Quality treating method of ceramic frit

A ceramic glaze and processing method technology, which is applied in the field of ceramic technology, can solve the problems of large glaze usage, long time required, and increased cost, and achieve the effect of bright ceramics, reduced usage, and reasonable energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

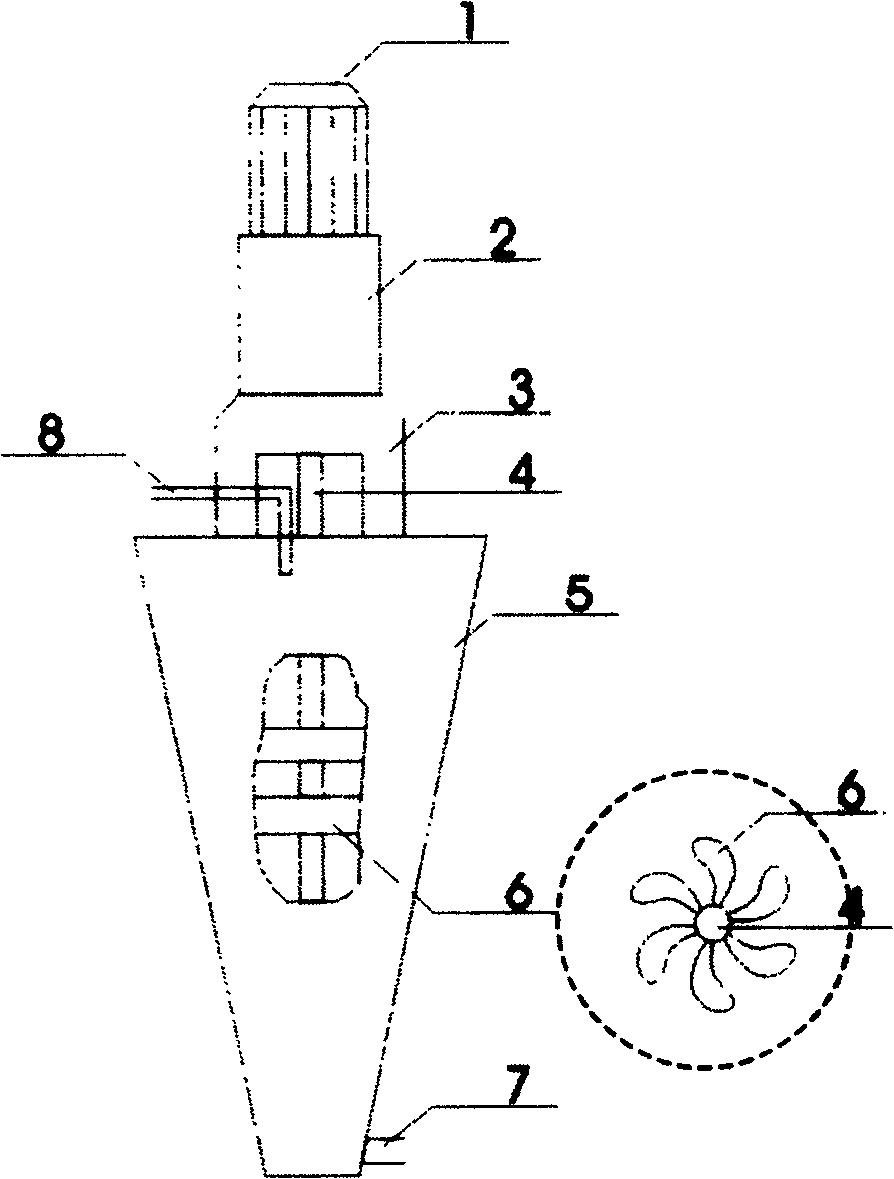

Image

Examples

experiment example

[0036] 1) After mixing the ceramic glaze (rutile titanium dioxide produced in Sichuan, with a particle size of D90<60 μm, 200 kg; 1300 kg of feldspar, with a particle size of D90<50 μm), add water to make a mixed slurry with a solid content of 50%;

[0037] 2) Mix the above-mentioned slurry with 4.5 kilograms of dispersant (9000 type, produced by Rohm and Haas Company), and use the following equipment to carry out ultrafine treatment contrast experiments respectively, with a laser particle size analyzer (JL1001 type, produced by Dandong Instrument Research Institute) Measure the particle size distribution of the powder after refinement to indicate the ultra-fine effect of the powder;

[0038] A. Ball mill (MQYG900*900 type, produced by Henan Liming Luqiao Heavy Industry Co., Ltd.): one-time feeding, continuous start-up and grinding for 15 hours, stop, take out materials, take samples, measure particle size, D90<45μm.

[0039]B. Stirring mill (SX type, produced by Wuxi Xinda Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com