waste treatment, in particular to a garden waste composting machine. Aiming at the problem of low pulverization efficiency of the existing composting machine, the following proposal is proposed, including a box body, which is rotatably connected with a first A straight shaft and a second straight shaft, the first straight shaft is sleeved and fixed with a first rotating roller, the second straight shaft is sleeved and fixed with a second rotating roller, the outer walls of the first rotating roller and the second rotating roller are provided with A plurality of grooves, a first chute is provided on the inner wall of one side of the groove, a first slider is slidably connected to the first chute, a moving block is fixed on the inner side of the first slider, and the moving block is arranged in the groove. A breaking knife is fixed on top of the block. In the present invention, the driving mechanism drives the first straight shaft and the second straight shaft to rotate, and then drives the first rotating roller and the second rotating roller. Under the action of centrifugal force and the first spring, the crushing knife moves back and forth in the groove, thereby The crushing knife is moved and crushed, thereby eliminating the dead angle of crushing and improving the crushing efficiency.

Owner:广东绿润环境科技有限公司

Food crushing and processing machine capable of preventing residues on inner wall

ActiveCN112517143AReduce wasteStable force transmissionHollow article cleaningGrain treatmentsElectric machineryStructural engineering

The invention relates to the technical field of food processing, in particular to a food crushing and processing machine capable of preventing residues on the inner wall. The food crushing and processing machine comprises a crushing box and a base arranged at the bottom of the crushing box, the crushing box comprises a box body, a feeding groove is formed in the position, close to the left side, of the top of the crushing box, a discharging groove is formed in the bottom of the box body, and a crushing cavity is formed in the front side of the box body and used for providing a working space for crushing; and a crushing mechanism is arranged in the crushing cavity and comprises a crushing device, the crushing device comprises a crushing disc, and a motor is arranged at the rear side of thecrushing disc. According to the food crushing and processing machine, by arranging a scraping plate, the motor drives the scraping plate to rotate along the inner wall of the box body through a transmission rod, so that residual food attached to the inner wall is separated; and a movable spring is extruded to deform to generate elastic force, and the scraping plate is tightly attached to the innerwall to rotate under the action of the elastic force, so that the scraping effect of the scraping plate is improved.

Owner:湖南创美食品有限公司

A high-pressure water jet spiral cutting groove loosening blasting method

ActiveCN103697775BImprove breathabilityHigh mechanical strengthBlastingMetal working apparatusBlast effectsEconomic benefits

The invention provides a method of loose blasting by high-pressure water jet helical cutting. The method includes the steps: 1, drilling; 2, performing high-pressure water jet helical cutting; 3, charging; 4, sealing holes; 5, blasting. The method has the advantages that a crack zone formed by the method compared to traditional loose blasting is wider, coal seam permeability is greatly improved, control holes are fewer, and the cost is reduced; through the application of the water jet helical cutting manner, the defects of traditional mechanical cutting, such as tool jamming and drill locking, are overcome; the size of jet seams is determined by jet parameters, so that the problem that the size of the seams affects blasting effect is solved; helical cutting can be performed in axial and radial directions alternatively, through the application of the helical cutting manner, the range of crack zone is greatly enlarged and compensating space is provided for blasting, cut density can be adjusted, blasting lumpiness is controlled, and energy availability is improved; accordingly, economic benefit is increased on the premise of effectively preventing coal and gas outburst.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com