A high-pressure water jet spiral cutting groove loosening blasting method

A high-pressure water jet and loose blasting technology, which is applied in blasting, metal processing, etc., can solve the problems of increasing workload and cost, blocking gas migration channels, etc., to prevent occurrence and development, enhance coal gas permeability, and Effect of Gas Pressure Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

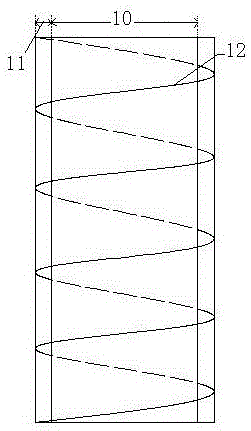

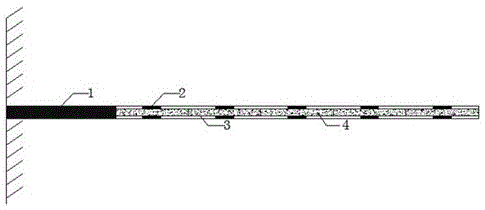

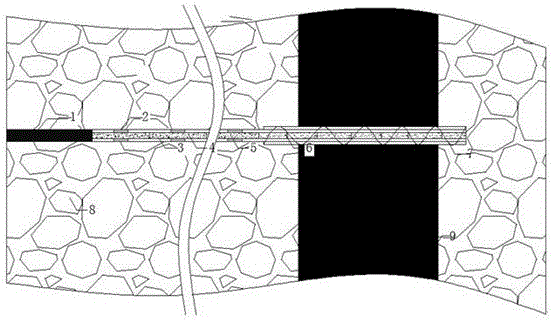

[0022] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , figure 2 , image 3 As shown, a high-pressure water jet spiral cutting groove loosening blasting method is characterized in that: comprising the following steps: comprising the following steps:

[0023] (1) Drilling: Use a drilling rig to drill a hole at the selected position of the coal and rock mass, with a diameter of 113 mm, and construct to the exact position according to the design plan;

[0024] (2) High-pressure water jet grooving: Spiral grooving is performed on the borehole at a position 0.5m outward from the starting end of the coal seam, and ends at a position 0.5m outward from the end end of the coal seam, so that a spiral jet slot is formed on the wall of the hole , the groove depth is 2-4cm;

[0025] (3) Charging: put the explosive with the detonator into the PVC pipe and then send the PVC pipe into the drill hole, using uncoupled charging and pos...

Embodiment 2

[0032] A high-pressure water jet spiral cutting groove loosening blasting method is characterized in that: comprising the following steps: comprising the following steps:

[0033] (1) Drilling: Use a drilling rig to drill a hole at the selected position of the coal and rock mass, with a diameter of 94mm, and construct it to the exact position according to the design plan;

[0034] (2) High-pressure water jet grooving: Spiral grooving is performed on the borehole at a position 0.5m outward from the starting end of the coal seam, and ends at a position 0.5m outward from the end end of the coal seam, so that a spiral jet slot is formed on the wall of the hole , the groove depth is 1-4cm;

[0035] (3) Charging: put the explosive with the detonator into the PVC pipe and then send the PVC pipe into the drill hole, using uncoupled charging and positive detonation;

[0036] ⑷Sealing the hole: send the PVC pipe filled with yellow sand into the drill hole and seal the hole with yellow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com