Liquid mixing device for double mixing of chemical production feed liquid

A technology for chemical production and material use. It is used in mixers, mixers with rotary stirring devices, transportation and packaging. It can solve problems such as low mixing efficiency, prolong service life, improve flexibility, and reduce stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

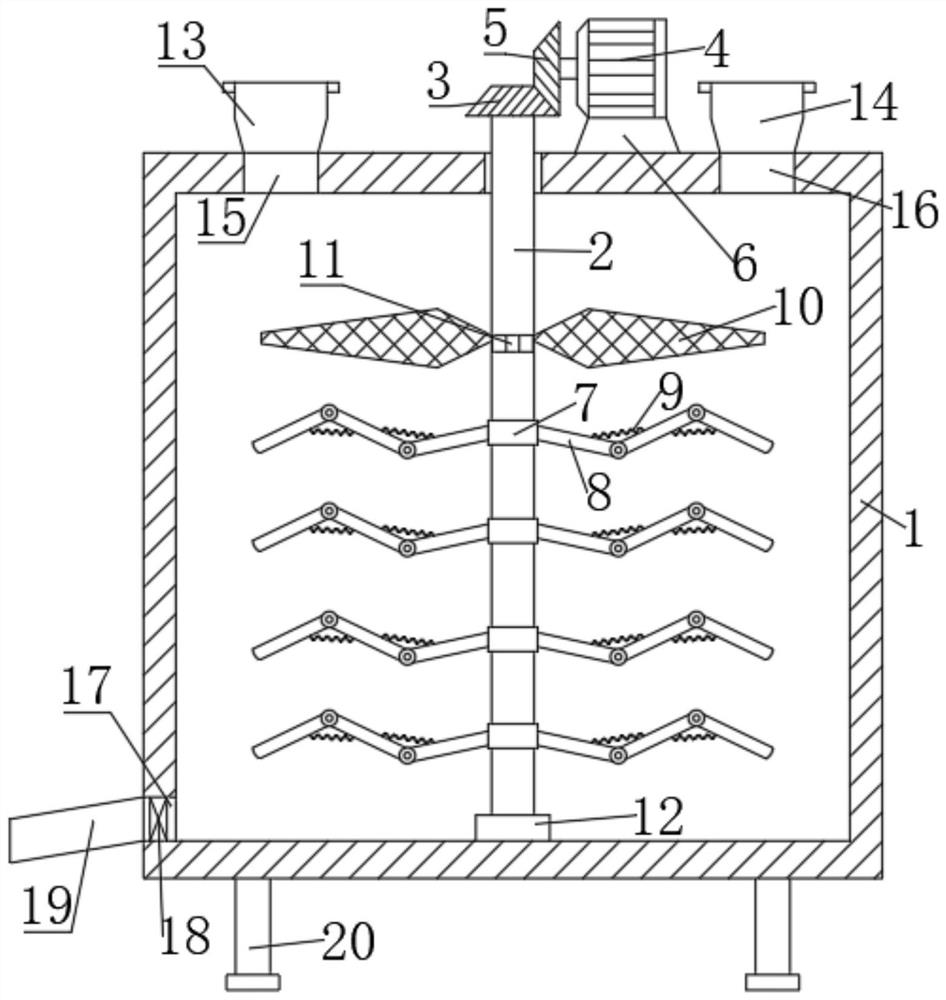

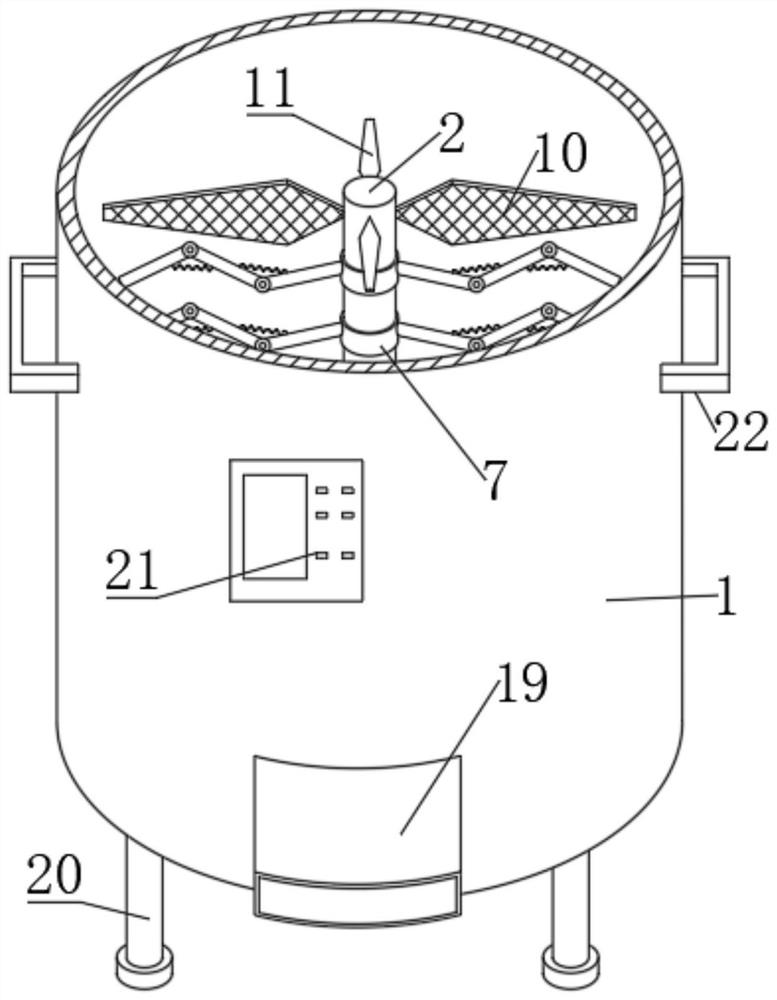

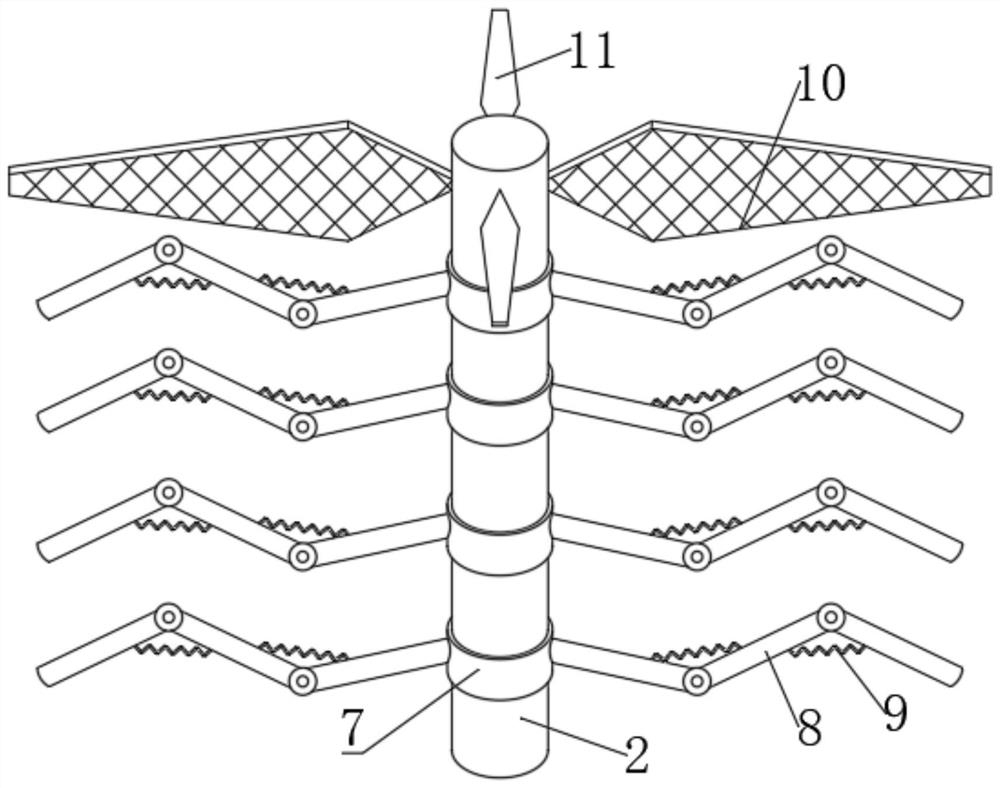

[0028] refer to Figure 1-3 , a liquid mixing device for double-mixing material and liquid for chemical production, comprising a box body 1, a plurality of feet 20 are symmetrically fixed on both sides of the bottom of the box body 1 by bolts, and a stirring mechanism is arranged inside the box body 1, and the stirring mechanism is located in the box body 1 The bottom of the inner wall is fixed with a bearing 12 by bolts, the top of the bearing 12 is nested and fixed with a straight shaft 2, and the top of the straight shaft 2 extends out of the box 1 and the first bevel gear 3 is fixed with bolts, and the straight shaft 2 is sleeved and fixed with bolts. A plurality of fixed rings 7 distributed up and down, both sides of the fixed ring 7 are fixed with a stirring assembly by bolts, the stirring assembly includes a plurality of stirring rods 8 and a first spring 9, and two adjacent stirring rods 8 are connected by hinge rotation , the first spring 9 is fixed between two adjace...

Embodiment 2

[0032] refer to Figure 1-5 , a liquid mixing device for double mixing of materials and liquids for chemical production, two first chute 23 are arranged symmetrically on both sides of the fixed ring 7, the first chute 23 is set as a narrow mouth structure, and the first chute 23 is slidingly connected with The first slider 24, the first slider 24 and the adjacent stirring rod 8 are rotatably connected by a hinge, the inner side of the stirring rod 8 is provided with a second chute 26, and the second chute 26 is slidably connected with a second slider 27 , both sides of the first spring 9 are respectively fixedly connected with two second sliders 27 .

[0033]When in use, the stirring assembly follows the first slider 24 to move back and forth in the first chute 23 under the action of the second spring 25 during the stirring process, thereby further increasing the stirring track of the stirring assembly, thereby improving the mixing efficiency. The first chute 23 is set to a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com