Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Reduce electrostatic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

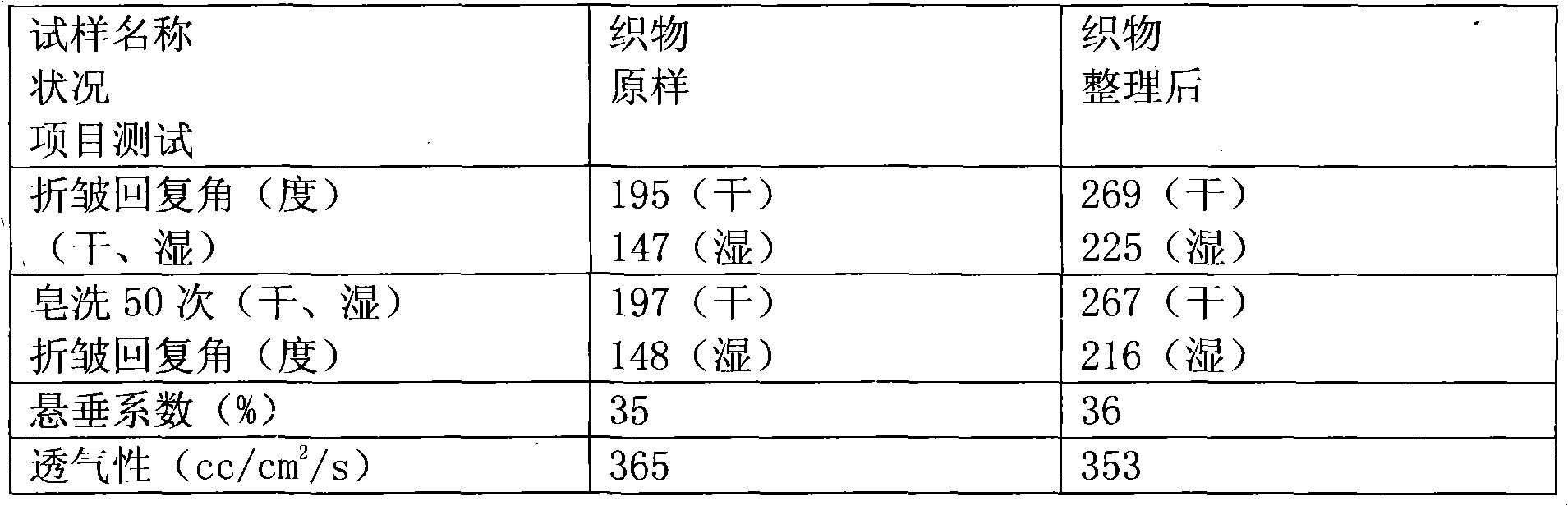

Antibiotic moisture absorption function finishing technique for polyester/cotton blended fabric

The invention provides a relative functional finishing technology which not only can maintain characteristics of smooth feeling of polyester / cotton fabric, good crease resistance, excellent strength and dimensional stability, and easily washing and quickly drying, but also can overcome defects that polyester / cotton fabric has low moisture absorption, poor breathability and developed bacteria caused by sweat stains, thereby affecting the health of people. The invention adopts a special moisture adsorption and perspiration finishing agent SW and an antibacterial finishing agent SCJ-891, and the finishing technology is produced by processing the polyester / cotton fabric according to post finishing technological process of common fabric.

Owner:SHENGHONG GRP CO LTD

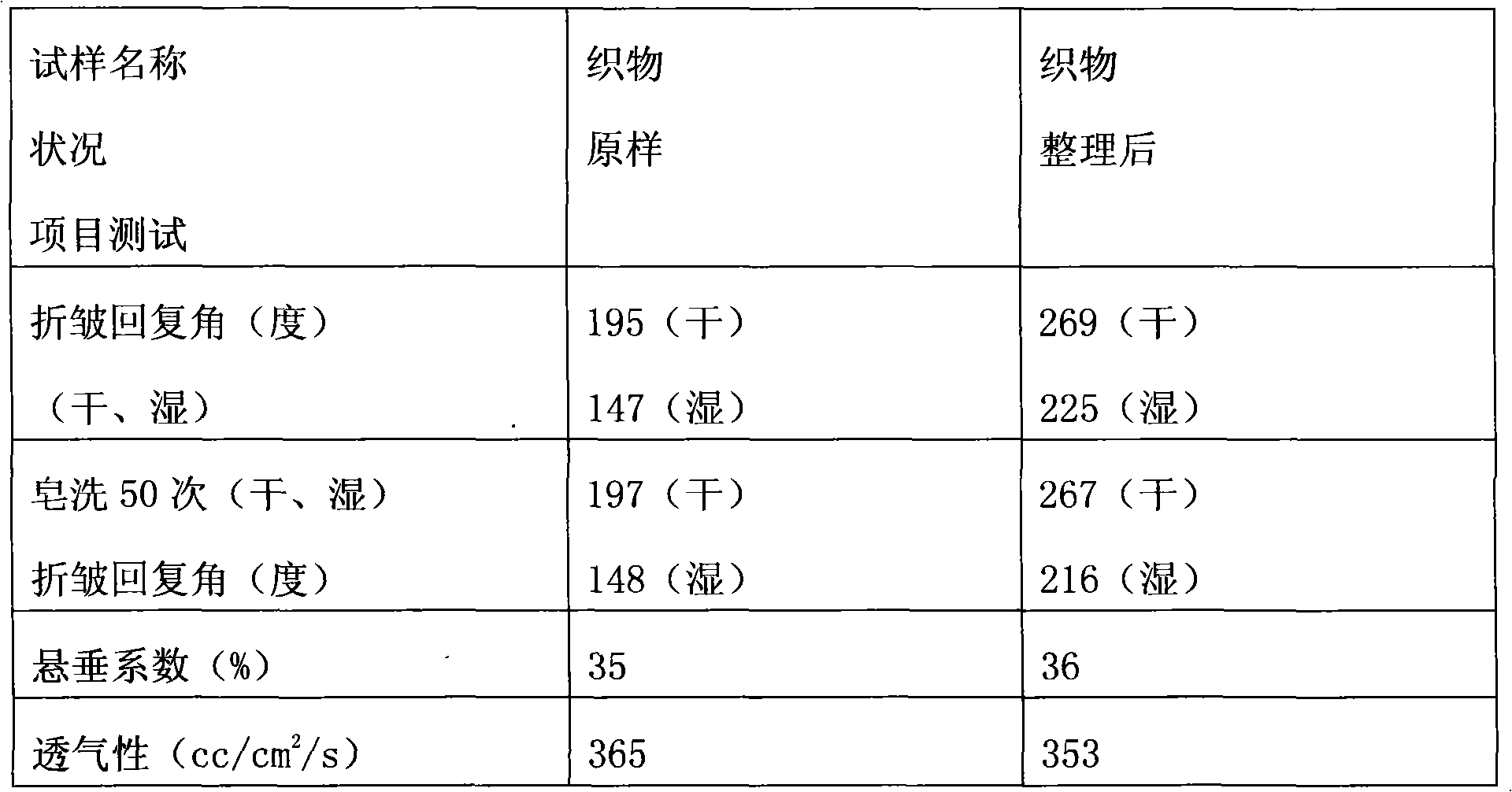

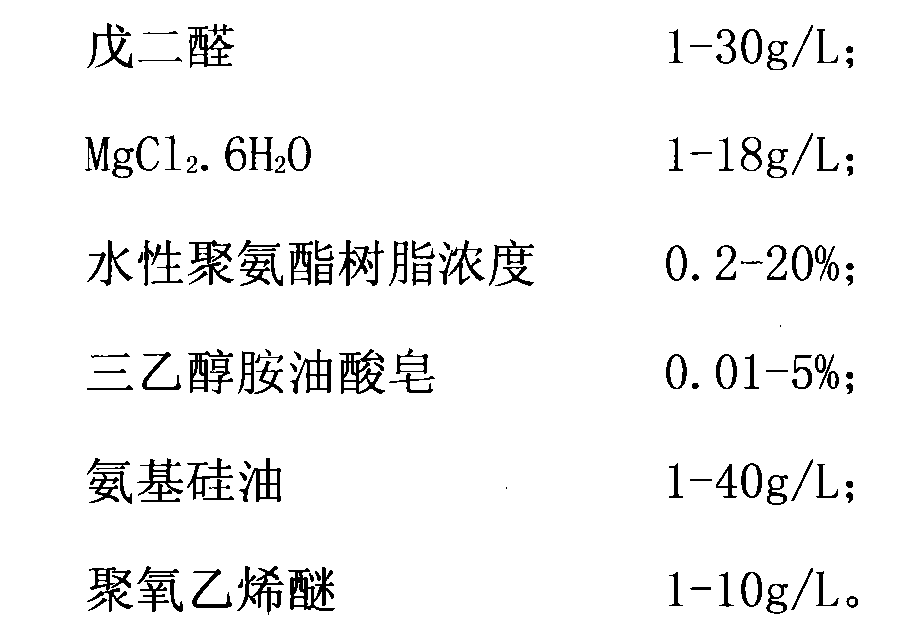

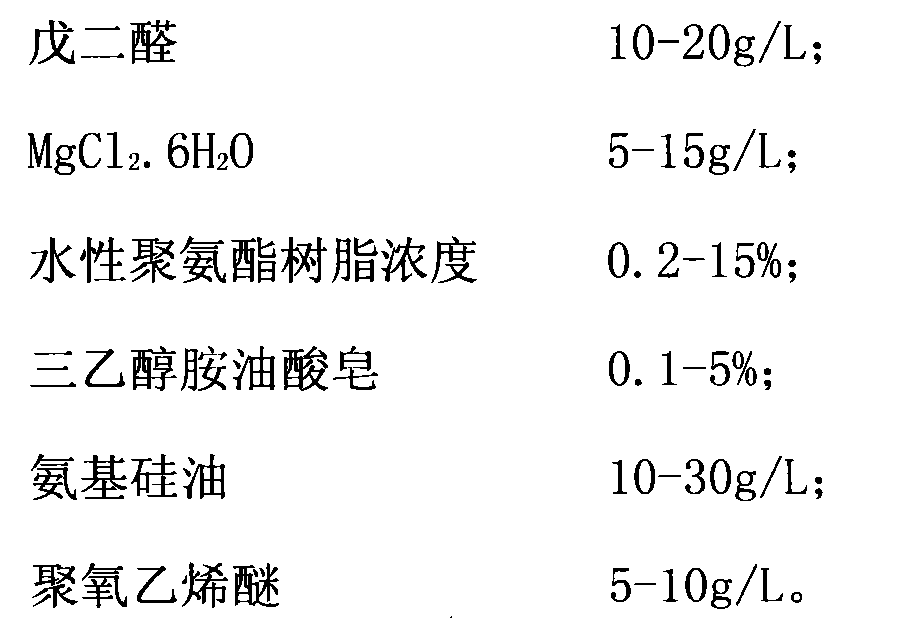

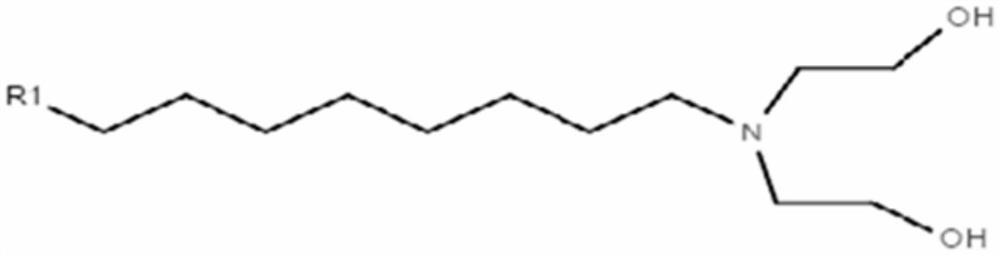

Anti-creasing softener

The invention provides an anti-creasing softener which comprises the following raw materials: 1-30g / L of glutaric dialdehyde, 1-18g / L of MgCl2.6H2O, 0.2-20 percent (in concentration) of aqueous polyurethane resin, 0.01-5 percent of triethanol amine oleate soap, 1-40g / L of amino silicone oil and 1-10g / L of polyethenoxy ether. The anti-creasing softener provided by the invention is nonpoisonous and harmless to human bodies, has good moisture absorption property and air permeability, has no influence on the color and the whiteness of fabrics, has soft hand feeling, good anti-creasing performance and improved washing-resisting property and is an ideal and green anti-creasing softening agent.

Owner:TIANJIN BIJIA PHARMA CO LTD

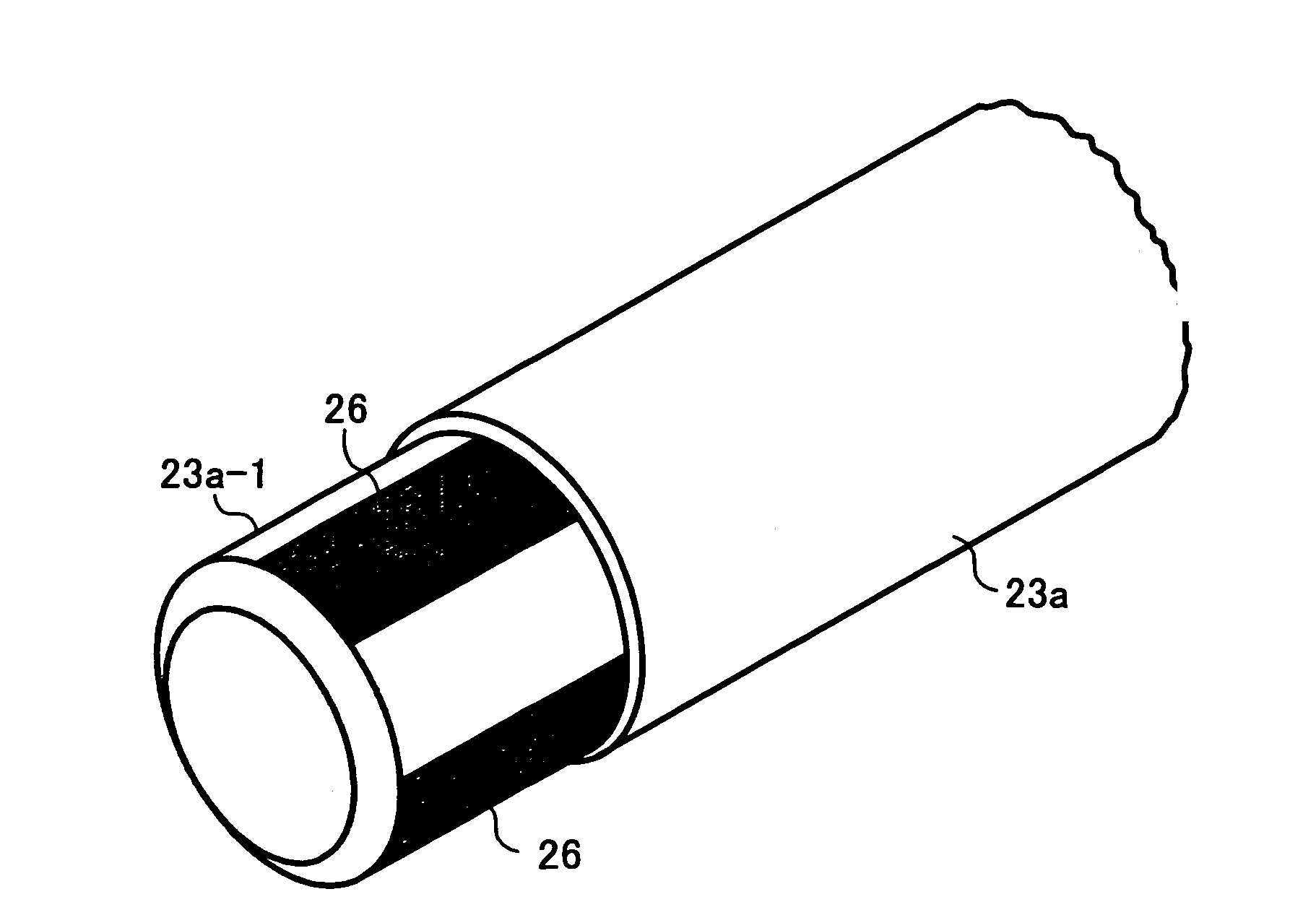

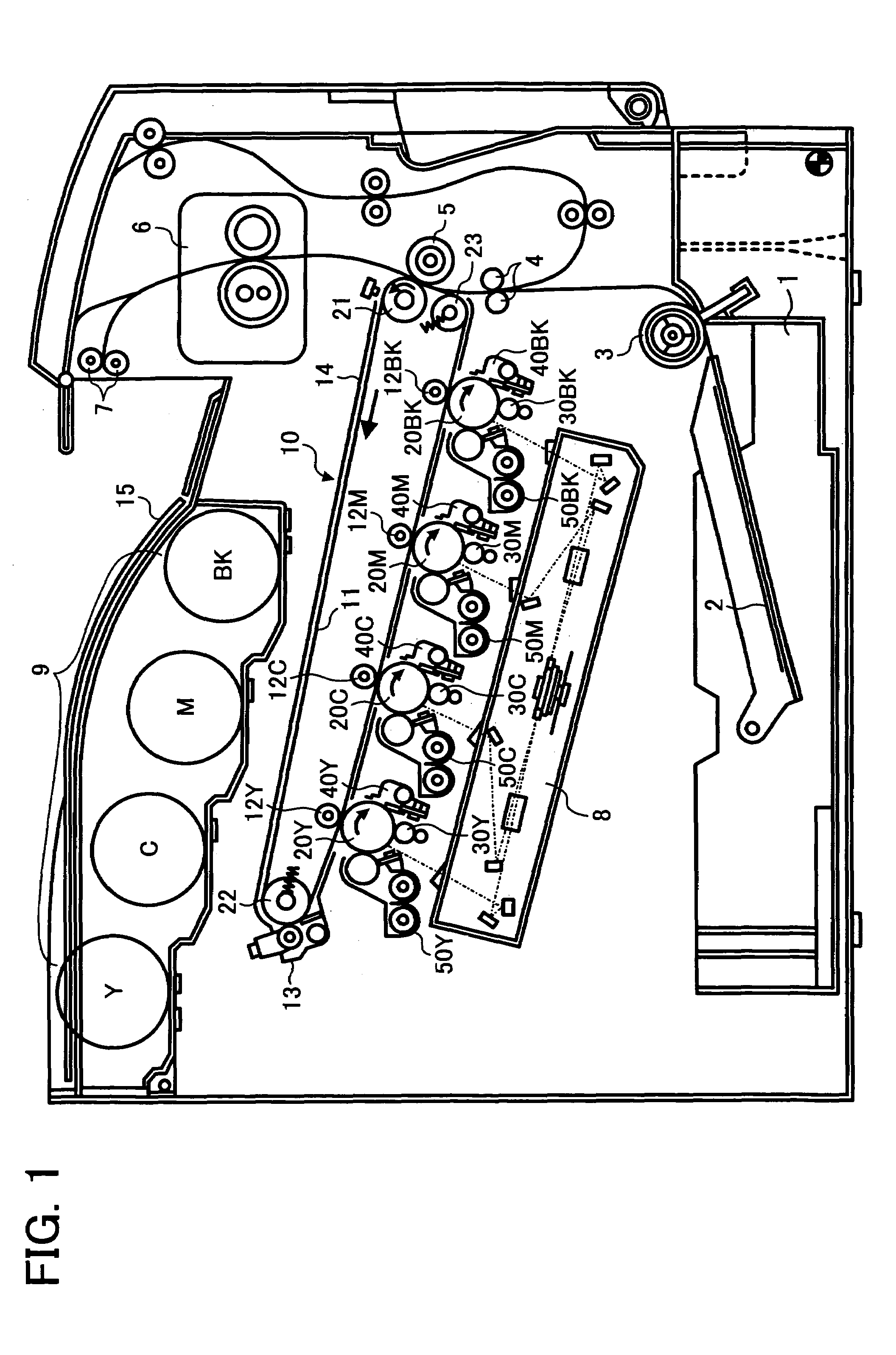

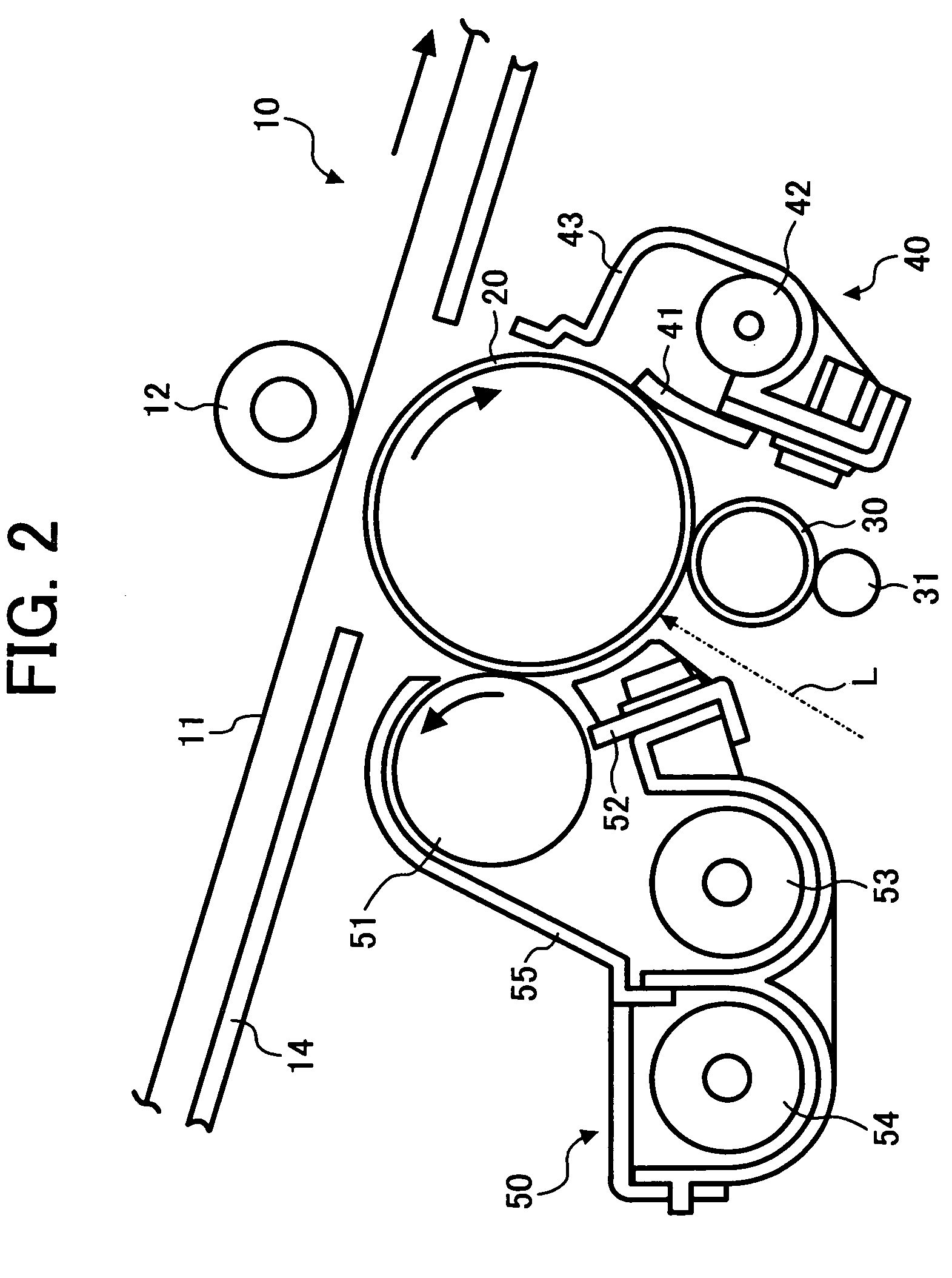

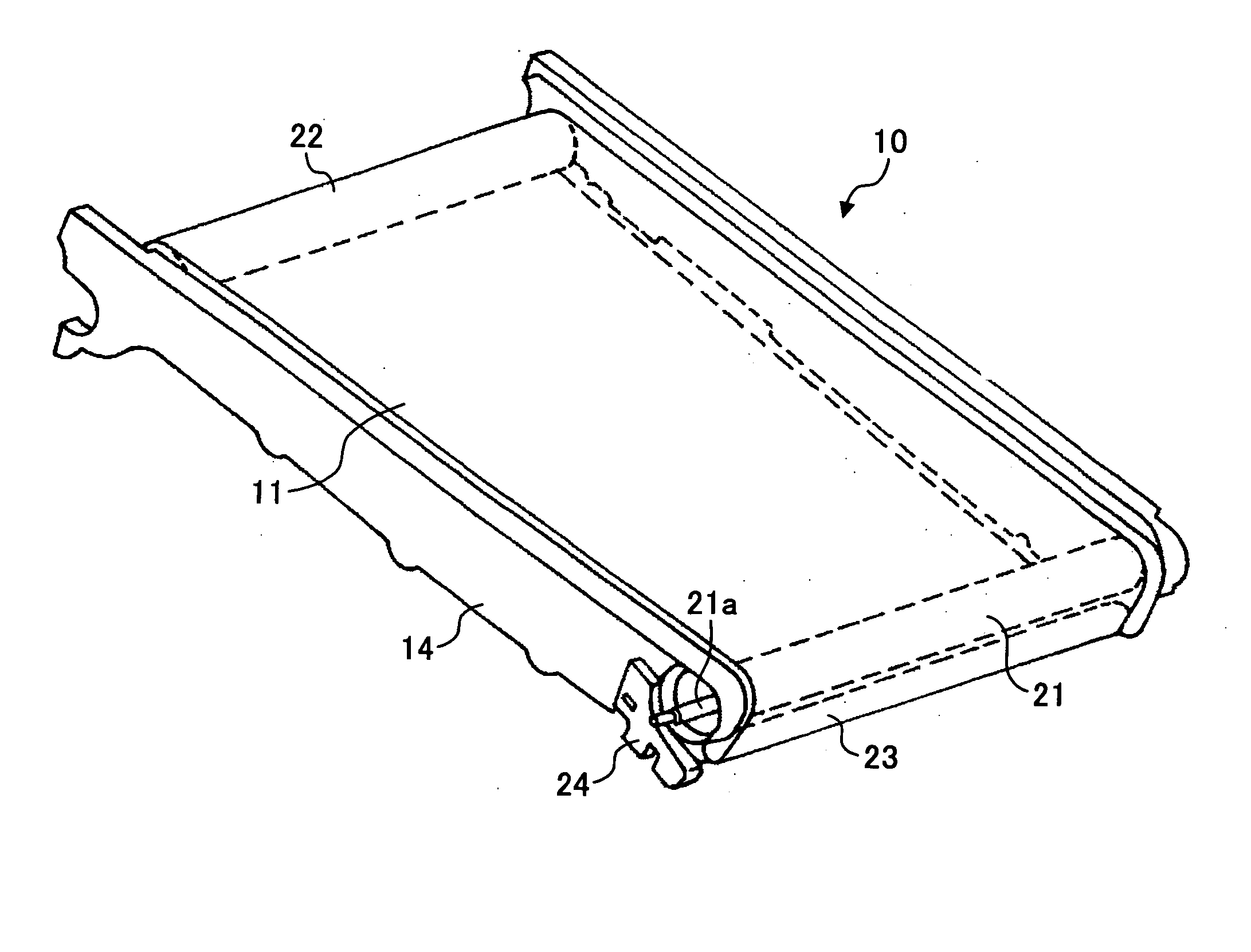

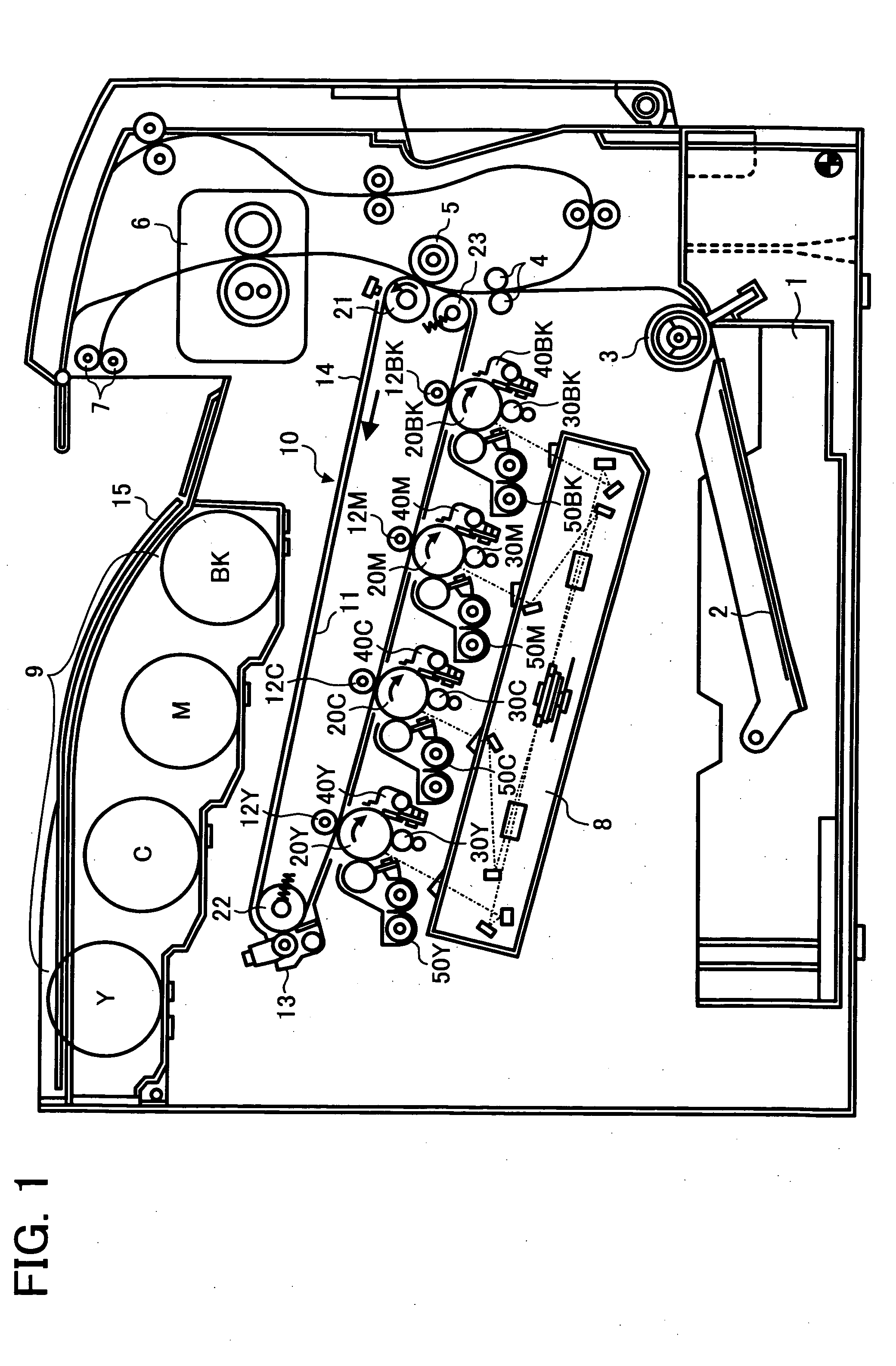

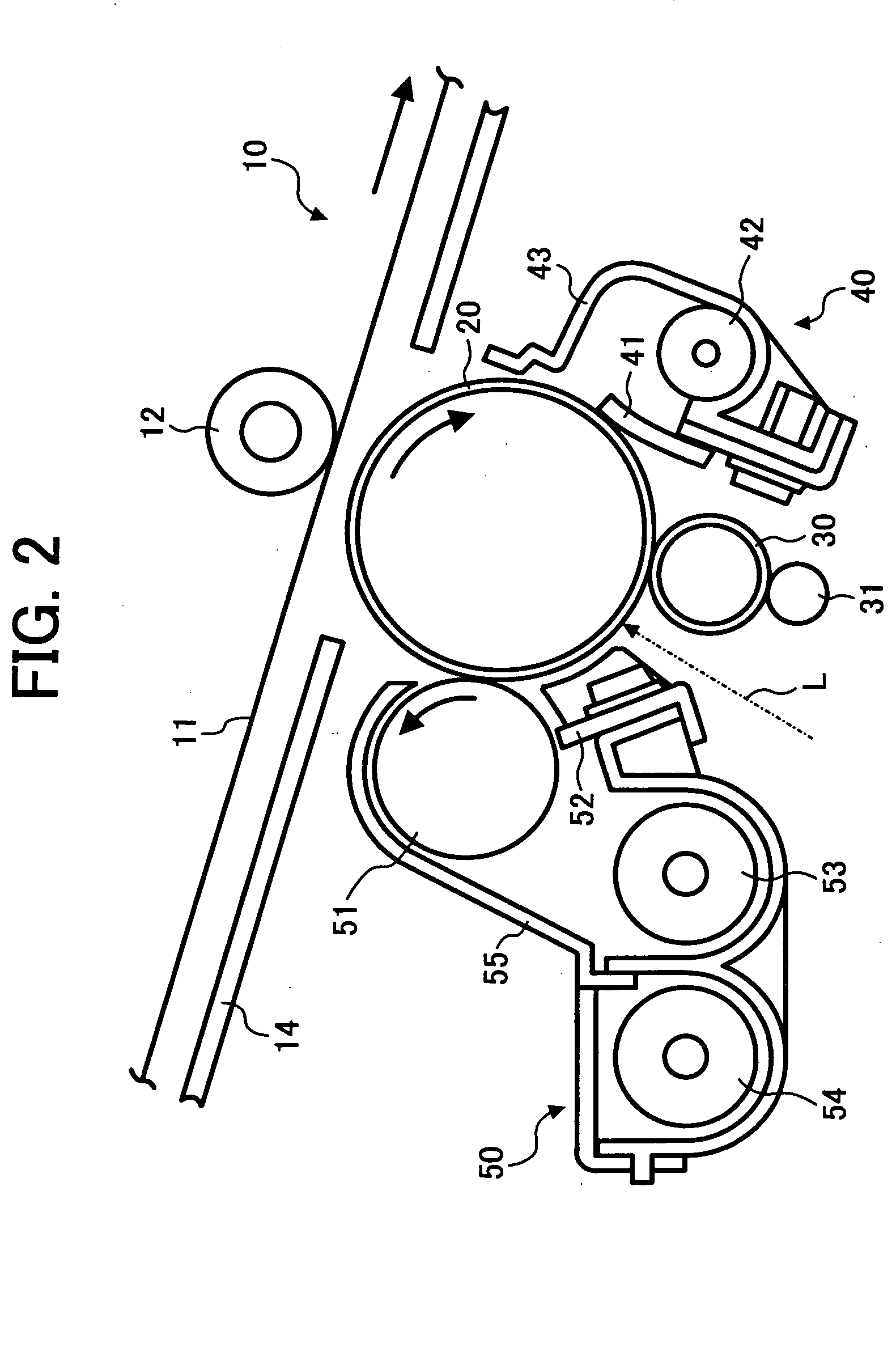

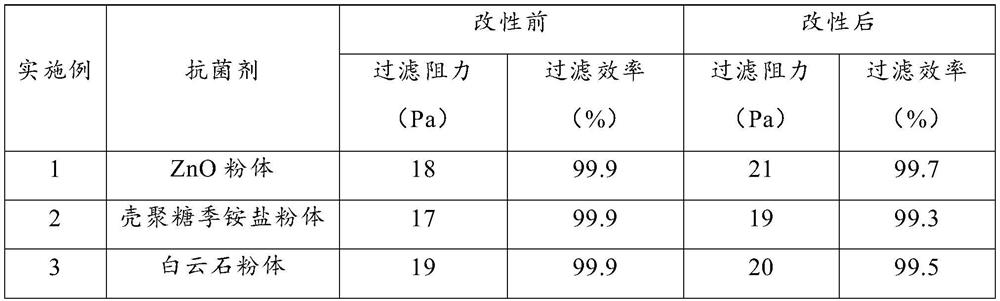

Endless belt device and image forming apparatus using the device

ActiveUS7277667B2Small sizeImprove detection accuracyElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

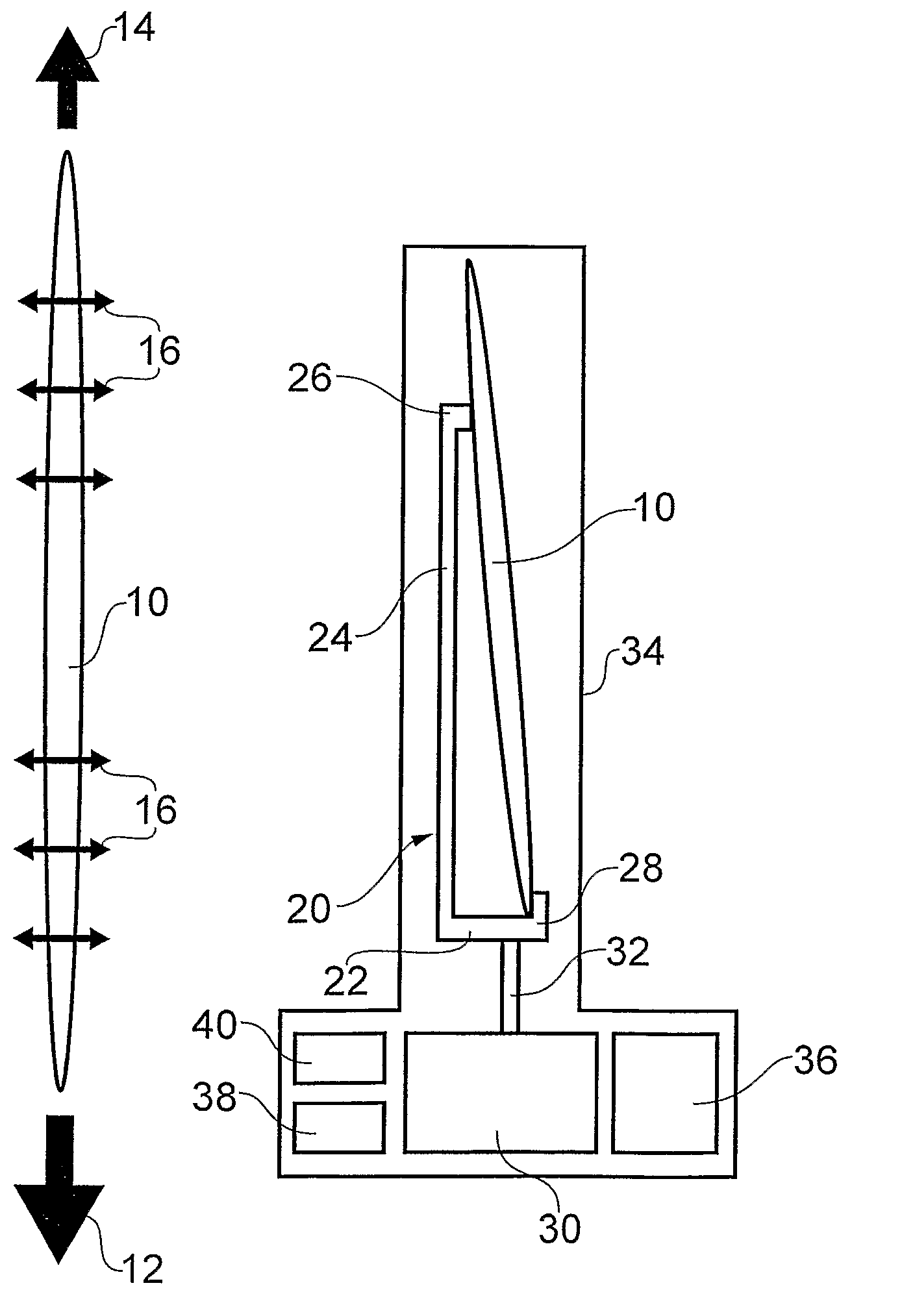

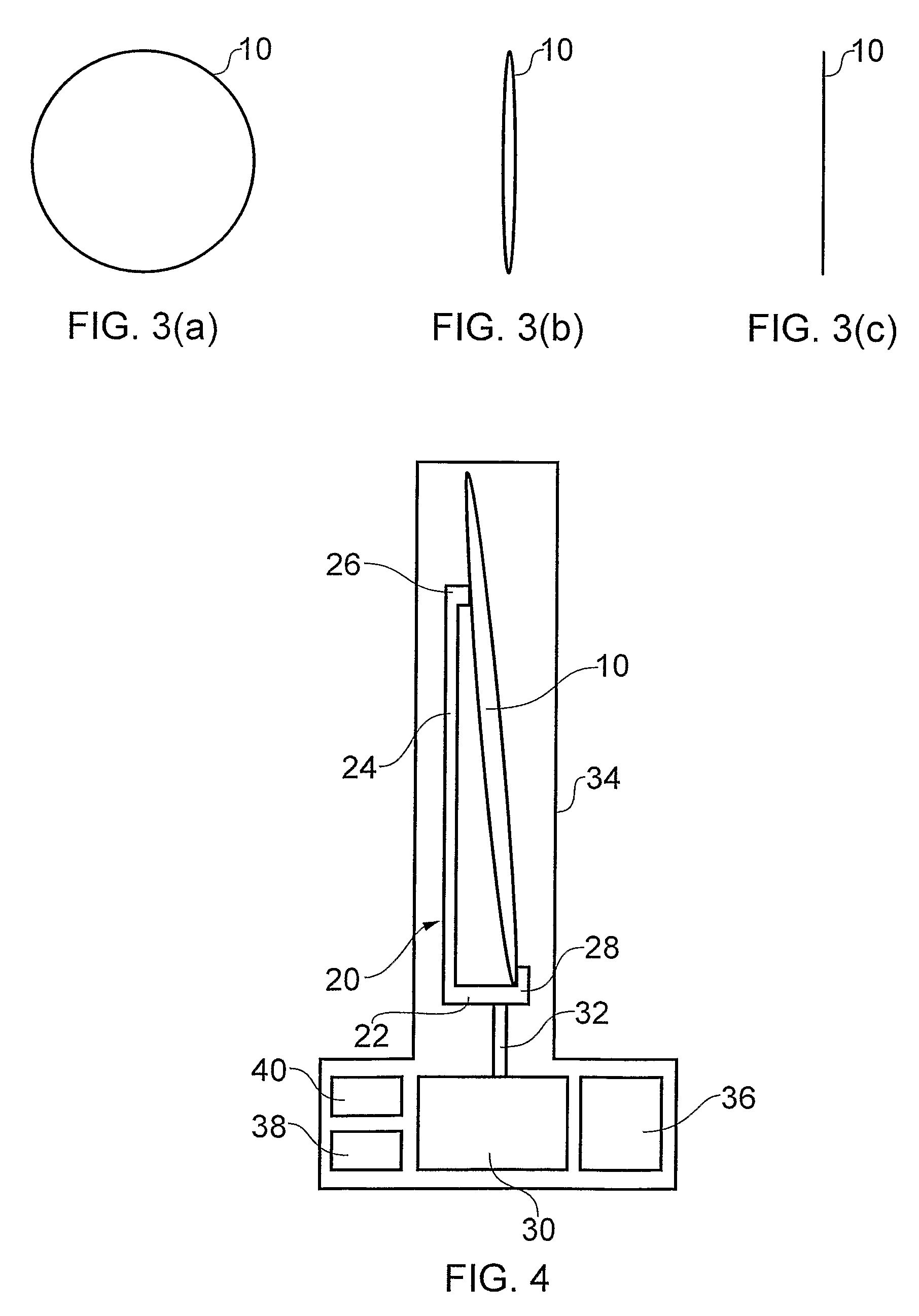

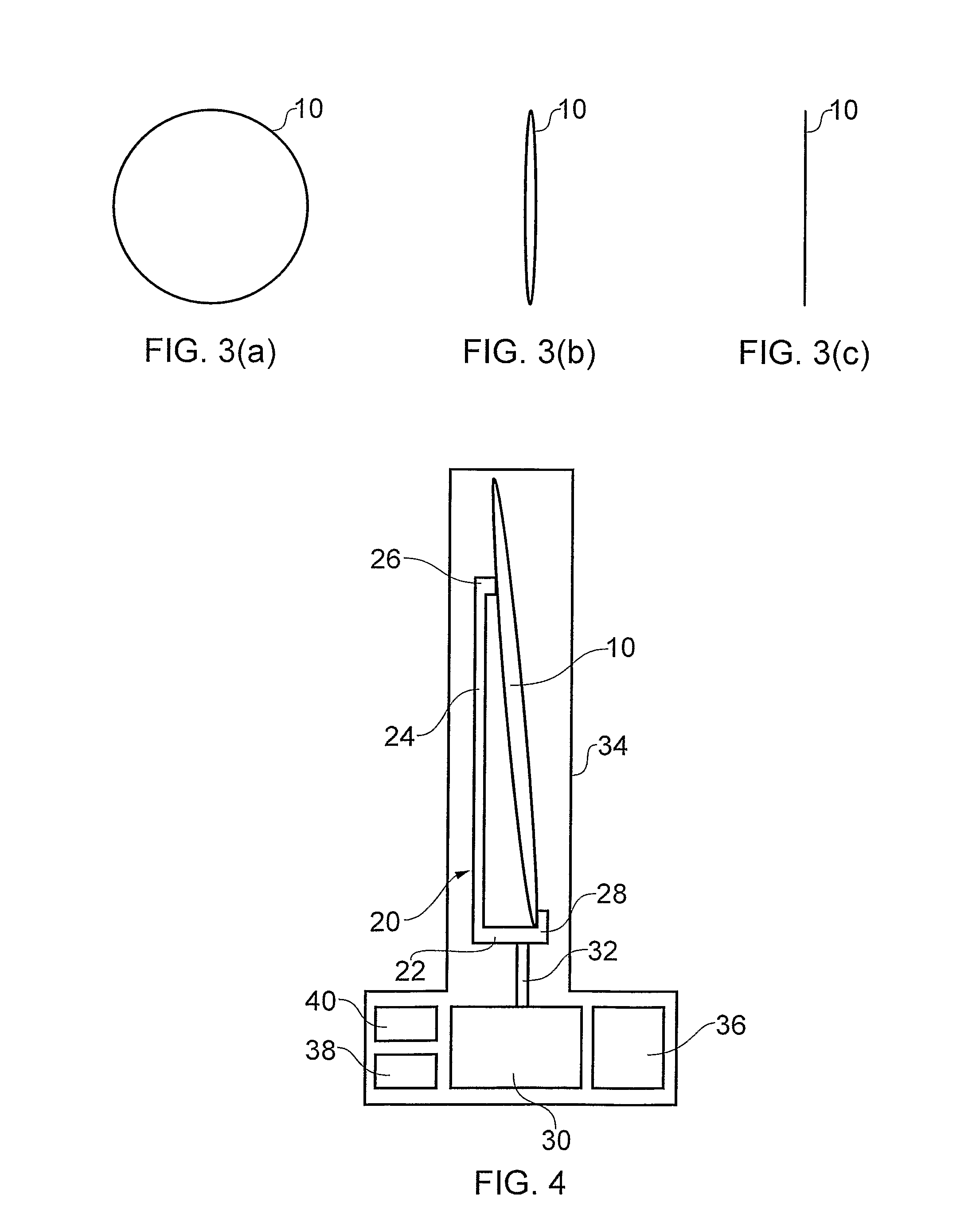

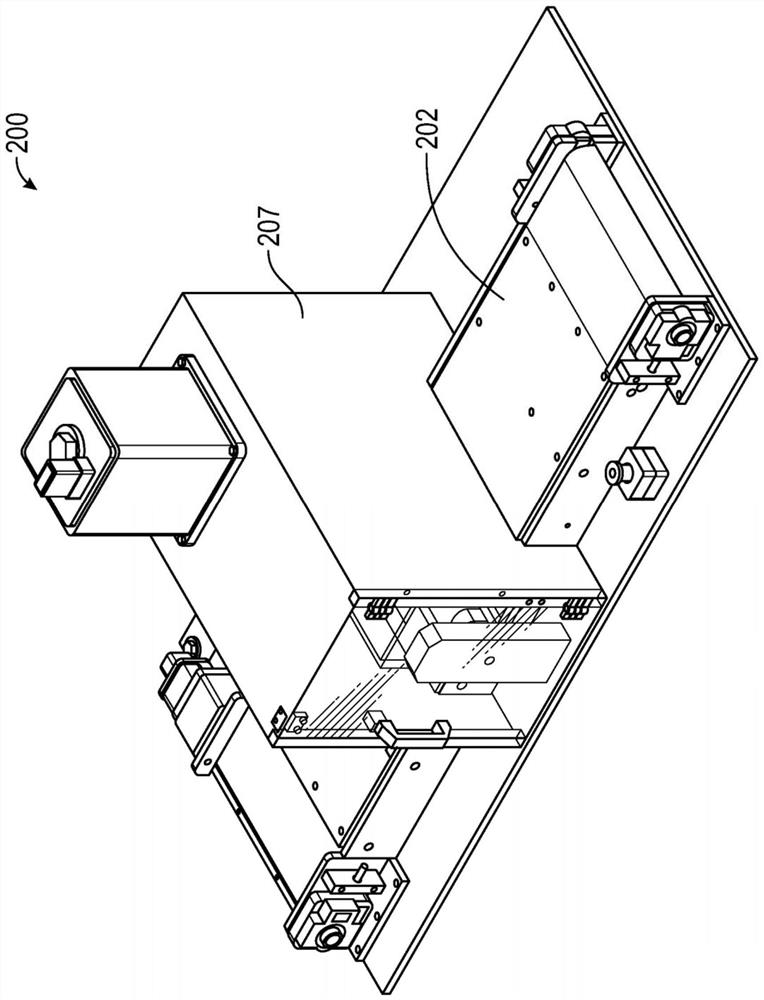

Semiconductor wafer metrology apparatus and method

InactiveUS8357548B2Reduce current influenceEliminate the effects ofSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyEngineering

A semiconductor wafer metrology technique comprising performing atmospheric buoyancy compensated weighing of a wafer, in which the wafer is weighed in a substantially upright condition. A vertical or near vertical wafer orientation causes the surface area in the direction of a force (weight) sensor to be reduced compared with a horizontal wafer orientation. Hence, the electrostatic force components acting in the same direction as the wafer weight force component is reduced.

Owner:METRYX

Method for manufacturing antistatic nylon fastening tape

ActiveCN101851861AAccelerate the dissipation of static electricityReduce electrostatic effectFibre typesDry-cleaning apparatus for textilesTitanium dioxideYarn

The invention discloses a method for manufacturing an antistatic nylon fastening tape. The method comprises the steps of: performing the steps of weaving, cleaning, whitening, dehydrating and drying and the like on a nylon fastening tape, wherein the step of weaving a ground yarn is to arrange a silver-plated nylon ground yarn every other 5 to 8 common nylon ground yarns; after the step of whitening, resin finishing and antistatic finishing are respectively performed on the nylon fastening tape; an antistatic film is formed on the surface of the treated nylon fastening tape so as to reduce the specific resistance of the fastening tape effectively, and reduce electrostatic generation and accelerate electrostatic dissipation; and a part of the silver-plated nylon in the ground yarns of the fastening tape and titanium dioxide added in the step of resin finishing form an invisible conductive network to accelerate electrostatic dissipation and reduce an electrostatic effect. The antistaticnylon fastening tape manufactured by the method has a specific resistance less than 10<5> ohm-cm and obvious antistatic effect, can be used as a matched fastening tape of an antistatic clothing, and can be used in a workplace with high antistatic requirement. Therefore, the use of the fastening tape is expanded; and the added value of the fastening tape is improved.

Owner:WUXI PAIHO TEXTILES CO LTD

Crease-proofing softening finishing agent for soybean fiber fabric

The invention discloses a crease-resistance flexible finishing agent of soybean fiber cloth, which comprises the following parts: 1-30g / L biformyl, 1-18g / L MgCl2 .6H2O, 0.2-20% aqueous polyurethane, 0.01-5% triethanolamine, 1-40g / L softening agent ZH-S40, 1-10g / L penetrant JFC. The invention possesses excellent absorbent quality and air permeability without poisons, which is an ideal green crease-resist flexible finishing agent.

Owner:TIANJIN ZHONGHE SCI & TECH DEV

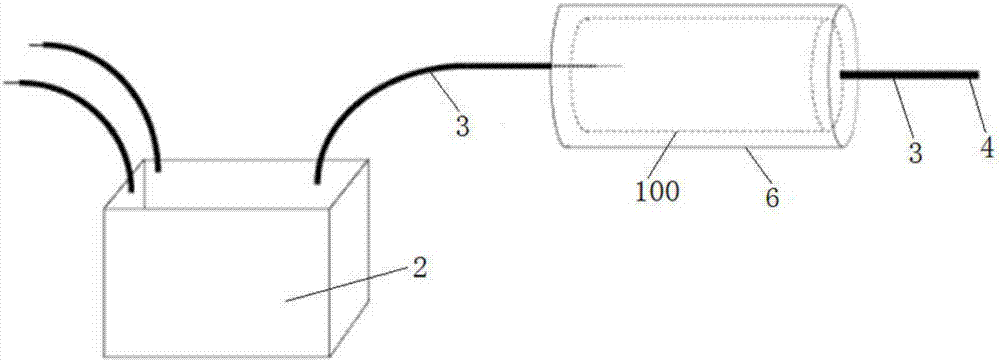

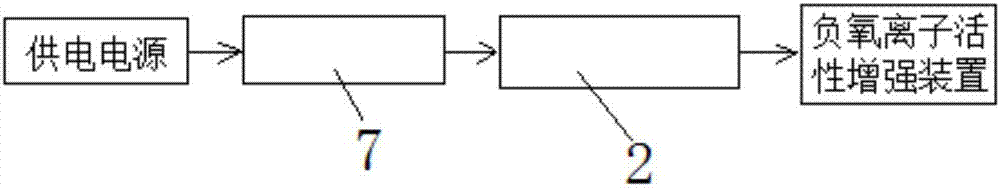

Negative oxygen ion activity enhancing device and humidifier provided with same

ActiveCN107196190AHigh activityReduce voltageMechanical apparatusElectrical apparatusIon clustersPhysical chemistry

The invention discloses a negative oxygen ion activity enhancing device and a humidifier provided with the same. The negative oxygen ion activity enhancing device is characterized by comprising one or more free electron accelerators, and is capable of improving the depressurization effect and ozone reduction effect and enhancing activity of negative oxygen ions. The humidifier can realize the effects that water mist of small particles and the negative oxygen ions generated by a negative oxygen ion releasing part are combined to form O<2><->(H<2>O)<n> ion clusters, the air conductivity is increased, the excess static electricity is guided away, and the electrostatic effect is greatly reduced.

Owner:TSINGHUA UNIV

Neutral endopeptidase inhibitor salt crystal form and preparation method thereof

ActiveCN106065006AImprove stabilityReduce electrostatic effectOrganic compound preparationOrganic chemistry methodsEndopeptidaseCrystal

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

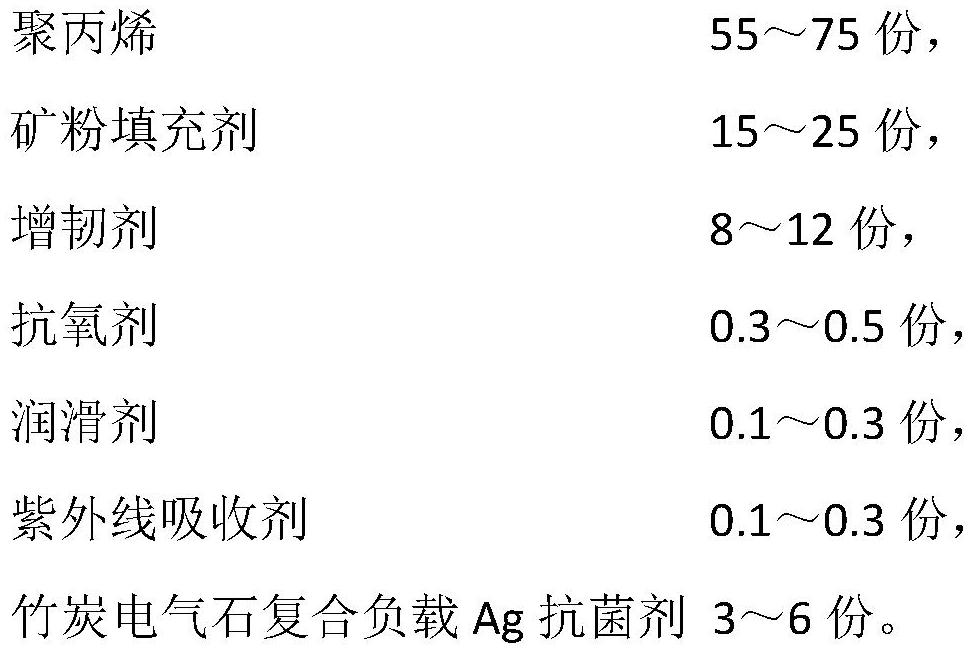

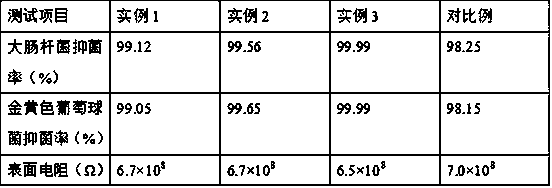

Bamboo charcoal and tourmaline composite Ag-loaded antibacterial agent, antibacterial polypropylene composition and preparation method

ActiveCN112694677ALong-lasting antibacterial effectFacilitated releaseEscherichia coliStaphylococcus aureus

The invention provides a bamboo charcoal and tourmaline composite Ag-loaded antibacterial agent, an antibacterial polypropylene composition and a preparation method. The bamboo charcoal and tourmaline composite Ag-loaded antibacterial agent is prepared from bamboo charcoal and tourmaline powder through Ag loading modification. The preparation method comprises the following steps that bamboo charcoal powder is loaded with Ag, tourmaline powder is loaded with Ag, and a bamboo charcoal powder Ag-loaded antibacterial agent and a tourmaline powder Ag-loaded antibacterial agent are mixed according to the ratio of (1-3): 1. The prepared composite antibacterial agent is added into a polypropylene composition, and through the mutual auxiliary effect of Ag, bamboo charcoal and tourmaline, multiple antibacterial modes such as silver ion slow release, bamboo charcoal adsorption and negative ion sterilization are achieved, and the efficient and lasting antibacterial effect on common bacteria such as escherichia coli and staphylococcus aureus is achieved.

Owner:ORINKO NEW MATERIAL CO LTD

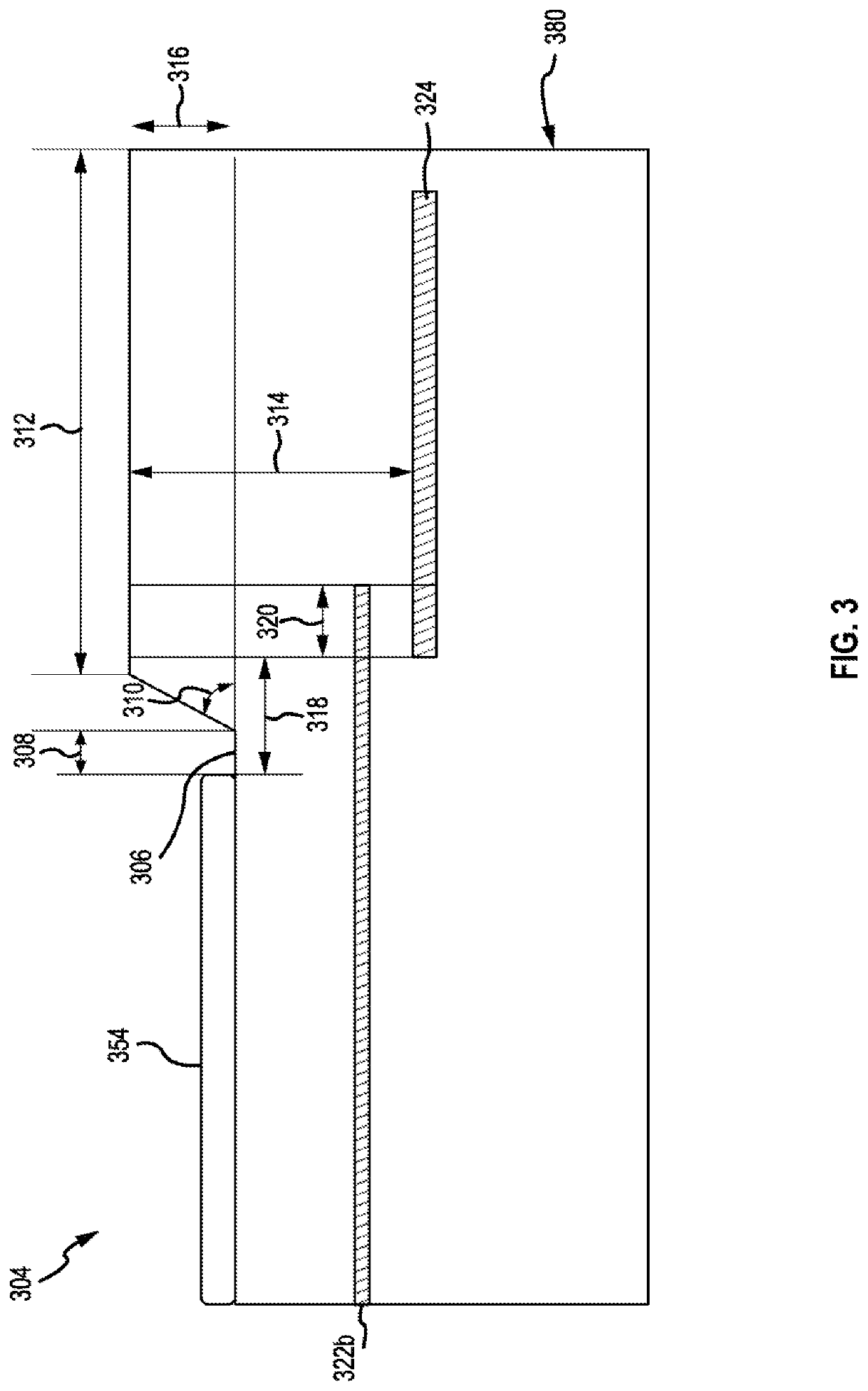

Semiconductor wafer metrology apparatus and method

InactiveUS20100285614A1Reduce current influenceEliminate the effects ofSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyEngineering

A semiconductor wafer metrology technique comprising performing atmospheric buoyancy compensated weighing of a wafer, in which the wafer is weighed in a substantially upright condition. A vertical or near vertical wafer orientation causes the surface area in the direction of a force (weight) sensor to be reduced compared with a horizontal wafer orientation. Hence, the electrostatic force components acting in the same direction as the wafer weight force component is reduced.

Owner:METRYX

Preparation method of anti-static bacteriostatic polyester staple fiber

InactiveCN107761191AReduce crystallinityGood hygroscopicityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention discloses a preparation method of an anti-static bacteriostatic polyester staple fiber, belonging to the technical field of polyester staple fibers. The preparation method comprises thesteps of carrying out high-temperature anaerobic sintering on bamboo chips, so as to obtain activated carbon; blending and compounding the activated carbon with polyester, so as to generate an artificial fiber; and blending and stretching a natural mulberry fiber with the artificial fiber during traction and wiredrawing, so as to obtain the anti-static bacteriostatic polyester staple fiber. The preparation method has the beneficial effects that the smooth execution of a subsequent processing process of textile is promoted; the adopted activated carbon is prepared by sintering the bamboo chipsunder high-temperature anaerobic conditions, bamboos are acidic, the prepared activated carbon is acidic, and the growth and propagation of bacteria under the acidic condition are inhibited, so that abacteriostatic effect is achieved; and relatively deep stripes are longitudinally distributed on the surface of the mulberry fiber, the surface comprises a middle cavity structure and more micro-holes, the activated carbon is inserted into the micro-holes of the mulberry fiber, the interfacial adhesive force between the mulberry fiber, and the polyester fiber is increased by virtue of the activated carbon, and a durable bacteriostatic effect is achieved, so that the bacteriostatic activity of the polyester staple fiber is enhanced, and the polyester staple fiber has wide application prospectsin the textile field.

Owner:常州五荣化工有限公司

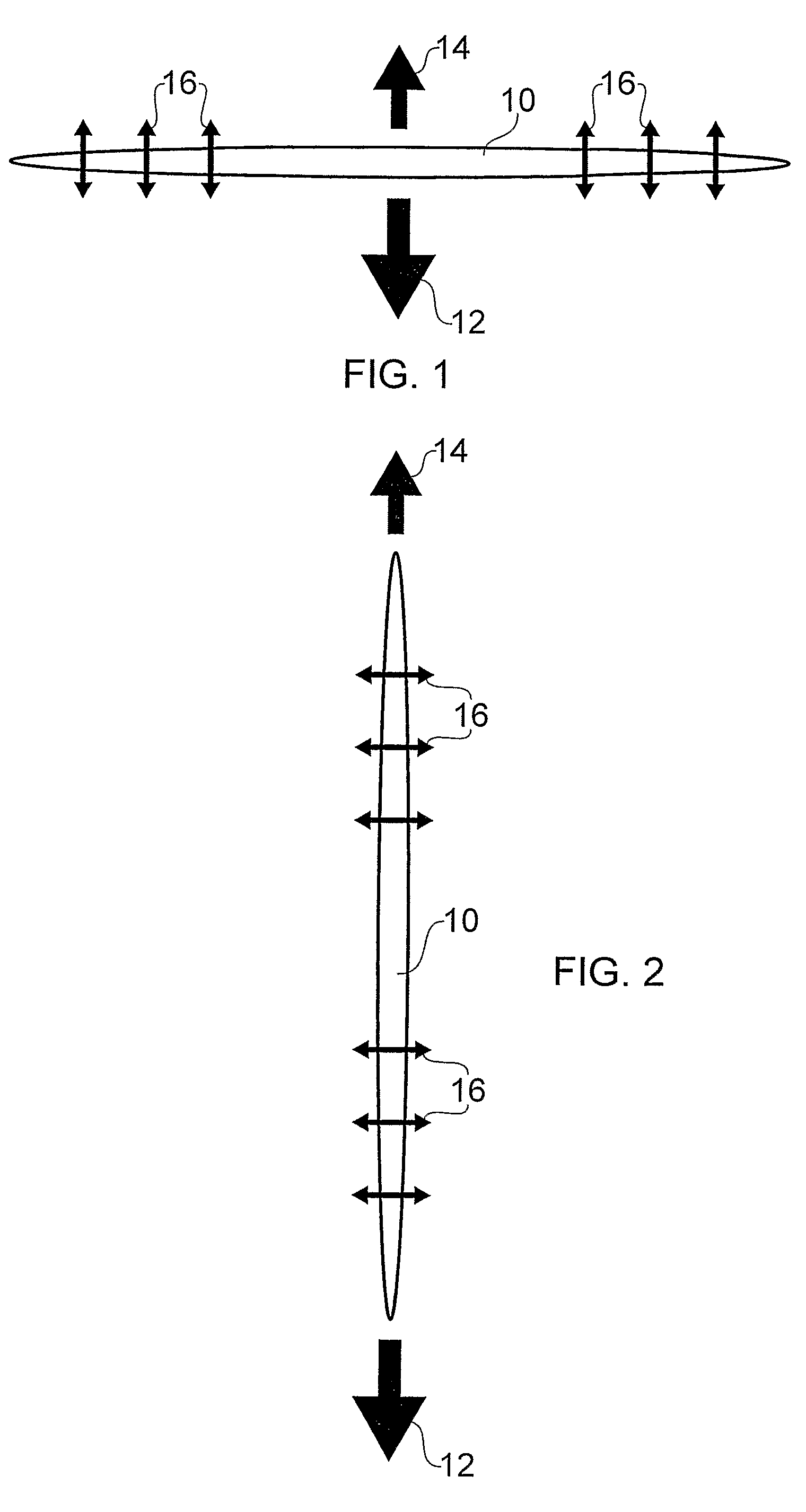

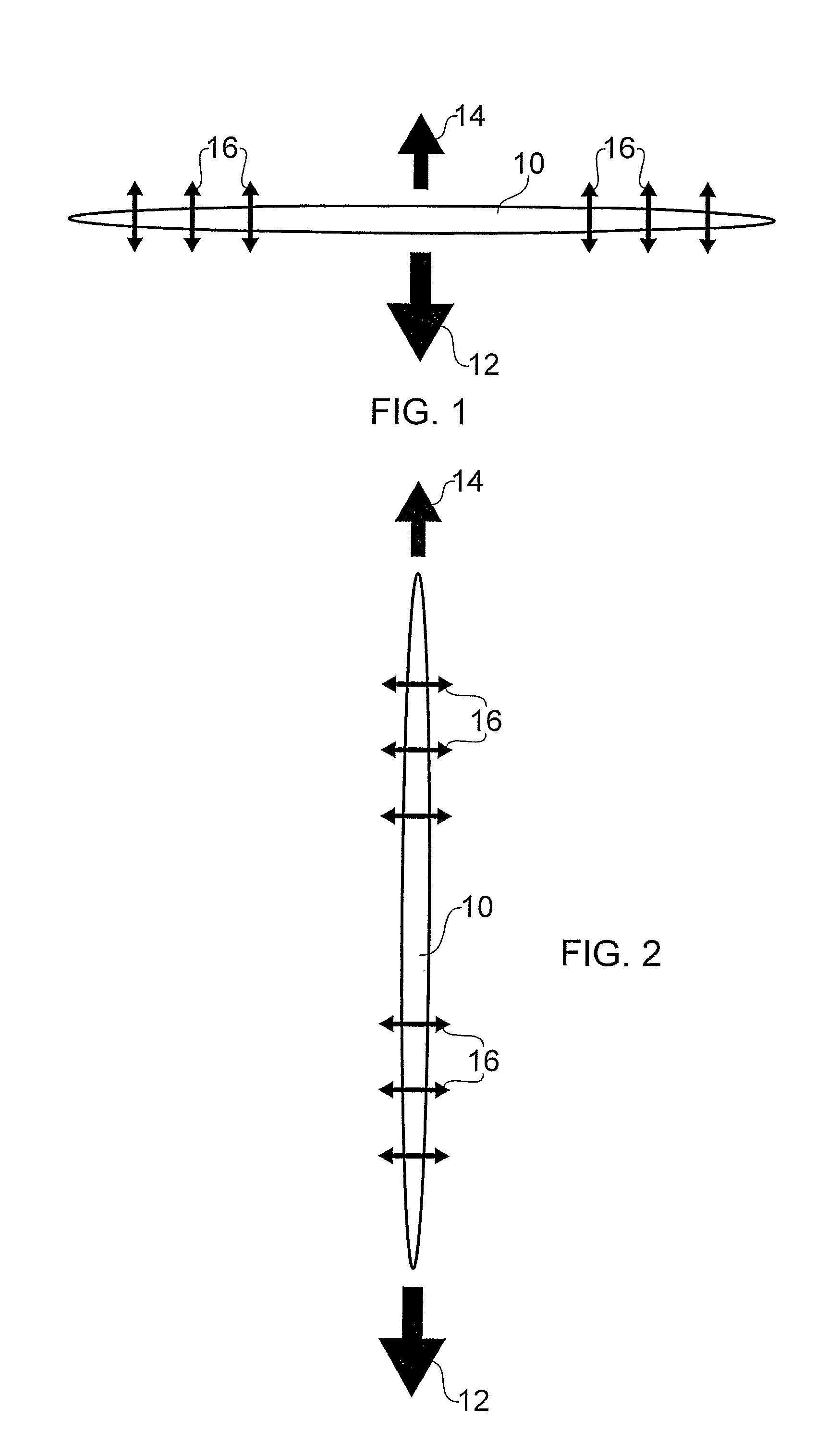

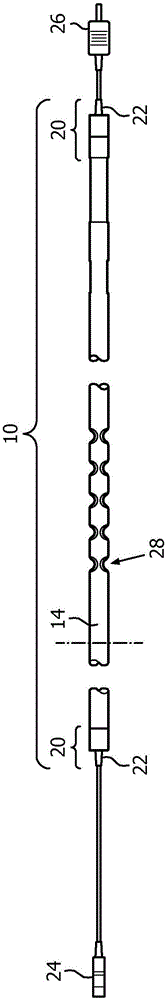

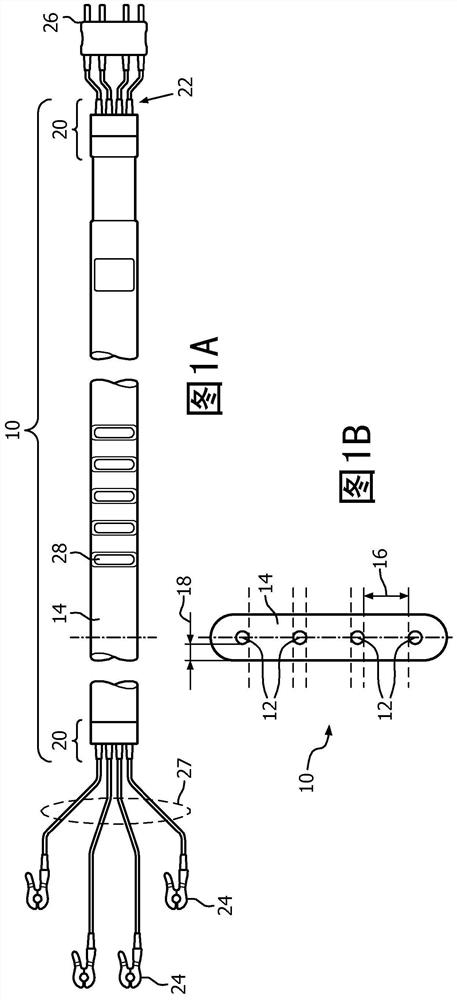

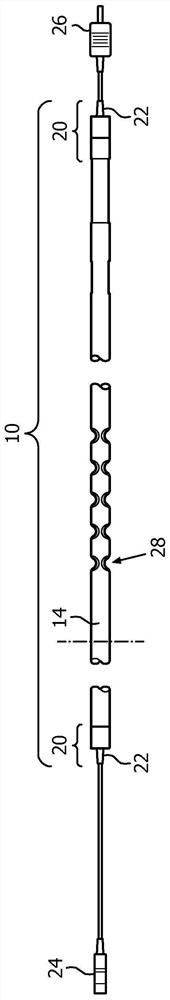

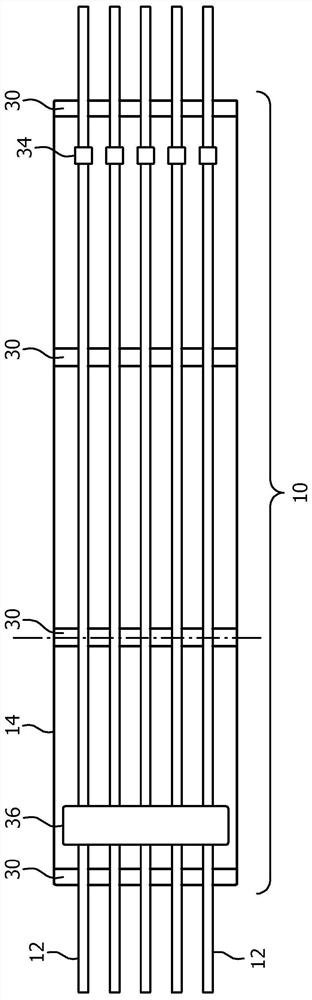

Planar magnetic resonance safe cable for biopotential measurements

ActiveCN105813556AReduced variation in inductionReduce electrostatic effectElectrotherapyMagnetic measurementsElectrical resistance and conductanceEcg signal

A magnetic resonance (MR) safe cable (10) includes four or more controlled resistance electrically conductive wires (12) disposed in a parallel planar configuration, and a stiff non-proton emitting substrate (14) which holds the four or more controlled resistance conductive wires in the parallel planar configuration. The wires (12) terminating at one end in connectors which electrically connect to ECG electrodes (64) which are attached to the subject. The cable is configured to extend the one end into an imaging region of an MR scanner (62) during imaging to carry ECG signals to associated equipment.

Owner:KONINKLJIJKE PHILIPS NV

Endless belt device and image forming apparatus using the device

ActiveUS20060104677A1Reduce in sizeEnhance detectionElectrographic process apparatusEngineeringMechanical engineering

Owner:RICOH KK

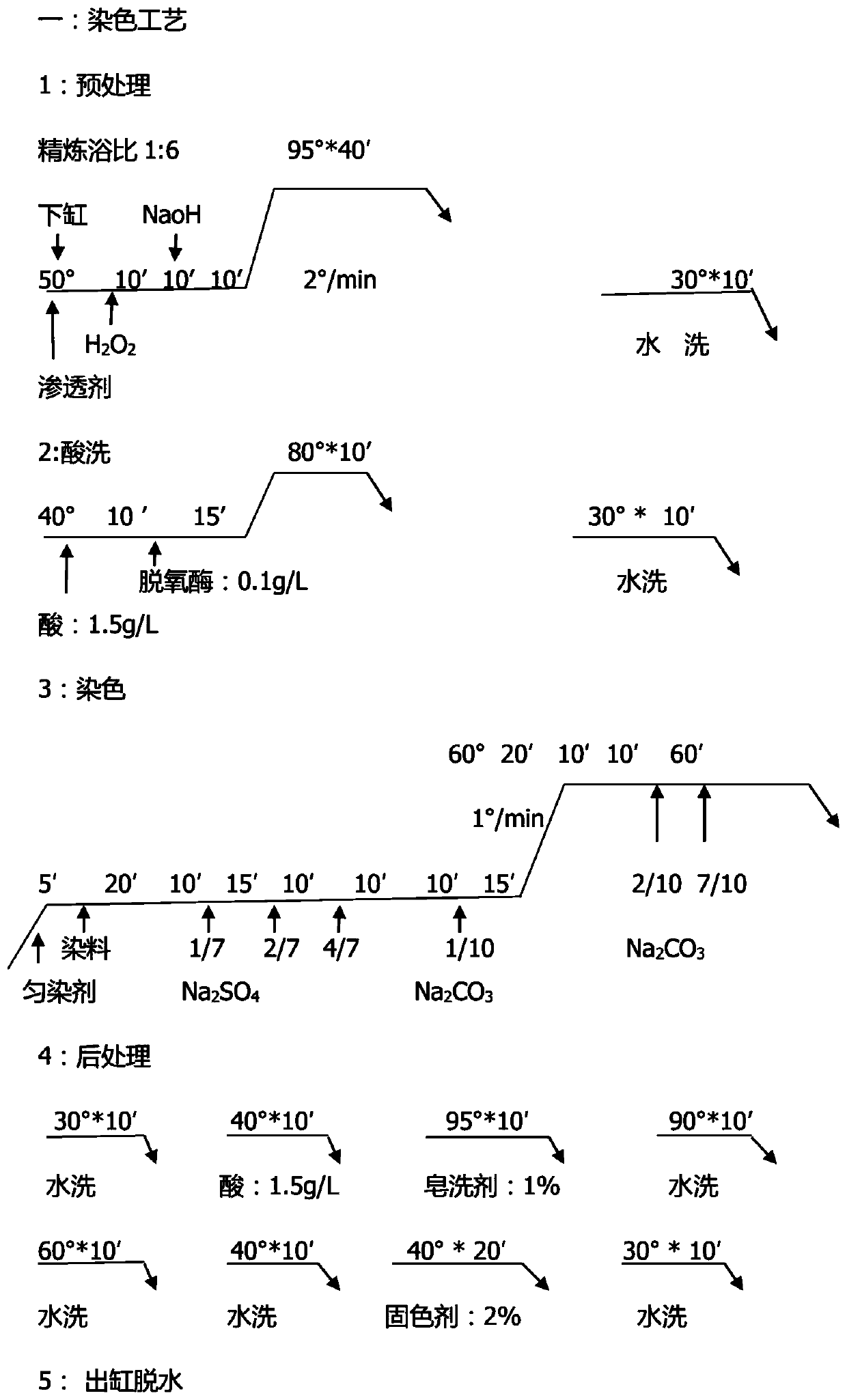

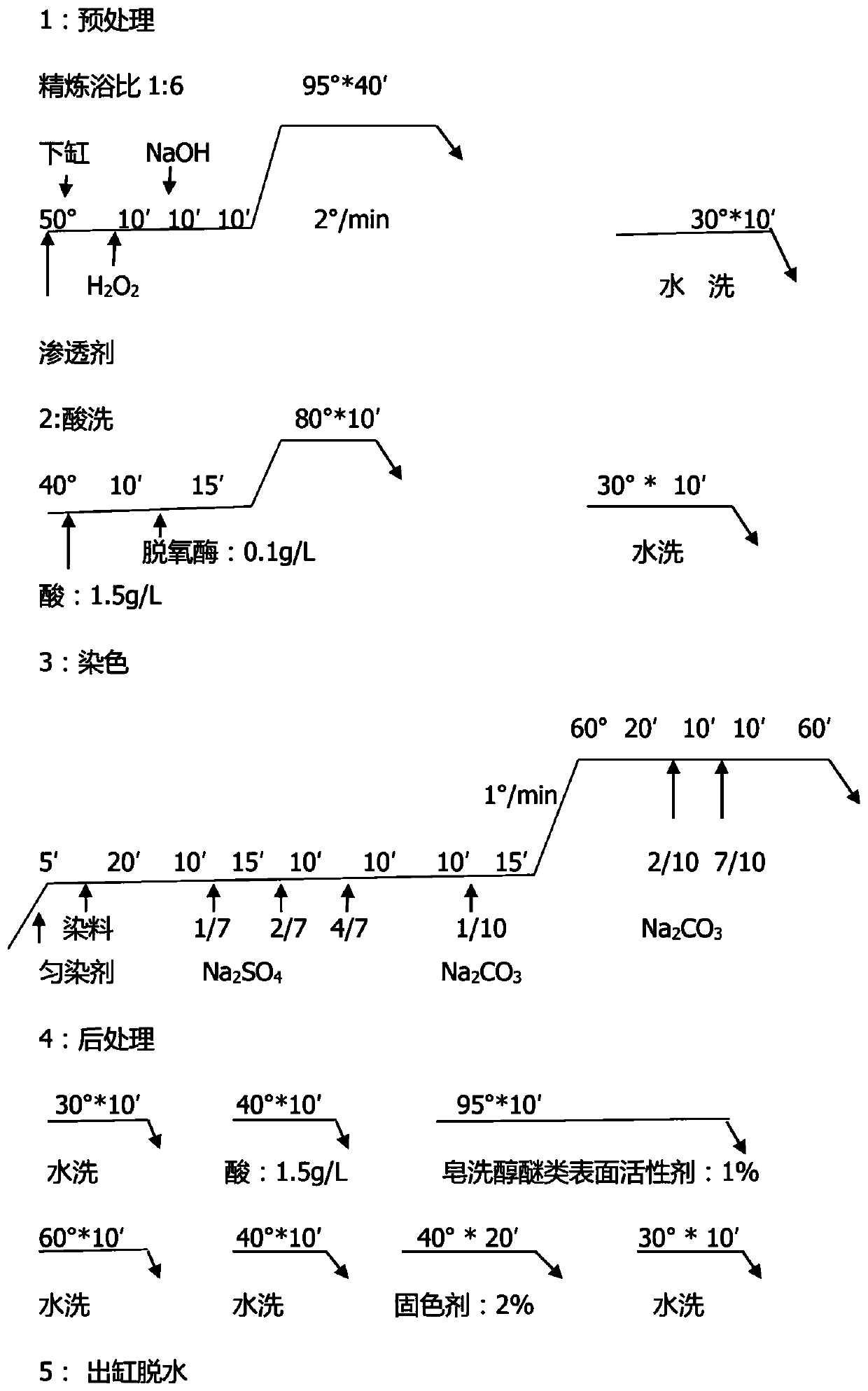

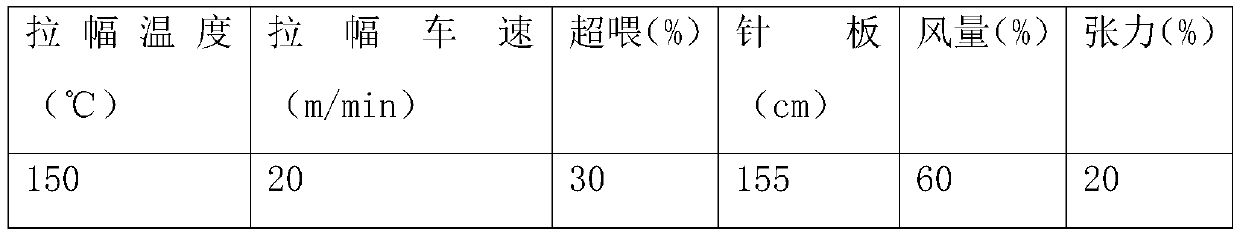

Dyeing technology of chemical fibers

The invention provides a dyeing technology of chemical fibers and relates to the field of dyeing of chemical fibers. A dyed chemical fiber product can be obtained through steps of pretreatment, purification treatment, presetting, dyeing, reduction and soaping, fixation and smooth setting. Oil solutions, stained oil dirt, dust, pigments and the like added in chemical fiber spinning and weaving processes are removed during pretreatment, the purification treatment is added to the technology, staged heating is adopted in the dyeing process, a leveling agent and a penetrating agent are added, a fixation foam liquid is sprayed for fixation, so that the dye utilization rate in the production process is high, the produced chemical fibers have full color, high color fastness and good uniformity, meanwhile, energy consumption is low, and little wastewater is produced.

Owner:马鞍山市永运家纺有限公司

Preparation method for anti-wrinkling textile fabric

InactiveCN108823986AImprove wrinkle resistanceGood drapabilityPhysical treatmentBiochemical fibre treatmentEpoxyAlcohol

The invention relates to a preparation method for anti-wrinkling textile fabric. The method comprises the following steps: according to the parts by weight, taking 5-10 parts of epoxy chloropropane, 8-15 parts of fatty alcohol-polyoxyethylene ether, 1-5 parts of amino silicon oil, 7-15 parts of a water-soluble polyurethane resin, 10-25 parts of an ammoniated epoxy resin, 10-15 parts of lactic acid, 30-50 parts of ethyl alcohol, 18-35 parts of polyacrylate and 500-800 parts of water, uniformly mixing the raw materials, to obtain treating fluid, and dipping a textile fabric matrix in the treating fluid, performing pressing treatment and oxygen bleaching treatment on the textile fabric, washing and drying the textile fabric after the oxygen bleaching treatment, to obtain the anti-wrinkling textile fabric. The preparation method is simple in operation, and the obtained textile fabric has the good anti-wrinkling effect.

Owner:FOSHAN YIXIANG DISI CLOTHING DESIGN CO LTD

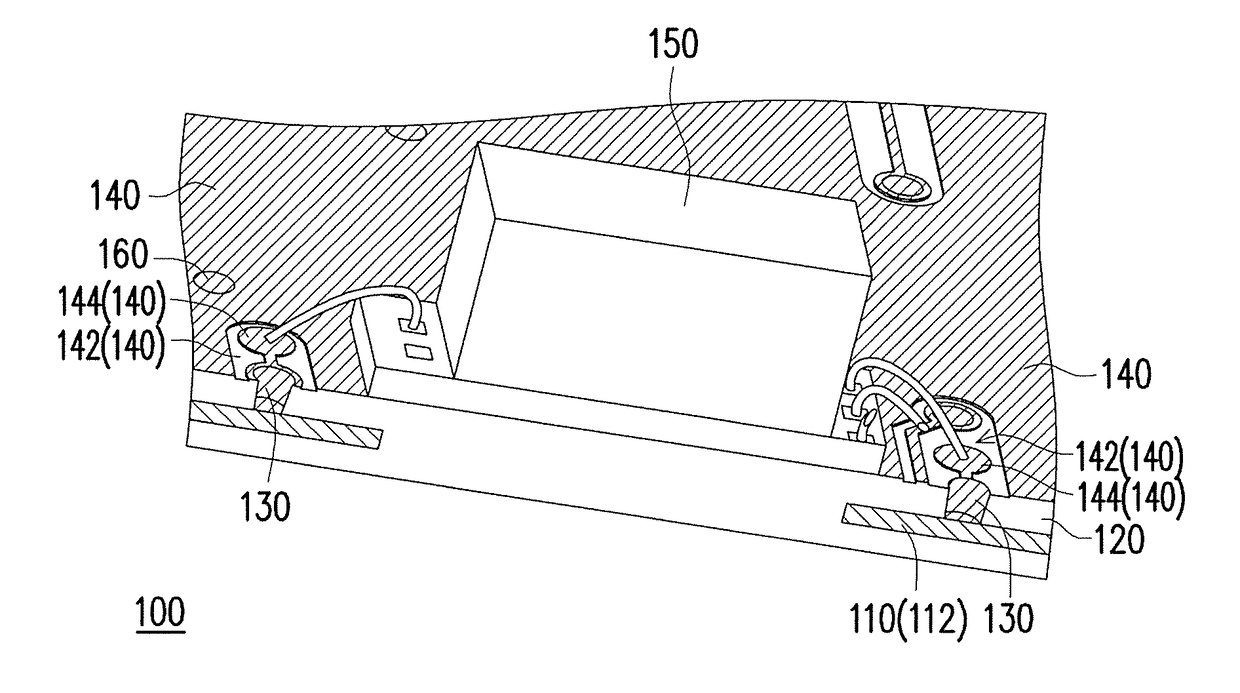

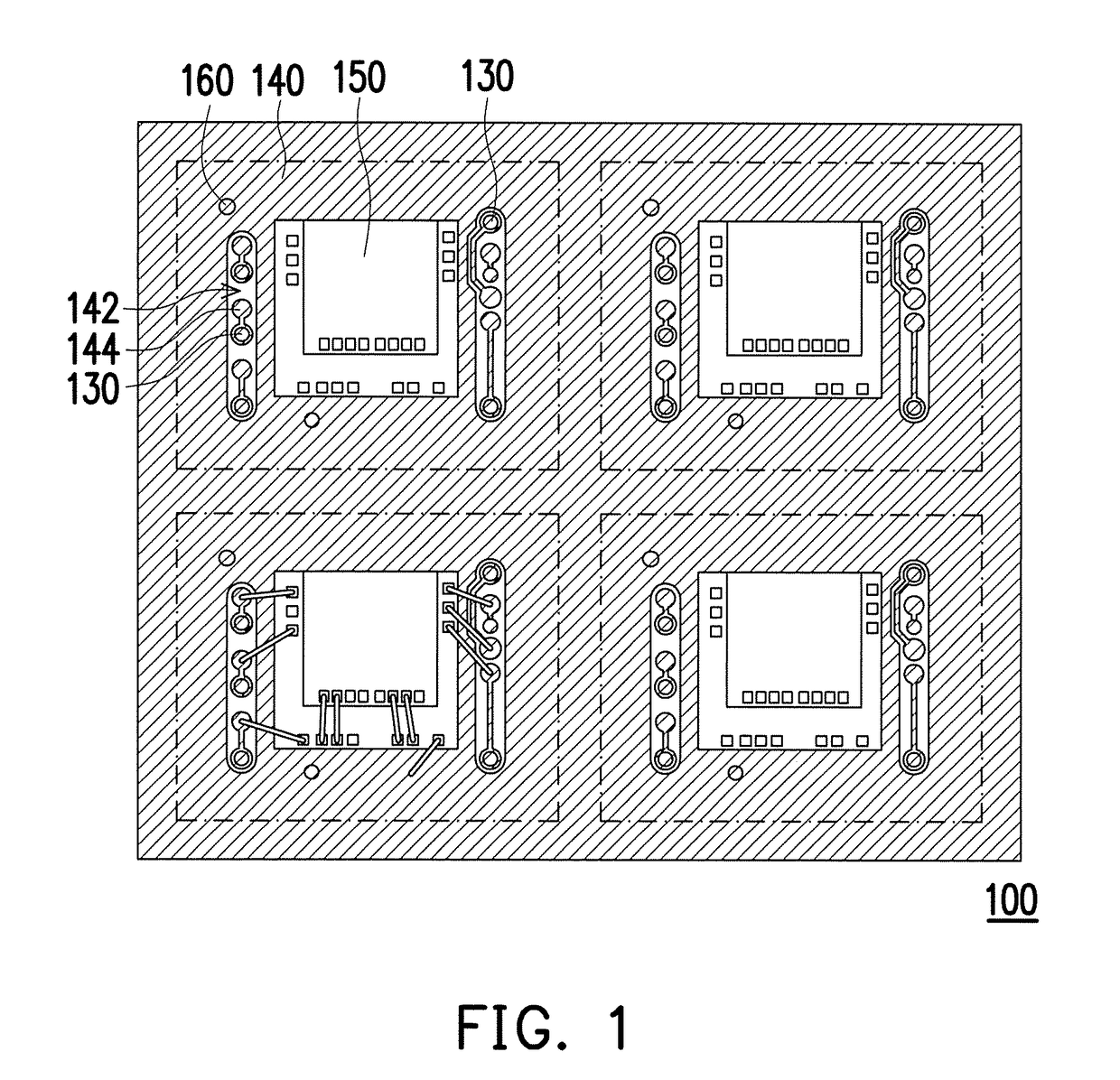

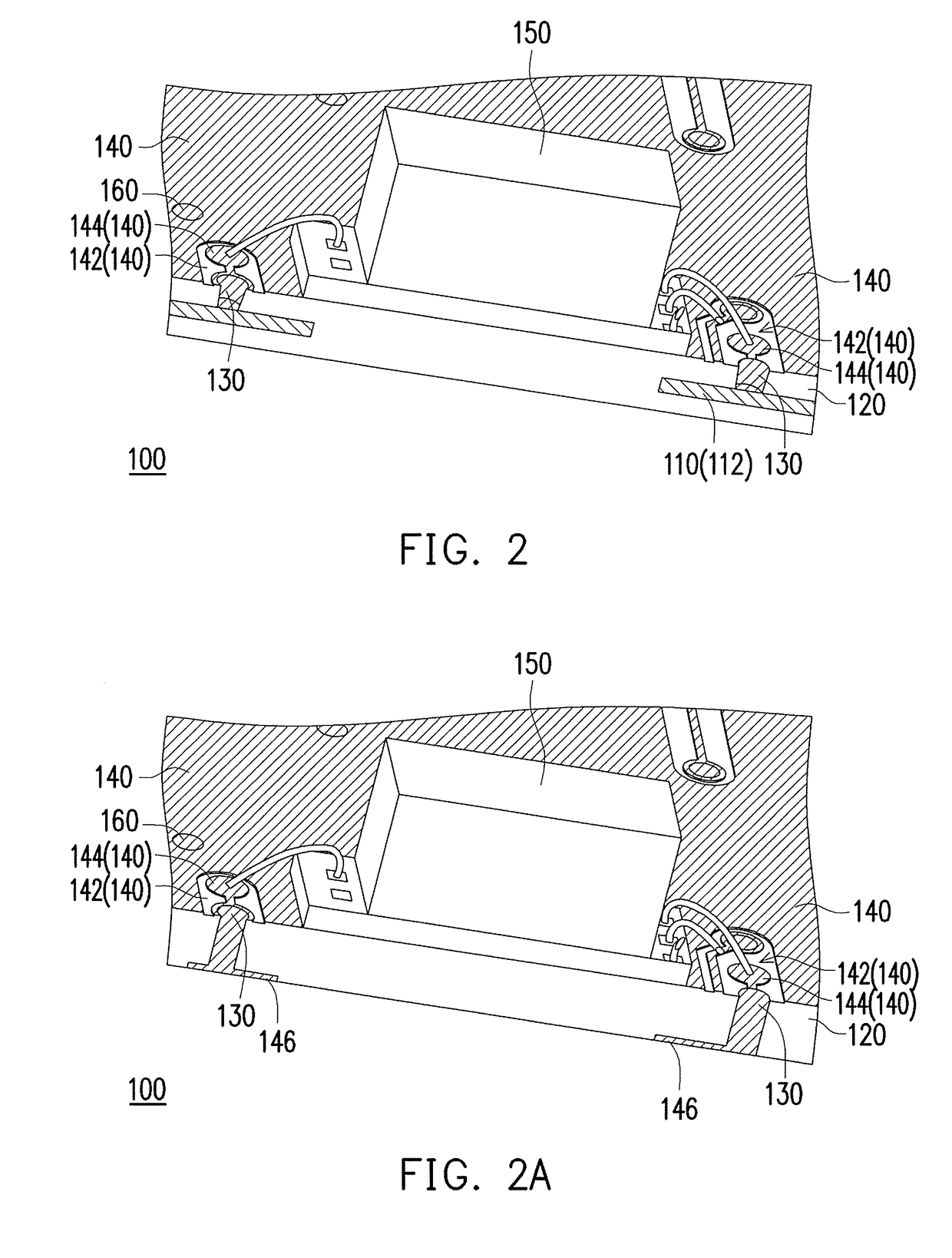

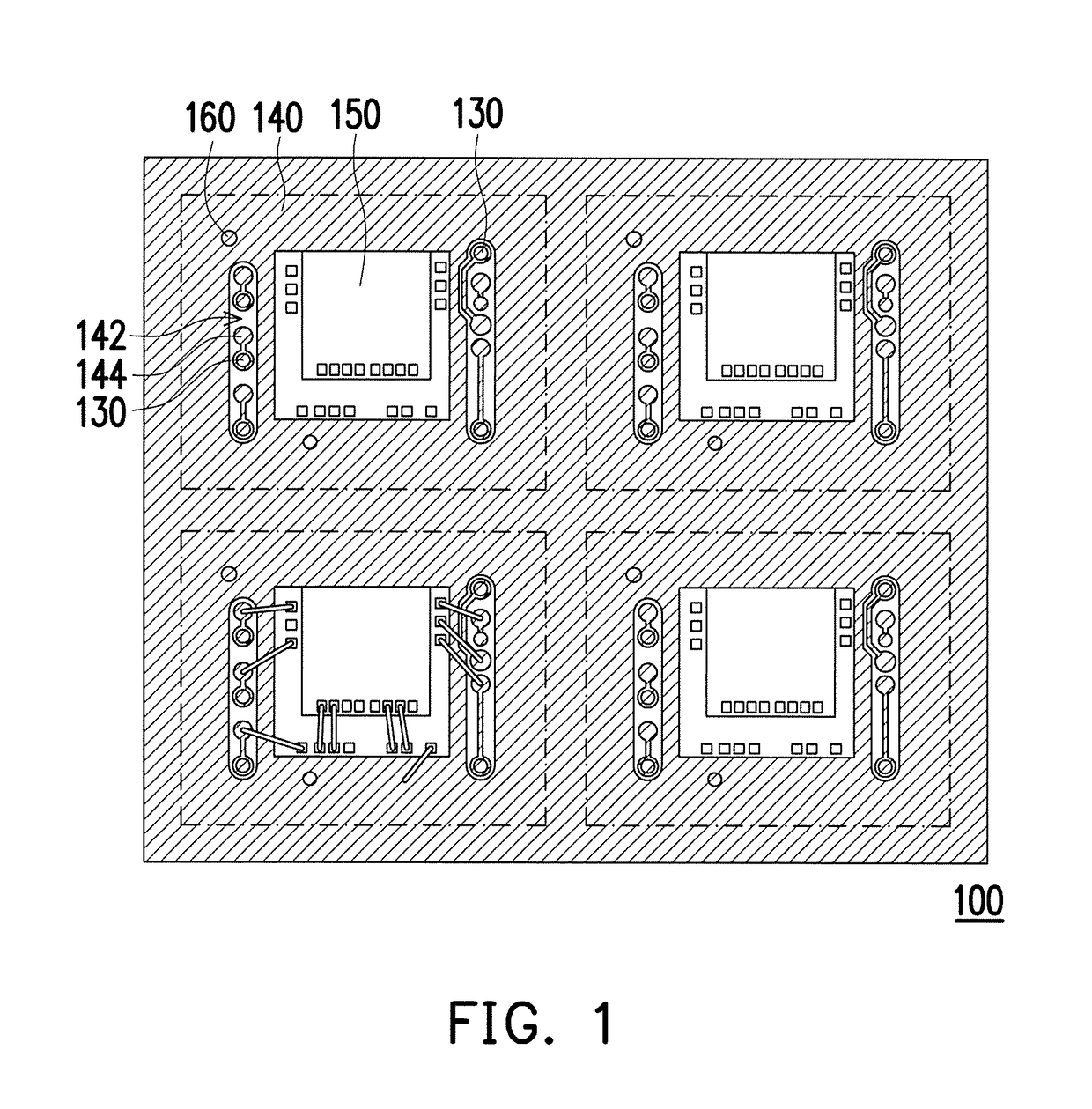

Package structure

InactiveUS20180294218A1Simplify processProduction cost be reduceSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A package structure includes a lead frame, an insulator, a plurality of conductive vias, a patterned metal layer, and a chip. The lead frame includes a plurality of contacts. The insulator covers the lead frame. The conductive vias are disposed on the insulator and connected to the contacts. The patterned metal layer covers an outer surface of the insulator and includes a groove and a circuit portion. The circuit portion is connected to and covers the conductive vias and contacts. The groove surrounds the circuit portion such that the circuit portion is electrically insulated from the rest of the patterned metal layer. A surface of the insulator exposed by the groove is lower than the outer surface. The chip is disposed on the insulator and electrically connected to the circuit portion.

Owner:IBIS INNOTECH

Shrinkproof and anti-wrinkle softening agent

The invention provides a shrinkproof and anti-wrinkle softening agent, which is composed of the following raw materials: 1-30g / L of 35% acetaldehyde aqueous solution, 1-18g / L of MgCl2.6H2O, 0.2-20% of solvent type polyamino resin and 0.01-5% of ethanediol nascent soap. The shrinkproof and anti-wrinkle softening agent is non-toxic and harmless to human bodies, has good hygroscopicity and air permeability, does not influence color and whiteness of fabrics, has soft handfeel and good anti-wrinkle performance, improves washability and is an ideal green anti-wrinkle soft finishing agent.

Owner:TIANJIN BIJIA PHARMA CO LTD

Crease resistant textile fabric

InactiveCN108842442AImprove wrinkle resistanceIncrease elasticityBiochemical fibre treatmentWrinkle resistant fibresEpoxyWater soluble

The invention relates to crease resistant textile fabric. The fabric comprises the following raw materials in parts by weight: 5 to 10 parts of epoxy chloropropane, 8 to 15 parts of fatty alcohol-polyoxyethylene ether, 1 to 5 parts of amino-silicone oil, 7 to 15 parts of water soluble polyurethane resin, 10 to 25 parts of ammoniated epoxy resin, 10 to 15 parts of lactic acid, 30 to 50 parts of ethanol, 18 to 35 parts of polyacrylic ester, and 500 to 800 parts of water. The fabric has a good crease resistant effect.

Owner:FOSHAN YIXIANG DISI CLOTHING DESIGN CO LTD

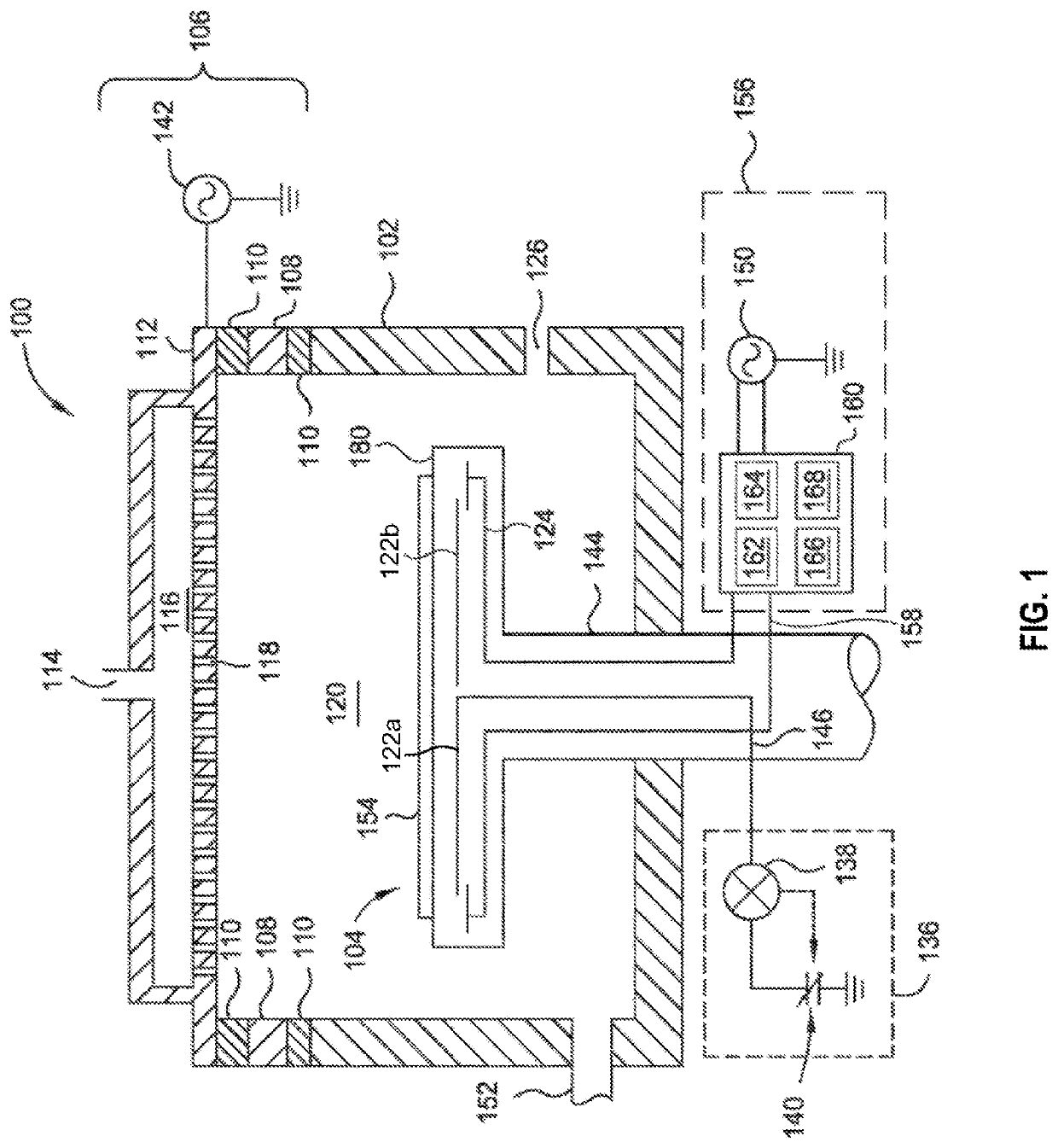

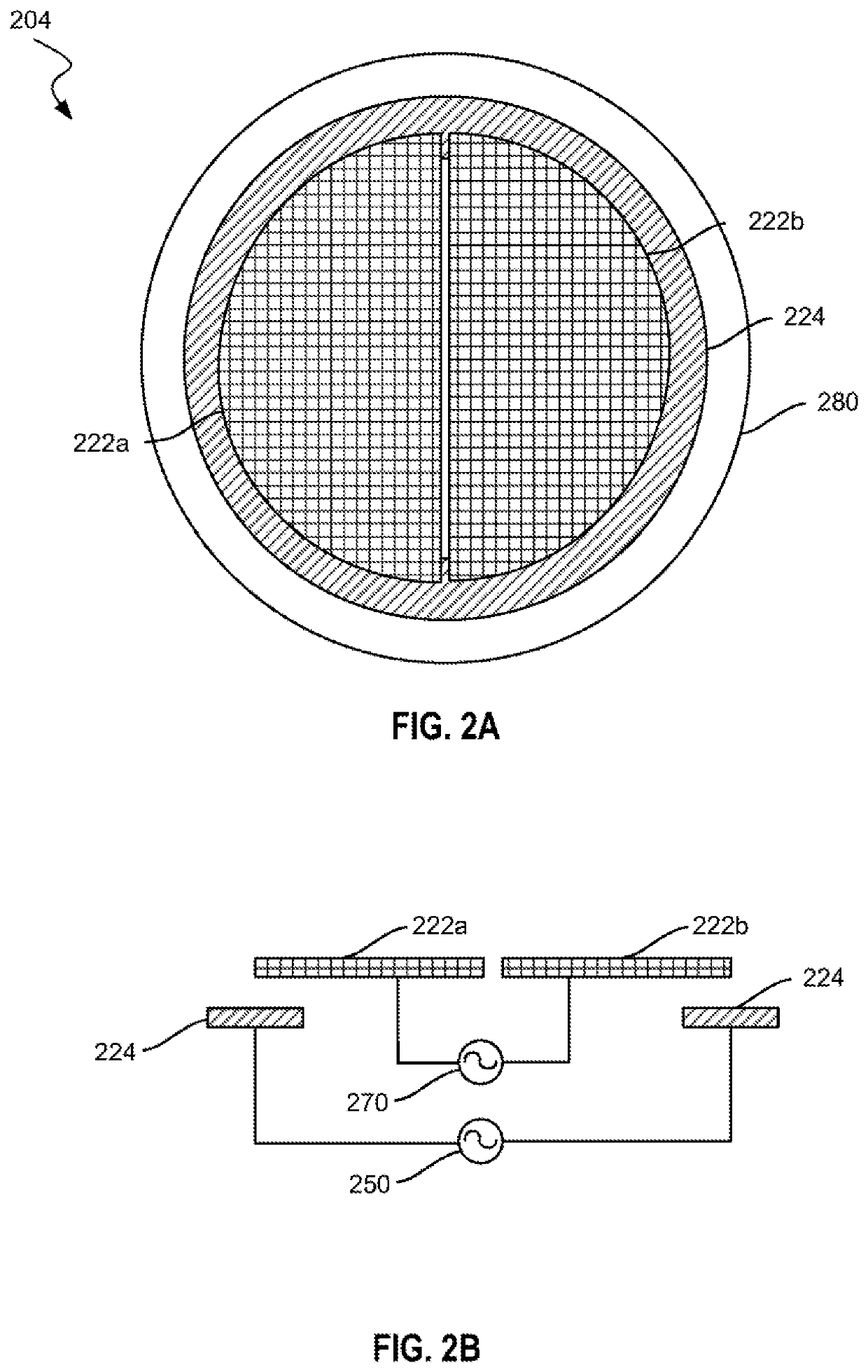

Edge uniformity tunability on bipolar electrostatic chuck

PendingUS20210159107A1Improve adjustabilityImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Embodiments of the present technology may include an electrostatic chuck. The chuck may include a top surface, defining a recessed portion of the chuck. The recessed portion of the chuck may be configured to support a substrate. The chuck may further include a first electrode and a second electrode. The first electrode and the second electrode may be disposed within the chuck. The first electrode and the second electrode may be substantially coplanar. In addition, the chuck may include a third electrode. The third electrode may be disposed within the chuck. Furthermore, the third electrode may have an annular shape. The third electrode may be separated from the first electrode and the second electrode. In addition, the third electrode may be substantially parallel to the first electrode and the second electrode. Systems and methods including the electrostatic chuck are also described.

Owner:APPLIED MATERIALS INC

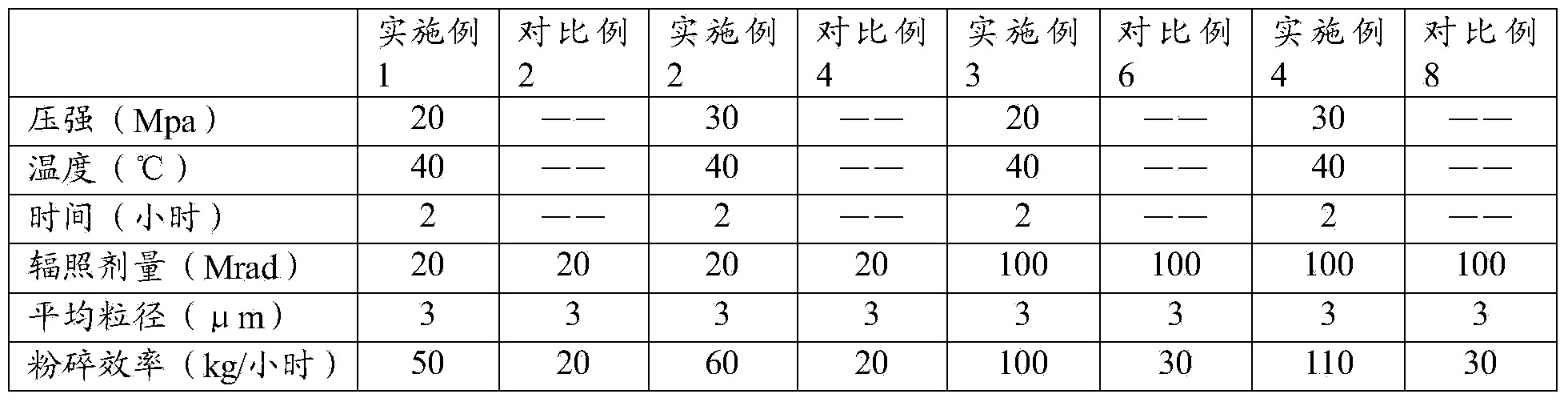

Method for preparing polytetrafluoroethylene micropowder by carrying out swelling treatment on polytetrafluoroethylene through adopting supercritical carbon dioxide

ActiveCN103951844AGas-liquid dualityImprove liquidityBulk chemical productionPolytetrafluoroethyleneNanotechnology

The invention discloses a method for preparing polytetrafluoroethylene micropowder by carrying out swelling treatment on polytetrafluoroethylene through adopting supercritical carbon dioxide. After being subjected to swelling treatment by adopting supercritical carbon dioxide, the polytetrafluoroethylene is subjected to pressure relief and carbon dioxide release, and then is ground and smashed into polytetrafluoroethylene micropowder. The method comprises the following steps: I, carrying out swelling treatment on polytetrafluoroethylene through adopting supercritical carbon dioxide; II, reducing the pressure of the polytetrafluoroethylene obtained in the step I to be normal pressure, and releasing carbon dioxide; III, treating the polytetrafluoroethylene obtained in the step II, by adopting radiation modification technology; IV, grinding and smashing the polytetrafluoroethylene obtained in the step III. The method is very unique and novel, and simple in preparation technology, the grinding and smashing efficiency of the polytetrafluoroethylene is greatly improved, the average particle size of the polytetrafluoroethylene micropowder is greatly reduced, and the polytetrafluoroethylene micropwoder has good dispersion capability, and is good in dispersion performance in a matrix as a blending modification additive, and obvious in modification effect.

Owner:SUZHOU NORSHINE PERFORMANCE MATERIAL

Manufacturing method of antistatic hat fabric

InactiveCN107630351AImprove conductivityHigh carbon contentPhysical treatmentCarbon fibresVacuum pumpingPolymer science

The invention discloses a manufacturing method of an antistatic hat fabric. The antistatic hat fabric is prepared from modified bamboo fibers, modified polyacrylonitrile fibers, silk, Musa textilis Nee fibers, chitin fibers and rabbit hair through blending. The processing method of the modified bamboo fibers and modified polyacrylonitrile fibers comprises (1) low-temperature carbonization: carbonizing the polyacrylonitrile fibers in a carbonization furnace, (2) antistatic treatment: putting bamboo fibers and carbonized polyacrylonitrile fibers in clean water, carrying out heating treatment andrespectively immersing the fibers in an antistatic agent, (3) ionizing impregnation: immersing the bamboo fibers and carbonized polyacrylonitrile fibers subjected to the antistatic treatment in a conductive agent solution and carrying out ionization, (4) carburization: putting the ionized bamboo fibers into an inclosed tank, carrying out vacuum-pumping, feeding an atomized carbon black solution into the fibers and carrying out carburization and (5) curing: putting the carburized bamboo fibers and the ionized polyacrylonitrile fibers into a vacuum tank and carrying out oxidation.

Owner:安徽省创安体育用品有限公司

Manufacturing method of water-repellent flame-retardant hook-and-loop fastener

InactiveCN111877002AAccelerate diasporaReduce electrostatic effectHeat resistant fibresDry-cleaning apparatus for textilesMetal meshProcess engineering

The invention provides a manufacturing method of a water-repellent flame-retardant hook-and-loop fastener. The manufacturing method comprises the following specific steps of weaving a nylon hook-and-loop fastener according to the arrangement rule that one silver-plated nylon bottom yarn is arranged every 6-9 common nylon bottom yarns; cleaning the hook-and-loop fastener; sequentially performing flame-retardant finishing and water-repellent finishing on the nylon hook-and-loop fastener; performing resin finishing on the nylon hook-and-loop fastener; performing anti-static finishing on the nylonhook-and-loop fastener subjected to resin finishing; and dehydrating the nylon hook-and-loop fastener in a dehydrator. When the hook-and-loop fastener prepared by the method is used in an extreme environment, the electrostatic effect is reduced by a metal net formed by the silver-plated bottom yarns and the fine titanium dioxide added in resin finishing. In addition, an antistatic agent is used for finishing, so that static electricity generation is reduced, static electricity dissipation is accelerated, the static effect is reduced, and the fabric is suitable for flammable and combustible environments. Through flame-retardant finishing and water-repellent finishing, the flame-retardant performance and the water-repellent performance of the fabric are improved respectively, so that the fabric is suitable for high-temperature, high-humidity or soaking environments.

Owner:天津兴华织造有限公司

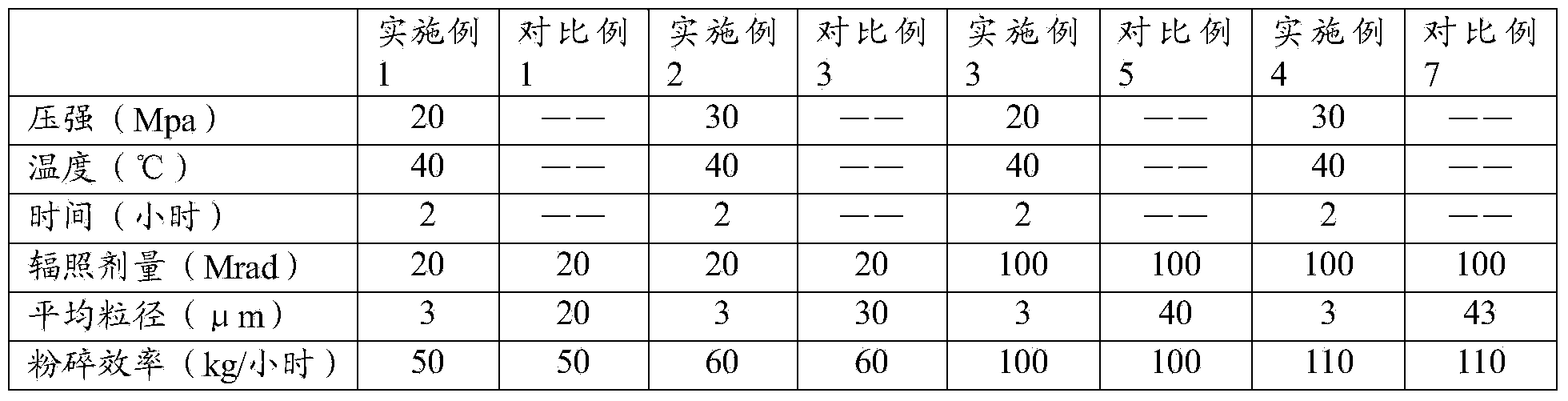

Antibacterial and antiviral modification method of electret melt-blown non-woven fabric

PendingCN114016284AImprove adsorption efficiencyHigh fastnessBiochemical fibre treatmentFibre typesPolymer scienceNonwoven fabric

The invention provides an antibacterial and antiviral modification method of an electret melt-blown non-woven fabric. Firstly, a powder antibacterial agent is subjected to high-voltage electric polarization, and then the powder antibacterial agent is filtered and adsorbed through an electret melt-blown non-woven fabric in a powder antibacterial agent airflow blowing mode, so that the powder nano-antibacterial agent is attached to the surfaces of fibers of the electret melt-blown non-woven fabric through an electrostatic adsorption effect, and the electret melt-blown cloth with excellent antibacterial and virus-killing performance is prepared. In the whole modification process, no harsh technical conditions are needed, the electrostatic adsorption effect of the melt-blown non-woven fabric is not changed or reduced, no adhesive covers, the antibacterial and virus-killing performance of the powder nano-antibacterial agent can be exerted to the maximum extent, and the antibacterial and virus-killing performance of the melt-blown non-woven fabric is improved. The electrostatic effect and filtering permeability of the electret melt-blown non-woven fabric are reserved to the maximum extent, and the electret melt-blown non-woven fabric has important market economic value.

Owner:WUHAN TEXTILE UNIV +1

Package structure

InactiveUS10134668B2Meet demandLow production costSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A package structure includes a lead frame, an insulator, a plurality of conductive vias, a patterned metal layer, and a chip. The lead frame includes a plurality of contacts. The insulator covers the lead frame. The conductive vias are disposed on the insulator and connected to the contacts. The patterned metal layer covers an outer surface of the insulator and includes a groove and a circuit portion. The circuit portion is connected to and covers the conductive vias and contacts. The groove surrounds the circuit portion such that the circuit portion is electrically insulated from the rest of the patterned metal layer. A surface of the insulator exposed by the groove is lower than the outer surface. The chip is disposed on the insulator and electrically connected to the circuit portion.

Owner:IBIS INNOTECH

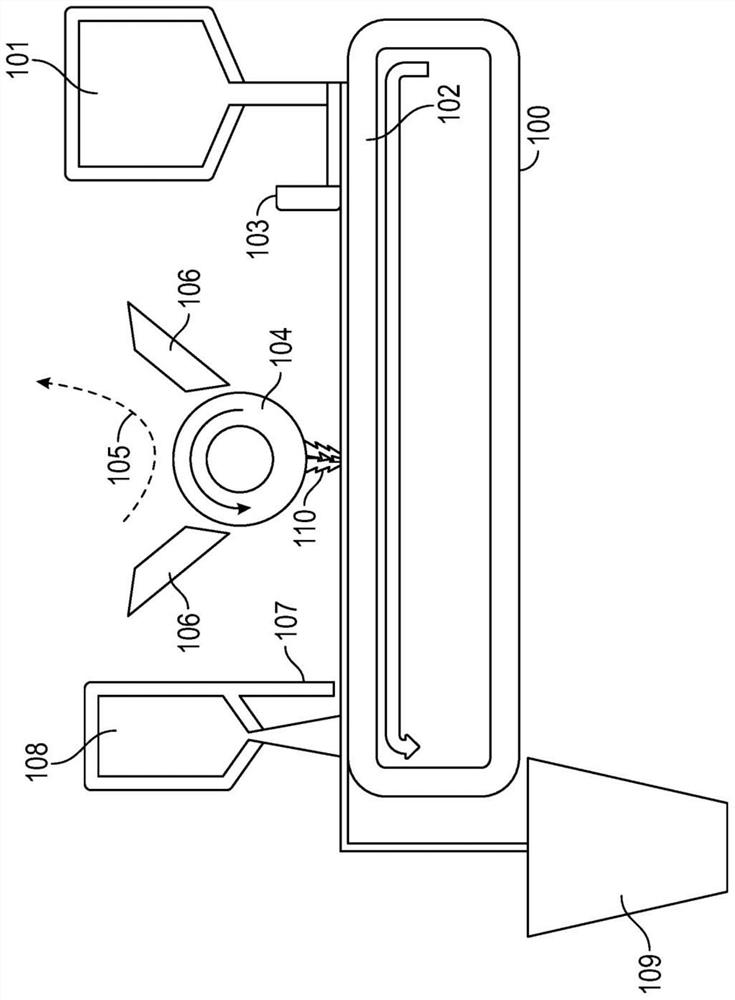

Continuous treatment with plasma

ActiveCN113710358AEliminate static electricityReduce electrostatic effectAlternating current plasma display panelsUnknown materialsMicrobiologyBacteriophage

The present invention relates to a continuous method for producing products with molecules or macromolecules attached thereto and apparatus for carrying out this method. The method comprises the steps of: (a) placing the object on or in the proximity of a surface; (b) controlling the electrical potential of the surface with respect to its surroundings; (c) activating the object by exposing it to an electrical discharge; (d) contacting the object with the molecule or macromolecule to be attached. Such macromolecules include bacteriophage. Thus products of methods of the invention are for prevention and amelioration of bacterial contamination of the product of methods of the invention or materials in contact with said products.

Owner:FIXED PHAGE

Method for improving surface static electricity of carbon sanded fabrics

ActiveCN111535060AReduce electrostatic effectQuality improvementDyeing processVegetal fibresProcess engineeringSurface-active agents

The invention belongs to the technical field of dyeing and finishing technology. In order to eliminate static electricity on the surface of the fabric in the carbon sanding process of the existing fabric, a tentering process of an anti-static auxiliary needs to be added. However, the anti-static auxiliary will make the fabric feel soft. In order to achieve the same sanding effect, the tension of the sanding and the time for sanding are needed to increase, which will increase the probability of contamination of the variegated wool. Therefore, it is necessary to add an air-softening and hair-removing process of an anti-pilling machine, which significantly increases processing cost. In view of the above problems, the invention provides a method for improving surface electrostatic properties of carbon sanded fabrics. Alcohol-ether surfactants are added during the soaping process of the fabric after dyeing, the tentering process of the anti-static auxiliary before the sanding and the air-softening and hair-removing process after the sanding are eliminated, and the time of sanding is reduced at the same time. The method reduces the electrostatic effect of the fabric without increasing washing, and reduces the processing cost.

Owner:QINGDAO JIFA GROUP +1

Fully-degreased pearl wool and preparation method thereof

InactiveCN111117029AReduce extravasationPrevent spontaneous combustionFlat articlesMonoglycerideFoaming agent

The invention relates to fully-degreased pearl wool and a preparation method thereof. The fully-degreased pearl wool is prepared from the following raw materials in parts by weight: 100-155 parts of polyethylene, 10-19 parts of titanate modified calcium carbonate, 1-3 parts of talcum powder, 1-3 parts of a silane coupling agent, 10 to 15 parts of a modified VAE emulsion, 3 to 10 parts of degreasedmaster batch, 3 to 10 parts of antistatic master batch and 10 to 20 parts of a foaming agent, wherein the foaming agent is butane. According to the invention, polyethylene particles, the degreased master batch, the antistatic master batch and the like are preferably selected and mixed according to a certain ratio, a certain amount of butane gas is introduced to prepare the fully-degreased pearl wool; and compared with common pearl wool directly added with monoglyceride, the phenomenon of grease exosmosis on the surface of the pearl wool is reduced.

Owner:平湖市富利源塑业有限公司

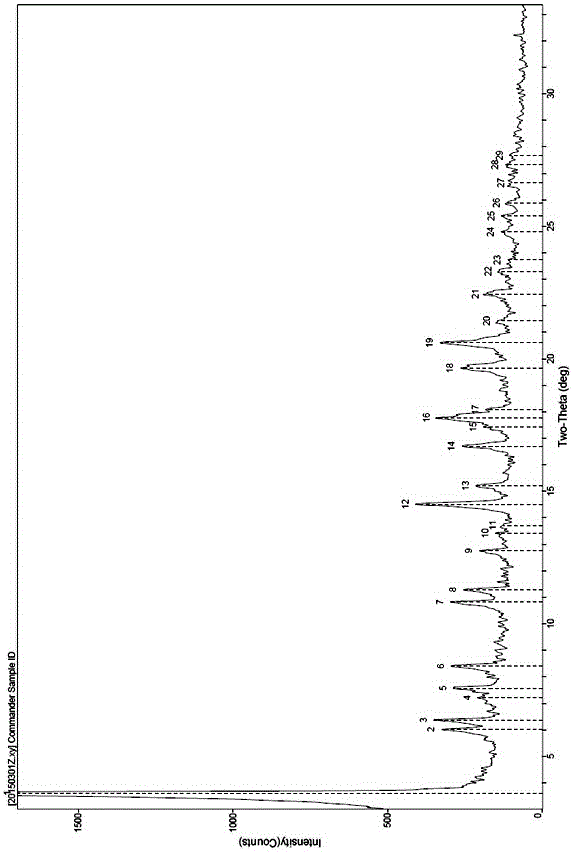

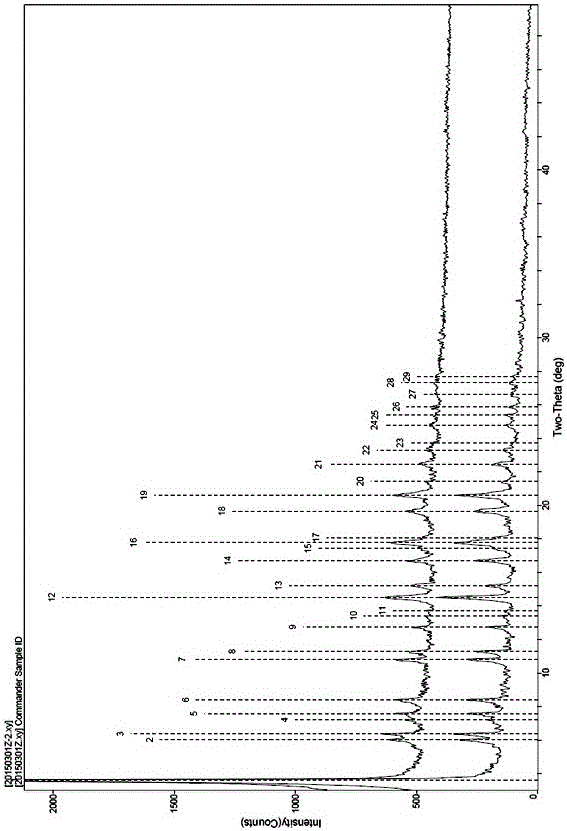

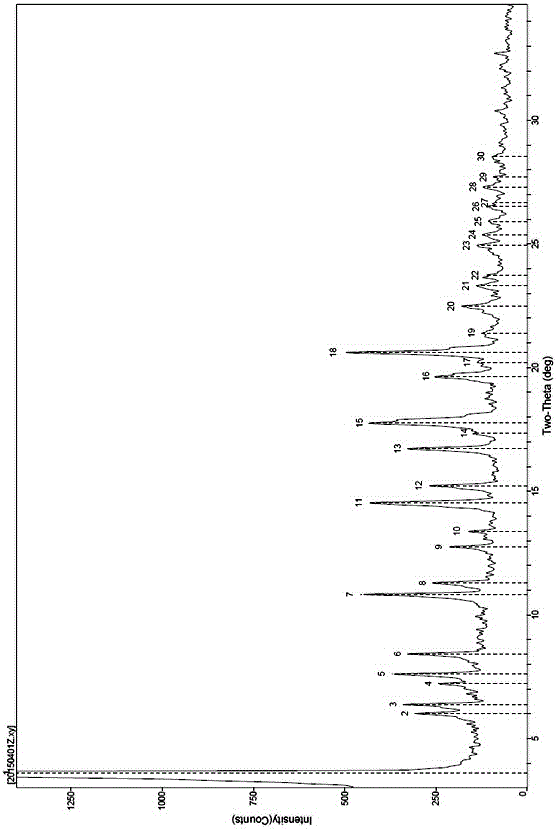

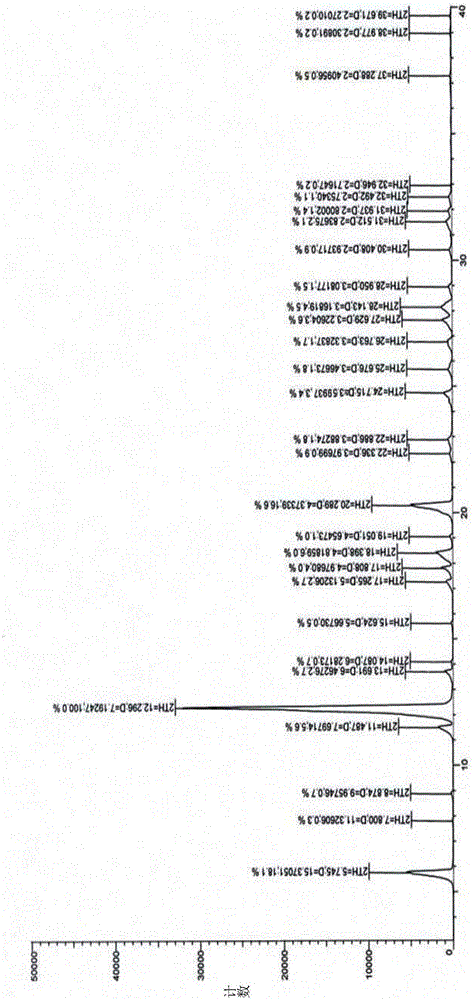

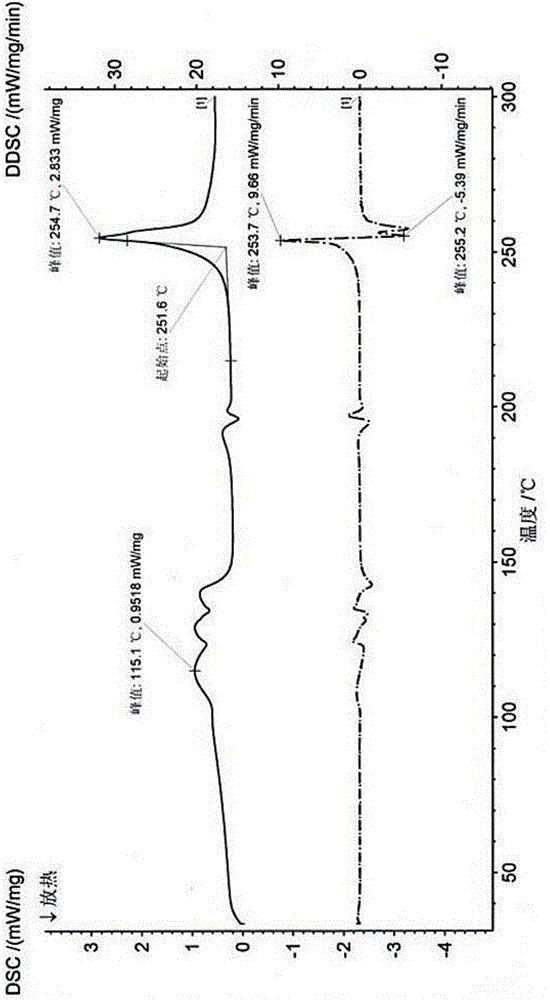

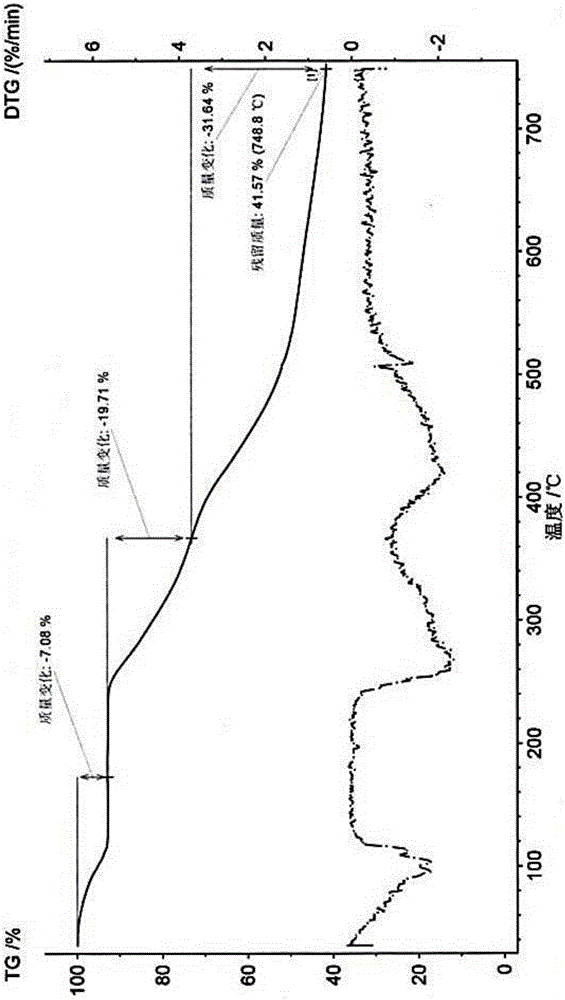

New crystal form of pemetrexed diacid and preparation method thereof

ActiveCN106478632ANon-hygroscopicImprove stabilityOrganic active ingredientsOrganic chemistry methodsX-rayPyrrole

The invention discloses a new crystal form of pemetrexed diacid and a preparation method thereof. Specifically, the invention relates to a new crystal form of N-{4-[2-(2-amino-4, 7-dihydro-4-oxy-1 H-pyrrole [2, 3-d] pyrimidine-5-yl) ethyl] benzoyl}-L-glutamate dehydrate and a preparation method thereof, wherein an XRPD (X-ray powder diffraction) spectrum of the new crystal form at least contains diffraction peaks of 2theta + / -0.20 degree of 5.7, 11.5, 12.3, 18.4, 20.3, 27.6 and 28.1. The new crystal form has the advantages of good stability, high purity, simple preparation and easy operation, and is suitable for industrial production.

Owner:JIANGSU HANSOH PHARMA CO LTD +1

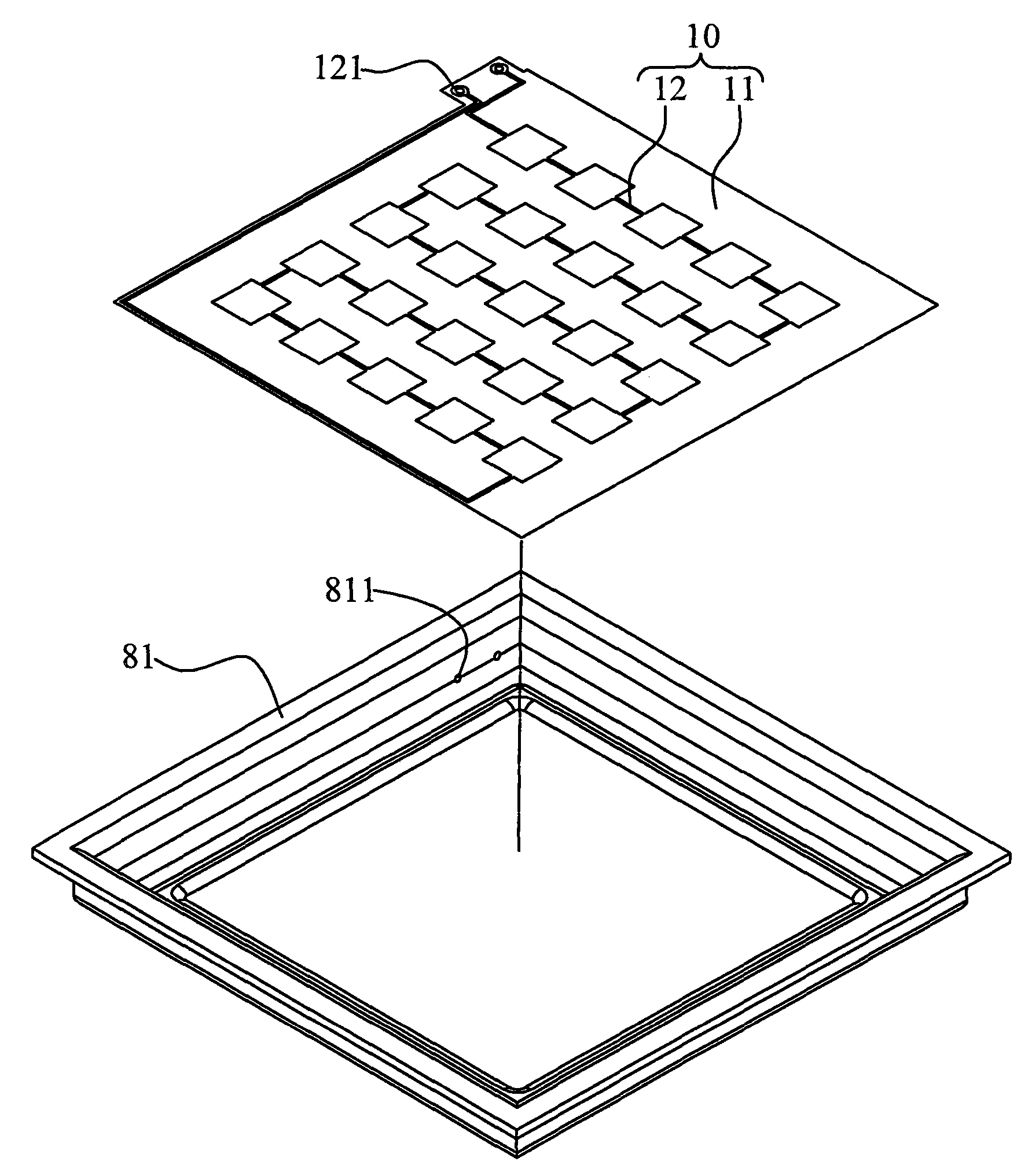

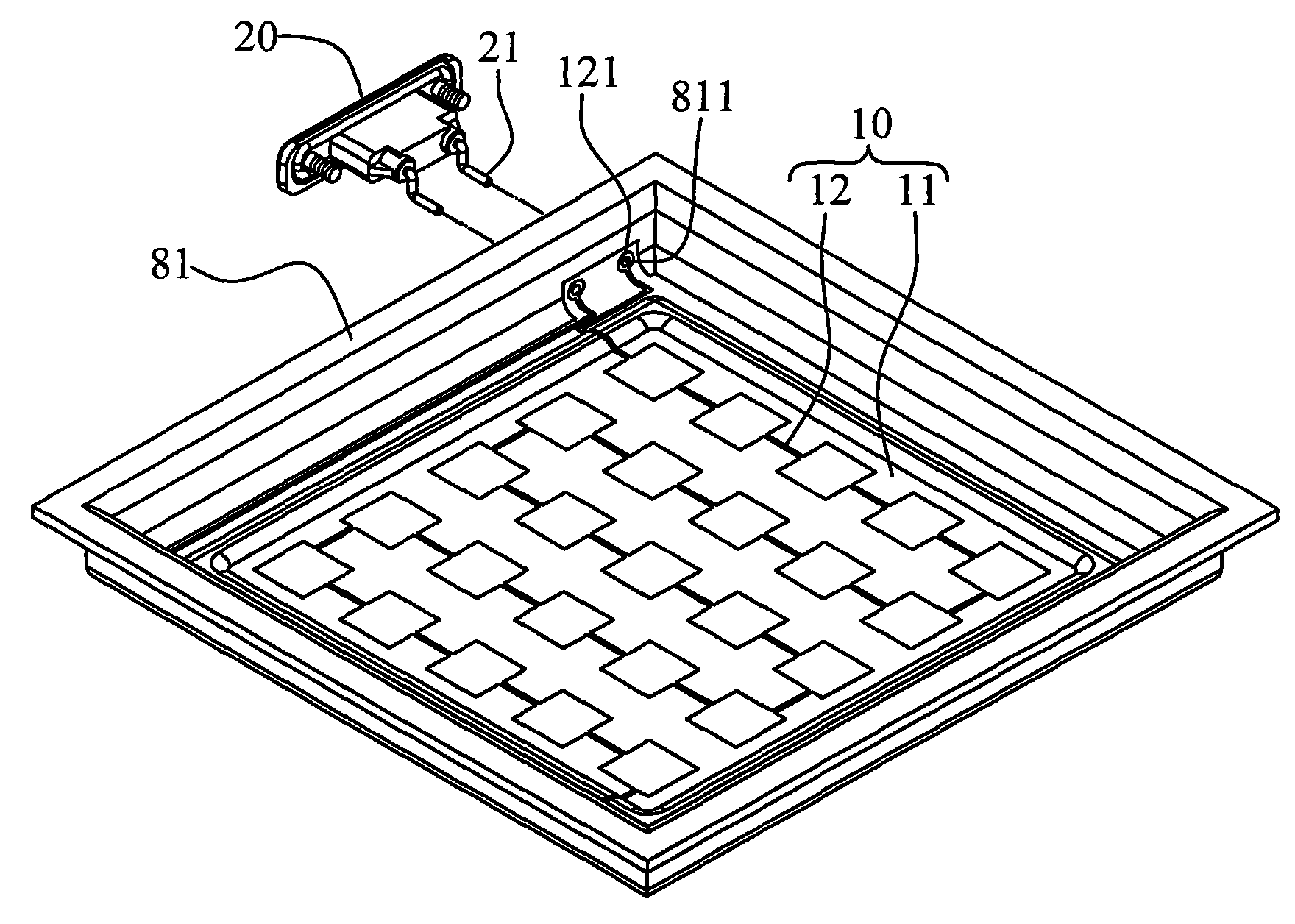

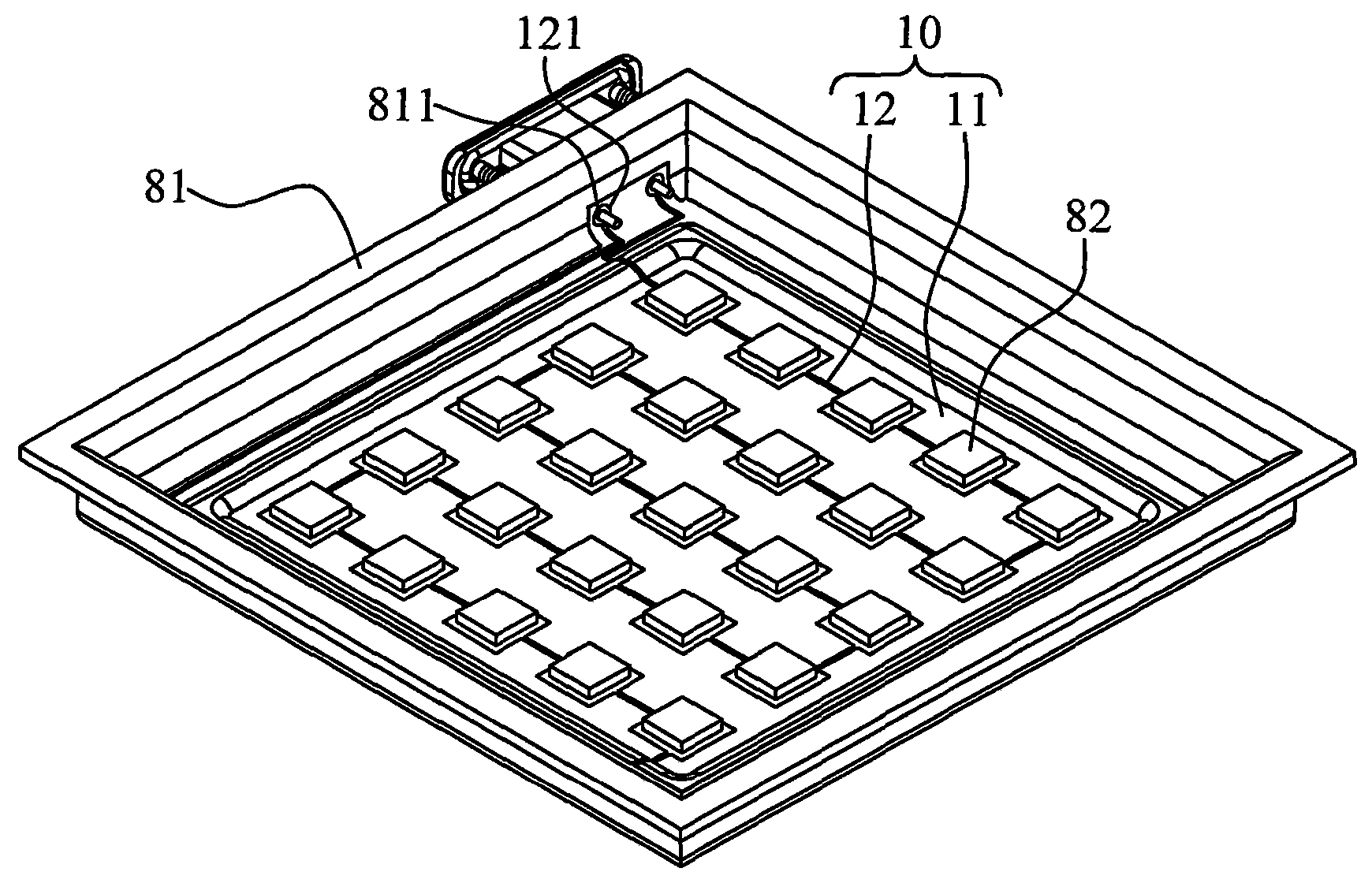

Conductive coating structure for lighting device

InactiveCN102042571BReduce electrostatic effectImprove yieldPoint-like light sourceElectric circuit arrangementsElectricityConductive coating

Owner:LIANG MENG PLASTIC SHARE

Planar MR Safety Cables for Biopotential Measurements

ActiveCN105813556BReduced variation in inductionReduce electrostatic effectElectrotherapyMagnetic measurementsEcg signalElectrical connection

A magnetic resonance (MR) safety cable (10) comprising: four or more controlled resistance conductive wires (12) arranged in a parallel plane configuration; and a hard non-proton emitting substrate (14), It maintains the four or more controlled resistance conductive lines in the parallel plane configuration. The wire (12) terminates at one end in a connector electrically connected to ECG electrodes (64) attached to the subject. The cable is configured to extend one end into the imaging region of the MR scanner (62) to carry ECG signals to associated equipment during imaging.

Owner:KONINKLJIJKE PHILIPS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com