Server mainboard assembling guide device

A guide device and server technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as scratches, no space to add positioning columns, scrapped motherboards, etc., to eliminate work waste, increase visibility, and easily The effect of being aligned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

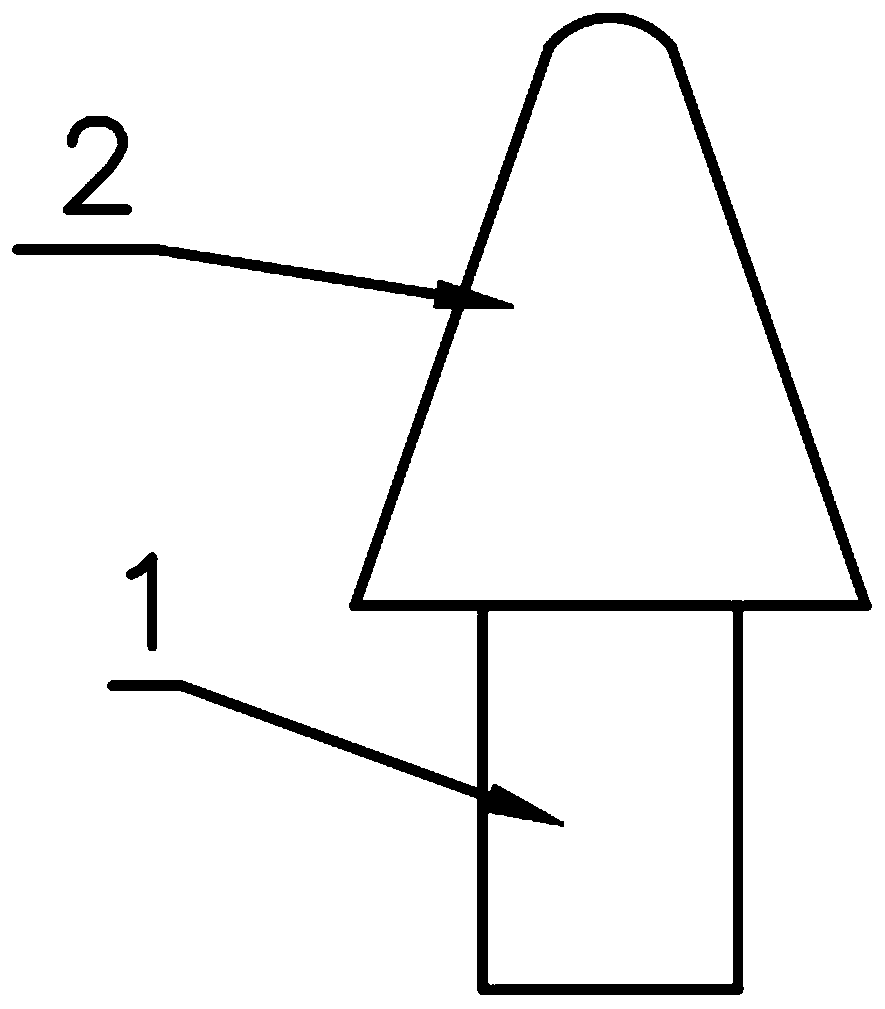

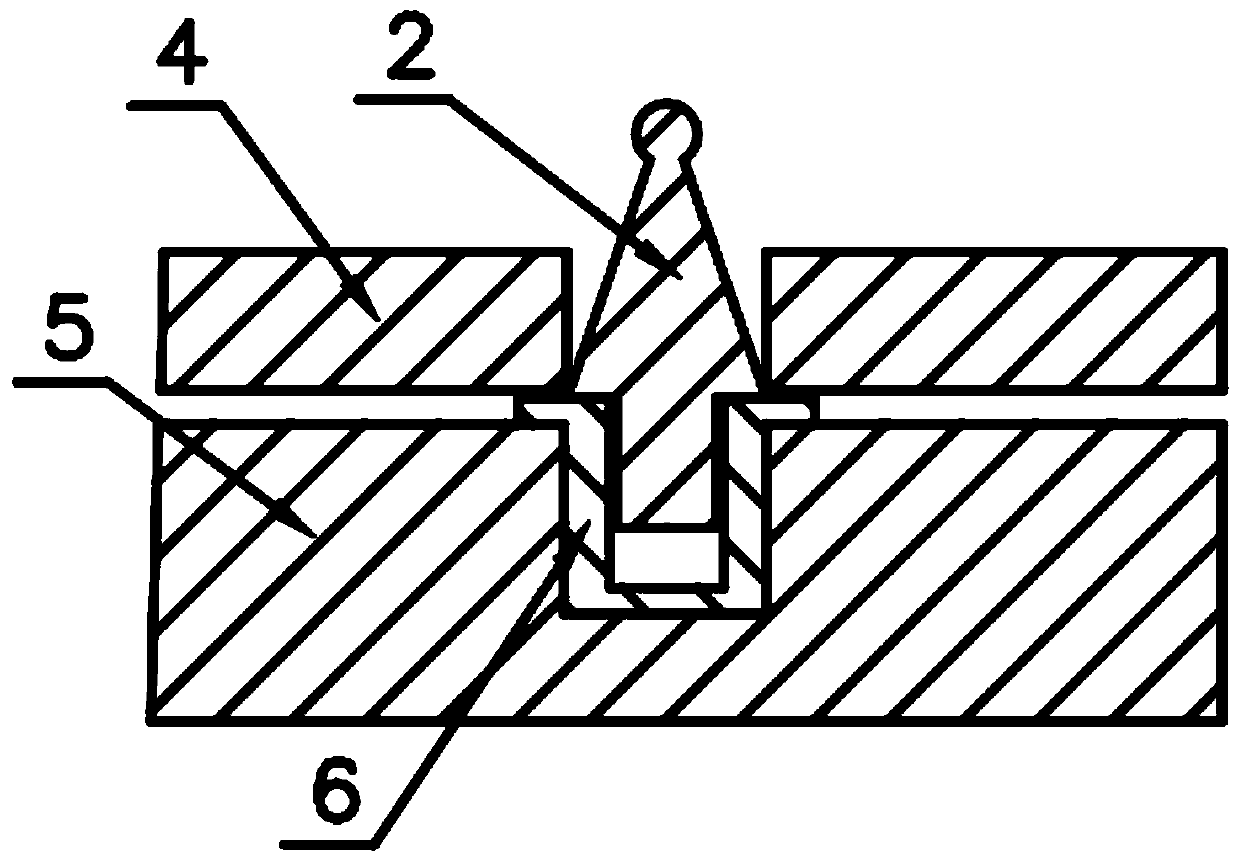

[0030] Such as figure 1 , a server motherboard assembly guide device, including a positioning column 1, the positioning column 1 is a cylinder, the positioning column 1 is connected with the threaded hole 6 on the assembly plate 5, and the positioning column 1 is connected with the guide head 2, The outer surface of the guide head 2 is a cone, the top of the guide head 2 is a smooth surface head, the guide head 2 is matched with the positioning hole on the main board 4, and the diameter of the conical bottom surface of the guide head 2 is less than or equal to the positioning hole of the main board 4 diameter of.

[0031] The diameter of the conical bottom surface of the guide head 2 is greater than the diameter of the threaded hole 6 .

[0032] The angle between the conical generatrix of the guide head 2 and the bottom surface of the cone is equal to 45°.

Embodiment 2

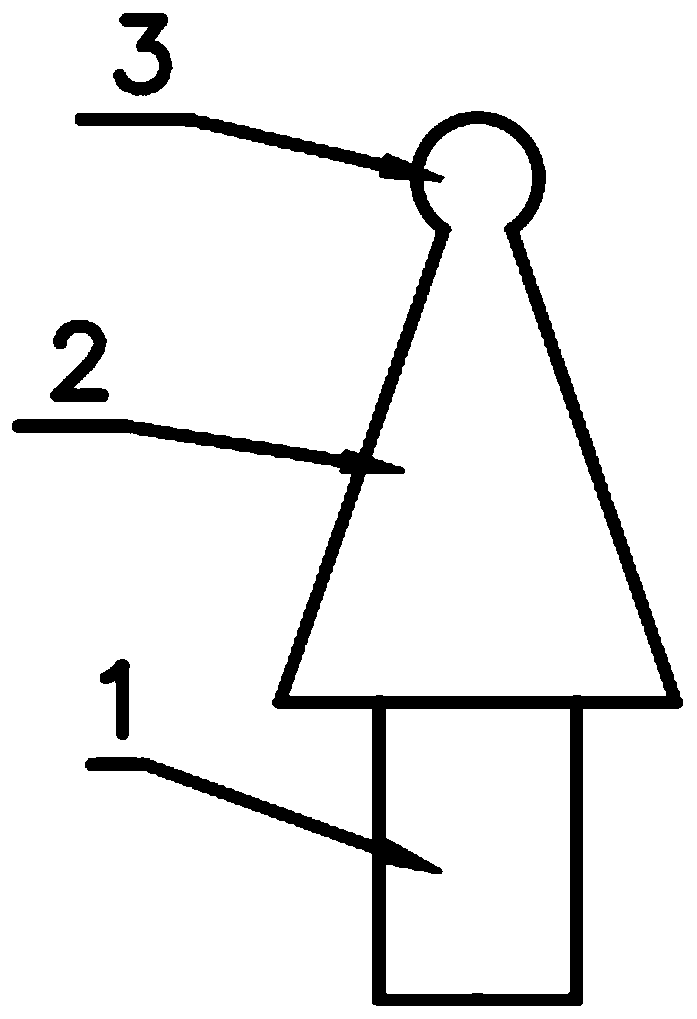

[0034] Such as figure 2 , 3 , a server motherboard assembly guide device, including a positioning column 1, the positioning column 1 is a cylinder, the positioning column 1 is connected with the threaded hole 6 on the assembly plate 5, and the positioning column 1 is connected with the guide head 2, The outer surface of the guide head 2 is a cone, the top of the guide head 2 is a smooth surface head, the guide head 2 is matched with the positioning hole on the main board 4, and the diameter of the conical bottom surface of the guide head 2 is less than or equal to the positioning hole of the main board 4 diameter of.

[0035] The upper part of the guide head 2 is connected with the anti-collision ball 3, and the diameter of the anti-collision ball 3 is smaller than the diameter of the conical bottom surface of the guide head 2.

[0036] The diameter of the anti-collision ball 3 is larger than the section diameter of the contact surface between the anti-collision ball 3 and ...

Embodiment 3

[0039] Such as figure 1 , a server motherboard assembly guide device, including a positioning column 1, the positioning column 1 is a cylinder, the positioning column 1 is connected with the threaded hole 6 on the assembly plate 5, and the positioning column 1 is connected with the guide head 2, The outer surface of the guide head 2 is a cone, the top of the guide head 2 is a smooth surface head, the guide head 2 is matched with the positioning hole on the main board 4, and the diameter of the conical bottom surface of the guide head 2 is less than or equal to the positioning hole of the main board 4 diameter of.

[0040] The diameter of the conical bottom surface of the guide head 2 is greater than the diameter of the threaded hole 6 .

[0041] The surface of the guide head 2 adopts a color obviously different from that of the main board 4 and the assembly board 5 .

[0042] A fluorescent layer is provided on the surface of the guide head 2 .

[0043] The included angle be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com