Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Protection against corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Normal temperature spraying detergent for aluminum alloy and preparation method thereof

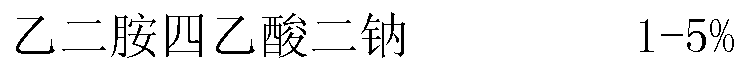

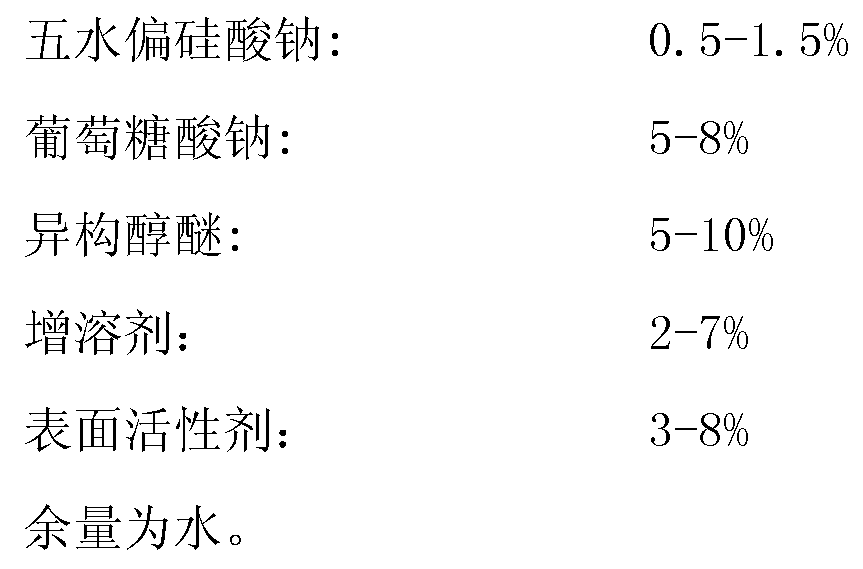

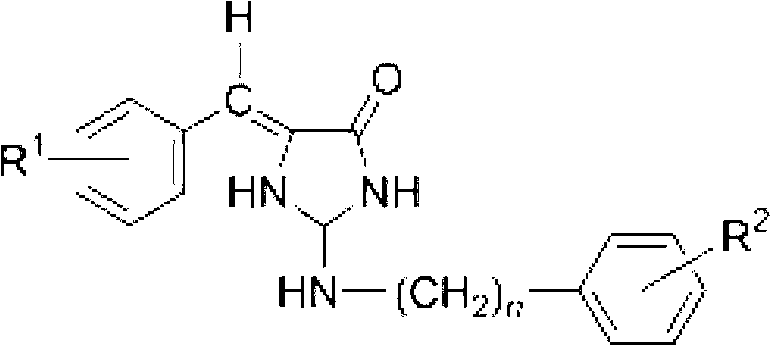

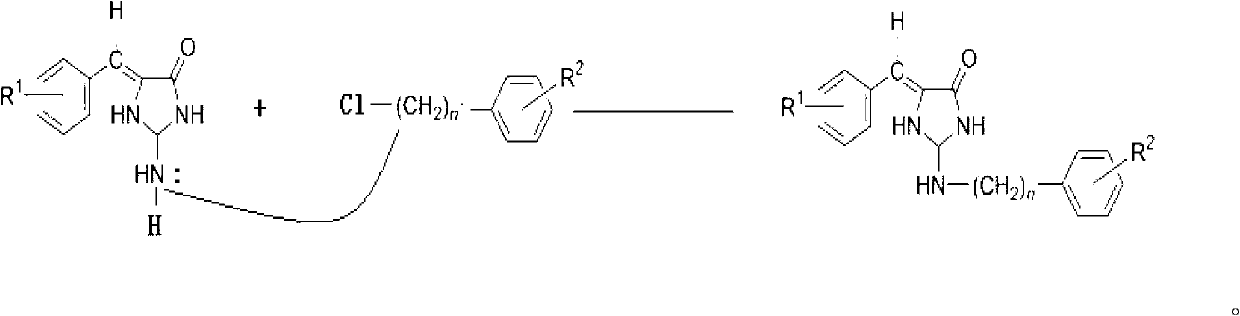

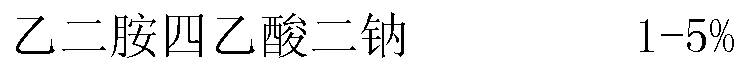

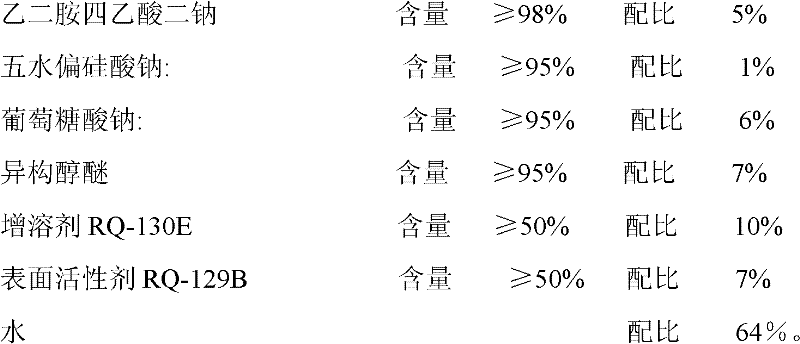

The invention relates to a normal temperature spraying detergent for aluminum alloy and a preparation method thereof. The detergent comprises the following raw materials in percentage by weight: 1 to 5 percent of ethylene diamine tetraacetic acid, 0.5 to 1.5 percent of sodium metasilicate pentahydrate, 5 to 8 percent of sodium gluconate, 5 to 10 percent of heterogeneous alcohol ether, 2 to 7 percent of solubilizing agent, 3 to 8 percent of surfactant, and the balance of water. The detergent can be used at normal temperature, and does not need heating so as to save the energy; the detergent does not corrode the treated aluminum alloy parts, does not leave white spots on the surfaces of the parts, and can increase the brightness of the parts; and the detergent has long service life and low using concentration, is safe and environment-friendly, saves the working time, and improves the working efficiency.

Owner:华阳新兴科技(天津)集团有限公司

Special water-based cleaning agent for aluminum magnesium alloy

The invention discloses a special water-based cleaning agent for aluminum magnesium alloy. The special water-based cleaning agent comprises the following raw materials in parts by weight: 1-6 parts of triethanolamine, 2-10 parts of sodium carbonate, 5-10 parts of sodium bicarbonate, 4-12 parts of heterogeneous alcohol ether, 6-20 parts of alkylolamides, 5-15 parts of a magnesium alloy corrosion inhibitor, 5-10 parts of an aluminum alloy corrosion inhibitor, 8-20 parts of an anionic surfactant, 3-10 parts of hydrophilic alcohol, 0-6 parts of a stabilizer and 50-100 parts of water. The special water-based cleaning agent for aluminum magnesium alloy disclosed by the invention is strong in detersive power, high in cleaning speed, few in residues after being washed, anti-static, and good in corrosion inhibition property, and can prevent the metal from being corroded.

Owner:CHAOHU GUANGFENG METAL PROD

Extended Operation Engine Coolant Composition

ActiveUS20140366817A1Excellent pitting protectionLow toxicityLiquid coolingMachines/enginesEngineeringCooling fluid

The invention relates to an engine coolant composition, and a method of increasing the operational life of a coolant composition in an engine, wherein an isononanoic acid is incorporated into the generally glycol based coolant fluid in place of nitrous acid or its salt to reduce pitting corrosion on iron containing surfaces.

Owner:VGP IPCO LLC

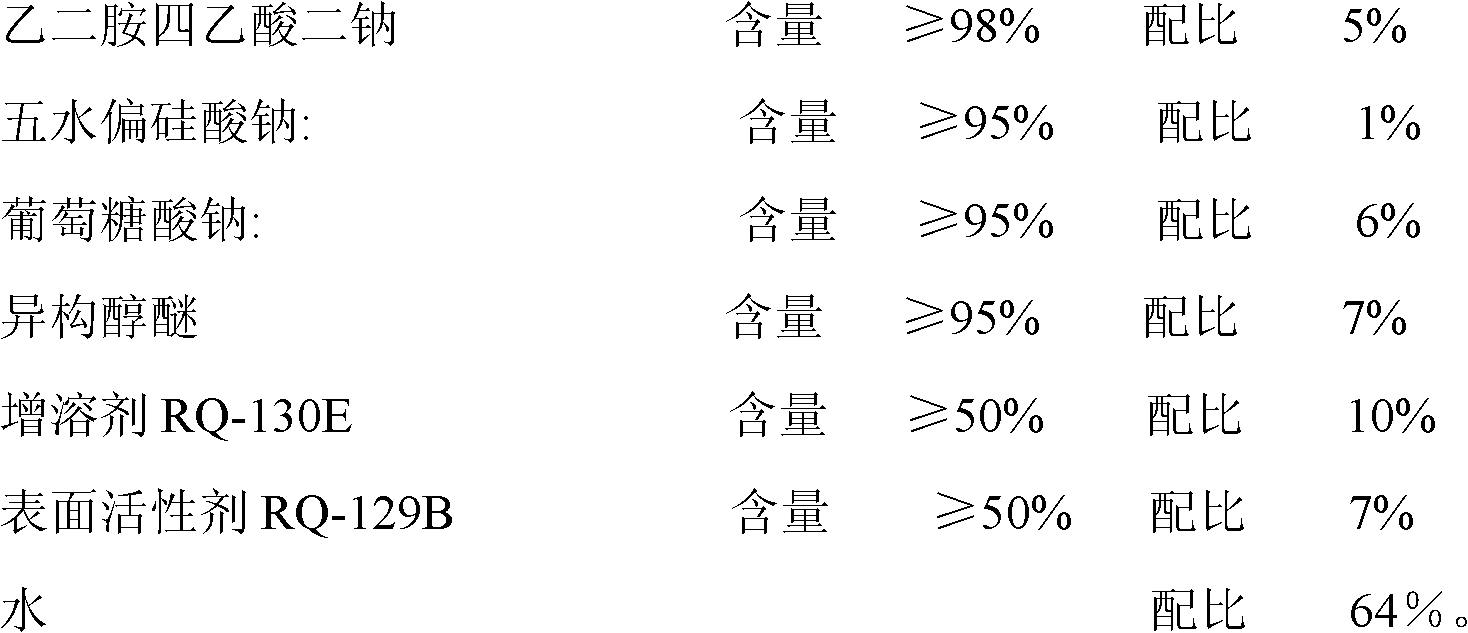

High-impermeability cement-based composite material and method for preparing same

The invention relates to a high-impermeability cement-based composite material and a method for preparing the same. The high-impermeability cement-based composite material comprises, by weight, 20-30parts of 525 white cement, 40-60 parts of quartz sand, 18-20 parts of titanium dioxide powder, 10-12 parts of fly ash, 5-15 parts of chitosan nanogel, 3-5 parts of polyacrylate emulsion, 1-10 parts ofpitchstone vitrified micro-spheres, 0.5-2 parts of PVA (polyvinyl alcohol) celluloses, 6-8 parts of ionic liquid, 10-12 parts of crop straw powder, 3-6 parts of clay, 3-5 parts of diatomaceous earth,3-5 parts of maleic anhydride, 1-3 parts of whiskers, 3-6 parts of silane coupling agents, 0.5-2 parts of cellulose ether, 0.3-2 parts of redispersible latex powder, 0.1-3 parts of superplasticizers,0.5-2 parts of inorganic pigment and 60-70 parts of water. The method includes preparing composite materials from the maleic anhydride, the clay, the diatomaceous earth and the PVA celluloses; mixingand stirring the composite materials and other raw materials with one another to obtain the high-impermeability cement-based composite material which is a product.

Owner:吴远怀

Stainless steel equipment cleaning agent, cleaning solution and cleaning method

The invention relates to a stainless steel equipment cleaning agent. The stainless steel equipment cleaning agent comprises the following effective components in parts by weight: 5-8 parts of polyglycolic acid, 7-10 parts of biochemical fulvic acid and 2-5 parts of amino acetic acid, wherein water is added for complementing into 100 parts, so that a cleaning solution can be prepared. A method for cleaning stainless steel equipment by utilizing the cleaning agent comprises the following steps: (1) preparing raw materials: weighing the following components in parts by weight: 5-8 parts of polyglycolic acid, 7-10 parts of biochemical fulvic acid, 2-5 parts of amino acetic acid and balance of water, wherein the total parts by weight of polyglycolic acid, biochemical fulvic acid, amino acetic acid and water is 100 parts; (2) taking two thirds of water and heating to 50 minus or plus 5 DEG C, adding amino acetic acid and uniformly stirring, adding biochemical fulvic acid, and stirring for dissolution, so that a solution A is obtained; (3) taking the rest of water, adding polyglycolic acid, and stirring for dissolution, so that a solution B is obtained; (4) introducing the solution A into equipment to be cleaned and circulating for 5-10 minutes, and then introducing the solution B and carrying out circulation cleaning. The stainless steel equipment cleaning agent has few components, is environment-friendly and produces less corrosion to the equipment, and descaling rate is more than 98%.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

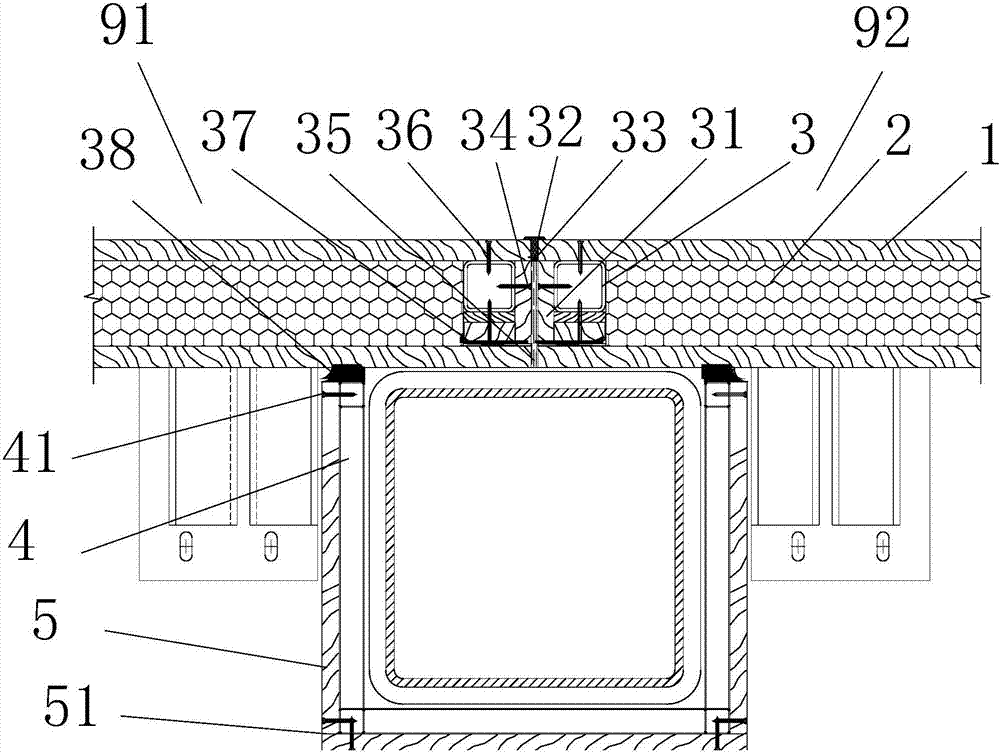

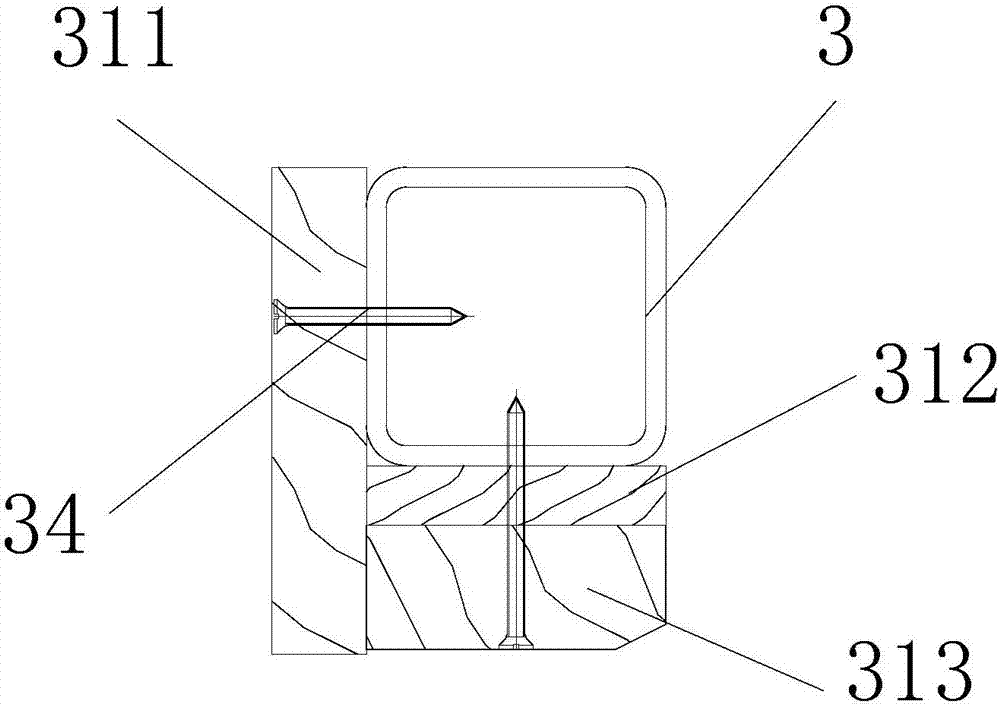

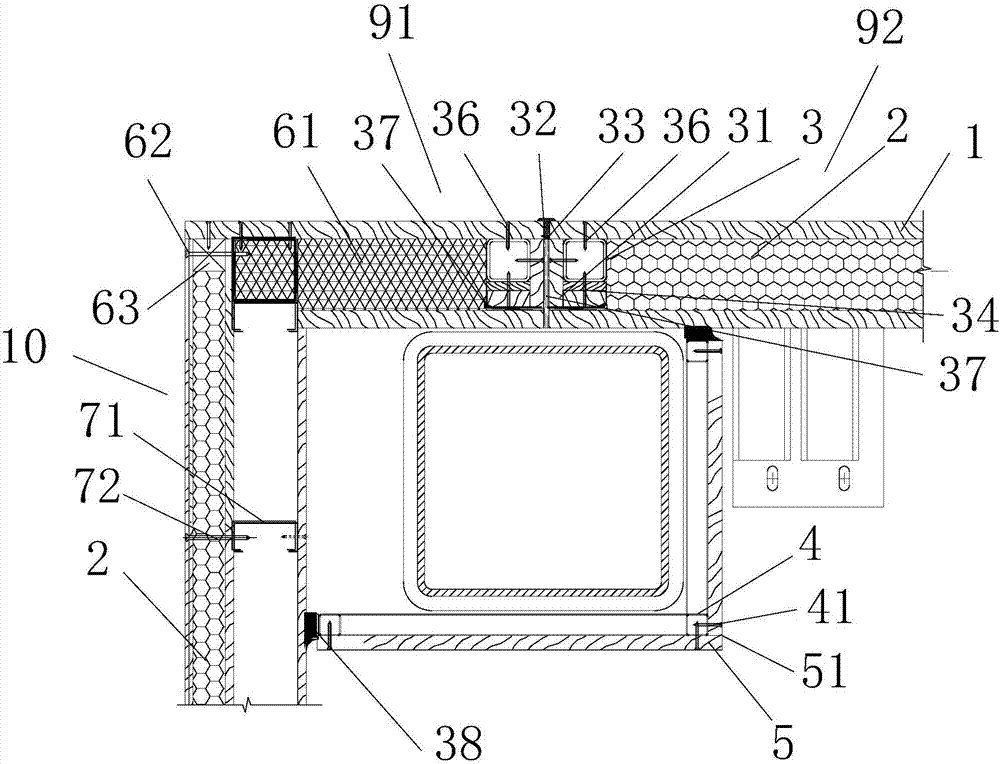

Wall structure with no cold bridge

The invention discloses a wall structure with no cold bridge. The wall structure comprises a first wall module and a second wall module. The two wall modules each comprise panels on the two sides and a heat preservation layer arranged on the inner sides of the panels. The end of each wall module is provided with an outer wall keel steel pipe. The upper sides of the outer wall keel steel pipes make contact with the panels on the upper layers of the wall modules. One side and the lower portion of each outer wall keel steel pipe is each provided with a structural plate. The seam between every two adjacent structural plates of the two outer wall keel steel pipes is filled with a polyethylene foam slat, an elastic sealant and a rubber strip from top to bottom. According to the wall structure, by arranging the rubber strips and the elastic sealants at the butt joint seams of outer wallboards, water and dust are effectively prevented from entering, and the anti-corrosion and cleaning effects are achieved for protecting internal steel components, so that a heat preservation structure integrated board achieves the purposes of mechanical and durable qualification, fire prevention, heat preservation, energy saving, environmental protection and safe and reliable mounting process.

Owner:HEBEI ZHUOQIU IND CO LTD

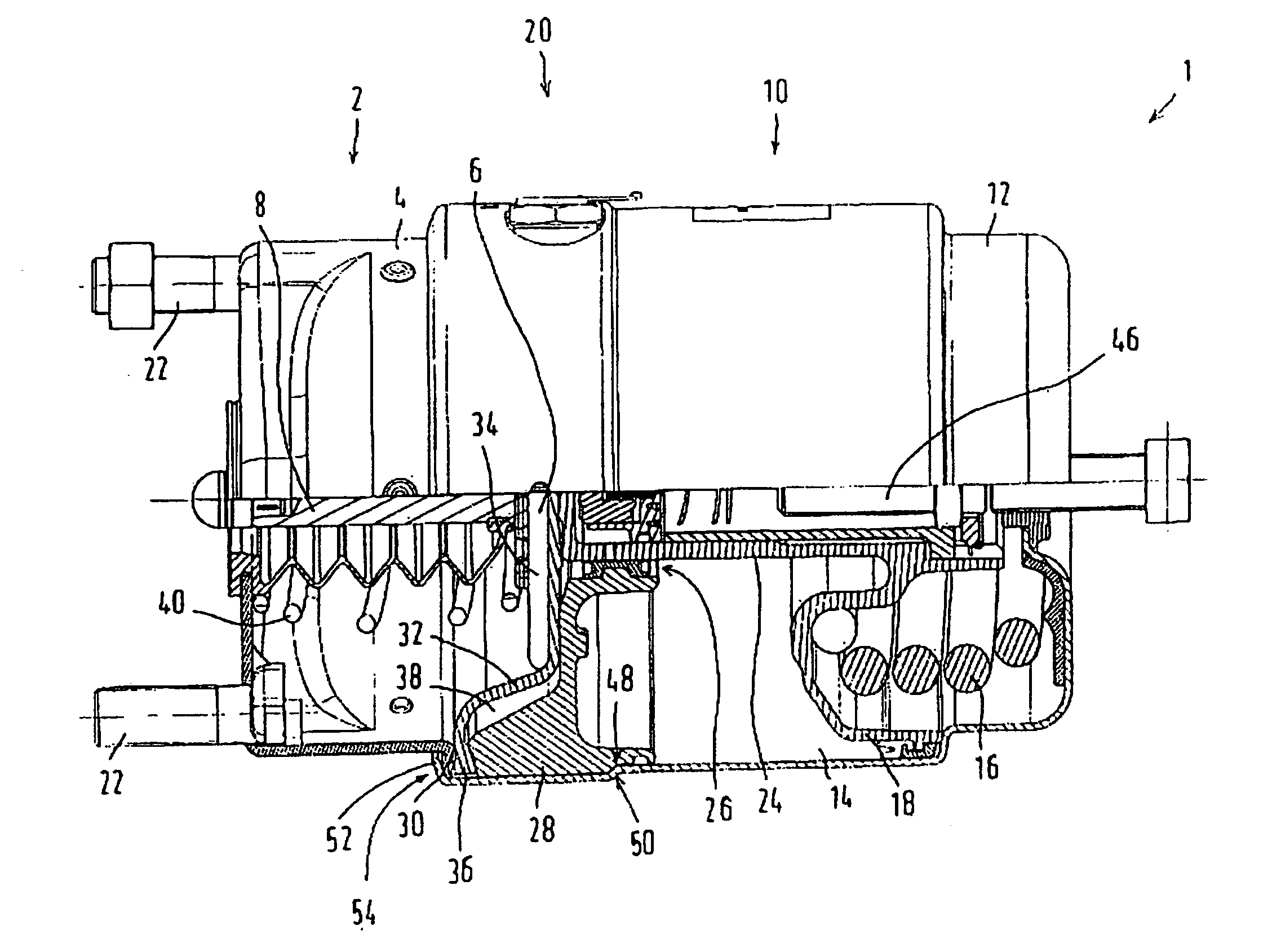

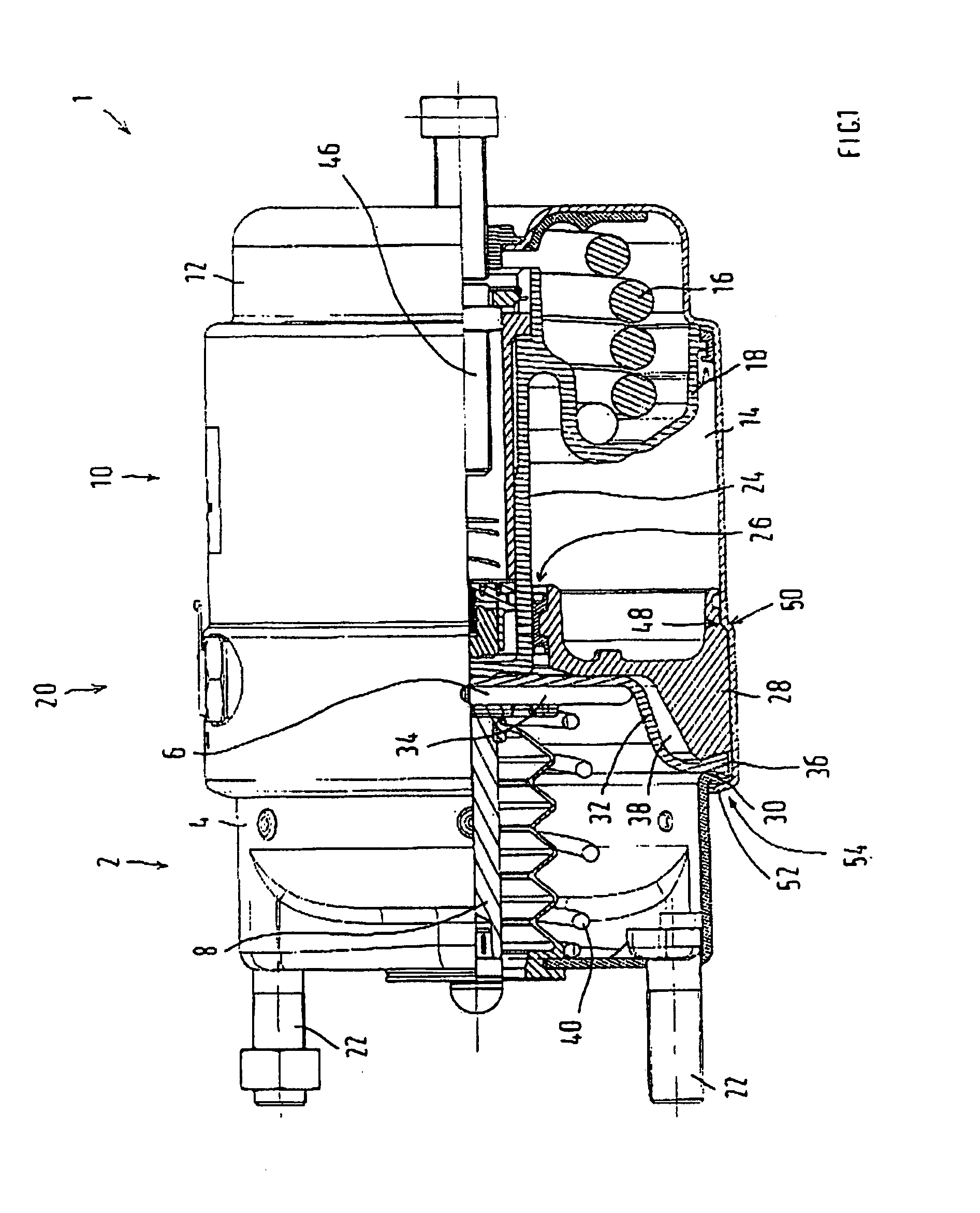

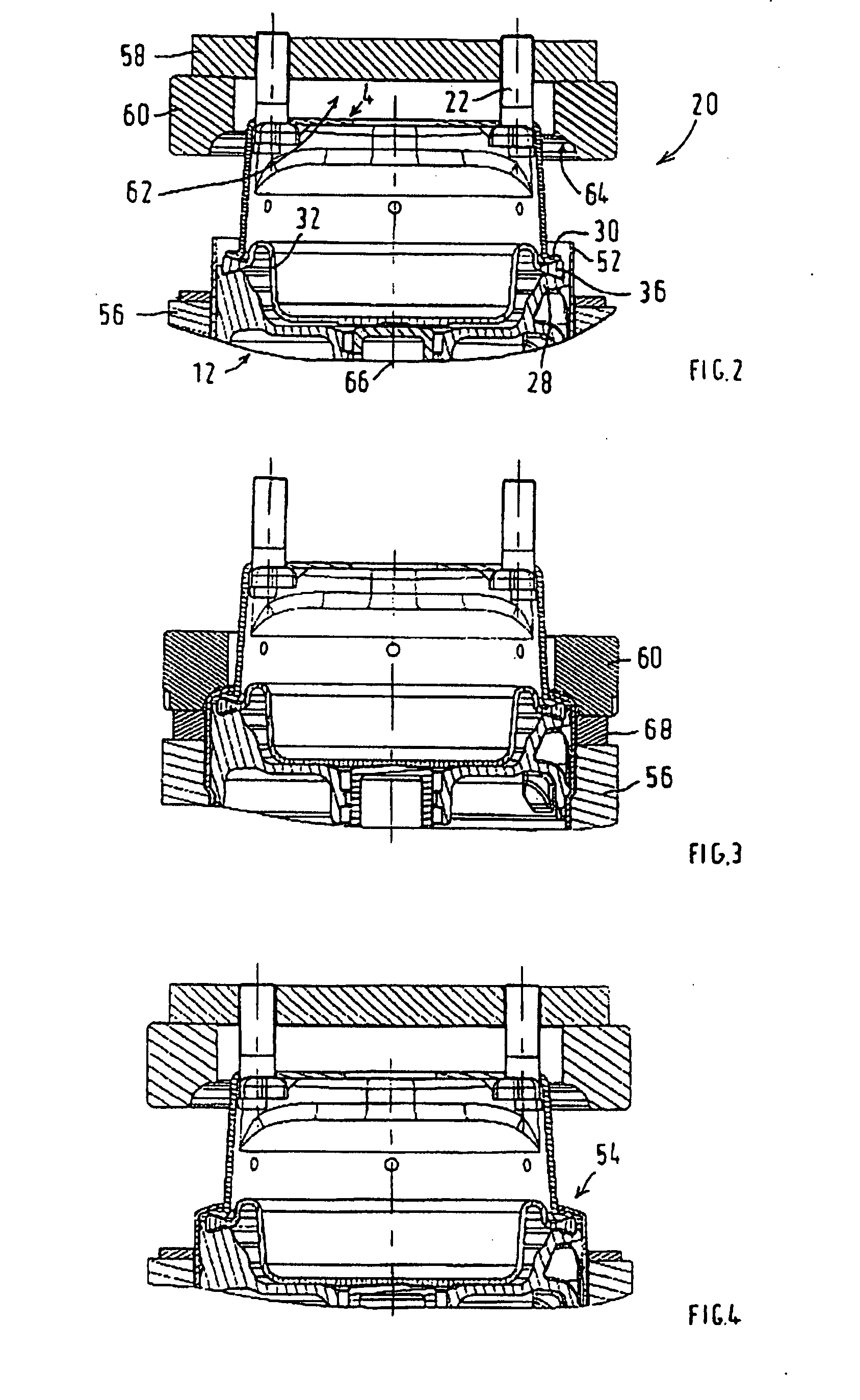

Method for manufacturing steel housings, composed of at least two housing components, for assemblies installed in vehicles

ActiveUS20080034570A1No damageWell barrier effectRopes and cables for vehicles/pulleyCouplings for rigid shaftsIn vehicleCorrosion prevention

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

Ceramic coating material with characteristics of high-temperature resistance, high blackness, coking resistance and corrosion resistance

InactiveCN108299870AImprove stabilityNon-volatileAnti-corrosive paintsCeramic coatingTitanium nitride

The invention discloses a ceramic coating material with characteristics of high-temperature resistance, high blackness, coking resistance and corrosion resistance, wherein the ceramic coating materialcomprises a binder, a filler, an auxiliary agent and water, the binder comprises, by mass, 7-15% of silica sol, 5-7% of styrene-acrylic emulsion, 1-3% of sodium oxide, and 3-5% of alumina monohydrate, and the filler comprises, by mass, 2-5% of zirconia, 1-3% of iron oxide red, 1-3% of silicon nitride, 0.2-0.5% of titanium nitride, 1-3% of magnesium oxide, 3-6% of chromium oxide, 1% of alumina, 0.5-1% of copper oxide, 5-7% of kaolin, 1.9-2.5% of mica powder, 0.5-0.7% of sodium-based bentonite, 1-3% of cerium oxide, 1-3% of neodymium oxide, 1-3% of lanthanum oxide, 1-3% of yttrium oxide, 0.2-0.4% of molybdenum oxide, and 1-3% of niobium oxide.

Owner:甘肃华鑫石化科技有限公司

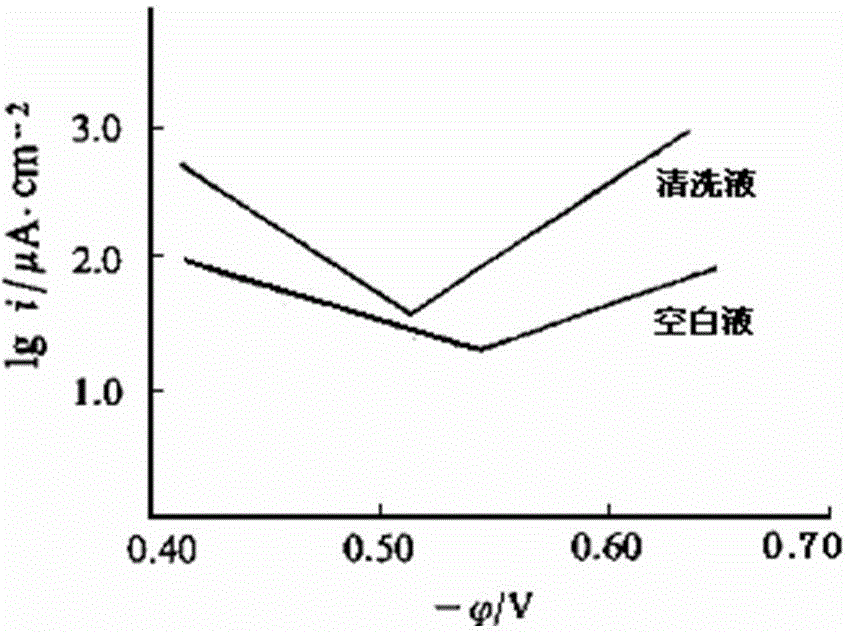

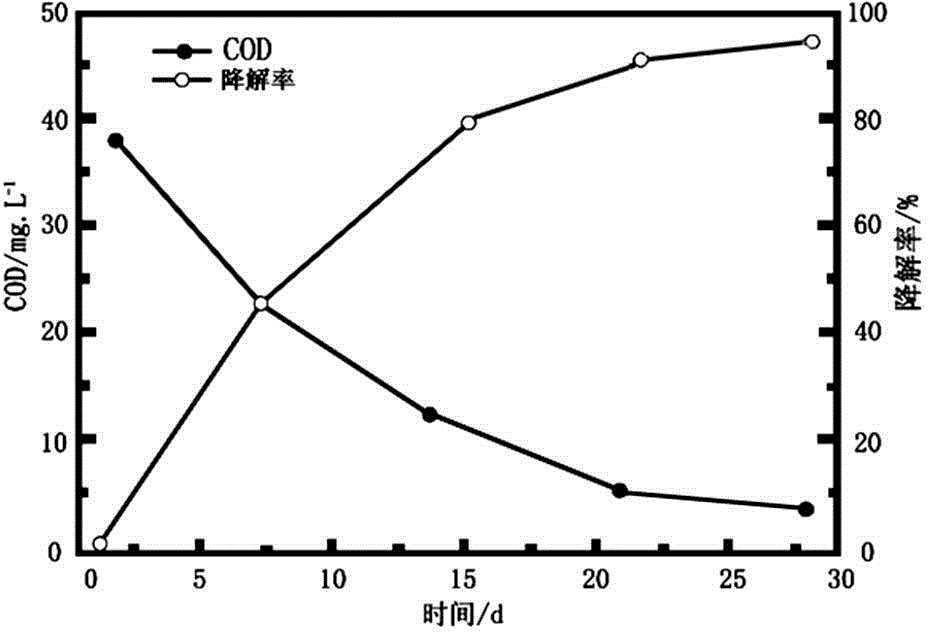

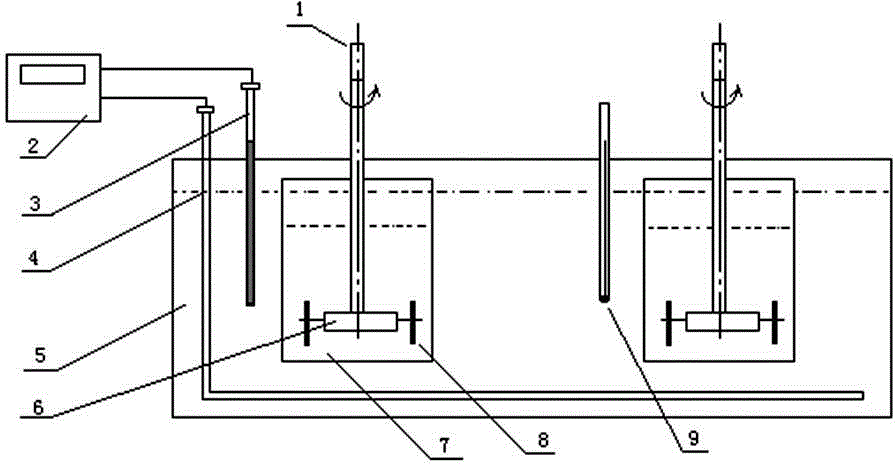

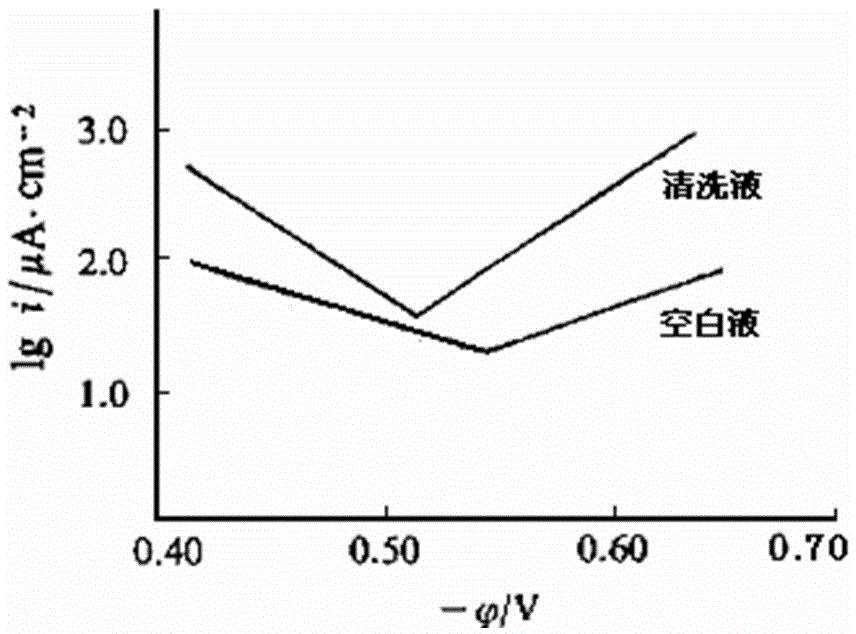

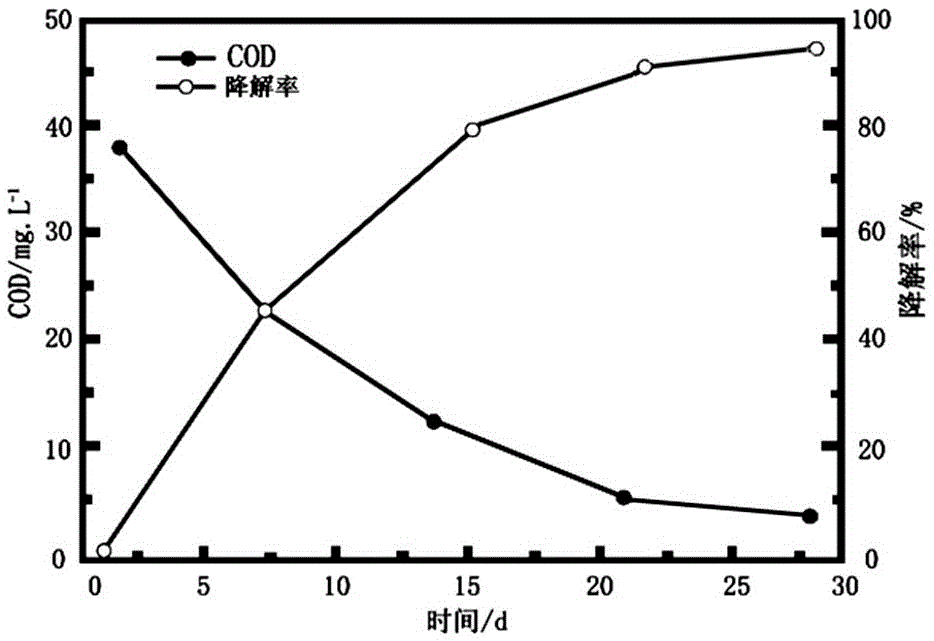

Silt stripping method for circulating cooling water system

ActiveCN101985125AProtection against corrosionReduce corrosionOrganic detergent compounding agentsSurface-active detergent compositionsTurbidityPeak value

The invention discloses a silt stripping method for a circulating cooling water system, which comprises the following steps of: preparing a silt stripping auxiliary agent by using sodium dodecyl benzene sulfonate, triethanolamine, polydimethyl silicon ether, sodium polyacrylate and water, adding the silt stripping auxiliary agent into cooling water in a ratio of 400 to 500mg / L for one-time circulation, adding a strong oxidizing agent into the normal circulating cooling water in a ratio of 2,000 to 3,000mg / L, and injecting clear water into the cooling water while circulating when the turbidity reaches a peak value to displace suspended matters in the cooling water. The consumption of the strong oxidizing agent is relatively reduced by 40 to 60 percent, the washing rate reaches over 99 percent, and the service life of the circulating cooling water system is prolonged, so the silt stripping method for the circulating cooling water system has the advantages of low strong oxidizing agent consumption, low metal pipeline corrosion, high washing rate, safe system operation and capability of prolonging the service life of the system.

Owner:浙江川宁环保科技有限公司

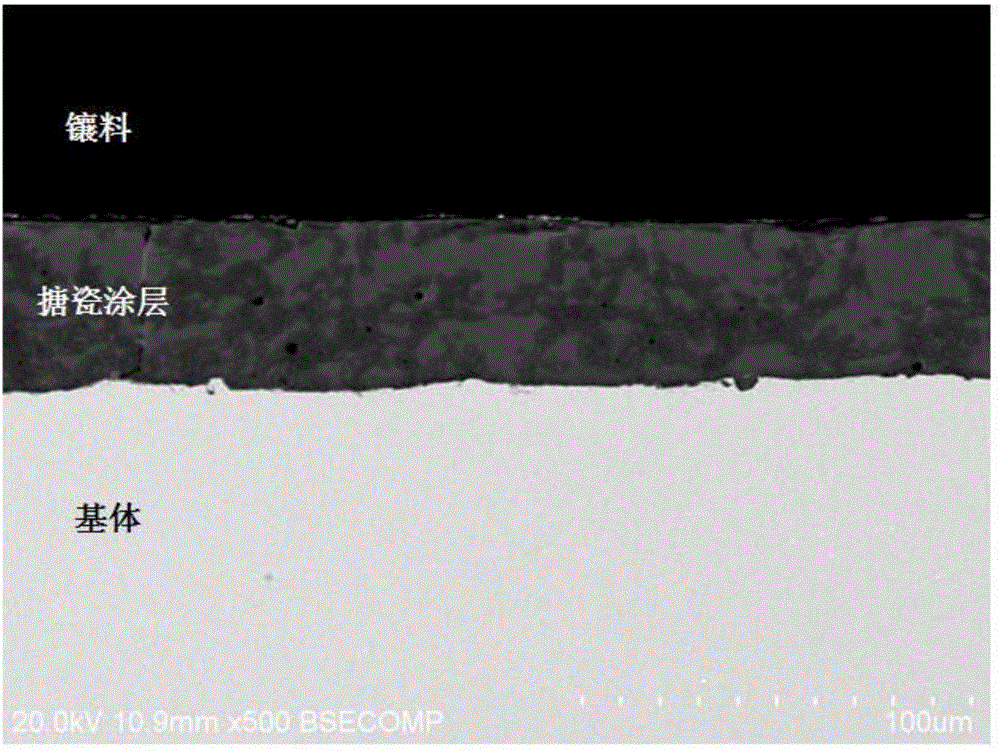

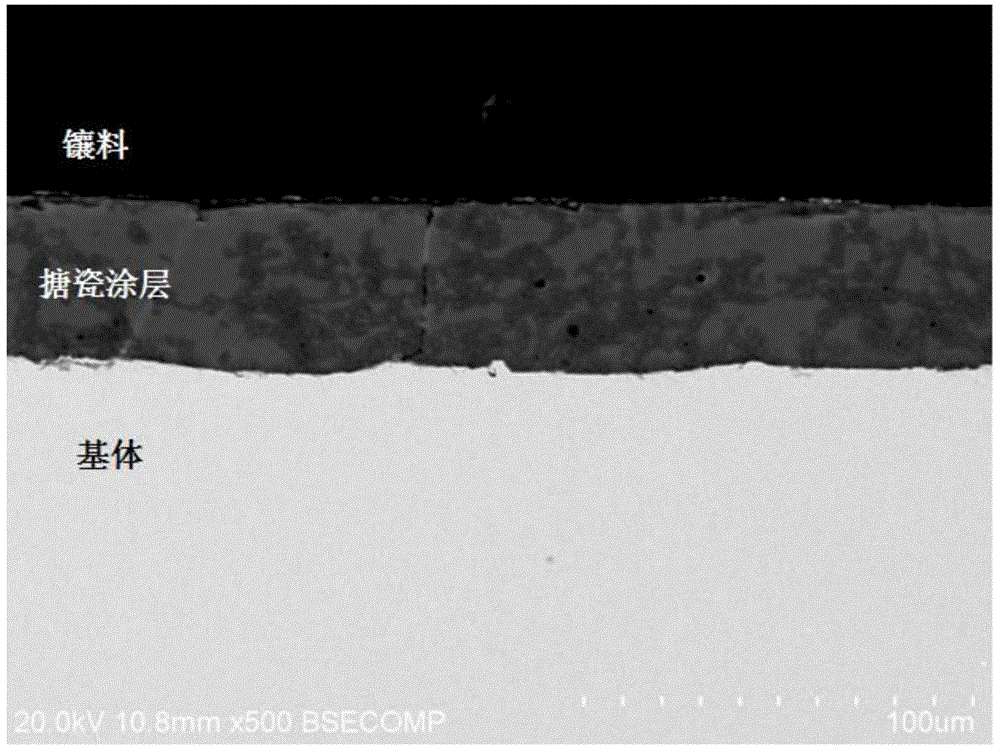

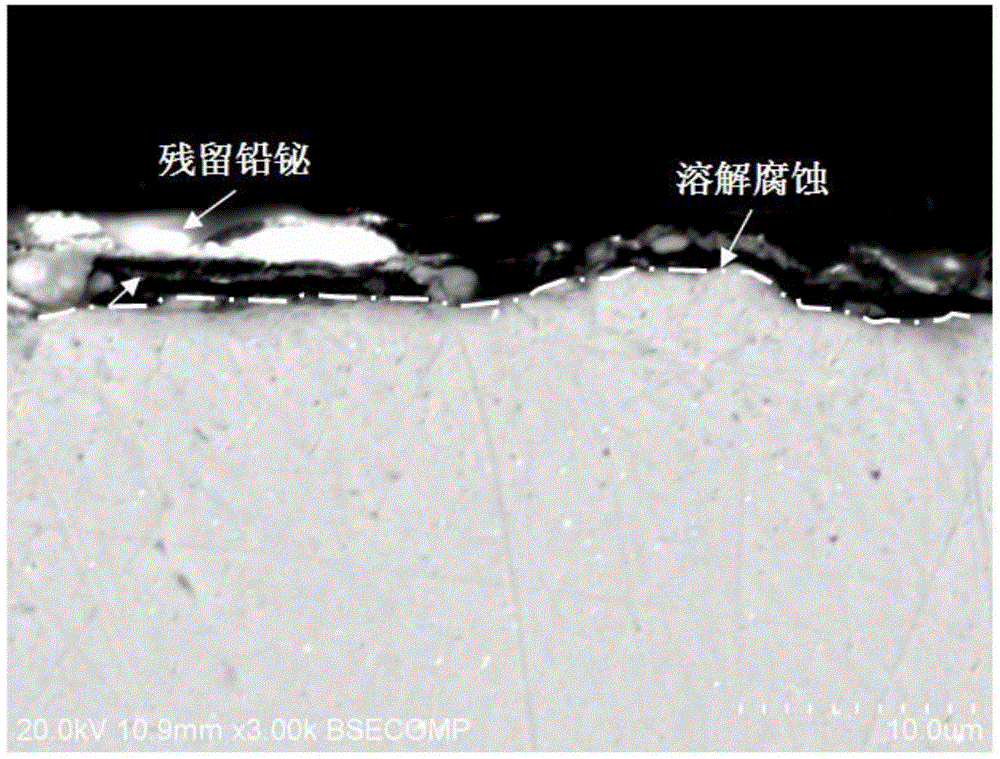

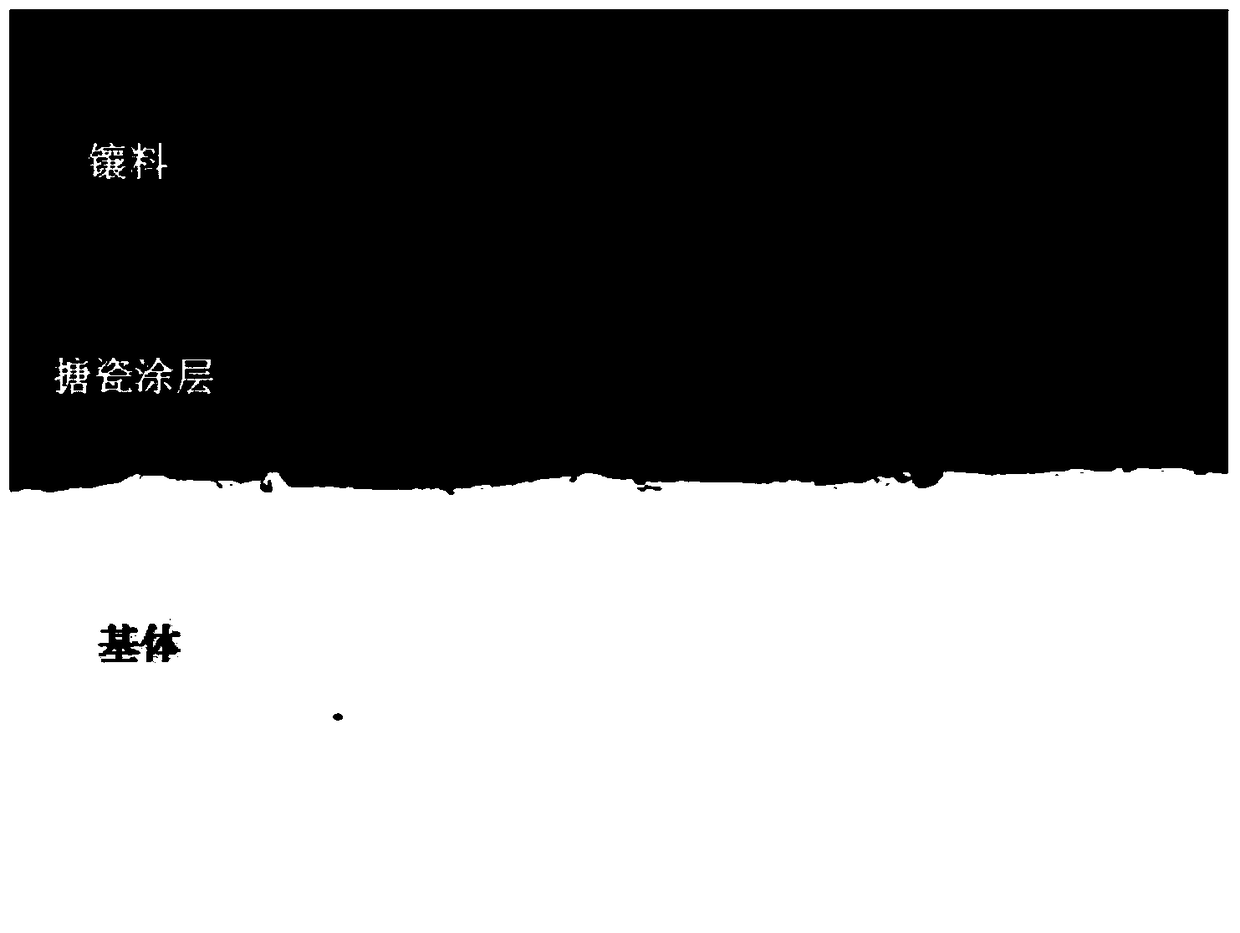

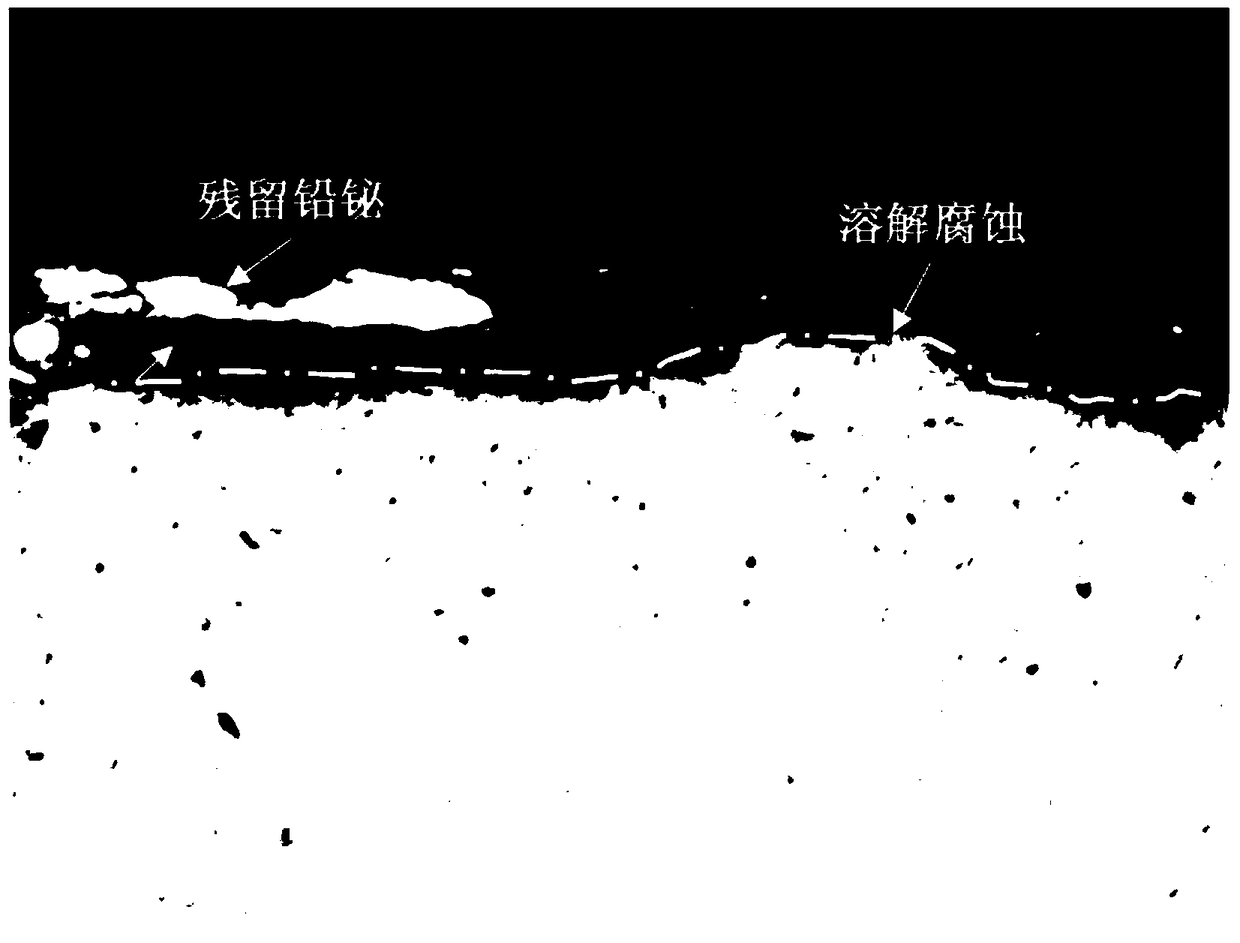

Method for improving resistance of martensite heat-resistant steel to liquid metal corrosion

ActiveCN105386051AImprove liquid metal corrosion resistanceExtended service lifeLiquid metalMartensite

The invention aims at providing a method for improving resistance of martensite heat-resistant steel to liquid metal corrosion. The method is characterized in that an enamel powder layer is sprayed to the surface of the martensite heat-resistant steel, and an enamel coating is prepared after a curing reaction is made. The surface of the martensite heat-resistant steel is treated through the method, the liquid metal corrosion resistance of metal can be effectively improved, and the service life of a metal material is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Stainless steel cladding steel plate and manufacturing method thereof

PendingCN112318964AImprove corrosion resistanceImprove integrityMetal rolling arrangementsMetal layered productsMetallurgySS - Stainless steel

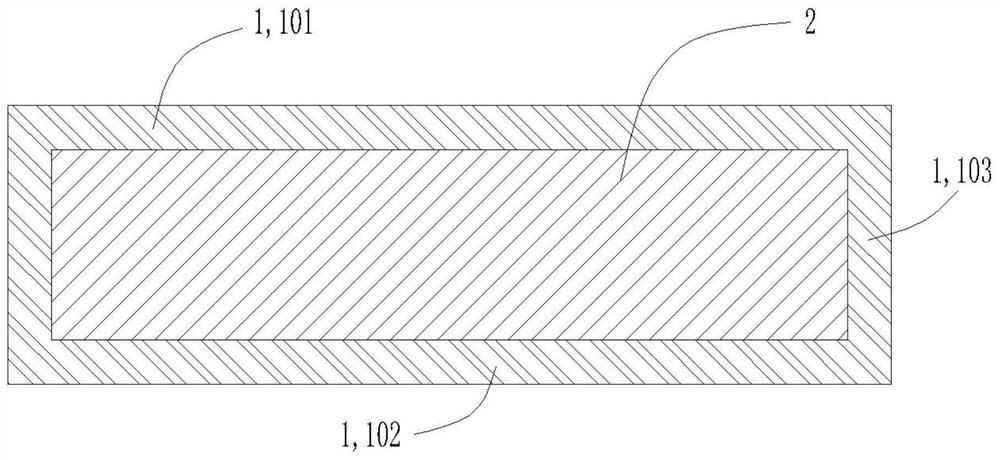

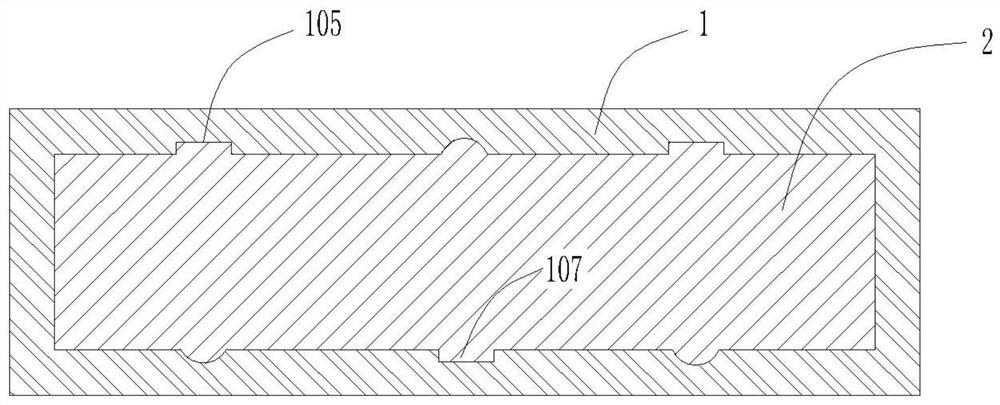

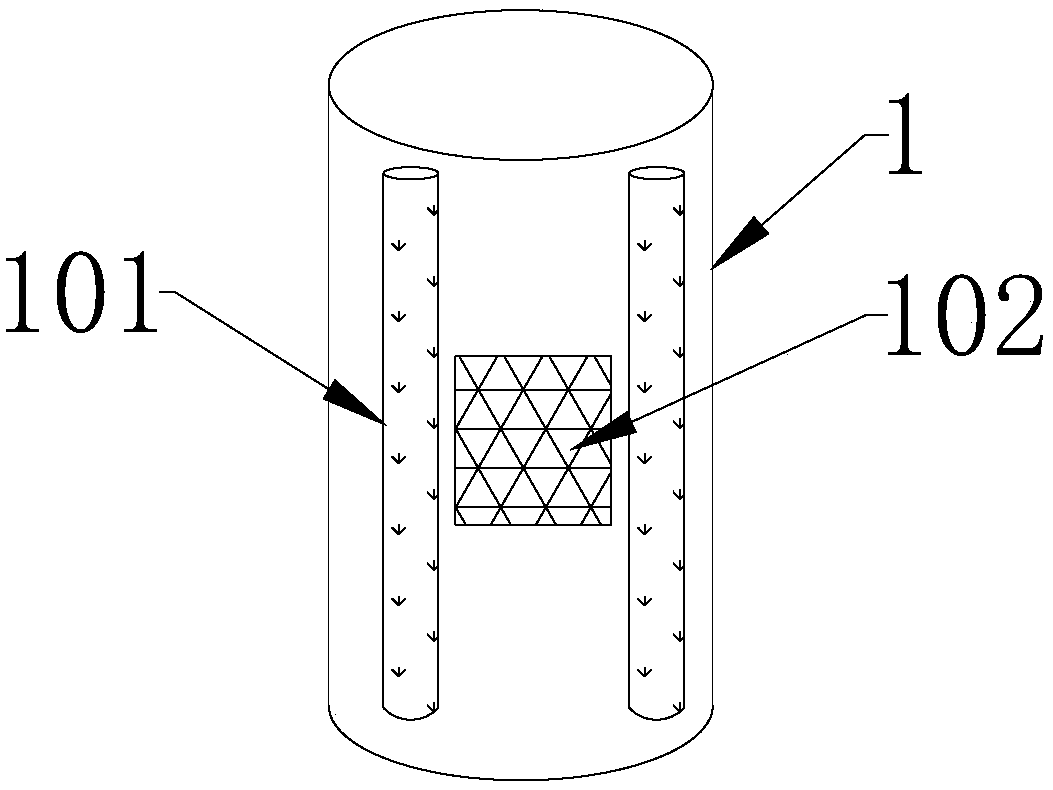

The invention discloses a stainless steel cladding steel plate which comprises an outer stainless steel layer (1) and an inner steel core layer (2); the outer stainless steel layer (1) wraps the periphery of the inner steel core layer (2), the outer stainless steel layer (1) and the inner steel core layer (2) are formed through hot rolling bonding, and metallurgical bonding is formed between the outer stainless steel layer (1) and the inner steel core layer (2). The outer stainless steel layer (1) comprises a stainless steel upper layer (101), a stainless steel lower layer (102) and a stainless steel side wall layer (103), and the ratio of the thickness of the stainless steel upper layer (101) to the thickness of the inner steel core layer (2) is 1:(1.5-50). The corrosion resistance of thestainless steel cladding steel plate is greatly improved, except the joint parts of the two ends of the stainless steel cladding steel plate and other components, the stainless steel cladding steel plate is coated with stainless steel in the upper, lower, front and rear directions, so that the internal inner steel core layer is strictly protected, and the inner steel core layer is not corroded due to contact with the outside or a third medium. The invention further discloses a manufacturing method of the stainless steel cladding steel plate.

Owner:HUNAN 3T NEW MATERIAL

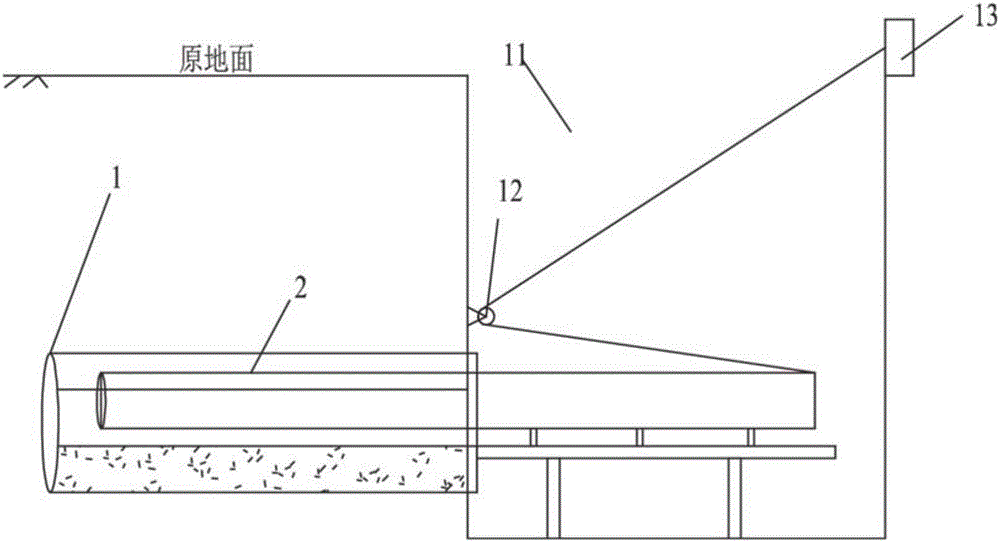

Water application pipeline laying facility

InactiveCN106764052AReduce frictionAvoid damage and deformationPipe laying and repairPipesEngineeringRetaining wall

The invention relates to the technical field of pipeline laying and provides water application pipeline laying facility which comprises a first water retaining wall mounted at an entrance port of a sleeve, wherein a pipeline-through hole for penetrating into a pipeline is formed in the first water retaining wall. When the water application pipeline laying facility is applied to pipeline laying, after the end part of the to-be-laid pipeline penetrates into the pipeline-through hole in the first water retaining wall, liquid can be injected into a liquid accommodating chamber. At the moment, the pipeline entering the sleeve undergoes vertical upward buoyancy, then the acting force for a pipeline laying process is reduced, the requirements on the laying equipment as well as the operation complexity are lowered, the construction safety and laying speed are improved, and the pipeline is laid in place for sure. Moreover, since a support member is mounted in advance and then drives the pipeline to enter the sleeve, the damage and deformation of the support member can be prevented; meanwhile, the frictional resistance against the pipeline is reduced under the buoyancy, and thus the pipeline is effectively protected from outer corrosion.

Owner:BEIJING MUNICIPAL BRIDGE MAINTENANCE MANAGEMENT +1

Extended operation engine coolant composition

The invention relates to an engine coolant composition, and a method of increasing the operational life of a coolant composition in an engine, wherein an isononanoic acid is incorporated into the generally glycol based coolant fluid in place of nitrous acid or its salt to reduce pitting corrosion on iron containing surfaces.

Owner:VGP IPCO LLC

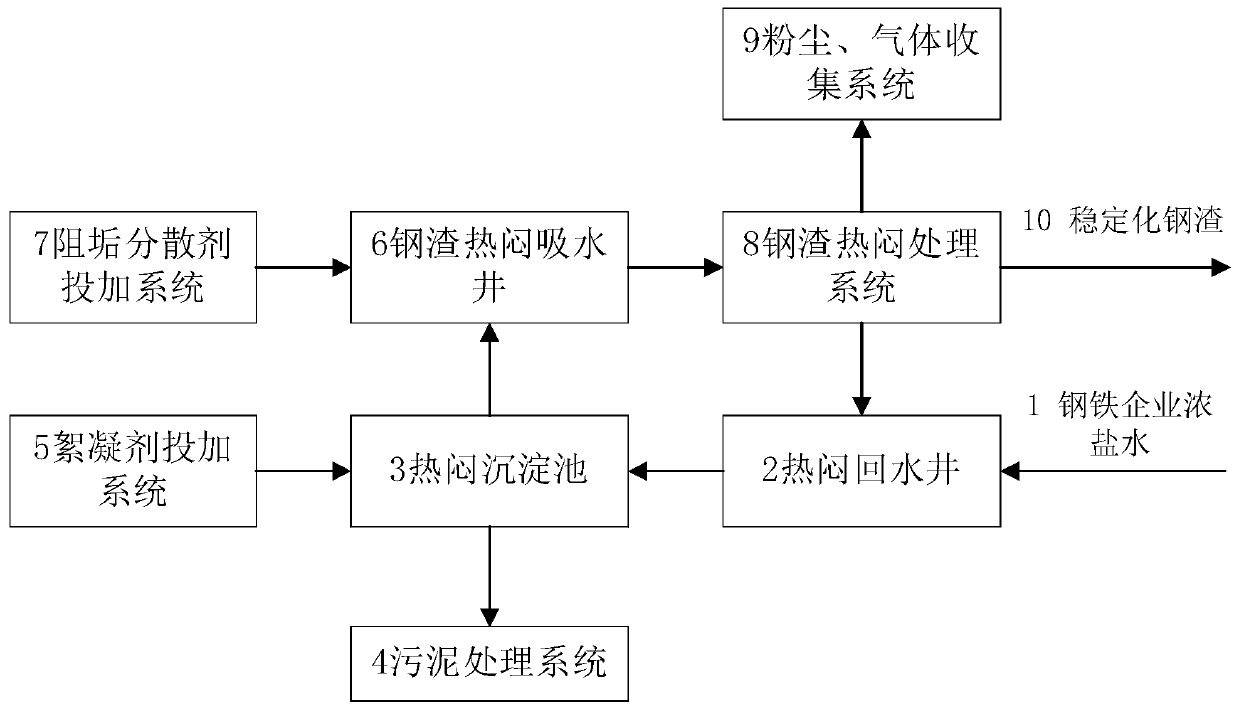

Device for recycling strong brine for steel slag hot-disintegration treatment and treatment method

ActiveCN111500803AProtection against corrosionAvoid secondary pollutionSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processProduction lineWater use

The invention relates to a device for recycling strong brine for steel slag hot-disintegration treatment and a treatment method, and belongs to the technical field of environmental protection. The strong brine of an iron and steel enterprise is directly conveyed to the steel slag hot-disintegration water return well through a centrifugal pump, reacts with hot-disintegration water return alkali liquor and then is lifted by a slurry pump to enter a hot-disintegration settling pond to be quickly settled, supernate automatically flows into a steel slag hot-disintegration water suction well, and sludge in the settling pond enters a secondary steel slag treatment production line after being concentrated and dehydrated. A scale inhibition and dispersion agent is added into the hot-disintegrationwater suction well to prevent a hot-disintegration water system from scaling, and dust and steam generated in the steel slag hot-disintegration process are collected through a gas collecting hood to be treated. According to the device and the treatment method, the iron and steel enterprise can treat the strong brine with the lowest cost, and the strong brine is consumed.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

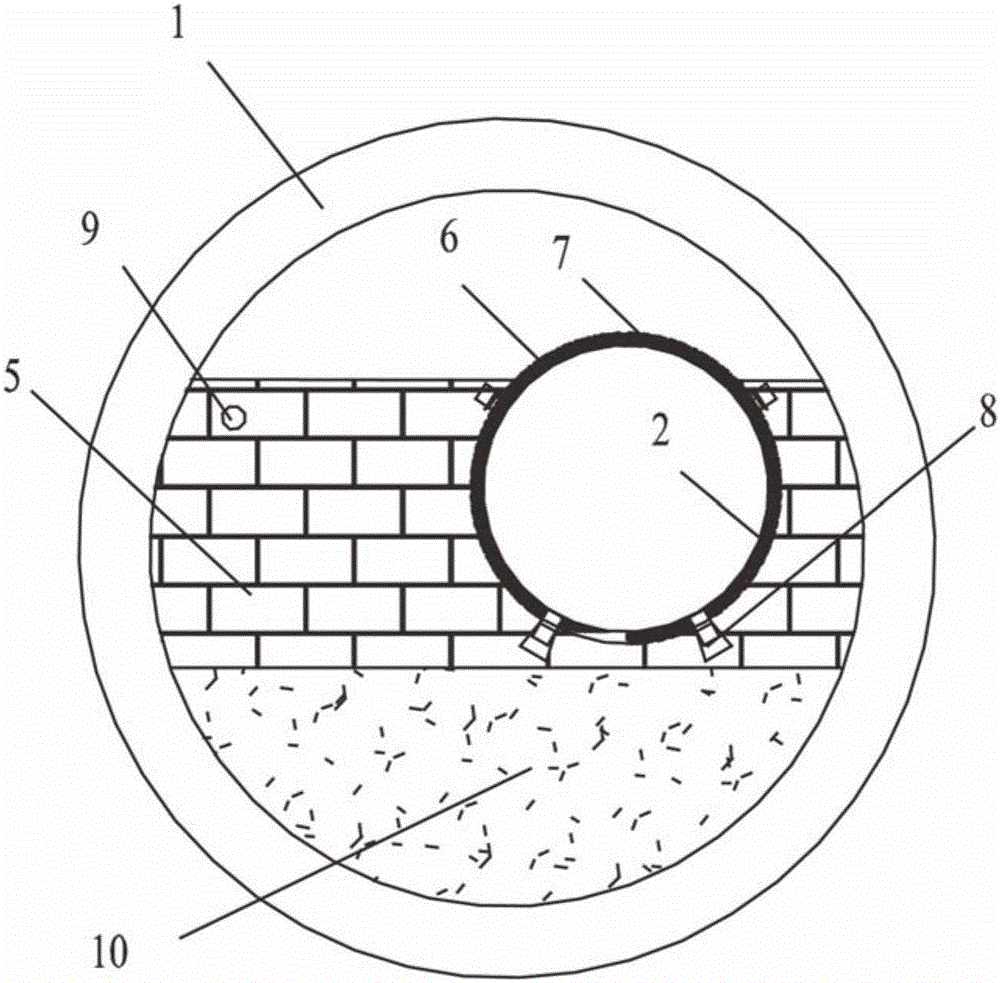

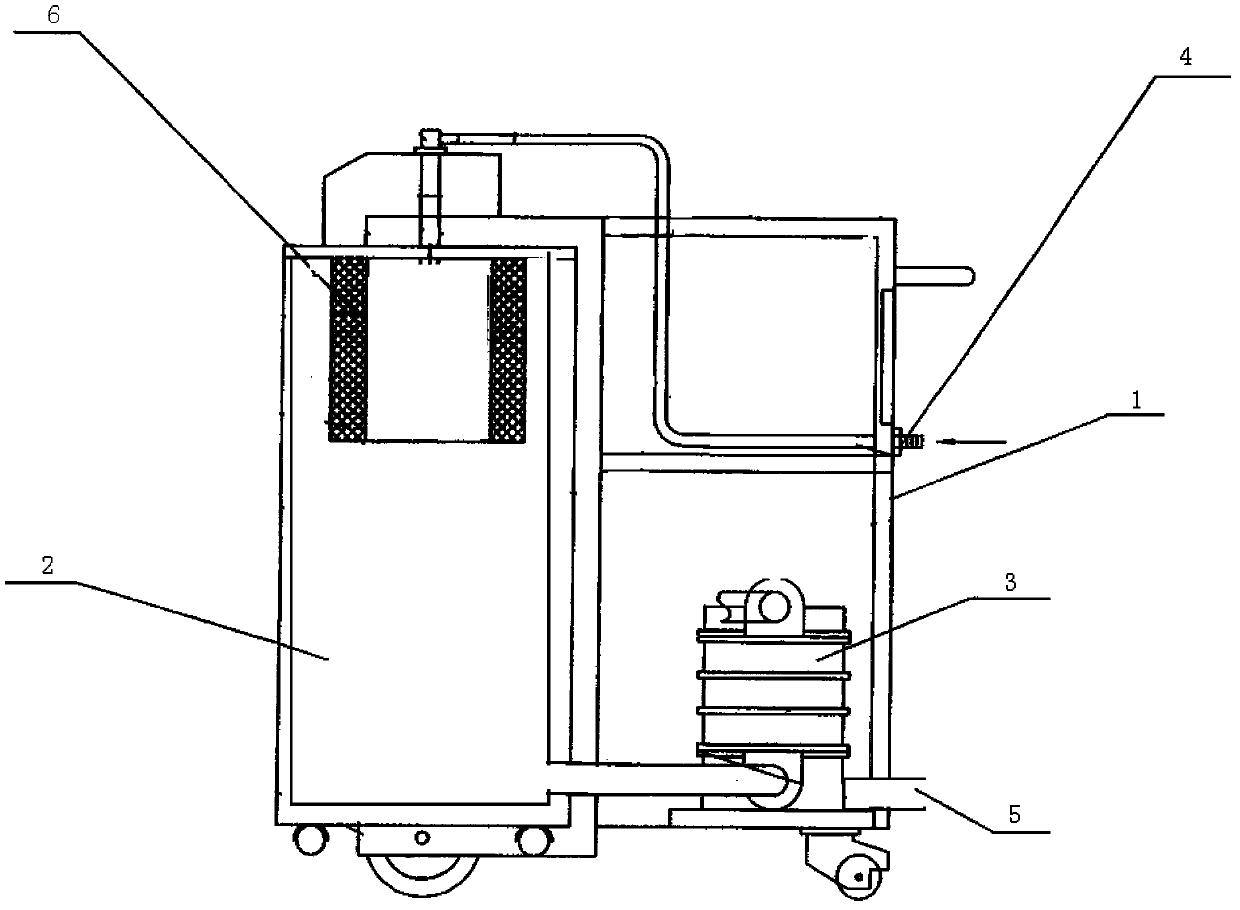

High temperature dust collector

InactiveCN103387326AHigh temperature resistantEasy to cleanGlass furnace apparatusEngineeringTemperature resistance

The invention provided with a high temperature dust collector. The high temperature dust collector comprises a body (1) and an air chamber (2) arranged in the body (1), a fan (3), an air inlet pipe (4), an air outlet pipe (5) and a metal screen (6), wherein the air inlet pipe (4), the air chamber (2), the fan (3) and the air outlet pipe (5) are successively connected, and the metal screen (6) is arranged between the air inlet pipe (4) and an air inlet of the air chamber (2). The high temperature dust collector provided by the invention has the characteristics that a filter bag which is made of a metal material is adopted to replace the traditional filter bag, the high temperature dust collector is high temperature resistance and is easy to clean, and the application range is wide.

Owner:HUAERRUN GLASS IND

Preparation method of core-shell ceramsite fracturing propping agent for oil and gas collection

ActiveCN114349475ALow densityImprove stress resistanceFluid removalDrilling compositionIron powderSludge

The invention relates to a preparation method of a core-shell type ceramsite fracturing propping agent for oil and gas collection, which comprises the following steps: (1) grinding municipal sludge containing organic matters into powder, and then granulating and drying to obtain a core precursor; (2) uniformly mixing clay and scrap iron powder, then adding water, and uniformly stirring, so as to obtain inner coating layer slurry; and (3) mixing clay and water, and uniformly stirring to obtain the outer coating layer slurry. And (4) immersing the inner core precursor into inner coating layer slurry to uniformly coat the outer surface of the inner core precursor, then taking out the inner core precursor, drying, then immersing the obtained particles into outer coating layer slurry again to uniformly coat the outer surface of the inner core precursor, then taking out the particles, drying, uniformly placing the particles, and then calcining to obtain the composite material. The ceramsite fracturing propping agent is obtained after completion. The core-shell type fracturing propping agent disclosed by the invention is low in density and has good compression resistance, and the purposes of reducing the density of the fracturing propping agent and keeping the good compression resistance of the fracturing propping agent are achieved.

Owner:SHENGLI OILFIELD FANGYUAN CERAMIC IND CO LTD

Cleaning agent, cleaning liquid and cleaning method for stainless steel equipment

The invention relates to a stainless steel equipment cleaning agent. The stainless steel equipment cleaning agent comprises the following effective components in parts by weight: 5-8 parts of polyglycolic acid, 7-10 parts of biochemical fulvic acid and 2-5 parts of amino acetic acid, wherein water is added for complementing into 100 parts, so that a cleaning solution can be prepared. A method for cleaning stainless steel equipment by utilizing the cleaning agent comprises the following steps: (1) preparing raw materials: weighing the following components in parts by weight: 5-8 parts of polyglycolic acid, 7-10 parts of biochemical fulvic acid, 2-5 parts of amino acetic acid and balance of water, wherein the total parts by weight of polyglycolic acid, biochemical fulvic acid, amino acetic acid and water is 100 parts; (2) taking two thirds of water and heating to 50 minus or plus 5 DEG C, adding amino acetic acid and uniformly stirring, adding biochemical fulvic acid, and stirring for dissolution, so that a solution A is obtained; (3) taking the rest of water, adding polyglycolic acid, and stirring for dissolution, so that a solution B is obtained; (4) introducing the solution A into equipment to be cleaned and circulating for 5-10 minutes, and then introducing the solution B and carrying out circulation cleaning. The stainless steel equipment cleaning agent has few components, is environment-friendly and produces less corrosion to the equipment, and descaling rate is more than 98%.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

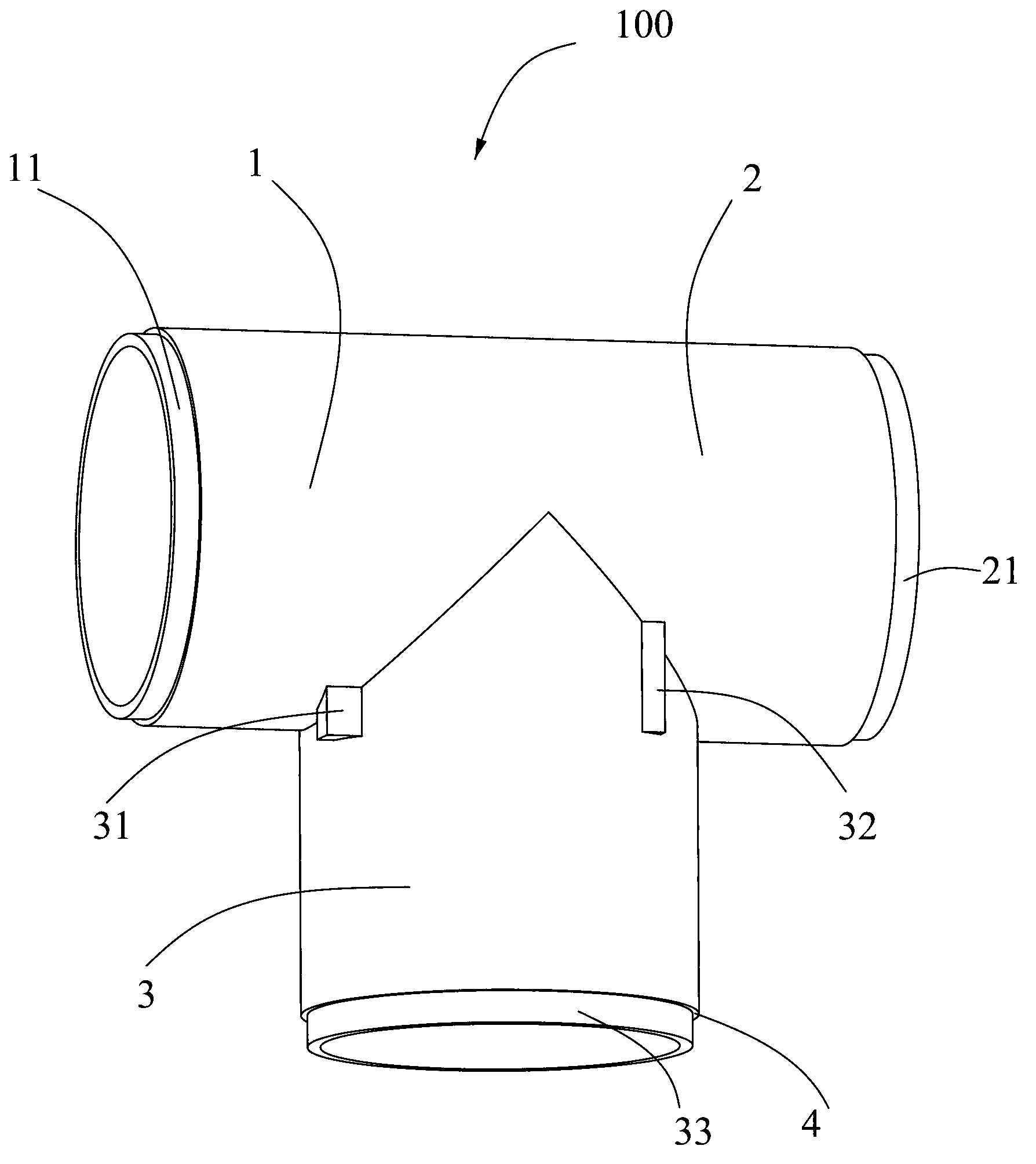

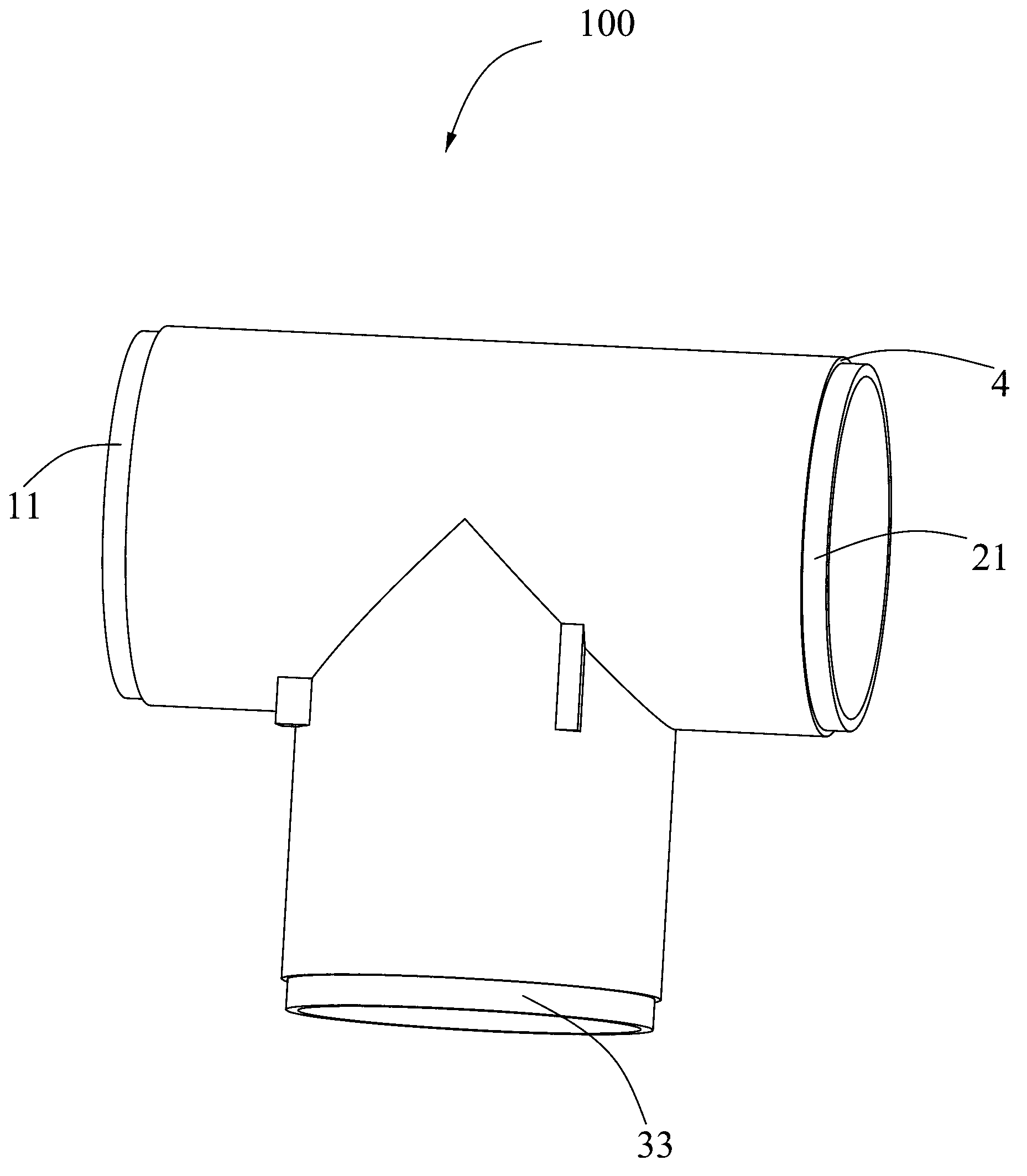

Steel pipe

InactiveCN103322358AProtection against corrosionLow costCorrosion preventionPipe protection against corrosion/incrustationArchitectural engineeringSteel tube

A steel pipe comprises a first through pipe, a second through pipe and a third through pipe. The first through pipe and the second through pipe are arranged on the same horizontal line, the first through pipe and the second through pipe are arranged at two ends of the third through pipe respectively, an axial lead of the first through pipe and an axial lead of the second through pipe are the same line, an axial lead of the third through pipe is perpendicular to the axial lead of the first through pipe, and paint is sprayed on the outer lateral walls of the first through pipe, the second through pipe and the third through pipe. By spraying paint at low cost on the outer lateral walls of the first through pipe, the second through pipe and the third through pipe evenly, the steel pipe is protected from corrosion, manufacturing cost is reduced, and the steel pipe is easy to manufacture.

Owner:NINGBO KINGMAYER GROUP CHIZHOU STEEL PIPE MFG

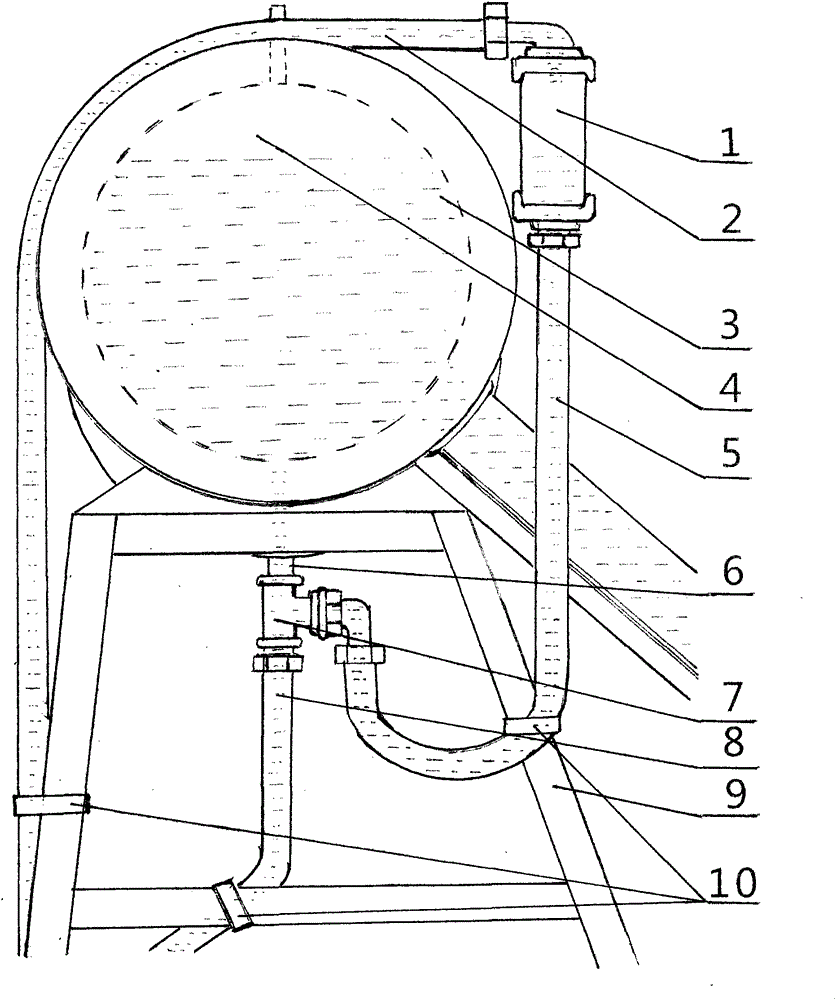

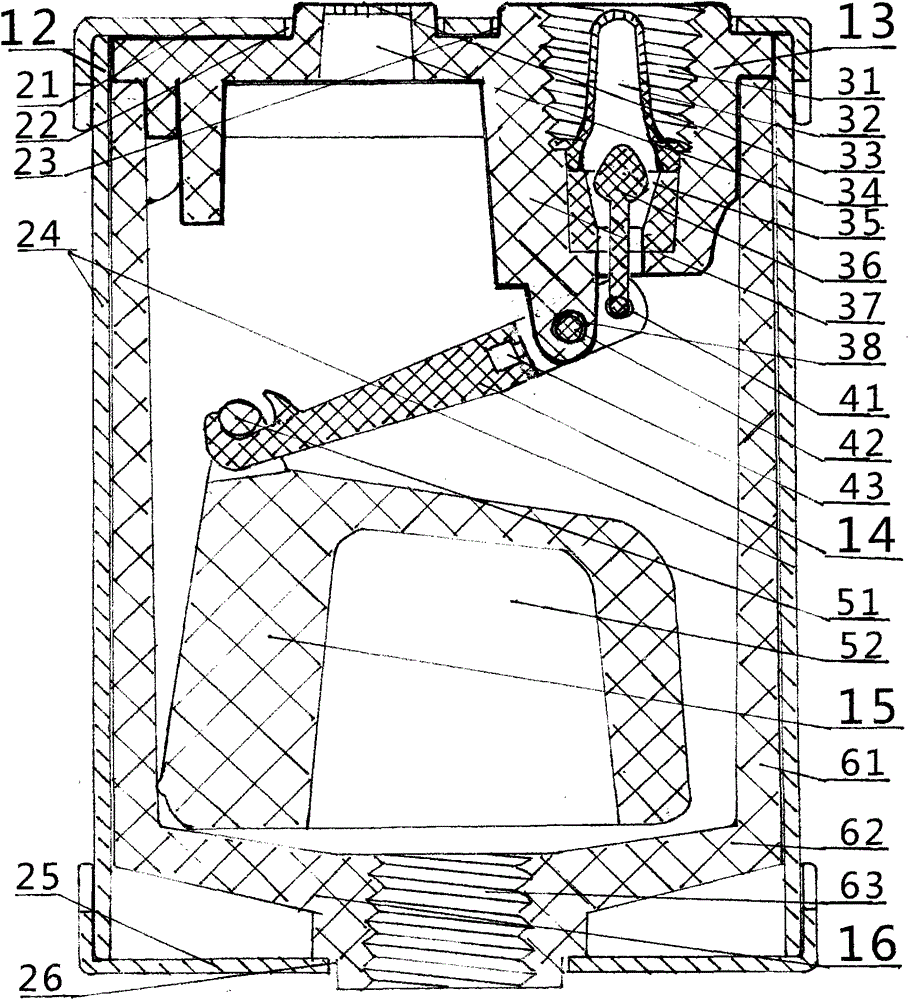

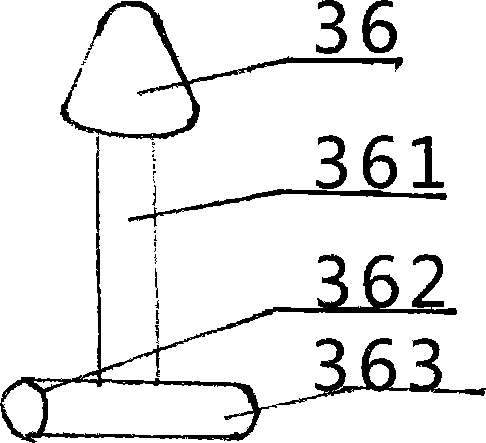

Overflow-free internally piloted valve

InactiveCN105090599ATransportation safetySafe installationSolar heating energyOperating means/releasing devices for valvesSolar waterEngineering

The invention provides an overflow-free internally piloted valve and an installation method. The overflow-free internally piloted valve is a liquid level internally piloted device. The overflow-free internally piloted valve is mainly characterized in that a protective cover is arranged outside the internally piloted valve for protection, the internally piloted valve is internally provided with a conic valve port and a valve plug, the valve is closed tightly through the pressure of tap water, and therefore the valve can be operated for a long time without deformation; the distance between a head hole of a valve handle and a rotary shaft is short and the lever effect is large; suspended matter is manufactured into a floating body and is heavy after being dewatered and capable of floating on water and free of expansion or deformation, and a large floating ball is not needed for closing the valve; and a filter net pipe and a filter net are arranged so as to prevent impurities and winged insects from entering the valve. Due to the fact that the internally piloted valve is accurately opened and closed and is durable and proper in shape, the internally piloted valve can be installed at the front portion, the rear portion, the left portion, the right portion, the outer side, the inner side, the near portion and the far portion of a solar water tank or other water tanks or heat storage devices, spaces are reserved for the water tanks and the heat storage devices, and liquid cannot overflow even when the liquid expands.

Owner:朱科锋

A preparation method of core-shell ceramsite fracturing proppant for oil and gas collection

ActiveCN114349475BLow densityImprove stress resistanceFluid removalDrilling compositionIron powderSludge

The invention relates to a preparation method of a core-shell ceramsite fracturing proppant for oil and gas collection, comprising: (1) pulverizing municipal sludge containing organic matter, then granulating and drying to obtain a core precursor. (2) Mix clay and scrap iron powder evenly, then add water and stir evenly to obtain inner coating layer slurry. (3) Mix the clay and water and stir evenly to obtain the outer coating layer slurry. (4) Immerse the core precursor in the inner coating layer slurry to make the outer surface uniform, then take out the inner core precursor to dry, and then immerse the obtained particles in the outer coating layer slurry to make the outer surface uniform Hang the slurry, then take out the particles and dry them. After the completion, arrange the particles evenly, and then calcinate. After the completion, the ceramsite fracturing proppant is obtained. The core-shell type fracturing proppant of the present invention not only has low density, but also has good compression resistance, and realizes the purpose of reducing the density of the fracturing proppant while maintaining its good compression resistance.

Owner:SHENGLI OILFIELD FANGYUAN CERAMIC IND CO LTD

Coating process of galvanized spray paint for submersible ship carrier

ActiveCN101698189BImprove adhesionMeet the needs of special environmental operationsHot-dipping/immersion processesPretreated surfacesLacquerSand blasting

The invention discloses a zinc-galvanizing and paint-spraying coating process for a submerged boat carrier, which comprises the following steps of: (1) sand blasting treatment for a base material; (2) hot zinc-galvanizing treatment; (3) roughening treatment for a zinc-galvanized layer; (4) spraying a base paint; and (5) spraying a finish paint. In the process, a workpiece is subjected to zinc galvanizing, and a zinc layer is an anode coating which has a function of electrochemical protection; by the hot zinc-galvanizing treatment for the base material, the corrosion resistance of the product is greatly improved; the sand blasting treatment for the base material before the zinc-galvanizing treatment, the natural cooling treatment after the zinc-galvanizing treatment and the sand blasting treatment before paint spraying respectively improve the adhesive force between the base material and the zinc layer, and between the zinc layer and the paint, and guarantee the surface quality; and the surface of the zinc-galvanized workpiece is sprayed with the antirust paint so as to effectively protect the base material, prevent rust and corrosion, prolong the service life and meet requirements on special working environment of the submerged boat carrier and other large-scale mechanical parts.

Owner:QINGTE GRP

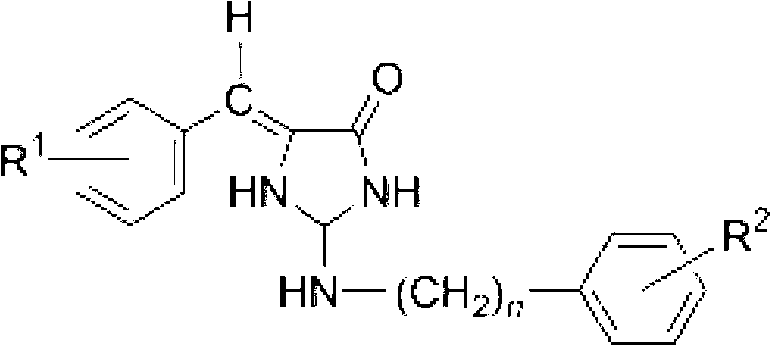

Anticorrosion hard film inhibiter for oil tube

InactiveCN102758206AImprove corrosion resistanceProtection against corrosionSalt resistanceCyclohexanone

The invention discloses an anticorrosion hard film inhibitor for an oil tube. The anticorrosion hard film inhibitor comprises components by weight percentage as follows: 1 to 5% of perchloro-ethylene resin, 15 to 30% of cyclohexanone, 20 to 40% of dimethylbenzene, 5 to 30% of p-phenylenediamine, 1 to 5% of sodium tungstate, and 1 to 10% of imidazoline derivative. The anticorrosion hard film inhibitor has high anticorrosion performance on protecting the oil tube in storing and transporting; and the salt spray resistance can last for 150 hours to the maximum; the hard film inhibitor is easy to remove; and the anticorrosion hard film inhibitor is simple in manufacture technology, convenient for construction, and low in production cost.

Owner:和盛包装科技(海宁)股份有限公司

Silt stripping method for circulating cooling water system

ActiveCN101985125BProtection against corrosionReduce corrosionOrganic detergent compounding agentsSurface-active detergent compositionsTurbidityPeak value

The invention discloses a silt stripping method for a circulating cooling water system, which comprises the following steps of: preparing a silt stripping auxiliary agent by using sodium dodecyl benzene sulfonate, triethanolamine, polydimethyl silicon ether, sodium polyacrylate and water, adding the silt stripping auxiliary agent into cooling water in a ratio of 400 to 500mg / L for one-time circulation, adding a strong oxidizing agent into the normal circulating cooling water in a ratio of 2,000 to 3,000mg / L, and injecting clear water into the cooling water while circulating when the turbidityreaches a peak value to displace suspended matters in the cooling water. The consumption of the strong oxidizing agent is relatively reduced by 40 to 60 percent, the washing rate reaches over 99 percent, and the service life of the circulating cooling water system is prolonged, so the silt stripping method for the circulating cooling water system has the advantages of low strong oxidizing agent consumption, low metal pipeline corrosion, high washing rate, safe system operation and capability of prolonging the service life of the system.

Owner:浙江川宁环保科技有限公司

Normal temperature spraying detergent for aluminum alloy and preparation method thereof

The invention relates to a normal temperature spraying detergent for aluminum alloy and a preparation method thereof. The detergent comprises the following raw materials in percentage by weight: 1 to 5 percent of ethylene diamine tetraacetic acid, 0.5 to 1.5 percent of sodium metasilicate pentahydrate, 5 to 8 percent of sodium gluconate, 5 to 10 percent of heterogeneous alcohol ether, 2 to 7 percent of solubilizing agent, 3 to 8 percent of surfactant, and the balance of water. The detergent can be used at normal temperature, and does not need heating so as to save the energy; the detergent does not corrode the treated aluminum alloy parts, does not leave white spots on the surfaces of the parts, and can increase the brightness of the parts; and the detergent has long service life and low using concentration, is safe and environment-friendly, saves the working time, and improves the working efficiency.

Owner:华阳新兴科技(天津)集团有限公司

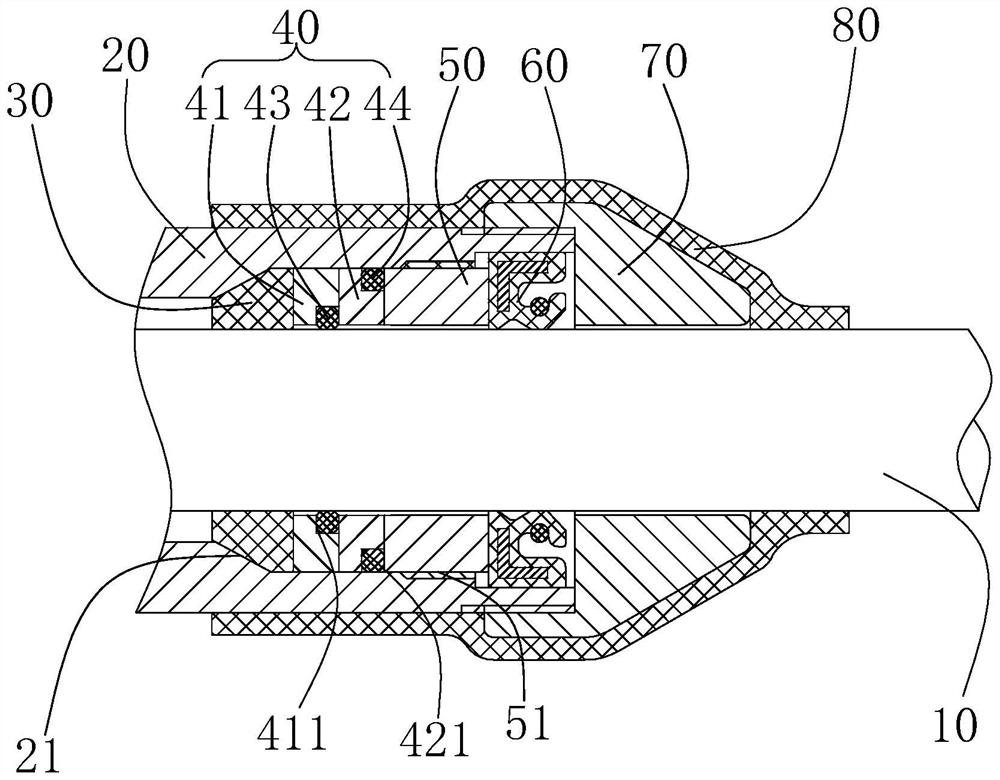

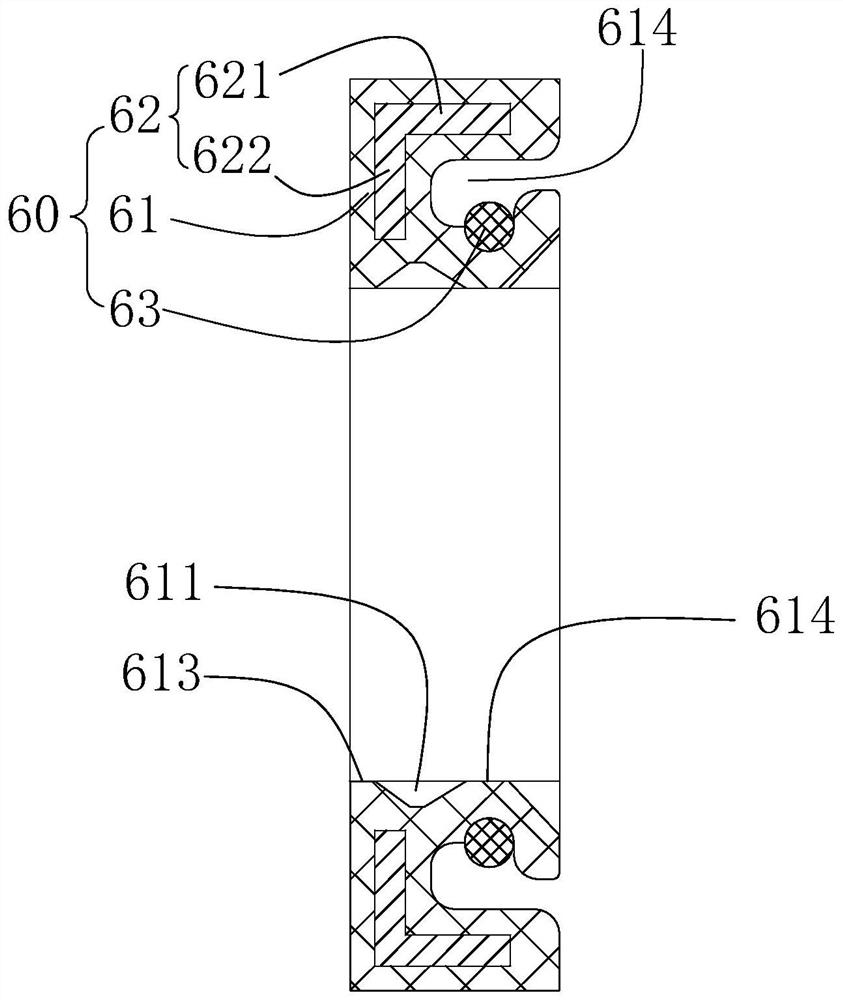

Inhaul cable end waterproof sealing device using framework spring sealing ring

PendingCN114135671AExtended service lifeExcellent organizational rigidityEngine sealsBridge structural detailsRubber ringEngineering

An inhaul cable end waterproof sealing device using a framework spring sealing ring comprises a rubber sealing ring arranged on an inhaul cable in a sleeving mode, a two-way groove pressing ring arranged on one side of the rubber sealing ring, a threaded pressing ring arranged on one side of the two-way groove pressing ring and a sealing ring arranged on the other side of the two-way groove pressing ring. And the framework spring sealing ring is arranged on one side of the threaded pressing ring. The framework spring sealing ring comprises an inner groove rubber ring arranged on one side of the threaded pressing ring and an annular steel framework arranged in the inner groove rubber ring. The annular steel framework comprises an outer ring and an inner ring integrally formed with the outer ring. The outer ring protrudes out of the inner ring in the direction facing the hole opening of the anchorage device connecting cylinder, and the inner ring protrudes out of the outer ring in the direction facing the auxiliary sealing lip. Compared with a traditional rubber sealing ring, the framework spring sealing ring is more excellent in structure rigidity, longer in service life, more durable in sealing structure and better in anti-shaking effect.

Owner:SHANGHAI PUJIANG CABLE +1

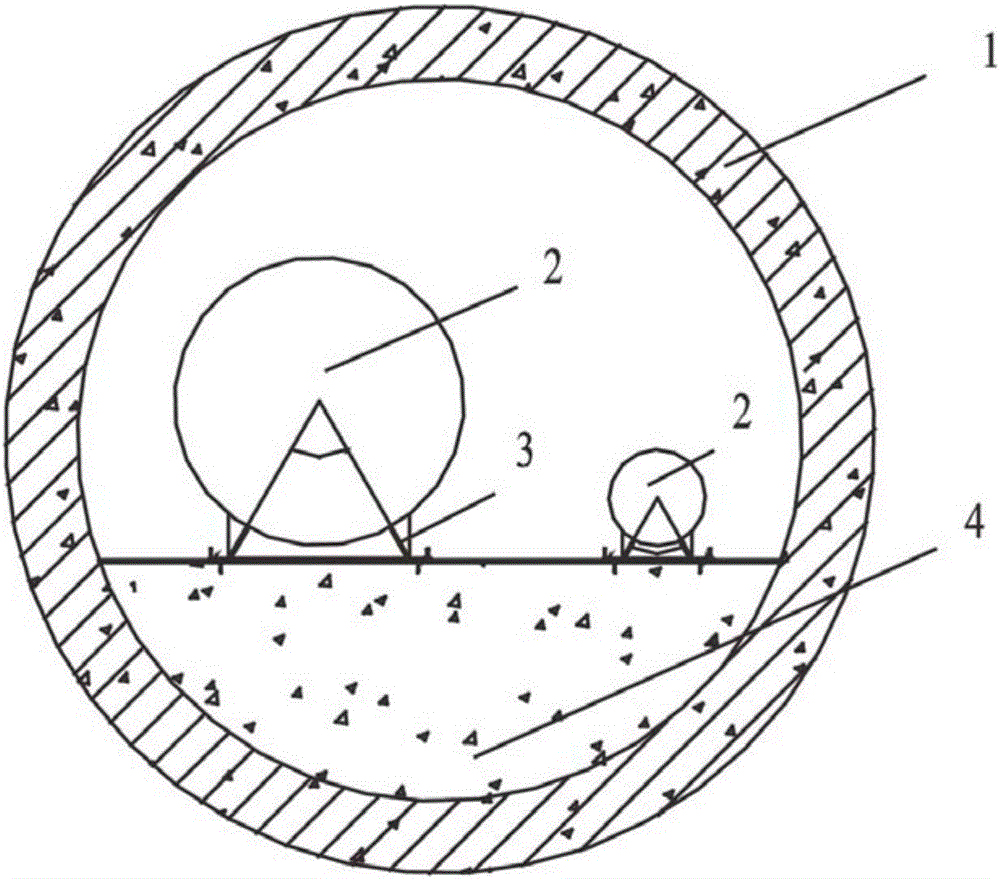

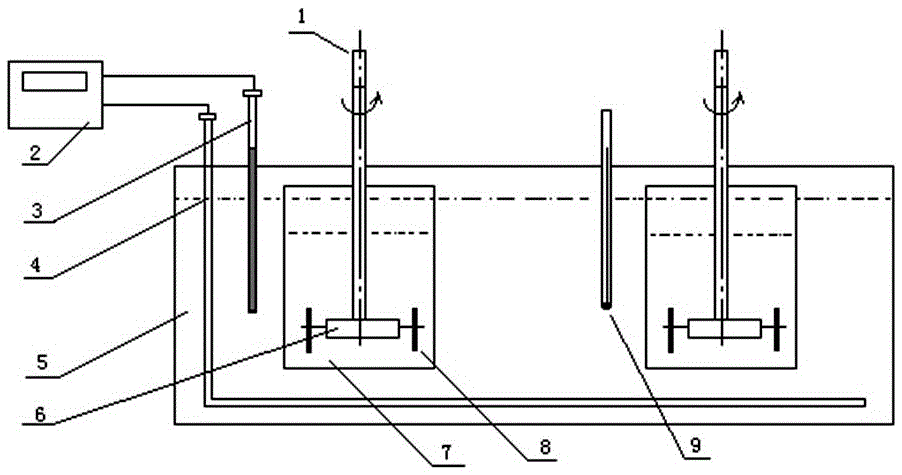

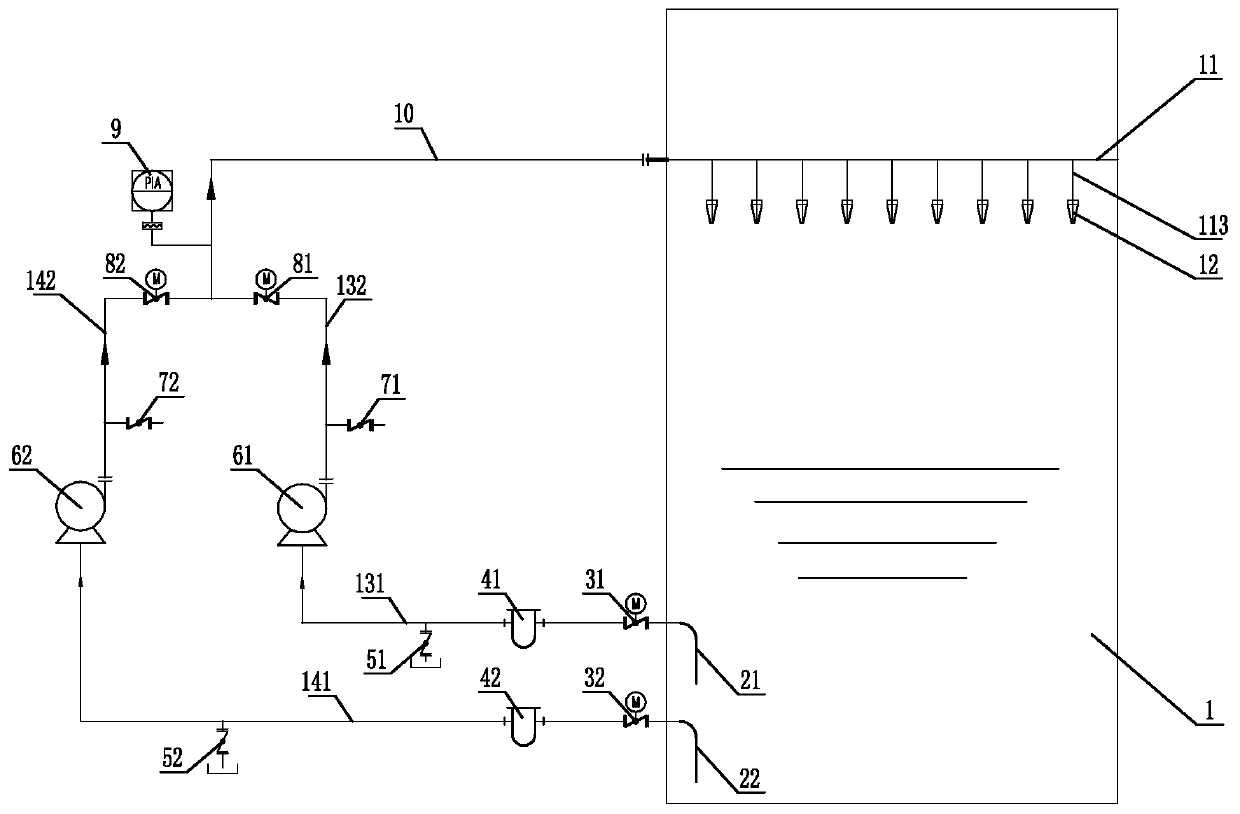

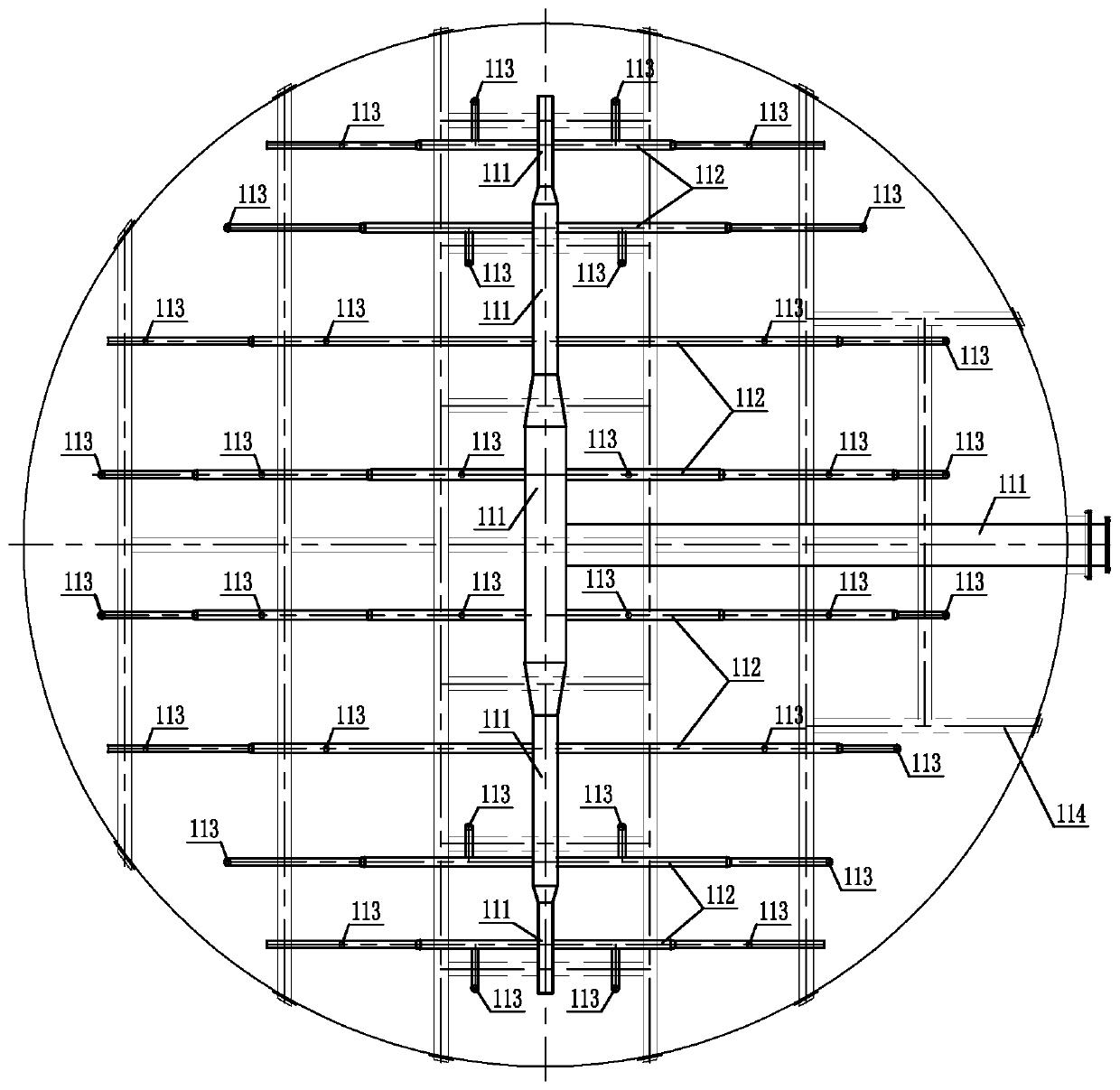

Ammonia-process flue gas desulfurization hydraulic stirring system and operation method thereof

PendingCN111282464APromote crystallizationReduce engineering investment costGas treatmentFlow mixersProcess engineeringSlurry

The invention relates to an ammonia-process flue gas desulfurization hydraulic stirring system and an operation method thereof. A sleeve, a hydraulic stirring and conveying device, a connecting pipeline and a disturbance distribution pipe network are connected in sequence. A pressure transmitter is arranged on the connecting pipeline. One end of the sleeve is connected with the bottom of a desulfurization column concentration section, the desulfurization column concentration section is made of carbon steel and is subjected to glass flake preservative treatment for storing ammonium sulfate slurry, and crystallization of ammonium sulfate is carried out in the desulfurization column concentration section. The disturbance distribution pipe network is arranged in the desulfurization column concentration section; and a plurality of disturbance nozzles are mounted on the disturbance distribution pipe network in a posture that the nozzles face downwards. The hydraulic stirring and conveying device conveys slurry at the bottom of the desulfurization column concentration section upwards to the disturbance distribution pipe network through the sleeve and the connecting pipeline and then sprays the slurry downwards through the disturbance nozzles. The stirring and uniform distribution of the ammonium sulfate slurry in the desulfurization column concentration section can be simultaneously realized, the engineering investment cost is low, the operation is simple, and the crystallization of the ammonium sulfate slurry is facilitated.

Owner:CHINA UNITED ENG

Manufacturing method for alloy hammer head

The invention discloses a manufacturing method for an alloy hammer head. The manufacturing method comprises the following steps of: preparing materials, preparing lost foam, casting and forming, thermal treatment, and anti-corrosion treatment. The hammer head product manufactured by the manufacturing method is reasonable in process, and phenomena such as hole shrinkage, cracks and crystalline penetration of the hammer head product are effectively avoided, and therefore, the hammer head is high in internal structure compactness, and is good in product hardness and wear resistance.

Owner:江苏双星特钢有限公司

A method for improving the liquid metal corrosion resistance of martensitic heat-resistant steel

ActiveCN105386051BImprove liquid metal corrosion resistanceExtended service lifeLiquid metalMartensite

The invention aims at providing a method for improving resistance of martensite heat-resistant steel to liquid metal corrosion. The method is characterized in that an enamel powder layer is sprayed to the surface of the martensite heat-resistant steel, and an enamel coating is prepared after a curing reaction is made. The surface of the martensite heat-resistant steel is treated through the method, the liquid metal corrosion resistance of metal can be effectively improved, and the service life of a metal material is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Viscoelastic body corrosion prevention method for pipe fitting in narrow space

InactiveCN111389694ALow processing level requirementsCorrosion isolationGeneral water supply conservationCorrosion preventionWeather resistanceAdhesive belt

The invention relates to a viscoelastic body corrosion prevention method for a pipe fitting in a narrow space. The method comprises the steps that rust is manually removed, clear water flow is used for removing superficial filth on the pipe fitting, the pipe fitting is dried with hot air to achieve a water-vapor-free condition, viscoelastic body coating is painted, PE protective tape is wound, bolt corrosion prevention is conducted, corrosion prevention is conducted on special dissimilar parts, and colored paint is painted according to standardized specifications. The method can solve the problem that mechanical rust removal is unavailable in a workplace where the operation space is narrow. Furthermore, the viscoelastic body material has excellent adhesive property, is high in chemical resistance, ageing resistance and weather resistance, has good cold flow property, self-repairing function and electric insulation performance, and is safe and environment-friendly.

Owner:北京永逸舒克防腐蚀技术有限公司

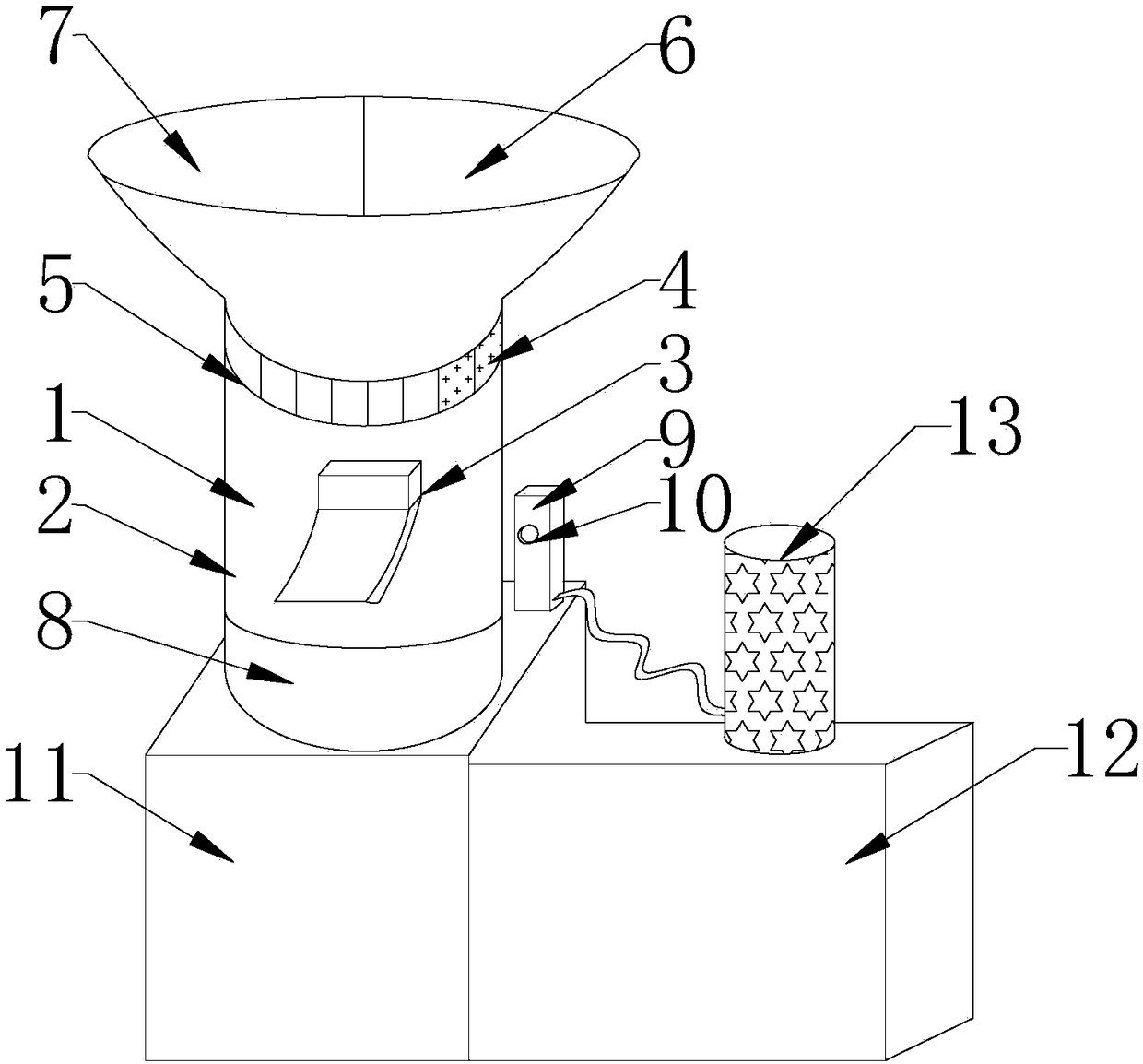

Novel compound fertilizer centrifugal granulating device

InactiveCN108404811AAvoid burnsAvoid damageGranulation in rotating drumsFertilizerAgricultural engineering

The invention discloses a novel compound fertilizer centrifugal granulating device. The novel compound fertilizer centrifugal granulating device comprises a compound fertilizer granulating device bodyand a temperature control device, wherein the temperature control device is arranged in the middle part of the interior of the compound fertilizer granulating device body, and is fixedly connected with the compound fertilizer granulating device body; an outer casing of a granulating machine is arranged at the surface of the compound fertilizer granulating device body, and is fixedly connected with the compound fertilizer granulating device body; the surface of the outer casing of the granulating machine is provided with a material outlet, and the material outlet is fixedly connected with theouter casing of the granulating machine. The novel compound fertilizer centrifugal granulating device has the advantage that the temperature control device is worked by using a power source starting press button, so that when the compound fertilizer centrifugal granulating device is used for granulating a compound fertilizer, the internal temperature of the compound fertilizer granulating device body is increased, and can be well controlled by the temperature control device, thereby preventing the scald of a user in the use process, preventing the damage to the parts in the compound fertilizergranulating device body due to overhigh temperature, and intermittently reducing the economic cost of a consumer.

Owner:袁文林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com