Preparation method of ultrahigh strength titanium alloy hot-rolled bar

A high-strength titanium alloy and ultra-high technology, which is applied in the field of preparation of ultra-high-strength titanium alloy hot-rolled bars, can solve the problem of high deformation resistance of ultra-high-strength titanium alloy bars, affect the application of ultra-high-strength titanium alloy materials, and reduce ultra-high-strength titanium alloys. Mechanical properties and other issues, to achieve excellent organizational uniformity and performance uniformity, excellent tensile strength and elongation, and the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] Step 1. Heat the Ti-1300 ultra-high-strength titanium alloy rod with a diameter of Φ45mm to 810°C and keep it warm for 25 minutes;

[0025] Step 2. The Ti-1300 ultra-high-strength titanium alloy bar after heat preservation treatment in step 1 is heated up to 840 ° C for 5 minutes and then rolled for 10 passes. The rolled Ti-1300 ultra-high-strength titanium alloy bar Cool in air to room temperature, cut to length, and obtain a Ti-1300 ultra-high-strength titanium alloy hot-rolled bar with a diameter of Φ8mm; the deformation of a single-pass rolling in the rolling is 20%.

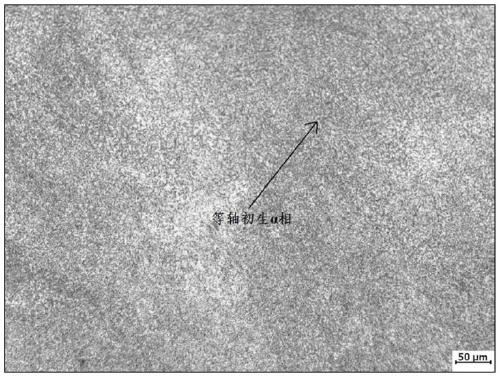

[0026] After testing, the Ti-1300 ultra-high-strength titanium alloy hot-rolled bar in this embodiment has a tensile strength of 1600 MPa after solution aging heat treatment, an elongation of 12%, a uniform equiaxed structure, and excellent comprehensive performance matching; The solution aging heat treatment process is as follows: heat the Ti-13...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] Step 1: Heat the Ti-5553 ultra-high-strength titanium alloy rod with a diameter of Φ50mm to 810°C and keep it warm for 28 minutes;

[0045] Step 2. The Ti-5553 ultra-high-strength titanium alloy bar after heat preservation treatment in step 1 is heated up to 840 °C in 6 minutes and then rolled for 8 passes, and the rolled Ti-5553 ultra-high-strength titanium alloy bar is Cool in air to room temperature, cut to length, and obtain a Ti-5553 ultra-high-strength titanium alloy hot-rolled rod with a diameter of Φ12 mm; the deformation of a single-pass rolling in the rolling is 15%.

[0046] After testing, the Ti-5553 ultra-high-strength titanium alloy hot-rolled bar in this embodiment has a tensile strength of 1530 MPa after solution aging heat treatment, an elongation of 11%, a uniform equiaxed structure, and excellent comprehensive performance matching; The solution aging heat treatment process is as follows: heat the...

Embodiment 3

[0054] This embodiment includes the following steps:

[0055] Step 1. Heat the Ti-1300 ultra-high-strength titanium alloy rod with a diameter of Φ55mm to 815°C and keep it warm for 30 minutes;

[0056] Step 2. The Ti-1300 ultra-high-strength titanium alloy bar after heat preservation treatment in step 1 is heated up to 840 ° C for 10 minutes and then rolled for 5 passes. The rolled Ti-1300 ultra-high-strength titanium alloy bar Cool in air to room temperature, cut to length, and obtain a Ti-1300 ultra-high-strength titanium alloy hot-rolled bar with a diameter of Φ20 mm; the deformation of a single-pass rolling in the rolling is 10%.

[0057] After testing, the Ti-1300 ultra-high-strength titanium alloy hot-rolled bar in this embodiment has a tensile strength of 1650 MPa after solution aging heat treatment, an elongation of 12%, a uniform equiaxed structure, and excellent comprehensive performance matching; The solution aging heat treatment process is as follows: heat the Ti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com