Method for preparing polytetrafluoroethylene micropowder by carrying out swelling treatment on polytetrafluoroethylene through adopting supercritical carbon dioxide

A technology of polytetrafluoroethylene micropowder and polytetrafluoroethylene, which is applied in the production of bulk chemicals, etc., can solve the problem of large average particle size of polytetrafluoroethylene micropowder, poor performance of polytetrafluoroethylene micropowder, uneven particle size dispersion, etc. problem, to achieve good flow and transfer performance, no electrostatic effect, no self-agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

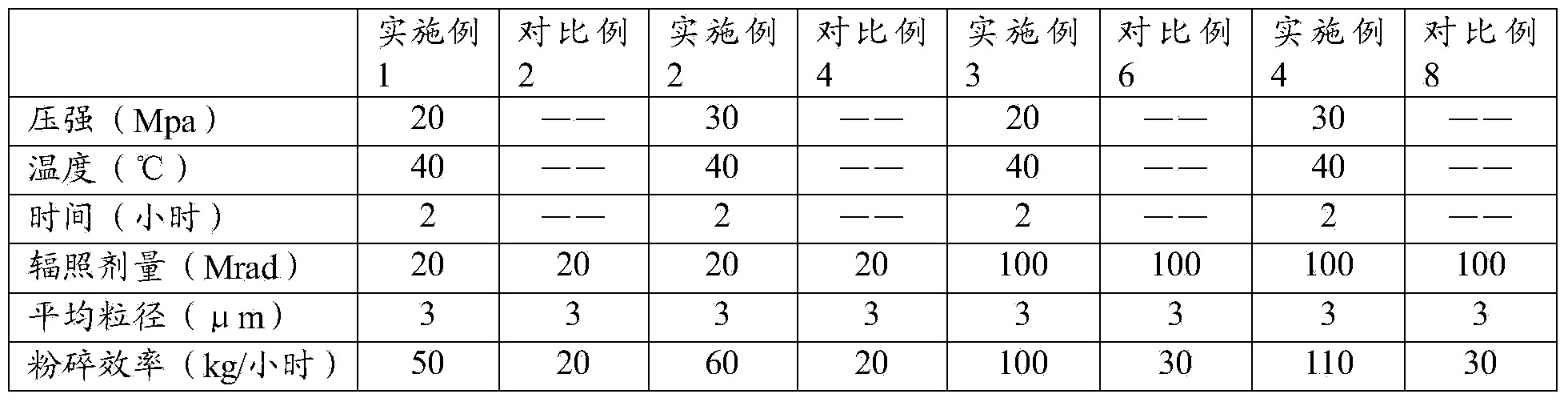

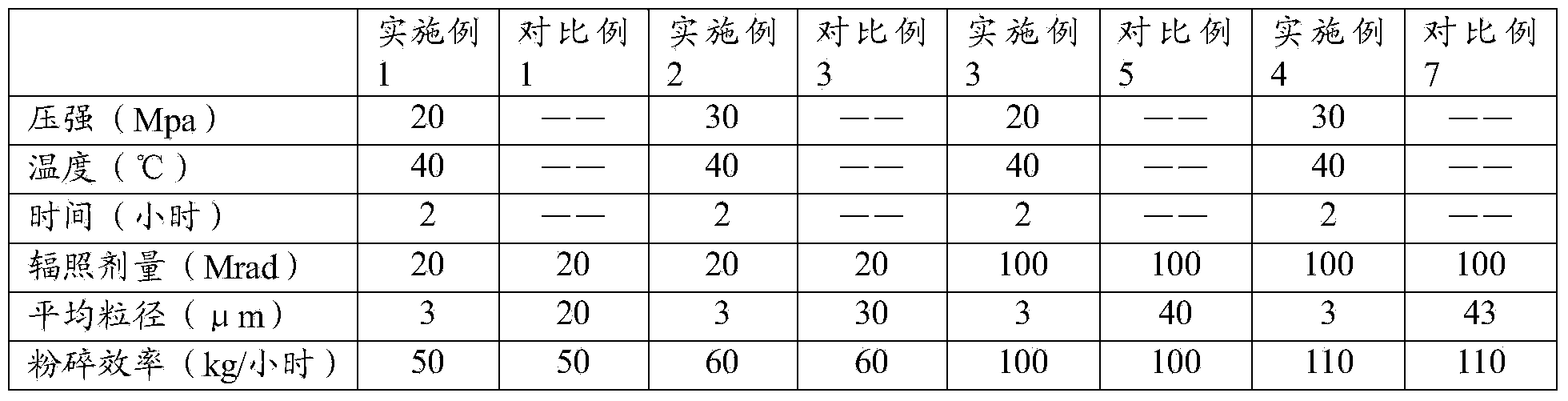

Embodiment 1

[0023] (1) Put the polytetrafluoroethylene raw material in a high-pressure stainless steel container.

[0024] (2) Use a high-pressure pump to press carbon dioxide into the high-pressure stainless steel container. The high-pressure stainless steel container maintains a pressure of 20MPa, a temperature of 40°C, and a swelling time of 2 hours. During this period, the carbon dioxide penetrates into the polytetrafluoroethylene, and the carbon dioxide is saturated in the polytetrafluoroethylene. , PTFE swelling.

[0025] (3) Pressure relief, the gas pressure in the high-pressure stainless steel container is reduced to normal pressure, and the carbon dioxide in the polytetrafluoroethylene is released to form expanded polytetrafluoroethylene with a porous structure.

[0026] (4) Using the GJ~2 type electron accelerator, the polytetrafluoroethylene with expanded and porous structure is treated with radiation modification technology, and the radiation dose is controlled at 20 Mrad.

...

Embodiment 2

[0035] (1) Put the polytetrafluoroethylene raw material in a high-pressure stainless steel container.

[0036] (2) Use a high-pressure pump to press carbon dioxide into the high-pressure stainless steel container. The high-pressure stainless steel container maintains a pressure of 30MPa, a temperature of 40°C, and a swelling time of 2 hours. During this period, carbon dioxide penetrates into the polytetrafluoroethylene, and the carbon dioxide is saturated in the polytetrafluoroethylene. , PTFE swelling.

[0037] (3) Pressure relief, the gas pressure in the high-pressure stainless steel container is reduced to normal pressure, and the carbon dioxide in the polytetrafluoroethylene is released to form expanded polytetrafluoroethylene with a porous structure.

[0038] (4) Using the GJ~2 type electron accelerator, the polytetrafluoroethylene with expanded and porous structure is treated with radiation modification technology, and the radiation dose is controlled at 20Mrad.

[0039...

Embodiment 3

[0047] (1) Put the polytetrafluoroethylene raw material in a high-pressure stainless steel container.

[0048](2) Use a high-pressure pump to press carbon dioxide into the high-pressure stainless steel container. The high-pressure stainless steel container maintains a pressure of 20MPa, a temperature of 40°C, and a swelling time of 2 hours. During this period, the carbon dioxide penetrates into the polytetrafluoroethylene, and the carbon dioxide is saturated in the polytetrafluoroethylene. , PTFE swelling.

[0049] (3) Pressure relief, the gas pressure in the high-pressure stainless steel container is reduced to normal pressure, and the carbon dioxide in the polytetrafluoroethylene is released to form expanded polytetrafluoroethylene with a porous structure.

[0050] (4) Using the GJ~2 type electron accelerator, the polytetrafluoroethylene with expanded and porous structure is treated with radiation modification technology, and the radiation dose is controlled at 100Mrad.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com