Garden waste melting machine

A garden waste and material machine technology, applied in the field of waste treatment, can solve the problems of low crushing efficiency of chemical material machines, achieve the effect of improving the crushing effect and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

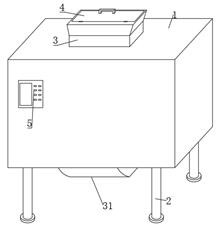

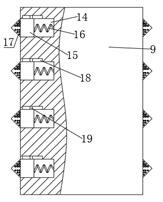

[0029] refer to Figure 1-4 , a garden waste chemical machine, including a box body 1, a plurality of legs 2 are symmetrically fixed on both sides of the bottom of the box body 1 by bolts, and a first straight shaft 8 and a second straight shaft 11 are connected to the inside of the box body 1 through hinge rotation. , the second straight shaft 11 is set obliquely behind the first straight shaft 8, the first straight shaft 8 is sleeved and fixed with a first rotating roller 9, the second straight shaft 11 is sleeved and fixed with a second rotating roller 13, the first The peripheral outer wall of the rotating roller 9 and the second rotating roller 13 is provided with a plurality of grooves 14 distributed in an annular array, the inner wall of one side of the groove 14 is provided with a first chute 18, and the first chute 18 is slidably connected with a first chute. block 19, the inner side of the first slide block 19 is fixed with a moving block 15 by bolts, the moving bloc...

Embodiment 2

[0033] refer to Figure 1-6, a garden waste chemical machine, the box body 1 is connected with a third straight shaft 27 by hinge rotation, the third straight shaft 27 is arranged above the discharge trough plate 31, and the third straight shaft 27 protrudes from the side close to the motor 7 A fourth pulley 28 is sleeved and fixed on the outside of the box body 1, a third pulley 26 is sleeved and fixed on the first straight shaft 8, and the same second belt is sleeved on the third pulley 26 and the fourth pulley 28. , the outer wall of the circumference of the third straight axis 27 is fixed with multiple groups of struts 29 by bolts, and the top of each group of struts 29 is fixed with the same distribution plate 30 by bolts, and the cross sections of the distribution plate 30 and the discharge trough plate 31 are all arranged in an arc The outer wall of the distribution plate 30 is provided with a plurality of embedding grooves 32, and a second spring 34 is fixed by bolts i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com