Normal temperature spraying detergent for aluminum alloy and preparation method thereof

A technology of aluminum alloy and cleaning agent, which is applied in the field of chemical cleaning and antirust, can solve the problems that the workpiece cannot reach the cleaning quality, affects the cleaning quality, and the workpiece is corroded, so as to increase the cleaning power at room temperature, be convenient to use, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

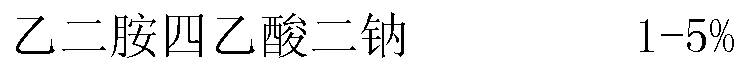

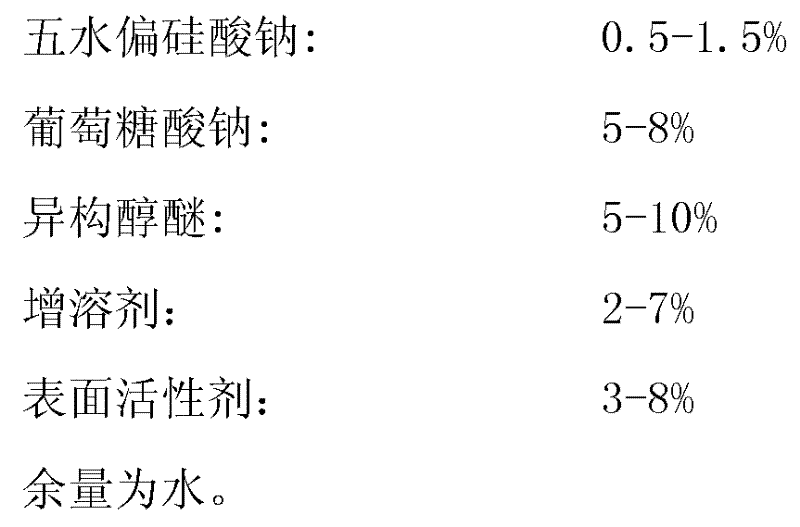

[0022] Embodiment 1: a kind of aluminum alloy room temperature spray cleaning agent, its constituent raw material and its weight percent are respectively:

[0023]

[0024] A preparation method of an aluminum alloy room temperature spray cleaning agent, the steps are as follows:

[0025] (1) Add the reaction amount of water into the reaction kettle, add the reaction amount of sodium metasilicate pentahydrate, sodium gluconate, and disodium edetate at 25-40°C and stir, and keep the reaction for 20 minutes.

[0026] (2) Add isomeric alcohol ether and surfactant RQ-129B (fatty alcohol polyoxyethylene ether) to the reaction kettle and stir until completely dissolved, then add solubilizer RQ-130E (dipropylene glycol methyl ether), and continue stirring for 30 Minutes until the solution is clear and transparent, keep the temperature of the reactor at 35-40°C during the reaction.

[0027] (3) After the reaction is completed, it is naturally cooled to room temperature, and after s...

Embodiment 2

[0029] A kind of aluminum alloy room temperature spray cleaning agent, its constituent raw material and weight percentage thereof are respectively (taking 1000g water-based antirust agent as example):

[0030]

[0031] The steps of the preparation method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com