Automatic jet-flow crushing tool for natural gas hydrate solid-state fluidization and mining

A solid-state fluidized mining and jet breaking technology, which is used in the production of fluids, drilling with liquid/gas jets, drilling tools, etc., can solve the problems of low jet pressure, low breaking efficiency, and difficult-to-break tools to close, so as to avoid gas outflow. , the effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

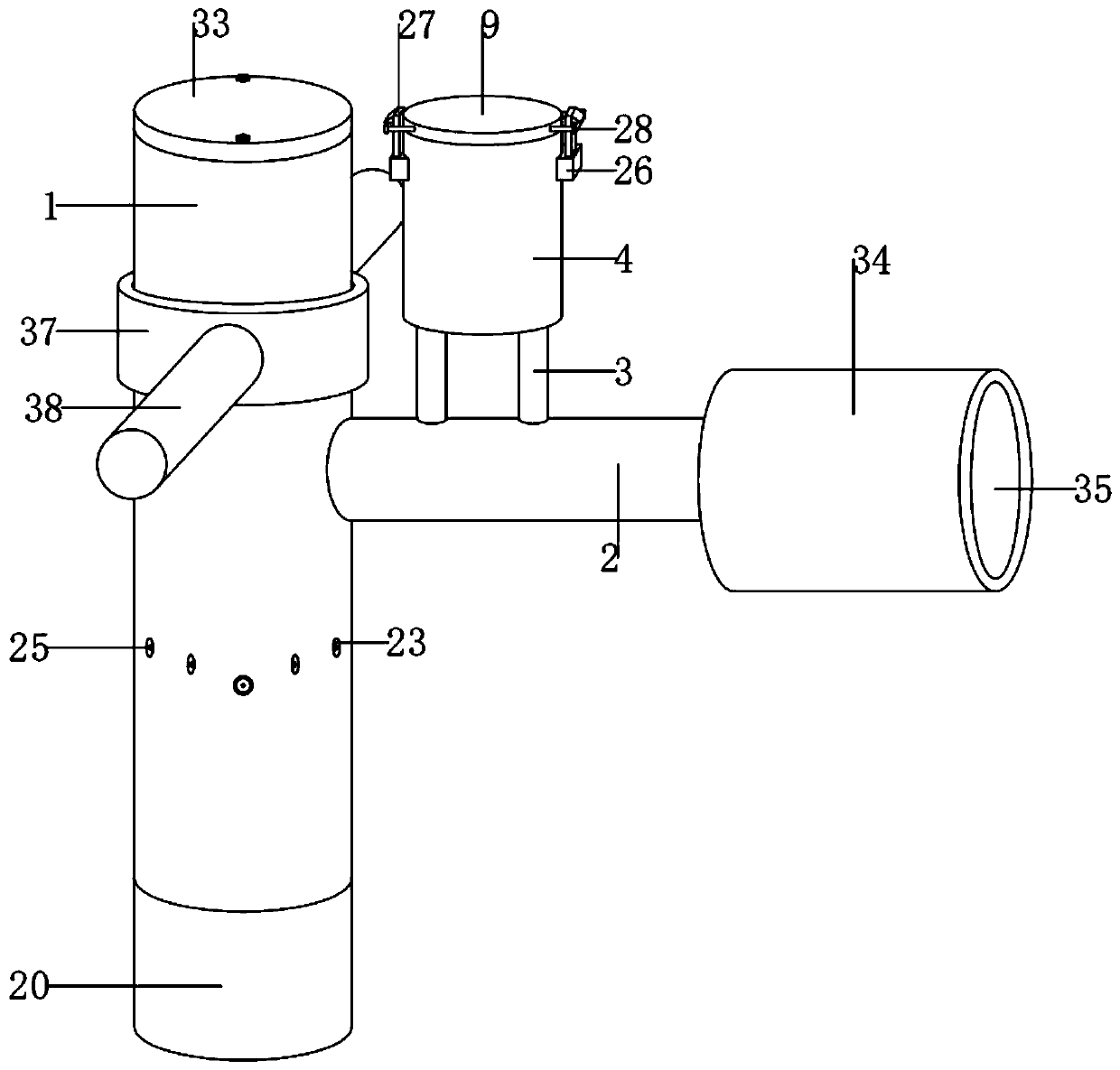

[0025] see Figure 1-5 , the present invention provides the following technical solutions:

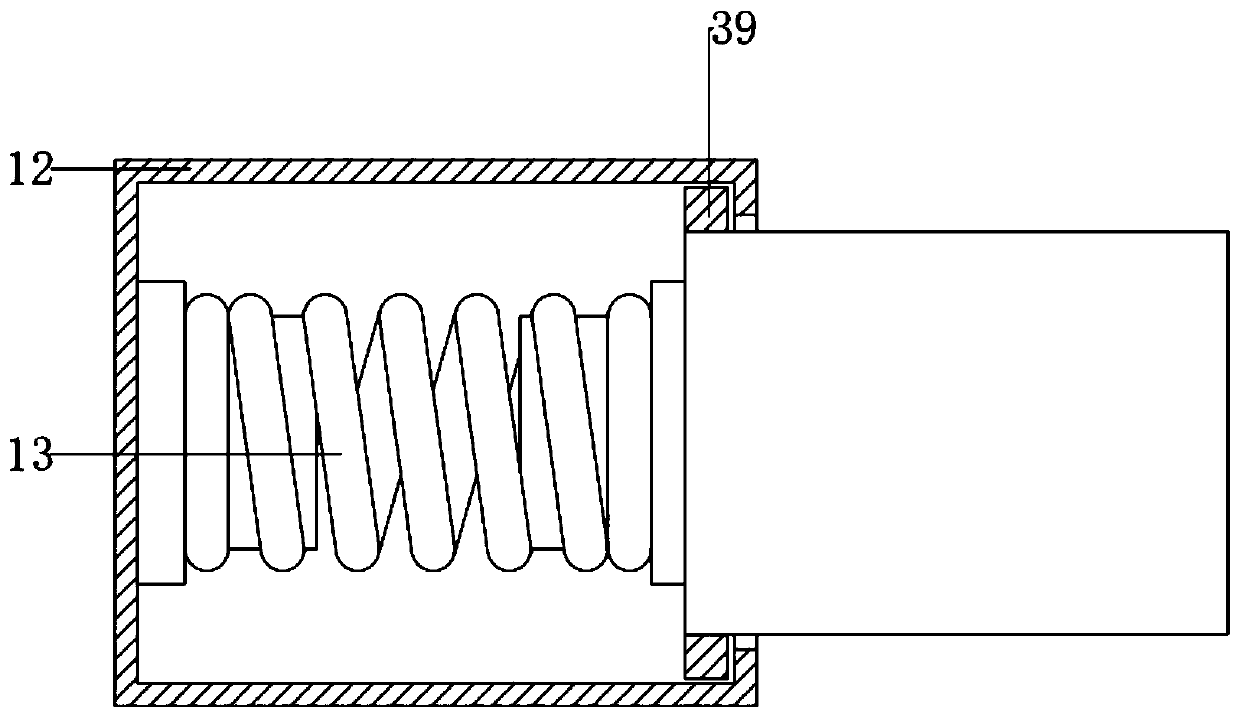

[0026]An automatic jet crushing tool for natural gas hydrate solid fluidization mining, comprising a crushing pipe 1, the right end of the crushing pipe 1 is connected with a connecting pipe 2 through a thread, the connecting pipe 2 is connected with the crushing pipe 1, and the upper end of the connecting pipe 2 is fixedly connected with a Two compression tubes 3, the compression tube 3 is connected with the connecting tube 2, the upper end of the compression tube 3 is fixedly connected with a compression tube 4, the compression tube 4 is connected with the two compression tubes 3, and the inner wall of the compression tube 4 is slidingly connected with a The first rubber plug 5, the upper end of the first rubber plug 5 is fixedly connected with the connection block 6, the upper end of the connection block 6 is fixedly connected with the pressure plate 7, the upper end of the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com