Rotary drawing machine

A technology of stretching machine and rotating body, which is applied in the field of bottle cap production machinery, can solve the problems of heavy equipment occupation, slow production speed, strong impact force, etc., reduce the chance of oil pollution, fast production speed, and low weight small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

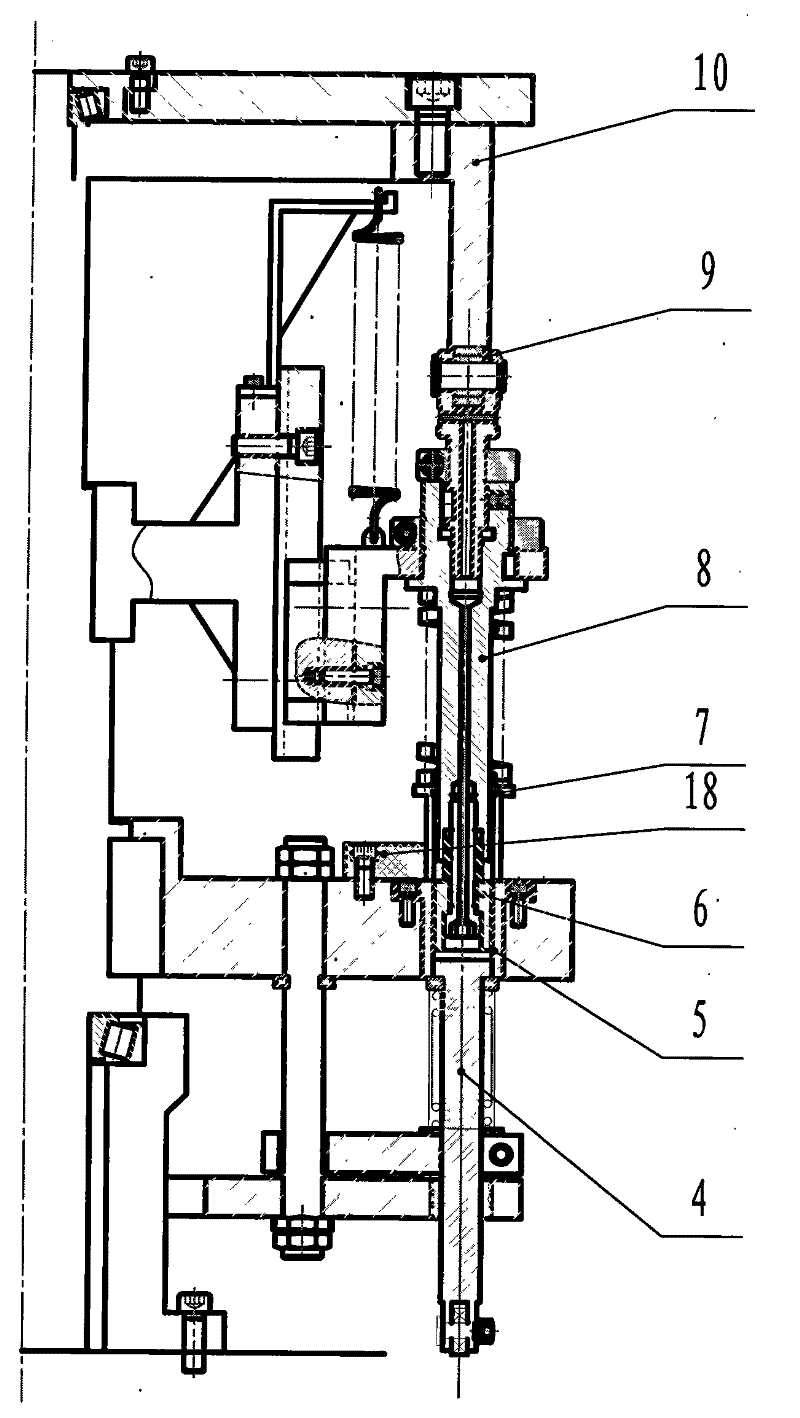

[0013] Example 1, see figure 1 , 2 , 3. Taking 8 rotating stretching stations as an example, the main shaft 3 is processed into a main shaft 3, and the main shaft gear 2, worktable 20, lower cam 12, lower rotating body 17, and upper rotating body are installed on the main shaft 3 in sequence from bottom to top 16. The pillar 24, the upper cam 10 and the cover plate 21, the main shaft gear 2 meshes with the motor gear 1 and the two dial gears 11 respectively, the motor gear 1 drives the main shaft gear 2 and the main shaft 3 to rotate, and the main shaft 3 drives the upper rotating body 16, The lower rotating body 17 moves, and the workpieces on the upper and lower rotating bodies are rotated and stretched, and the main shaft gear 2 drives the two dial gears 11 to rotate;

[0014] Rolling guide rails 14 are respectively installed at the eight equally divided stations of the upper rotating body 16. The rolling guide rails 14 are equipped with connecting blocks 22 and are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com