Crushing device for soil improvement

A crushing device and soil improvement technology, applied in grain processing and other directions, can solve problems such as incomplete crushing, and achieve the effects of complete crushing, complete crushing, and increasing crushing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

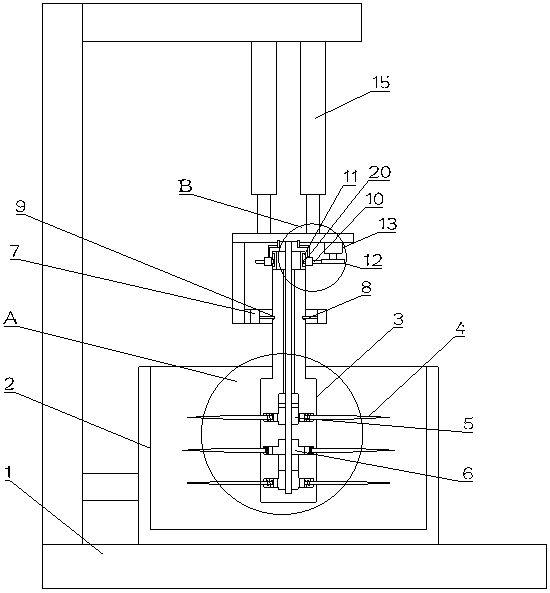

[0026] see figure 1 , in Embodiment 1 of the present invention, it is a structural diagram of a crushing device for soil improvement provided by the embodiment of the present invention, including: a support base 1, a crushing cylinder 2 and crushing parts; the crushing cylinder 2 is fixedly installed on the support base 1; The crushing part is arranged on the support seat 1; wherein, the crushing part includes a rotating shaft 3 which is rotatably arranged on the supporting seat 1, and the rotating shaft 3 can jump up and down during the rotation process, and the surface array of the rotating shaft 3 is provided with a plurality of crushing parts. Knife 4, a fixed rod 18 is slidingly arranged inside the rotating shaft 3, and the fixed rod 18 is fixedly installed on the support base 1, and the fixed rod 18 drives the crushing knife 4 to protrude intermittently through a transmission mechanism.

[0027] Specifically, the raw materials that need to be processed are added to the c...

Embodiment 2

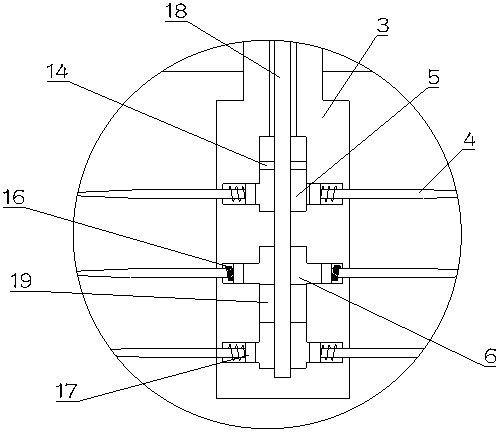

[0029] see figure 2 , the main difference between this embodiment 2 and embodiment 1 is that as a preferred embodiment of the present invention, the transmission mechanism includes a plurality of second cavities 6 arranged inside the rotating shaft 3, and the inside of the second cavities 6 A second piston 19 is arranged to slide up and down, and the second piston 19 divides the second cavity 6 into an upper cavity and a lower cavity, wherein a crushing knife 4 is arranged in the upper cavity and the lower cavity, and the crushing knife 4 elastically slides It is arranged in the upper cavity or the lower cavity; the inside of the second cavity 6 is filled with medium; when the rotating shaft 3 jumps up and down, the position of the second piston 19 in the second cavity 6 changes, at this time a cavity Being squeezed, the other chamber is stretched, so that one of the crushing knives 4 in different chambers is in a stretched state, and the other is in a contracted state.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com