Plate-strip rolling mill roll system vibration inhibiting system and method based on hydraulic cylinder control

A hydraulic cylinder and rolling mill technology, applied in vibration control, rolling mill control devices, metal rolling, etc., can solve the problems of not considering the influence of stability, large error of control effect, etc., achieve simple and effective vibration detection, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

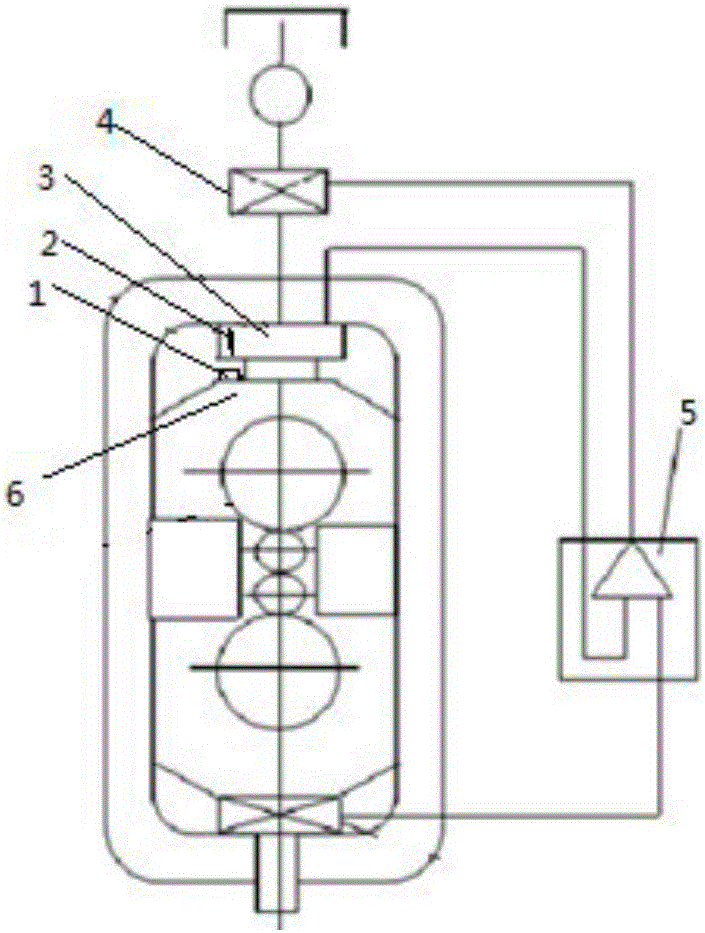

[0023] The following is attached figure 1 And embodiment the present invention is described in further detail.

[0024] Such as figure 1 As shown, a strip mill roll system vibration suppression system and method based on hydraulic cylinder control, the vibration suppression system includes an acceleration sensor (1), a temperature sensor (2), a temperature regulator (4), a total control device (5 ).

[0025] The acceleration sensor (1) is arranged at the bottom of the hydraulic cylinder rigid body (3), and the temperature sensor (2) is arranged at one side of the hydraulic cylinder rigid body (3); the hydraulic cylinder rigid body (3) is connected with the temperature regulator (4), and the temperature is regulated Device (4) is connected with total control device (5).

[0026] The acceleration sensor (1) is used to complete the collection of vibration analog signals; the temperature sensor (2) is used to complete the collection of hydraulic cylinder oil temperature analog ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com