Organic fertilizer pollution-free treatment device and treatment method

An organic fertilizer and processing device technology, which is applied in the direction of promoting the drying of solid materials, such as preliminary treatment, heating device, grain treatment, etc., can solve the problems of increasing production and processing costs, affecting use, caking, etc. effect, the effect of improving the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

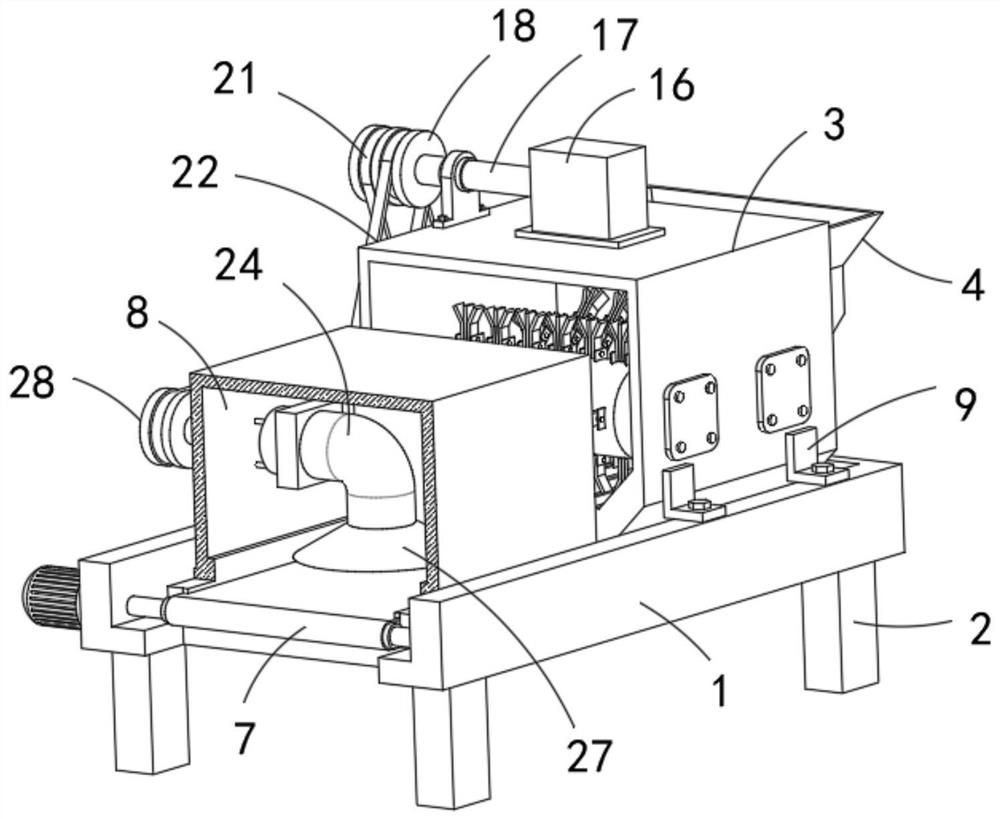

[0032] refer to Figure 1-6 , a pollution-free processing device for organic fertilizers, comprising a workbench 1 and a plurality of pillars 2, the plurality of pillars 2 are fixedly connected to the lower end of the workbench 1, the upper end of the workbench 1 is provided with a rectangular groove, and one side of the rectangular groove extends To the outside of the workbench 1, a housing 3 is fixedly connected in the rectangular groove, and the outer wall of the housing 3 is provided with a support mechanism connected with the workbench 1. The support mechanism includes L One end of the L-shaped bracket 9 away from the housing 3 is correspondingly connected to the upper end of the workbench 1, and the L-shaped bracket 9 is fixedly connected to the housing 3 and the workbench 1 by fastening screws respectively. In use, the disassembly and assembly between the housing 3 and the workbench 1 can be realized, thereby facilitating the storage of the housing 3 and reducing the oc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com