Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Realize temperature detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

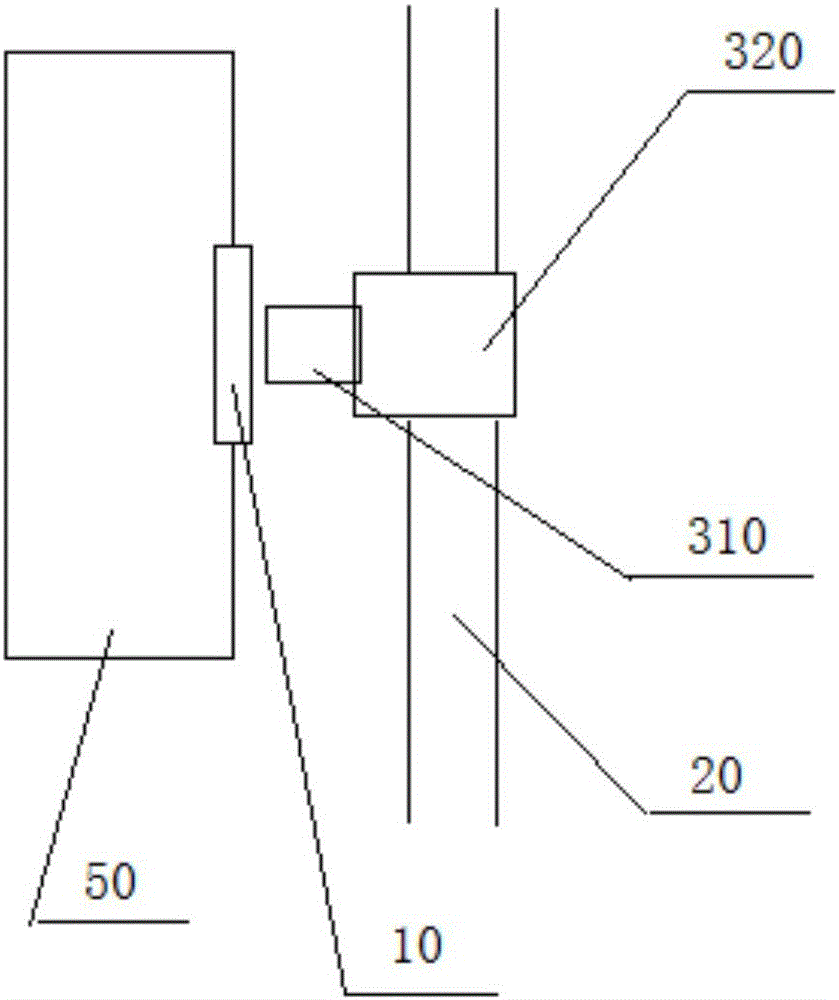

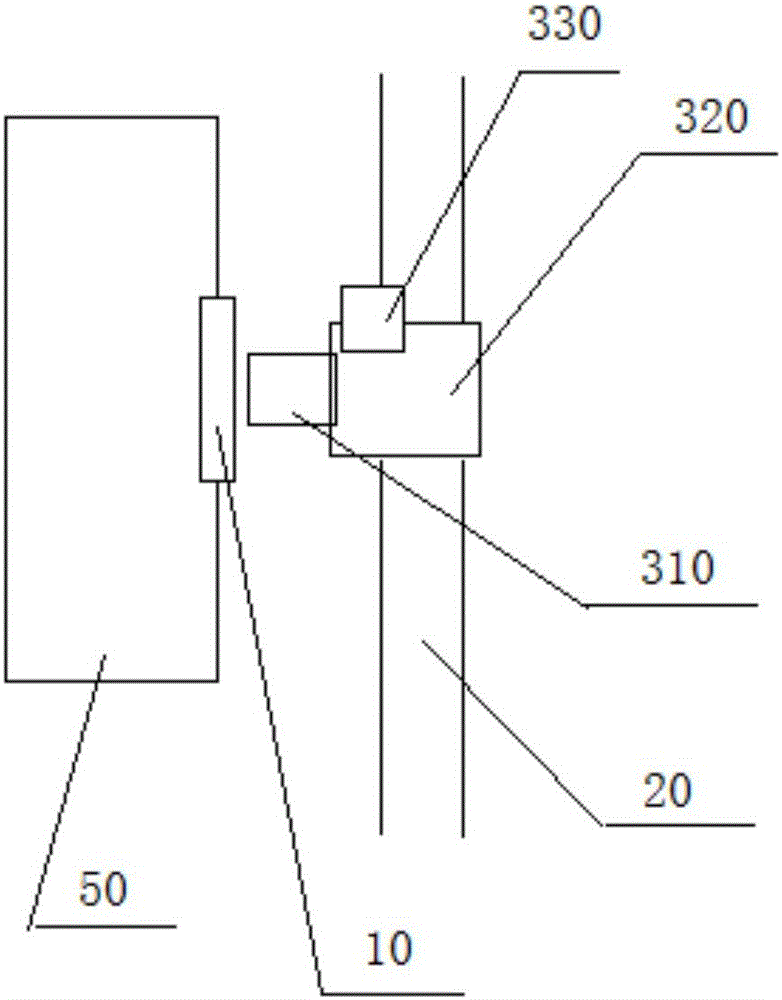

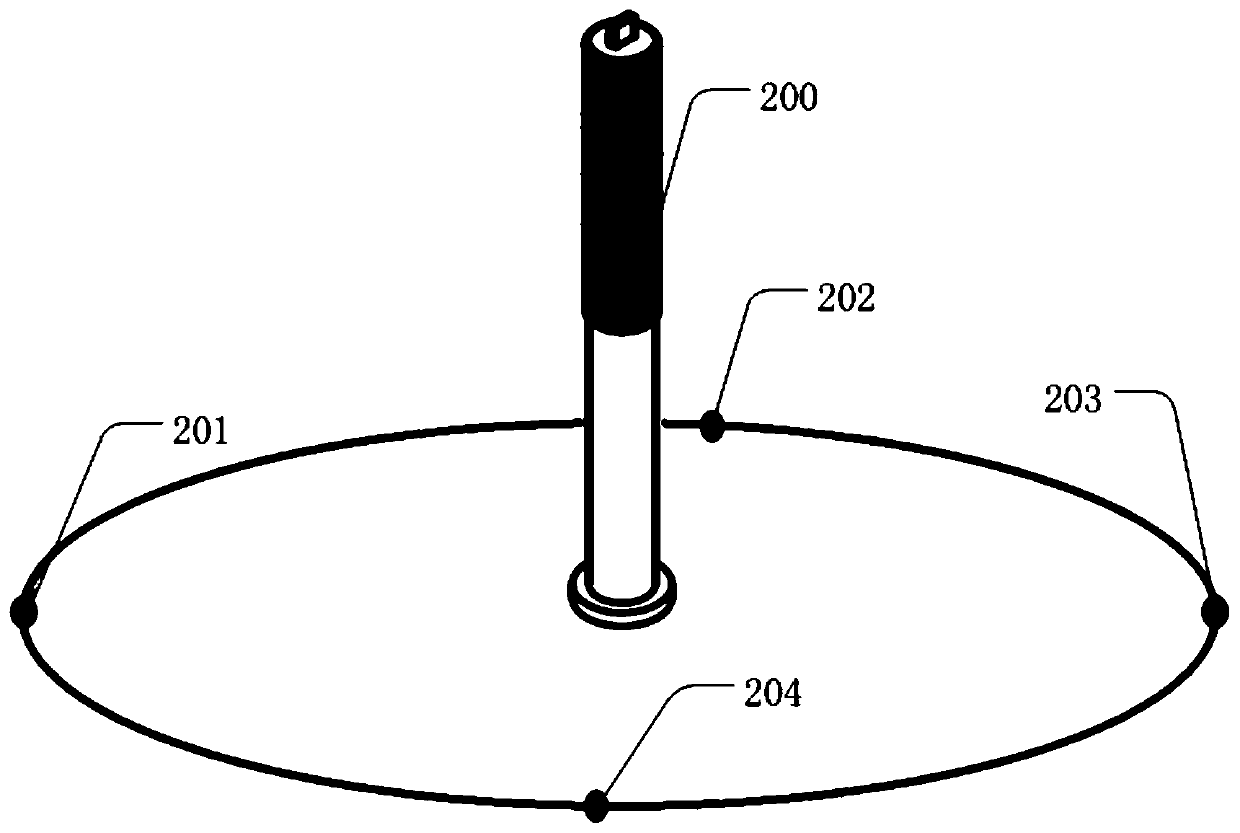

High voltage switch cabinet online temperature detection device, method and system

InactiveCN106197681ARealize temperature detectionLow costRadiation pyrometryThermographic cameraPower equipment

The invention relates to the field of power equipment online monitoring, in particular to a high voltage switch cabinet online temperature detection device, method and system. The device comprises an infrared detection window installed on a monitoring body, a main patrol track and a monitoring robot installed on the track; the monitoring robot comprises an infrared thermal imager and an adjusting mechanism which is used for adjusting the position of the infrared thermal imager, the monitoring robot can conduct patrolling along the main patrol tack according to a preset patrolling route, and in the patrolling process, the monitoring robot reaches a preset position according to preset position information corresponding to the infrared detection window and controls the infrared thermal imager to obtain an infrared image inside the monitoring body from the infrared detection window. The device only needs one infrared detection window, temperature detection on the interior of the switch cabinet is achieved from the exterior of the switch cabinet, the cost is reduced, and meanwhile temperature detection with few blind spots on interior equipment of the switch cabinet is achieved.

Owner:北京殷图网联科技股份有限公司

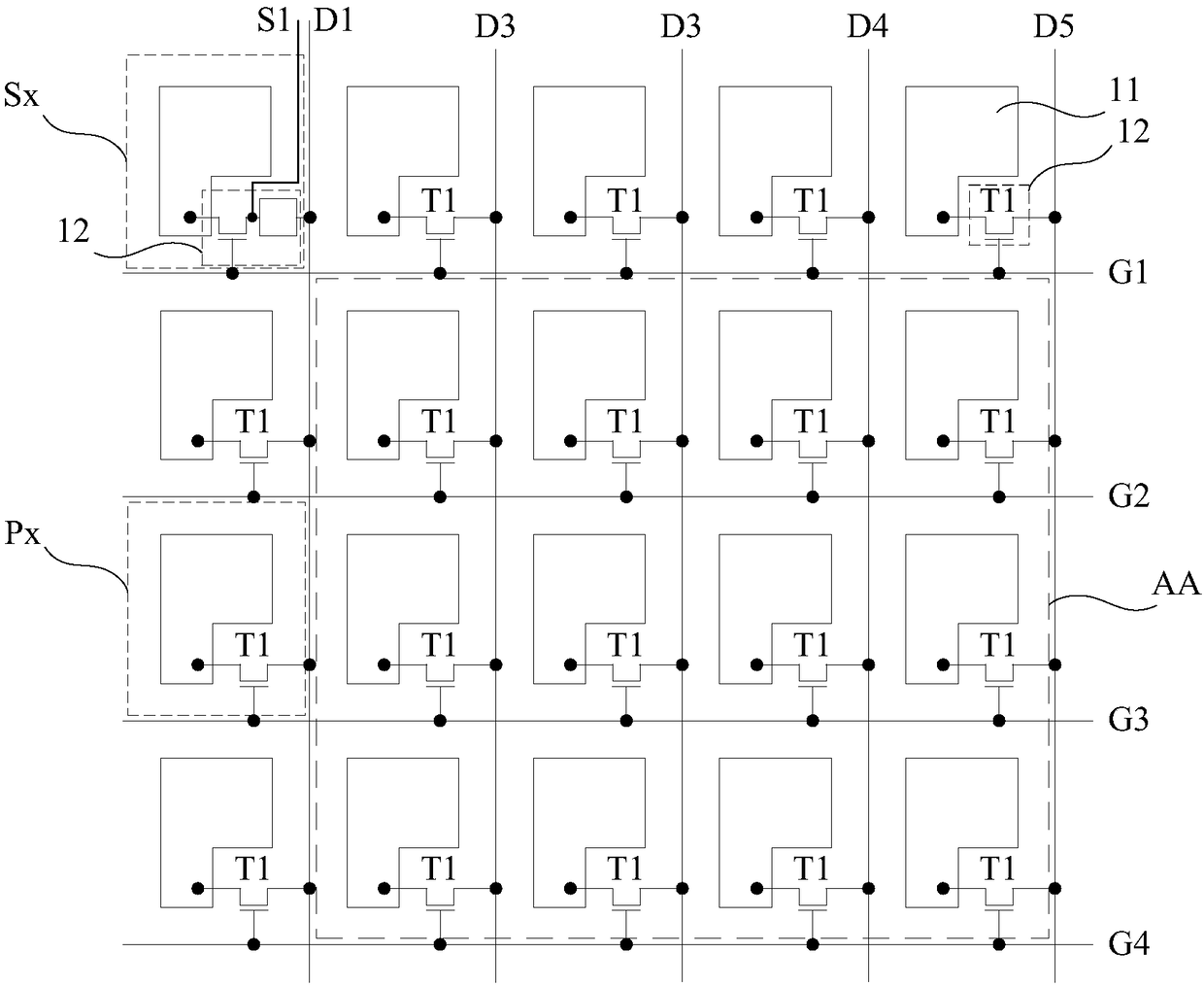

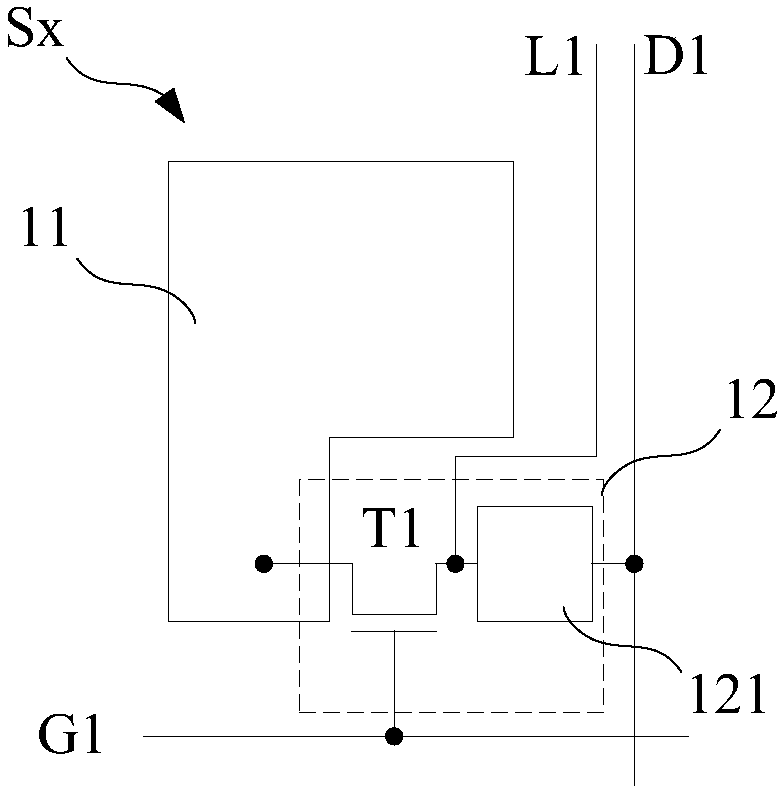

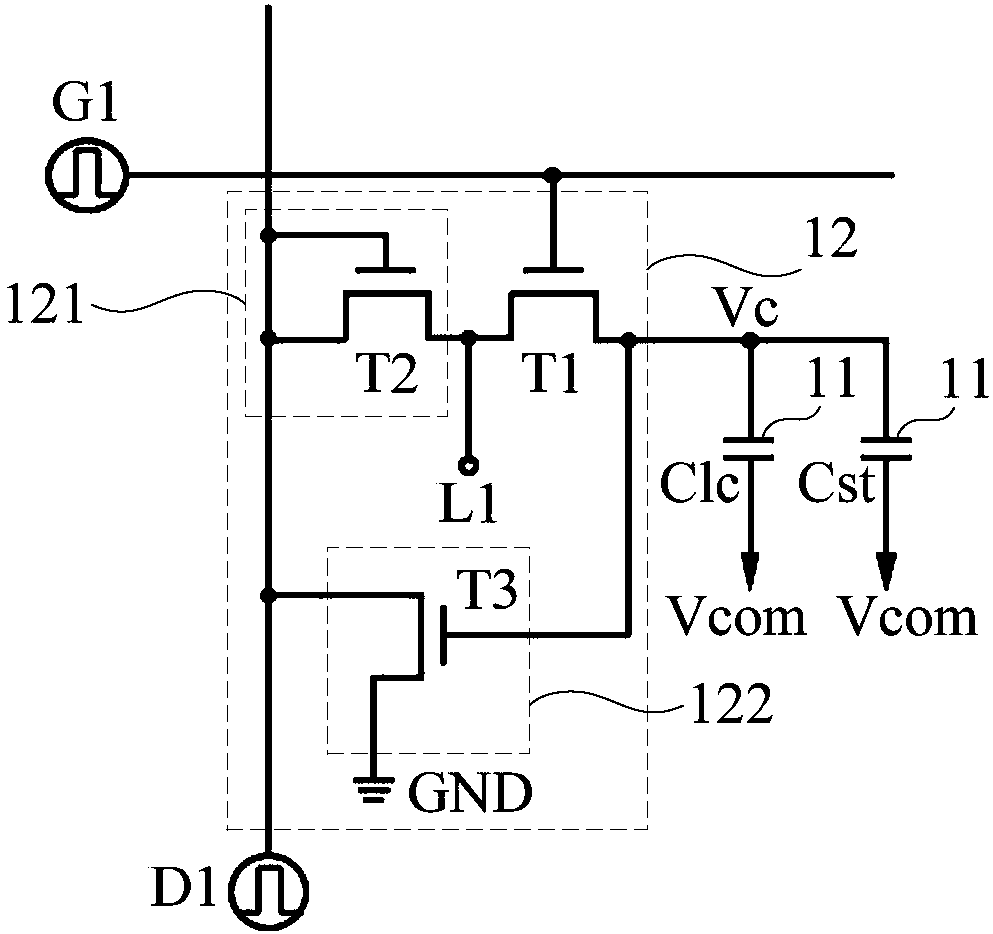

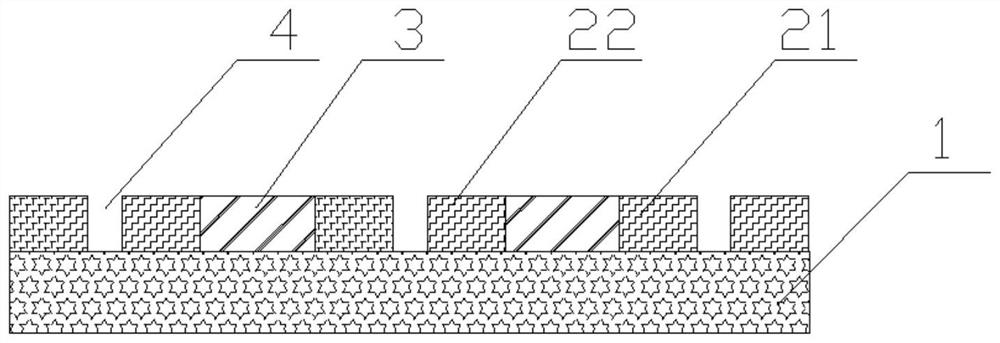

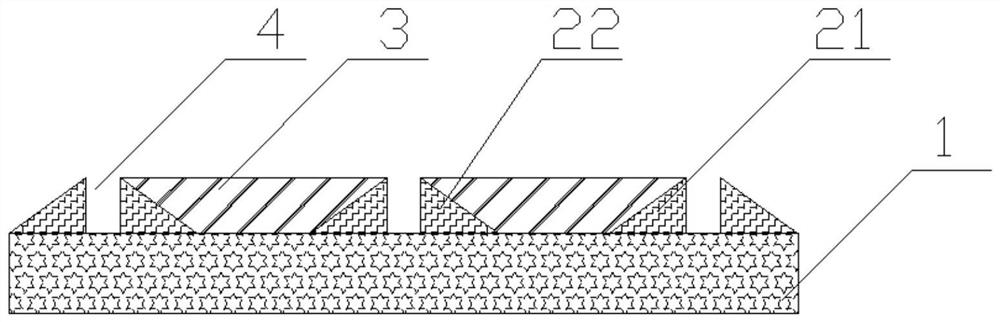

Array substrate, display device and temperature detection method and device

ActiveCN108445654ARealize temperature detectionThermometers using electric/magnetic elementsUsing electrical meansElectricityDisplay device

The invention provides an array substrate, a display device and a temperature detection method and device, and belongs to the field of display. The array substrate comprises a plurality of pixel units, multiple grid wires, multiple data wires and at least one temperature sensing and detecting wire, each pixel unit is provided with a pixel electrode and a pixel circuit, wherein the pixel circuit comprises a first pole and a first transistor connected with the pixel electrode in the pixel unit, and at least one temperature sensing pixel unit is included in the pixel units; the grid electrode ofeach first transistor is connected with one of the grid wires; each pixel circuit is connected with one of the data wires; the second pole of the first transistor in each temperature sensing pixel unit is connected with one temperature sensing and detecting wire, and the pixel circuit in each temperature sensing pixel unit comprises a switching module which is configured into electrically connecting the data wire with the second pole of the first transistor when effective electrical level exists on the data wire. By means of the array substrate, temperature detection of the interior of a display screen can be achieved in a simple manner.

Owner:BOE TECH GRP CO LTD +1

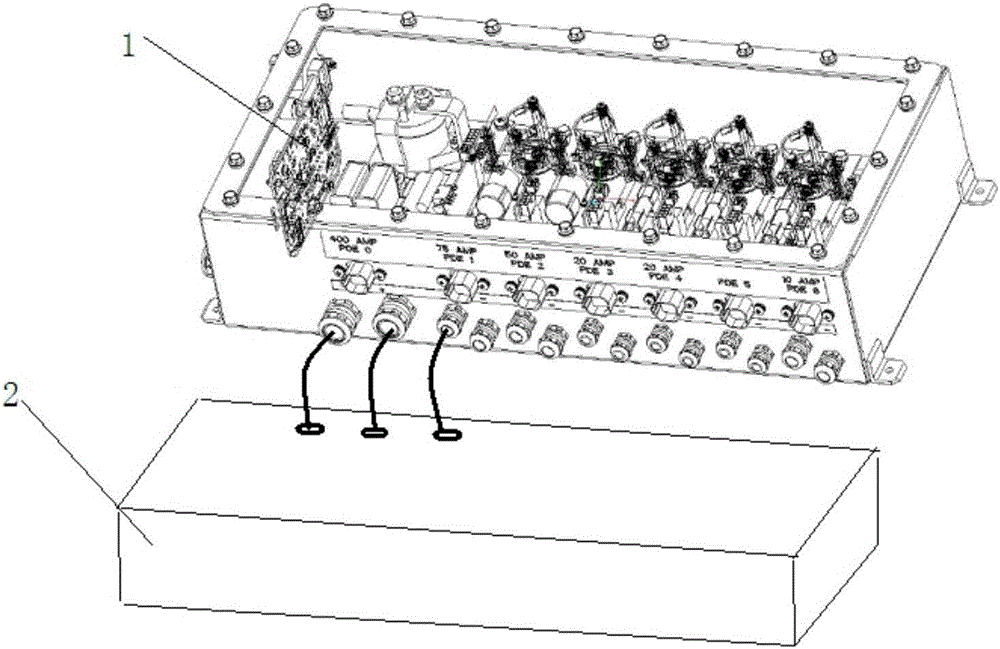

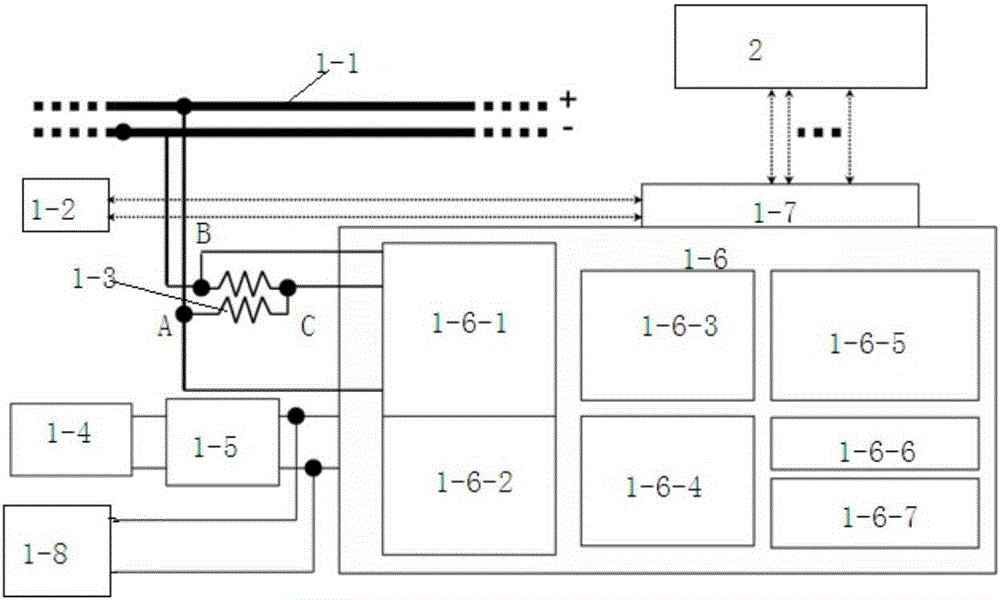

Full electric vehicle multi-load high-voltage dc modular system

ActiveCN106696705AAchieve insulationReduce complexityElectric devicesTesting electric installations on transportOn boardLow voltage

The invention relates to the technical field of the electric vehicle, in particular to a full electric vehicle multi-load high-voltage dc modular system, comprises a CPU and a vehicle load, the device has the characteristics that: the CPU is connected in parallel with the vehicle load; the CPU comprises a high voltage power input bus, a vehicle HSCAN bus, a voltage sensor, a vehicle low-voltage power supply, a low voltage regulator, a control CPU module and a communication interface, wherein, the control CPU module comprises an analog signal conditioning module, an isolate the fault diagnosis module, a diagnosis and prediction module, a user configuration table power distribution module, an on-board diagnosis module and a safety function module, the device can combine well the high-voltage dc system with the electric attachment, can be reused on different platforms and can be continuously updated to meet new technical specifications.

Owner:TOP GEAR POWERTRAIN TECH CO LTD

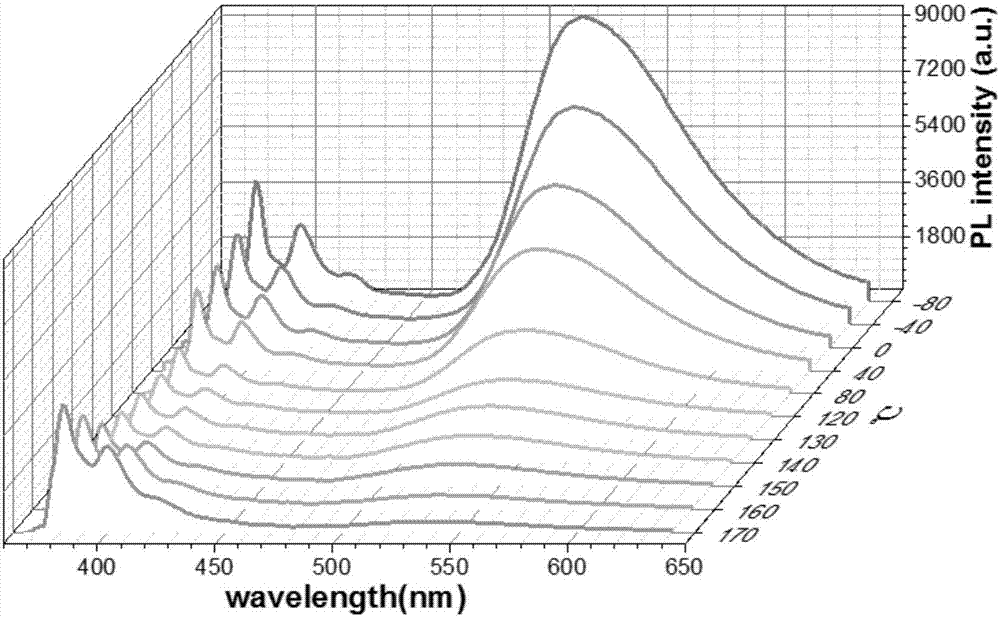

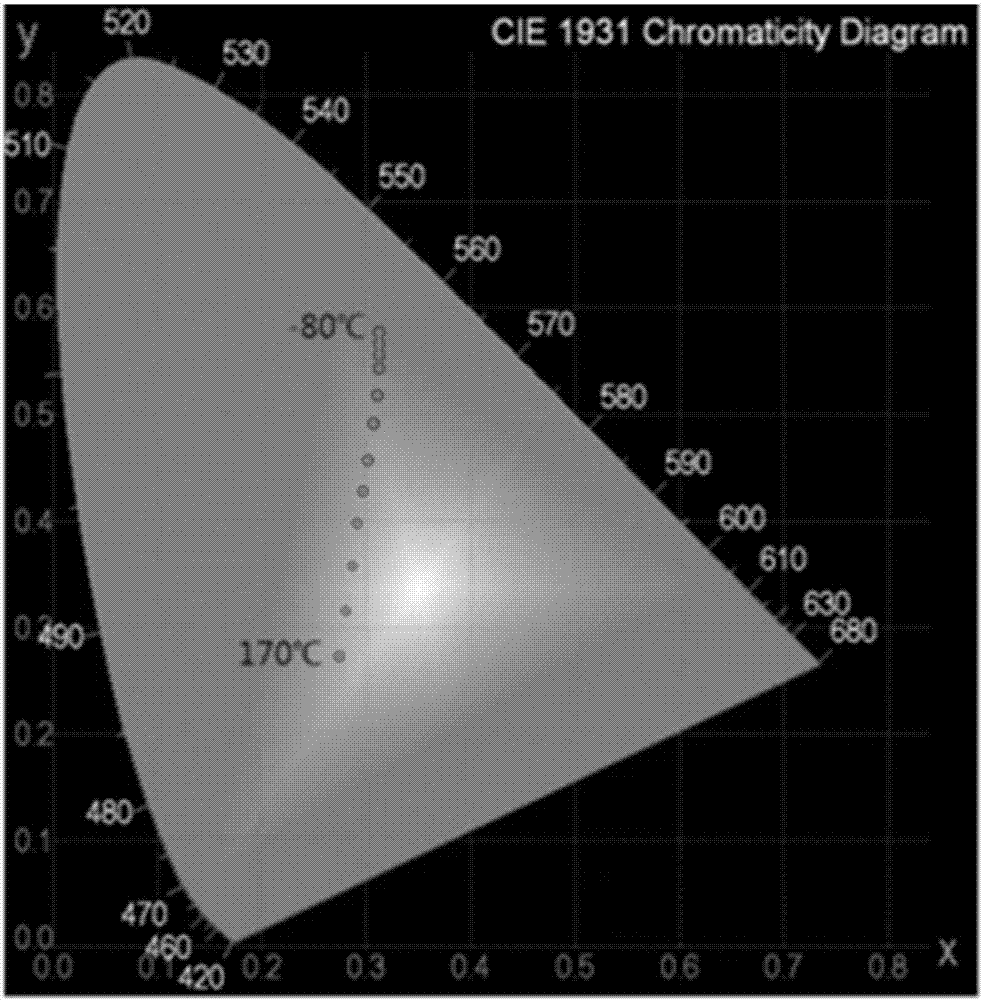

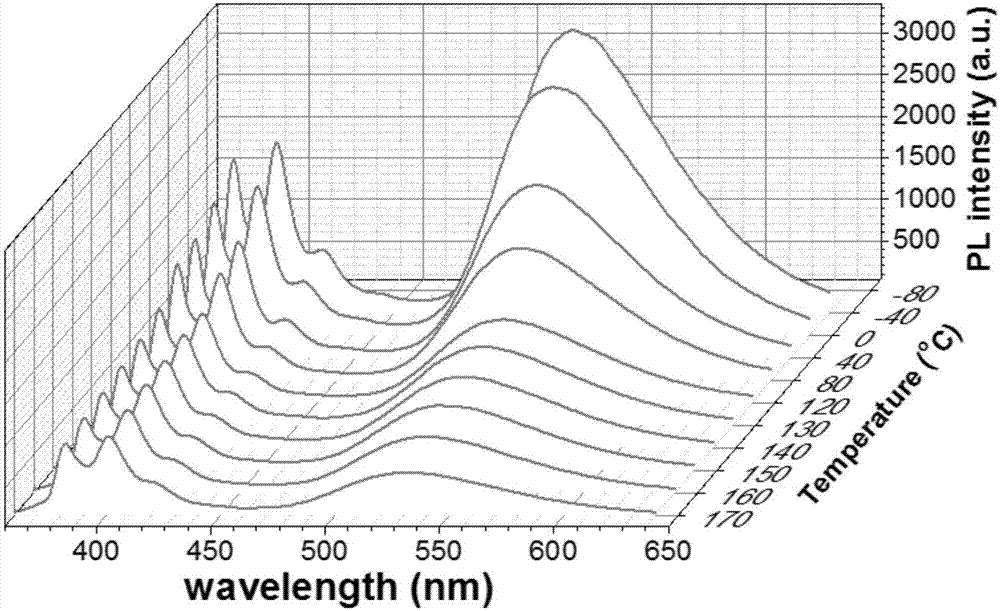

Dual-luminescence organic fluorescent temperature sensing film and preparation method thereof

ActiveCN107573926ARealize temperature distribution detectionRealize temperature detectionThermometers using physical/chemical changesLuminescent compositionsOrganic filmLuminescence

The invention discloses a dual-luminescence organic fluorescent temperature sensing film and a preparation method thereof. The organic fluorescent temperature sensing film is prepared from an organicfluorescent compound blending material and a polymer. The organic fluorescent compound blending material is prepared by blending a triaryl phosphoric-oxygenic compound and a great Stokes shift compound. The triaryl phosphoric-oxygenic compound serves as a blue light material and has stable luminescence property at a high temperature; another fluorescent material has great Stokes shift, the luminescence peak wavelength of the fluorescent material is larger than that of the blue light material, and the absorption peak wavelength of the fluorescent material is smaller than that of the blue lightmaterial. The organic fluorescent temperature sensing film disclosed by the invention first realizes temperature distribution detection in the field of solid organic films by virtue of naked eye chromaticity recognition, can serve a solid rigidity or flexibility form, can be applied to real-time temperature detection in different environments, has extremely wide detection range and thermal distribution gradient response property and can realize temperature detection by virtue of a spectrograph or a colorimeter.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

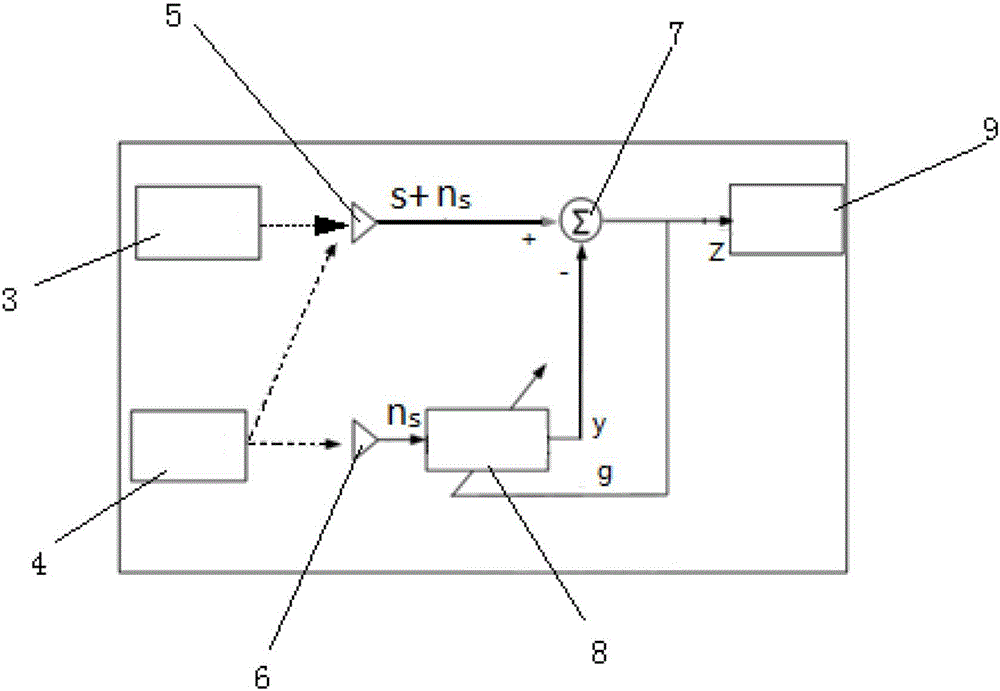

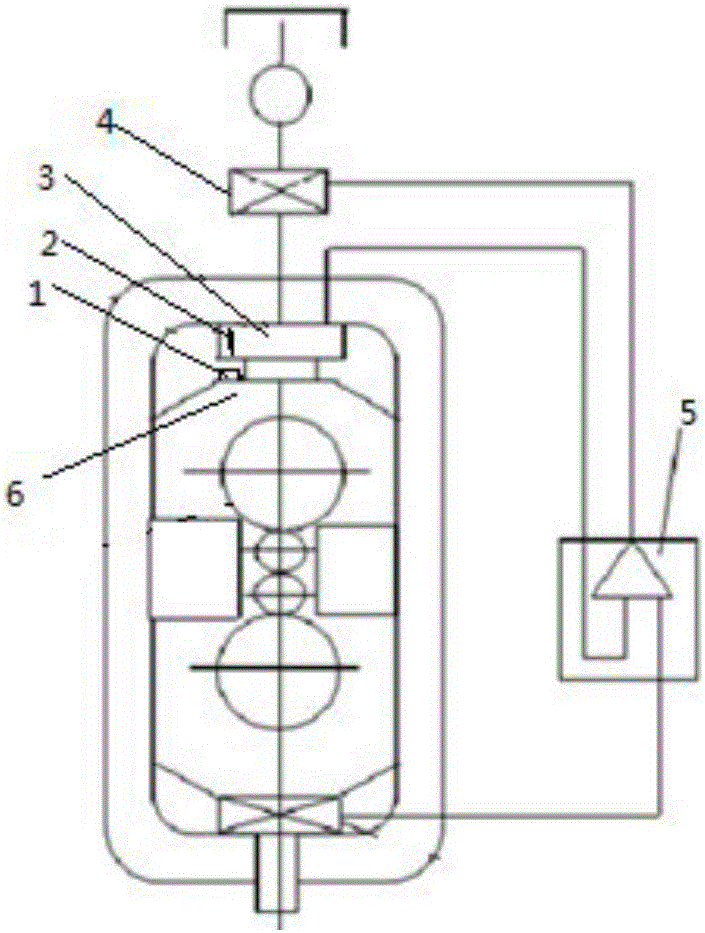

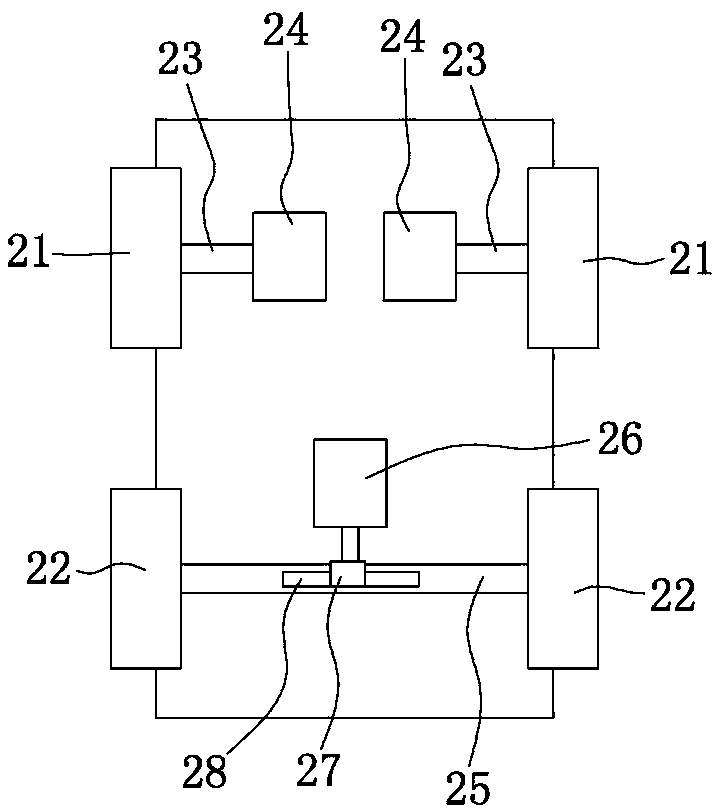

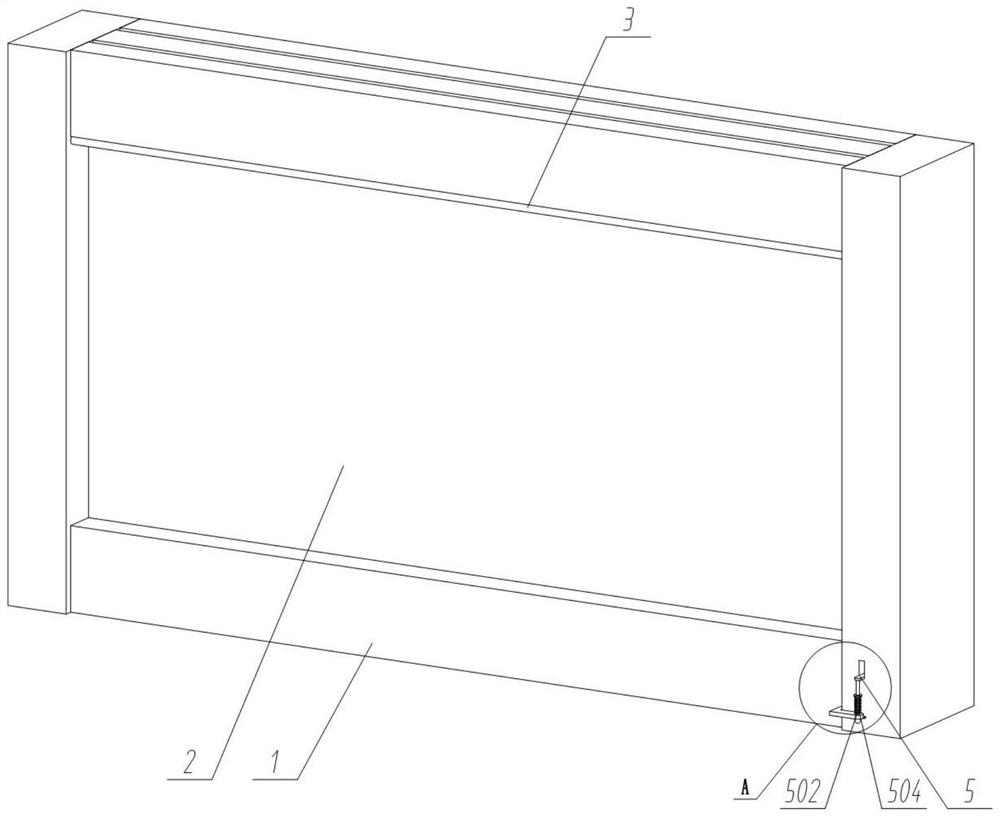

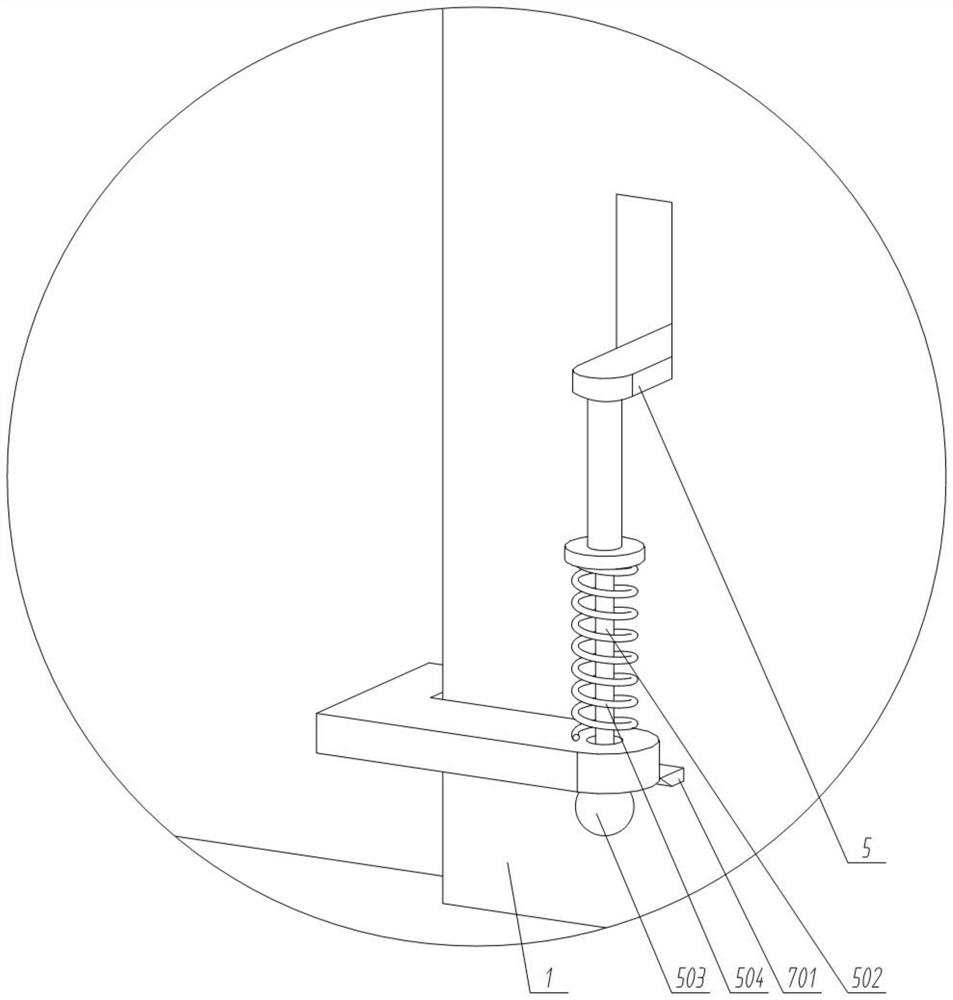

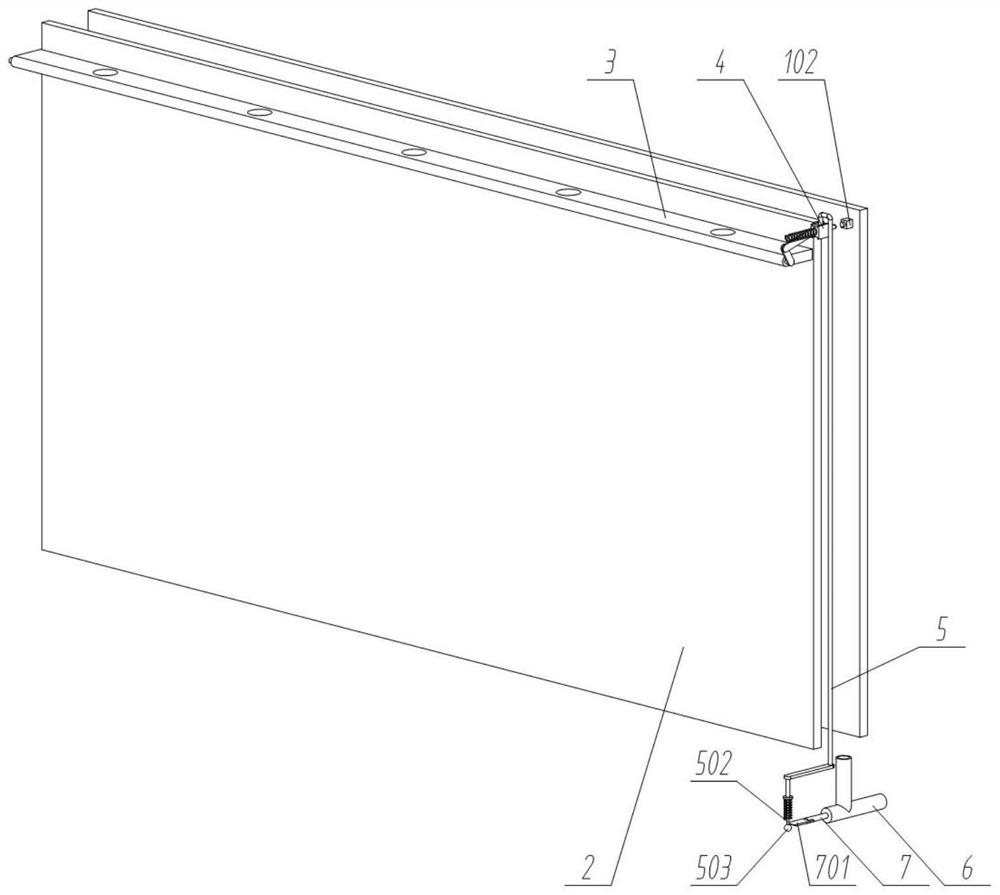

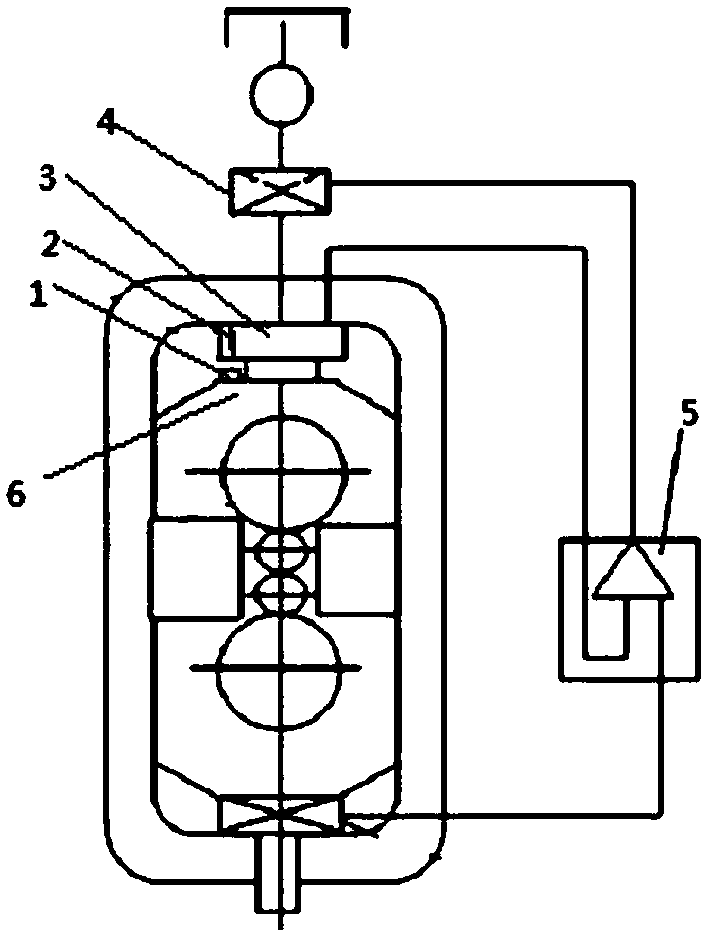

Plate-strip rolling mill roll system vibration inhibiting system and method based on hydraulic cylinder control

InactiveCN105903769ASimple and effective vibration detectionQuality improvementVibration control deviceMetal rolling arrangementsClosed loopOil temperature

The invention discloses a plate-strip rolling mill roll system vibration inhibiting system and method based on hydraulic cylinder control. An acceleration sensor (1) is arranged at the bottom of a hydraulic cylinder rigid body (3). A temperature sensor (2) is arranged on a side of the hydraulic cylinder rigid body (3). The hydraulic cylinder rigid body (3) is connected with a temperature adjuster (4). The temperature adjuster (4) is connected with a comprehensive control device (5). According to the invention, related technique for roller vertical vibration inhibition is realized through performing control over oil temperature of a hydraulic cylinder of a rolling mill screwdown gear and a rolling vibration inhibition closed-loop system combining hydraulic cylinder oil temperature and roll system vibration parameters are proposed based on theoretical study and field practice, help is provided for solving rolling mill vertical vibration problems. The system is simple in structure and can realize a rolling mill roll system vibration inhibiting device achieving mutual feedback adjustment of vibration and temperature conveniently and quickly.

Owner:BEIJING UNIV OF TECH

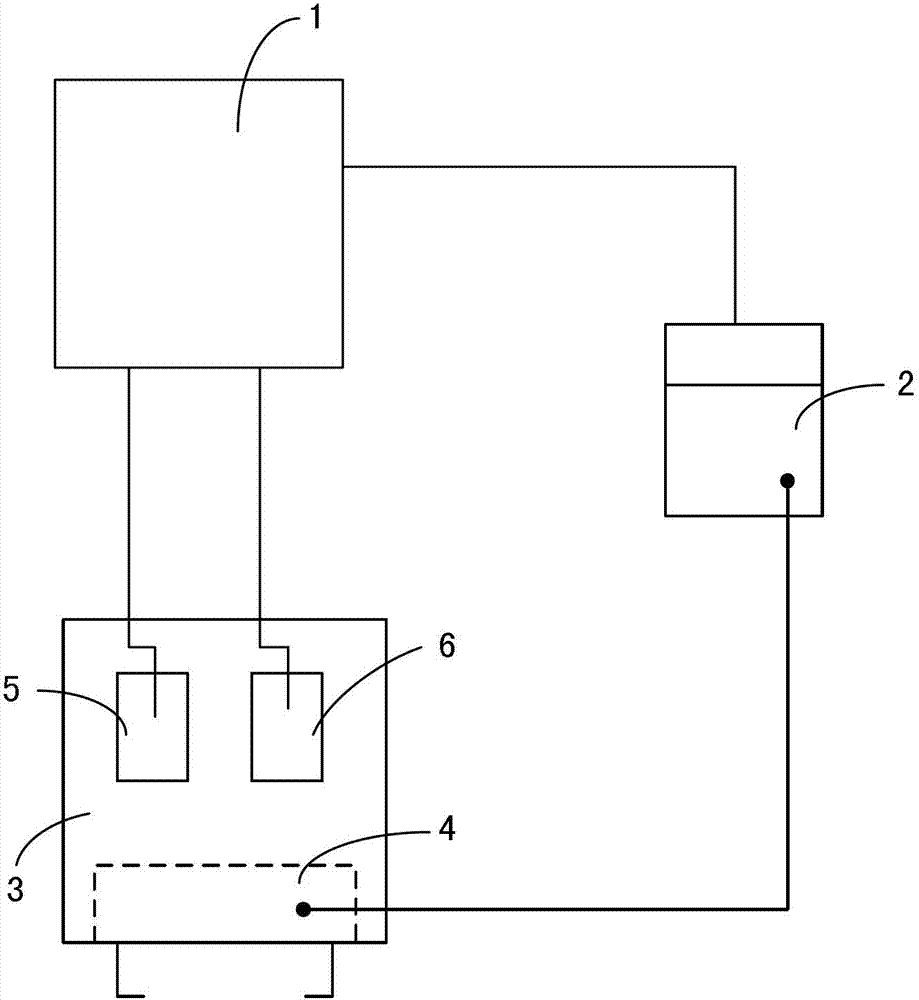

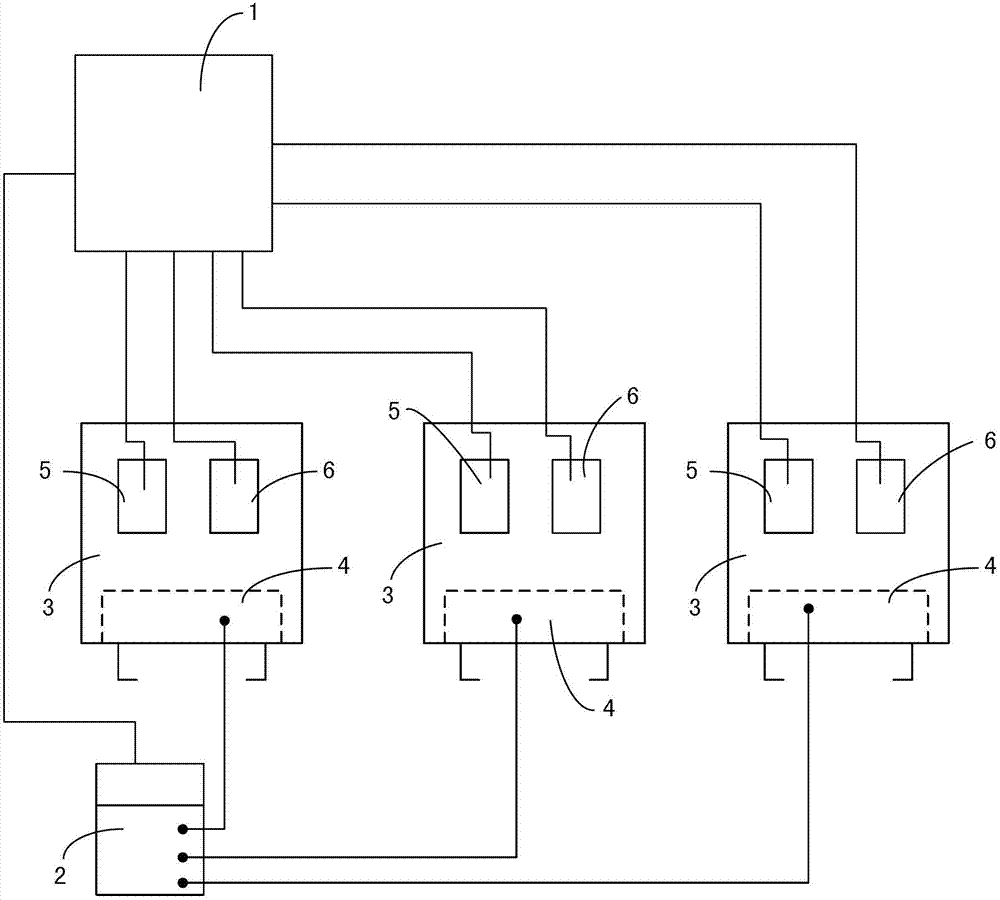

Sodium-sulfur cell batch detecting system

InactiveCN103197252AIncrease profitAchieve voltageElectrical testingEmbedded systemIntelligent control system

The invention discloses a sodium-sulfur cell batch detecting system. The sodium-sulfur cell batch detecting system comprises a plurality of batch detecting furnaces, an intelligent control system, temperature controllers, collection controllers, and a charging-discharging device, wherein sodium-sulfur cells to be tested are arranged inside the batch detecting furnaces, the temperature controller and the collection controller are all arranged on each batch detecting furnace and are respectively connected with the intelligent control system, the charging-discharging device is respectively connected with the sodium-sulfur cells to be tested inside each batch detecting furnace and is connected with the intelligent control system. The sodium-sulfur cell batch detecting system enables the collection controllers to be separated from the batch detecting furnaces and the charging-discharging device so that the charging-discharging device does not need to be accompanied around the batch detecting furnaces in the process of temperature rise and temperature fall, and accordingly detection of voltage and temperature of a single cell in the period can be achieved. Data such as the voltage and the temperature of the single cell collected by the collection controller, guide the operation strategy of the charging-discharging device.

Owner:SHANGHAI ELECTRIC SODIUM SULFUR ENERGY STORAGE TECH +2

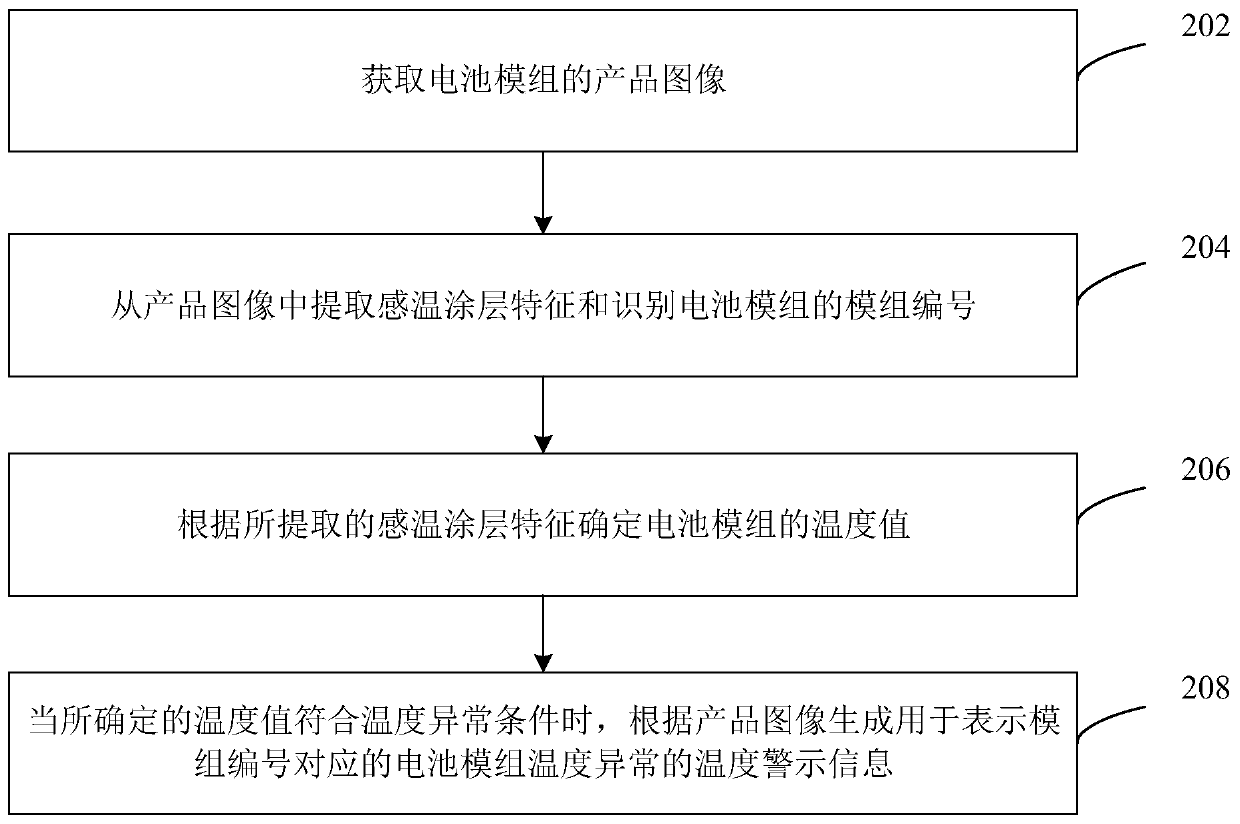

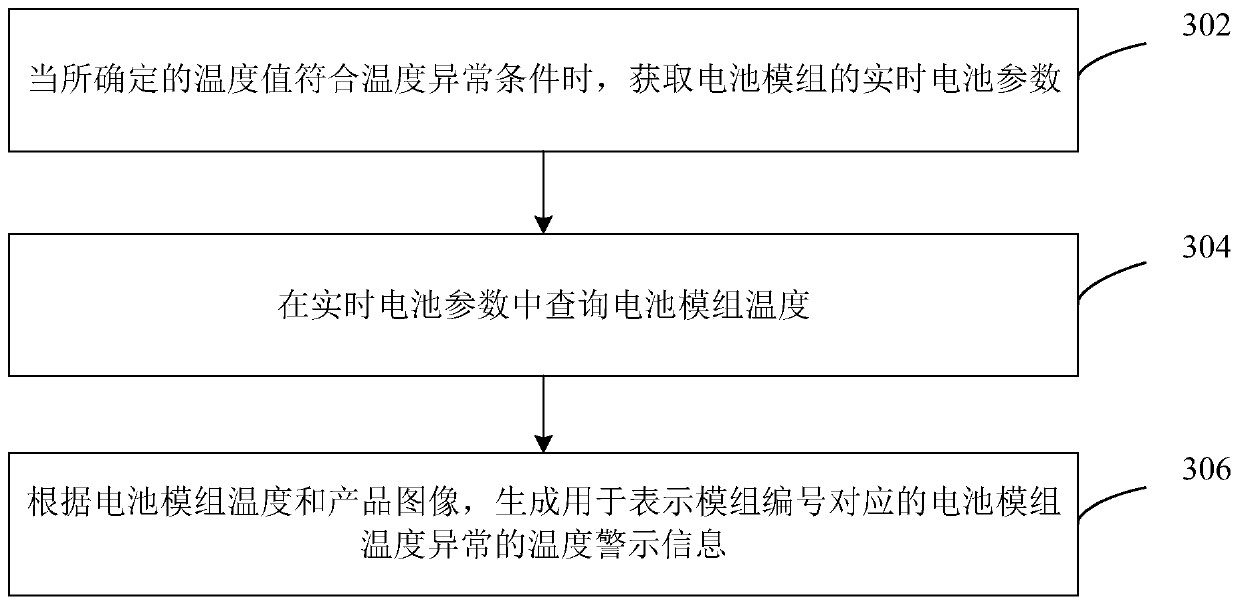

Temperature early warning method for energy storage battery, device, computer apparatus and storage medium

InactiveCN109932066AGood distinctionRealize temperature detectionThermometer detailsThermometers using physical/chemical changesElectrical batteryEngineering

The present invention relates to a temperature early warning method for an energy storage battery, a temperature early warning device for an energy storage battery, a computer apparatus and a storagemedium. The method includes the following steps that: the product image of a battery module set is obtained; temperature sensing coating features are extracted from the product image, and the module set number of the battery module set is identified from the product image; the temperature value of the battery module set is determined according to the extracted temperature sensing coating features;and when it is determined that the temperature value meets a temperature abnormal condition, temperature warning information indicating that the temperature of the battery module set corresponding tothe module set number is abnormal is generated according to the product image. With the method adopted, detecting personnel can quickly find the battery module set with abnormal temperature accordingto the product image in the temperature warning information, and therefore, temperature early warning efficiency can be improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

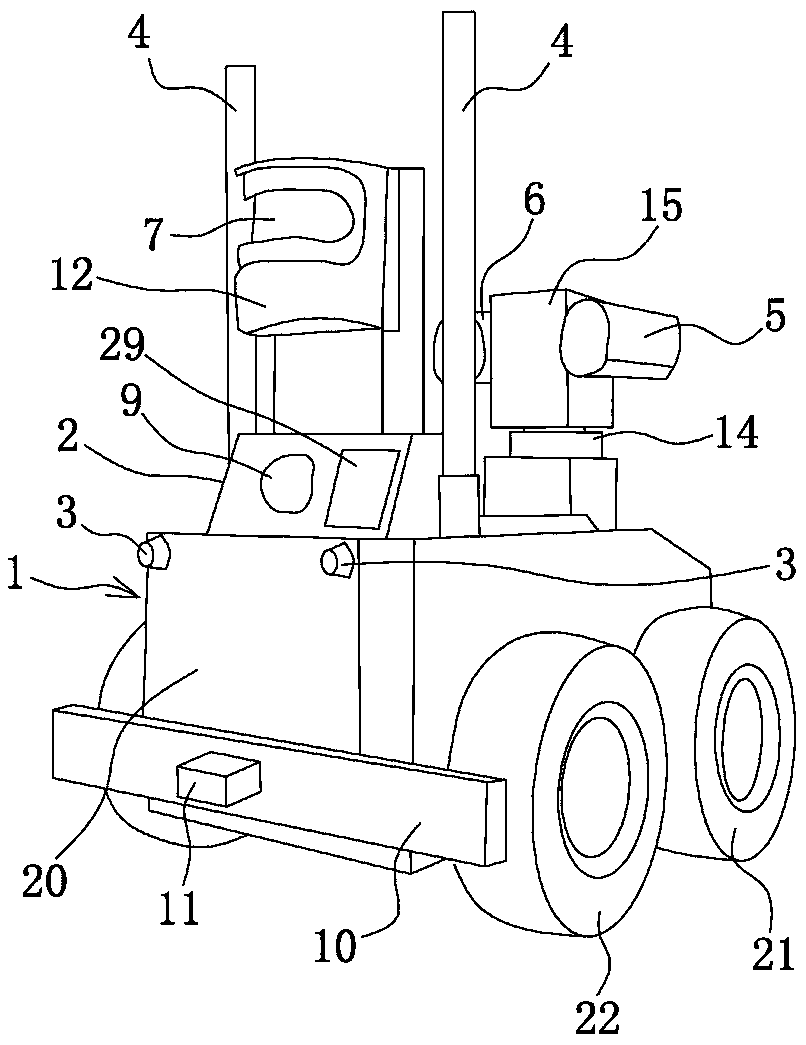

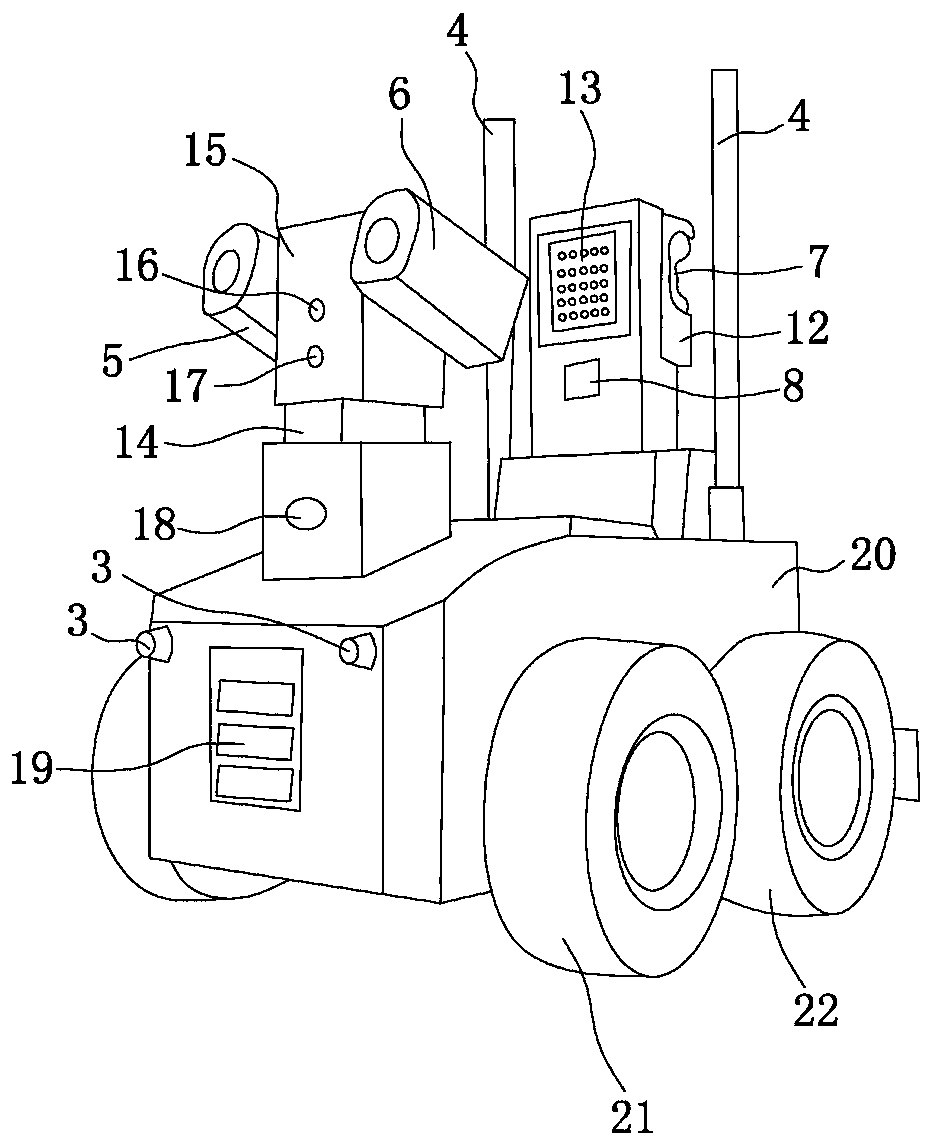

Robot for Intelligent factory

InactiveCN111136663AEnsure production safetyReduce volumeRadiation pyrometryManipulatorSmart factoryRemote control

The invention provides a robot for an intelligent factory, and belongs to the technical field of intelligent robots. The robot solves the problems of low patrol efficiency and the like of an existingintelligent factory. The robot for the intelligent factory comprises a movable base and a body mounted on the movable base. A storage battery is arranged in the movable base. Obstacle avoidance sensors are arranged on the movable base. A control processor is arranged in the body. The control processor is used for controlling the moving of the movable base, the signal analysis judgment of the sensor and the management of the storage battery. A wireless antenna for being in communication with a remote control terminal is arranged on the movable base. A camera for acquiring video information, aninfrared temperature measuring instrument for temperature measuring, a laser radar sensor for distance and speed measurement and an alarm device for giving out an alarm are arranged on the body. The obstacle avoidance sensors, the storage battery, the wireless antenna, the infrared temperature measuring instrument, the laser radar sensor and the alarm device are all connected with the control processor. The robot for the intelligent factory has the beneficial effects of being high in patrol efficiency, good in applicability and the like.

Owner:浙江汇丰汽车零部件股份有限公司

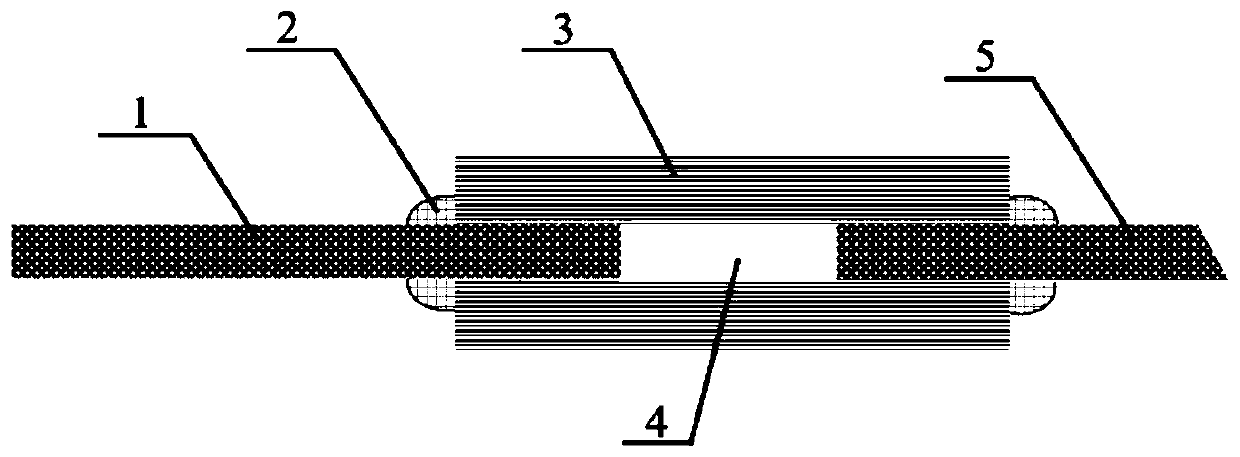

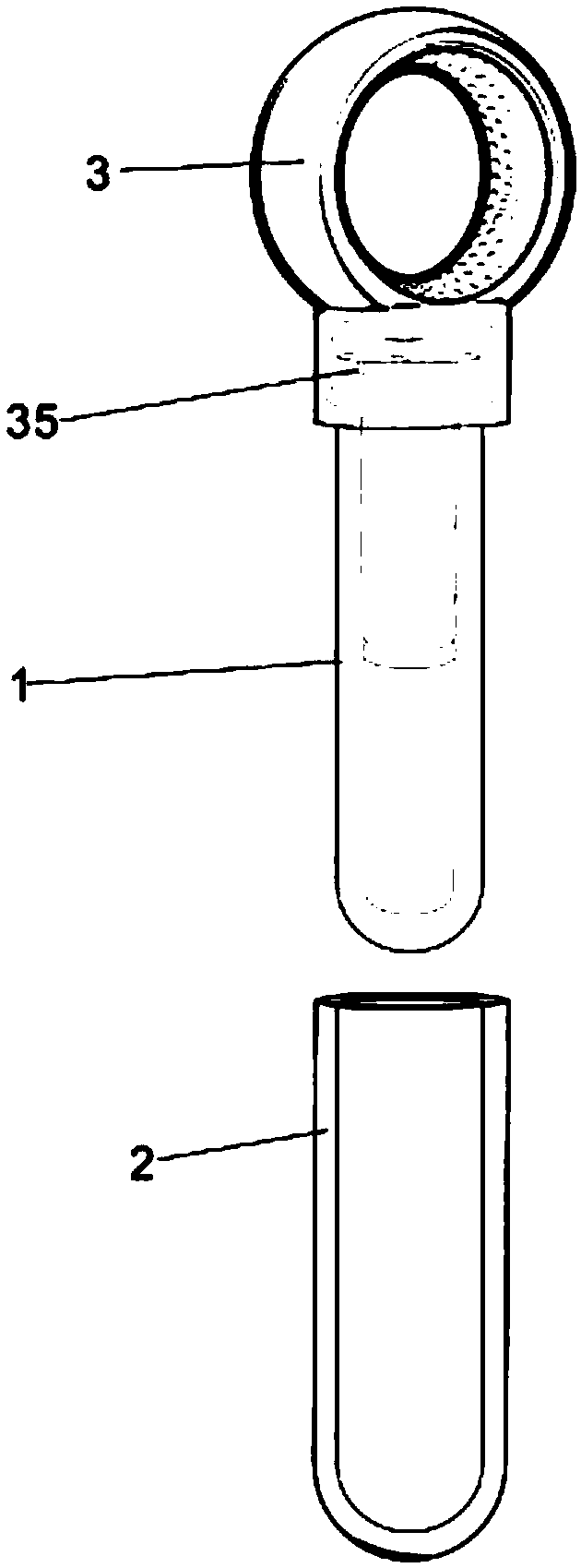

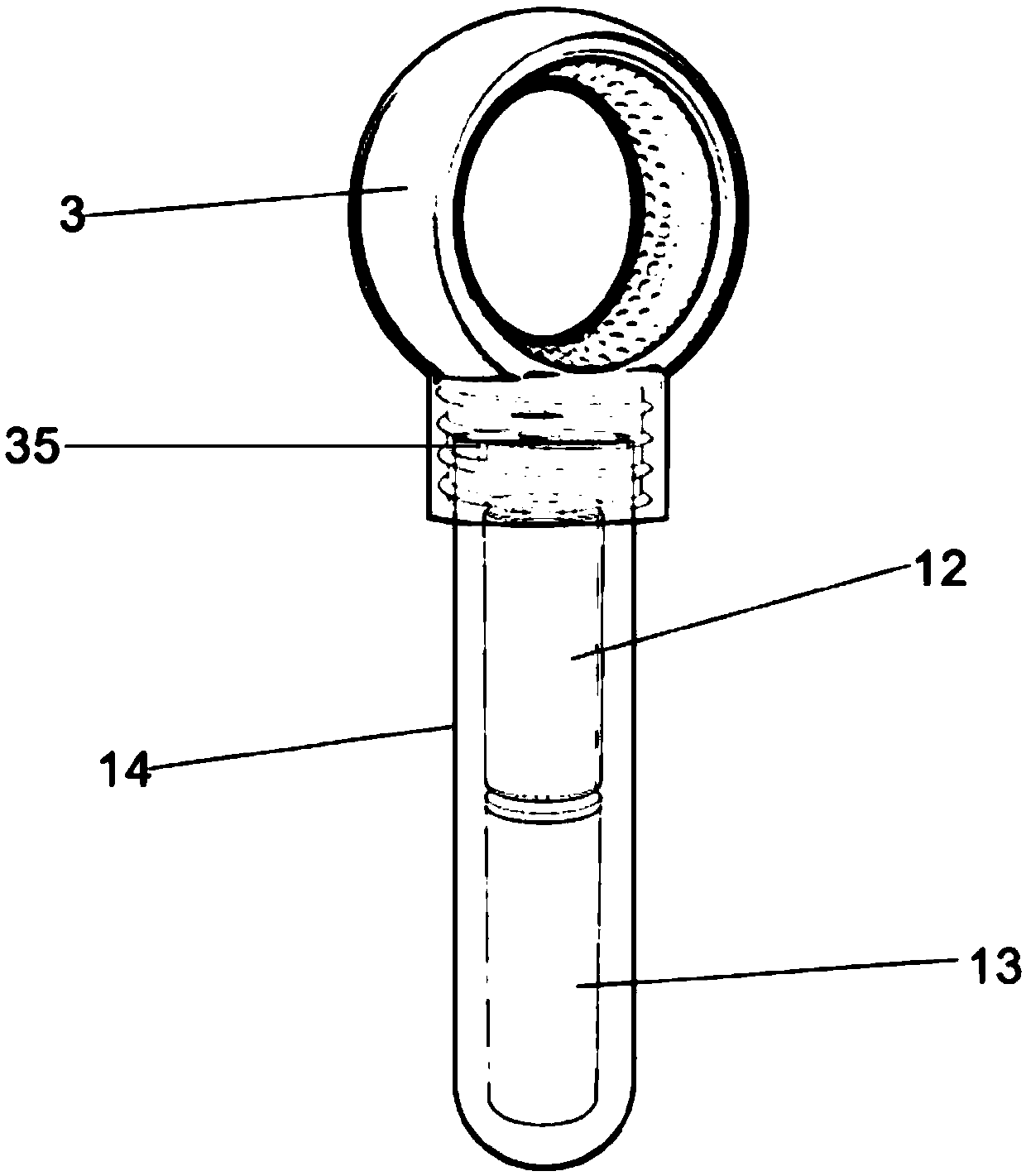

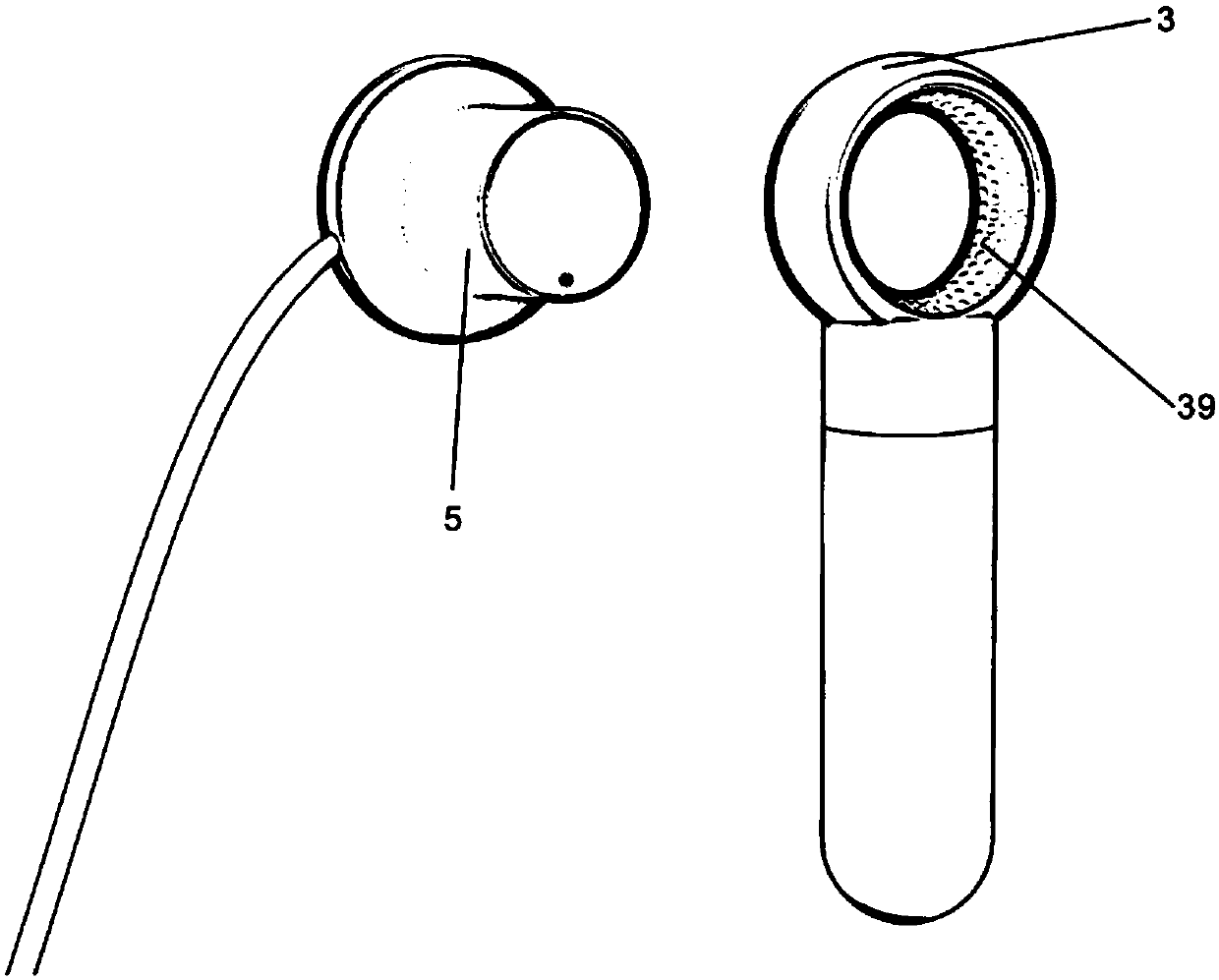

Sapphire fiber F-P high temperature sensor provided with inclination reflection surface as well as preparation method and temperature sensing system thereof

InactiveCN110617901AImprove structural stabilityQuality improvementThermometers using physical/chemical changesTurbine bladeHot Temperature

The invention provides a sapphire fiber Fabry-Perot (F-P) high temperature sensor provided with an inclination reflection surface as well as a preparation method and a temperature sensing system thereof, solving the problems that interference spectral quality of an existing sapphire fiber F-P high temperature sensor can be easily polluted by high temperature glue and dust and the interference spectral quality is influenced by other reflection surfaces except an F-P reflection surface, and having important research significance in high temperature detection fields such as aeroengine turbine blades, high temperature tail gas and metallurgical industry. The high temperature sensor provided by the invention comprises a sapphire fiber 1, a sapphire fiber 5 provided with the inclination reflection surface at the tail end and a ceramic ferrule 3; the sapphire fiber 1 and the sapphire fiber 5 provided with the inclination reflection surface are inserted into the ceramic ferrule 3, an air-filled cavity which can produce F-P interference is reserved between the end surfaces of the sapphire fibers 1 and 5 which are inserted into the ceramic ferrule 3, and high temperature cermica glue 2 is utilized for fixing respectively among the ceramic ferrule 3, the sapphire fiber 1 and the sapphire fiber 5 provided with the inclination reflection surface.

Owner:BEIHANG UNIV

Server and non-contact storage equipment temperature monitoring device thereof

InactiveCN108804293ARealize temperature detectionGuaranteed uptimeHardware monitoringHysteresisEquipment temperature

The invention discloses a non-contact storage equipment temperature monitoring device of a server. The non-contact storage equipment temperature monitoring device of the server comprises a PCB, a plurality of plug-in grooves and a temperature sensor; the plurality of plug-in grooves are arranged on the PCB and used for installing storage equipment; and the temperature sensor is arranged on the PCB, corresponds to the installation position of each plug-in groove, and is used for calculating the temperature by detecting heat radiation of each storage equipment. According to the non-contact storage equipment temperature monitoring device of the server disclosed by the invention, the heat radiation manner of the storage equipment in each plug-in groove is detected through the temperature sensor arranged on the PCB; the temperature of each storage equipment is directly calculated; the detection process is simple; furthermore, the precision is relatively high; compared with the reverse calculation detection manner through detection of the environmental temperature in the prior art, the hysteresis quality of the detection result is eliminated; and furthermore, the heat radiation detectionmode cannot influence running of the storage equipment itself. The invention further discloses a server, having the above benefits.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

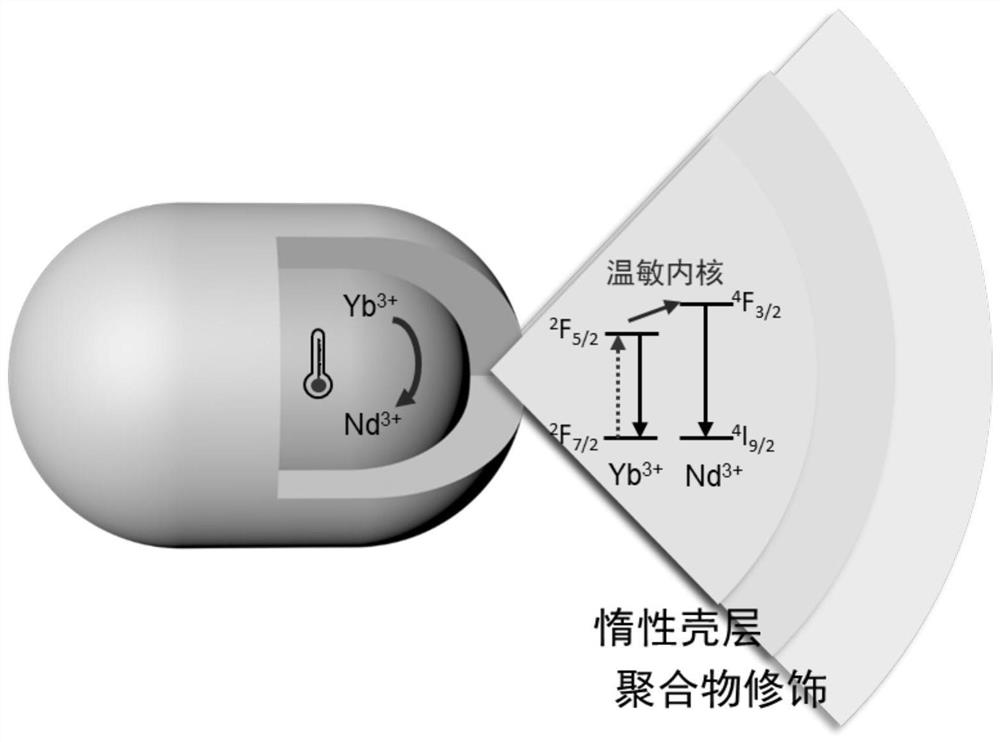

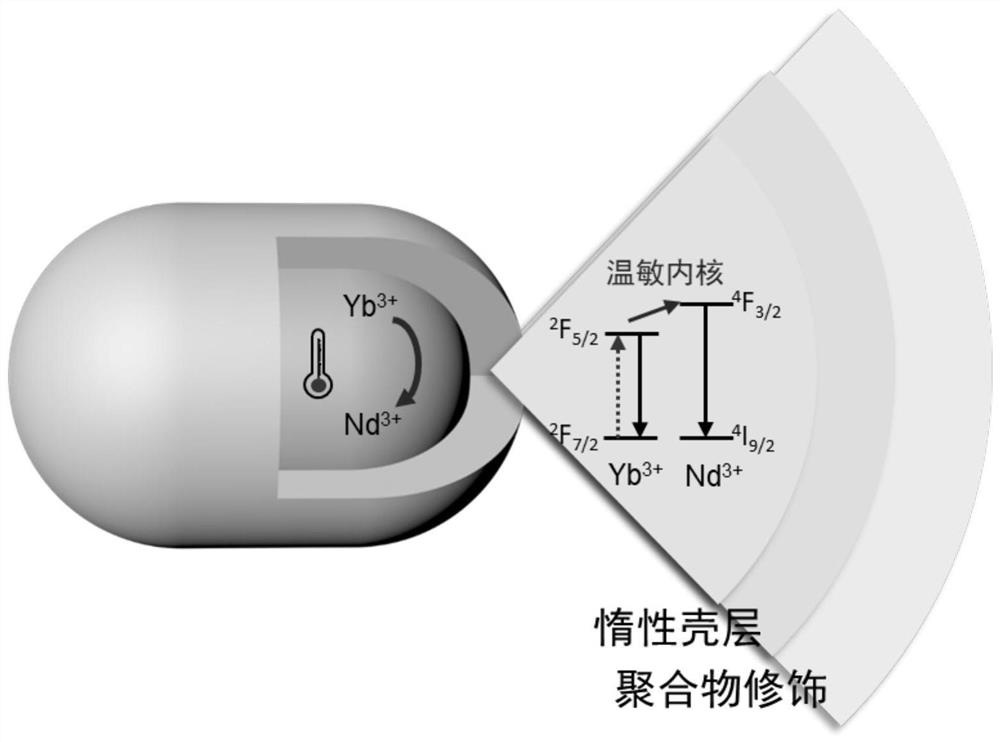

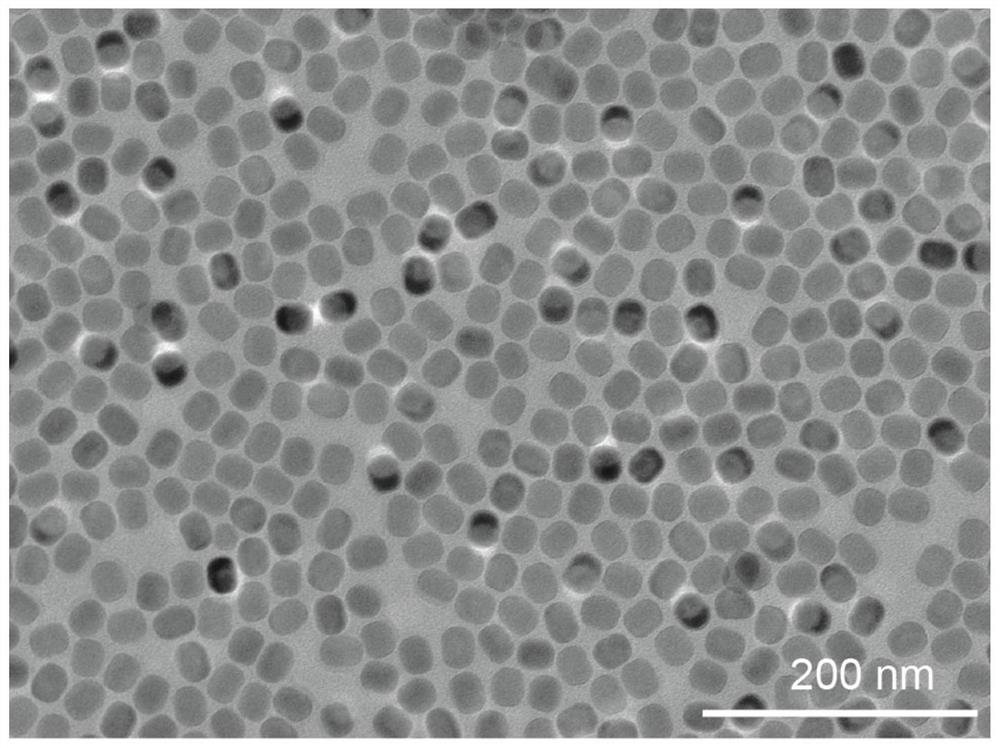

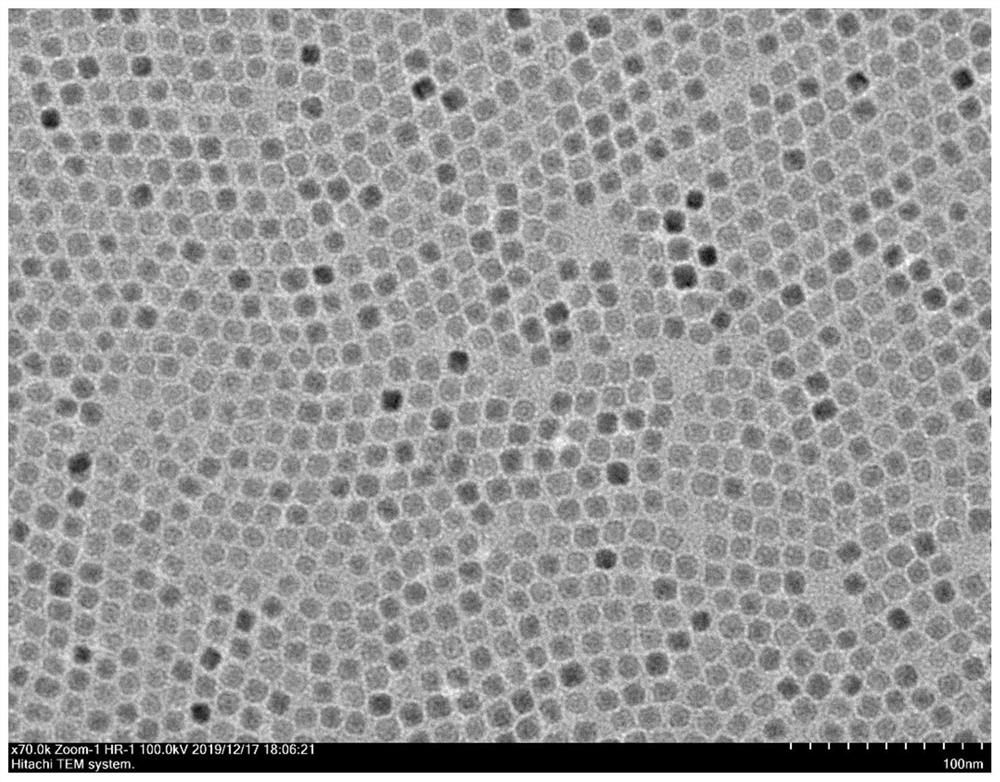

Temperature measurement method based on rare earth luminescence lifetime temperature probe

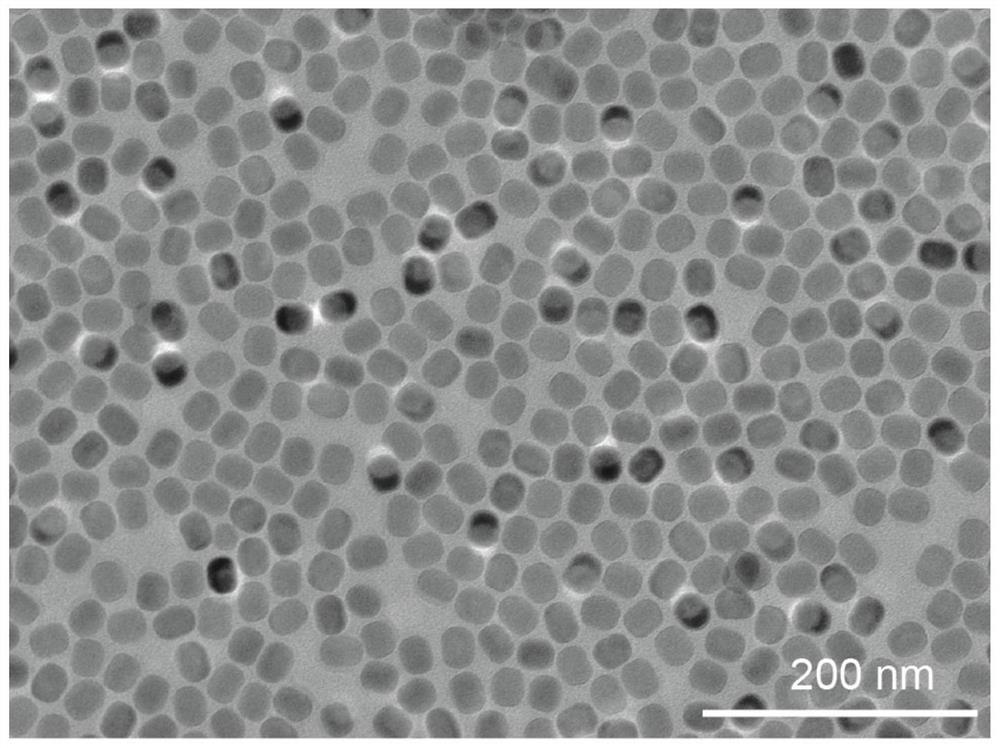

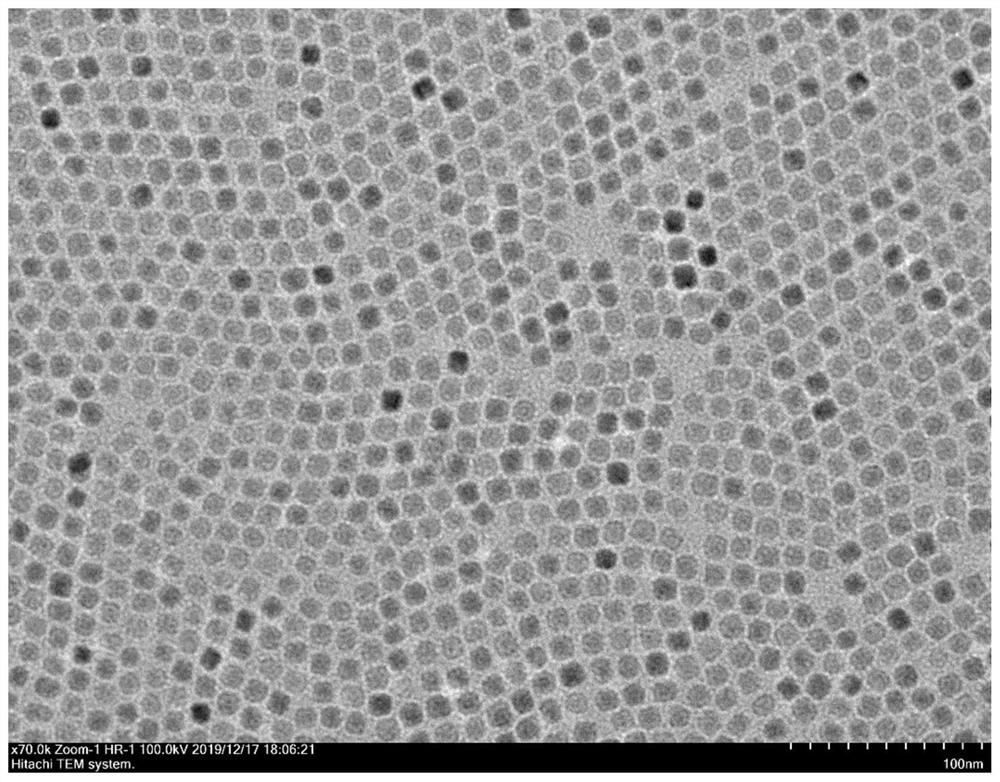

ActiveCN112111275AAvoid detection errorsImprove accuracyMaterial nanotechnologyNanoopticsWave bandNear infra red

The invention discloses a temperature measurement method of an internal quenching type rare earth luminescence lifetime temperature probe, and the method realizes temperature detection based on fluorescence lifetime change. The center of an adopted material is a nano core doped with rare earth trivalent ions Yb<3+> and B<3+>, the periphery of the material is an inert shell layer, a phonon auxiliary energy transfer process exists between the Yb<3+> and the B<3+> rare earth ions, and the service life of the rare earth ions is changed along with the change of temperature due to the fact that phonons participate in the energy transfer process. The inert shell layer can play a role in protecting the service life of the light-emitting core from changing along with the change of the environment (except the temperature), the light-emitting waveband is in the 700-1700nm region, and the water solubility can be improved by using a ligand to modify the surface. The near-infrared luminescence lifetime temperature probe can realize accurate temperature measurement in different complex environments (including living bodies), and has the advantages of internal quenching temperature sensitivity, near-infrared band luminescence, nanoscale, accuracy, quantifiability, good stable dispersibility and the like.

Owner:FUDAN UNIV

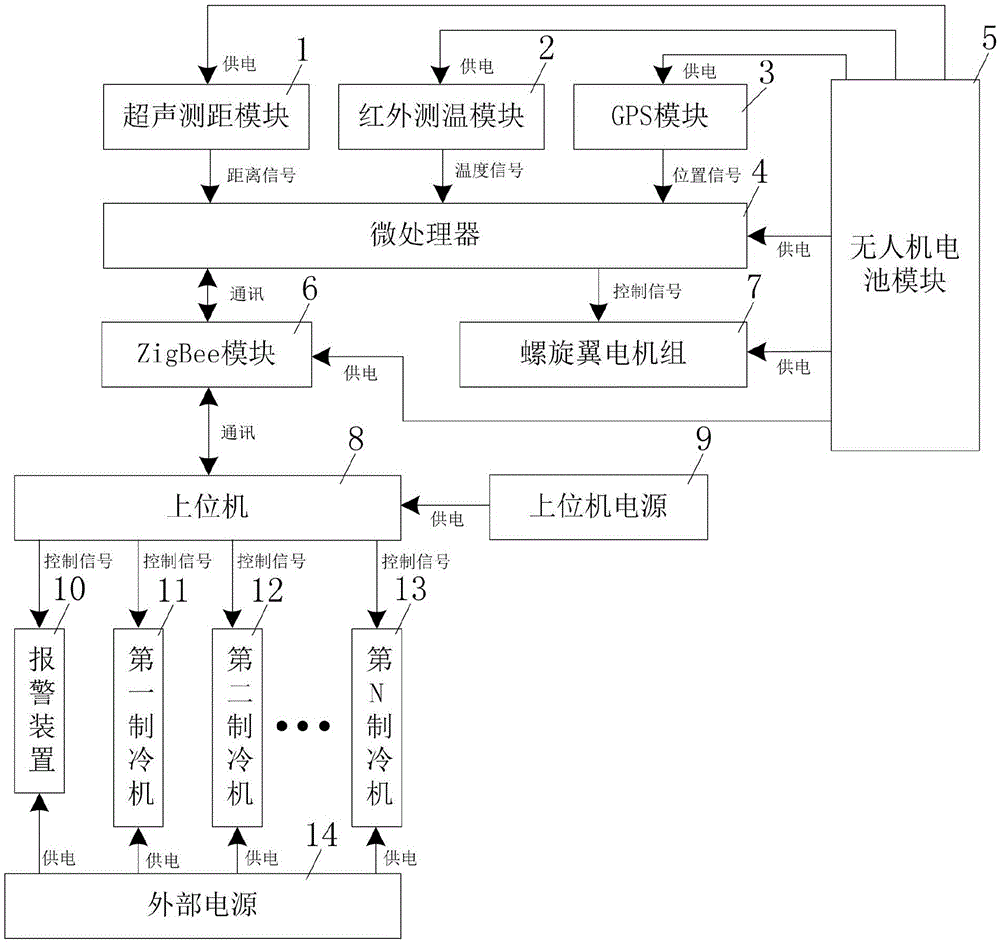

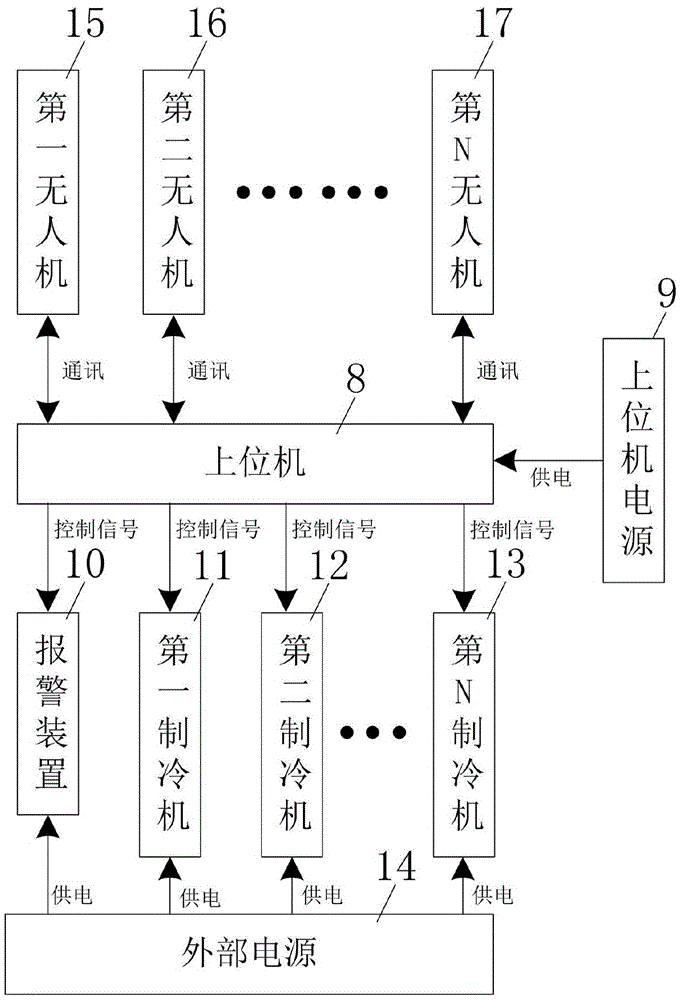

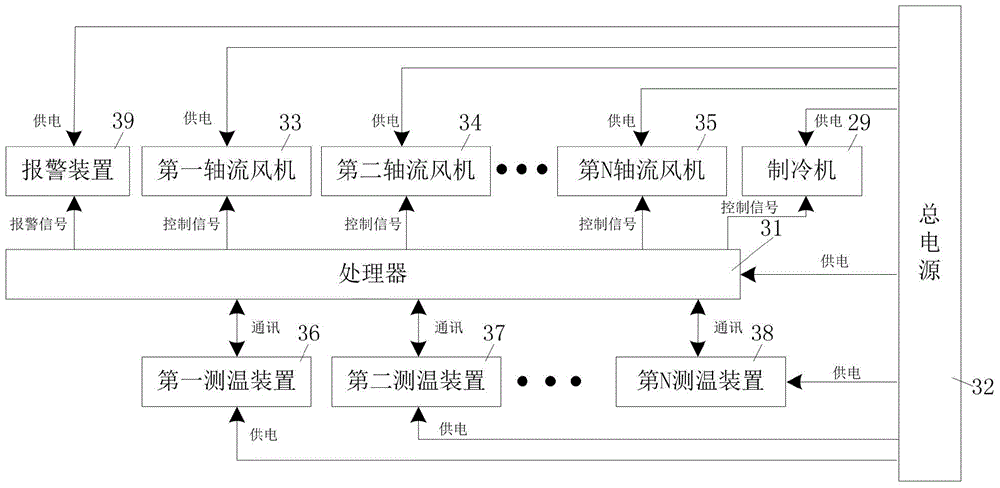

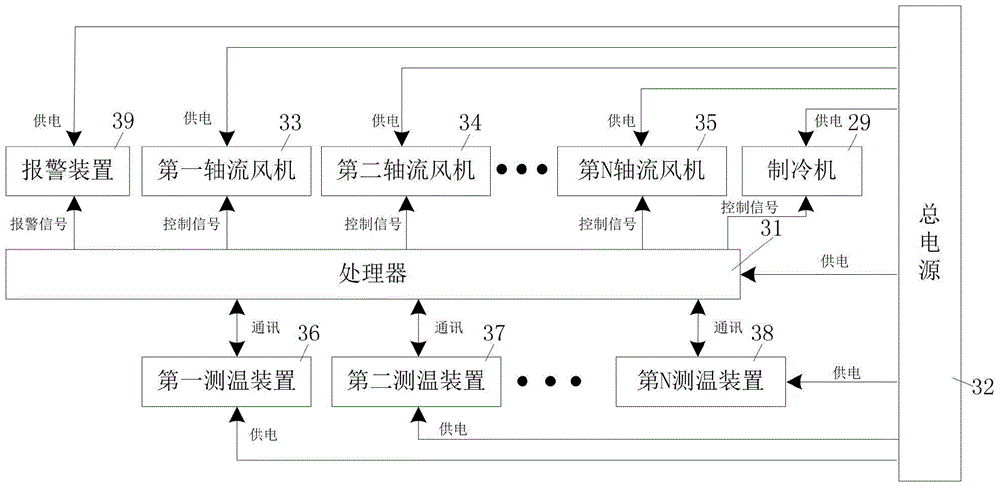

Unmanned aerial vehicle infrared temperature measurement-based refrigerated warehouse temperature control system

InactiveCN105487577AAchieve flightRealize temperature detectionAuxillary controllers with auxillary heating devicesEngineeringInfrared temperature measurement

The invention discloses an unmanned aerial vehicle infrared temperature measurement-based refrigerated warehouse temperature control system. The unmanned aerial vehicle infrared temperature measurement-based refrigerated warehouse temperature control system includes a first unmanned aerial vehicle, a second unmanned aerial vehicle, an N-th unmanned aerial vehicle, an upper computer, an upper computer power source, an alarm device, a first refrigerator, a second refrigerator, an N-th refrigerator and an external power source; the upper computer is wirelessly connected with the first unmanned aerial vehicle, the second unmanned aerial vehicle and the N-th unmanned aerial vehicle; the upper computer is electrically connected with the upper computer power source, the alarm device, the first refrigerator, the second refrigerator and the N-th refrigerator; the first refrigerator, the second refrigerator and the N-th refrigerator are electrically connected with the external power source; and the first unmanned aerial vehicle, the second unmanned aerial vehicle, the N-th unmanned aerial vehicle respectively include an ultrasonic ranging module, an infrared temperature measurement module, a GPS module, a microprocessor, an unmanned aerial vehicle battery module, a ZigBee module and a spiral wing motor group. With the unmanned aerial vehicle infrared temperature measurement-based refrigerated warehouse temperature control system of the invention adopted, temperature detection can be realized, and corresponding control can be performed according to measured temperature, and alarms can be emitted according to the measured temperature.

Owner:陈星宏

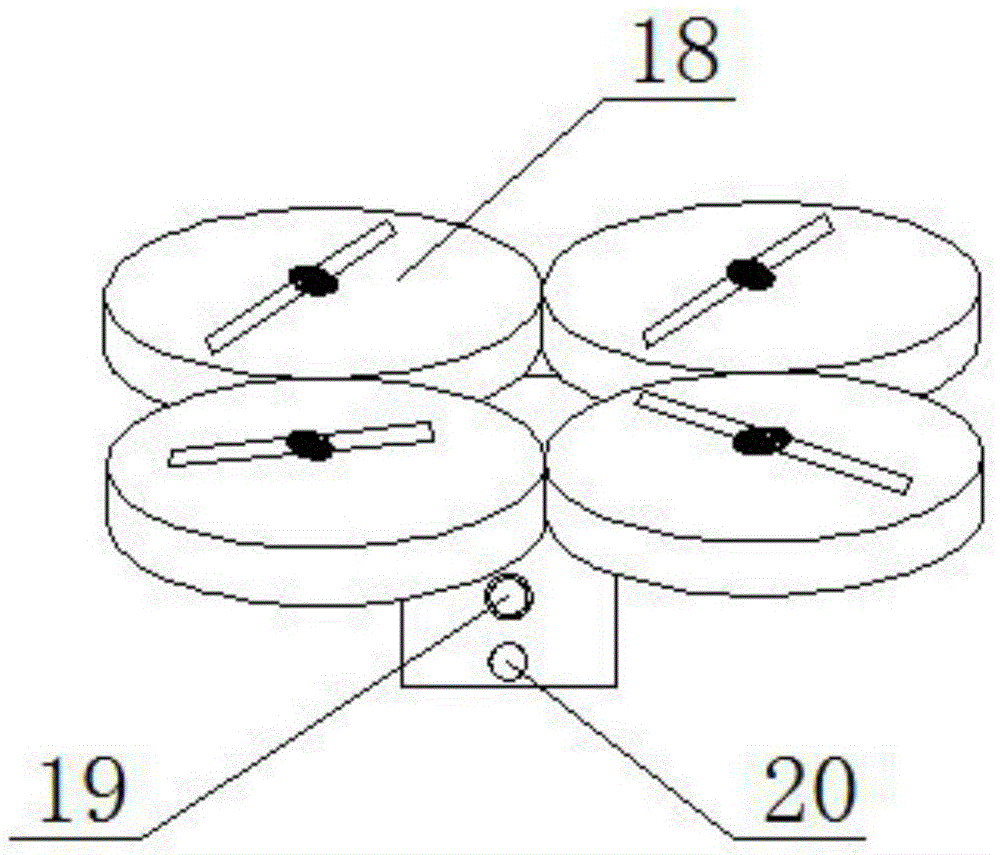

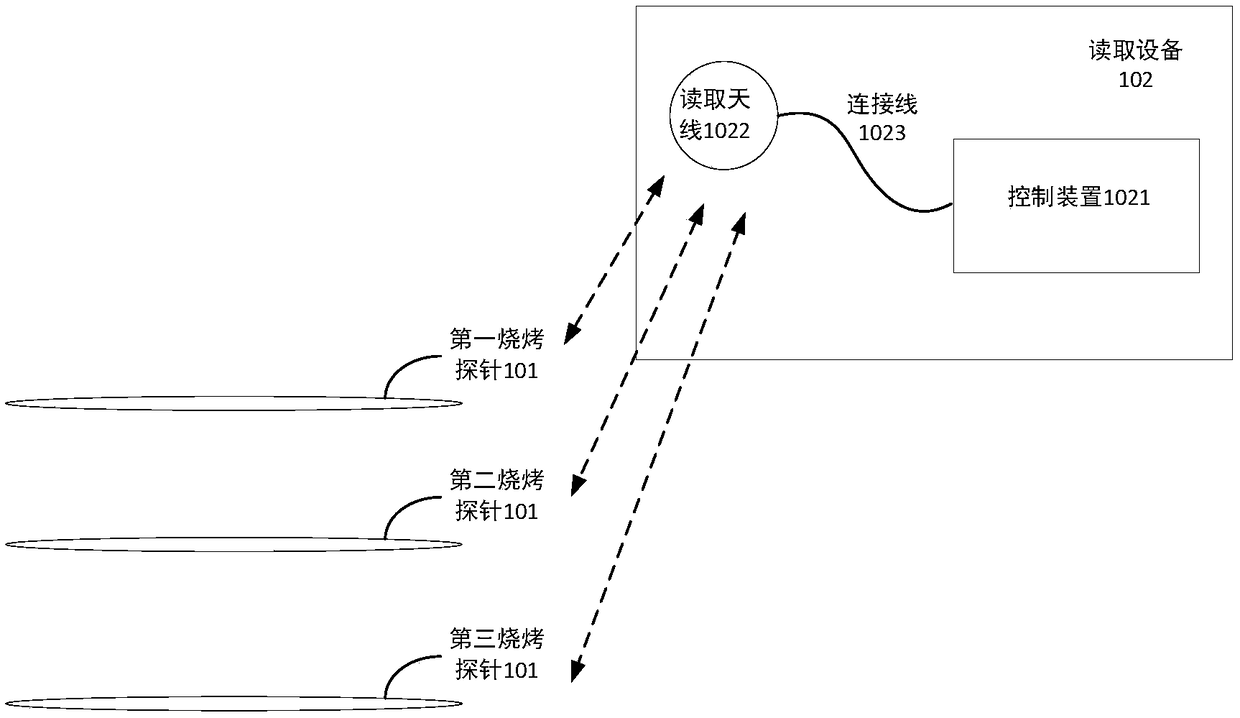

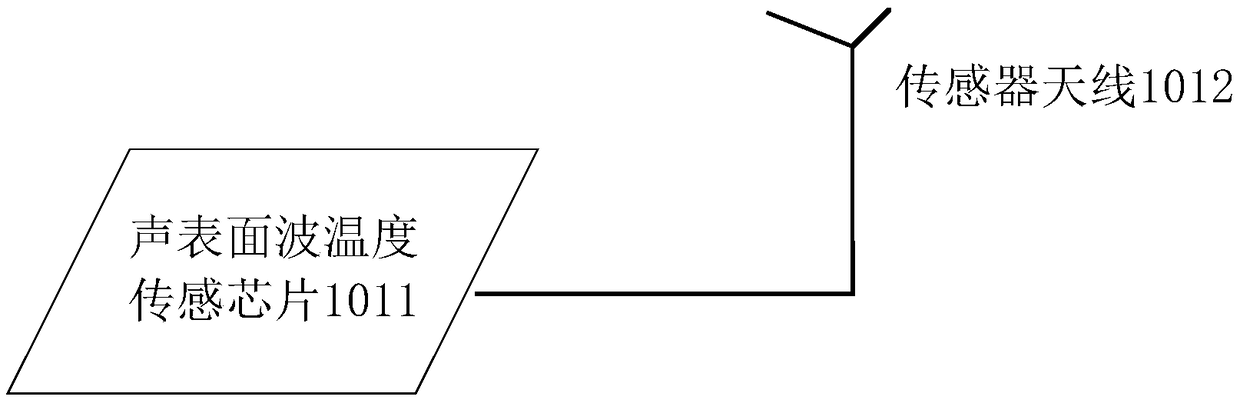

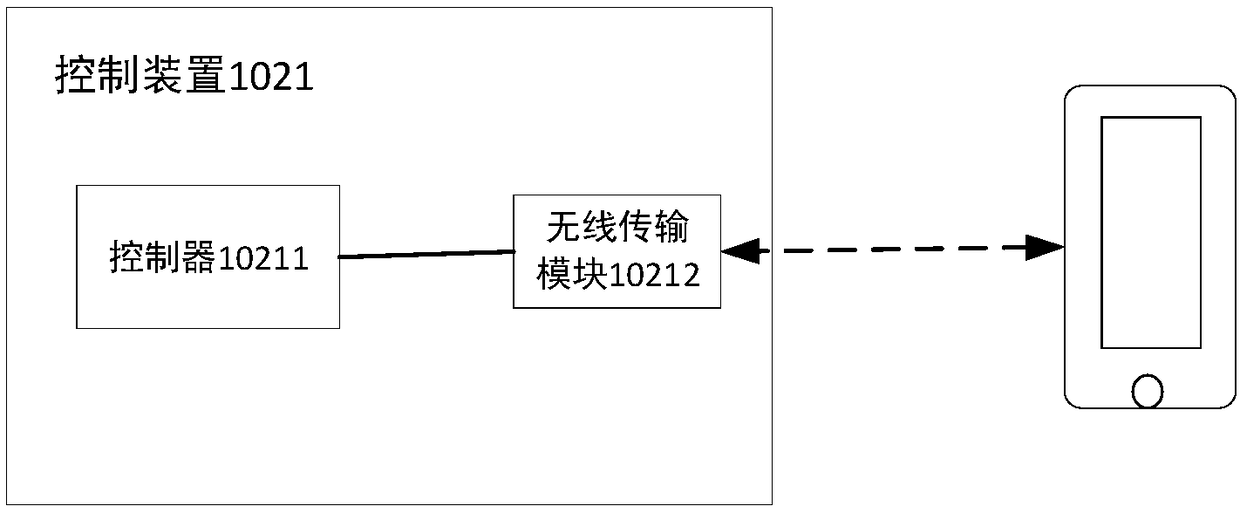

System and method for detecting barbecue temperature

InactiveCN109470380ARealize temperature detectionThermometers using physical/chemical changesTemperature measurementElectrical and Electronics engineering

The embodiment of the invention provides a system and method for detecting barbecue temperature. The system comprises a barbecue probe and reading equipment; the barbecue probe comprises a wireless temperature measurement sensor and is used for detecting the temperature of barbecued foods, receiving a first wireless signal emitted by a reading antenna and feeding back a second wireless signal, andthe second wireless signal is a signal which is generated after the barbecue probe feeds back the first wireless signal and carries temperature information of the barbecued foods; the reading equipment comprises a control device and the reading antenna, and the control device is used for controlling the first wireless signal emitted by the reading ante and analyzing the second wireless signal received by the reading antenna so as to determine the temperature of barbecue probe. In the system, wireless transmission between the reading equipment and the barbecue probe is adopted for avoiding usage of metal wires.

Owner:SHENZHEN HYPERSYNES CO LTD

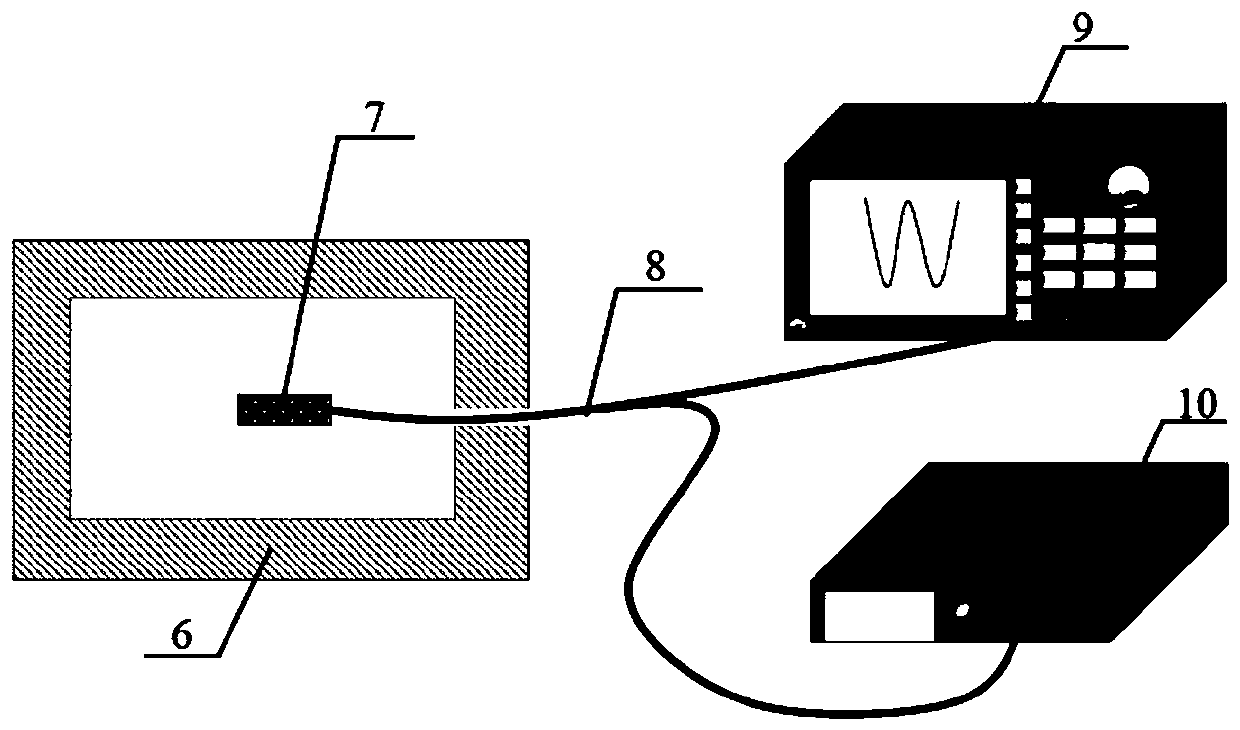

Atmospheric Raman-Rayleigh scattering temperature measurement laser radar and inversion method

ActiveCN106483531AEliminate the effects ofExpand the range of temperature measurement spaceElectromagnetic wave reradiationICT adaptationRayleigh scatteringEcho intensity

The invention discloses an atmospheric Raman-Rayleigh scattering temperature measurement laser radar and an inversion method. The laser radar comprises a laser transmitting unit (1), a receiving telescope (2), a receiving optical fiber (3), a signal detecting unit (4) and a signal processing unit (5). A high-resolution spectrum detection method is adopted to measure Rayleigh scattering spectral signals generated on atmospheric molecules by laser higher than 30km or above and Raman scattering spectral signals generated on atmospheric molecules by laser lower than 30km; and inversion is carried out to obtain the temperature of atmosphere at 30km, or above or below can be obtained based on a characteristic that the Raman scattering spectrum is in direct proportion to the Rayleigh scattering spectrum in echo intensity, and therefore, the temperature measurement space range of the Rayleigh scattering temperature measurement laser radar can be expanded. The atmospheric Raman-Rayleigh scattering temperature measurement laser radar has the advantages of wide temperature measurement height range and small temperature measurement error.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

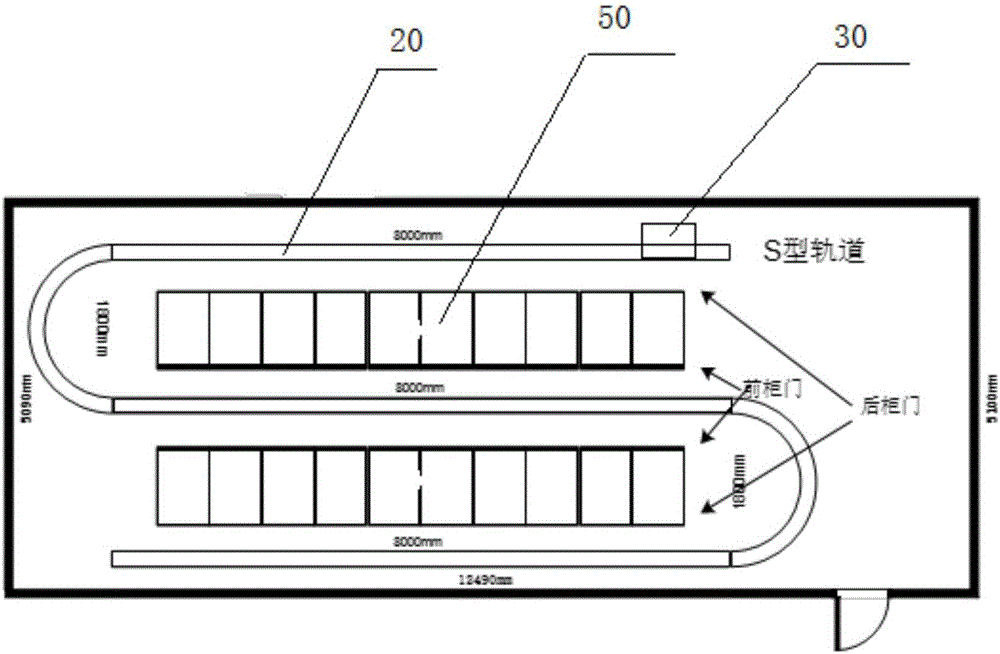

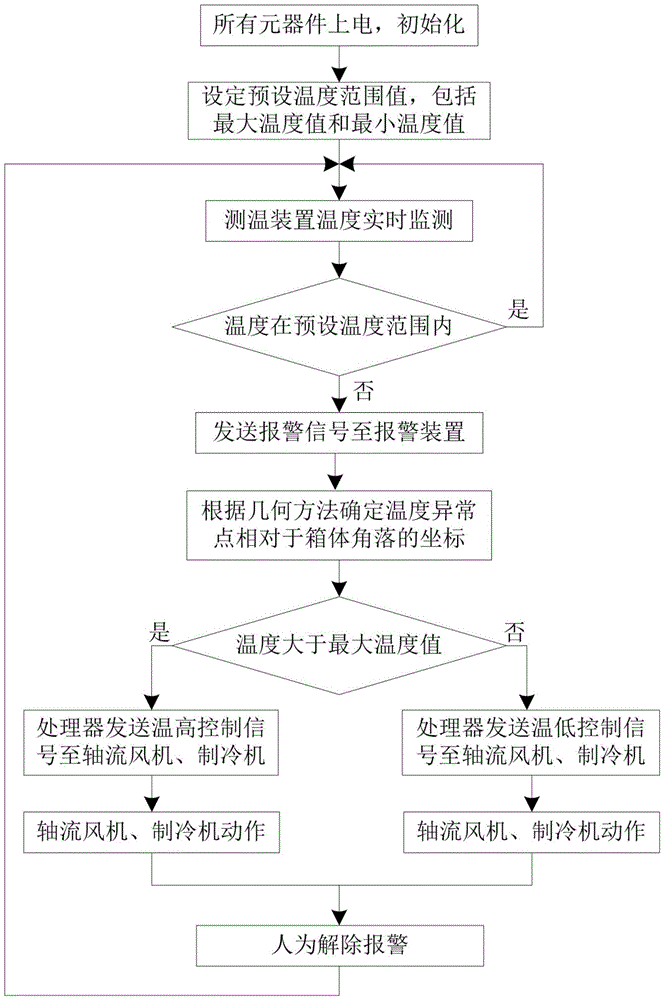

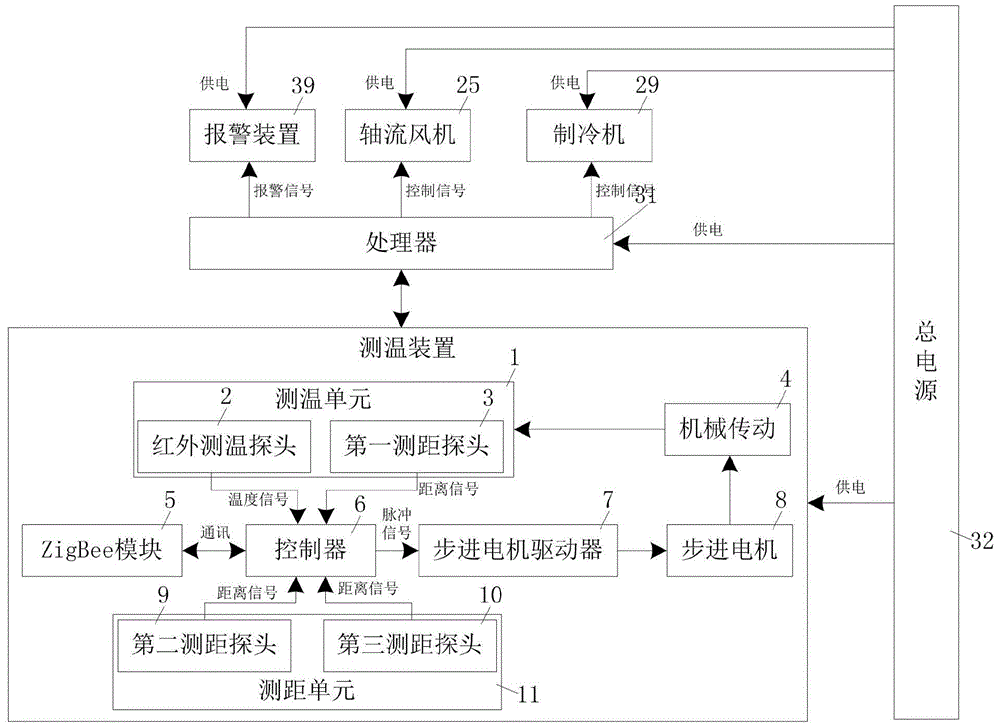

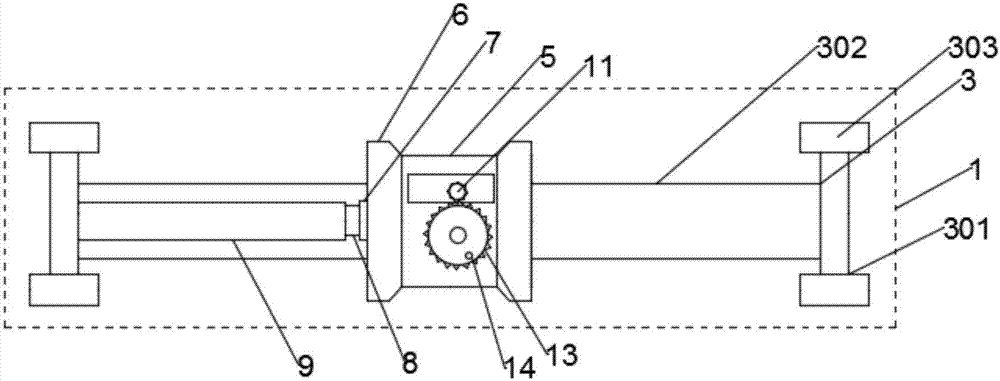

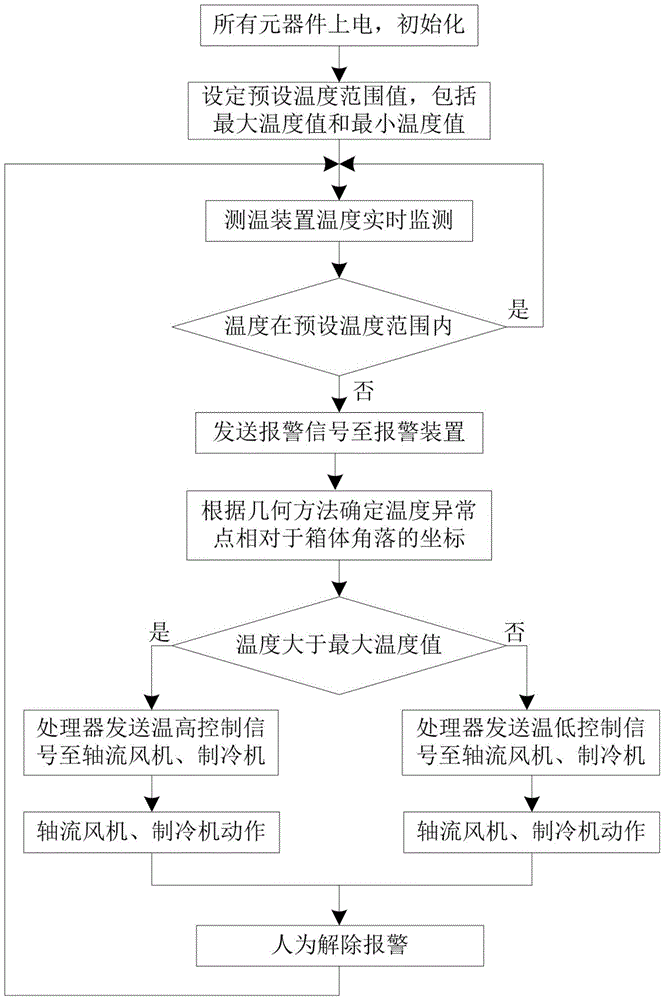

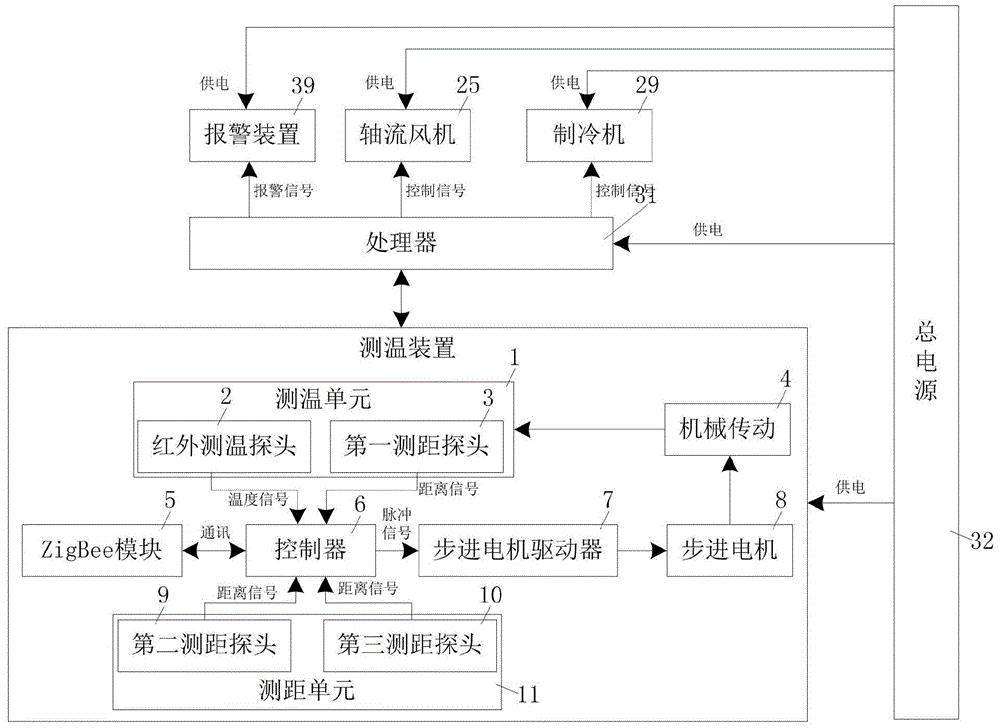

Swing type infrared temperature measurement device-based refrigerating box temperature control method

ActiveCN105676906ARealize temperature detectionRadiation pyrometryTemperature control using plurality of sensorsTemperature controlControl signal

The invention discloses a swing type infrared temperature measurement device-based refrigerating box temperature control method. The method comprises the steps of 1, powering on and initializing all components; 2, setting a preset temperature range; 3, monitoring the temperature in real time by a temperature measurement device; processing a signal by a processor; and repeating the step 3 when the measured value of the temperature is within the preset temperature range; otherwise, conducting the step 4; 4, sending an alarm signal to an alarm device by the processor; and determining the coordinates of an abnormal temperature point relative to the corner of a cabinet by the processor according to the geometric method; 5, according to different judgments on whether the temperature signal is larger than a maximum temperature value or not, sending different control signals to an axial-flow fan and a refrigerating machine by the processor so as to drive the axial-flow fan and the refrigerating machine to run; 6, manually removing the alarm and repeating the step 3. According to the technical scheme of the invention, the temperature detection is realized. Meanwhile, based on data detected by the temperature measurement device, the temperature control and the abnormal alarm are enabled.

Owner:铜陵金建投资发展有限公司

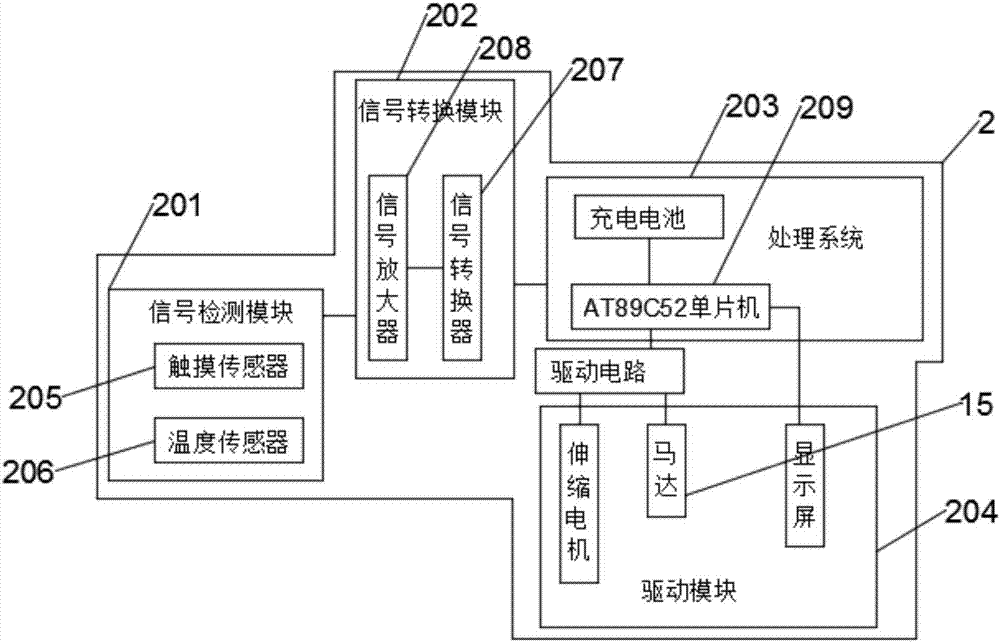

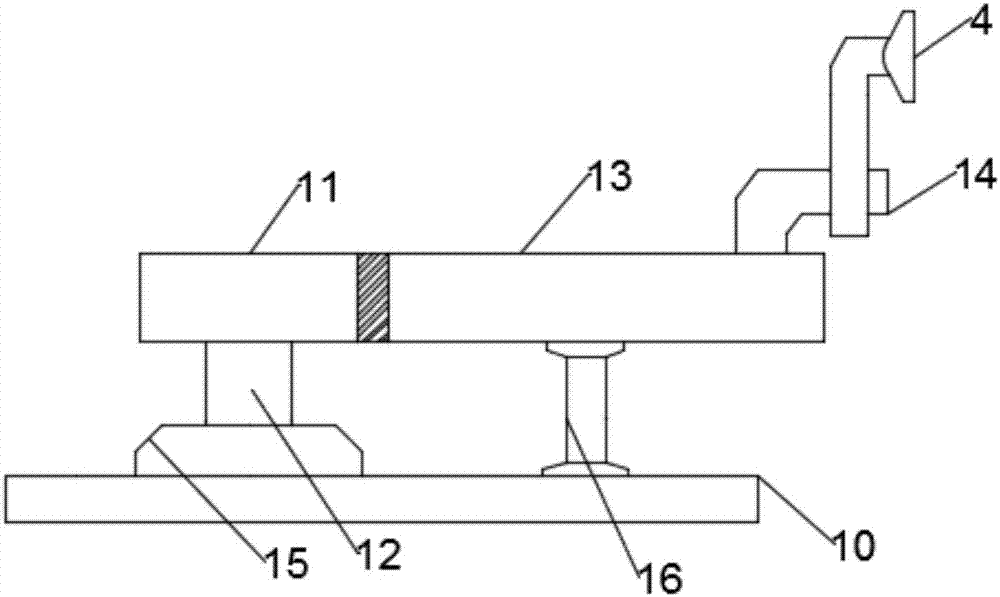

Induction type shower equipment for smart home

InactiveCN107569146ARealize temperature detectionRealize intelligent controlComputer controlBathsEngineeringIntelligent control

The invention discloses induction type shower equipment for smart home. The induction type shower equipment comprises a shower device and an induction control system, wherein the shower device comprises a fixed mount and a shower nozzle; the fixed mount comprises a locating rod and a fixing rod; a sliding sleeve is arranged on the surface of the fixing rod; a fixed seat is connected to one end ofthe sliding sleeve; a screw hole is kept in the fixed seat; a screw rod is arranged in the screw hole; a telescopic rod is connected to the outer end of the exterior of the screw rod; the telescopic rod and the locating rod are fixedly connected; a mounting base is arranged on the surface of the sliding sleeve; a driving gear is arranged in the mounting base; the driving gear is driven by virtue of a rotating shaft; the rotating shaft is rotated by virtue of a motor; and the driving gear, which is meshed with a driven gear disc, is rotated. Shower position and angle can be automatically adjusted as required; and and meanwhile, temperature detection and intelligent control can be implemented; therefore, the shower equipment is worthy of popularizing.

Owner:WUHU YANGYU ELECTROMECHANICAL TECH DEV

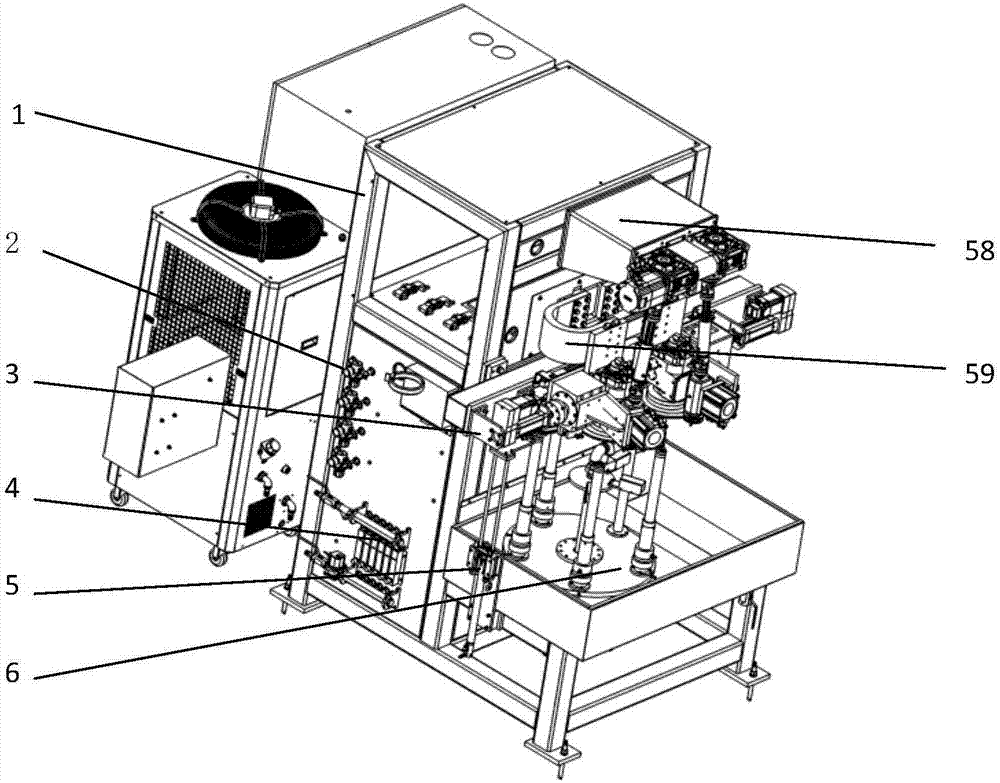

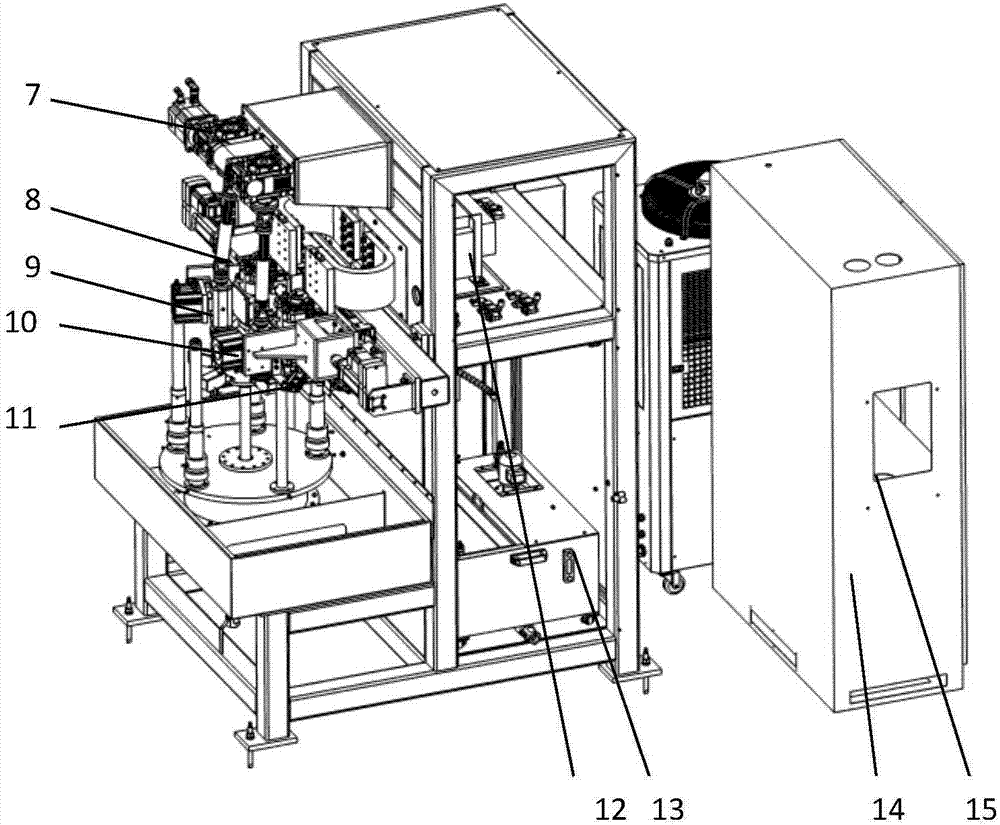

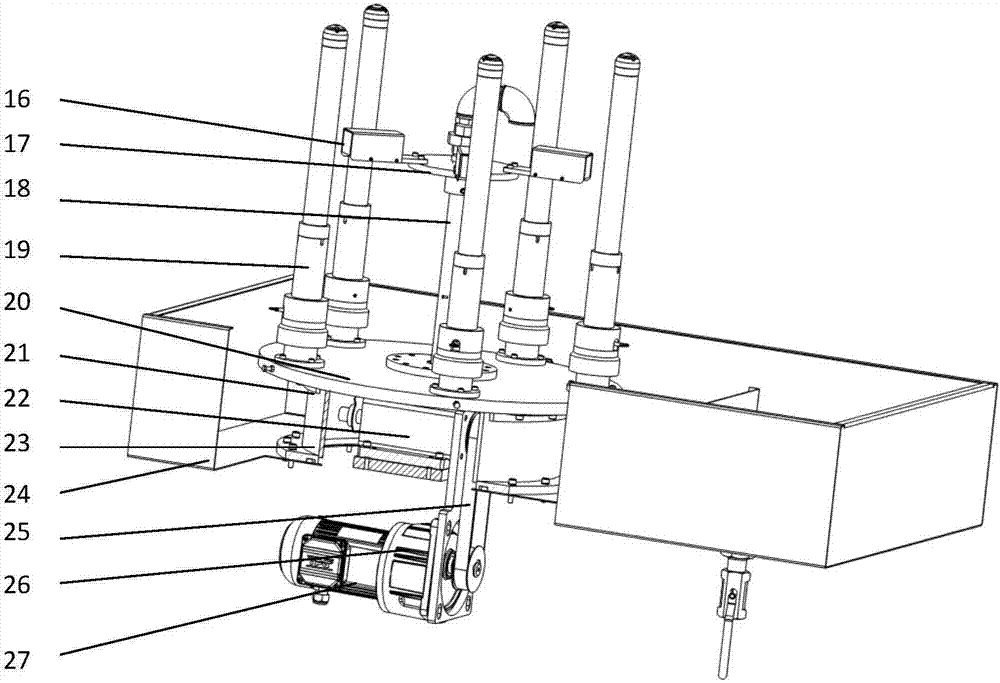

Seam welder for automatically welding oil storage cylinder and base of automobile damper

PendingCN107877050ARealize automatic feeding processRealize temperature detectionWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelMachine control

The invention discloses a seam welder for automatically welding an oil storage cylinder and a base of an automobile damper and belongs to the technical field of resistance welding equipment. The seamwelder is used for welding the oil storage cylinder and the base of the automobile damper. According to the technical scheme, the seam welder is characterized in that a welding transformer is installed inside a welder body; a welding controller is installed in an electric control box; a rotating worktable is located on the lower-front portion of the welder body; a seam-welding wheel driving mechanism is installed on the upper portion of the welder body; two output shafts of the seam-welding wheel driving mechanism are connected with a left driving wheel compression assembly and a right drivingwheel compression assembly correspondingly; pressurizing mechanisms are installed in front of the welder body, and the left driving wheel compression assembly, the right driving wheel compression assembly and a displacement detecting mechanism are all provided with the pressurizing mechanisms; a water blowing device is installed on the left side of the lower-front portion of the welder body; a cooling water tank assembly is placed on the lower-rear portion of the welder body; the electric control box is placed behind the welder body; and a water channel assembly and an air channel assembly are both installed on the left side of the welder body. The automation degree is promoted greatly, and the production efficiency is improved.

Owner:TANGSHAN KAIYUAN AUTOWELDING SYST

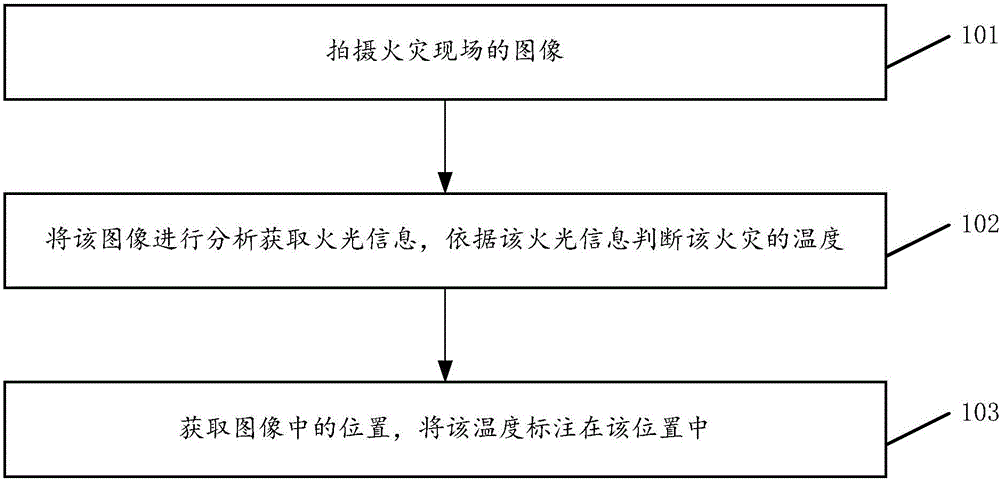

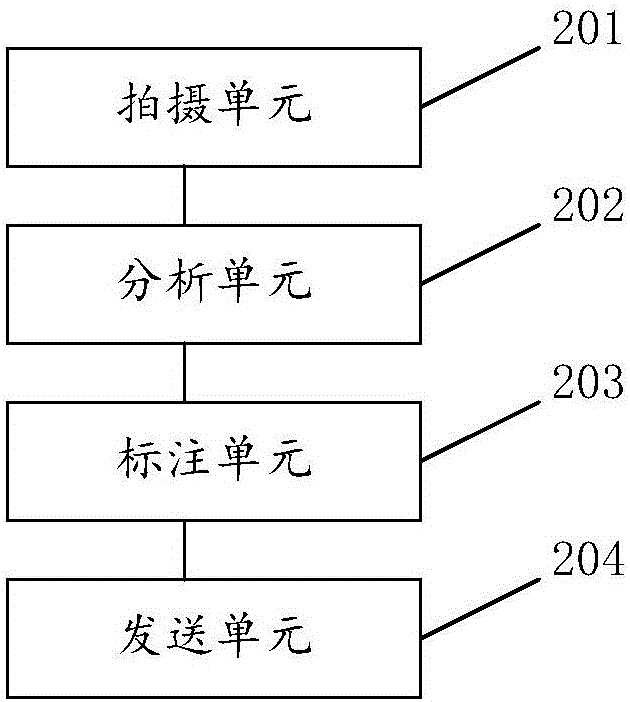

Method and system for detecting temperature of fire

The invention discloses a method and a system for detecting temperature of fire. The method comprises the following steps: taking pictures of a fire site; analyzing the images to obtain flame information, and according to the flame information, determining temperature of the fire. The technical scheme is advantaged by detecting temperature of fire.

Owner:冯旋宇

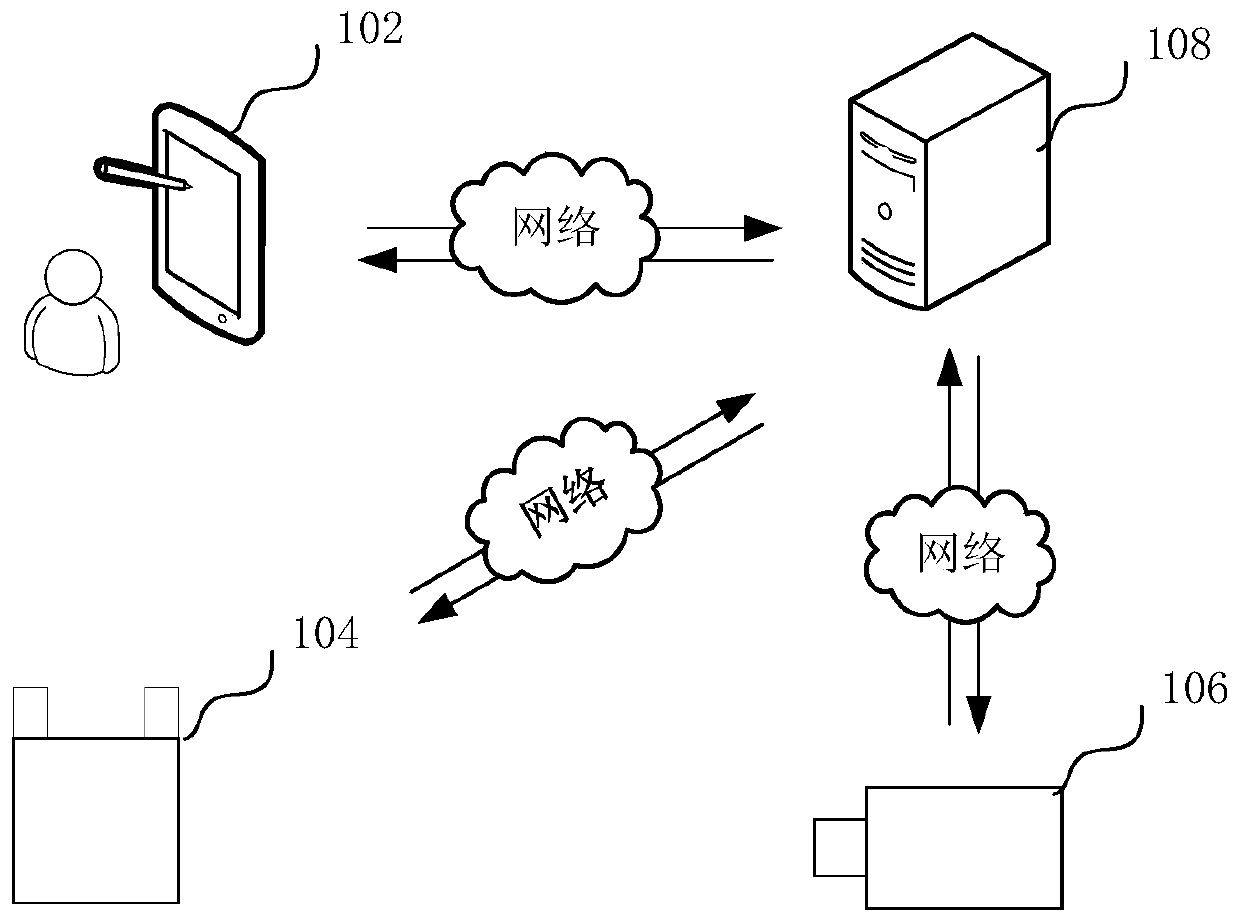

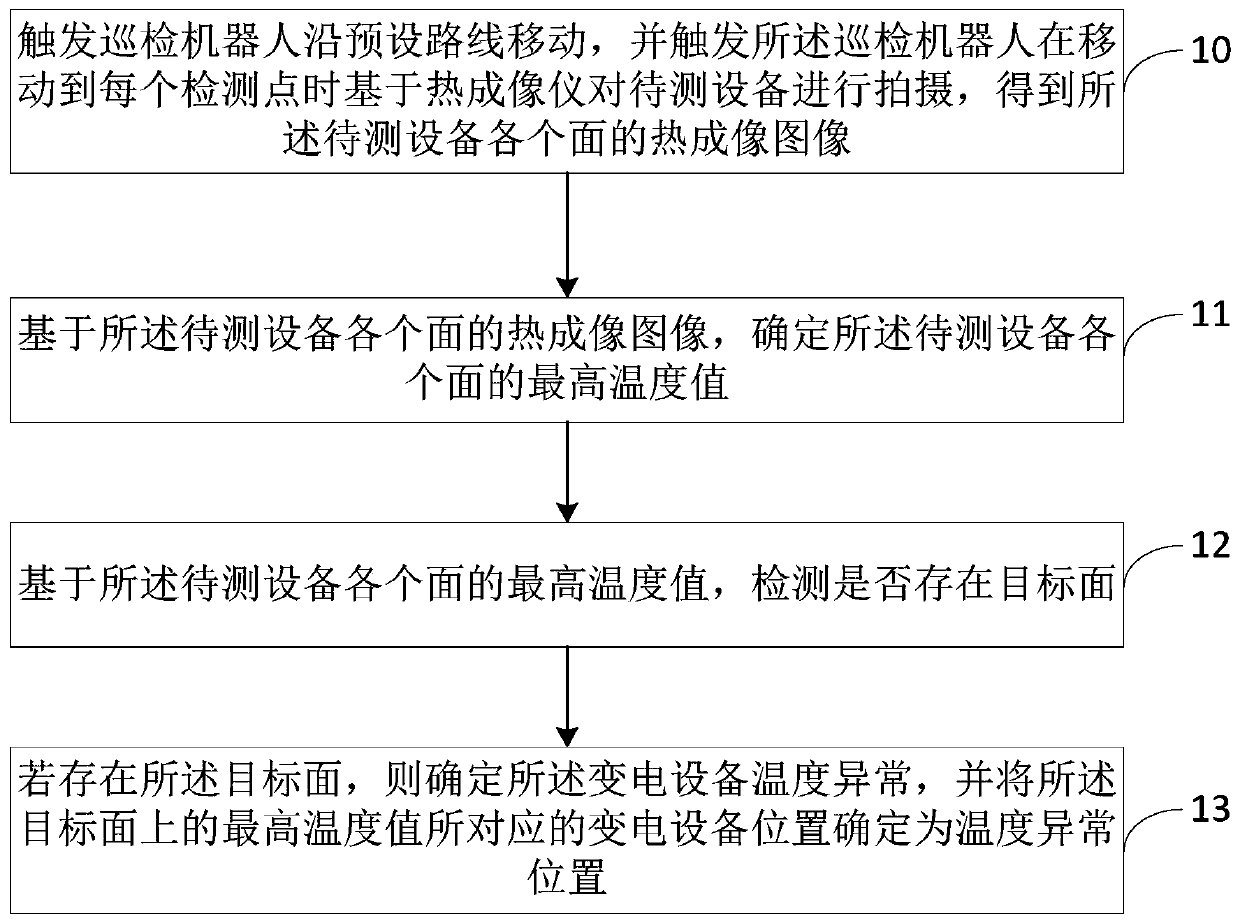

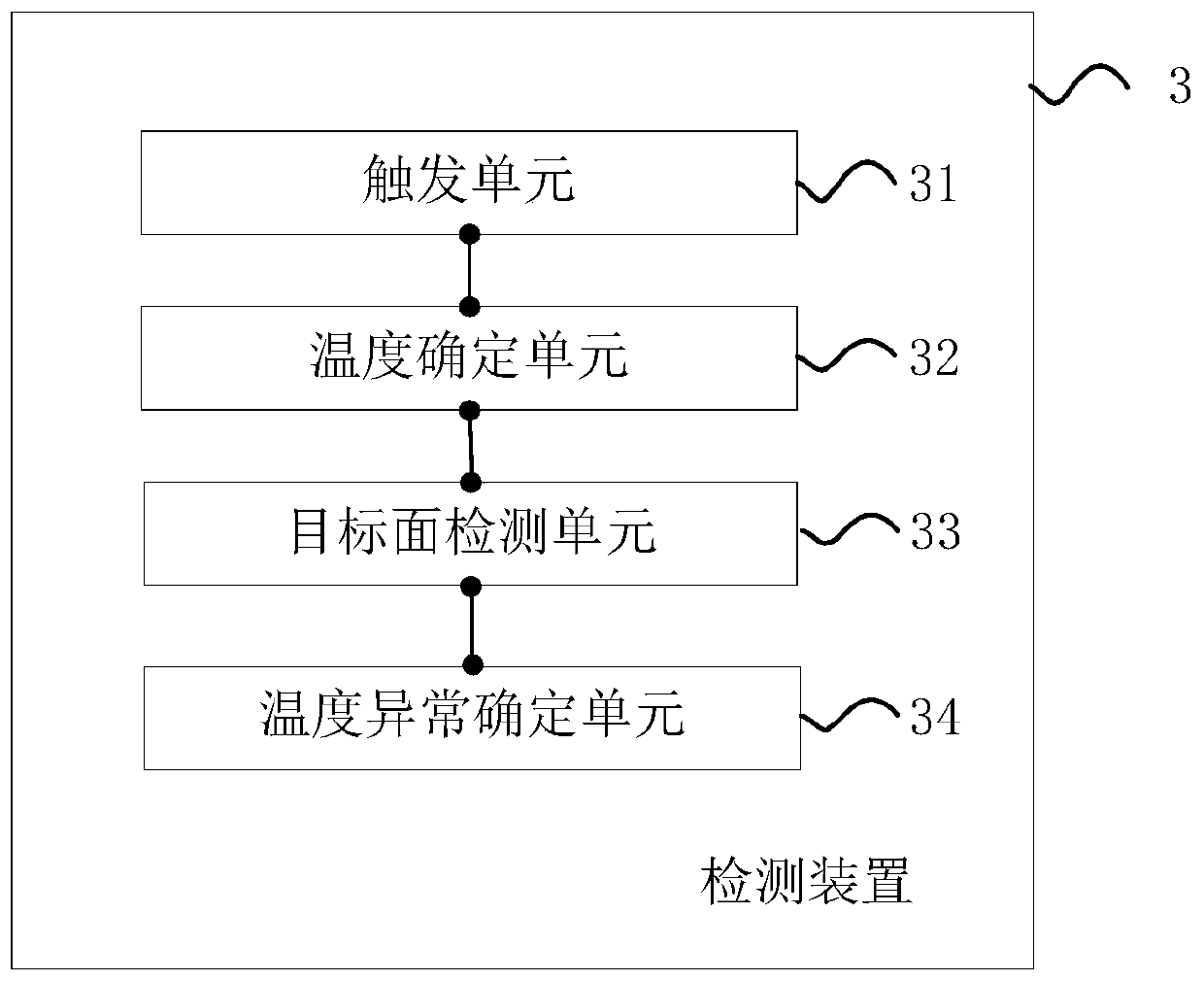

Temperature detection method, detection device and terminal equipment of substation equipment

ActiveCN107588855BRealize temperature detectionImprove accuracyRadiation pyrometryTarget surfaceAbnormal positions

The invention is suitable for the field of power equipment monitoring technology, and provides a detecting method, a detecting device, terminal equipment and a computer-readable storage medium for temperature of transformer equipment. The detecting method comprises the steps of triggering an inspection robot to move along a preset route, and triggering the inspection robot to perform photographingon the transformer equipment based on a thermal imaging instrument when the inspection robot moves to each detecting point, obtaining the thermal image of each surface of the transformer equipment, and furthermore determining the highest temperature of each surface of the transformer equipment; detecting whether a target surface exists based on the highest temperature of each surface of the transformer equipment; and if the target surface exists, determining temperature abnormity of the transformer equipment, and determining the transformer equipment position which corresponds with the highest temperature on the target surface as a temperature abnormal position. The detecting method, the detecting device, the terminal equipment and the computer-readable storage medium have advantages of realizing omnibearing temperature detection on the surface of the transformer equipment, improving detecting efficiency and detecting result accuracy.

Owner:国网江西省电力有限公司超高压分公司 +1

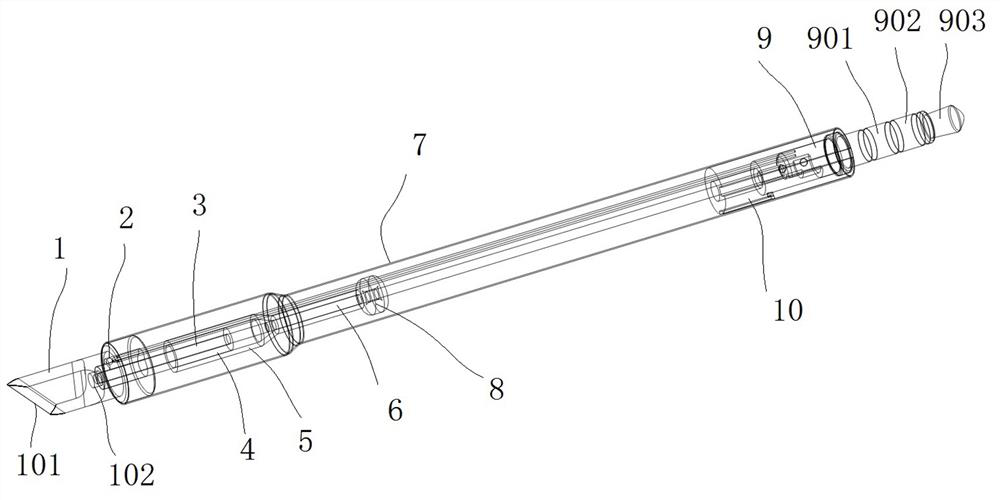

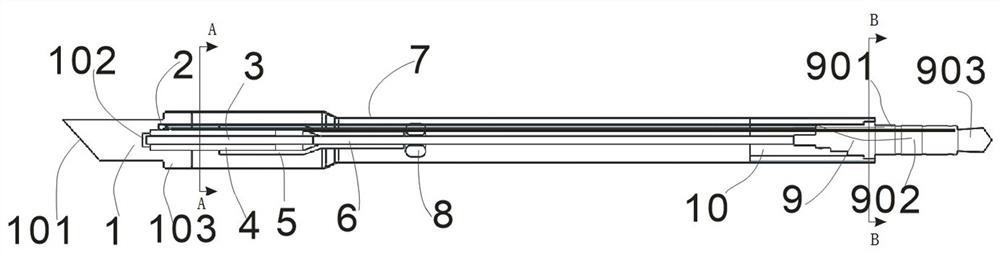

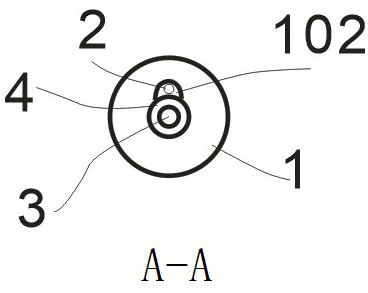

High-power-density soldering iron

InactiveCN112404638AReduce feverImprove heating efficiencySoldering ironMetallurgyHigh power density

The invention relates to a soldering iron core, in particular to a high-power-density soldering iron. The soldering iron comprises a soldering iron head, wherein the tail of the soldering iron head isarranged at the end of an outer steel pipe; the soldering iron core is arranged in the outer steel pipe; a temperature measurement discharge hole is formed in the rear end of the soldering iron head;a temperature sensor and a ceramic tube are arranged in the temperature measurement discharge hole; a discharge needle is arranged in the ceramic tube; and the head of the discharge needle is inserted into the temperature measurement discharge hole through the center of the ceramic tube. The high-power-density soldering iron has the characteristics of high heating efficiency, compact structure, excellent temperature stability and the like.

Owner:武汉文宇创新科技有限公司

A temperature control method for refrigerators based on a swinging infrared temperature measuring device

ActiveCN105676906BRealize temperature detectionRadiation pyrometryTemperature control using plurality of sensorsTemperature controlControl signal

The invention discloses a swing type infrared temperature measurement device-based refrigerating box temperature control method. The method comprises the steps of 1, powering on and initializing all components; 2, setting a preset temperature range; 3, monitoring the temperature in real time by a temperature measurement device; processing a signal by a processor; and repeating the step 3 when the measured value of the temperature is within the preset temperature range; otherwise, conducting the step 4; 4, sending an alarm signal to an alarm device by the processor; and determining the coordinates of an abnormal temperature point relative to the corner of a cabinet by the processor according to the geometric method; 5, according to different judgments on whether the temperature signal is larger than a maximum temperature value or not, sending different control signals to an axial-flow fan and a refrigerating machine by the processor so as to drive the axial-flow fan and the refrigerating machine to run; 6, manually removing the alarm and repeating the step 3. According to the technical scheme of the invention, the temperature detection is realized. Meanwhile, based on data detected by the temperature measurement device, the temperature control and the abnormal alarm are enabled.

Owner:铜陵金建投资发展有限公司

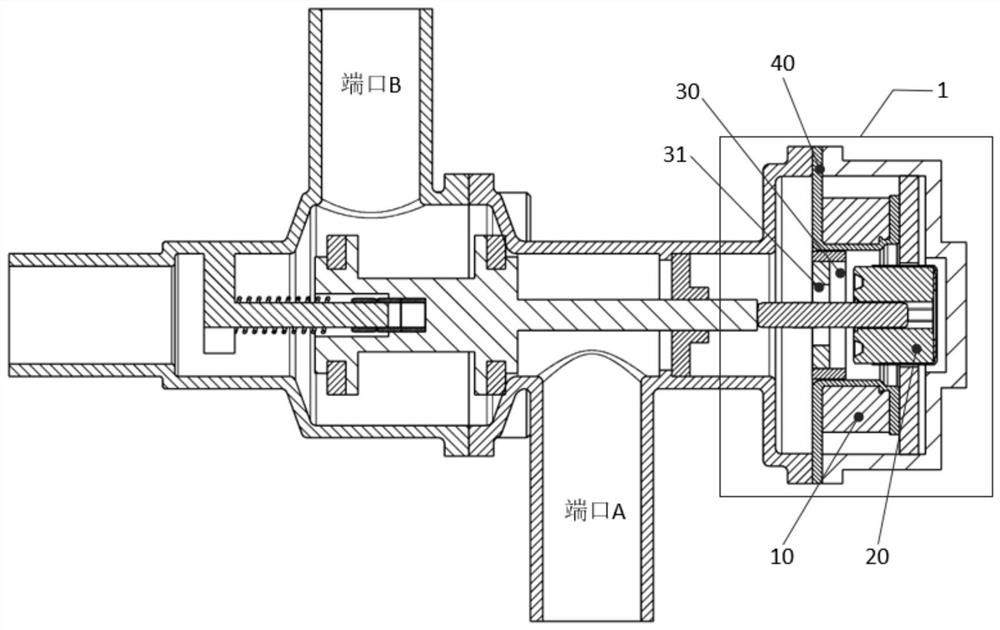

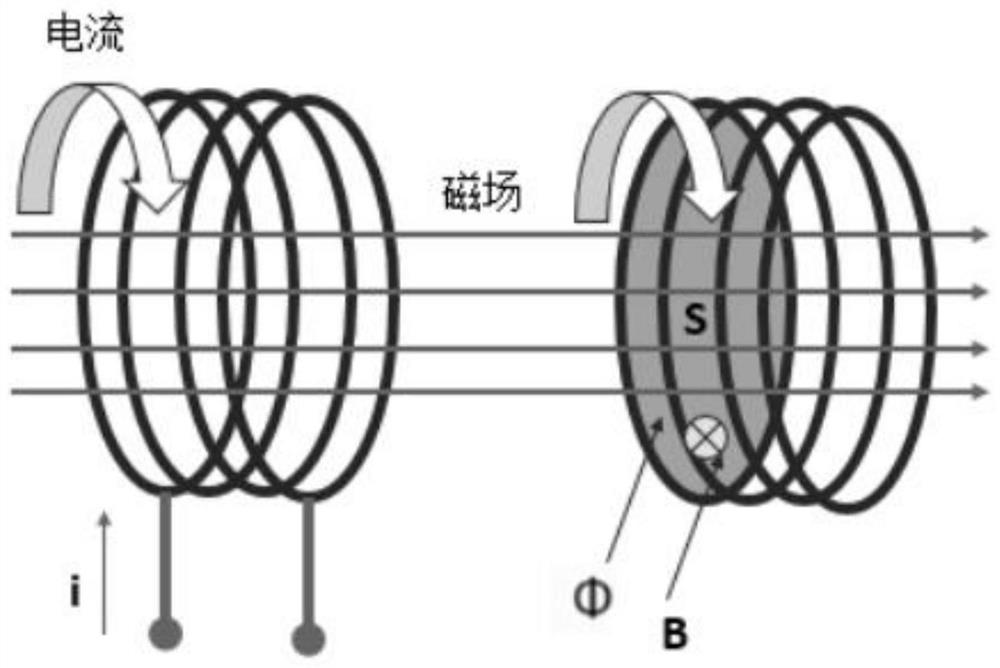

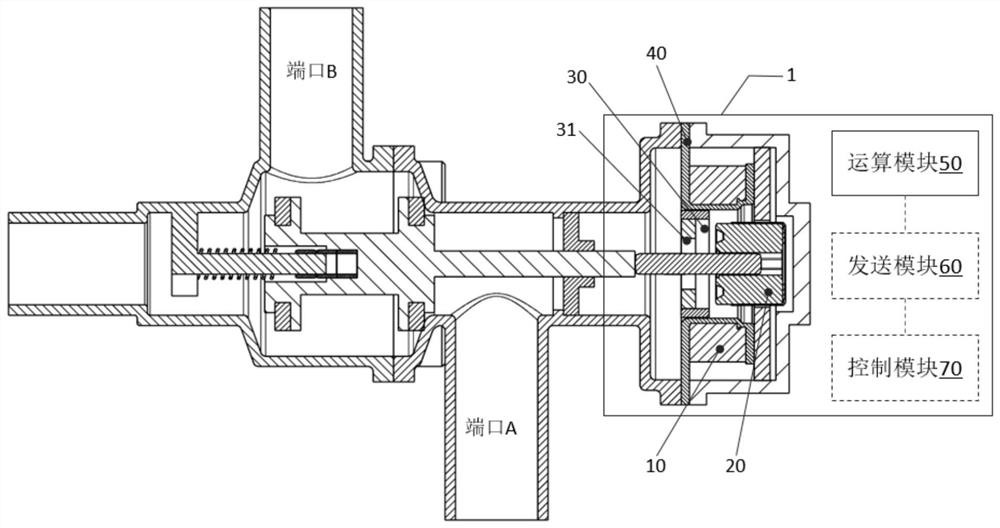

Electromagnetic valve and heat management method

PendingCN111828712ALow costIncrease temperatureOperating means/releasing devices for valvesTransformers/inductances coolingHeat managementEngineering

The invention provides an electromagnetic valve and a heat management method. The electromagnetic valve comprises a coil, a magnetic core and a cavity, wherein the coil forms an electromagnetic fieldunder an electrified circumstance, and the electromagnetic field disappears after outage of the coil; the magnetic core acts according to an electromagnetic force generated by the electromagnetic field to control a fluid flowing in a pipeline provided with the electromagnetic valve; and the cavity is provided with a flow guide hole, the flow guide hole is used for importing the fluid into the cavity and exporting the fluid in the cavity, and the coil is immersed in the fluid under a circumstance that the fluid is stored in the cavity. The electromagnetic valve provided by the invention is higher in performance while keeping an unchanged cost or is lower in cost while keeping unchanged performance. The heat management method provided by the invention can achieve coil temperature detection without a sensor, so that a hardware structure of an electromagnetic valve control circuit can be simpler.

Owner:SCHAEFFLER TECH AG & CO KG

A system and method for suppressing vibration of a strip mill roll system based on hydraulic cylinder control

InactiveCN105903769BImplement vibration detectionAchieving Vibration EffectsVibration control deviceMetal rolling arrangementsHydraulic cylinderVertical vibration

The invention discloses a plate-strip rolling mill roll system vibration inhibiting system and method based on hydraulic cylinder control. An acceleration sensor (1) is arranged at the bottom of a hydraulic cylinder rigid body (3). A temperature sensor (2) is arranged on a side of the hydraulic cylinder rigid body (3). The hydraulic cylinder rigid body (3) is connected with a temperature adjuster (4). The temperature adjuster (4) is connected with a comprehensive control device (5). According to the invention, related technique for roller vertical vibration inhibition is realized through performing control over oil temperature of a hydraulic cylinder of a rolling mill screwdown gear and a rolling vibration inhibition closed-loop system combining hydraulic cylinder oil temperature and roll system vibration parameters are proposed based on theoretical study and field practice, help is provided for solving rolling mill vertical vibration problems. The system is simple in structure and can realize a rolling mill roll system vibration inhibiting device achieving mutual feedback adjustment of vibration and temperature conveniently and quickly.

Owner:BEIJING UNIV OF TECH

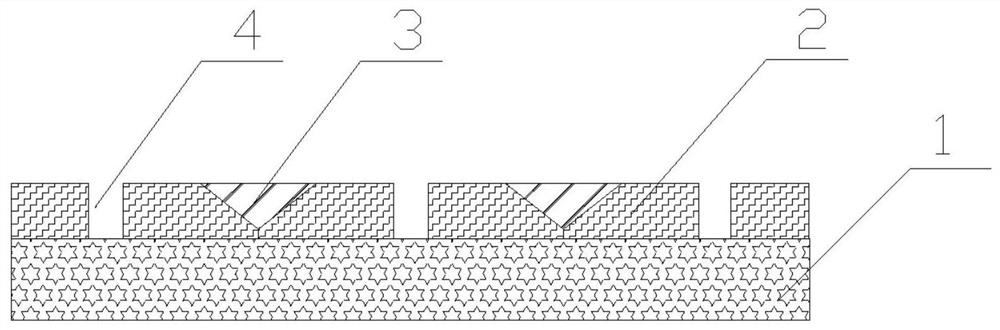

Temperature detection device based on surface plasmon

PendingCN113607302ASimple device structureReduce volumeThermometers using physical/chemical changesSurface plasmon polaritonLight spectrum

The invention belongs to the field of temperature detection and particularly relates to a surface plasmon-based temperature detection device. The device comprises a transparent elastic material layer, a metal array structure and a thermal expansion material block, wherein the metal array structure is arranged on the transparent elastic material layer, the metal array structure is composed of metal units arranged periodically, notches are formed in the metal units, gaps are formed between the metal units, and the thermal expansion material block is arranged in the notches. The thermal expansion material block expands and the gap is narrowed due to the change of the temperature, so the position of the resonance valley in the emergent spectrum is moved, and temperature detection is realized through the position movement of the resonance valley. According to the device, temperature detection is realized based on surface plasmon, temperature detection is realized by detecting optical signals, and the device is simple in structure, is more beneficial to use in a severe environment, and is high in detection precision, small in size and convenient to integrate.

Owner:YUNNAN NORMAL UNIV

A temperature measurement method based on rare earth luminescence lifetime temperature probe

ActiveCN112111275BAvoid detection errorsImprove accuracyMaterial nanotechnologyNanoopticsRare earth ionsPhysical chemistry

Owner:FUDAN UNIV

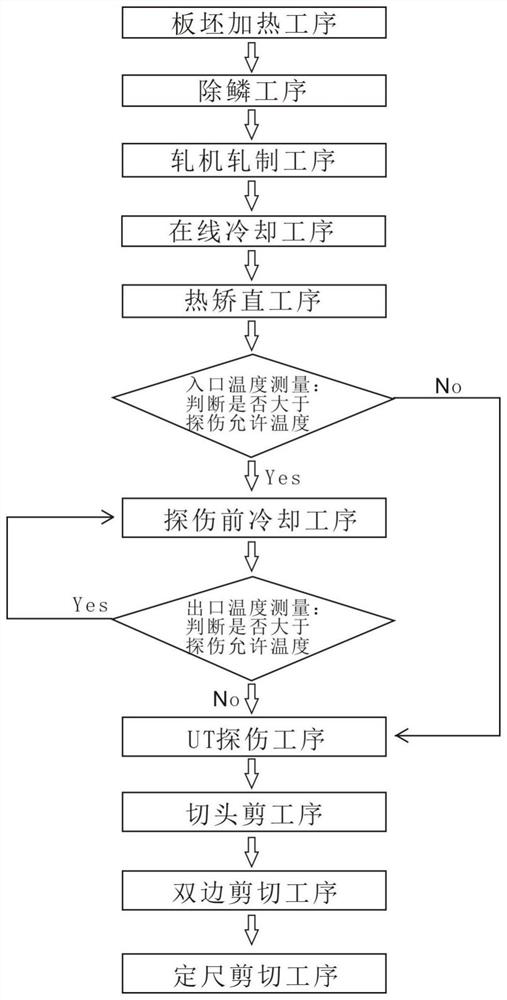

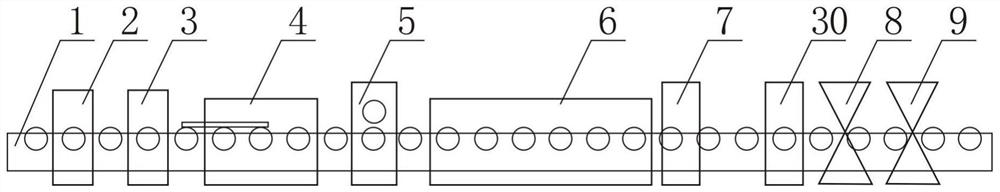

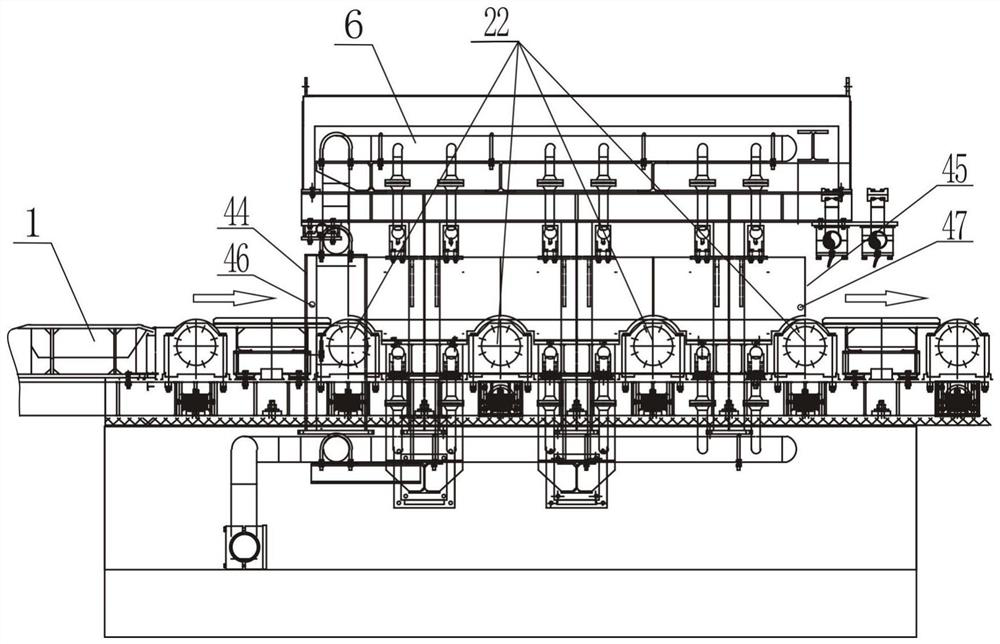

A single-line production process for medium and thick plates

ActiveCN111282990BReduce running timeImprove work efficiencyMeasuring devicesWork cooling devicesThick plateProcess engineering

The invention relates to the field of iron and steel smelting, and specifically discloses a single-line production process for medium and thick plates, which sequentially includes a rolling mill rolling process, an online cooling process, a thermal straightening process, a cooling process before flaw detection, a UT flaw detection process, and a cutting process. , bilateral shearing process and cut-to-length shearing process, in the production process of the present invention, the equipment used in each of the above-mentioned processes is arranged along a steel plate conveying line, and an online cooling device before flaw detection is used in the cooling process before flaw detection. The production process of the present invention prevents the steel plate from being hoisted by the traditional overhead crane, and does not need to be transferred from the steel plate conveying line to the cooling bed for cooling, which greatly saves the operation time, improves the work efficiency, reduces the production cost, and solves the problems of operation. The bottleneck problem of production occurs; the production process of the present invention is not limited by the length of the plate to be processed, and can produce and process plates of different specifications, especially for the processing of super long plates, the present invention has more advantages.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Silicon optical chip temperature sensor

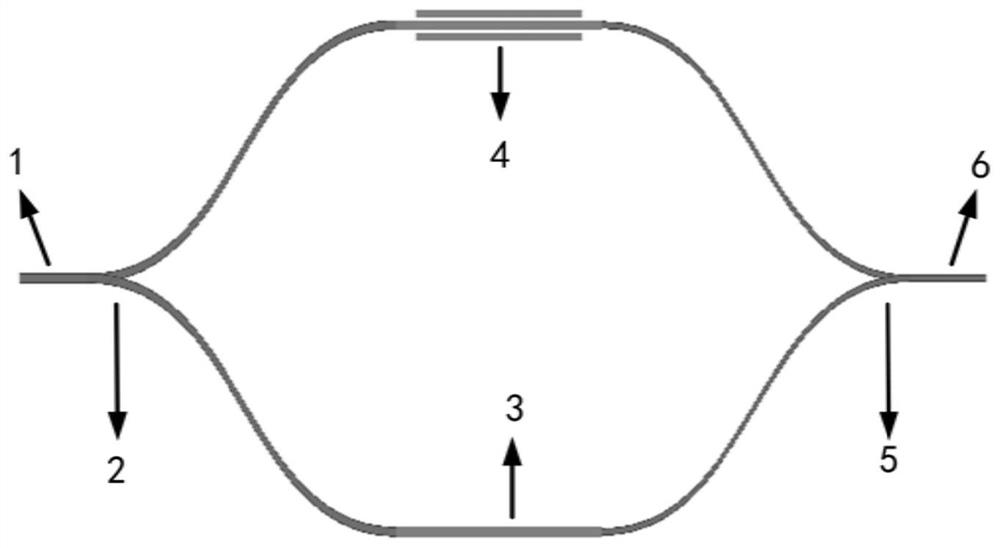

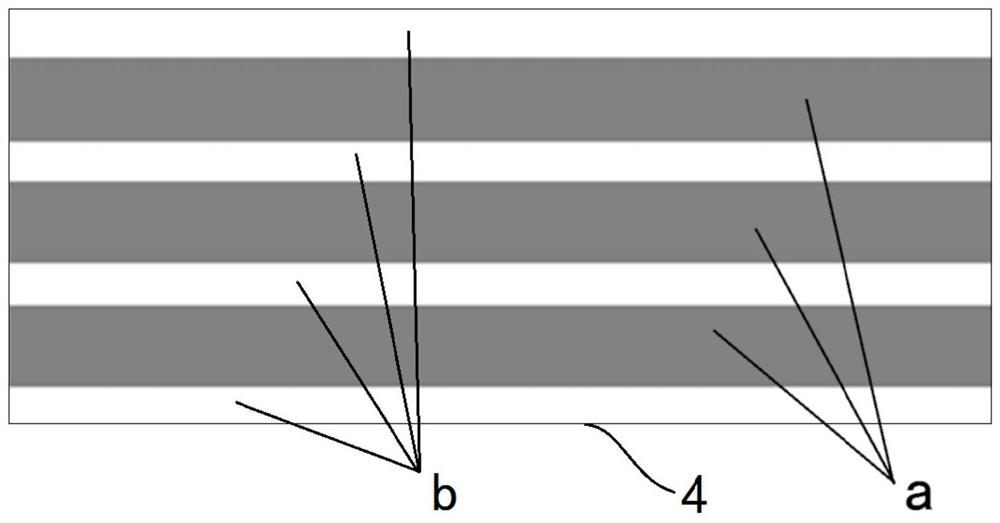

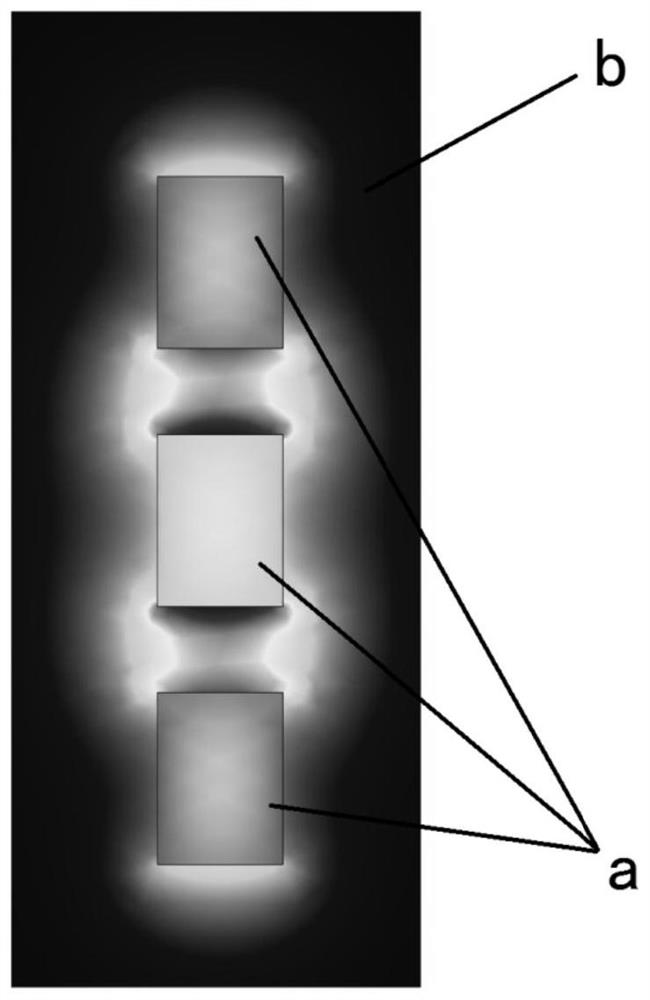

PendingCN112985634ARealize temperature detectionHighly integratedThermometers using physical/chemical changesLight signalWaveguide

The invention relates to a silicon optical chip temperature sensor, which comprises an input waveguide provided with a silicon dioxide cladding, a lead-in Y-shaped waveguide, a first sensing waveguide, a second sensing waveguide, a lead-out Y-shaped waveguide and an output waveguide; the input waveguide is connected with the input end of the lead-in Y-shaped waveguide; the two output ends of the lead-in Y-shaped waveguide are respectively connected in series with the first sensing waveguide and the second sensing waveguide and then are respectively connected with the two input ends of the lead-out Y-shaped waveguide, and the output end of the lead-out Y-shaped waveguide is connected with the output waveguide; the second sensing waveguide comprises three silicon waveguides which are tightly arranged side by side, and two ends of the silicon waveguide positioned in the middle are respectively connected with a lead-in Y-shaped waveguide and a lead-out Y-shaped waveguide; wherein in the first sensing waveguide, an optical signal is bound to be propagated in the silicon waveguide; and in the second sensing waveguide, the optical signal is bound to be propagated in the silicon dioxide cladding between the adjacent silicon waveguides. According to the temperature sensor, temperature detection of the built-in integrated silicon optical chip is realized, and the reliability is high.

Owner:武汉科宇智联信息技术有限公司

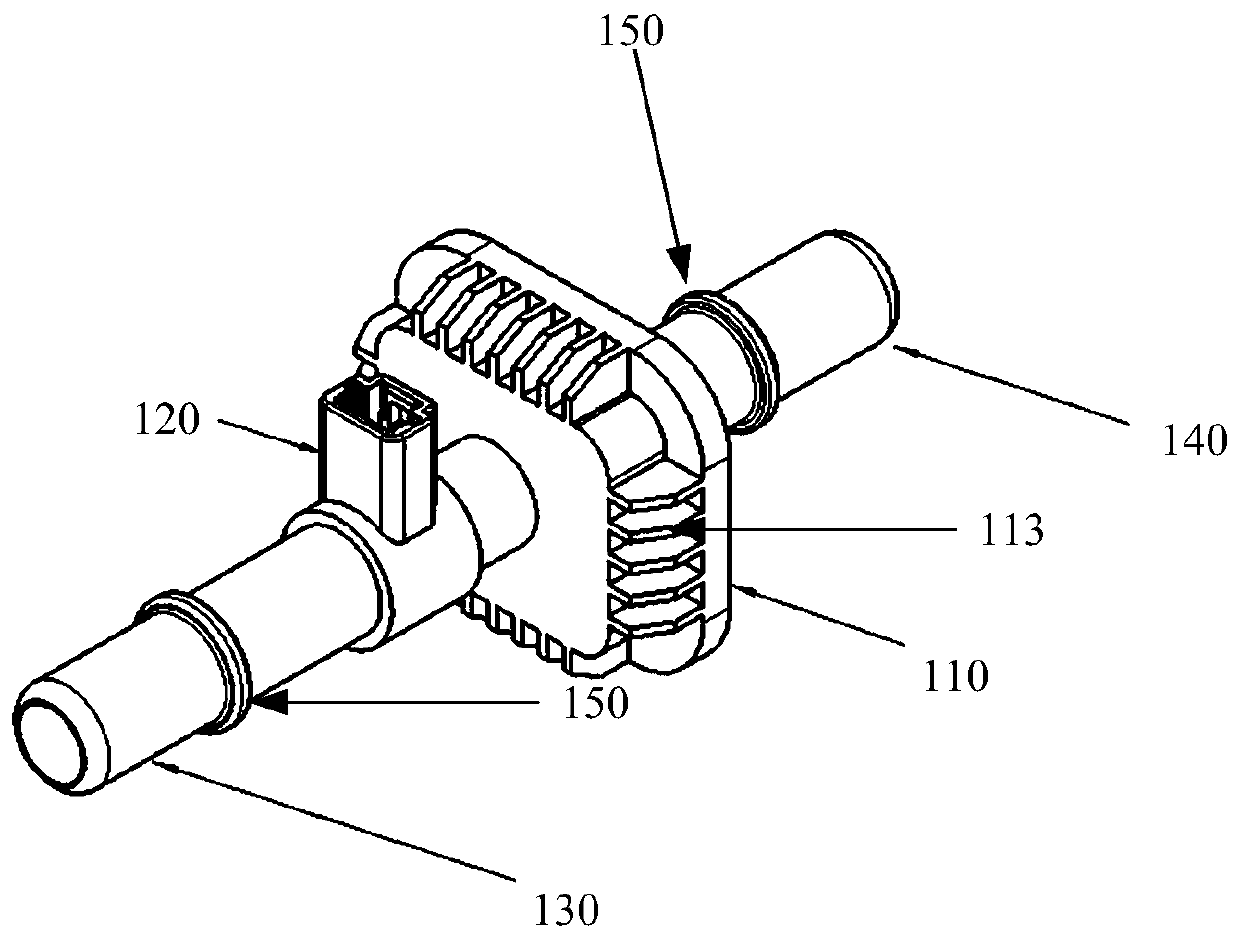

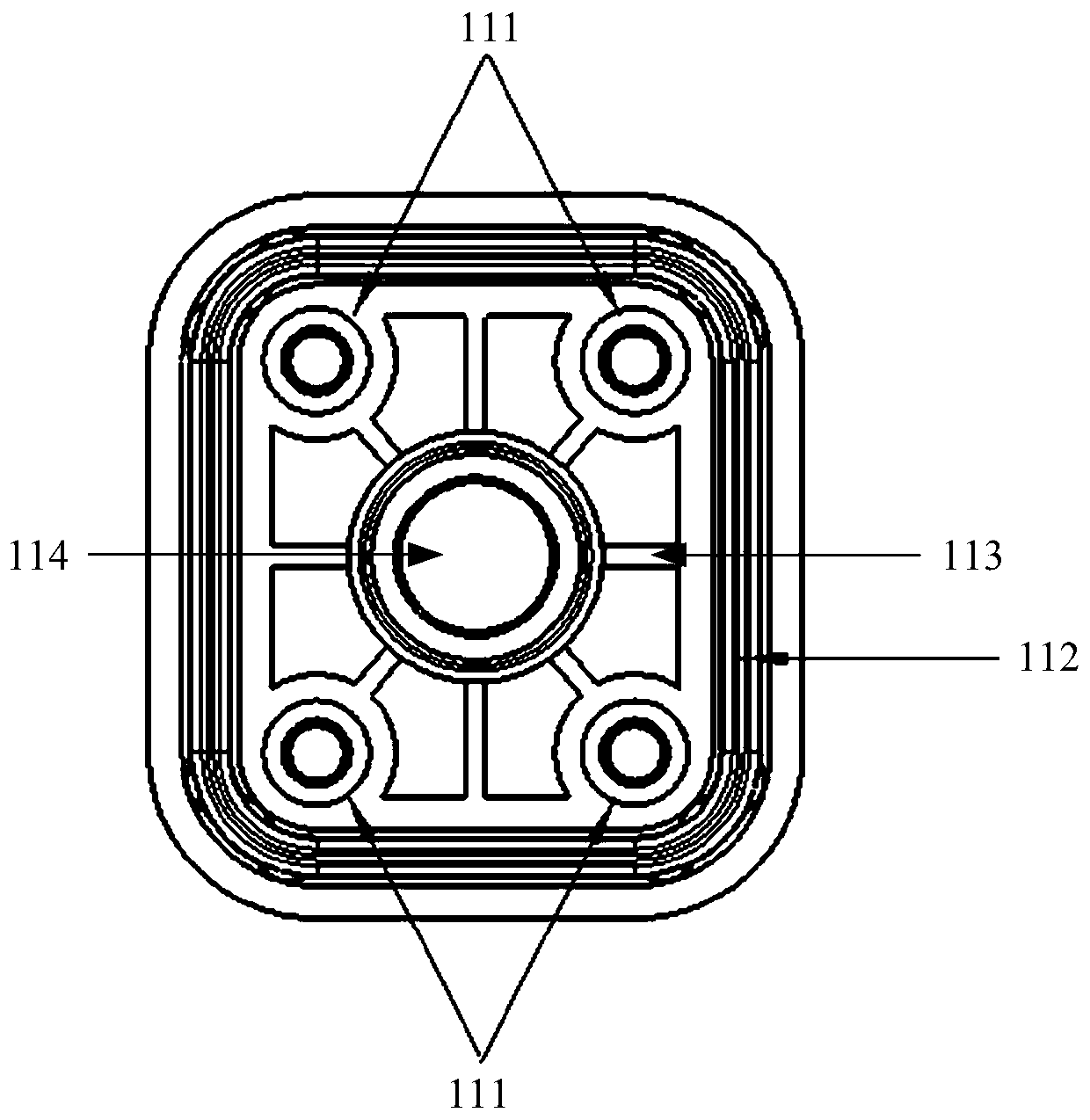

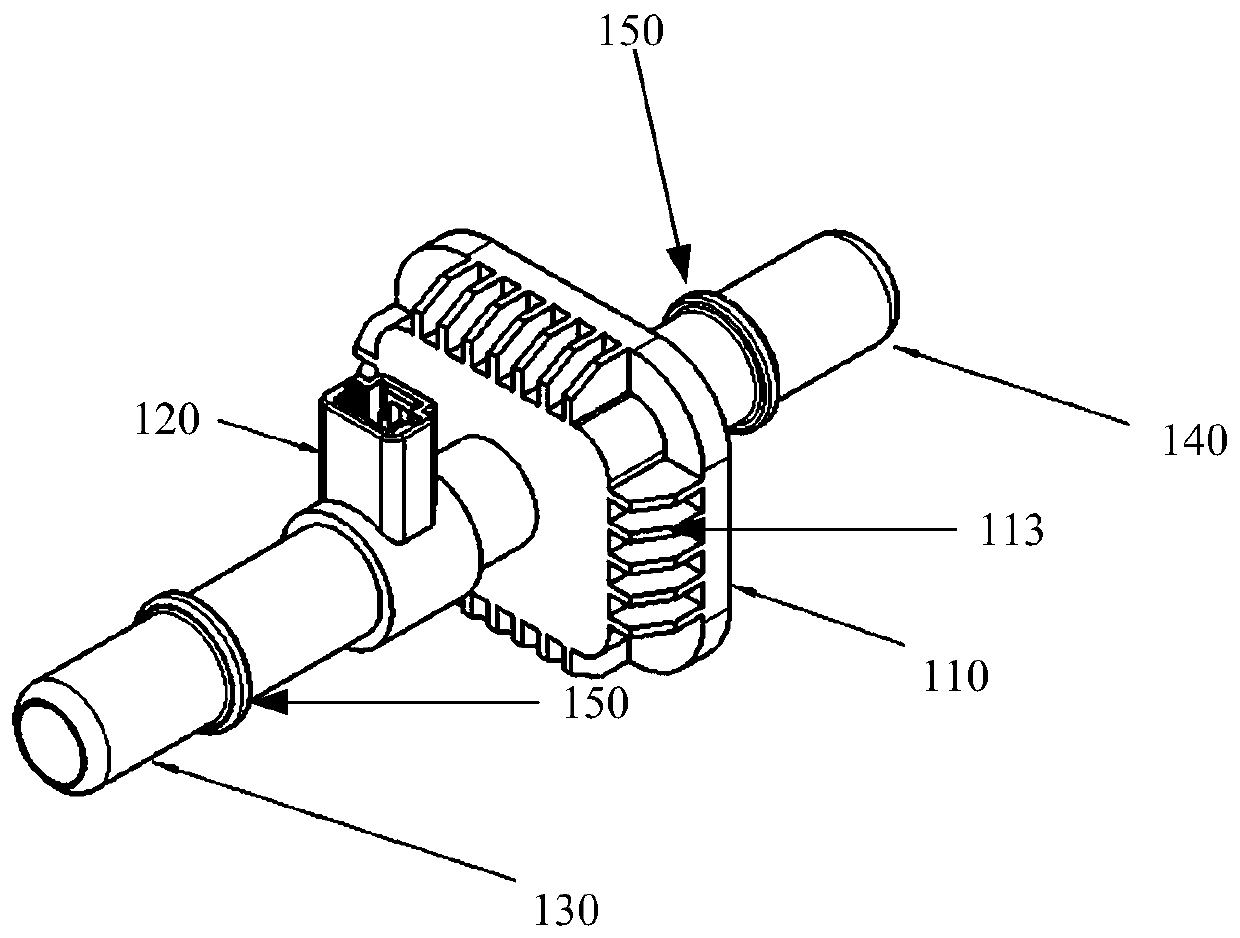

Single-channel sealing connection device

PendingCN111180831AAchieving tightnessImprove consistencySecondary cellsTemperature measurement of flowing materialsThermal management systemMechanical engineering

The invention provides a single-channel sealing connection device and a battery pack thermal management system. The single-channel sealing connection device comprises a flange joint, a temperature sensor, a first quick plug connector and a second quick plug connector, wherein the first quick plug connector is connected with a first connecting surface of the flange joint; the second quick plug connector is connected with the second connecting surface of the flange joint; the temperature sensor is integrated on the first quick plug connector and used for detecting the temperature of liquid flowing in the first quick plug connector; and the first quick plug connector and the second quick plug connector are used for being plugged into a matched female connector on an external water pipe.

Owner:WM SMART MOBILITY (SHANGHAI) CO LTD

Beverage bottle opener with heating function and heating method

PendingCN109250666ARealize temperature detectionEasy accessBottle/container closurePower operated devicesEngineeringControl circuit

The invention discloses a beverage bottle opener with a heating function and a heating method. The beverage bottle opener comprises an annular component and a rod. The rod is connected with the annular component, the annular component comprises a shell, vertical stripes are arranged on the inner wall of the shell, and a detection hole is formed in a joint of the outer wall of the shell and the rod; a processor, an infrared temperature measurement module, a power control circuit and a wireless charge coil are arranged in the shell, the processor is electrically connected with the infrared temperature measurement module and the power control circuit, and an end of the infrared temperature measurement module is arranged at the detection hole; the rod comprises a rod shell, a heating tube anda battery, and the heating tube and the battery are arranged in the rod shell; the battery is arranged on the upper portion of the heating tube and is electrically connected with the heating tube andthe power control circuit. The beverage bottle opener and the heating method have the advantages that bottle caps can be conveniently rotationally unscrewed by the beverage bottle opener, beverage further can be heated by the beverage bottle opener, and accordingly hot beverage can be obtained.

Owner:AUKEY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com