Treatment production line of lead frame

A lead frame and production line technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unreasonable operation settings and low efficiency, achieve optimal processing results, reduce contact area, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention is described in detail below in conjunction with accompanying drawing:

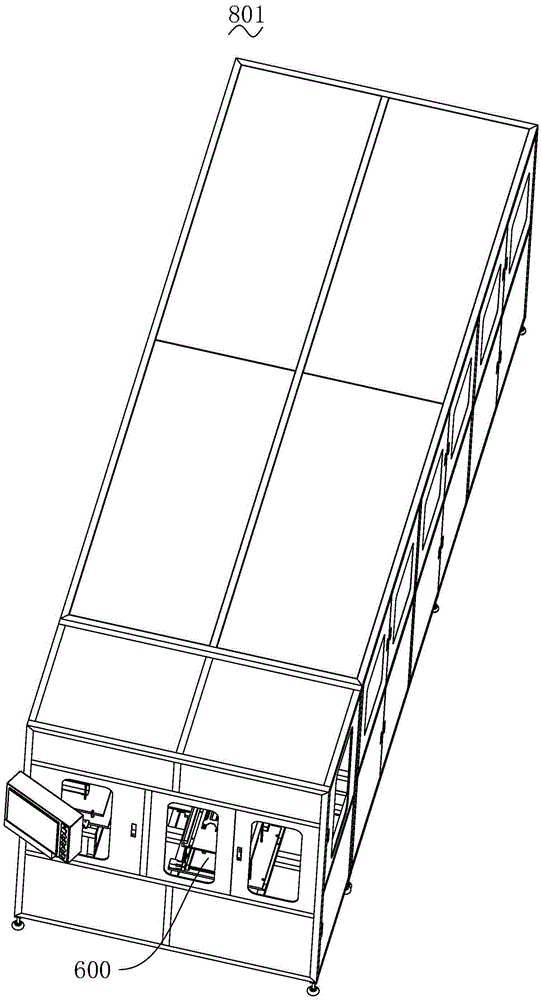

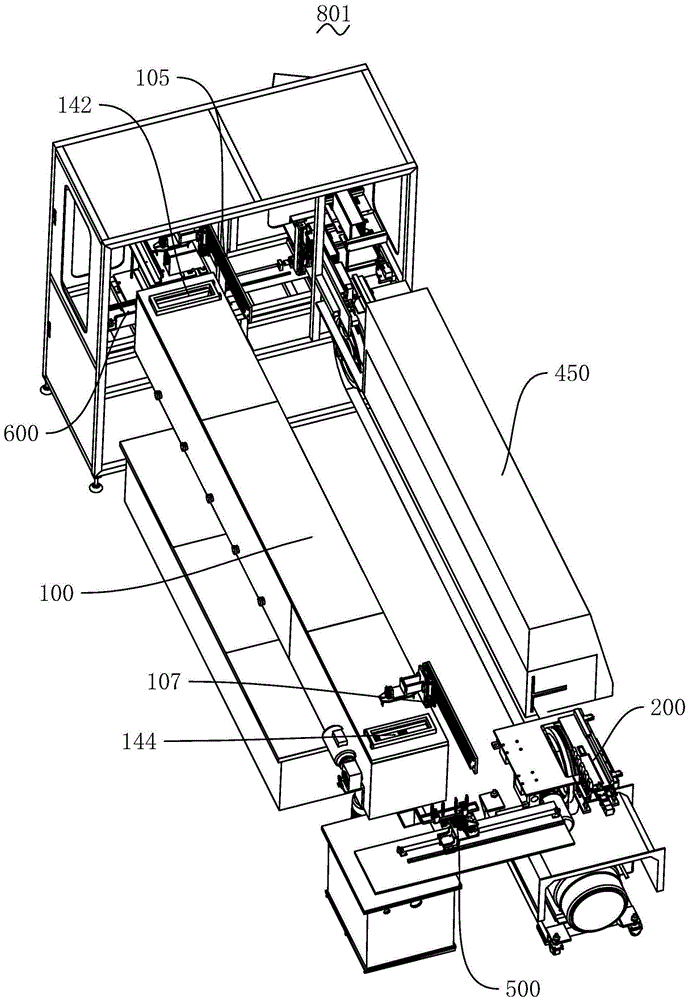

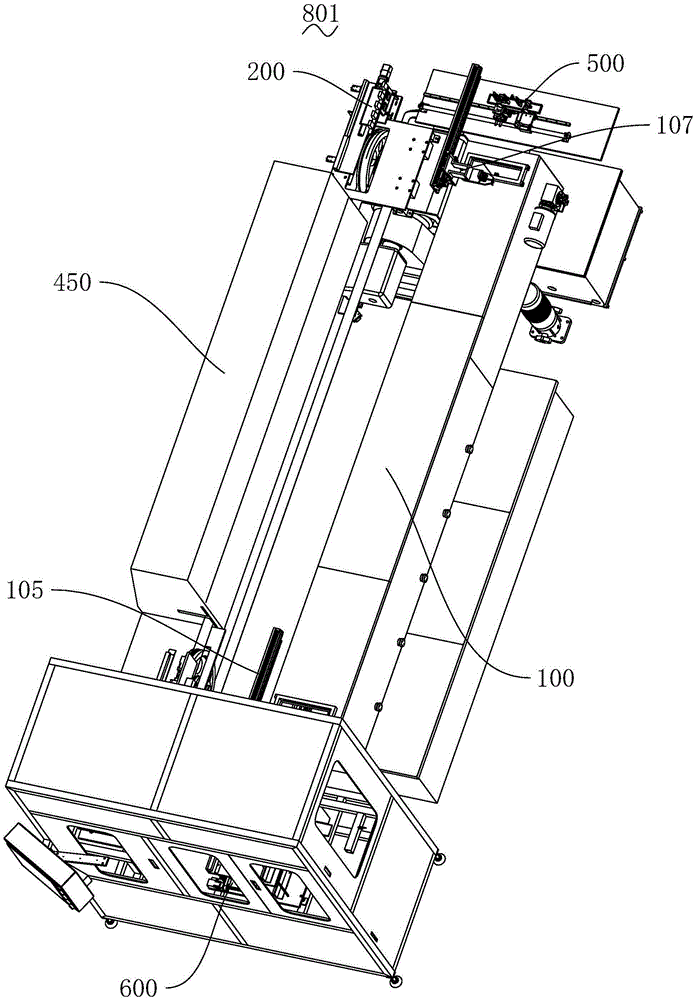

[0087] see Figure 1 to Figure 3 , which is a schematic structural diagram of a lead frame processing production line 801 provided by the present invention. The lead frame processing production line 801 includes a lead frame retrieving mechanism 600 , a lead frame processing tank 100 , a lead frame clamp 500 , a lead frame pushing device 200 and a water knife 450 . According to requirements, in this embodiment, in order to facilitate the automatic transfer operation, the processing production line 801 of the lead frame includes a corresponding feeding device and a feeding device. The lead frame processing production line 801 also includes corresponding computer control equipment, casings, brackets, etc., which are not the focus of the present invention, and will not be described in detail here.

[0088] Please also refer to Figure 4 , the discharging device includes a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com