Sodium-sulfur cell batch detecting system

A sodium-sulfur battery, batch detection technology, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problem that the charging and discharging equipment does not have a temperature detection control function, etc., to achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

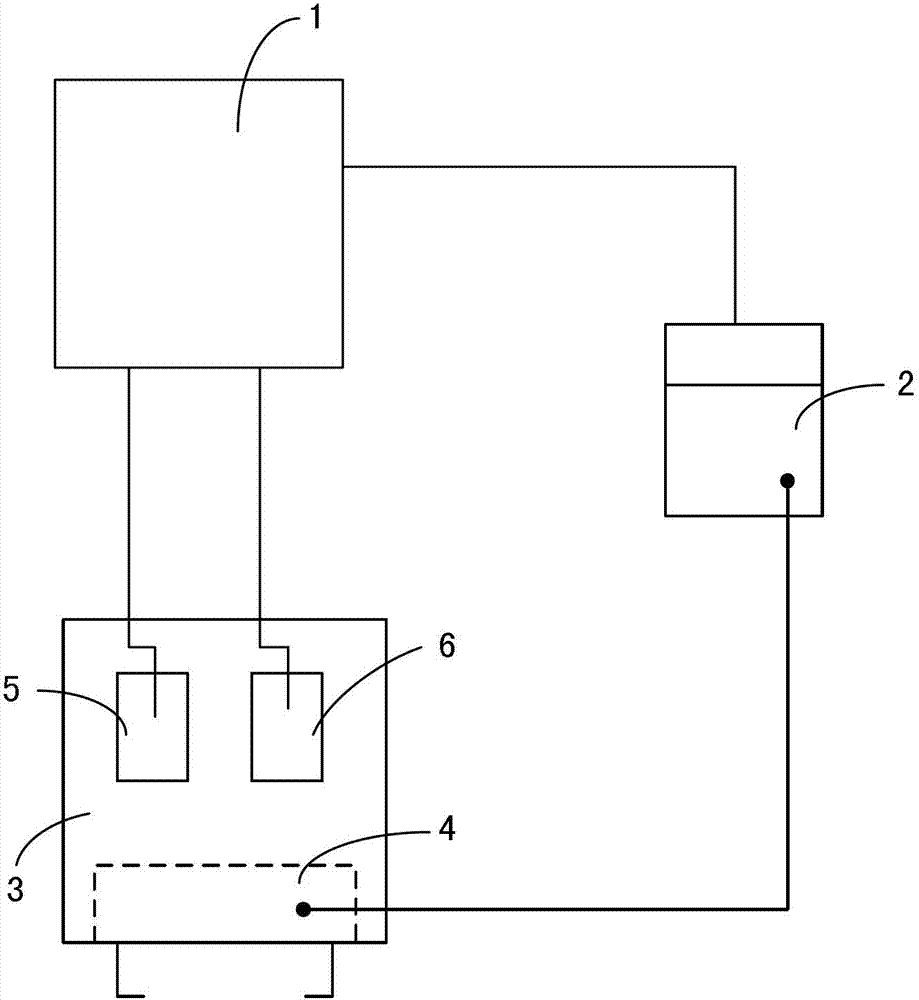

[0016] see figure 1 , the sodium-sulfur battery batch testing system of the present invention comprises a batch testing furnace 3, a sodium-sulfur battery 4 to be tested located in the batch testing furnace 3, a charging and discharging device 2 connected to the sodium-sulfur battery to be tested 4, and an intelligent control system 1. The temperature controller 5 and the collection controller 6 are installed on the batch testing furnace 3 and connected to the intelligent control system 1 respectively, and the intelligent control system 1 is connected to the charging and discharging equipment 2 .

[0017] The acquisition controller 5 collects the battery voltage and temperature signals in the batch test furnace 3, and uploads them to the intelligent management system 1. At the same time, the total voltage, charge and discharge depth, internal resistance and other data during the charging and discharging process will also be uploaded to the intelligent management system. 1. Th...

Embodiment 2

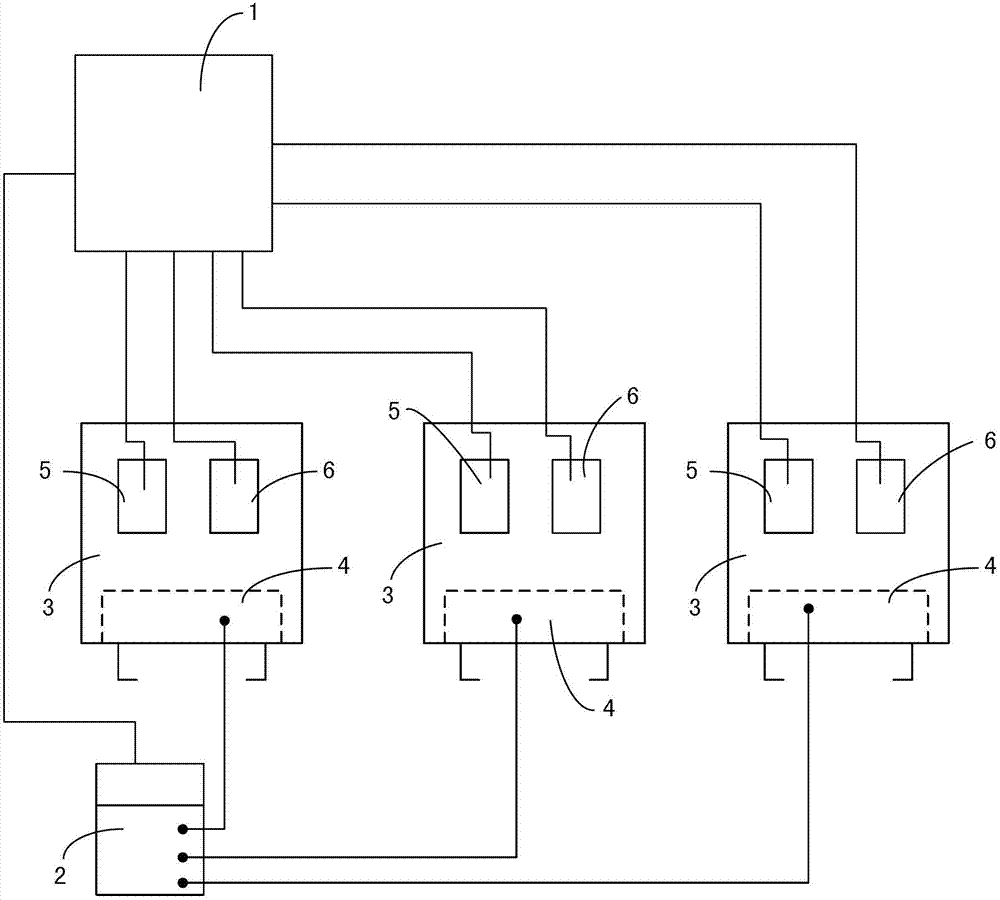

[0019] see figure 2 , the sodium-sulfur battery batch testing system of the present invention includes three batch testing furnaces 3, a sodium-sulfur battery to be tested 4 respectively arranged in each batch testing furnace 3, and a temperature controller respectively arranged on each batch testing furnace 3 5 and acquisition controller 6, charging and discharging equipment 2 and intelligent control system 1, wherein: charging and discharging equipment 2 is respectively connected with each sodium-sulfur battery 4 to be tested, and temperature controller 5 and acquisition controller 6 are respectively connected with intelligent control system 1 connection, the charging and discharging device 2 is connected with the intelligent control system 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com